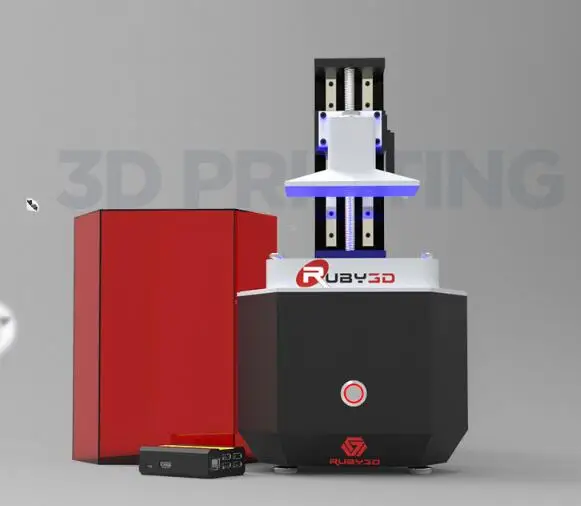

3D laser printing machine

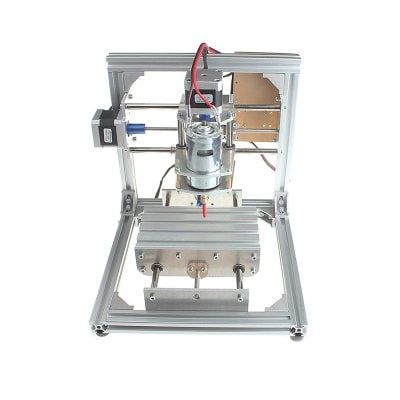

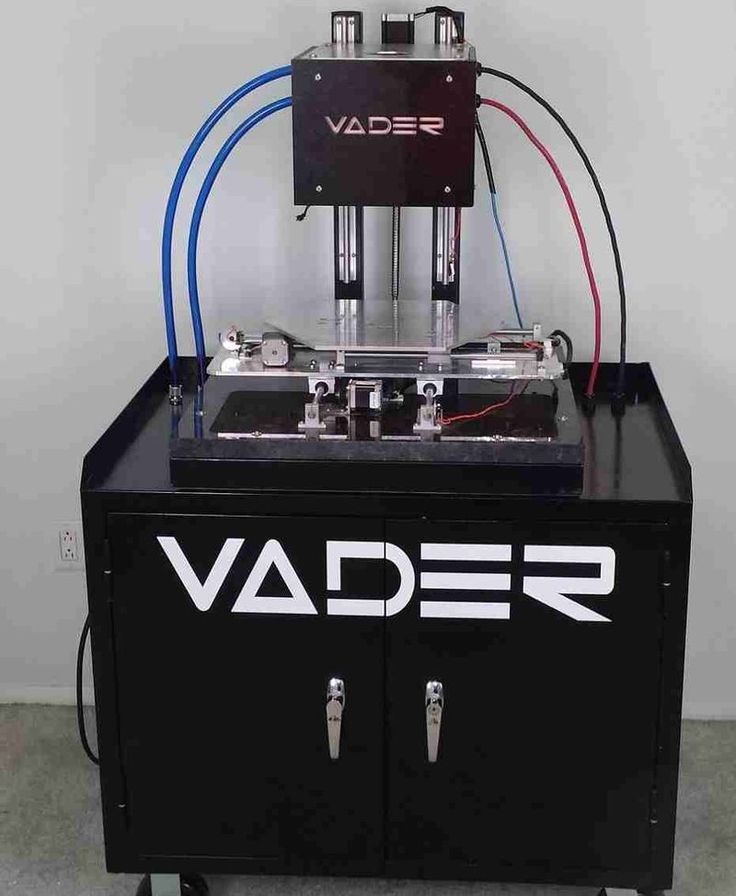

Best 3D Printer, Laser Engraver, CNC Carver for Sale

3D printing can create virtually anything from just about any material at a fraction of the cost and time traditionally associated with such processes, from mission-critical parts for airplanes to building blocks for custom homes and everyday items — ranging far beyond what we can imagine today.But what exactly is 3D printing? How does it work? And why should you use it?Well, we're glad you asked! Here's everything to know about using a 3D printer.

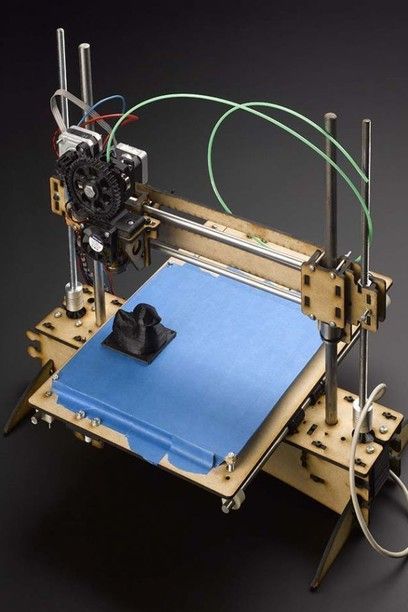

We have probably heard of 3D printing and maybe even done some experimenting with it. Still, most people don't know what 3D printing is. 3D printing is one of the hottest new technologies in the world right now—and it's not going away any time soon. It's a process that allows us to create physical objects by putting together thin layers of material, layer by layer, until we get to the final product. We can do this on almost any material: metal, plastic, ceramic, glass—even food!So, what does this mean for our everyday life? It means that if we have an idea for something we want to make but don't have the time or resources to make it ourselves (or if we are just too busy), then 3D printing can help.

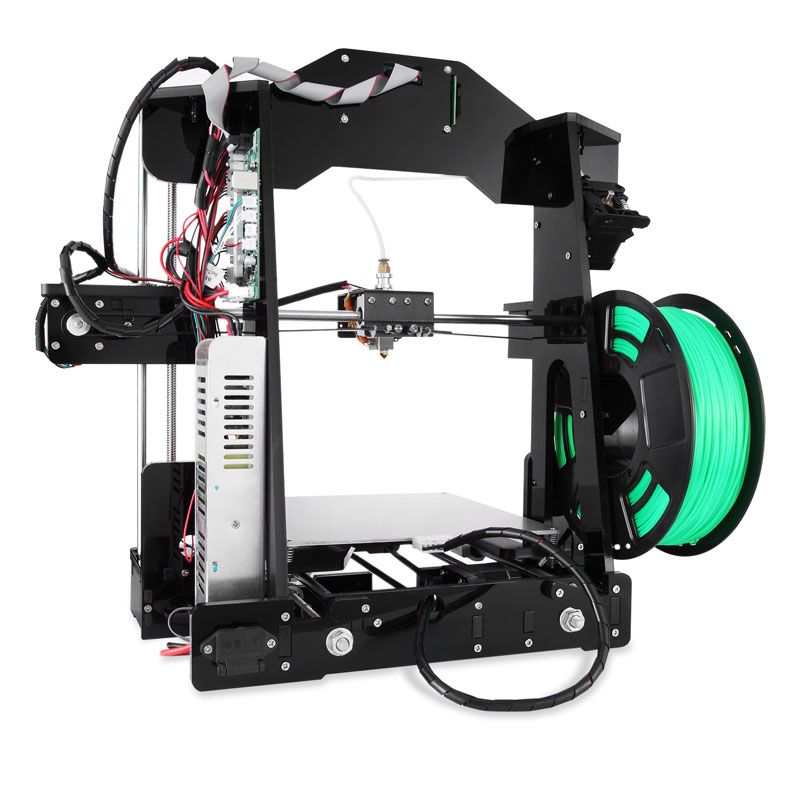

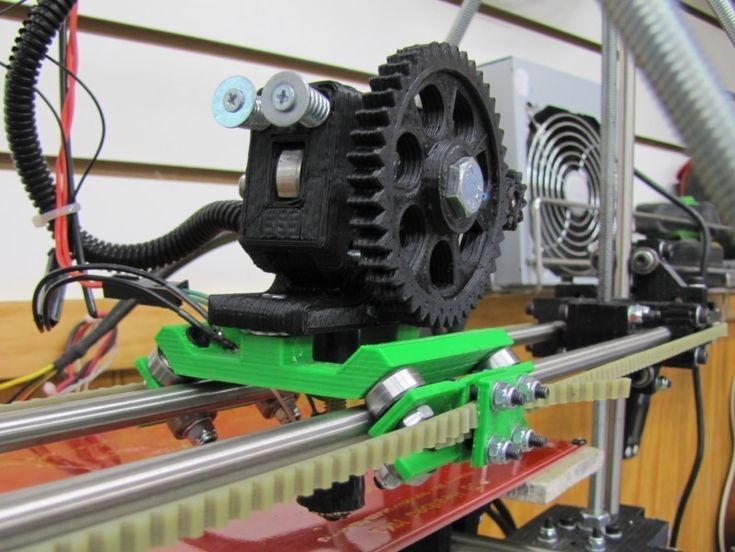

3D printing works like this: First, you download a model online or design one yourself. Then, you import the model into the slicing software for processing. Finally, you print the model by using a 3D printer. The printer does this by laying down successive layers of material, one after another until the object is completed. The printer needs to know the size of each layer and where it should be placed for the object to come together correctly.

Additionally, the printer needs a supply of raw materials (typically plastic) that can be melted down and formed into shapes. Once these raw materials have been melted down into their final shape, they are extruded through tiny holes in what's called a "printhead." This printhead feeds the material through small holes into whatever space it needs filling with plastic filament.

The printer doesn't actually create anything out of nothing; it creates an object from a previously existing model or blueprint. Since every part of this process is done by computerized machinery, there are no limitations on how complex or detailed our creation can be—the only limit is our imagination!

The possibilities for what can be created with this technology are endless. 3D technology allows us to design and create our own products without having to worry about how they will fit together or whether they will function properly. Some benefits 3D technology offers include: It Offers Many Design Possibilities. We can choose from hundreds of different materials, colors, and designs. The flexibility offered by this technology means no two items will be the same.

3D technology allows us to design and create our own products without having to worry about how they will fit together or whether they will function properly. Some benefits 3D technology offers include: It Offers Many Design Possibilities. We can choose from hundreds of different materials, colors, and designs. The flexibility offered by this technology means no two items will be the same.

1.It's Inexpensive To Use

It doesn't cost a lot to get started with a 3D printer. All you need is a computer and internet access. We can choose from many different types of printers with varying price ranges. The cheaper models will still print quality models, but they may not be able to handle large projects like furniture or large items that need to be printed out in multiple pieces.

2.Sustainable and reduces waste

3D printers have a huge environmental impact because they are extremely energy efficient. Instead of creating parts from waste plastic or scrap metals, we can create them from recycled materials like aluminum and plastic, reducing the amount of waste material in landfills by up to 90%.

3.Make Custom Products at a Minimal Cost

3D printing can be used to make clothes, costume jewelry, toys, figurines, and more. We also use 3D printers to make items for ourselves or sell them as gifts. Additionally, we can customize our own shoes, use 3D printers for rapid prototyping (which means we can quickly create working prototypes), manufacture, and even in greenhouses where tropical plants are grown.

3D technology has come a long way since the first 3D printer was built in 1984, and today there are many different types of printers on the market. 3D printers come in all shapes and sizes, and their capabilities vary greatly depending on our chosen brand and model. For instance, beginners who want a feel of 3D technology before splashing money on a superior model can buy entry-level printers for as low as $1000. When choosing a suitable printer, some key features to keep in mind include:

· Good resolution (or print quality): A high-resolution 3D printer will produce better results than one with a lower resolution. Remember, we need to see the details clearly when designing our project.

Remember, we need to see the details clearly when designing our project.

· Print size: The print size is the size of the finished object. It's usually measured in millimeters or inches, but some models have larger (and smaller) print sizes than others. When looking to make full-size products, we must know what size is right for our needs before investing in a machine!

· Speed: The printer's speed determines how quickly it can do its job—if it's slow, it can't support large projects like furniture or art pieces.

from 3105 reviews

Fast reliable service

Fast reliable service

Avichai Rebibo

Filter Cartridge for Air Purifier (2 Pcs)

02/19/2023

F350,Great Machine!!

No trouble for 45 days.Great that the drive is a feed screw, not a belt!

YM

Snapmaker 2.0 Modular 3D Printer F350/F250

02/19/2023

Works great.

I’ve never felt the need to try anything different. Just bought the first replacement after two years of regular printing, I don’t need it, just wanted to have a spare ready for when I do. Keep it clean and it lasts very well.

Keep it clean and it lasts very well.

P. B. H.

Print Sheet with Double Sided Printing Stickers for Snapmaker 2.0

02/17/2023

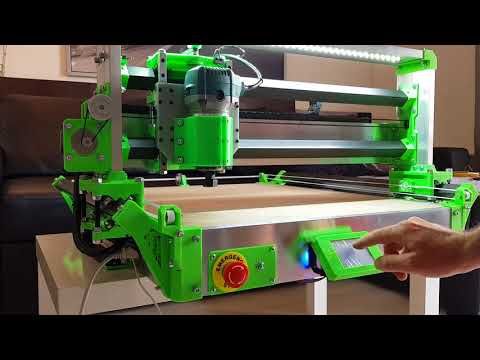

Emergency Stop Button - a must ?

YES ! The snapmaker motors are really strong and they can destroy not only material. Like each professional machine has to have a Stop Button it should be mandatory for such powerful tools.

Wolfgang Hass

Snapmaker 2.0 Emergency Stop Button

02/15/2023

This module is everything as described,, great module

Darren Williams

Snapmaker 10W High Power Laser Module

02/13/2023

So so quiet

I purchased this along with the new power module. It makes a huge difference in the amount of noise when printing. It's virtually silent now (power module fan still makes noise, but a lot less than before) so I can still work or watch TV without having to turn the Snapmaker off.

Rob Simmons

Linear Module for Snapmaker 2.0

02/12/2023

Snapmaker 2. 0

0

I have the original as well. The 2.0 differences are many including much quiter, larger print area, and smoother operation. WIFI capability makes for easier file transfer. I thought I'd give up my original but it still has its purpose. Terrific experience.

Ken J

Snapmaker 2.0 Modular 3D Printer F350/F250

02/11/2023

Excellent Build Plate Sheets

They work as they should. Sturdy and hold the model well anchored.

Ian Hodgson

Carbon Fiber Sheet (3 Pcs)

02/06/2023

Fantastic

This printer is fantastic .Realy fast and the mirroring is just amazing. Snapmaker did it again a very solide printer and easy and fun to use. It Would be good to have the profile available for simplifier 3D.

Chantal Gingras

Snapmaker J1 High Speed IDEX 3D Printer

01/31/2023

10W Laser Module

New to laser engraving / cutting, but very pleased with results so far on various projects I’ve attempted with different materials.

Mark Skinner

Snapmaker 10W High Power Laser Module

01/29/2023

Unsure

I cannot give it a rating at this time, as I am still waiting for the artisan to show up.

Norm Berg Berg

Filter Cartridge for Air Purifier (2 Pcs)

01/28/2023

Quality

Simple to setup and does the job very well…a Quality product all over.

Alen Budimlic

Snapmaker Air Purifier

01/27/2023

Quality

Its such a quality product, you can see it from packaging to actually using it. Highly recommend.

Alen Budimlic

Snapmaker Rotary Module

01/27/2023

Great. Love it

I think everyone should have an enclosure. Such a difference maker when using the machine. 5 stars even if I have a few things I would fix. When putting together read the instructions and examine every piece. A lot of the pieces look the same but are not. I find it's a little more difficult to change bases and the modulesnon my 350, a quick connect system could help with that. Looking at you snapmaker. Might upgrade the fan. Other then that no more crazy blue light in the corner of my office. It's a pretty good product.

Looking at you snapmaker. Might upgrade the fan. Other then that no more crazy blue light in the corner of my office. It's a pretty good product.

Andrew St. Yves

Enclosure for Snapmaker 2.0

01/20/2023

Lazer upgrade

New 10w Lazer unit. Makes cutting and engraving such easyer. The material thickness measure is fast and accurate. The cutting process much better than the original Lazer.

A worthwhile upgrade.

Graham Peters

Snapmaker 10W High Power Laser Module

01/17/2023

3D Printer vs Laser Cutter? Which to Buy for Your Side Hustle? – Smart Desktop Laser Cutter and Engraver

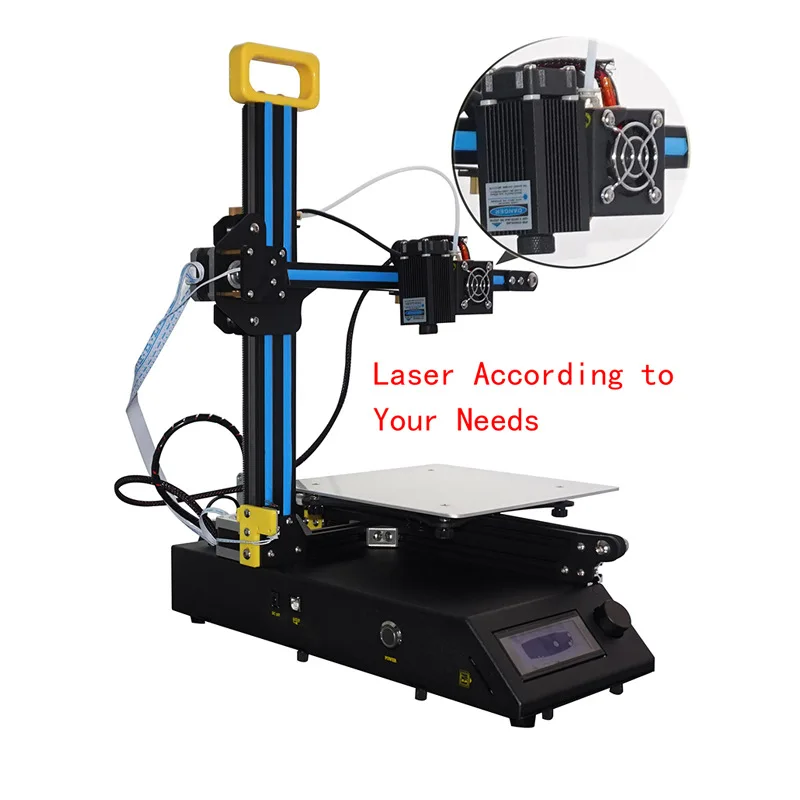

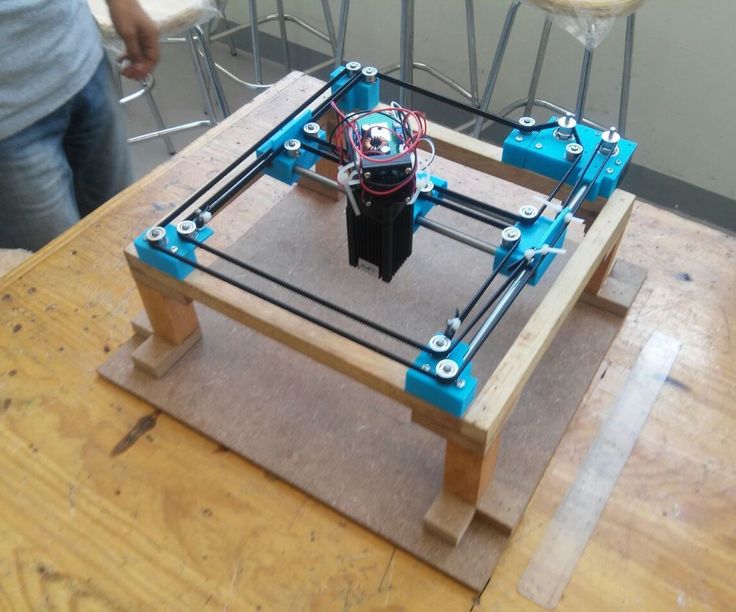

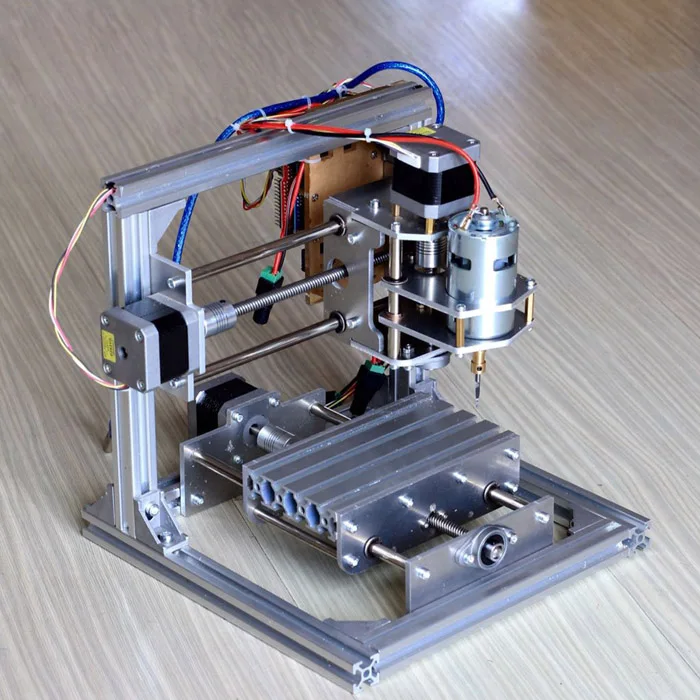

So, you have decided to get yourself a side hustle to generate some extra income. There are several types of hobby machines and you have narrowed it down to either a 3D printer or a laser engraver.

In this section we’ll discuss which one could do the best for you in regards to earning some extra money.

Initial Investment and Start up Costs

Obviously the most important question anyone will ask is, “How much is this going to cost me?” It is of course a great question and one with a lot of different answers.

Each technology has a couple of different entry cost points. But it should be noted that a lower buy-in cost may come with some surprises.

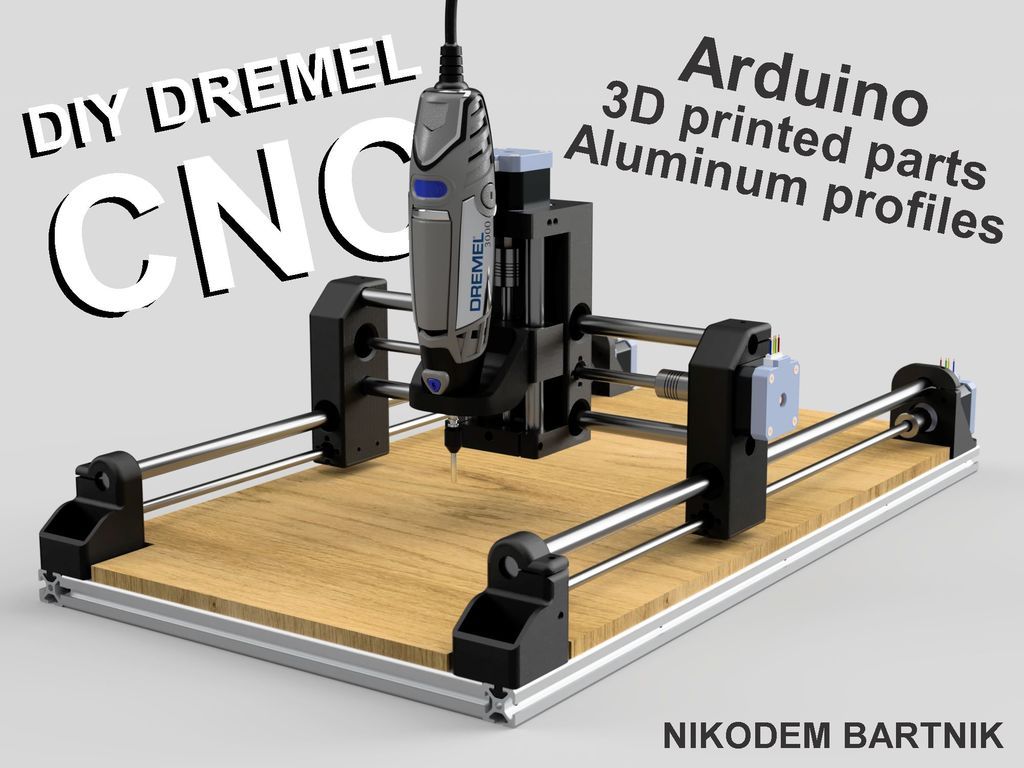

Machine cost

The 3D printer community has no shortage of suppliers, and no shortage of price entry points. After doing research you may find some machines that are darlings of the DIY community offered for very reasonable and tempting low costs.

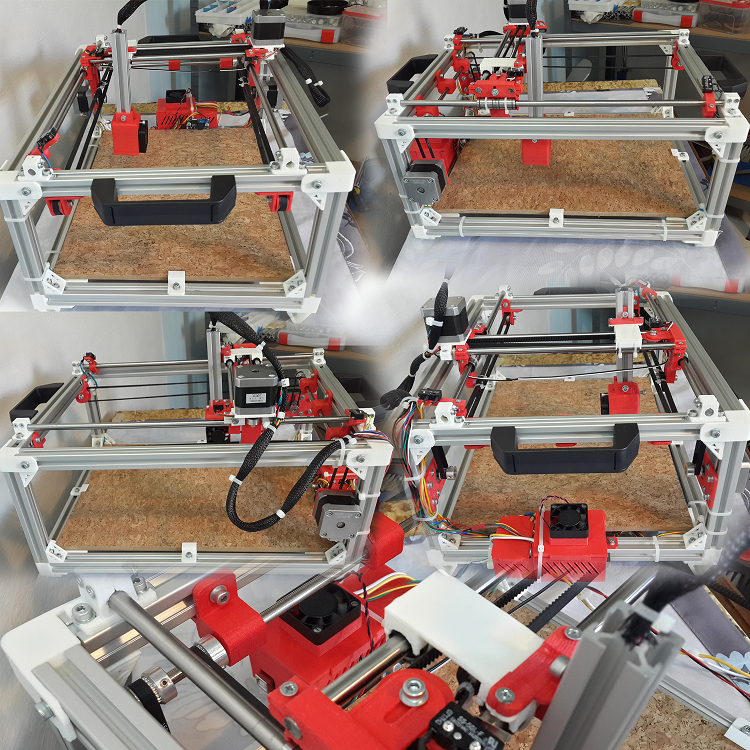

The catch, however, is that the stock kits, while adequate, only become great platforms after applying the DIY community enhancements.

You might see articles or videos online telling you the modifications that you need to do to transform your printer into a powerhouse machine.

In other words you need to spend some serious time with the machine to upgrade it prior to it making you any money. Also, you should consider the implications to the manufacturer warranty once you have rebuilt the machine.

3D printers with a solid reputation right out of the box are available at much higher costs but the lead times are considerable. Order one today and it might come to you in 2 to 3 months.

The entry point for a decent 3D printer is probably around $600 to $700 but higher quality tiers are available.

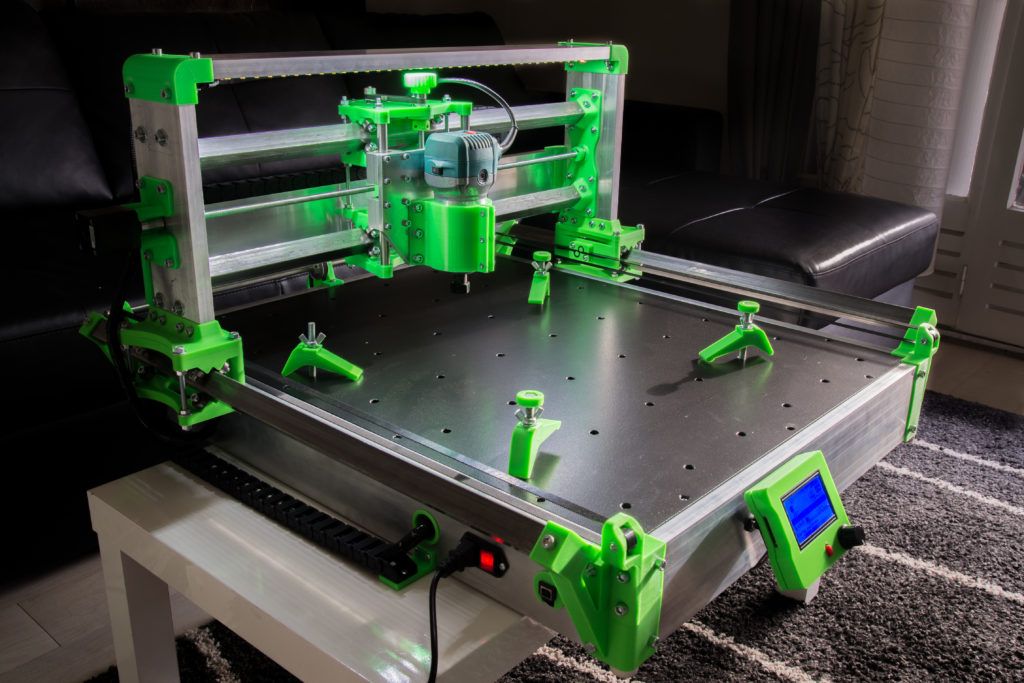

Conversely the buy-in point for a laser cutter such as the xTool D1 Pro is also just over $600.

The xTool D1 Pro is currently “state of the art” for desktop lasers. A user, at a minimum will probably want an Air Assist kit which is important for creating clean engravings and even more important for cutting operations.

All things considered, the buy-in costs similar until you get to consumables. In order to use a laser engraver all you need is something to engrave on.

Material cost

To use a 3D printer you must purchase filament which is about $25 to $30 a spool. There are different kinds of plastics such as PLA, PETG, ABS, and FLEX which are common materials.

Each one of those types of plastics come in different colors. Unless you are printing one item in one color you’ll probably want a variety of colors for your customers.

3D printer filaments are hygroscopic which means they will absorb water and should be stored in low humidity conditions. Most serious 3D printing operations have special storage containers built that use desiccant materials to maintain low humidity.

In regards to laser consumables it depends on what you intend to laser engrave on.

Some popular items are tumblers, mugs, cups, leather patches, glass engraving, making jewelry or making signage. Consumable purchase costs can vary greatly depending on which direction you go with your business.

For example someone making earrings from plywood will spend very little on thin plywood sheets compared to someone who is engraving Yeti tumblers which are fairly expensive per unit items.

Finding Your Niche

This is the hard part. Finding something that customers want to buy and then finding a place to sell it in.

For me it was making sushi boards. I live near a large military community that has frequent post assignments in Japan. So consequently there are a large number of people in my area who have lived in Japan and for some reason they seem to want their very own sushi board. You just never know what that niche can be.

I have also found that real estate companies provide gifts to new home purchasers at closing. Personalized items with the home address and family name on them are popular.

Personalized items with the home address and family name on them are popular.

Kids sports teams also have ceremonies at the end of the season and everyone gets a plaque or a tumbler with their name and number engraved on it.

Engraved pens and pencils are popular for giveaway items for small businesses.

The possibilities for finding your niche are almost endless but you have to find it, and then you have to exploit it. One good solid customer can really make your side hustle explode.

Study your local area and don’t just make the things that other makers are producing. Be unique, do your research, and you will surely find that item that people want.

Realistically, I think making and selling laser engraved or laser cut parts are more likely to turn you a profit than 3D printing parts.

I think it may be harder to find a 3D printed widget that will sell reliably. You are probably more likely to find customers for 3D printed parts just by advertising that you provide 3D printer services and will print requested items for a price.

You are probably more likely to find customers for 3D printed parts just by advertising that you provide 3D printer services and will print requested items for a price.

The Learning Curve

Oh, the dreaded learning curve. You’ve never done anything like this before and you probably know that you aren’t going to buy a 3D printer or a laser cutter and just plug it in and start making money.

You are going to make mistakes, and you are going to waste material, and you are going to make a costly mistake or two. Or three.

With a 3D printer the only way to practice is to consume expensive filament materials.

With a laser you can practice on scrap wood or cardboard. You can also engrave on wood at extremely low power and then sand off the engraving with an electric sander and start over. You can wrap tape, or thick paper, or cardboard around an expensive Yeti and do a test burn before you do the final burn.

All I can say is that if you ruin a project, keep that material and use it for a test piece. That way it isn’t a total loss.

Anyone can learn to 3D print or laser engrave but the key to becoming a Maker and maximizing your profits is to learn how to cut material costs and to reduce waste. Maybe if you are cutting out keychains you might find a way to make 10 fits on your material instead of 8.

That is a layout feature usually referred to as “Nesting”. Maybe you can make a template to engrave 10 pencils or pens at one time perfectly instead of doing just one a time and every one being a little different.

Key elements like this can make your work stand out from your competitors and make you the sought-after artisan.

Payback Period: How Long Before You Make A Profit

You aren’t really making a profit until your initial investment in the machine and consumables are paid for. And you also have to factor in your training time and the materials you used to learn your craft.

And you also have to factor in your training time and the materials you used to learn your craft.

Not long ago I saw a story where a guy bought a laser, spent a few days figuring out the rotary operations and then got an order for 300 tumblers to be processed. He literally paid for his initial investment with that first job, and then some.

While that is entirely possible, it is more likely you will need some time to find your niche product and build up your business via word of mouth. Like any worthwhile endeavor it can come down to what you put into it and your level of commitment.

It might be of some benefit to price items lower in the beginning to achieve a customer base. Word of mouth is powerful and even providing free items to influential people or businesses can pay huge dividends moving forward.

I.C.T 3D Laser marking of printing machines of fiber 20W 30 W from the Chinese manufacturer

SHARE TO:

- Model: I.

C.T-510

C.T-510 - Product brand: I.C.T 9000 Product Description

I.C.T 3D Fiber Laser Marking Printing Machine 20W

Introduction:

This block is used to label the text, barcode, 2D codes and graphics on the printed circuit board, I.C.T Laser laser marking is used mainly in PCB industry. It can seamlessly connect the SMT assembly line and support the online data transmission and information return of the MES system.

Functions:

1. The performance of CO2 laser, fiber laser, green laser and UV laser is stable.

2. Adopted high speed vibrating mirror, high precision, high speed and stable performance.

3. CCD positioning is fast and accurate and can be automatically recognized after marking.

4. The software interface is humanized, the operation is simple and easy to learn, and the editing function is powerful.

4. The software interface is humanized, the operation is simple and easy to learn, and the editing function is powerful. 5. Automatically read the 2D code and save the data. Automatically records and wake up when it can't read.

6. Compared to conventional printing, no consumables, no pollution, no maintenance. 7. It performs the function of anti-printing data to avoid re-labeling information. 8. It can be easily connected with SMT Line and System MES.

Driving system

The Japanese disc and movement system is adopted to ensure high precision and stable operation of the machine. XY Axis Design Design improves work efficiency and is easy to maintain.

Control system

PLC and motion control card drive, high quality brand to ensure the stability of the machine, the overall safety standards, easy to maintain and repair.

Brand System

Various types of lasers can be selected, CCD identification automatic detection, bad brand function and visual correction to combat FPC expansion and contraction.

Transport System

The unique conveyor system can effectively prevent stuck PCB. The motor controls the speed and the stop position is accurate. Directions and output PCB are freely available.

Characteristics:

9000 Frequent questions 9 99SOME I.C.T-400 I.C.T-510 LASE TYPE Ultraviolet laser, green laser, fiber-laser, Laser COO2 0094Wavelength UV Laser: 355 nm, Green Laser: 532 nm, Fiber Laser: 1064 nm, CO2 Laser: 10640 nm Laser Power UV Laser: 3W (5W optional) , Green laser: 7W, Fiber laser: 20W, CO2 Laser: 30W external flipper) PCB size <="" d=""> <="" d=""> Range marking <380mm*320mm* mm PCB size L50*W80MM~L450*W350mm; Thickness 0.  5 mm-6 mm

5 mm-6 mm Speed marking <7000 mm/s Accuracy marking ± 0.05 mm Minimum character height 0.1mm ~ 0.4mm Read code function Automatically read two-dimensional code and store data, automatically record and alarm

Power L1200 *h2500 mm Air Pressure 0.5 ~ 0.6 MPa

Q: What can we do for you?

A: Total SMT machines and solutions, professional technical support and service.

Q: Are you a trading company or manufacturer?

A: OEM & ODM Service available.

Q: What is your delivery date?

A: The delivery date is about 35 days after payment is received.

Q: What's your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Q: What are your main customers?

A: Huawei, Foxconn, Vtech, Sumida, Kemet, Vishay, Bosch, Canon.

Q: Why choose us?

A: Leading SMT supplier in China; Trade Assurance up to $560,000; Professional after sale service.

I.C.T Global Service

Success Experience:

ETA Customer in 35 Countries

1. We help customers build many new factories around the world.

2 Training of more than 500 experts and technicians for customers.

3. became the most reliable Chinese partner for you.For setting up SMT Factory, we can do for you:

1. We provide you with a complete SMT solution

2. We provide the core technology with our

We provide the core technology with our

equipment 3. We provide the most professional technical service

4. We have rich experience at SMT Factory

5. We can solve any question about SMTvideo

related products

SMT SMD hot air soldering oven Manufacturer of soldering oven

I.C.T-T4 | High Quality SMT PCB Table Soldering Oven

ICT-W2 | Economical High Quality Wave Soldering Machine THT PCB

ICT-W3 | High Quality Automatic Lead Free DIP Double Wave Soldering Equipment

W4 High Performance Lead Free Nitrogen PCB Soldering Machine Manufacturer

I.C.T-L3020 | High standard built-in axial and radial insert with odd shaped component

Selective wave soldering machine with good performance and high stability

I.C.T-SCR640 | Fastening Desktop TM

IKT TKR-M | Automatic rotary conveyor SMT PCB

ICT NB-M | Buffer SMT PCB NG

I.C.T | IR Auto Fast Stencil Soldering Station

ICT SMT Semi Auto Stencil Printer Solder Paste Printing Machine

I.

C.T-510 | Three-dimensional laser marking of printing vehicles green color of a laser marking machine from the Chinese manufacturer

C.T-510 | Three-dimensional laser marking of printing vehicles green color of a laser marking machine from the Chinese manufacturer SHARE TO:

- Model: I.C.T-510

- Product brand: 9000 I.C.T

- PCB Laser Marking 9000

Input:

This unit is used for marking text, barcode, 2D code and graphics on PCB, i.c.t Laser marking is mainly used in PCB industry. It can seamlessly connect the SMT assembly line and support the online data transmission and information return of the MES system.

Functions:

1. The performance of CO2 laser, fiber laser, green laser and UV laser is stable.

2. Adopted high speed vibrating mirror, high precision, high speed and stable performance.

3. CCD positioning is fast and accurate and can be automatically recognized after marking. 4. The software interface is humanized, the operation is simple and easy to learn, and the editing function is powerful.

5. Automatically read the 2D code and save the data. Automatically records and wake up when it can't read.

6. Compared to conventional printing, no consumables, no pollution, no maintenance. 7. It performs the function of anti-printing data to avoid re-labeling information. 8. It can be easily connected with SMT Line and System MES.

Driving system

The Japanese disc and motion system is adopted to ensure high precision and stable operation of the machine. XY Axis Design Design improves work efficiency and is easy to maintain.

Control system

PLC and motion control card drive, high quality brand to ensure the stability of the machine, the overall safety standards, easy to maintain and repair.

Brand System

Various types of lasers can be selected, CCD identification automatic detection, bad brand function and visual correction to combat FPC expansion and contraction.

Transport System

The unique conveyor system can effectively prevent stuck PCB. The motor controls the speed and the stop position is accurate. Directions and output PCB are freely available. 9Ol000 laser: 355 nm, green laser: 532 nm, fiber laser: 1064 nm, CO2 laser: 10640 nm 20W, CO2 Laser: 30W

The motor controls the speed and the stop position is accurate. Directions and output PCB are freely available. 9Ol000 laser: 355 nm, green laser: 532 nm, fiber laser: 1064 nm, CO2 laser: 10640 nm 20W, CO2 Laser: 30W

5 ~ 0.6 MPa

5 ~ 0.6 MPa 9000 c. you?

A: Total SMT machines and solutions, professional technical support and service.

Q: Are you a trading company or manufacturer?

A: OEM & ODM Service available.

Q: What is your delivery date?

A: The delivery date is about 35 days after payment is received.

Q: What's your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Q: What are your main customers?

A: Huawei, Foxconn, Vtech, Sumida, Kemet, Vishay, Bosch, Canon.

Q: Why choose us?

A: Leading SMT supplier in China; Trade Assurance up to $560,000; Professional after sale service.

Our company

I.C.T is our company

About I.C.T:

I.C.T is a leading plant planning solution provider.