Hp 3d printer announcement

HP launches HP Jet Fusion 5420W 3D printing system; debuts new Metal Jet applications at Formnext

×

Expand

HP

HP Jet Fusion 5420W.

HP has announced the launch of its HP Jet Fusion 5420W 3D printing system as part of a new machine series that facilitates the additive manufacture of white parts.

At Formnext, the company is also showcasing its HP Metal Jet S100 solution for the first time in Europe, with a new production application from John Deere a feature of its booth (Hall 12.1; D59).

“Additive manufacturing delivers on today’s most urgent market demands including sustainable innovation, hyper-personalisation, and business resiliency,” said Didier Deltort, President of Personalization & 3D Printing, HP Inc. “Together, with our global network of partners and customers, we are scaling additive manufacturing to meet these needs.”

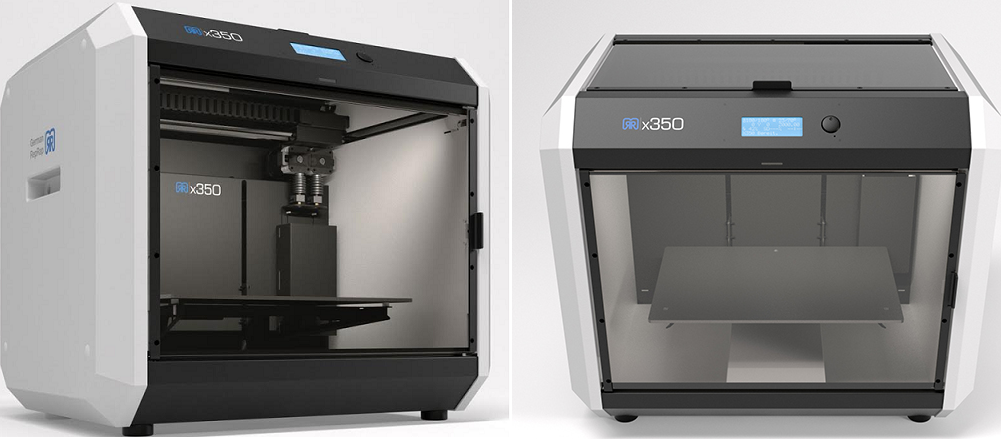

HP Unveils New Jet Fusion 5400 SeriesTo enable entirely new production applications, HP is adding the new HP Jet Fusion 5400 Series to its existing Jet Fusion portfolio, with the HP Jet Fusion 5420W the series' first product. This product has been designed to enable the high-quality additive manufacture of white parts and is said to provide all the benefits of HP's Multi Jet Fusion technology, initially commercialised via the 4200 and 5200 Series. HP says the new machine is ideal for the automotive, consumer goods, healthcare, and industrial markets. Early customers using the new system to produce innovative white applications include DI Labs, Prototal Industries, and Weerg.

“HP continues to provide us with the advancements we need to push the boundaries of additive manufacturing and produce the final parts our customers need,” said Jan Löfving, CEO, Prototal Industries. “Beyond the industrial grade production HP delivers, we are seeing immediate interest in the new white applications made possible by the latest addition to HP’s Multi Jet Fusion family. As a proud Digital Manufacturing Partner in HP’s DMN, we are equipped to take on bold, innovative projects and help companies get the most value out of AM production. ”

”

HP has also announced since announced its cumulative 100 million Multi Jet Fusion parts milestone at last year's Formnext, more than 70 million additional parts have been printed in the past 12 months. Among them are the following applications, also on show at Formnext.

×

Expand

- Using their HP Jet Fusion fleet, GKN Forecast 3D produced 60,000 spoiler closeout seals with BASF ULTRASINT TPU01 (thermoplastic polyurethane) for General Motors. Innovative vapour polishing and drying processes enabled by AMT cleared a bottleneck, halved production time, and were used to finish parts, eliminating the need for post-print dyeing. The seals close out gaps on the left and right sides of the rear spoiler, improving finish and fuel efficiency, and the spoiler closeout seal recently earned top prize in the additive manufacturing category at the 51st annual SPE Automotive Innovation Awards.

- Demonstrating the power of hyper-personalisation, Smith I/O MAG Imprint 3D Goggles are produced with Multi Jet Fusion technology and offer a truly custom fit based on the individualized features of a person’s face. Named one of Time Magazine’s Best Inventions of 2022, these first-of-their-kind goggles eliminate light leaks, air gaps, and hot spots for world class performance on the slopes.

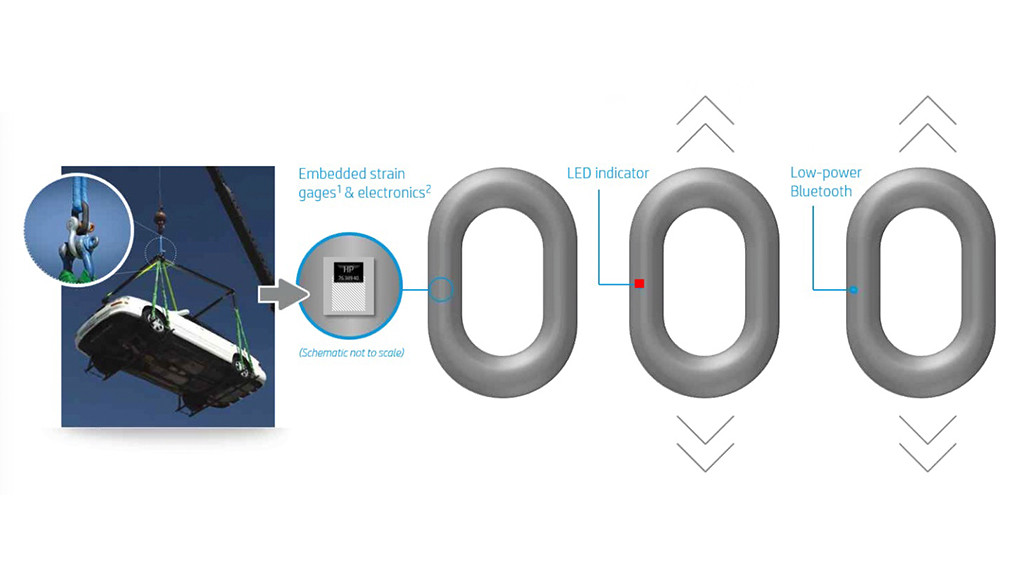

Launched in September, HP’s Metal Jet S100 Solution is enabling industrial customers, such as Domin Digital Motion, Lumenium, and Schneider Electric, to achieve 'better productivity, low part cost, and outstanding quality' per HP. John Deere, the global manufacturing leader of agricultural and construction equipment, is the latest adopter - using Metal Jet technology for the production of a valve in the tractor fuel system.

Together with GKN, John Deere is now manufacturing Metal Jet-printed valves in its agricultural machinery. In addition to significant productivity gains and environmental benefits, the high-quality part is said to be functional in extreme weather conditions. John Deere is also leveraging HP’s Multi Jet Fusion technology to optimise its production processes using 3D printed prototypes to test and fine tune components and parts such as windshield holders, reducing pre-assembly from 30 days to ten, delivery times by up to ten weeks, and overall production costs by between 20 to 25 percent.

In addition to significant productivity gains and environmental benefits, the high-quality part is said to be functional in extreme weather conditions. John Deere is also leveraging HP’s Multi Jet Fusion technology to optimise its production processes using 3D printed prototypes to test and fine tune components and parts such as windshield holders, reducing pre-assembly from 30 days to ten, delivery times by up to ten weeks, and overall production costs by between 20 to 25 percent.

“Our focus on innovation and sustainability is at the core of everything we do for our customers,” said Dr. Jochen Müller, Manager Global Digital Engineering at John Deere. “We are proud to be among the first in the agricultural industry to leverage the benefits 3D printing for both prototyping and final parts production. Leveraging industrial 3D printing platforms for polymers and metals, we are discovering opportunities to deliver more efficient, reliable, and sustainable equipment.”

Materials, post processing, and DMN updatesOn materials, HP partner Lubrizol has announced the new ESTANE 3D M88A TPU, a flexible and highly durable material which enables complex geometries and lattice structures. And in post-processing, HP and AMT have announced a new strategic alliance to provide customers with 'seamless, fully automated post processing support' through the entire 3D printing production workflow.

And in post-processing, HP and AMT have announced a new strategic alliance to provide customers with 'seamless, fully automated post processing support' through the entire 3D printing production workflow.

Together, HP and AMT are working to help customers more efficiently and cost effectively apply post processing capabilities like unpacking, cleaning, surface finishing, colouring, sporting and quality control for applications produced with HP’s industrial Jet Fusion 3D printing portfolio. In addition to its partnership with AMT, HP is collaborating across the post processing ecosystem to ensure customers have access to a broad range of alternatives from providers including AM Flow, DyeMansion, and Rösler Group AM Solutions. DyeMansion is offering advanced post processing options for Multi Jet Fusion customers including surface finishing and colouring for white parts produced with the new Jet Fusion 5420W Solution.

Supplementing the updates from HP on materials and post-processing, the company has also announced Oechsler as a new Digital Manufacturing Partner in HP’s DMN. Oechsler is the first to take advantage of the joint post processing support with AMT and develop a range of applications.

Oechsler is the first to take advantage of the joint post processing support with AMT and develop a range of applications.

“At Oechsler, we choose to work with companies who have a shared vision of working together to deliver optimal outcomes. HP and AMT building a comprehensive approach from printing to an integrated post processing solution is a critical step in the adoption of additive manufacturing at scale,” said Matthias Weisskopf, General Manager, OECHSLER Motion.

HP's commitment to sustainability

In line with its sustainability commitments, HP has announced it is offering its customers using polymer-based technologies a new Virtucycle recycling and buyback programme by Arkema. The programme enables interested HP customers to sell used PA11 and PA12 powders, and printed parts, as opposed to disposing materials via costly, environmentally harmful practices such as landfilling or burning.

Want to discuss? Join the conversation on the Additive Manufacturing Global Community Discord.

Gain 3D printing insights from Boeing, Jack Wolfskin and more at the TCT Conference @ Formnext. Get your pass here.

Get your FREE print subscription to TCT Magazine.

HP Unveils New 3D Printer for Dyeable White Parts, New Metal 3D Printed Parts for John Deere - 3DPrint.com

HP (NYSE: HPQ) unveiled its first broadly available metal 3D printer, the Metal Jet S100, at IMTS earlier this year. At Formnext 2022, the company is building on that development by showcasing parts made with the technology for farm and construction equipment giant John Deere. More than that, HP is also unveiling a new multi jet fusion (MJF) 3D printer for white parts at the event.

John Deere’s Metal 3D Printed Parts

John Deere (NYSE: DE) has been exploring the use of additive manufacturing (AM) for some time. As competitors, like Caterpillar, were more public about deploying the technology, there were rumblings that John Deere had used it here and there, even for end parts. Now is the first time that the company has let the world in on its real world application of AM. Specifically, the ~$40 billion heavy equipment maker enlisted Metal Jet service provider GKN Additive to 3D print valves for its tractor fuel system.

Now is the first time that the company has let the world in on its real world application of AM. Specifically, the ~$40 billion heavy equipment maker enlisted Metal Jet service provider GKN Additive to 3D print valves for its tractor fuel system.

Image courtesy of Sarah Saunders/3DPrint.com

The parts are said to cut production time while also withstanding the harsh environmental circumstances that these machines are exposed to. It has also been announced that the company is using MJF for prototyping and design work for parts such as windshield holders that have introduced a number of benefits. This includes cutting pre-assembly time from 30 to 10 days, delivery times by up to 10 weeks, and production costs by between 20 to 25 percent.

“Our focus on innovation and sustainability is at the core of everything we do for our customers,” said Dr.

Jochen Müller, Manager Global Digital Engineering at John Deere. “We are proud to be among the first in the agricultural industry to leverage the benefits 3D printing for both prototyping and final parts production. Leveraging industrial 3D printing platforms for polymers and metals, we are discovering opportunities to deliver more efficient, reliable, and sustainable equipment.”

New Jet Fusion 5400 Series Unveiled with White Parts

HP also unveiled the start of a new MJF line, the HP Jet Fusion 5400 Series, which was kicked off with the HP Jet Fusion 5420W Solution, for 3D printing white parts. Traditionally, MJF parts have been black due to the nature of the process. An infrared-absorbent black ink makes it possible for the parts to be fused by the printer’s infrared lamps. To achieve a color like white, the new machine likely uses a clear infrared-reactive coating.

- A head brace/helmet 3D printed using the HP Jet Fusion 5420W and colored using DyeMansion post-processing technology.

Image courtesy of HP.

Image courtesy of HP.

- A head brace/helmet 3D printed using the HP Jet Fusion 5420W and colored using DyeMansion post-processing technology. Image courtesy of HP.

I say this because HP’s full-color MJF technology relied on this technique. Interestingly, the company discontinued its full-color system, which some in the industry have seen as a confusing move, given that only HP has been able to achieve large-scale production of industrial quality full-color parts with 3D printing. Perhaps, the company will introduce a new 5400 3D printer will feature full-color capabilities.

- A brace 3D printed using the HP Jet Fusion 5420W and colored using DyeMansion post-processing technology. Image courtesy of HP.

- A brace 3D printed using the HP Jet Fusion 5420W and colored using DyeMansion post-processing technology. Image courtesy of HP.

In the mean time, customers can use products like those offered by DyeMansion to dye the white parts to create vibrantly colored, 3D printed objects. This is a long-time in the making for the 3D printer manufacturer. Early customers for the new 5420W printer include DI Labs, Prototal Industries, and Weerg. Jan Löfving, CEO of Prototal Industries, said of the product:

This is a long-time in the making for the 3D printer manufacturer. Early customers for the new 5420W printer include DI Labs, Prototal Industries, and Weerg. Jan Löfving, CEO of Prototal Industries, said of the product:

“HP continues to provide us with the advancements we need to push the boundaries of additive manufacturing and produce the final parts our customers need. Beyond the industrial grade production HP delivers, we are seeing immediate interest in the new white applications made possible by the latest addition to HP’s Multi Jet Fusion family. As a proud Digital Manufacturing Partner in HP’s DMN, we are equipped to take on bold, innovative projects and help companies get the most value out of AM production.”

Image courtesy of Sarah Saunders/3DPrint.com

Other Formnext Announcements

As of Formnext 2022, HP has announced that its MJF technology has been used to produce over 170 million parts so far, with more than 70 million made in just the last year. The company is showcasing some of these items at the 2022 event.

The company is showcasing some of these items at the 2022 event.

For instance, 60,000 spoiler closeout seals were made for GM by GKN Forecast 3D using BASF ULTRASINT TPU01. Thanks to vapor polishing and drying techniques from AMT, the parts took half the time to make, while eliminating the need for post-print dying. Additionally, Smith I/O MAG Imprint 3D Goggles are being made with MJF for custom-fit.

HP also announced a partnership with long-time collaborator AMT to offer “seamless, fully automated” post processing support for 3D printing production. The two firms are offering customers a diverse array of automation solutions to tackle the complete MJF manufacturing workflow, such as unpacking, cleaning, surface finishing, coloring, sporting and quality control. As the first user, Oechsler is showcasing the results of the collaboration. The German manufacturer is also a new addition to HP’s Digital Manufacturing Network (DMN).

“At Oechsler, we choose to work with companies who have a shared vision of working together to deliver optimal outcomes.

HP and AMT building a comprehensive approach from printing to an integrated post processing solution is a critical step in the adoption of additive manufacturing at scale,” said Matthias Weisskopf, General Manager of OECHSLER Motion.

HP has also pointed out that its relationship with AMT is not exclusive, so that customers can also rely on post-processing and automation solutions from such firms as AM Flow, DyeMansion, and Rösler Group AM Solutions.

Finally, via Arkema’s Virtucycle Program, HP is allowing customers to sell used PA11 and PA12 powders, and printed parts. This is in contrast to the current disposal practice that ultimately results in landfilling and burning.

For those at Formnext, all of this is on display at the HP booth at Formnext (Hall 12.1; booth D59).

Subscribe to Our Email Newsletter

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: DyeMansion • hp • HP Jet Fusion 5400 • HP Jet Fusion 5420W • john deere • metal 3d printing • Metal Jet

Please enable JavaScript to view the comments powered by Disqus.

Reviews, news and announcements of new 3D printers, how to choose a 3D printer or start printing

Reviews, news and announcements of new 3D printers, how to choose a 3D printer or start printingAll reviews Anycubic Creality Phrozen CreatBot FlashForge Elegoo Reviews Voxelab Peopoly QIDI Tevo

01/31/2022

Review: 5 Entry-Level Photoresin MSLA Printers Affordable

Have you been looking for an inexpensive resin printer to get into 3D printing? And we. ..

..

01/29/2022

Anycubic

Anycubic Vyper Test & Review: An Impressive Affordable 3D Printer

Announced in 2020, during Anycubic's fifth anniversary celebration,...

01/21/2022

Creality

Creality Ender 3 S1 Review The updated Ender 3 3D printer

The Creality Ender 3 has been extensively redesigned with modern features....

12/13/2021

Creality

Anycubic

Voxelab

5 Inexpensive 3D printers for beginners

Thinking about buying an inexpensive 3D printer for beginners? We will introduce you...

11/22/2021

CreatBot

CreatBot D600 Pro Review: A big 3D printer for little money

The CreatBot D600 Pro is a professional, large-scale 3D printer with...

27.10.2021

Ortur Laser Master 2 overview: large low power laser

Ortur Laser Master 2 is a simple and affordable laser engraver...

10/22/2021

Reviews

FlashForge

FlashForge Adventurer 4 review: premium 3D printing at the price of an amateur printer

We started admiring the Adventurer 4 at the unpacking stage, when. ..

..

10/01/2021

CreatBot

CreatBot F1000 Review: A High-Performance, Affordable Industrial 3D Printer

CreatBot F1000 is an industrial-size 3D printer with auto-elevating double...

07/23/2021

Creality

Creality Halot-One overview, description and specifications

07/23/2021

Anycubic

Anycubic Vyper Review: Features and Specs

We've been waiting. On its 5th anniversary in 2020, Anycubic...

1 2 3 … 6

Request a call back

Telephone

By clicking on the button, you agree to the privacy policy of

Item added to cart

Go to cart

Product added to comparison

Compare products

Cannot compare more than 4 products

Invoice or quotation request

Organization name:

Your e-mail

Your phone

Name of contact person:

Legal address:

Comment:

By clicking on the button, you agree to the privacy policy of

Goods on the way, find out when the delivery is

Your name:

Your e-mail

Your phone

By clicking on the button, you agree to the privacy policy

Contact us

How to call

By phone +7(495)155-45-19. Your call will be answered by an answering machine. We won't call back if you don't speak up. Each request is processed, we contact clients in accordance with requests. Prepare the information you want to report, send it to the answering machine and we will call you back. We kindly request: do not be silent and do not hang up, this is just an answering machine. 🙂 Other most effective ways to get in touch:

Your call will be answered by an answering machine. We won't call back if you don't speak up. Each request is processed, we contact clients in accordance with requests. Prepare the information you want to report, send it to the answering machine and we will call you back. We kindly request: do not be silent and do not hang up, this is just an answering machine. 🙂 Other most effective ways to get in touch:

- Write to Telegam @techno3dru

- Whatsapp +74951554519

- Write Email [email protected]

Is the product in stock

On the product page, under the product name, there are 3 statuses:

- In Stock - We have this item in stock. Make a purchase with the Buy button.

- Pre-order - goods on the way, delivery soon. Find out about delivery times by clicking on 'Delivery times' or make a purchase using the Buy button.

- On order - The goods are delivered according to your order on a partial prepayment. Place an order using the Order button.

How to get an invoice for payment for legal entities

Add items to the cart, proceed to checkout. Payment method: Organization → Specify details → Get an invoice for payment

How to get a quotation

On the product page, click on the link Request a quote

How much is delivery

On the product page, block Delivery. With an accurate calculation of the cost and timing to your city. On the Delivery and payment page for more details about all delivery methods.

If you did not find your question among the questions, please contact us via

Whatsapp or Telegam

Inquiry

Contact person (full name):

Contact phone:

Email:

0001

HP has begun shipping its Jet Fusion 3D 4200 Printer to customers. The first to receive the devices are the company's partners who supported the development of the novelty - Jabil, Materialise and Shapeways.

The first to receive the devices are the company's partners who supported the development of the novelty - Jabil, Materialise and Shapeways.

Jet Fusion 4200 operates on the basis of “HP Multi Jet Fusion technology”, which is a modified SLS (Selective Laser Sintering): layers of special powder are poured layer by layer, the desired areas of the layer are selectively sintered under special lighting. Powder from unused areas can sometimes be reused. HP claims that its devices are more reliable, print faster (advantage up to x10) and better, and the infrastructure being created in the form of professional software and the market for materials will make their use as convenient as possible.

The printing process is as follows: the model file and powder are loaded into the Processing Station, which prepares the printing process in the ”Build Unit”. Next, the Build Unit is removed from the station and installed in the printer itself, and printing starts.

Main specifications of the Jet Fusion 3D 4200 Printer (without Processing Station):

- Maximum part size: 406 x 305x 406 mm

- Layer height: 0.

07 to 0.12 mm

07 to 0.12 mm - Device size: 2178 x 1238 x 1448 mm with a weight of 730 kg (unpackaged)

- Features: 380 volt power supply, 2 terabyte HDD, Ethernet interface

Processing Station weighs from 450 kg and measures from 1926 x 1245 x 2400 mm to 3121 x 1571 x 2400 mm (with fast cooling installed).

Read more about HP Jet Fusion 3D printers here.

The Jet Fusion 4200 is currently printing with HP's proprietary 3D High Reusability PA12 resin (with the ability to reuse “excess” powder). The device will also support materials from alternative manufacturers (the concept of Open Platform). For example, Evonik recently announced the release of its plastic. Printing materials will also be supplied by BASF, Arkema and Lehmann and Voss.

Ramon Pastor, Vice President of HP, commented: “6 months ago we released information about our Jet Fusion 3D and a list of forward-thinking companies looking to join HP on the path to the industrial revolution.