Jobs that use 3d printing

9 Great 3D Printing Jobs

- 3D printing is a technology that creates a three-dimensional object using a computer-aided design (CAD).

- The 3D printing industry is rapidly growing thanks to its ability to create a wide range of versatile products in a fast, cost-effective way.

- For job seekers, the 3D printing industry offers some cool jobs on the cutting edge of the technology.

- This article is for professionals and entrepreneurs who want to work in the 3D printing industry.

President Barack Obama once said 3D printing has the “potential to revolutionize the way we make almost everything.” For that reason, the 3D printing industry was valued at $13.78 billion in 2020. And market research projections suggest it will continue its meteoric growth through 2028 – when it is expected to reach an estimated $59.65 billion.

As the 3D printing industry booms, what does it mean for job seekers? Here are 9 opportunities that will be created or get a boost from 3D printing.

What is 3D printing?

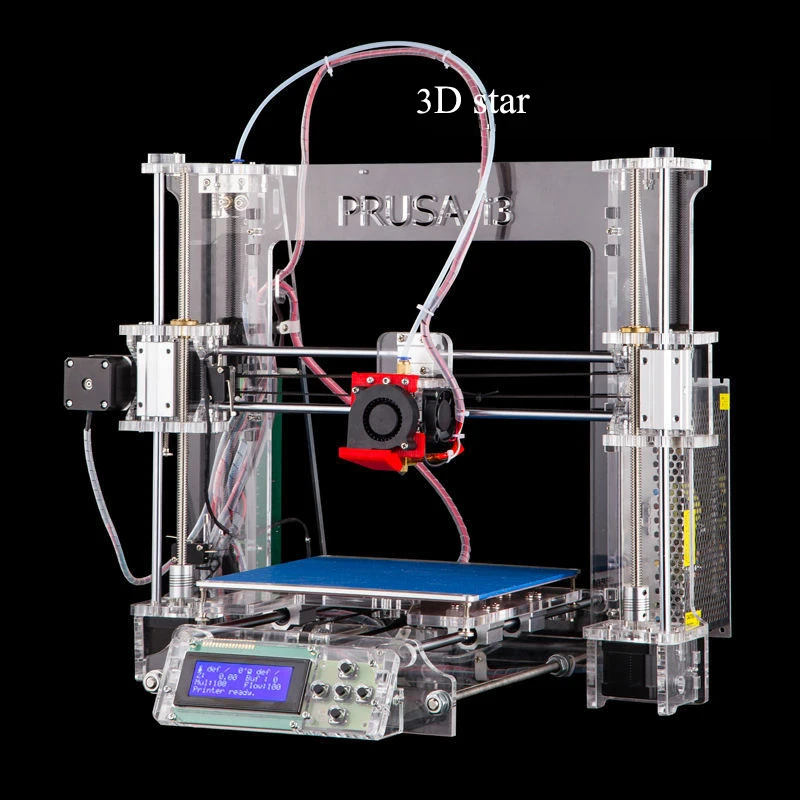

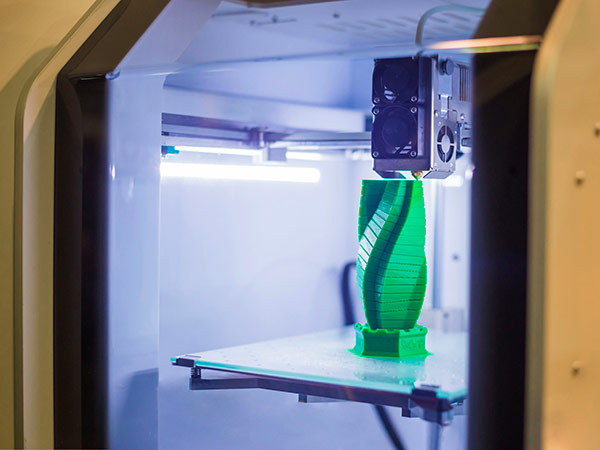

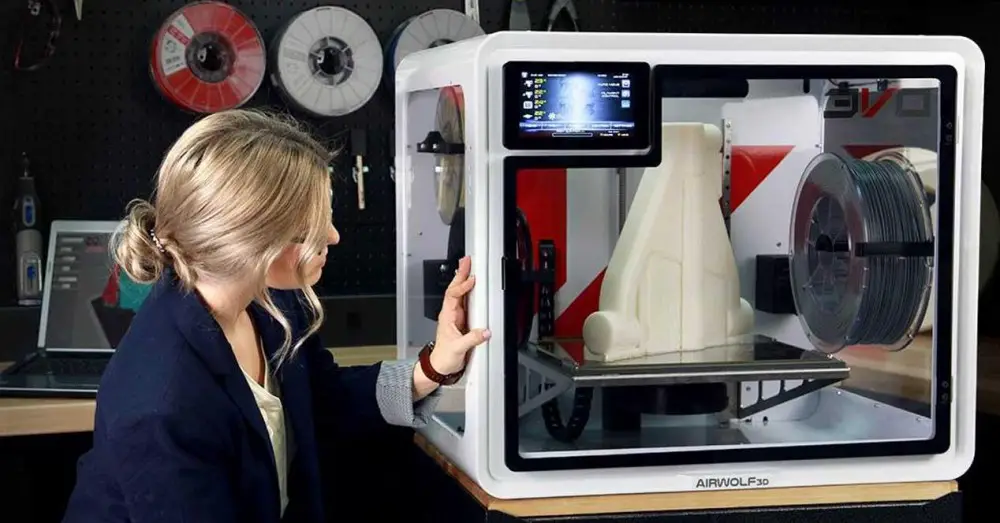

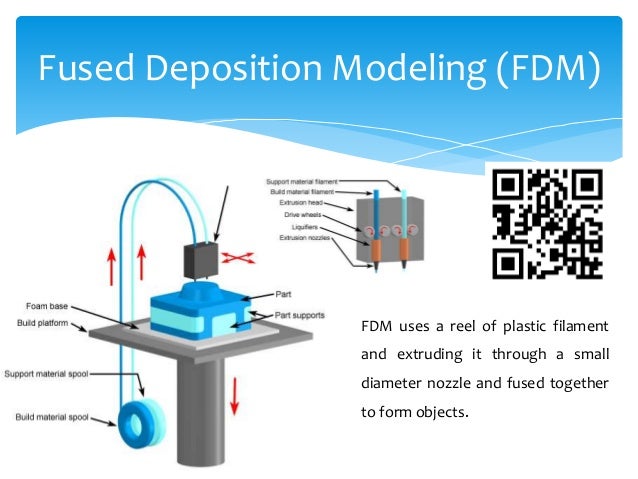

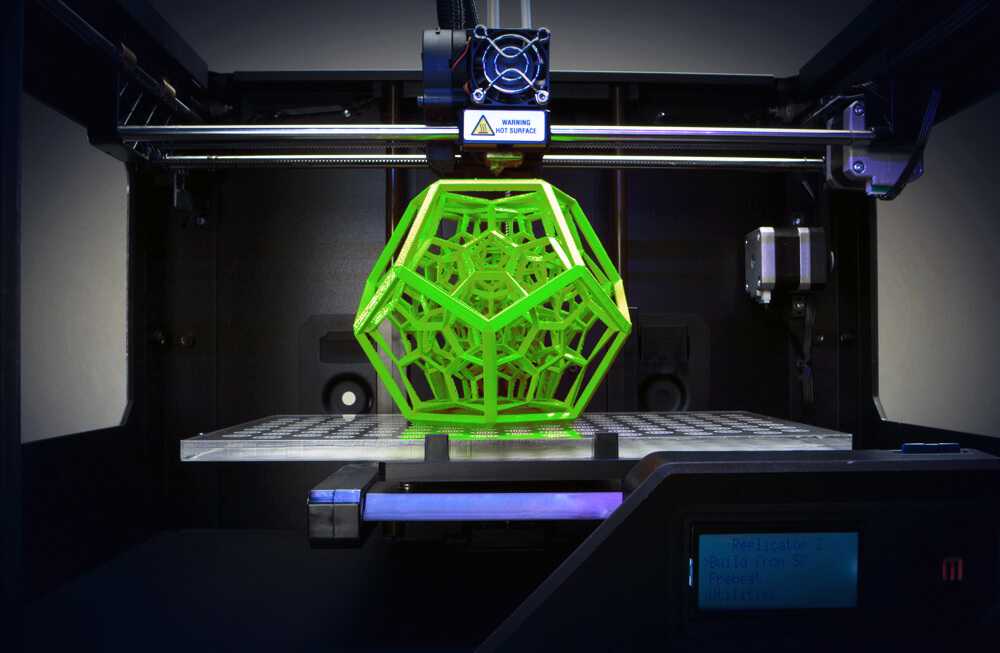

Rather than using ink and paper, a 3D printer uses materials like plastic, metal or ceramic to create a 3D model. By using computer-aided design (CAD) files as digital instructions to create an object, a 3D printer repeatedly covers a work surface with layers of material in precisely the right spots to create a structure from scratch.

While 3D printing can be used for large-scale structures, 3D printing is most useful in creating smaller, customized parts or prototype components for various uses – including automotive engineering or the medical industry. With the versatility of 3D printing, it’s a field that’s filled with opportunities. Let’s take a look at some of the areas 3D printing is being used today.

3D printing jobs

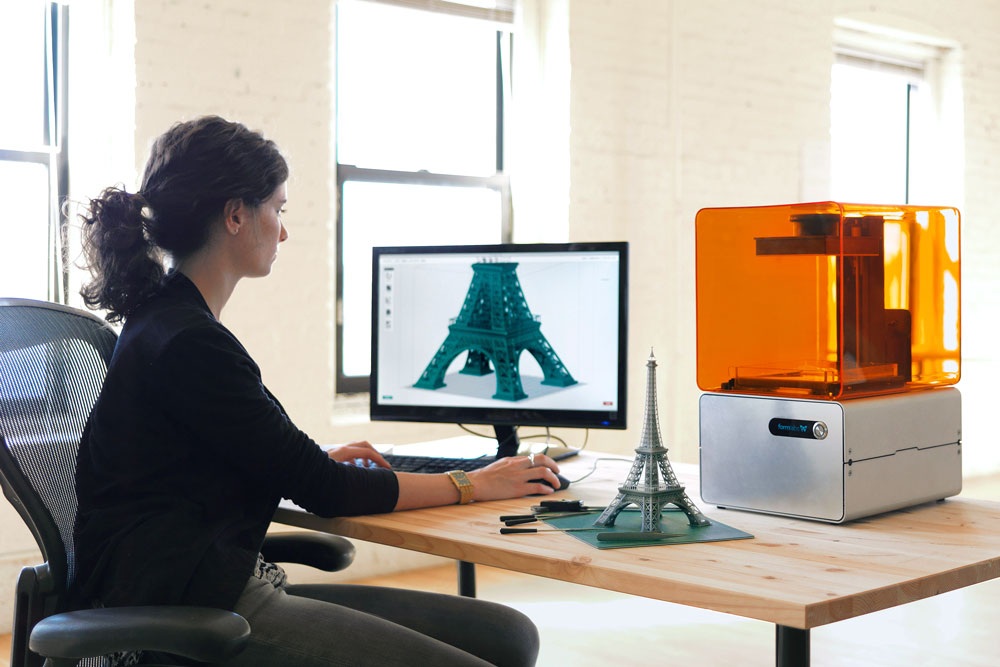

1. 3D design

3D printing relies heavily on designers who can take a product idea and bring it to life. Thanks to its growth, 3D printing will create jobs for 3D designers at 3D printing firms, in companies as part of creative teams and as freelancers.

3D printers are being used in many design disciplines – such as product design, medical device design, architectural visualization and entertainment design, said Erol Gunduz, a professor at New York University’s School of Continuing and Professional Studies (NYU-SCPS), which offers programs in 3D printing, design and modeling.

To be competitive, job seekers should gain hands-on experience in 3D technologies and stay current on how companies are using 3D printing. For instance, recent graduate student designers and researchers who are familiar with 3D printing methods have the benefit of knowing how to use the technology within their design process, Gunduz explains.

“This gives them a significant advantage when looking for career opportunities within creative fields,” Gunduz said.

Did you know? 3D printers can create replacement parts for the human body, among the many things that 3D printers make.

2. 3D CAD modeling

3D printing would not be possible without CAD experts who have the skills to convert product designs into digital blueprints that the printers need. Along with product designers, there will be a demand for 3D CAD modelers.

Along with product designers, there will be a demand for 3D CAD modelers.

“I see a lot more demand for CAD and 3D modeling jobs on the horizon because of 3D printing,” said Alex English, owner of ProtoParadigm. ProtoParadigm is a 3D printing business that also performs research and development on 3D printing hardware and new printing materials.

Although 3D CAD professionals are also needed to construct models for mass 3D printing, they are especially important for custom products.

“Bespoke manufacturing and custom prototyping both rely on the user’s ability to conceptualize the object they want and accurately create its digital representation,” English said.

Consequently, 3D CAD modeling jobs will require printing-specific modeling skills, such as feature size, geometrical constraints and knowledge of materials, English added.

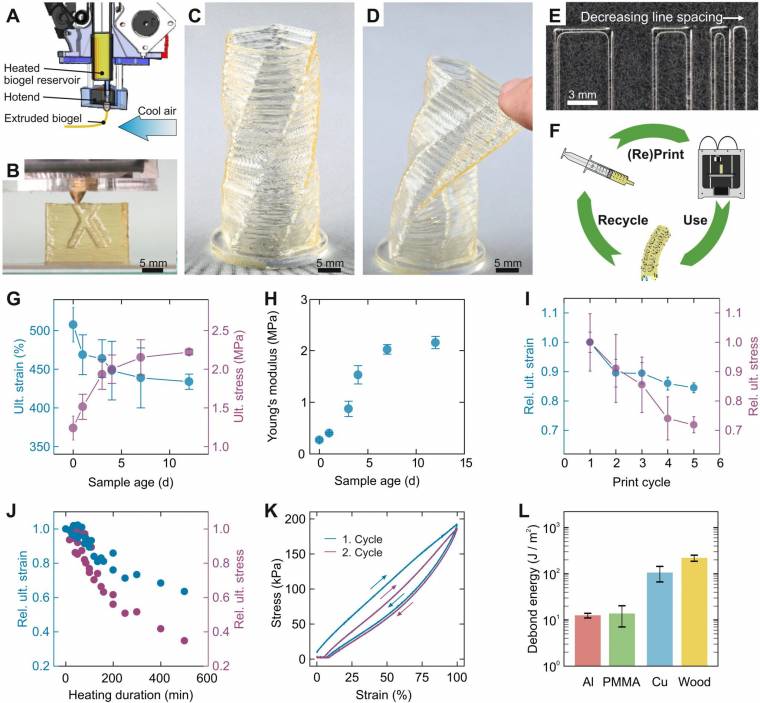

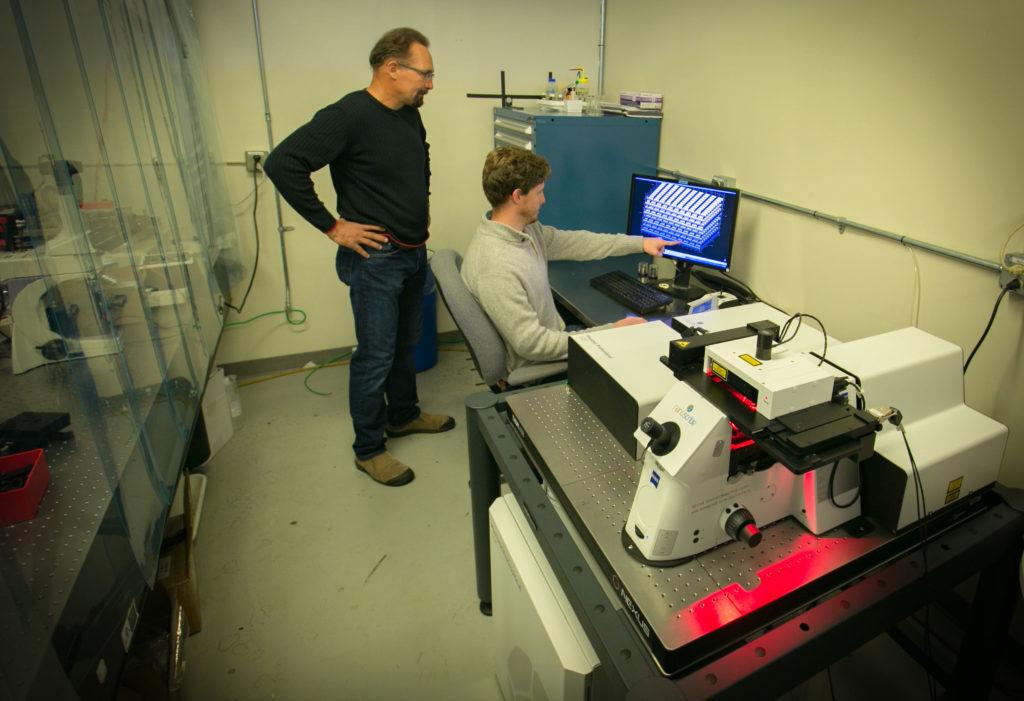

3. Research and development

3D printing is all the buzz – and not just in the gadget world. Just as the 3D printing industry will require more product designers and CAD modelers, jobs will open up for forward-thinking research and development professionals who understand the intersection of tech and consumer products.

“While 3D visualization technologies have been used in the past within various fields, such as engineering and scientific agendas, many artistic and consumer product industries – such as fashion design and jewelry design – are beginning to take advantage of 3D printing systems,” Gunduz said.

Companies will need people who can find the best way to utilize 3D printing for consumer products at the lowest cost possible.

“The ability to visualize a line of fashion accessories or jewelry designs before committing to working with expensive materials affords an advantage for companies to reduce costs in development cycles,” Gunduz said.

Tip: Is your business experimenting with 3D printing research and development? Consider these tax credits that are available to companies performing cutting-edge research.

4. Biological and scientific modeling

3D printing is not limited to consumer products; it creates many products that promote medical advancement and save lives. It can also create drone and defense equipment, and possibly even space food.

It can also create drone and defense equipment, and possibly even space food.

Accordingly, the 3D printing industry will need more engineers, designers and modelers who have a biomedical or scientific background to further innovate and produce highly advanced 3D-printed products.

“While all manner of designers will be able to print the things they design, there will be a high end to the market – particularly in medical, aerospace, military, and other high-precision or mission-critical applications – for those that better understand the printing technologies and how to design for their strengths and limitations,” English said.

5. Architecture and construction modeling

3D printing will disrupt various industries, particularly those that rely heavily on blueprinting or prototyping. For the construction industry, this paradigm shift will boost the need for 3D modelers that may replace current 2D construction planning solutions.

“In the architecture, engineering and construction industries, 3D printing will redefine the production of construction documents,” said Lira Luis, chief collaboration architect at Atelier Lira Luis LLC, a Chicago-based architecture and design firm.

Instead of 2D CAD modeling on paper, 3D printing can produce true-to-life models to better represent what structures will look like.

“As the 3D printing process becomes more streamlined, it could potentially eliminate the need for construction documents and move directly to printing full-scale mock-ups prior to construction of structures,” Luis said.

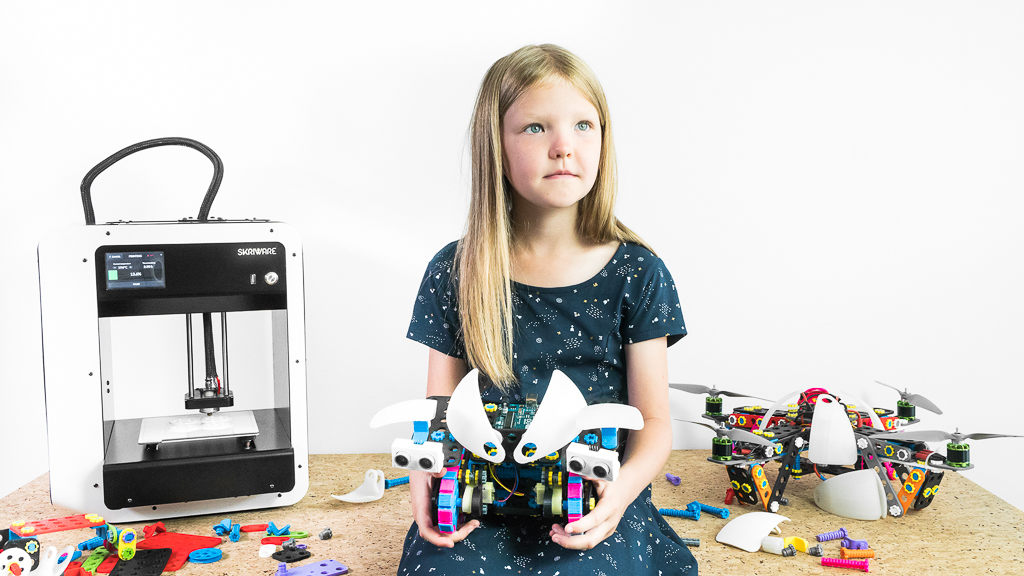

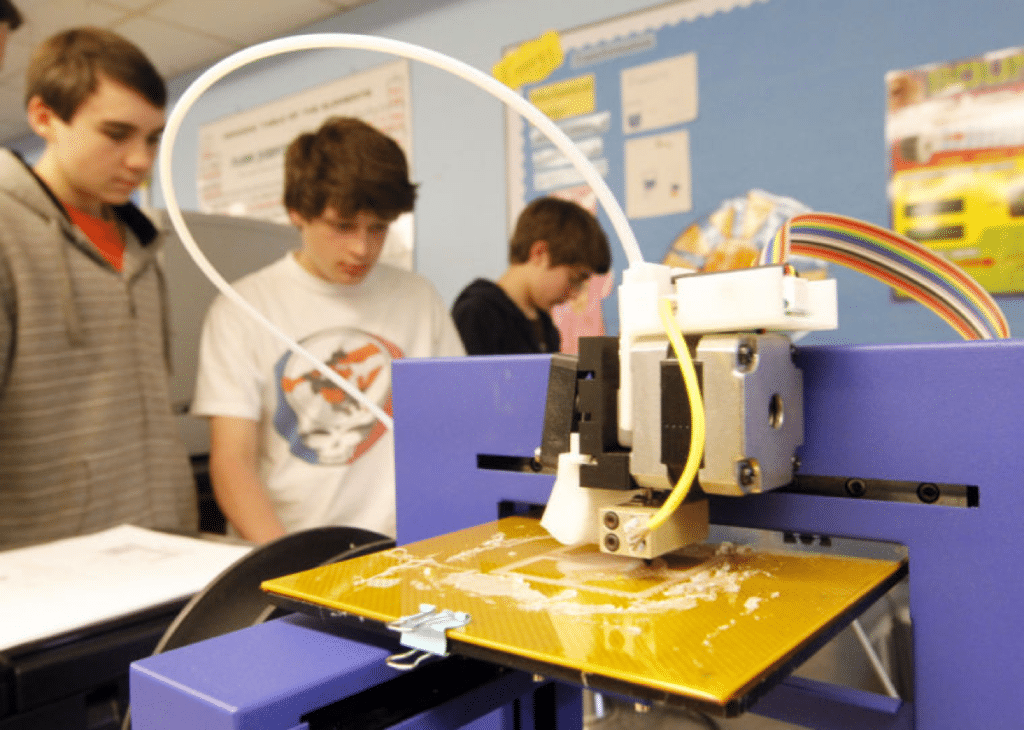

6. Education

What good are these jobs if no one has the qualifications to fill them? To help fill the skills gap, schools are developing – and some have already launched – 3D printing programs at all grade levels. This will open up jobs for educators who can teach the technical and business aspects of 3D printing.

“From an educational perspective, many K-12 schools are looking to 3D printing as a point of exposure for students within the arts as well as scientific areas of study,” Gunduz said. Colleges and universities are also launching 3D printing courses and certificate programs, such as NYU-SCPS’ certificate in 3D printing rapid prototyping.

Teachers will need to have a background in the 3D printing industry. They will also need specific skill sets to teach specialized courses and stay current on the latest trends.

“For educators, having an understanding of 3D modeling and 3D printing techniques will be invaluable, as the culture of fab labs is starting to gain support as an important aspect of education,” Gunduz said. “Teachers with 3D modeling and fabrication experience have a range of opportunities open to them within educational programs looking to incorporate this new technology.”

7. Legal professionals

3D printing is not confined to the tech world. As a creative field, the industry is wide open to legal issues, prompting a need for more lawyers and legal professionals who specialize in intellectual property (IP) rights.

“As 3D printing technologies advance and become more widely accessible, it will be easier for infringers to create, market, and sell products that infringe patents, copyrights, and valuable brands,” said Julie Matthews, partner at Edwards Wildman – an Am Law 100 firm with offices in the U. S., the U.K. and Asia. “As 3D printing technologies advance, new business models will emerge in which consumer products and their component parts can be copied, modified, juxtaposed with others and produced almost anywhere.”

S., the U.K. and Asia. “As 3D printing technologies advance, new business models will emerge in which consumer products and their component parts can be copied, modified, juxtaposed with others and produced almost anywhere.”

As a result, there will be an increased need for IP enforcement actions and lawsuits, as well as expanded services to monitor for infringements, Matthews explained.

Growth areas include IP ownership, scope of rights, licensing, fair use and international rights.

8. Startup companies

Thinking of starting a new business? 3D printing offers opportunities for innovation – not only in creating products, but also for entrepreneurship. 3D printing spans across various technical and design roles, many of which make great business ideas to support companies’ 3D printing needs.

“As 3D printing technologies advance and become readily accessible to home users, undoubtedly, this will lead to new business opportunities for individuals and companies offering onsite and remote 3D printing services, new product and industrial designers, and computer-aided design specialists,” Matthews said.

With 3D printing costing between $1,999 and $3,500, anyone with 3D printing knowledge can start their business.

Tip: Consider a 3D-printing-as-a-service franchise for your new business venture.

9. Administrative roles

3D printing companies don’t run on engineers and technicians alone. As the industry grows, new and established 3D printing companies will need employees to keep their business running smoothly. This includes operations and administrative staff, analysts, finance and sales professionals, and retail employees.

“The businesses that will spring up with new business models centered on 3D printing will also have a need for more common jobs that other businesses need, like marketing, clerical, shipping, etc.,” English said.

These jobs will open up in all types of 3D printing companies, including vendors, manufacturers and retail stores.

Business News Daily editorial staff contributed to the writing and reporting in this article. Source interviews were conducted for a previous version of this article.

Source interviews were conducted for a previous version of this article.

3D Printing Jobs of the Future

3D printing is one of the hottest STEM fields today. From airplane parts to cars, 3D printing is redefining the manufacturing industry.

“Multiple industries are reaping the benefits of utilizing 3D printing,” said Kforce Strategic Account Executive Tyler Brown. “Efficiencies are built, money is saved and new technologies constantly emerge.”

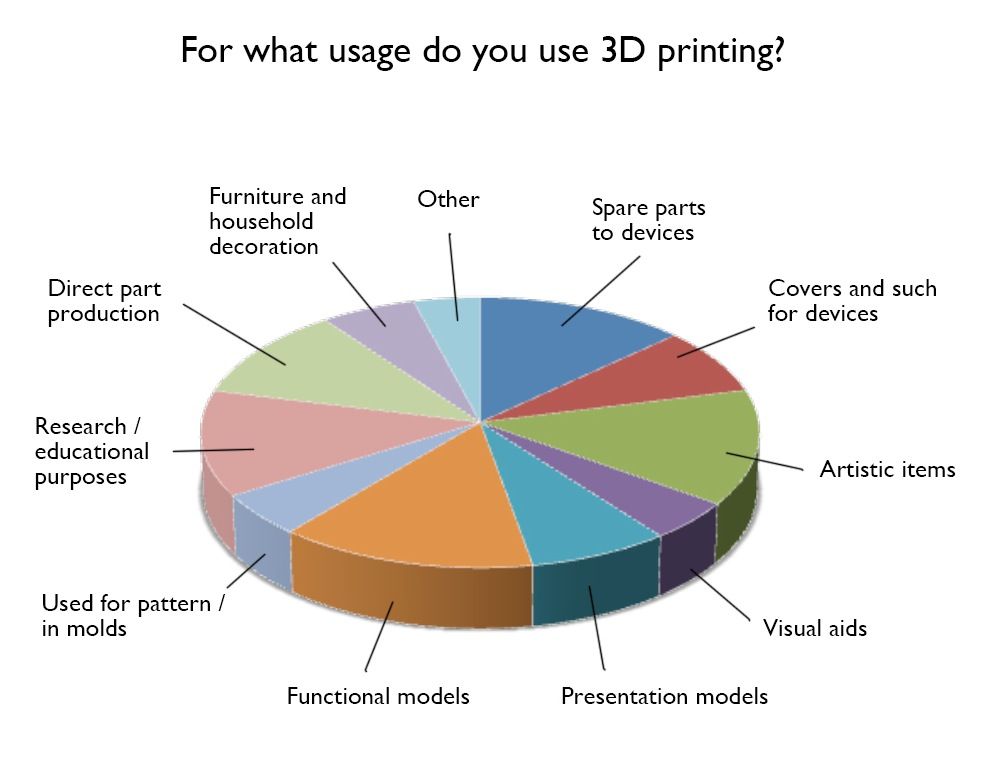

Also, nearly 41% are considering 3D printing adoption by 2022. As 3D printing continues to expand, so does the need for qualified professionals to break the mold. Organizations are searching for specialized individuals to understand the technology, operate and innovate.

Companies are looking for people who can quickly understand what 3D technology is capable of and start applying that to business problems.

— Tyler Brown

3D printing technology is still young. There is much exploration to be done to realize the breadth of capabilities within 3D printing. With any emerging domain, new 3D printing jobs are on the horizon. The future talent landscape of 3D printing will create new occupations as industries capitalize on this burgeoning technology’s potential.

There is much exploration to be done to realize the breadth of capabilities within 3D printing. With any emerging domain, new 3D printing jobs are on the horizon. The future talent landscape of 3D printing will create new occupations as industries capitalize on this burgeoning technology’s potential.

Check out these pioneering 3D printing jobs of the future below:

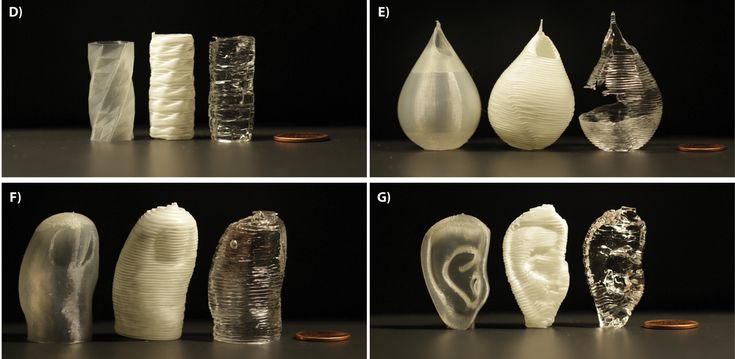

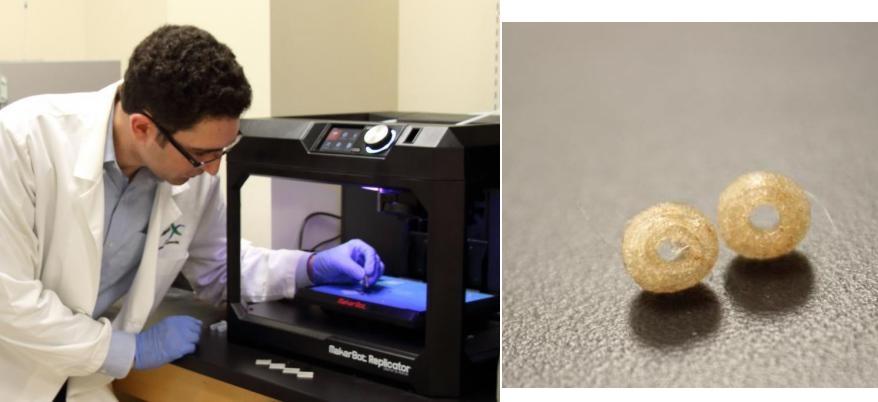

Biomedical Science: 3D organ and prosthetic designers

Perhaps one of the most significant spaces in the future of 3D printing is biomedical science.

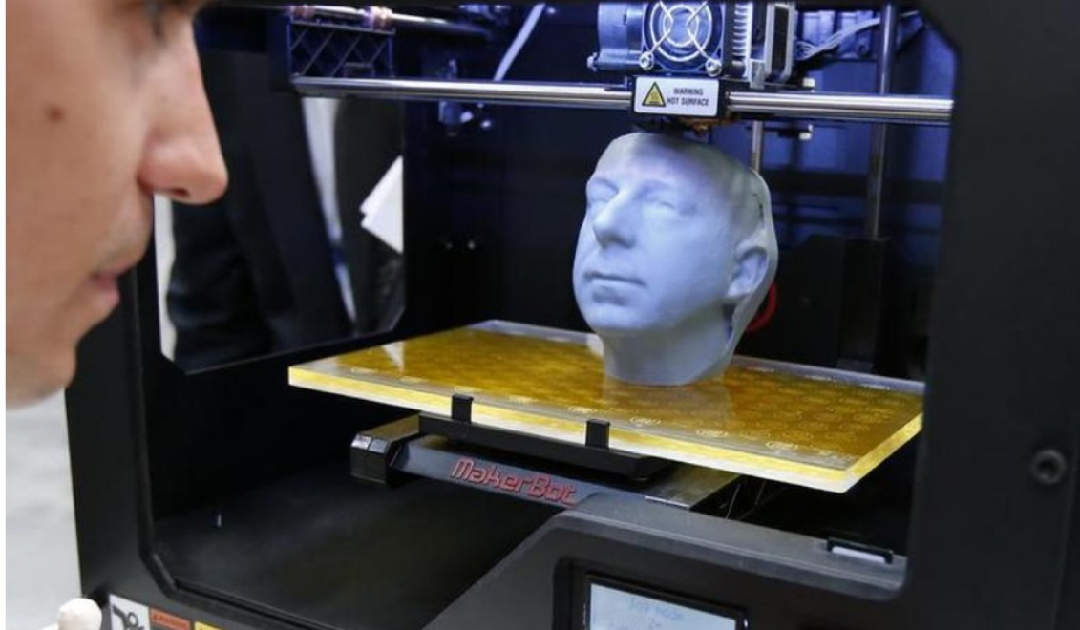

Undeniably, exciting things are happening. In less than a decade, scientists report that 3D bio-printed tissues will be available for use. Yes, you read that right! Researchers are currently developing 3D printing technology to print skin, build hearts and other vital organs.

3D printed organs, once approved for human use, will revolutionize the medical space. The possibilities are endless, and they will change lives. Long wait times for organ donations will cease to exist as doctors will have the ability to print organs when patients need it. Car accident and burn victims can have functional bio-printed skin grafts to heal wounds.

Long wait times for organ donations will cease to exist as doctors will have the ability to print organs when patients need it. Car accident and burn victims can have functional bio-printed skin grafts to heal wounds.

Search Jobs

Alongside printed tissues, 3D printing technologies are allowing for the custom design of prosthetics, making prosthetic limbs and other physical aids more accessible to people. Prosthetic wearers will soon enjoy tailored devices, improving their quality of life through the ability to do the activities they love.

Since 3D printed prosthetics are projected to cut cost and manufacturing time, more devices will also be available for consumption. In the U.S., advanced prosthetic limbs can range from $5,000 to $50,000. However, a 3D printed limb could be made for the price of an oil change—for as little as $50.

This application of 3D printing in the biomedical field will help change the way we treat patients and provide medical care. For this revolution to happen, new professionals such as 3D organ and prosthetic designers who understand biology, anatomy, technology and manufacturing will emerge.

For this revolution to happen, new professionals such as 3D organ and prosthetic designers who understand biology, anatomy, technology and manufacturing will emerge.

Job responsibilities:

- Using biomaterials and 3D printing technology to create bioengineered products

- Creating prototypes and fitting newly created organs and limbs for human use

- Executing end-to-end design and product implementation

- Designing algorithms to perform body functions

- Employing software to tackle bio-engineering solutions

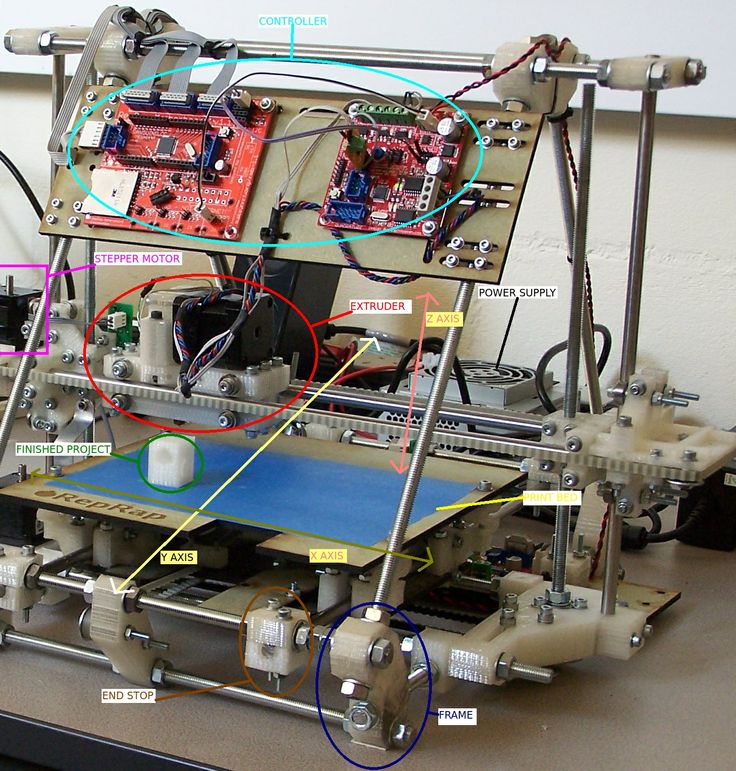

Computer Science: 3D printing software developers

Another growing STEM career alongside the onset of 3D printing technology is the high demand for software developers. This career is vital to discover the full potential of 3D printers and how to use the technology. In the years to come, experts forecast 3D printers to become universal household items like the desktop printer.

The current state of 3D printing doesn’t have a seamless interface for users with a non-technical background. Computer programmers are needed to create user-friendly software, features and functions to improve the accessibility of 3D printers.

As cloud-based 3D printing alternatives become more available, web developers will also rise in demand. Programmers with backgrounds in user experience, software testing and API integration will be an additional asset to the additive manufacturing industry.

Perfect candidates for this career field will be familiar with 3D printers or other manufacturing processes. Prospective employees for 3D printing jobs will also possess the ability to work along scrum teams to write efficient, testable code to solve challenging technical problems.

Job responsibilities:

- Integrating and testing software modules to debug interface issues

- Combining 3D CAS model geometry with programming knowledge

- Building new capabilities and optimizing existing code alongside evolving technology

- Designing cross-platform software based on specifications and required functionality

- Collaborating with scientists, engineers and technicians in the development of control software

Law: 3D printing IP and copyright lawyers

While 3D printing continues to unlock possibilities for manufacturing, it’s becoming increasingly easier to reproduce products.

Today, users can simply download computer-aided design (CAD) files to 3D printers for production. Greater access to 3D printing technology will create a new domain of law careers to prevent intellectual infringement, protect patents and provide legal services.

Effective management of intellectual property (IP) ownership will be pivotal for brand reputation to avoid similar catastrophes like digital sharing and piracy that ran rampant from the 90s through the early 2000s.

New arenas of 3D application in courtrooms might also emerge in liability cases to determine whether a product has faulty design during litigations. Firms could use 3D printers to prototype evidence, demonstrate findings in real-time and illustrate a product’s bad design before a courtroom’s eyes.

STEM careers in this field will demand legal practitioners who understand the concept of 3D printing, industry developments and the reaches of law for intellectual protection. If you have a passion for 3D printing and an affinity for intellectual law, a 3D printing lawyer might be the job for you.

Job responsibilities:

- Applying knowledge of the patent, copyright, intellectual property and licensing laws

- Protecting and defending the client’s intellectual property in court

- Understanding 3D printing techniques and additive materials for patent applications

- Using algorithms to design and replicate existing products for reproduction

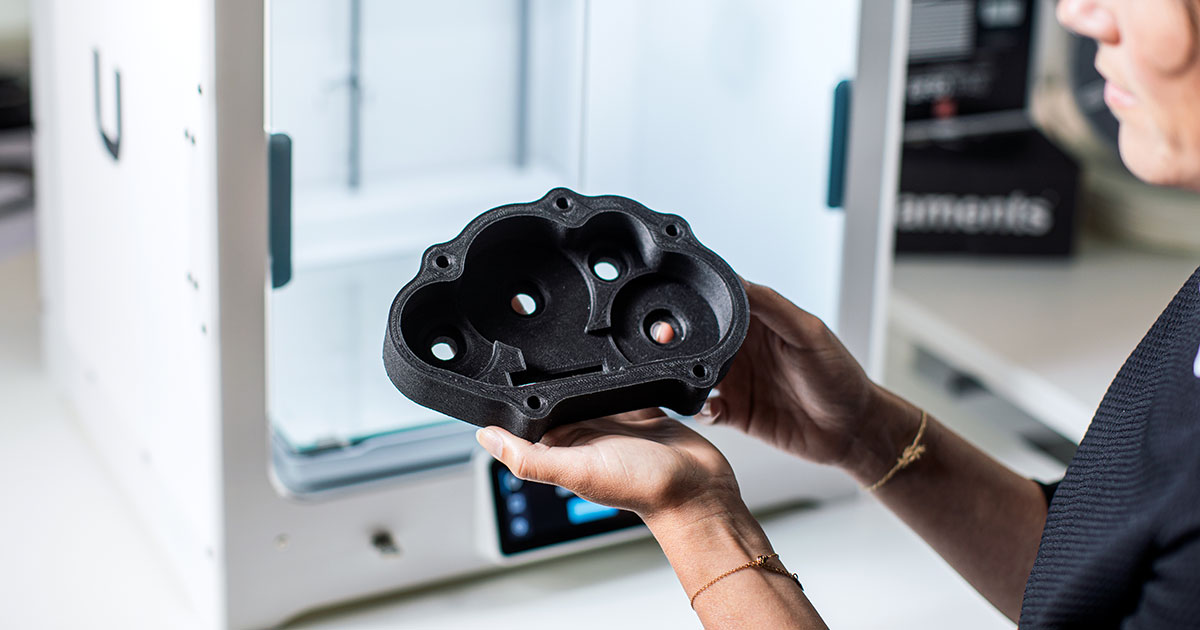

Automotive: 3D printing auto mechanics and engineers

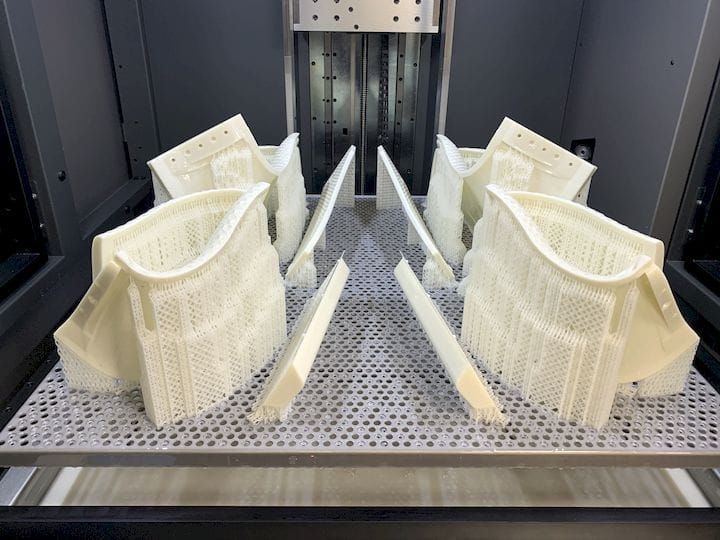

The automotive industry has already begun to create and develop 3D printed cars in the hopes of innovative products, an accelerated development process, efficient part replacement and further personalization.

Organizations are increasingly leveraging 3D printing to manufacture car parts independent from third parties. To date, companies have used 3D printing for prototyping as a cost-effective method for designing and testing new concepts with speed to market.

In the natural evolution of supply and demand, there will be a push to harness 3D technology for customization. Futurists foresee automobile customization for individual needs and specific driver experiences as a new market.

3D printed cars won’t be mainstream for some time, but when commercialization is finally scalable, who will design and repair the vehicles of the future? The answer—3D printing mechanics and engineers.

The automotive industry will need qualified talent who understand 3D printing concepts to create replacement parts and custom vehicles quickly per consumer demand.

Job responsibilities:

- Preparing schematics and drawings to construct prototypes

- Understanding consumer needs to achieve customer satisfaction

- Improving iteration cycles for product design and manufacturing

- Using technical knowledge of mechanics, materials and design to create components

Without a doubt, 3D printing is changing our world and will lead to one of the most groundbreaking STEM careers in the years to come. The future workforce of 3D printing will need talent interested in transcending traditional manufacturing techniques. This transportive technology will redefine how we engineer products and experiences to better our everyday lives.

The future workforce of 3D printing will need talent interested in transcending traditional manufacturing techniques. This transportive technology will redefine how we engineer products and experiences to better our everyday lives.

Those proficient in this rapidly evolving space will be pioneers who are determined to push the boundaries of 3D printing, curious to discover new applications and passionate about revolutionizing our future.

Are you a STEM professional looking to break into the 3D printing sector? Click here to learn how to highlight your experience on your resume to land a career in this ever-growing field.

Search Jobs

×

Our STEM Webinar Series is Now Available On Demand

No Thanks

20 Use Cases for 3D Printing

3D printing has progressed so rapidly in recent years that we will soon stop talking about what can be created using additive manufacturing. It will be easier to mention what cannot be done. Yes, this list will continue to grow rapidly. But for now, let's take a look at some examples showing the wide range of 3D printing possibilities. We warn you in advance: the list is far from complete.

It will be easier to mention what cannot be done. Yes, this list will continue to grow rapidly. But for now, let's take a look at some examples showing the wide range of 3D printing possibilities. We warn you in advance: the list is far from complete.

Fruit

A gift for impatient parents

Young parents often experience an irresistible desire to acquire all sorts of items, one way or another related to their child, even if not yet born. The Japanese company Fasotec offers future parents models of unborn babies made from images of real fetuses obtained using magnetic resonance imaging. The finished model consists of two materials - a fetal figurine made of white photopolymer, and a transparent material that imitates the shape of the mother's womb. At around $1,275, the fun isn't cheap, but Fasotec already has some competition. So, 3D Babies offers a similar service for only $200, although the size of the finished model is much smaller, and the quality is not quite on the same level.

Although the desire to get such a model may seem a bit strange, there is a perfectly logical explanation. As it turns out, the idea was originally aimed at giving blind parents the opportunity to "look" at the ultrasound of the unborn child.

Weapons

Functional 3D printed receiver from AR-15 without any numbers

The possibility of 3D printing of weapons has seriously alarmed law enforcement agencies around the world. After all, even simple FDM printers allow you to create all-plastic guns. Although such a weapon is primitive, even a disposable pistol with a single cartridge in the hands of a criminal can cost someone a life, and it is impossible to trace such a weapon. However, there are also people who believe that 3D printing of weapons should be allowed. Thus, the US Constitution gives citizens the right to freely carry weapons, although certain restrictions still apply. The non-profit organization Defense Distributed, which released the Liberator plastic pistol into the public domain, went further by unveiling the design of the lower receiver of the AR-15 carbine. AR-15 is actually a civilian counterpart, even a prototype of the M-16 automatic rifle, which is in service with several countries of the world. The lower part of the receiver bears the registration number - this is the only part of the rifle that cannot be purchased as a spare. Thus, the printing of this part can bypass the need to register weapons. Some countries have already banned the 3D printing of weapons, although it is not entirely clear how to apply this ban in practice.

AR-15 is actually a civilian counterpart, even a prototype of the M-16 automatic rifle, which is in service with several countries of the world. The lower part of the receiver bears the registration number - this is the only part of the rifle that cannot be purchased as a spare. Thus, the printing of this part can bypass the need to register weapons. Some countries have already banned the 3D printing of weapons, although it is not entirely clear how to apply this ban in practice.

Clothes

One of Snezhana Gross' designs

Some consumables for 3D printing, especially soft photopolymers, are quite suitable for making clothes and even underwear. The bra in the illustration was laser sintered from nylon. This design from Continuum Fashion aims to showcase the possibilities that 3D printing opens up for couturiers. However, don't think this is an experimental model: the company offers finished products for sale on the Shapeways website.

Russian designers did not bypass the new technology either: Snezhana Gross demonstrated casual wear designs integrating functional 3D printed components.

Art

Easy to print. Take a picture - as lucky

Would you like a replica of the Venus de Milo? No problem, just choose the material and printing method. True, marble is not yet on the menu, but sandstone imitators are already available. Gypsum was one of the first materials for 3D printing. A three-dimensional image of the original can be obtained using a regular photo and then converted to 3D. In addition, more and more 3D scanners have recently appeared on the market, including portable hand-held options that can capture images of large objects. It remains a mere trifle - to agree on a stereo photo session with the security of the Louvre.

Although, if you are too lazy to make digital models yourself, you can always download them.

Products

What's for breakfast?

Although giant hot dogs are still far away, 3D printers have already learned how to print minced meat. An example of this is the Foodini culinary printer, a simple and practical device using syringe extrusion. Moreover, printing is possible not only with minced meat, but also with any pasty product - dough, cheese, tomato puree. The only thing that Foodini is not yet capable of is heat treatment. It is to be expected that soon there will be devices that combine 3D printing with refrigeration units and, say, microwave ovens. Then sci-fi tales of "replicators" can come true. One press of a button, and the device will lay out the desired pizza and bake it to the delight of the user. Just one question: do you like thin dough or fluffy?

Moreover, printing is possible not only with minced meat, but also with any pasty product - dough, cheese, tomato puree. The only thing that Foodini is not yet capable of is heat treatment. It is to be expected that soon there will be devices that combine 3D printing with refrigeration units and, say, microwave ovens. Then sci-fi tales of "replicators" can come true. One press of a button, and the device will lay out the desired pizza and bake it to the delight of the user. Just one question: do you like thin dough or fluffy?

Characters

Parts of models used to animate ParaNorman's protagonist

Whether it's a miniature version of a giant robot from a favorite manga, a creepy alien creature from Alien, or a Keanu Reeves action figure (as in a black cape and sunglasses, and with a beard and a sandwich sitting on a bench), 3D printing allows you to create replicas of game and movie characters for the delight of fans. And the fact that such souvenirs can be printed even on household 3D printers opens up great opportunities for those who like to collect such models - after all, not all of them are available for sale. Do you want a model of a rare aircraft? Print it.

Do you want a model of a rare aircraft? Print it.

And what is most interesting, this application has already had the opposite effect. ParaNorman cartoon characters were still printed. Like the new RoboCop suit. True, inside it was still stuffing from a person. But why stop at simple visualization?

Home Robots

Early Terminator Prototype

The advent of inexpensive Arduino boards made it possible to design a wide variety of electronic devices at home. Here are your own 3D printed robots. You printed the case, inserted the servos and the board, and you have a new au pair. But what about people who do not understand programming or elementary soldering? Scientists from the Massachusetts Institute of Technology are developing a project aimed at automating the design and construction of domestic robots. Ideally, the user will only have to set the necessary functions for the future device, after which the system will compile the required design and send it to print. A few hours later, it will be possible to pick up a ready-made device - a robot-spider for wiping chandeliers or a machine for turning pancakes.

A few hours later, it will be possible to pick up a ready-made device - a robot-spider for wiping chandeliers or a machine for turning pancakes.

Aviation

3D printed part used in Chinese fifth generation fighter aircraft prototypes

The toy airplanes we have already mentioned. What about real ones? There is also a place for additive manufacturing in the aircraft industry, although here one cannot do without expensive industrial plants capable of creating high-quality parts, including all-metal ones. Leading aircraft manufacturers, including Boeing and Lockheed Martin, are already testing laser sintering and melting technologies for the production of ventilation systems, structural components and even jet engine parts. Chinese engineers, on the other hand, set to work on a real scale, creating installations for the additive production of parts weighing up to 300 tons.

Space

Dragon v2 is Space's latest creation

The space industry is not far behind the aviation industry in its interest in 3D printing. NASA successfully tested titanium rocket engine nozzles, and a few weeks ago, Elon Musk, the head of the private space company SpaceX, held a presentation of the new Dragon v2 orbiter, which also uses engines with 3D printed parts.

NASA successfully tested titanium rocket engine nozzles, and a few weeks ago, Elon Musk, the head of the private space company SpaceX, held a presentation of the new Dragon v2 orbiter, which also uses engines with 3D printed parts.

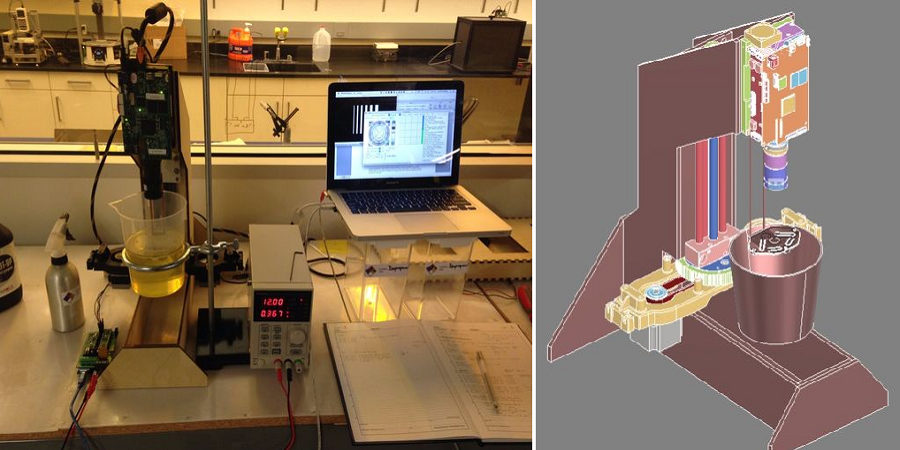

Bioprinting

Biopens can help treat fractures

Vessels, tissues, whole organs - several companies are simultaneously developing the production of organic imitators that are completely similar to natural tissues. Although transplantation of 3D printed organs is still far away, work in this direction is underway. In parallel with the production of organic tissues from scratch, methods are also being developed to restore damaged tissues, such as cartilage or bone. Devices called "biopens" are able to apply living cells to damaged areas, promoting their healing.

Prostheses

Titanium orthopedic prostheses with a porous structure for improved osseointegration

What if the tissues cannot be restored? 3D printing can help with prosthetics. Thus, the Swedish company Arcam creates installations for electron-beam melting, which make it possible to create virtually monolithic metal products, including titanium. Titanium orthopedic prostheses have become one of the most sought-after products created on the devices of this company - according to company statistics, their number exceeds thirty thousand copies.

Thus, the Swedish company Arcam creates installations for electron-beam melting, which make it possible to create virtually monolithic metal products, including titanium. Titanium orthopedic prostheses have become one of the most sought-after products created on the devices of this company - according to company statistics, their number exceeds thirty thousand copies.

Not only that, 3D printed limbs can compete with high-tech designs with one difference - their cost cannot be compared. How many people can afford a tens of thousands of dollars of prosthetic hands? How about a $50 fully functional prosthesis? And it's possible.

An even more common application of additive manufacturing is in dental prosthetics. If you have recently had a crown or bridge placed, it is possible that they were cast from models created with a stereolithography printer that prints with photopolymer resins.

Musical instruments

3D printed musical instruments

Guitars? Flutes? Drums? Easy. Broke your oboe - print a new one. Of course, professional musicians can argue: plastic guitar? Not serious. But who said that all tools have to be made of plastic? The same neck can be printed from wood resin, similar in density to natural wood. You can even print a composite carbon fiber core. And as far as simply decorating your favorite harpsichord, 3D printing can work wonders here. It would be fantasy!

Broke your oboe - print a new one. Of course, professional musicians can argue: plastic guitar? Not serious. But who said that all tools have to be made of plastic? The same neck can be printed from wood resin, similar in density to natural wood. You can even print a composite carbon fiber core. And as far as simply decorating your favorite harpsichord, 3D printing can work wonders here. It would be fantasy!

Shoes

Luc Fusaro's stylish trainers

Eight-time world sprint champion Usain Bolt is famous for his love of gold. This includes not only medals, but also cars and even shoes. During his contract with renowned manufacturer Puma, Bolt wore signature gold-plated sneakers. And more recently, engineer and designer Luke Fusaro has taken on the development of sports shoes that Usain would like. Its distinctive feature is its golden color. Oh yes - and it's also designed for 3D printing. The use of additive manufacturing has one important bonus, namely the ability to produce shoes that are precisely tailored to the size and contours of the athlete's foot. Such shoes are produced by laser sintering, although this technology has already had a competitor.

Such shoes are produced by laser sintering, although this technology has already had a competitor.

Drugs

3D printing can facilitate the production of mixed drugs and help with drug testing on living tissues often in combination with tissue engineering. Thus, the Organovo company directs its efforts to create artificial human liver tissues to test new drugs for toxicity without risk to human health. But the drugs themselves can also be printed by binding the drugs with a gel material. As a result, we get ordinary-looking pills, but with a complex content of drugs, tailored to a particular patient.

Cars

Doc Brown is introduced to 3D printing. That's about the reaction you'd expect.

Most automotive components can be printed, but it's not economically viable when it comes to mass production. But for prototyping new cars, 3D printing is great. As, however, for the production of unique machines or components. For example, you can print replacement parts for low-volume, discontinued models. Where else can you find parts for, say, the DeLorean that inspired the Back to the Future time machine? The only small company still making parts for this car is in Texas. Shipping parts can cost more than the machine itself, quite inexpensive.

Where else can you find parts for, say, the DeLorean that inspired the Back to the Future time machine? The only small company still making parts for this car is in Texas. Shipping parts can cost more than the machine itself, quite inexpensive.

Customization

Maximum glamor at minimum cost

Why not take a finished product and add decorative elements? Turn your bike into a work of art for everyone to envy. Gold-plated openwork fasteners on a black chassis will make passers-by look back. But it is not necessary to stop at the decorative aspect! Maybe you are not satisfied with the seat? Why not print a new one? Or add more comfortable handles? Klaxon style 1910s?

Furniture

One of Joris Laarman's clever designs

Toy furniture? No, not only. The advent of composite materials for FDM printing makes it possible to print "wooden" furniture, almost indistinguishable from the real thing. Actually, the material Laywoo-D3 could not do without real wood in the form of micro-sawdust. This stuff even smells like wood! Finished products are easily machined and varnished.

This stuff even smells like wood! Finished products are easily machined and varnished.

Or do you prefer metal furniture? Dutch designer Joris Laarman has created his own machine for metal 3D printing, without the use of expensive powders, vacuum chambers and lasers. The device draws with metal in the air, allowing you to create elegant interlaced designs.

Jewelry

Beautiful and functional

A clear demonstration of the precision of 3D printing is its application in jewelry. It should be said right away that not all technologies are suitable for this task. Widespread FDM printers are attractive due to their cost-effectiveness, but in terms of print quality they do not reach the standards of jewelry production. The most popular choice is laser (SLA) and projector (DLP) stereolithography - installations using these technologies allow printing photopolymer parts of extraordinary accuracy. Such products are used as master models when creating jewelry casting molds, greatly simplifying the production process.

But there is also an option for direct additive manufacturing of jewelry: laser sintering and melting technologies make it possible to create finished products from metal powder, including precious metal powders. True, the cost of such installations and materials is often too high for widespread use even by jewelers.

Construction

3D printing of buildings will help solve housing problems experimenting with the construction of concrete "boxes". True, these attempts are still quite primitive, because a real house will also need infrastructure - drainage, wiring ... Andrey Rudenko's attempts to build a full-fledged house are very promising. Andrey designed his own printer capable of printing with commercially available cement mixtures. Moreover, he already had competitors. Thus, the BetAbram company plans to put on sale printers for printing buildings up to 16x9m. The issue price is about $44,000 for the largest of the three models. True, "more" is not necessarily "better". Spanish developers are trying to go in the direction of miniaturization of 3D construction printers, creating robots that can use already built building elements as a working support.

Spanish developers are trying to go in the direction of miniaturization of 3D construction printers, creating robots that can use already built building elements as a working support.

Which method will be the most practical, time will tell. But if any of them succeeds, the construction industry can make a qualitative breakthrough, expressed in increased savings, safety and speed of building construction.

3D printers

What else can I print with a 3D printer? Another 3D printer! Even if not entirely yet: the necessary electronic and electromechanical components are not yet subject to printing, but this is only a matter of time. Almost all materials used or close analogues have already been tested by various additive manufacturing methods. It remains only to wait for the appearance of machines capable of using the full range of consumables. Then the RepRap project, which gave impetus to the development of compact self-replicating 3D printers, will come to a logical conclusion.

Article prepared for 3DToday.ru

10 industries that 3D printing is starting to change

3D printing has come a long way from printing small prototype buildings out of plastic. Today, 3D printing is fulfilling its potential in a range of industries, from aerospace to apparel and footwear.

This technology not only allows you to create items with incredible precision, but also saves money.

Today, there are many materials that allow you to make a wide variety of objects using 3D printing.

Below we will talk about the industries in which this technology is used.

1. Aerospace

In the aerospace industry, everything must be made with high precision. Precision plays a very important role here in the execution of every space mission, and the industry itself is extremely important for the development of mankind.

3D printing has already begun to change the industry, it is used to replace many parts that have become too expensive to produce. In addition, the technology is used to test prototypes.

In addition, the technology is used to test prototypes.

ULTEM 9085 is a thermoplastic commonly used in aircraft construction that can be melted down and used in 3D printing.

2. Architecture

3D printing technology saves time in building construction.

With this technology, printing houses is as fast as printing documents.

And when creating a design, you can share it with other users by placing an object in the database.

3. Food

While 3D printing doesn't save lives, it could change the way we think about food.

Nevertheless, experts note that in the future humanity will face a shortage of food, it is already becoming increasingly difficult to feed the growing population of the planet.

However, science is looking for ways to grow meat and use alternative materials to produce food.

4. Product design

Technology allows you to design something on a computer, then print it in an hour, test it, find flaws, redesign, print a second prototype - and all this takes only half a day.

Previously, concepts were produced, but now 3D printing technology makes it possible to get closer to an almost identical representation of products in a very short amount of time.

5. Medicine

3D printing plays an important role in almost every aspect of medicine. When it comes to prototyping, technology allows you to create ready-made models that will cost less and take less time to create, and these will be ready-made models that are completely usable.

Clarity and precision allows you to print ultra-fine lines that allow you to create the smallest tools.

In addition, 3D printing technology allows you to recreate parts of the human body using various materials. Scientists are constantly working to create new materials and textures.

6. Dentistry

Making dental models is very useful, but it is not always possible to make them taking into account the individual characteristics of a person.

3D printing technology allows you to make exact copies of a patient's teeth to replace them, or crowns that can last longer.

Objet Digital is a dedicated 3D printer designed for use in the field of dentistry.

He uses materials that are very similar in structure to bone to print teeth.

7. Construction

In Dubai, 3D printing is an increasingly common way to construct buildings. Cazza, a 3D printed construction company, plans to build the world's first 3D printed skyscraper.

They created special machines that can build buildings from the bottom up.

Companies around the world have expressed interest in such machines.

In addition, this method of building construction leaves less debris. During construction, environmentally friendly materials can be used.

8. Agriculture

It may seem strange to use this technology in agriculture, but it is true. Many farms need specialized tools, which cost between $8,000 and $12,000 and can take months to complete.

Many farms need specialized tools, which cost between $8,000 and $12,000 and can take months to complete.

PLA, or polylactic acid, is a material that is used for 3D printing and costs $0.25 per 1.5 cu. m. This can significantly save money and time for farmers who are looking to upgrade their machines.

9. Making clothes and shoes

So far, 3D printed clothes have not entered the mass market, but the idea of such clothes has been developed since 2013.

The idea is that in the future, customers can print clothes, which suits their individual sizes.

10. Organ printing

3D bioprinting is a new application that is developing at a rapid pace.

Scientists have made great progress in printing ribs, but they also believe that in the future it will be possible to print hearts, kidneys, livers and other organs.

Cell Link is a company that works with products of this kind, donor organs will soon become mostly artificial.