3D scanner malaysia

3D Scanner solution in Malaysia & Singapore

PLM Products & Brands

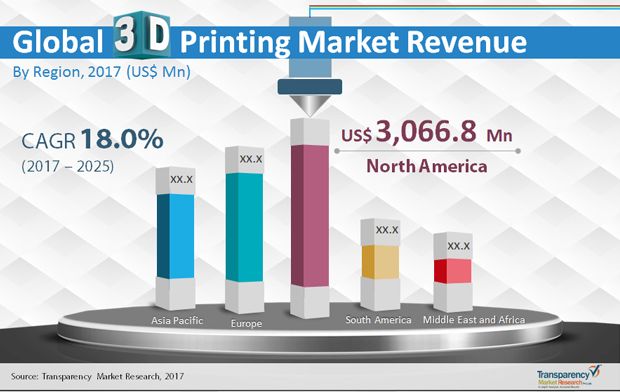

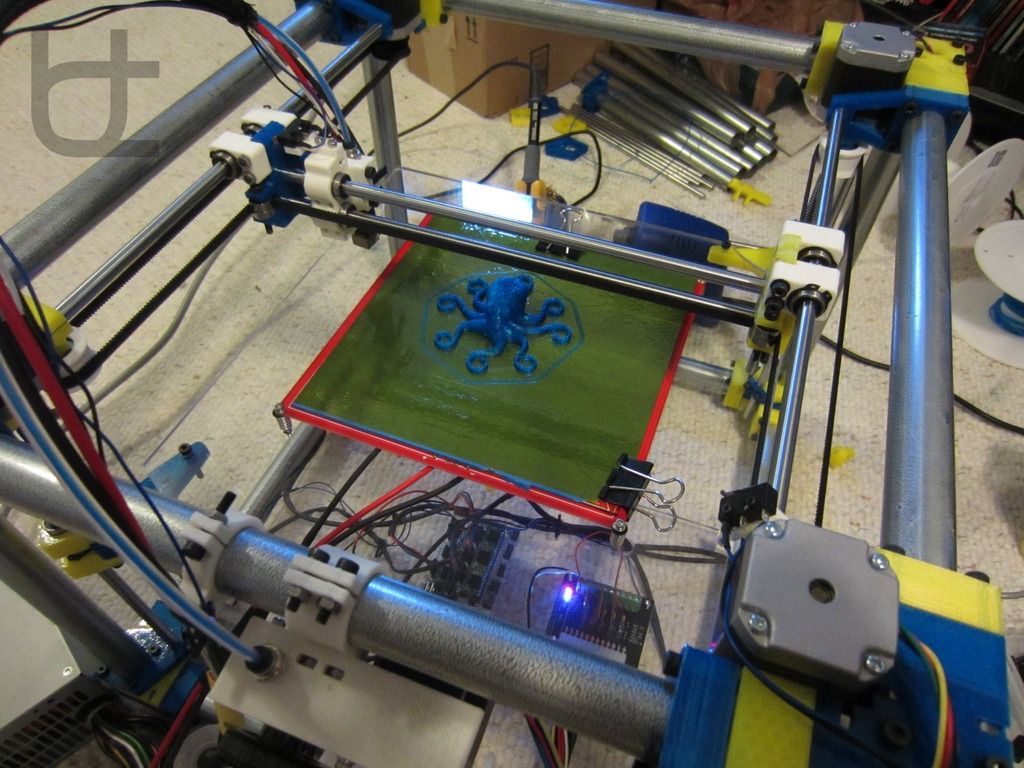

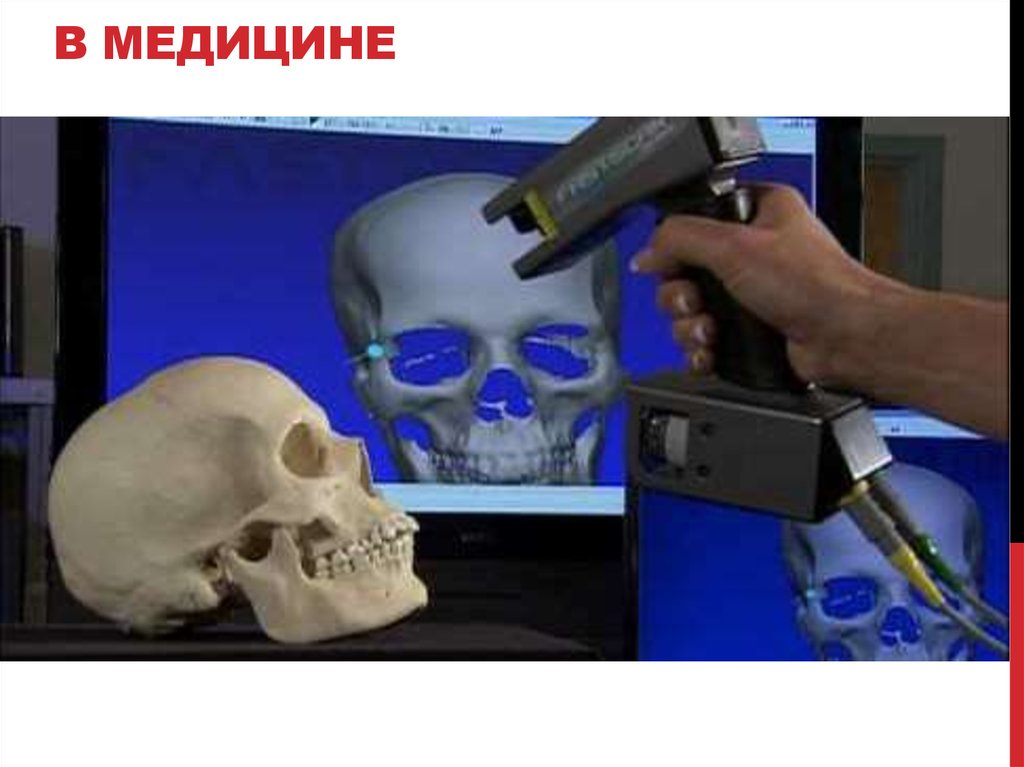

3-D scanners are used for creating life-like images and animation in movies and video games. Other applications of 3-D scanning include reverse engineering, prototyping, architectural and industrial modeling, medical imaging and medical device modeling. 3-D printers can use data from 3-D scans to create physical objects.

Not sure which 3D Scanner products or brands do you need?

Speak to our representative!

With more than 15 years of experience in PLM solution, our consultants and engineers are equipped with great skills and knowledge and ready to help.

Contact DTS

Alternatively checkout the following list of 3D Scanner products and brands:

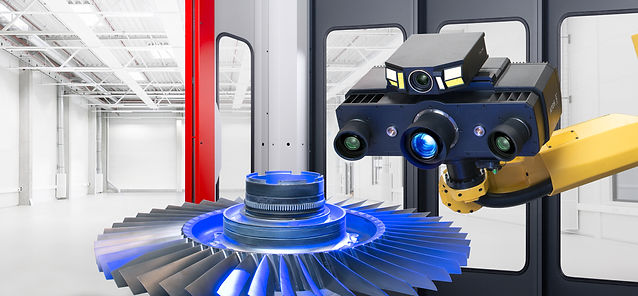

RobotScan E0505

Full Size & Mass Automatic Inspection

Accuracy: 0.015 mm

Measuring Range: Maximum

Scan Diameter: 500 mm

Light Source: Blue light

OptimScan 3M/5M

Extraordinary speed and accuracy for dimension inspection.

Accuracy: From 0.005-0.015 mm

Measuring Range: From under 1.5 meter

Light Source: Blue light (LED)

FreeScan UE Laser Handheld 3D Scanner

FreeScan UE is the blue laser handheld 3D scanner with its ergonomic and lightweight equipment design. It is easier to hold and operate, providing metrology-grade, high-precision inspection solutions for the automotive, transportation, aerospace industry, moulding inspection, energy generation, machinery manufacturing and etc.

OptimScan-5M Metrology 3D Scanner

OptimScan-5M 3D scanner is the latest blue light 3D scanner in the market. Featuring high-end outlook, structure, component and configuration. Its 5.0 megapixel cameras and blue light scanning technologies provide users with incredible scanning speed and precision, making it ideal for high-end applications such as defense, aerospace, and the mold industry, among others.

EinScan HX

EinScan HX is a handheld 3D scanner which integrates with blue LED light and blue laser. With LED light sources and a hybrid laser, it is compatible with a larger range of item sizes and can fulfil a variety of user needs.

With LED light sources and a hybrid laser, it is compatible with a larger range of item sizes and can fulfil a variety of user needs.

EinScan H

EinScan H makes human face scanning more comfortable by combining LED and invisible infrared light in a hybrid structure light technology. Built-in color camera and large field of view and provides high quality 3D data with full color ready-to-use in minutes.

EinScan Pro HD

EinScan Pro HD delivers unparalleled performance in capturing high resolution and accuracy by handheld scanning.The ultimate high-efficiency and professional-grade 3D scanning experience combines exceptional adaptability and powerful optimizations.Designers and engineers who care about high-quality 3D modelling will find a reliable assistant in this handheld 3D scanner.

Not sure which 3D Scanner products or brands do you need?

Speak to our representative!

With more than 15 years of experience in PLM solution, our consultants and engineers are equipped with great skills and knowledge and ready to help.

Contact DTS

3D Scanning – Trinventor Solution Malaysia

3D Scanning – Trinventor Solution MalaysiaWorld Is In Your Hands

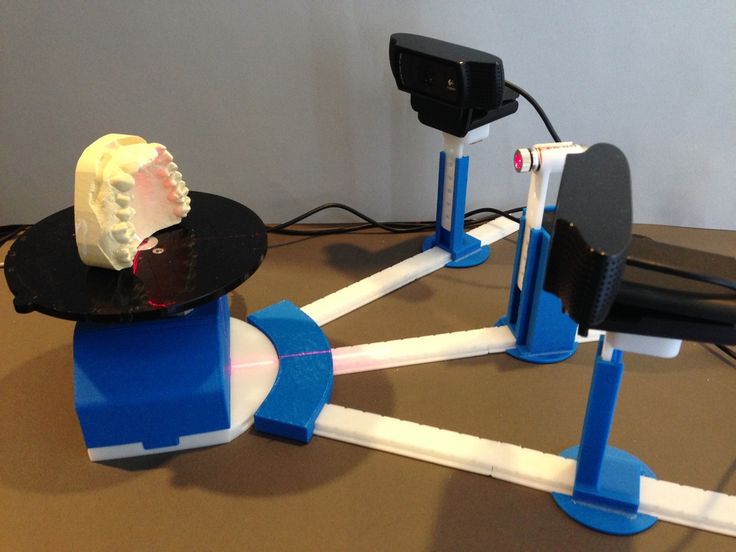

What is 3D Scanning / 3D Digitizing?3D scanners are powerful tools for professionals in several industries, such as automotive, aerospace, dental, and jewelry, as well as in more artistic applications such as video games, special effects, and animation movies. 3D scanning also known as 3D Digitizing is a process of analyzing a physical object from the real world to digitally collect all the data of the object from the shape to the appearance. With this process the object data will turn into a 3D digital model which is useful for a wide variety of applications such as reconstruct, reverse engineering, analyse, 3D print or simulate ideas.

3D Scanning TechnologiesIn order to 3D scan different type of objects, there are a lot of different technologies being used in 3D Scanners and each one has its pros and cons. In general the most common used technologies are: 3D Laser Scanning, Structured Light Scanning.

In general the most common used technologies are: 3D Laser Scanning, Structured Light Scanning.

3D Laser Scanning

3D Laser Scanning is certainly the most common and used 3D scanning technique. Digitally capturing the shape of the object using laser light to get a digital representation of the real object. These 3D scanners are able to measure really fine details and capture free-form shapes to generate highly accurate date (point clouds). This laser scanning technique is perfect for measurement and inspection of complex geometries. It allows getting measurements and data from where it is impractical with traditional methods. A scanner using laser light is a little bit like a camera, it can only capture what is in its field of view. With this process, a laser dot or line is projected on an object from the device and a sensor measures the distance to the surface of this object. By processing this data, it can then be converted into a triangulated mesh, and then a CAD model.

Structured Light Scanning

The basic function of a structured light scanner is simple, project a structured light pattern onto an object, then film it with at least one camera to capture the ways in which the object deforms the light pattern. By triangulating multiple images of the scan then calculate the dimensions of the object in all its complexity. Most scanners use a pattern of alternating stripes, similar to the shadows cast by sunlight shining through Venetian blinds. With finely calibrated stripes and accurate cameras, it’s possible to measure the dimensions of very small details. Structured light scanning is often used as an checper alternative to 3D laser scanning.

Types of 3D scanners for for Industrial Sphere Sphere

Fig. 1 exemplifies the typical classification of 3D scanners available in the market for performing their tasks for fulfilling the required functions. The 3D scanning devices are usually classified based on the principle employed to enable them to work. Based on this fact, the 3D scanners are of six types, namely, laser triangulation, structured light, photogrammetry, contact-based, laser pulse type, and optical-based. All these types are associated with several types of uniqueness, merits, and limitations as well. But with the technology continue to improve some manucaturer also producing Hybrid mode 3D scanner which improves scanning materials adaptability with less limitation for a wider range of applications

Based on this fact, the 3D scanners are of six types, namely, laser triangulation, structured light, photogrammetry, contact-based, laser pulse type, and optical-based. All these types are associated with several types of uniqueness, merits, and limitations as well. But with the technology continue to improve some manucaturer also producing Hybrid mode 3D scanner which improves scanning materials adaptability with less limitation for a wider range of applications

The domain of 3D scanning serves a variety of typical engineering sectors apart from the societal spheres. Fig. 2 reflects the several potential areas of 3D scanning applications that are most dominating, specifically in science and education sectors, design and manufacturing domains, reverse engineering fields, art & design, etc. The technology has several merits as well. Namely, improved workflow process, accurate resolves, automatised system as a whole, quality services, research perspectives, etc. , which enable this tool as a more specific quality service handle for the engineering sector in current time.

, which enable this tool as a more specific quality service handle for the engineering sector in current time.

If you are interested to know more please contact us today or browse through the list of 3D Scanner that we are offering.

Desktop 3D Scanners - EinScan Multifunctional 3D Scanner

Get a quote

Please fill out this form to receive a free quote within 24 hours (during working days).

AfghanistanALAND ISLANDSAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntigua And BarbudaArgentinaArmeniaArubaAustraliaAustriaAzerbaijanBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBolivia, Plurinational State OfBosnia And HerzegovinaBotswanaBouvet IslandBrazilBritish Indian Ocean TerritoryBrunei DarussalamBulgariaBurkina FasoBurundiCambodiaCameroonCanadaCape VerdeCayman IslandsCentral African RepublicChadChileChinaChristmas IslandCocos (Keeling) IslandsColombiaComorosCongoCook IslandsCosta RicaC?te D'IvoireCroatiaCubaCyprusCzech RepublicDenmarkDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEthiopiaFalkland Islands (Malvinas)Faroe IslandsFijiFinlandFranceFrench GuianaFrench PolynesiaFrench Southern TerritoriesGabonGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuamGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHeard Island And Mcdonald IslandsHoly See (Vatican City State)HondurasHong KongHungaryIcel andIndiaIndonesiaIran, Islamic Republic OfIraqIrelandIsle Of ManIsraelItalyJamaicaJapanJordanKazakhstanKenyaKiribatiKorea, Republic OfKosovoKuwaitKyrgyzstanLao People'S Democratic RepublicLatviaLebanonLesothoLiberiaLibyan Arab JamahiriyaLiechtensteinLithuaniaLuxembourgMacaoMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartiniqueMauritaniaMauritiusMayotteMexicoMicronesia, Federated States OfMoldova, Republic OfMonacoMongoliaMontenegroMontserratMoroccoMozambiqueMyanmarNamibiaNauruNepalNetherlandsNetherlands AntillesNew CaledoniaNew ZealandNicaraguaNigerNigeriaNiueNorfolk IslandNorthern Mariana IslandsNorwayNORTH KOREAOmanPakistanPalauPalestinian Territory, OccupiedPanamaPapua New GuineaParaguayPeruPhilippinesPitcairnPolandPortugalPuerto RicoQatarReunionRomaniaRussian FederationRwandaSaint BarthélemySaint HelenaSaint Kitts And NevisSaint LuciaSaint MartinSaint Pierre And MiquelonSaint Vincent And The GrenadinesSamoaSan MarinoSao Tome And PrincipeSaudi ArabiaSenegalSerbiaSeychel lesSierra LeoneSingaporeSlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSpainSri LankaSudanSurinameSvalbard And Jan MayenSwazilandSwedenSwitzerlandSyrian Arab RepublicTaiwan, Province Of ChinaTajikistanTanzania, United Republic OftestThailandTimor-LesteTogoTokelauTongaTrinidad And TobagoTunisiaTurkeyTurkmenistanTurks And Caicos IslandsTuvaluUgandaUkraineUnited Arab EmiratesUnited KingdomUnited StatesUruguayUzbekistanVanuatuVenezuela, Bolivarian Republic OfViet NamVirgin Islands, BritishVirgin Islands, U. S.Wallis And FutunaWestern SaharaYemenZambiaZimbabweMACEDONIASOUTH GEORGIADemocratic Republic of the Congo

S.Wallis And FutunaWestern SaharaYemenZambiaZimbabweMACEDONIASOUTH GEORGIADemocratic Republic of the Congo

* Which product are you interested in?* Desktop 3d scanner* Hybrid light source handheld 3d scanner* Multifunctional handheld 3d scanner* Multiple scan range 3d scanner* Other Products and Service

submit...

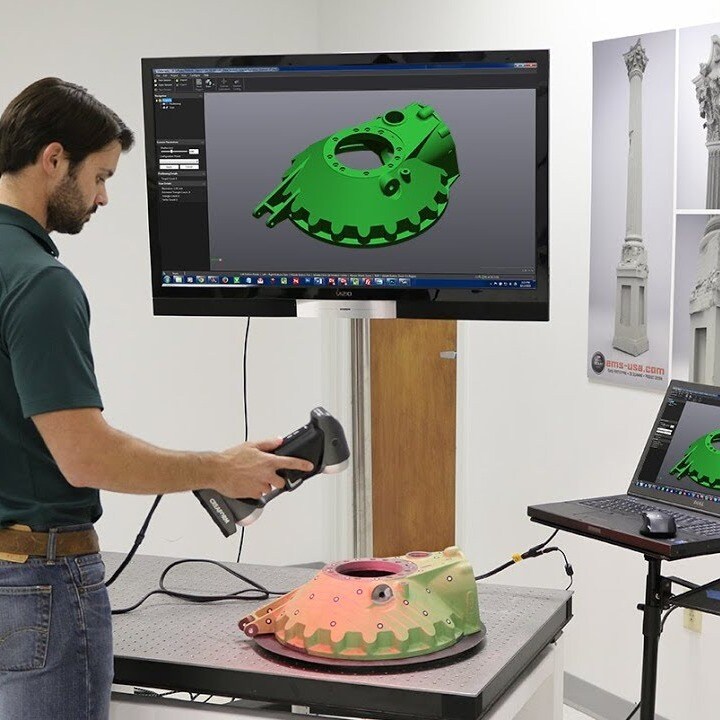

Using 3D scanning and 3D printing in reverse engineering

Reverse engineering is a way of creating digital models from physical ones. Together with 3D scanning and 3D printing, it is an effective tool for prototyping.

3D scanner able to quickly read the size and shape of complex models. Due to the presence of physical objects, it can help to significantly speed up the design. The ability to copy and reshape models allows you to print parts for all kinds of existing equipment. For example, printed fixtures can be used to secure a drill or saw, as well as to ensure precise assembly of parts. Create tight-fitting, reusable masks for sandblasting, painting or engraving.

Create tight-fitting, reusable masks for sandblasting, painting or engraving.

In this article, we will talk about reverse engineering a vent and explain how to scan a model for 3D printing. You'll also find tips for using reverse engineering tools here, from CAD software to 3D scanners and 3D printers.

To learn more about 3D scanning processes and technologies, download our white paper.

Download technical report

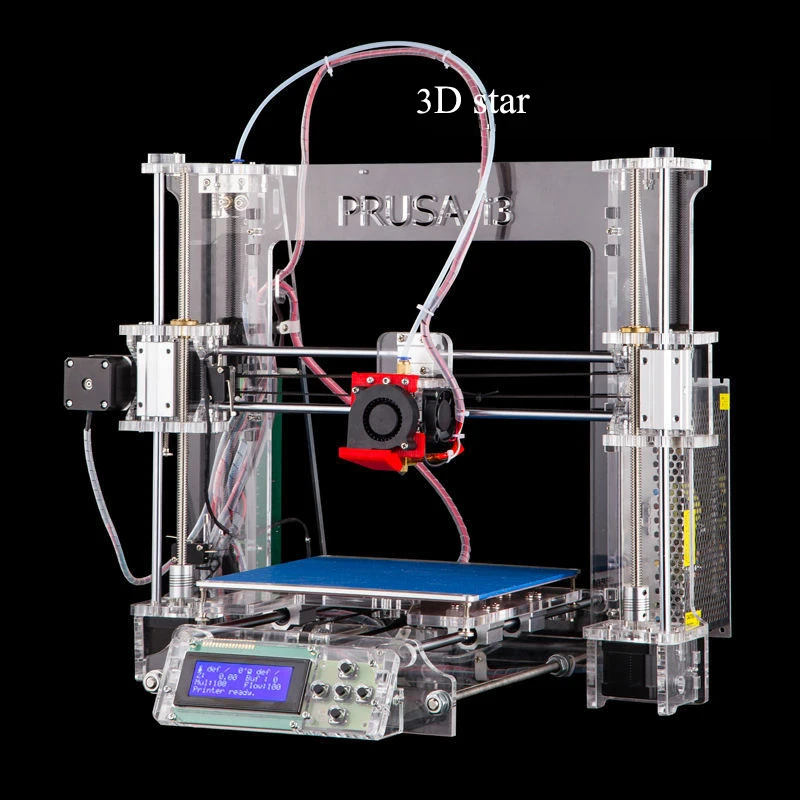

Looking for a 3D scanner for your 3D printer? Check out our guide to choosing the right 3D scanner for your 3D printer.

One of the major challenges in converting physical objects to digital is the incompatibility between two different types of 3D models: polygonal and solid .

The 3D scanner creates a polygonal mesh rather than a structural solid model. To modify a polygon model, you must convert it to a solid model.

The output from the 3D scanner will be polygon model in STL format, which is supported by most 3D printers. A polygon mesh is a collection of vertices and faces that define the shape of an object. It contains almost no information about the object, except for data on the position of the edges that determine the shape.

A polygon mesh is a collection of vertices and faces that define the shape of an object. It contains almost no information about the object, except for data on the position of the edges that determine the shape.

Engineers typically work with solid models that contain encoded information about the design of an object. With CAD, you can resize one element and update the rest of the model to reflect those changes.

Meshes do not contain information about the structure of the object, so CAD programs such as Solidworks and Onshape do not allow you to modify them directly. To make changes to the basic design of a scanned model, the mesh must be converted to a CAD drawing. It is this process that is called0021 reverse engineering .

Reverse engineering is used to create new models from existing ones when the original CAD design is not available.

For example, you can create replicas of damaged parts or use the complex surfaces of existing objects to create printed fixtures for customizing mass-produced and handmade items.

Let's walk through the process of building a prefabricated jig for the Volkswagen Golf vent.

Spray an anti-reflective spray on the object to improve scanning accuracy. Even a slight sheen can degrade the quality of the scan. Be sure to treat the reflective and transparent surfaces of with a matt finish.

Use anti-reflective spray to improve scan quality.

Use a high precision 3D scanner to capture all important parts of the model. Desktop light and laser scanners produce results with an accuracy of ±100 or better.

Find out how to choose a 3D scanner for your application in our white paper on 3D scanning:

Note : An object that has dimples sometimes needs to be rotated and scanned multiple times.

Some scanners generate mesh files that are too large to work with.

The scanner software allows you to correct small imperfections and make the image easier to edit in CAD. Try to reduce the model as much as possible, keeping all the important details.

Hint : Use the Meshmixer to edit the mesh.

Import the mesh into your CAD software to access reverse design tools. Use Geomagic for Solidworks for complex organic shapes.

Xtract3D is a more economical and lightweight alternative for simple flat surfaces.

Move and rotate the mesh to align it with the current structure elements.

Tip : Make your drawings easier by rotating the scanned model and aligning it with the orthographic projection directions.

Three methods of mold extraction are available in CAD to create a solid model: semi-automatic surfacing, automatic surfacing, and manual copying.

Semi-automatic surface creation

Complex curved surfaces are difficult to create manually. To do this, you can use the semi-automatic creation function, which generates surfaces based on areas obtained by scanning. In this case, the accuracy of the digitized surface depends on the sensitivity settings of the scanner.

Tip : Geomagic for Solidworks copies the surface using 3D model curves. Use the "brush" to manually add or remove areas on the image.

You may need to repeat this process several times with different sensitivity settings to capture all surfaces. They can then be cut and joined to create an editable solid model.

Use semi-automatic surfacing to create curved shapes if you need maximum editability and edge precision later on.

Formed surface after cutting.

Automatic generation generates a solid model from any closed mesh. This feature allows you to remove and add regions to the generated surface using standard CAD tools, but makes it difficult to move the main elements on the body itself.

This method is fine if you don't need to place the edges manually. So, when scanning a part of the human body to create non-standard ergonomically shaped products or making fixtures for repeatedly modifying a handmade object, automatic surface creation will reduce modeling time.