Stringing 3d printer

Stringing or Oozing | Simplify3D Software

Stringing or Oozing

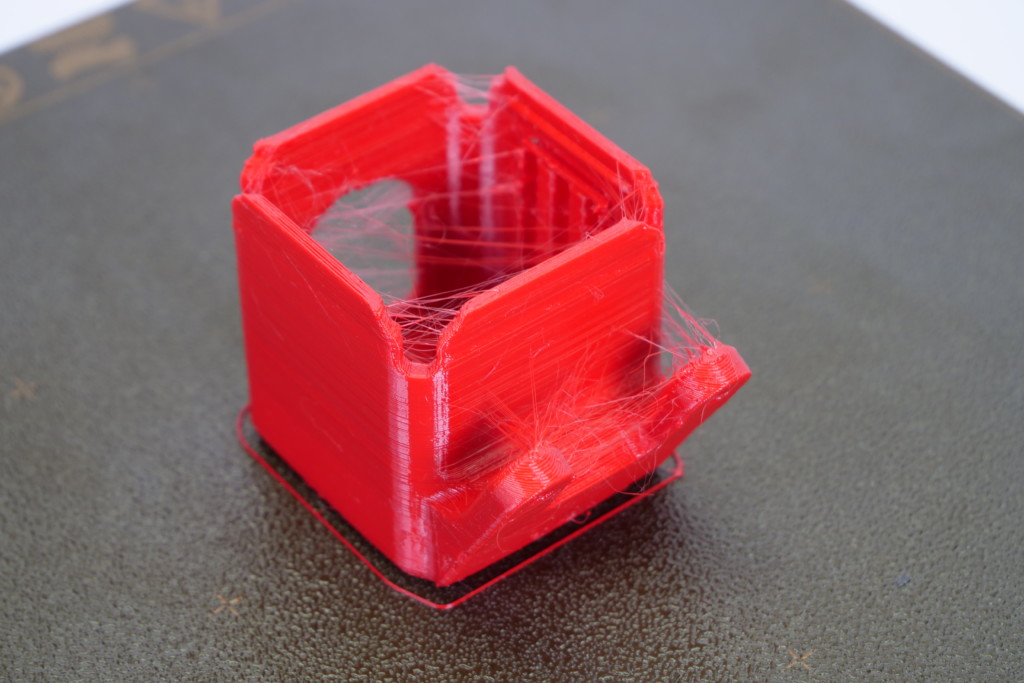

Stringing (otherwise known as oozing, whiskers, or “hairy” prints) occurs when small strings of plastic are left behind on a 3D printed model. This is typically due to plastic oozing out of the nozzle while the extruder is moving to a new location. Thankfully, there are several settings within Simplify3D that can help with this issue. The most common setting that is used to combat excessive stringing is something that is known as retraction. If retraction is enabled, when the extruder is done printing one section of your model, the filament will be pulled backwards into the nozzle to act as a countermeasure against oozing. When it is time to begin printing again, the filament will be pushed back into the nozzle so that plastic once again begins extruding from the tip. To ensure retraction is enabled, click “Edit Process Settings” and click on the Extruder tab. Ensure that the retraction option is enabled for each of your extruders. In the sections below, we will discuss the important retraction settings as well as several other settings that can be used to combat stringing, such as the extruder temperature settings.

Common Solutions

Retraction distance

The most important retraction setting is the retraction distance. This determines how much plastic is pulled out of the nozzle. In general, the more plastic that is retracted from the nozzle, the less likely the nozzle is to ooze while moving. Most direct-drive extruders only require a retraction distance of 0.5-2.0mm, while some Bowden extruders may require a retraction distance as high as 15mm due to the longer distance between the extruder drive gear and the heated nozzle. If you encounter stringing with your prints, try increasing the retraction distance by 1mm and test again to see if the performance improves.

Retraction speed

The next retraction setting that you should check is the retraction speed. This determines how fast the filament is retracted from the nozzle. If you retract too slowly, the plastic will slowly ooze down through the nozzle and may start leaking before the extruder is done moving to its new destination. If you retract too quickly, the filament may separate from the hot plastic inside the nozzle, or the quick movement of the drive gear may even grind away pieces of your filament. There is usually a sweet spot somewhere between 1200-6000 mm/min (20-100 mm/s) where retraction performs best. Thankfully, Simplify3D has already provided many pre-configured profiles that can give you a starting point for what retraction speed works best, but the ideal value can vary depending on the material that you are using, so you may want to experiment to see if different speeds decrease the amount of stringing that you see.

If you retract too slowly, the plastic will slowly ooze down through the nozzle and may start leaking before the extruder is done moving to its new destination. If you retract too quickly, the filament may separate from the hot plastic inside the nozzle, or the quick movement of the drive gear may even grind away pieces of your filament. There is usually a sweet spot somewhere between 1200-6000 mm/min (20-100 mm/s) where retraction performs best. Thankfully, Simplify3D has already provided many pre-configured profiles that can give you a starting point for what retraction speed works best, but the ideal value can vary depending on the material that you are using, so you may want to experiment to see if different speeds decrease the amount of stringing that you see.

Temperature is too high

Once you have checked your retraction settings, the next most common cause for excessive stringing is the extruder temperature. If the temperature is too high, the plastic inside the nozzle will become less viscous and will leak out of the nozzle much more easily. However, if the temperature is too low, the plastic will still be somewhat solid and will have difficulty extruding from the nozzle. If you feel you have the correct retraction settings, but you are still encountering these issues, try decreasing your extruder temperature by 5-10 degrees. This can have a significant impact on the final print quality. You can adjust these settings by clicking “Edit Process Settings” and selecting the Temperature tab. Select your extruder from the list on the left, and then double-click on the temperature setpoint you wish to edit.

However, if the temperature is too low, the plastic will still be somewhat solid and will have difficulty extruding from the nozzle. If you feel you have the correct retraction settings, but you are still encountering these issues, try decreasing your extruder temperature by 5-10 degrees. This can have a significant impact on the final print quality. You can adjust these settings by clicking “Edit Process Settings” and selecting the Temperature tab. Select your extruder from the list on the left, and then double-click on the temperature setpoint you wish to edit.

Long movements over open spaces

As we discussed above, stringing occurs when the extruder is moving between two different locations, and during that move, plastic starts to ooze out of the nozzle. The length of this movement can have a large impact on how much oozing takes place. Short moves may be quick enough that the plastic does not have time to ooze out of the nozzle. However, long movements are much more likely to create strings. Thankfully, Simplify3D includes an extremely useful feature that can help minimize the length of these movements. The software is smart enough that it can automatically adjust the travel path to make sure that nozzle has a very short distance to travel over an open space. In fact, in many cases, the software may be able to find a travel path that avoids crossing an open space all together! This means that there is no possibility to create a string, because the nozzle will always be on top of the solid plastic and will never travel outside the part. To use this feature, click on the Advanced tab and enable the “Avoid crossing outline for travel movement” option.

Thankfully, Simplify3D includes an extremely useful feature that can help minimize the length of these movements. The software is smart enough that it can automatically adjust the travel path to make sure that nozzle has a very short distance to travel over an open space. In fact, in many cases, the software may be able to find a travel path that avoids crossing an open space all together! This means that there is no possibility to create a string, because the nozzle will always be on top of the solid plastic and will never travel outside the part. To use this feature, click on the Advanced tab and enable the “Avoid crossing outline for travel movement” option.

Movement Speed

Finally, you may also find that increasing the movement speed of your machine can also reduce the amount of time that the extruder can ooze when moving between parts. You can verify what movement speeds your machine is using by clicking on the Speeds tab of your process settings. The X/Y Axis Movement Speed represents the side-to-side travel speed, and is frequently directly related to the amount of time your extruder spends moving over open air. If your machine can handle moving at higher speeds, you may find that increasing this settings can also reduce stringing between parts.

If your machine can handle moving at higher speeds, you may find that increasing this settings can also reduce stringing between parts.

Related Topics

How to Avoid 3D Print Stringing: The Ultimate Guide

Printing with FDM technology might result in a number of defects due to incorrect mode, uneven quality of consumables, or some printer-related issues. We will consider the process of thread formation during nozzle movement, generally known as stringing or oozing.

What causes filament stringing?

When the nozzle is idly moving from one printing area to another within one layer, the melted filament may slightly leak and form a string between the start and end points of the route. The defect occurs most often with PETG printing, but it is possible with other materials as well.

The main causes of stringing are:

- incorrect retraction settings;

- excessive nozzle temperature;

- filament exposed to humidity;

- low print speed;

- external nozzle contamination;

- defective nozzle;

- large melt zone or a large diameter nozzle.

It might be hard to determine a specific cause from external signs, that is why it is better to consistently check and rule out all the possible reasons.

Major problems and their solutions

Humidity

Wet filament makes it drastically more difficult to adjust the print mode, and it is relatively easy to detect excessive humidity.

Extremely wet PETG. Characteristic features can be clearly seen: loose surface of the part, filament lint over the entire length of the threads.

It is widely believed that PLA, PETG, and ABS have little moisture absorption. Indeed, many users do not encounter problems with wet filament. At the same time, manufacturers offer drying modes for most of their consumables.

When printing with damp filament, there is usually an extraneous sound similar to hissing or crackling. The surface of the printout comes out matte and porous, and strings are formed over the non-print area.

Credit: maker. pro

pro

In this case, threads occur when water in the filament starts to boil, and the steam provides an excessive output of plastic. When these signs are recognized, drying is definitely necessary.

Incorrect feeding and temperature

Wet filament is a factor that can be detected separately, but the others are similar and should be dealt with sequentially. To begin with, it is necessary to make sure that the right amount of plastic is fed and the temperature regime is correct. Overextrusion manifests itself in oozing blobs, distorted geometry of the print, and ribbed horizontal surfaces.

Credit: prusa3d.com

And in this case, strings are formed when an excessive amount of plastic starts leaking from the nozzle during its idle movement.

There are special test patterns called "temperature towers" to check the temperature mode. These are a sequence of vertically positioned identical elements printed at different nozzle temperatures.

There is also a plugin for automated creation of test patterns in Cura, so let's see how it works. To install the plugin, you must create an Ultimaker account and log in to it. This will give access to the repository.

Install the Calibration Shapes plugin. After reloading the slicer, the Parts for calibration item appears in the Extensions menu.

To set up the PETG print temperature, select Add a PETG TempTower. The temperature tower model will appear on the screen. Now it is time for a post-processing script (a set of scripts will be installed with the plugin).

The settings in the screenshot above are set for a temperature tower with a range from 260 °C to 230 °C in increments of 5; the layer height is 0.2 mm.

For PETG, it might make sense to print a second tower with lower temperatures. For instance, it applies to PLA+. The settings are the same, only the starting temperature is 230 °C.

A tower allows visually selecting the correct print temperature. A temperature that is too high results in blobs, indistinct outlines, and a large number of strings. Lower temperatures lead to disruptions in feeding and poor mechanical strength of the part. Our towers in the photos show that evident stringing stops after 230 °C, and at 215 °C there are issues with feeding and layer adhesion. That is why 220 °C will be the optimum printing temperature for this particular filament on this particular machine. Therefore, set the appropriate value in the Printing Temperature field and make sure that the other temperatures are synchronized (they are dependent on the first value, but can be set manually).

A temperature that is too high results in blobs, indistinct outlines, and a large number of strings. Lower temperatures lead to disruptions in feeding and poor mechanical strength of the part. Our towers in the photos show that evident stringing stops after 230 °C, and at 215 °C there are issues with feeding and layer adhesion. That is why 220 °C will be the optimum printing temperature for this particular filament on this particular machine. Therefore, set the appropriate value in the Printing Temperature field and make sure that the other temperatures are synchronized (they are dependent on the first value, but can be set manually).

Incorrect retraction

Retraction is used to prevent unwanted plastic leaking from the nozzle. This function will pull back the extruder before moving it over the non-print area. The basic settings for retraction in the slicer are length and speed. Insufficient length is a common cause of stringing. Excessive length leads to thread stretching, plastic getting into the cold zone, insufficient feed after moving the nozzle to the finish point, or plugging.

At too high a speed the thread will break in the melt zone or cause feed slippage. At too low — the thread will stretch without being pulled back inside the nozzle.

Terminal example: high print temperature with disabled retraction.

Typical values at which it is reasonable to start adjusting retraction are 30 mm/s speed, 1–2 mm length for a direct extruder, and 5–7 mm length for a Bowden. For instance, in Cura, retraction can be adjusted in the Travel section.

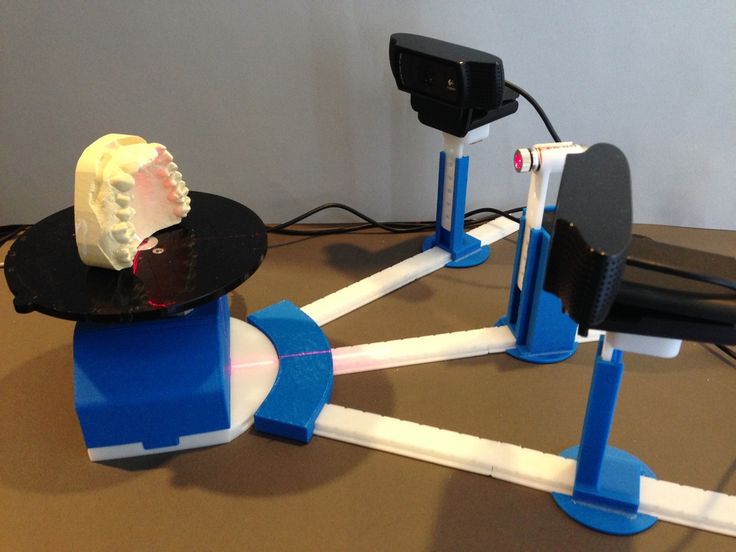

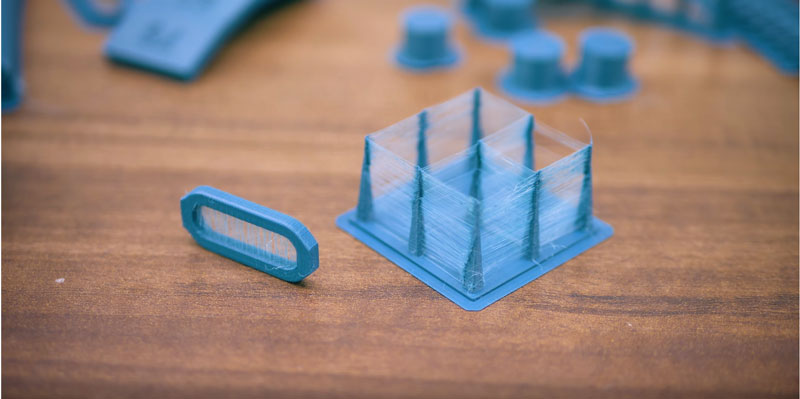

To check retraction, test patterns like "four square cones" are printed, but there are more functional tests to select retraction mode by analyzing a single printout. For example, this service generates a G-code with different retraction settings. It should be used with caution, because a large number of retracts per unit time occur during printing.

This service allows determining the optimal settings without having to reprint the test several times.

The default settings need to be adjusted for the printer in use. You can also reduce the number of vertical iterations — too high retraction makes no practical sense.

Appropriate settings for Kingroon KP3S with 0.4 mm nozzle, PETG.

The settings to attend to:

- X Dimension and Y Dimension.

- Nozzle Diameter.

- Filament Diameter.

- Start Temp — the optimal temperature for printing with the given material we have set in the previous step, or use the temperature recommended by the manufacturer.

- Extrusion Multiplier — the rate obtained by adjusting. At 1.0 there was a case of overextrusion, so here it is reduced to 0.97.

- Bed Temp.

- Number of Tests — we recommend to reduce it to 10, too high retraction speeds makes no practical sense.

- Travel Speed — idle speed, depends on the capabilities of the printer. Usually 80–150 mm/s.

- Custom Gcode — leave it as it is; if you need auto bed leveling before printing, delete ";".

- All other settings can be left by default.

The point of the test is as follows: the retraction length increases in increments of 0.5 mm along the perimeter, i.e. from 0.5 to 8 mm. The retraction speed increases with height, from 10 mm/s in increments of 5 mm/s.

The printout shows that when you increase the retraction length more than 1.5 mm, the quality of the protrusion does not change.

The photo shows the inadequate feed after retraction, which occurs when the length is too long and the speed is too high.

The final retraction length not only depends on the plastic and the type of extruder, it is also affected by a number of other parameters, such as the cooling efficiency of the hotend and design of the thermal barrier. Therefore, the settings for the same spool installed on different printers can vary significantly.

The printed test does not allow determining the exact retraction speed, so choose a standard value of 30 mm/s to avoid filament break and print at normal speed.

The "four cones" test, printed with the settings selected earlier. The retraction length is 1.5 mm, the speed is 30 mm/s. The printer is a Kingroon KP3S with the Titan direct extruder. Note that the printing of relatively large objects produces fewer strings than with "cones".

By comparison, the same test with PLA. No stringing already at a retraction length of 1 mm.

Different slicers have additional features designed to improve retraction performance and reduce stringing. For example, in Cura, it is Combing — moving to the next section not in a straight line, but over the already printed path.

Cura 4.11.0

If the Combing mode is on, stringing may be reduced. However, its use often leads to certain surface defects where it contacts with the nozzle.

Other factors

Worn or low-quality nozzles can also contribute to stringing. A normal nozzle has a thin channel in front of the outlet, but there are also nozzles that have virtually no channel. Practice shows that in the second case, the retraction works worse. Finally, it is reasonable to check that the nozzle is clean. The filament leftovers will drip and stick to the printout.

The inside of a quality nozzle.

Here, there is practically no output channel.

Speed also matters. It is more likely that the plastic will leak more at a low speed. The upper end is determined by the capabilities of the printer. On average, this value is in the 80–150 mm/s range.

Bottom line

To minimize stringing, you should first make sure that the filament is dry and that the temperature and feeding rate are correct. Only after that is it reasonable to proceed to the retraction settings adjustment. Specific length and speed will depend not only on the plastic, but also on the design of the extruder and the printer's hotend.

Increasing the volume flow with a longer nozzle

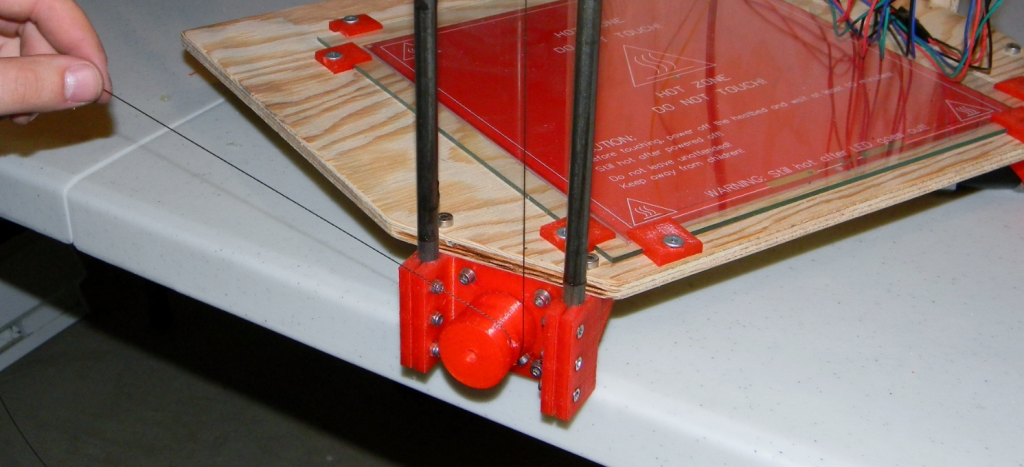

I want to increase the print speed by increasing the volume flow, which is currently 5 mm3/s. Large quantities cause the feed mechanism to skip steps.

I run at 190°C which helps with a lighter bridge with less stringing and personally see no reason to raise the temperature to the popular 205°C.

So my thought process is this: since I'm running at a lower temperature, there's still room for the heating block to provide more heat, I need a larger nozzle to store more heat and provide more surface area for transfer fillament (PLA) , to accelerate the melting of plastic inside the nozzle ( which seems to be problem ).

It's like using large iron soldering tips when we are faced with heating large surfaces to remove something large, as we need to stay at the exact temperature and also need to increase the heat input.

The suggested solution is to switch to the Volcano E3D "everything included" kit. It's cute and cool, but I don't think it's really necessary.

- Is it possible to simply switch to the volcano nozzle? (Manufacturer no.

: VOLCANO-NOZZLE-175-0400)

- Does it really help to increase extrusion speed noticeably?

Current setting:

- Ender 3 Pro no mods

- Classic nozzle 0.4 mm

▲ 0

Yes, Vulcan or Supervolcano allow higher flow rates (usually with larger nozzles), which is what they were designed for. Just a nozzle won't help you, you need that big nozzle shaft to be inside the volcano heater block or you won't be able to transfer heat.

According to Metaform measurements, the volume flow of the Volcanic hot end is greater than that of the conventional E3D V6 hot end.

, @ 0scar

▲ 2

This is based on opinion, but the volcano has flaws that affect print quality, mine is juicier and sloppier than the V6 with a shorter and more accurate melt zone. This is not a simple update, but rather a part of special applications. I think it makes no sense to use a volcano unless you fire large nozzles quickly, like 0.8mm.

Your flow rate is 5 mm 3 /s low, V6 is commonly known as volumetric flow ~13 mm 3/s against a volcano velocity of 25 mm 3 /s. This has to do with the low temperature you prefer, perhaps something not ideal with your extruder. I could see...

-

just living at a slow pace. I understand that I prefer print quality to print speed because one doesn't require human interaction while the other does.

-

do what everyone else does. gets hotter, the viscosity of the plastic is significantly reduced even with an increase of 5-10 degrees

-

increase the extruder torque. If you can safely increase the stepping current (know the limit for your driver and motor!) by trimming on the stepper driver, you can increase the torque before the motor skips steps. This can lead to an increase in engine temperature. If you increase the torque, at some point the filament will slip and be cut by the extruder gear.

Dual gear extruder designs like Bondtech can grab filament from both sides and increase filament grip if you want to push the filament like hell.

-

use a larger nozzle for faster printing at the desired temperature. I like the 6mm nozzle for large prints. It has most of the 0.4mm parts, but comes out with double plastic. Larger nozzle opening means less nozzle pressure at a given temperature and extruder feed rate

If you think the extruder might not be all it can be, try heating the nozzle hotter than usual and make the extruder run slowly and evenly, and pull the filament a little by hand, see if it skips steps easily with a little resistance. It must be pretty strong. I had a defective wire to the extruder which showed up in fine extrusion.

, @ ChinchillaWafers

Gone・Cults

Unfortunately, the job you are looking for has disappeared. ..

But don't panic!

Yes, this work is no more, it's sad... but you can always check the profile of the swah4d author who made this model, or even send him a direct message.

Otherwise, at Cults, we always have something to please your 3D printer. For example, look at these little hooligans:

01

OCTOPUS GUARDIAN

2,85 €

02Cloud Dock Nintendo Switch Lite

3.11 €

03Kushla Clock Tower - Baghdad, Iraq

Free

04Molten girl

€3.26 -thirty% 2.28 €

Snake care candle

2. 99 €

MONSTER TRUCK

1.88 €

07MOTORCYCLE CHOPPER STAMPED IN SITE

1.49 €

08Chibi Doctor Strange

Free

09Galarian Darmanitan

Free

10Blue Dragon / Glaucus Atlanticus ("Real Life Pokémon")

€1.40 -50% 0.70 €

Bob-Omb

€1.99 -35% 1.