Mazak 3d printer

INTEGREX i-400AM

Process: 5-Axis, HYBRID Multi-Tasking, Multi-Tasking

zoom

MACHINE DESCRIPTION:

As a fusion of additive technology and the most advanced Multi-Tasking capabilities, the INTEGREX i-400 AM (additive manufacturing) represents a highly innovative alternative to conventional processing in terms of part design and machining.

Perfect for small lot production of very difficult-to-cut materials, this HYBRID Multi-Tasking machine uses its additive capability to easily generate near-net-shape component features and then completes them via high-precision finish machining operations. If necessary, the machine will also laser mark parts.

The machine melts metal powder using fiber laser heat. Cladding heads, or additive manufacturing nozzles, apply the molten material layer by layer, each of which solidifies as the desired shape grows. Plus, the machine can join different types of metals together, which allows for the efficient repair of existing worn or damaged components such as aerospace turbine blades.

In terms of its Multi-Tasking capabilities, the INTEGREX i-400 AM provides full 5-axis machining to process prismatic parts from solid billets or castings (chuck or bar fed), round parts, highly contoured parts and now those with features built using additive technology.

MACHINE CHARACTERISTICS:

- Efficient turnkey solution offers DONE IN ONE® part processing

- Milling spindle provides a -30/+120-degree B-axis movement

- Turning spindle offers full C-axis contouring

- High-speed or high-accuracy cladding heads available

- Standard automatic tool changer loads cladding heads into milling turret

- Fully programmable NC tailstock

zoom

| Specification | Bed Length - | |

|---|---|---|

| Capacity | Maximum Swing | 25. 90 in / 658 mm 90 in / 658 mm |

| Maximum Machining Diameter | 25.900 in / 658 mm | |

| Maximum Machining Length | 59.800 in / 1519 mm | |

| Main Spindle | Maximum Speed | 3300 rpm | Motor Output (30 minute rating) | 30.0 hp / 40 kw | Motor Output (40 ED Rating) | 22 hp / 30 kw |

| Second Spindle | Maximum Speed | 4000 rpm | Motor Output (30 minute rating) | 35. 0 hp / 26 kw 0 hp / 26 kw |

Motor Output (40 ED Rating) | 30 hp / 22 kw |

| Milling Spindle | Motor Output (30 minute rating) | 30.0 hp / 22 kw | Motor Output (40 ED Rating) | 20 hp / 15 kw |

| Feed Axes | Travel (X Axis) | 24.20 in / 615 mm |

| Travel (X2 Axis) | 28.70 in / 730 mm | |

| Travel (Y Axis) | 10.20 in / 260 mm | |

| Travel (Z Axis) | 62. 40 in / 1585 mm 40 in / 1585 mm | |

| Travel (Z2 Axis) | 56.00 in / 1423 mm | |

| Travel (W Axis) | 62.00 in / 1574 mm | |

AM - Additive manufacturing

Hybrid multi-tasking machine - a fusion of 3D additive manufacturing and

Mazak's extensive multi-tasking experience

Simultaneous 5-axis machining center integrating the world's first blue laser additive manufacturing and machining

|

AM Technologies

AM technologies to best meet your application requirements

| Types of additive manufacturing |

Size |

Repair / modification |

Coating as sealing purpose |

Coating with metallurgical bond / Fine modeling |

Near net shape |

|---|---|---|---|---|---|

| Multi-Laser Metal Deposition [Heat generation] Laser |

Fine surface |

★★★ | ★★ | ★★★ | ★ |

| Laser Metal Deposition [Heat generation] Laser |

Mid - rough surface |

★★ | ★★ | ★★ | ★★★ |

| Wire Arc AM [Heat generation] Arc |

Rough surface |

★★* | ★★★ | ★ | ★★★* |

* Depends on application

Can be used for micro-additive manufacturing and cladding of thin base material that is affected by heat - Efficiently welds metal powder reduces effect on base material - Deviation of powder supply due to gravity is minimized even when AM head is tilted |

All processes, from machining to 3D additive manufacturing, are incorporated in just one machine to reduce production lead time

Machining

Additive manufacturing

(cladding)

Grinding

Gantry AM head

Gantry AM head drive is independent from milling spindle for large machining area.

Sample workpiece

Applicable models

|

High speed additive manufacturing - Powerful joint of different types of metal - High strength (same level as solid material) |

All processes, from machining to 3D additive manufacturing, are incorporated in just one machine to reduce production lead time

Process of additive manufacturing and machining

Sample workpiece

Applicable models

|

Wire Arc for high speed additive manufacturing - Readily available material and easy handling (especially active metals) - High speed additive manufacturing |

Integration of additive manufacturing and machining

wire arc AM

Simultaneous 5-axis machining

Material deposition by wire arc

Sample workpiece

Applicable models

Machine specifications vary by market.

Mazak Metal Laser 3D Hybrid Machine from Mazak

News

Yamazaki Mazak Corporation introduced the latest INTEGREX i-400AM hybrid multifunctional 3D printing machine. Since its founding in 1919, Mazak has been developing all kinds of machine tools for sale on the international market. The company manufactures advanced multifunctional CNC machine tools, laser processing systems and automation systems.

The INTEGREX i-400AM is equipped with several Ambit laser welding heads and is a multifunctional 3D printer for working with metals and alloys. The unit is capable of achieving high performance or high resolution by changing heads. INTEGREX i-400AM is designed for small-scale production and repair of parts made of difficult-to-machine materials used in the aerospace, energy and medical industries.

During operation, the INTEGREX i-400AM melts metal powders using fiber optic lasers. Weld heads deposit molten material in layers that solidify as the model is built. The system is able to fuse different types of metals, which is very useful when repairing worn and damaged parts, such as jet engine turbine blades.

Mazak offers a choice of two types of welding heads, providing either high speed or high accuracy. The tips are stored in the device itself and are automatically changed as needed. Users have the ability to specify the required type of head, depending on the intended production process and specific consumables.

In terms of versatility, the INTEGREX i-400AM provides five-axis positioning, allowing you to easily process parts of various shapes. The device is able to deflect the milling head at angles from -30 to +210 in the "B" axis, provide full movement in the "C" axis and is equipped with a programmable tailstock for the turntable.

The INTEGREX series was a turning point for Mazak. The company has always pursued the goal of creating the most advanced multi-functional machines, so the addition of additive manufacturing in the form of laser melting was obvious. The company is confident that the hybrid multifunctional machines will be appreciated by users.

The new machine premiered at JIMTOF in Tokyo this week. During the presentation, the company highlighted the device's ability to create composite parts. As an example, the deposition of nickel alloys on a stainless steel substrate was used.

Subscribe author

Subscribe

Don't want

1

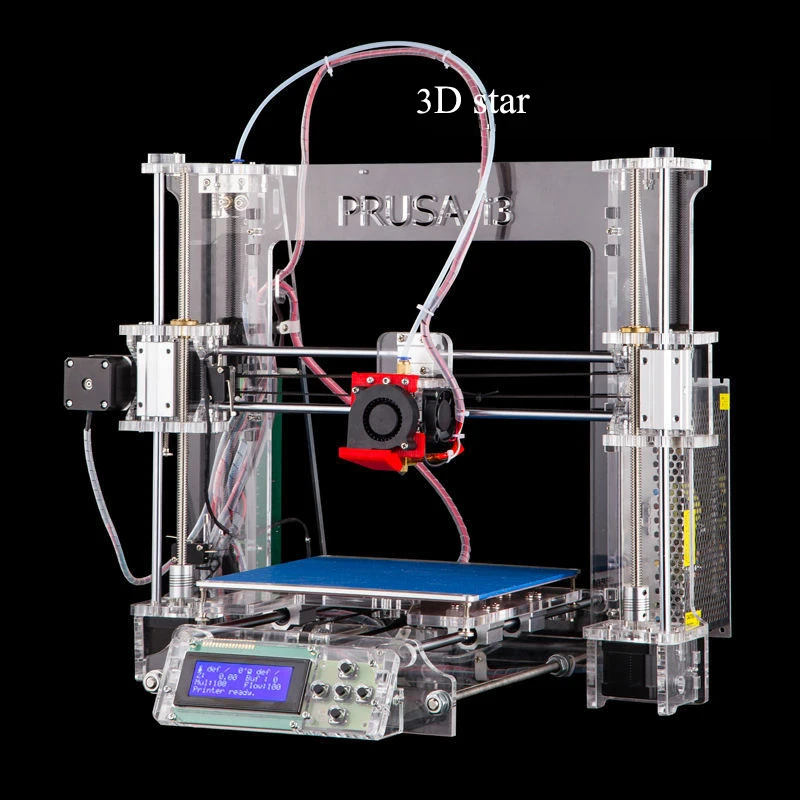

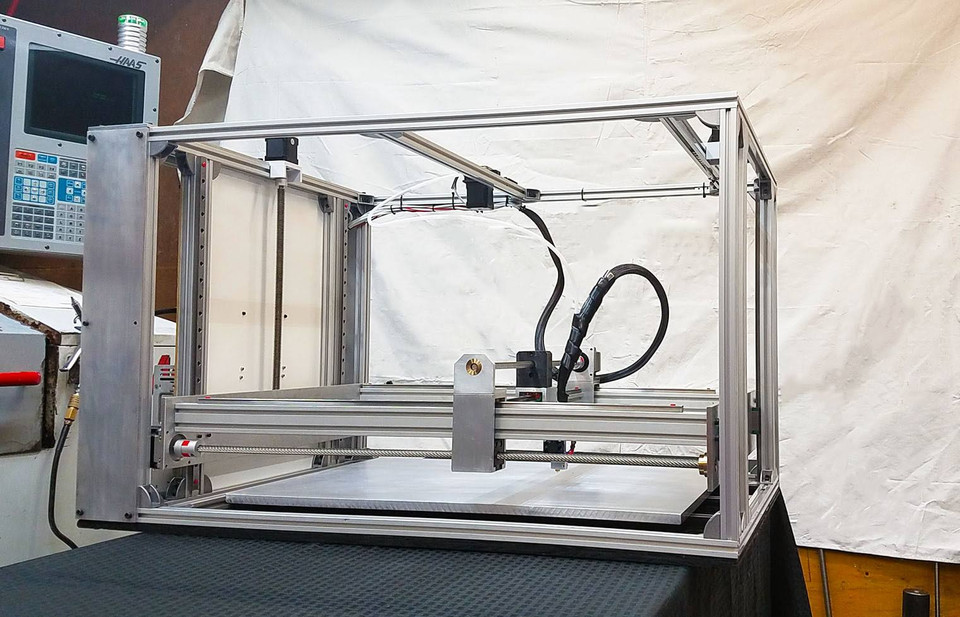

3D printer from desktop CNC milling machine

- home

- Articles

- This is interesting

- 3D printer from a desktop CNC milling machine

Installing a 3D printer print head on a desktop CNC, expands the possibilities of using a milling machine. Process control is also possible using the MACh4 program, widely known in the CNC environment. 3D printing requires an STL file, which is supported by all 3D printer software. To convert to STL, you can use Soildworks, google Sketchup and other programs.

For 3D printing on a desktop CNC machine, we use a 3D printer extruder, having previously replaced the temperature sensor with a K-type thermocouple, or purchase it in our store

1. Remove the spindle mount and fix the adapter bracket for installing the 3D printer head into the existing holes

with a spool of filament for 3D printing on a desktop CNC machine

4. Installation of additional software.

4.1 From http://cnc2printer3d.wordpress.com/software/ download Mach4 Addon conversion version 1.2, file setup1.2.exe.

Mach4 Addon installation package contains Skeinforge software, needed to be able to convert 3D files to G-code.

4.2 Download and install python language support https://www.python.org/download/

4.3 Run Mach4, select Mach4mill as usual. After launching the program, select “Pick Wizard” from the “Wizards” menu.

In the window that opens, find the "3d printer addon"

Double click on it to launch the window in which we select "Open STL File" print addon"

Select a file and press “open”. Wait until Mach4 finishes creating a 3D file, after which a window with 3D printing settings will open.

After setting, we return to the Mach4 window, where you need to click the “Post Gcode to Mach4” button. Save the received G-code.