Hero forge 3d printing

STL Downloads | Hero Forge®

Tell me about the downloadable 3D model files and home printing.

At the urging of many makers, tinkerers, inventors, and printers, we have begun offering digital print file distribution. This means, in addition to ordering 3D prints, users now have the option to buy the model file for their custom Hero Forge characters. These files can then be loaded into your 3D printing software for printing at home. Models are tessellated meshes with a polycount of up to 100,000 triangles. They are not rigged for animation.

Models are distributed via your Digital Downloads page in .stl file format. They are typically posted within 15-30 minutes of your purchase, but please allow for up to one business day. Digital models are only guaranteed to be available on your Digital Downloads page for six months from purchase.

Note that Hero Forge miniatures are finely detailed scale models. As a result, some home 3D printers do not have the ability to faithfully replicate the level of detail present in the source model or have issues printing thin, free-standing “wire” parts or the thin supports necessary to support a model during the build process. As a result, Hero Forge does not give any warranty about the models, and does not guarantee that the model will be fit for any particular purposes or be compatible with any specific make or model of printer.

We strongly recommend printing one of our free sample digital models before making a purchase. Sample models are available on your Digital Downloads page.

3D printers come in many shapes, sizes, and employ a wide range of technologies. Different technologies have different benefits and drawbacks. You are invited to submit photos of your prints, along with your printer’s make and model, materials used, and any pertinent settings used to create your print. The most common technologies are as follows:

SLA and DLP Printers

Some of the highest detail 3D printers are based on SLA (Stereolithography) and DLP (Digital Light Processing) technology. These printers use a pool of liquid resin which, by being exposed to a light source such as a projector or a laser, solidifies the liquid material into a solid layer by layer.

These printers most commonly function by submerging a “build platform” into a pool of liquid resin, allowing a light or laser on the underside to trace the layer’s shape, hardening it onto the build platform, which then serves as the foundation for the next layer. The platform then lifts from the resin, and is resubmerged again to print each successive layer.

SLA and DLP printers are known for producing some of the finest detail on the market, ideal for 30mm scale models for tabletop play. They also tend to be more expensive than other print technologies, both in terms of material costs and hardware.

Form2 by Formlabs

Material: “Gray Resin v3”

Settings: Printed at the maximum .025mm layer height. The models were oriented on their backs in order to allow high detail areas like the face and chest to remain free of support structures.

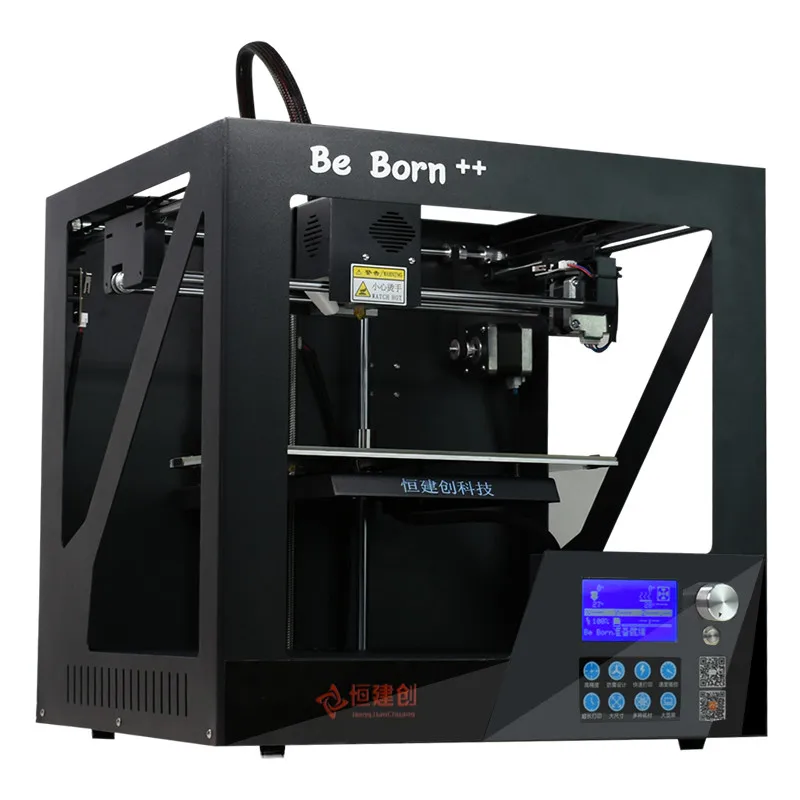

FDM Printers

The most common home 3D printers use FDM (fused deposition modeling) print technology. These machines start with a spool of ‘filament,’ typically a long wire of PLA or ABS plastic. The printer uses a heated nozzle to melt the filament, extruding onto a build tray similar to how a hot glue gun works. The material is extruded along a path predetermined by the controlling software. The melted material cools and solidifies, building the print layer by layer, with each new layer using the last as its foundation. This is one of the cheapest 3D printing technologies, and, while it does not match the detail levels of some other printing methods, is great for producing low-cost and large-scale models.

These machines start with a spool of ‘filament,’ typically a long wire of PLA or ABS plastic. The printer uses a heated nozzle to melt the filament, extruding onto a build tray similar to how a hot glue gun works. The material is extruded along a path predetermined by the controlling software. The melted material cools and solidifies, building the print layer by layer, with each new layer using the last as its foundation. This is one of the cheapest 3D printing technologies, and, while it does not match the detail levels of some other printing methods, is great for producing low-cost and large-scale models.

There are many, many companies producing a wide range of printers with a multitude of features, options, and settings. Common brands include Makerbot, LulzBot, XYZprinting, and many more. While we cannot test or provide recommended settings for every printer on the market, what follows are user-submitted images of their prints, along with any settings or material information they’ve provided. We encourage users to print and submit images of our sample models so we can add them to our directory!

We encourage users to print and submit images of our sample models so we can add them to our directory!

Da Vinci Jr. 1.0

Material: “PLA”

Settings: Vertical orientation, 200 micron resolution, raft with supports, slow print speed.

Dremel 3D Idea Builder 3D20

Material: PLA

Settings: Layer Height: 0.12mm, Speed: 2000mm/min, Had to rotate the models X:-90º to stand upright. Support structures were needed.

L3 MK2

Maker Select Plus

Material: PLA

Mono Price Select Mini

Material: Hatchbox Gold PLA, 1.75mm

Settings: For Model 1 (Paladin) - 0.04375mm layer height, on back rotated 45 degrees back, grid support. For Model 2 (Elf) - 0.04375mm layer height, laying flat on back, grid support.

MonoPrice IIIP

Material: PLA

Settings: Layer height: .1. Shell thickness: 1. 2. Bottom/top thickness: 1.2. Fill density 10%. Print speed: 40. Printing temp: 210c. Bed temp: 65c.

2. Bottom/top thickness: 1.2. Fill density 10%. Print speed: 40. Printing temp: 210c. Bed temp: 65c.

Robo3D R1+

Material: PLA

Settings: Printed at .1mm layer height.

Trinus

Material: PLA filament 1.75mm

Settings: Printed 45deg orientation, 1mm thickness, normal print speed, heated bed, base down, 0.1 layers.

Ultimaker 2+

Material: PLA

Up! Plus2

Material: PLA

Settings: Printed at 0.15mm layer resolution with a 0.4mm nozzle.

Do you have a question not covered by this guide? Please Contact Us!

About Our Products | Hero Forge®

Physical Minis Starting at $19.99 - Digital at $7.99

Hero Forge® offers a comprehensive range of materials and formats to meet any and all of your custom miniature needs. Our Custom Plastic and Premium Plastic are great options for players who love to paint their miniatures themselves. For table-ready minis right out of the box, try out unique Color-Printed Plastic miniatures. Hero Forge® also offers Digital STL files for 3D-printing enthusiasts who enjoy printing their own miniatures at home and full-color 3D Digital miniatures for use in your favorite virtual tabletop programs. Hero Forge® Pro and Pro Plus subscribers can also take advantage of unlimited tokens for character sheets, virtual tabletops, and more.

For table-ready minis right out of the box, try out unique Color-Printed Plastic miniatures. Hero Forge® also offers Digital STL files for 3D-printing enthusiasts who enjoy printing their own miniatures at home and full-color 3D Digital miniatures for use in your favorite virtual tabletop programs. Hero Forge® Pro and Pro Plus subscribers can also take advantage of unlimited tokens for character sheets, virtual tabletops, and more.

PHYSICAL PRODUCTS

3D Color-Printed Plastic

- ●●○○○Durability

- ●●●●○Detail

Our custom color miniatures are the apex of tabletop miniatures without you needing to lift a paintbrush. Color-printed miniatures are printed in an “inkjet” style 3D print with water soluble supports, meaning no sprues will mark up your beautiful gradients and fine decals.

Learn More

3D PRINTED BASE PLASTIC

- ●●●●○Durability

- ●●●●○Detail

Anything you design in Hero Forge®’s character creator can be printed in our durable yet detailed plastic. All plastic miniatures come in a smooth matte gray and pre-primed for easy painting.

All plastic miniatures come in a smooth matte gray and pre-primed for easy painting.

Learn More

3D Printed Premium Plastic

- ●●●○○Durability

- ●●●●●Detail

Premium plastic is the optimal material for all hobbyists looking for maximum detail. Take your tabletop RPG experience to another level with the perfect replica of your player character. All premium plastic miniatures are printed in SLA, coming in a glossy black finish.

Learn More

3D Printed Bronze

- ●●●●●Durability

- ●●●●●Detail

Our custom bronze miniatures are the epitome of tabletop epicness. Bronze miniatures are printed using the lost wax method and maintain the highest level of detail fidelity. Polished to a luminous shine and incredibly smooth to the touch, every detail of your custom character will gleam.

Learn More

Color Standees (Currently Unavailable)

- ●●●●●Durability

- ●●●●●Detail

Each color standee is precision cut to the unique outline of your character and rendered front, back, and base in full, high-resolution color. All color standees can be taken apart for flat storage, making them incredibly easy to use and portable enough to take on all of your adventures.

DIGITAL PRODUCTS

STL Download

STL Digital Downloads are for the 3D printing hobbyist looking to print their very own Hero Forge® design at home. Every Hero Forge® mini can be purchased as a downloadable STL file. Each miniature’s 3D model is distributed as a zipped .stl file with a file size around 5-10mb.

Learn More

3D Digital

Each custom digital miniature is a fully 3D model with all of your detailed color, effects, and posing. Use your Hero Forge® access key to connect your Hero Forge® account to supported virtual tabletops and all of your 3D digital minis will automatically sync to the tabletop.

Use your Hero Forge® access key to connect your Hero Forge® account to supported virtual tabletops and all of your 3D digital minis will automatically sync to the tabletop.

Learn More

Pre-Made Digital Packs

Each month, Hero Forge releases beautifully designed Pre-Made Digital Packs that include STL and 3D Digital files for five themed minis. Each pack is $7.99 and can also be purchased with 1 digital credit.

Learn More

SPECIALTY MATERIALS

Painted Plastic (Available exclusively to Kickstarter Backers)

- ●●●○○Durability

- ●●●●○Detail

For supporting us on Kickstarter, backers of the appropriate tier have access to hand-painted miniatures. Hand-painted miniatures are printed in our premium plastic and painted using traditional miniature painting techniques.

Learn More

2X Scale Nylon Plastic

- ●●●●●Durability

- ●●●○○Detail

When standard scale just won’t cut it, we offer custom nylon miniatures at two hundred percent the size of our standard 30mm scale miniatures. Our Nylon plastic is white and has a porous, slightly rough texture. These behemoth miniatures still maintain excellent detail even at the increased size.

Learn More

Gift Cards

Gift Cards

Give your adventuring party, friends, and loved ones the ability to bring their characters to life with a Hero Forge® gift card! Our user-friendly gift cards are delivered instantly via email and can be used on any Hero Forge® miniature, digital or physical!

Please note that gift cards cannot be applied to Hero Forge® Pro and Pro Plus Digital Download subscriptions.

Learn More

OTHER PRODUCTS

Polyhedral Dice

- Opaque: $9.99

- Translucent: $9.99

- Metal: $34.99

Roll our opaque, translucent, and metal dice in your next campaign! Each material comes in a variety of colors and features easy-to-read numbers.

How a 3D Printer Can Save You Money How a 3D Printer Can Save You Money

The justification for investing in a new, modern 3D printer is that it actually saves money.

New research confirms that buying a 3D printer to make plastic iPhone cases (or paper towel holders) at home saves money in the long run. This does not mean that 3D printers will soon crowd out stores or lead to the closure of factories in China or Vietnam. But it's fair to assume that this technology creates a world where you could end up printing a lot of products at home or at your local workshop.

“Printing money” (or rather, saving money)

For example, purchasing an open source RepRap 3D printer can not only pay off, but actually lead to money savings if you print on it (by at least) 20 household items per year (for example: shower curtain rings and safety razors). A recent study (known to the general public as the “life-cycle economic analysis of distributed manufacturing using open source 3D printers”) challenges not only the skepticism of the world’s major manufacturers, but also the wariness of 3D printing experts who believe that this technology is still in its infancy.

Today we already have the ability to print with plastic, and this opens up a huge potential for making thousands of products that are already in our homes and that we use every day. The range of printed material is expanding rapidly, and it is likely that consumers are likely to print many products themselves instead of buying them.

Owners of RepRap 3D printers can save between $300 and $2,000 per year, depending on which 20 household items they print. RepRap 3D printer owners can also continuously improve their open source 3D printer and even print new parts (as technology advances) rather than having to purchase a new 3D printer every few years.

RepRap 3D printer owners can also continuously improve their open source 3D printer and even print new parts (as technology advances) rather than having to purchase a new 3D printer every few years.

3D printed cups

Other costs associated with the 3D printing process

Despite its merits, assembling an open source 3D printer is a labor-intensive DIY process. RepRap spare parts cost $500-600 and in order to assemble them, you need to spend about 24 hours of working time. And a beginner may need to first learn the assembly process at an appropriate workshop or use an online assembly guide. However, beginners can pay double the price of a collected RepRap. (It's still a good deal compared to so-called polished models like the $2,000 Makerbot Replicator 2.)

Also, don't expect, for example, that the iPhone's plastic case (made from 3D printing) will have the same quality or gloss as a store-bought version. Today, 3D printers still render objects with very small steps or ridges on the sides (no smooth finish). Of course, the object can be smoothed with a nail polish remover and painted, but this is additional labor.

Today, 3D printers still render objects with very small steps or ridges on the sides (no smooth finish). Of course, the object can be smoothed with a nail polish remover and painted, but this is additional labor.

Is the quality of products resulting from the 3D printing process on par with the quality of products that are made in a traditional production and then sold? Unfortunately not: it doesn't even come close to factory quality.

Disadvantages of 3D printing

Today, 3D printers are able to print products with unusual shapes and unique customer requirements: they are well suited for printing a limited number of expensive parts for jet fighters or a custom implant to restore a destroyed part of the skull (both of which are already happened). However, this technology is not yet capable of making items from a variety of materials, and is too slow and too expensive to produce a large number of items.

Very inexpensive and relatively uncomplicated mass-produced items (such as plastic trash cans) will be made in large industrial centers for a long time. Such products, which are produced in the hundreds of thousands or millions, are not good candidates for 3D printing due to the speed and cost of the process.

Such products, which are produced in the hundreds of thousands or millions, are not good candidates for 3D printing due to the speed and cost of the process.

No one has done a definitive study comparing the cost of 3D printing plastic products locally to the cost of making plastic products in a Chinese factory and shipping them around the world. But some experts believe that industrial production is still able to easily compete with 3D printing. One reason for this is that industrial grade 3D printing requires more energy per unit than traditional industry.

How 3D printing could be used in mass production

3D printing technology could improve over the next 10 to 15 years to the point where it can compete with industrial production. This can be compared to how personal computers took over large electronic computers in less than 10 years.

3D printers still have a long way to go in order to take their place among the must-have household gadgets.

You will be able to make toys (like McDonalds Happy Meal), but hardly anyone will like having to buy a device for $300 or $400 (the price range of cheap modern 3D printers) in order to make such toys themselves. For this to happen, print quality needs to go up and the price of the device goes down.

For this to happen, print quality needs to go up and the price of the device goes down.

However, 3D printing is still able to compete with factory-made products. 3D printing allows the customer to customize the final product design and have it produced on site immediately. For example, toy stores may someday be able to offer a custom doll with unique characteristics based on a 3D scan of a customer's face or body. (One company (3D Systems) is already offering custom 3D printed Star Trek figurines.)

Even a savvy engineer can build many simple 3D printable pieces that fit together as tightly as Lego to create larger or more complex objects such as chairs and cabinets. It could be called a 3D printed version of IKEA furniture that needs to be assembled by yourself.

Order and print anywhere

The ability to print anything, almost anywhere, gives 3D printing a huge advantage over factories. The military in the US has recognized this advantage by placing 3D printers on ships and in remote battlefields in order to recreate equipment prototypes and possibly someday make vehicle replacement parts.

Global shipping company DHL is already thinking about how 3D printing will impact the way and where you shop for products in the future. According to a 2012 DHL report, the full opportunity for a "customizable lifestyle" scenario is given to 2050. It will be a world in which 3D printing devices in homes or local shops will replace the mass production industry in most cases. In such a world, only raw materials and digital developments will cross national borders.

A small glimpse of this future can already be seen at Kraftwurx. It is a Houston-based company that operates in the digital marketplace with orders for simple 3D printed products (such as metal jewelry and plastic figurines) around the world. The Kraftwurx network consists of more than a hundred 3D printing companies scattered around the planet: this allows buyers and sellers to save on international shipping and paying duties on imported goods.

Breakthroughs in 3D printing technology

This future may become even closer as 3D printing technology begins to overcome its current limitations. Companies involved in 3D printing continue to work on making 3D printers cheaper and better. Better software is allowing more people to create and share designs for 3D printing online, both for free and for sale.

Companies involved in 3D printing continue to work on making 3D printers cheaper and better. Better software is allowing more people to create and share designs for 3D printing online, both for free and for sale.

So what does all this mean right now? A printed watch strap or shower head that you can make at home is not yet comparable in quality or aesthetics to the same products you can buy at your local store. But if you have the time, money, and patience to invest in a 3D printer, then you can start saving money today (if you're happy with the quality of the 3D print).

Will consumers be willing to continue paying $50 for an iPad stand when they can print it themselves for $1 or buy it (pre-printed) for $2 on eBay?

The Masters Movement, IP Litigation and Law Reform

October 2019

Author: Matthew Rimmer * Professor of Law in Queensland University of Technology and Innovation KTU), Brisbane, Australia

3D printing is a branch of technology based on the principle of additive manufacturing (as opposed to the principle of subtractive manufacturing, which is the basis of traditional manufacturing). 3D printing is also associated with the Craftsmen Movement, a social movement whose main idea is to develop designs for various products and share them.

3D printing is also associated with the Craftsmen Movement, a social movement whose main idea is to develop designs for various products and share them.

Currently, the development of 3D printing is in a transitional phase. The consumer "3D printing revolution", which aimed to have a 3D printer in every home, has failed. MakerBot, a pioneer in 3D printing, is having trouble with its changing approach to intellectual property (IP) issues, disrupting its ties to the open source software community, and the user audience turned away from it. As former MakerBot CEO Bre Pettis said in an interview, "The open source community has kicked us out of their paradise." As a result, MakerBot was acquired by Stratasys, a leader in the 3D printing industry, which restructured and repurposed it.

Some other key players also went bankrupt. In particular, TechShop, a membership-funded and open-to-all network of studio-workshops for home craftsmen, went bankrupt. Maker Media, which publishes Make magazine and hosts craft festivals in the United States, has gone under external control. Make magazine founder Dale Doherty is trying to revitalize his project with a new structure he created called Make Community LLC.

Industrial 3D printing continues to grow

While personal 3D printing has not developed as expected, there has been growth in a number of other forms and categories of 3D printing. Along with robotics and big data, 3D printing has become one of the promising technologies in the manufacturing industry. Companies specializing in information technology and design are working to improve the way 3D printing is used. Significant investments, especially from transport companies, have been attracted by the technology of 3D printing of metal products. In addition, there have been large-scale experiments related to the application of 3D printing in the healthcare sector, including 3D printing in dentistry, 3D printing in medicine, and bioprinting.

As technology improves and develops, there have been several cases of lawsuits being filed in the courts, as well as certain political developments regarding the regulation of the 3D printing industry. Our recently published book 3D Printing and Beyond explores some of the major developments in IC and 3D printing. In particular, it analyzes the issues of 3D printing in relation to areas such as copyright law, trademark law, patent law, and trade secrets (as well as some of the broader issues related to the regulation of 3D printing). In addition, the book highlights the use of open licensing mechanisms in the field of 3D printing.

3D printing and copyright law

A few years ago, there was a panic that the widespread use of 3D printing would lead to a wave of large-scale infringements of authors' rights, similar to the situation that arose with the advent of the Napster file-sharing network . Although such fears have not yet materialized, there have been various conflicts related to copyright and 3D printing. For example, Augustana College (United States) objected to 3D scanning of Michelangelo's statues, even though they were not subject to copyright protection and were clearly in the public domain. The American cable television network HBO has blocked the sale of an iPhone stand in the form of an "iron throne" from the TV series "Game of Thrones", made according to the drawings of designer Fernando Sosa using 3D printing. United States singer-songwriter Katy Perry demanded a ban on the sale of the same designer's 3D-printed "shark on the left" figurine (nevertheless, the product subsequently reappeared in Shapeways 3D Printing Systems' catalogue). The heirs of the French-American artist Marcel Duchamp opposed the production of a 3D-printed set of chess pieces based on the works of this artist.

For example, Augustana College (United States) objected to 3D scanning of Michelangelo's statues, even though they were not subject to copyright protection and were clearly in the public domain. The American cable television network HBO has blocked the sale of an iPhone stand in the form of an "iron throne" from the TV series "Game of Thrones", made according to the drawings of designer Fernando Sosa using 3D printing. United States singer-songwriter Katy Perry demanded a ban on the sale of the same designer's 3D-printed "shark on the left" figurine (nevertheless, the product subsequently reappeared in Shapeways 3D Printing Systems' catalogue). The heirs of the French-American artist Marcel Duchamp opposed the production of a 3D-printed set of chess pieces based on the works of this artist.

3D printing was also subject to the on-demand removal of content under the Digital Millennium Copyright Act (USA). Shapeways and a number of other 3D printing firms have raised concerns about the implications of this regime for online platforms and 3D printing intermediaries.

Shapeways and a number of other 3D printing firms have raised concerns about the implications of this regime for online platforms and 3D printing intermediaries.

In addition, discussions took place on issues related to the use of technical protection measures in the context of copyright law and 3D printing. For example, the US Copyright Office has confirmed a limited technical protection exception for 3D printing stocks.

3D printing and design law

Developments in 3D printing have also raised the issue of product repair rights.

Efforts have been made across the European Union to recognize the right to repair in order to support consumer rights and develop a circular economy. In this regard, one of the important factors in achieving changes in the behavior of companies and consumers has become the European Greening Directive (Directive 2009/125/EC).

In July 2019, the United States Federal Trade Commission held a Hearing on "Can't be Repaired: A Workshop on Product Repair Restrictions. " Significant differences remain between IP owners and right-to-repair advocates in the United States. Presidential candidate Elizabeth Warren has called for legislation to secure the right to repair for the benefit of farmers in the agricultural regions of the United States.

" Significant differences remain between IP owners and right-to-repair advocates in the United States. Presidential candidate Elizabeth Warren has called for legislation to secure the right to repair for the benefit of farmers in the agricultural regions of the United States.

Significant and first-of-its-kind litigation has taken place in Australia regarding the right to repair under industrial design law ( GM Global Technology Operations LLC v S . . - S - Auto Parts Pty Ltd [2019] FCA 97). The Australian Treasury is considering policy options regarding the practice of sharing vehicle repair information.

Australian Capital Territory (ACT) Consumer Affairs Minister Shane Rettenbury called for recognition of the right to repair from the rostrum of the Consumer Affairs Forum, which includes ministers from both Australia and New Zealand. Federal Minister Michael Succar asked the Australian Productivity Commission to look into the matter.

Federal Minister Michael Succar asked the Australian Productivity Commission to look into the matter.

Calls for right-to-repair laws, both at the provincial and federal levels, are also being heard in Canada. As Laura Tribe, Executive Director of Open Media, noted in this regard, “We are committed to ensuring that people have the opportunity to be the real owners of the products they own.”

3D printing and trademark law

3D printing also brings uncertainty to trademark law and related legal regimes, including product substitution, identity rights, commercial use of characters, and trade dress. The legal conflict surrounding Katy Perry's trademark application for the "shark on the left" image provides some insight into some of the issues that arise in this regard.

Regarding bioprinting, Advanced Solutions Life Sciences sued Biobots Inc. Due to the alleged violation of its trademark rights ( Advanced Solutions Life SCENCES LLC V Biobiots 9007. Advanced Solutions Life Sciences owns and uses the registered trademark Bioassemblybot for 3D bioprinting and tissue growth.

Advanced Solutions Life Sciences owns and uses the registered trademark Bioassemblybot for 3D bioprinting and tissue growth.

3D printing and patent law

According to the 2015 WIPO Global Intellectual Property Report, Revolutionary Innovation and Economic Growth, 3D printing patent applications are on the rise. Some industrial 3D printing companies, including 3D Systems and Stratasys, have managed to build large 3D printing patent portfolios. Large industrial companies, including GE and Siemens, have also accumulated significant patent assets in 3D printing and additive manufacturing. Information technology companies, including Hewlett Packard and Autodesk, also play an important role in the 3D printing industry.

With the growing commercial importance of 3D printing in the manufacturing industry, there have been a significant number of litigations related to 3D printing of metal products. In July 2018, as part of the “Desktop Metal Inc.” v. Markforged, Inc. and Matiu Parangi (2018 Case No. 1:18-CV-10524), a federal jury found that Markforged Inc. did not infringe two patents owned by rival Desktop Metal Inc. (See Desktop Metal Inc. v. Markforged, Inc. and Matiu Parangi (2018) 2018 WL 4007724 (Massachusetts District Court, jury verdict). In this regard, the CEO of Markforged Inc. .” Greg Mark stated, “We are pleased with the jury's verdict that we have not infringed patents and that Metal X technology, which is the latest addition to the Markforged 3D printing platform, is based on our own Markforged's proprietary designs." For its part, a spokesman for Desktop Metal noted that it was "satisfied that the jury recognized the validity of all claims in both Desktop Metal patents, which were discussed in a lawsuit against the company "Markforged"

1:18-CV-10524), a federal jury found that Markforged Inc. did not infringe two patents owned by rival Desktop Metal Inc. (See Desktop Metal Inc. v. Markforged, Inc. and Matiu Parangi (2018) 2018 WL 4007724 (Massachusetts District Court, jury verdict). In this regard, the CEO of Markforged Inc. .” Greg Mark stated, “We are pleased with the jury's verdict that we have not infringed patents and that Metal X technology, which is the latest addition to the Markforged 3D printing platform, is based on our own Markforged's proprietary designs." For its part, a spokesman for Desktop Metal noted that it was "satisfied that the jury recognized the validity of all claims in both Desktop Metal patents, which were discussed in a lawsuit against the company "Markforged"

In 2018 (after the above verdict) Desktop Metal Inc. and Markforged Inc. entered into a confidential financial agreement that settled all other litigation between them. However, in 2019 Markforged Inc. filed another lawsuit against Desktop Metal Inc. due to the fact that, according to her, the latter violated that part of the agreement, which concerned non-disclosure of negative information.

due to the fact that, according to her, the latter violated that part of the agreement, which concerned non-disclosure of negative information.

3D printing and trade secrets

In addition, the first litigation regarding 3D printing and trade secret legislation took place. In 2016, Florida-based 3D printing startup Magic Leap filed a lawsuit in federal court for the Northern District of California against two of its former employees for misappropriation of trade secret information within the meaning of Trade Secret Protection Act (“ Magic Leap Inc ." v Bradski et al (2017) case no. 5:16-cvb-02852). In early 2017, a judge granted the defendants' request to stay the case, stating that Magic Leap had failed to provide "a reasonable degree of specificity" to the disclosure of alleged trade secrets. Subsequently, the judge allowed Magic Leap to amend the text of its submission. In August 2017, the parties entered into a “confidential agreement” in connection with this issue. In 2019Mafic Leap sued the founder of Nreal for breach of contract, fraud, and unfair competition (Magic Leap Inc. v. Xu, 19-cv-03445, U.S. District Court for the Northern District of California (San Francisco)).

In 2019Mafic Leap sued the founder of Nreal for breach of contract, fraud, and unfair competition (Magic Leap Inc. v. Xu, 19-cv-03445, U.S. District Court for the Northern District of California (San Francisco)).

3D printing and open licensing

In addition to proprietary IP protections, the 3D printing industry has a widespread practice of open licensing. Companies with a free distribution philosophy include Prusa Research (Czech Republic), Shapeways (Netherlands-US) and Ultimaker (Netherlands). Members of the Craft Movement used open licensing mechanisms to share and distribute 3D printing files. As noted in The State of the Commons 2017, the Thingiverse platform was one of the most popular platforms using Creative Commons licenses.

Other issues arising from the development of 3D printing

In addition to IP issues, the development of 3D printing also raises a number of other legal, ethical and regulatory issues. In healthcare, regulators have faced challenges with personalized medicine. The United States Food and Drug Administration and the Australian Health Products Administration held consultations on the development of a balanced set of regulations for medical 3D printing and bioprinting. The European Parliament has adopted a resolution calling for a comprehensive approach to the regulation of 3D printing.

In healthcare, regulators have faced challenges with personalized medicine. The United States Food and Drug Administration and the Australian Health Products Administration held consultations on the development of a balanced set of regulations for medical 3D printing and bioprinting. The European Parliament has adopted a resolution calling for a comprehensive approach to the regulation of 3D printing.

Litigation regarding 3D printing of firearms is also ongoing in the United States. Several state attorneys general have sued the current administration to obstruct an agreement between the federal government and Defense Distributed. Several criminal cases have been filed in Australia, the United Kingdom, the United States and Japan in connection with attempts to 3D print firearms. Legislators are debating the feasibility of criminalizing crimes related to possession of digital blueprints for 3D printed firearms.

Footnotes

* Dr. Matthew Rimmer is Head of the KTU Research Program on Intellectual Property Law and Innovation and is also involved in the KTU Research Center for Electronic Media, the KTU Australian Health Law Research Center and the KTU Research Program in International Law and global governance.