Ham radio 3d printer projects

▷ ham radio 3d models 【 STLFinder 】

Ham Radio Love

thingiverse

Ham radio love

Ham Radio Callsign Keychain

thingiverse

Ham Radio Callsign Keychain by TA7LDU

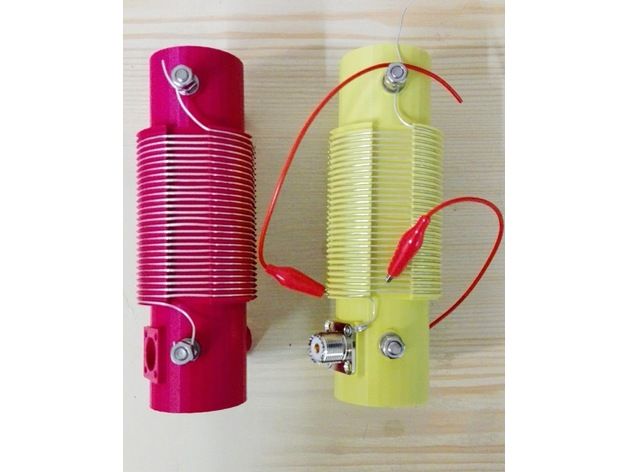

Antenna Coupler HAM Radio

thingiverse

Ham Radio Antenna Coupler!! For a 1 Inch OD tube! ...https://www.youtube.com/watch?v=dv5FACcWDwY&lc

ICOM 2730A HAM radio

grabcad

A suitable stand in for the HAM radio made by ICOM. ...I used this to create my 3D printed mounting brackets.

Ham Radio Antenna Enclosure

thingiverse

Print body and lid separately for better results. ... Both body and lid should be printed vertically, standing position. Updated Version to be updated by user demand. Ham Radio Antenna Enclosure (BF-F8HP - BaoFeng)

Duplex Ham Radio Hotspot

thingiverse

This is a case for a Duplex Ham Radio hotspot. Put the Hotspot hat together with the raspberry pi and then put it in the case. ... The screws are M2, you will need 6 of them.

Ham radio speaker reflector

thingiverse

This is to redirect the sound from the top mounted speaker of a ham radio towards the operator. ...There are indents on the bottom for 5mm x 1mm magnets.

...There are indents on the bottom for 5mm x 1mm magnets.

ham radio front stand

thingiverse

A three level stand for ham radios with a bale. Made for a Yaesu FT-857, this will work with many other radios. There are indents on the bottom for stick on rubber pads to prevent sliding. ... UPDATE 12 November 2019: added sloped side to the short...

Ham Radio Microphone Bracket

thingiverse

I wanted a way to set my microphone on the cart I use for my ham radio gear. It has 13mm rods along the edges, so I wanted it to just 'clip' onto the rod. It prints OK but it doesn't clip as well as I would like and the fit is very tight. But it...

But it...

Ham Radio pack

thingiverse

These are parts for a Ham Radio Manpack, which uses OpenBeam for the structure, and laser cut acrylic for the panels. It is designed to sit inside a Voodoo Tactical 2 Tier pack (Update Jan 2020 - this is no longer offered). This is designed to host a...

$3.00ApocalypseSurvivor Ham Radio Operator

myminifactory

Contains 6 props and 1 Ham Radio Operator 35mm scale Check out my patreon to get the newest miniatures released. ... patreon.com/sarksfoundry

WW2 HAM Radio 3D model

cgtrader

This is a model of a Vintage WW2 Era HAM Radio. Textures maps and UV data are included. 4k texturemaps for metal/rough setup. 129568 polys. Multiple texture sets. If you have any questions feel free to message me! ...

Textures maps and UV data are included. 4k texturemaps for metal/rough setup. 129568 polys. Multiple texture sets. If you have any questions feel free to message me! ...

Ham Radio Windom Antenna Support

thingiverse

Lightweight, pocket-sized, portable windom antenna support for ham radio. Toroids used in my configuration are very small (T80) and also it is the windings wire. Instructions Printed with both pla...

HAM Radio Balun & UnUn Housing

thingiverse

The case for a ham radio UnUn or Balun with FT 240-43 or FT240-31 toroid. ...

The innovative feature is the self-locking mounting fixture for the long lambda\2 HyEndFed antenna wire and eyelet for guy rope with a carabiner.

...

The innovative feature is the self-locking mounting fixture for the long lambda\2 HyEndFed antenna wire and eyelet for guy rope with a carabiner.

CB/Ham Radio Mic Holder

thingiverse

This is designed to hold an external mic for stationary ham/CB radios at your radio bench/table. ... The holes are 2mm in the diameter to hang the holder via nails.

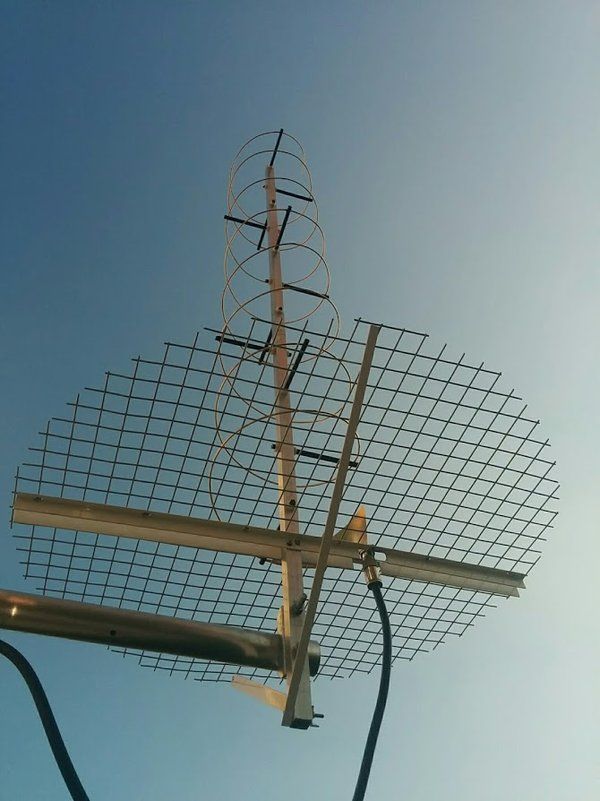

Ham Radio Dipole Antenna Support

thingiverse

Small support for Ham Radio Dipole Antennas. It is ideal for portable lightweight and multiband dipoles. Good infill and shells will mean stronger against traction. Holes can be used for wire fixing (multiple arms or suspension ropes), mast hooks and. ..

..

Baofeng HAM Radio Window Mount

thingiverse

Mount for a Baofeng UV-5R and similar HAM Radio HTs. Attach a 2-1/2" suction cup tool to your window or other suitable flat surface and this mount slides on with a friction fit. I got my suction cups from Princess Auto here in Canada but I'm...

Yaesu HAM Radio Mount & Bezel

thingiverse

... and then have the radio inserted. Rooftop console here: http://def-is.com/en/shop/storage-systems/product/view/8/9.html HAM Radio here: https://www.yaesu.com/indexVS.cfm?cmd=DisplayProducts&ProdCatID=106&encProdID=FD01F8F398F2B94A9C9F4299F3D18732

ON AIR Sign (Ham Radio)

thingiverse

I made this ON AIR sign to show when I have my power supply on and doing ham radio things. I plan to put a thin film in to diffuse the light from LEDs that will be wired in, and then I will hardwire it to my power supply as the power indicator. I...

I plan to put a thin film in to diffuse the light from LEDs that will be wired in, and then I will hardwire it to my power supply as the power indicator. I...

Wireless ham radio frequency counter

thingiverse

If you want a wired varinat of this thing check this: http://www.thingiverse.com/thing:1160233 I have my 11m ham radio perfect PLL aligned using these types of counters and a simple multimeter. BOM: -Use 4pcs M3x10mm and 4pcs M3x20mm bolts for the...

Ham Radio customizable mounting bracket

thingiverse

We designed this for the Icom ID-5100, so the defaults fit that radio, but in general you should be able to customize for almost any ham radio of roughly the same shape. You'll need a good ruler or calipers to measure the radio dimensions and in...

You'll need a good ruler or calipers to measure the radio dimensions and in...

Ham radio stand

thingiverse

it locks on to the "feet" of the radio so it won't slip out. Print Settings Printer: Prusa i3 Rafts: No ...

Ham Radio Mounting Block

thingiverse

This has holes for mounting the radio face plate to it, but it slips into the card holder that is in the well of the console. Seems to work fairly well. Used Fusion 360 to model it, and sliced it with Slic3r. Printed it on end, 190 mm high, on a...

Printed it on end, 190 mm high, on a...

Aselsan 48XX Series Ham Radio Desktop Holder

thingiverse

This is ham radio desktop holder for Aselsan 48XX Series

Aselsan 48XX Series Ham Radio Holder

thingiverse

This is radio holder for aselsan 48xx series ham radio with compatible meanwell LRS-350-12KO

Ham Radio WorkBench Power Strip Box

thingiverse

A personally designed project to fit my assembled 12v DC Anderson Powerpole power strip kit. ...The PCB was designed by Ham Radio Workbench.com This is my first CAD project in about 7 years, and its rough.

...The PCB was designed by Ham Radio Workbench.com This is my first CAD project in about 7 years, and its rough.

Classic Ham Radio Amp Meter Bezel

myminifactory

I designed this replacement part for a client that has a collectible ham radio amp that had a broken bezel around the meter. This object was made in Tinkercad. ...https://www.tinkercad.com/things/lYcX5iRpTuu

Stand for IC 705 HAM Radio

thingiverse

Simple but very effective Stand for the new ICOM IC-705 Ham Radio.

Works perfect for me and can not wobble by Design.

Two 4mmx10 Screws needed. Printing time about 30 min.

...

Printing time about 30 min.

...

Ham Radio Transceiver Low-poly 3D model

cgtrader

Ham Radio Transceiver. Game Ready Model. ... Transceiver 2192 Tris + LOD 176 Tris Microphone 1547 Tris + LOD 446 Tris Speaker 437 Tris + LOD 113 Tris 2048x2048 Textures Specular map (in alpha channel) Normal map Reflect map (in alpha channel)

Ham Radio Workbench DC Power Strip Case

pinshape

This is the case for the Ham Radio Workbench Podcast 12V DC Power Strip project. File contains STL of base and DXF of top. Buy it printed here. ...https://rocketcity3d. ecwid.com...

ecwid.com...

[email protected] | Home

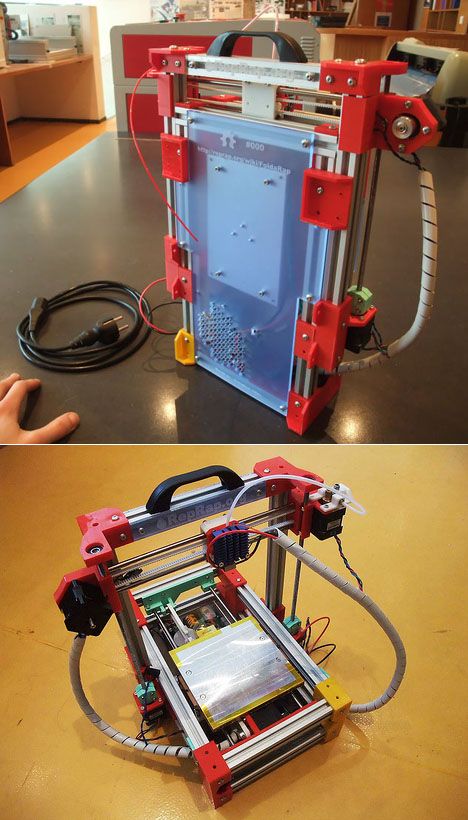

3D Printing For Radio, Electronic & Computer Projects

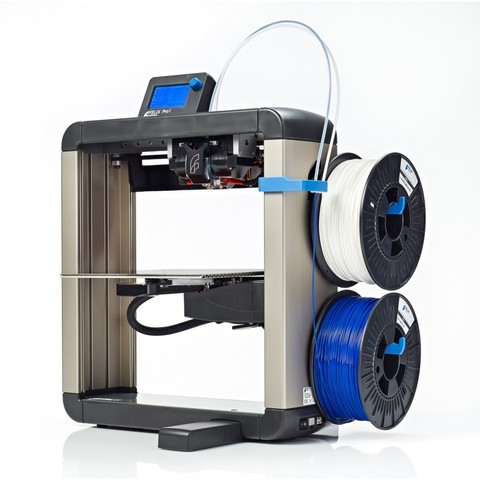

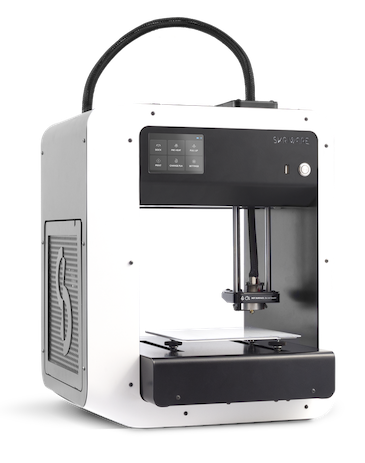

[email protected]Welcome to the 3D Printing For Radio, Electronics & Computer Projects group. The purpose of this group is to share information that relates to using 3D printers for radio, electronic and computer projects. Topics include learning how to use a 3D printer and the software (CAD, slicers, etc.) that controls it.

Amateur radio has a long history of hams helping each other to advance their skills related to radio technology. It is my goal of this group that we share information to help each other in using 3D printers in building radio, electronic or computer projects.

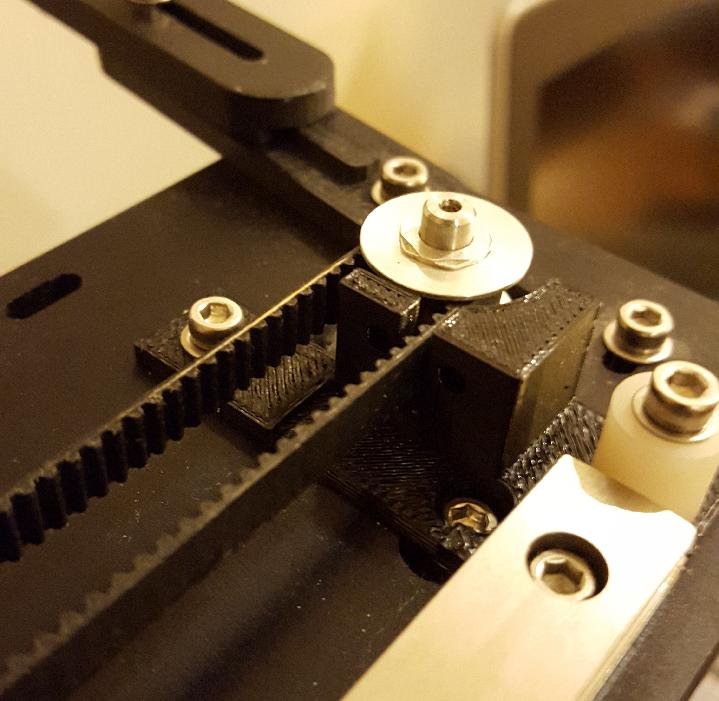

Below is an outline of the major phases of creating a part. It starts with the idea of needing a part for a project. Next, is designing it, then manufacturing it and finally using the part. Upon using the part you might decide to improve it and do another iteration of this process to create an improved version of the part.

Upon using the part you might decide to improve it and do another iteration of this process to create an improved version of the part.

Objective: 3D print a part from a STL file.

What is needed

- A part STL file containing the part design.

- Amateur radio STL files are available on the internet and from other hams.

- Slicer software (Cura, etc.) to control the 3D printer from the part STL design.

- Slicer takes the STL file and makes multiple print layers for the 3D printer to print.

- Also, the slicer sets up the 3D printer for printing.

- Filament type that is best the application and for the part requirements.

- There are several filament types: PLA, ABS, etc.

- 3D printer that support the filament type and is big enough to print the part.

- ABS filament requires heated print bad and enclosed printer to control the printer temperature environment.

- 3D printer calibration (bed leveling, etc.)

It may takes a lot of time (>hours) to print a part and expect to do multiple prints to adjust the slicer settings for best print quality.

Designing a Part

The next step is adding the ability to design a part and create the part STL file.

There are two major categories of 3D design software:

- 3D mechanical CAD software (OpenSCAD, Fusion 360 etc.)

- 3D mechanical CAD software is the best for part design.

- 3D modeling software (Blender, etc.).

It takes 3D print process knowledge to successfully design a part for 3D printing.

--- Phases of 3D Printing ---1. Need a Part Phase

- A part is needed for a radio, electronic or computer projects.

- Use a computer to design a part and create a STL file for the slicer software.

- Design a part with CAD software

- OpenSCAD

- Tinkercad

- Fusion 360

- 3D modeling software

- Blender for Beginners: Get Started with this Tutorial

- STL file format

- Slicer software takes CAD files (STL) and creates 3D printer control files (gcode).

- All3DP list of slicer software.

- Ultimaker Cura

- All3DP Cura Tutorial: Master Cura Slicer Software Settings

- All3DP Best Sites for Free STL Files & 3D Printer Files/Models

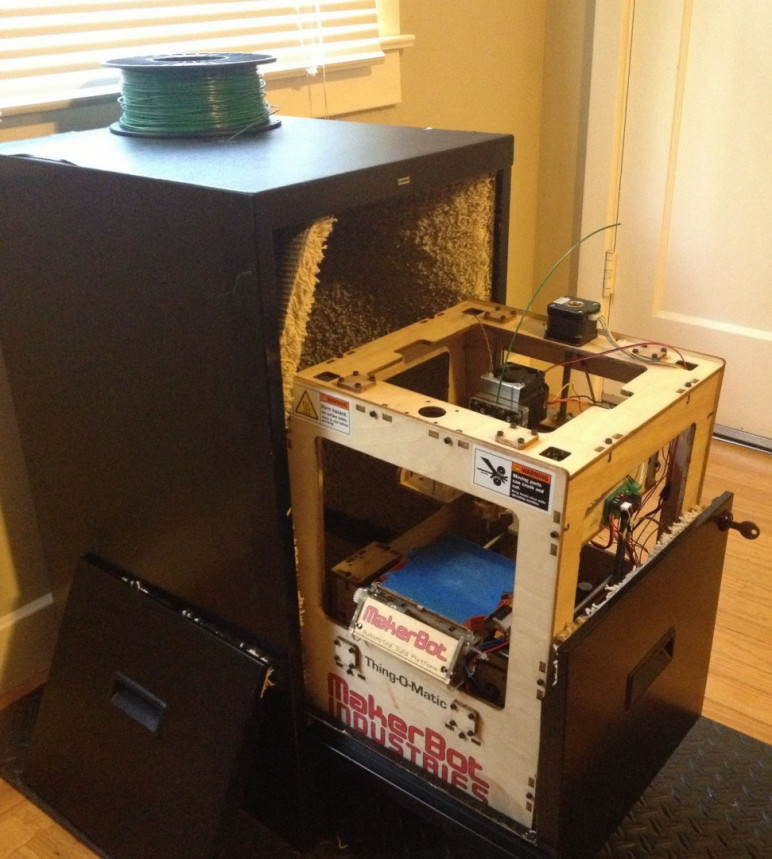

- MakeBot Thingiverse

- Makexyz

- Yeggi

- STLFinder

- STLBase

- Mito3D

- MyMiniFactory

- Octoprint - printer control software

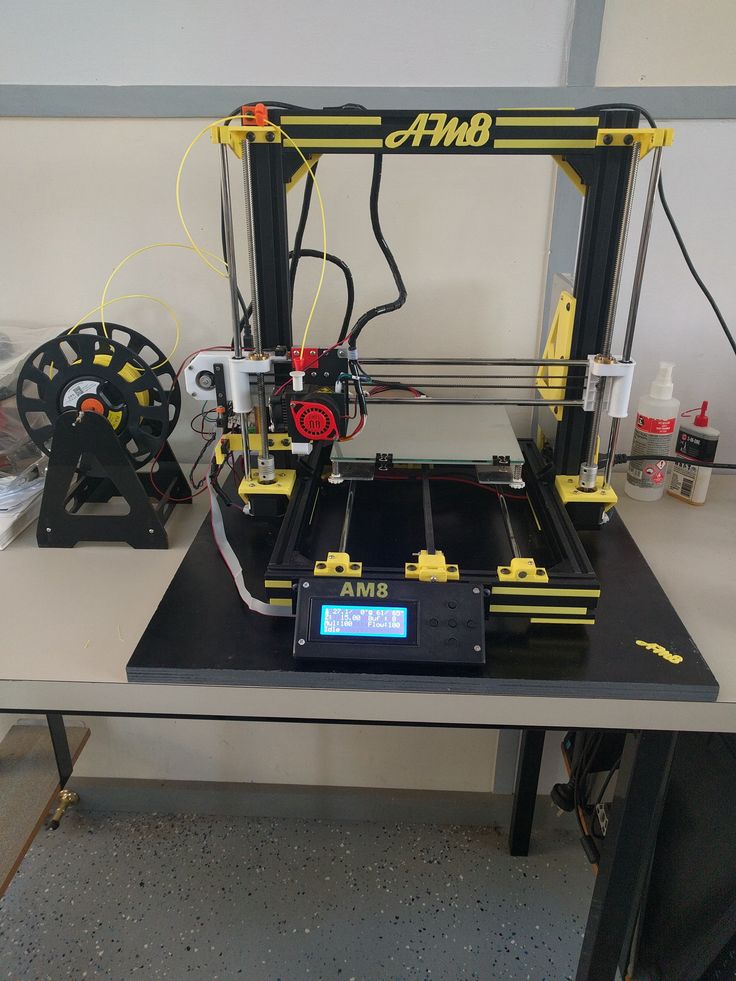

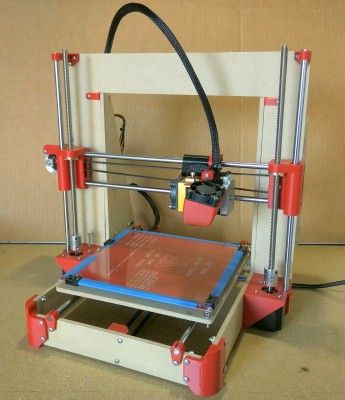

- 3D printers

- Creality

- Ender 3

- ALL3DP review

- Ender 3 Pro

- Creality files

- ALL3DP review

- Creality Ender 3 Pro Review: An Ideal First or Tenth 3D Printer

- GearLab review

- Amazon customer reviews

- Simple Ender 3 Pro Review – Worth Buying or Not?

- Creality Ender 3 Pro Review: A High-quality, Budget 3D Printer

- Creality Ender 3 Pro Review: An Excellent 3D Printer To Start With

- Hackspace Issue 26 January 2020 racking #4 4.

75/5.00

75/5.00

- Forum

- Videos

- Ender 3

- Amazon 3D Printers

- Creality

- 3D printing filament ultimate guide

- Wood 3D Printing Guide: How to 3D Print Wood

- Hands-on Review: TPU Filament

- Finishing & painting the part

- The Best Paint for Plastic (PLA, ABS, PETG, Nylon)

- Use the part and determine if improvements are required.

--- 3D Printing Resources ---

- Wikipedia

- 3D printing

- 3D printing processes

- Fused filament fabrication & fused deposition modeling (FDM) printers

- List of 3D printer manufacturers

- 3D modeling

- Blender (software)

- OpenSCAD

- STL (file format)

- G-code

- Marlin Firmware

- Cura (software)

- 3D printing filament

- PLA - Polylactic acid

- Hands-on Review: PLA Filament

- ABS - Acrylonitrile butadiene styrene

- TPU - Thermoplastic polyurethane

- Hands-on Review: TPU Filament

- PETG

- Hands-on Review: PETG Filament

- PLX

- Hands-on Review: PLX Filament

- Reprapper

- Episode 01 - Slicing basics of 3D printing

- PLA - Polylactic acid

- Magazine

- 3D Make & Print – 13th Edition, 2021

- 3D Make & Print – 2nd Edition, 2015

- Make Shed

- Newsletters

- ALL3DP

- Best 3D Printer Slicer Software in 2021

- Best Sites for Free STL Files & 3D Printer Files/Models

- Shells in a Nutshell

- What Is Retraction?

- 3D PRINTER G-CODE COMMANDS: LIST & TUTORIAL

- 3DPrinting.

com

com

- What is 3D Printing?

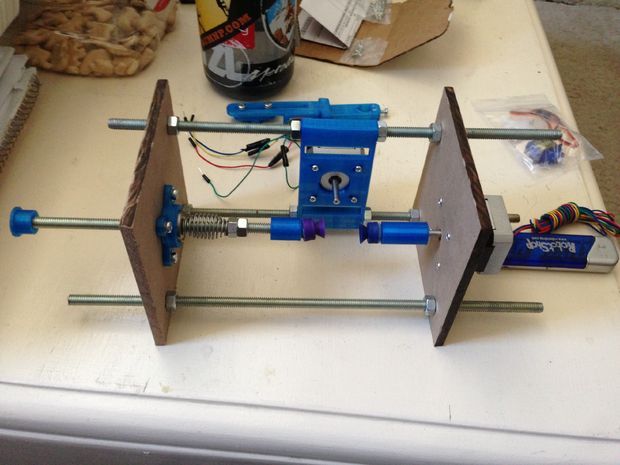

- Building a 3D Printer from Scratch

- Simplify3D

- G-Code Tutorial

- ALL3DP

- 3D Printing Service

- Sculpteo

- 3D Learning Hub

- Sculpteo

- Videos

- YouTube 3D Printing Amateur Radio videos

- YouTube 3D Printing Tutorials videos

- Books On-line

- Amazon 3D Printing books

- Books at Library

- 3D Printing for Dummies 2nd Edition

- Websites

- 3D Printing In Amateur Radio

- 3D printed parts for ham radio

- Facebook

- 3D printing for amateur radio

- Cura Users

- Creality

- Portland 3D Printing Lab

- Website

- YouTube

- Presentations

- 3D PRINTER PRIMER for AuxComm

- 3D Printing for the Amateur Radio Operator

- Articles

- 3D printing and amateur radio

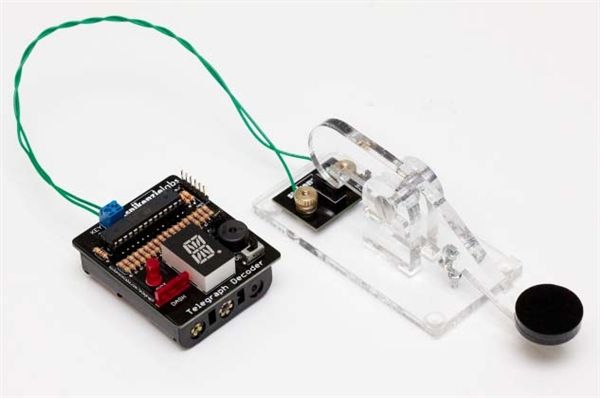

- A 3D Printed Key for Straight Key Night

- Internet Archive

- 3D printing

- Free Software In The 3D Printing Community

- Hackspace Issues: 3, 24, 28, 26, 30, 36 & 41

- Software

- Blender

- Tutorial

- Tinkercad vs Fusion360

- The 7 Best Free STL Editors to Edit and Repair your STL Files

- Blender

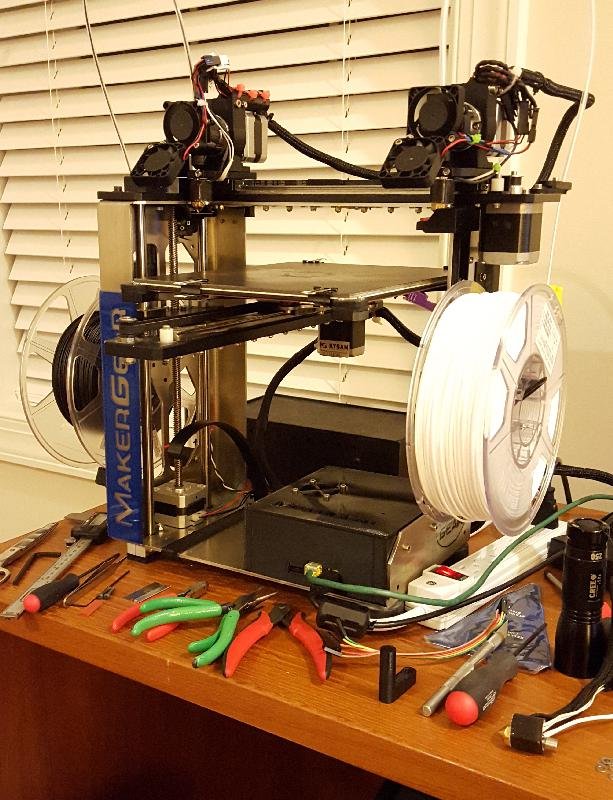

Doing 3D printing in Portland, OR area

- AB7FZ, Mike

- MakerGear M2, OpenSCAD

- KI7ZSR, Andre

- Ender 3 Pro, PLA, PET, PETG (Nylon), TPU, TinkerCAD, Cura

- Mods: 32-bit controller

- Ender 3 Pro, PLA, PET, PETG (Nylon), TPU, TinkerCAD, Cura

- KE7MSU, Mark

- OpenSCAD

- KJ7NWK, Nick

- WA9ONY, David

- Ender 3 Pro, PLA, OpenSCAD 2021.

01 Ubuntu, Cura 4.10 Ubuntu

01 Ubuntu, Cura 4.10 Ubuntu

- Mods: hood, limit switches, bed leveler

- Ender 3 Pro, PLA, OpenSCAD 2021.

73 David Haworth, WA9ONY

Group Owner/Moderator

Group Settings

- All members can post to the group.

- Posts to this group do not require approval from the moderators.

- Posts from new users require approval from the moderators.

- Messages are set to reply to group.

- Subscriptions to this group do not require approval from the moderators.

- Archive is visible to anyone.

- Wiki is visible to members only.

- Members can edit their messages.

- Members can set their subscriptions to no email.

Top Hashtags

[See All] No used hashtags.Message History

print | Radio amateur and programmer

Skip to main content

Skip to secondary content

Posts related to 3D printing will be posted here.

Posted by by admin

Hello everyone. In this I review and test plastic for a 3D printer from plastiq, which I bought for 462r in CSN. For example, I print a lamb under the M24 nut.

Here is a 3D model of a lamb (drawn in NX) - https://disk.yandex.ru/d/XOmpymRITw-msQ

I bought plastic here - https://www.dns-shop.ru/product/d7fdb266d0753332/ plastik-plastiq-abs/

Here is a table of standard nut sizes: Read more

Heading: 3D printing, Tests/reviews | Tags: 3D printing, Review | Add a commentPosted by by admin

Here are materials for creating a lighting power system for shooting photos and videos.

Materials:

PSU 12v 5a - https://aliexpress.ru/item/32880700331.html

PSU 12v 2a - http://got.by/5hz06m //got.by/5hz09c

Connectors - http://got.by/5hz0dt

Case model (developed in NX 7.5) - download

Heading: 3D printing, Power supplies, Other | Tags: g, PSU, PSU, lighting, power, softbox | Add a commentPublished by admin

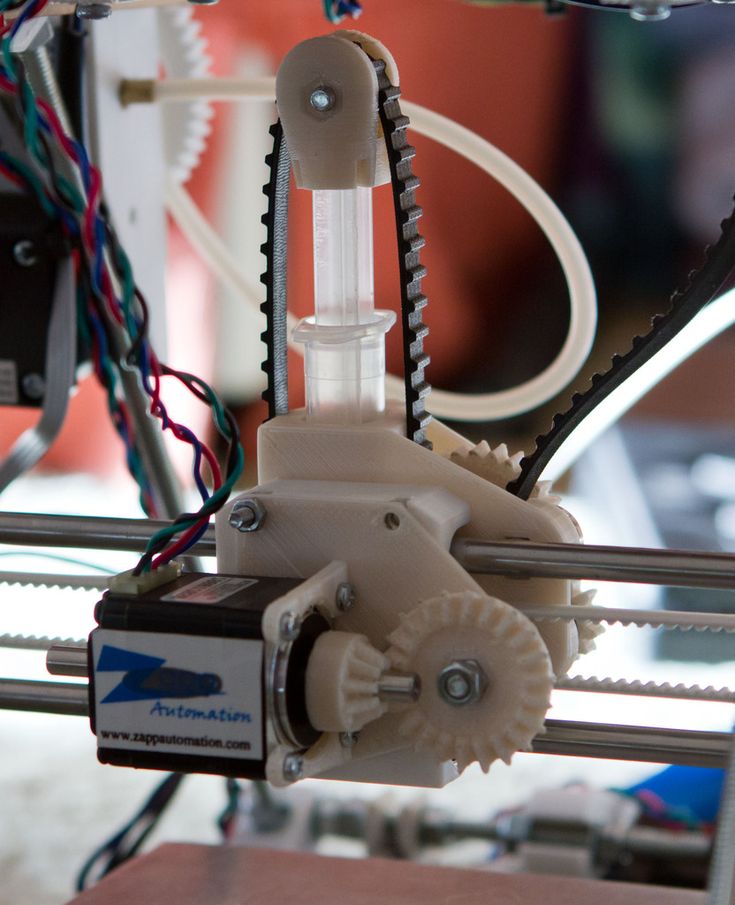

This video shows a mechanical 3D printed counter by me. The video shows a demonstration of the work and the internal structure.

Download the model from the Yandex disk.

The design is very simple and does not require much plastic. The thing is very interesting, I do not regret that I printed it.

Details in the video. Thank you all for your attention.

Cheap extruder for 3D printer - http://ali.pub/19cjb

Inexpensive plastic for a printer (filament) - http://ali.pub/f6air

Useful things for a radio amateur (I personally checked all the goods from the list):

Cheap soldering dryer - http://goo. gl/u3c3ZE

gl/u3c3ZE

Soldering iron with temperature controller, ceramic heater and a set of tips - http://ali.pub/k2huw

Arduino UNO - http://goo.gl/L9THC5

Adapter from USART to USB (very cool thing) - http://goo .gl/nyT2b3

Good cheap radio - http://goo.gl/qJjlzh

Universal socket - http://goo.gl/cIY18x

Tapered drills for textolite - http://goo.gl/DhkX7D

Solderless breadboards - http://goo.gl/Y1cejA

Very cheap digital SDR receiver - http://goo.gl/jyaQwb

Solder breadboards - http: //goo.gl/i3jdij

Posted by admin

Hello. I recently needed to redesign the filament spool holder. As a result, models of coil clamps and bearing supports were drawn and printed.

Bearings 22x8x7 mm. Bought here.

Filament can be bought here

I used M8 threaded stud as the axis. I tightened the clamps with ordinary nuts.

I tightened the clamps with ordinary nuts.

Device review video:

In the end, I settled on this coil clamp model (more reliable and more economical than a truncated cone):

Printed with 10% infill, it is strong enough.

Here is a link to a folder with models and drawings for Solid Edge.

Thank you all for your attention. If you have any suggestions - write.

Heading: 3D printing, Mechanical devices | Tags: 3d-print, 3d-printing, 3d-printer, spool holder, filament holder, on bearings, printing | Add a commentPosted on by admin

Hello.

Continuation of this post.

Here is the unpacking video:

And here is the plastic testing video:

I bought it here - http://prostoplast.ru/.

Thank you all for your attention.

Heading: 3D printing, Tests/reviews | Tags: 3D printing, 3D printer, ABS, Filament, ProPlast, Test, Plastic test | Add a commentThe site is powered by WordPress

3D printers will help colonize the Moon and Mars

Source: Country ROSATOM

Tomsk Polytechnic University, one of the flagship universities of Rosatom, has begun manufacturing a mock-up of a space 3D printer. In 2022, Russian cosmonauts will start printing light and durable parts on such a printer right on board the ISS. Over the past seven years, TPU has implemented a series of space projects, and now several more are in the works. Aleksey Yakovlev, director of the TPU School of Engineering for New Production Technologies, told CP about how 3D printing technologies and composite materials will make the life of astronauts more comfortable, help unravel the mysteries of nature and colonize the Moon and Mars.

In 2022, Russian cosmonauts will start printing light and durable parts on such a printer right on board the ISS. Over the past seven years, TPU has implemented a series of space projects, and now several more are in the works. Aleksey Yakovlev, director of the TPU School of Engineering for New Production Technologies, told CP about how 3D printing technologies and composite materials will make the life of astronauts more comfortable, help unravel the mysteries of nature and colonize the Moon and Mars.

— How did the space series of TPU projects start?

— From Decree No. 218 of the Russian government on cooperation between universities and enterprises. In 2013, together with Energia Rocket and Space Corporation and the Institute of Strength Physics and Materials Science (IFPM) of the Siberian Branch of the Russian Academy of Sciences, we entered into a mega-project to create a quality control technology for joints produced by friction stir welding. The developments were needed for the manufacture of elements of the hulls of a new generation of rocket and space technology.

The developments were needed for the manufacture of elements of the hulls of a new generation of rocket and space technology.

In 2015, Tomsk Polytechnic University, in collaboration with Energia and ISPMS, created the Research and Education Center "Modern Production Technologies" and the Advanced Research Center "Multilevel Dynamic Modeling of Materials and Structures". A year later, the Scientific and Educational International Network Center for Life Testing of TPU Materials was opened. All these divisions entered the advanced materials engineering center, where research can be carried out and developments can be promoted into space.

Into space on the second attempt

— Like the Tomsk-TPU-120 satellite? As far as I know, the world's first spacecraft, the body of which was made on a 3D printer.

— It was our gift for the 120th anniversary of the Tomsk Polytechnic University. This is the only university satellite that has a certificate from Roscosmos and NASA. The idea to create a satellite named after TPU came to Rector Petr Chubik. He suggested that the aircraft be a secret and transmit a sound signal to Earth in different languages, and radio amateurs from all over the world could catch this signal. The project was completed in less than a year. The electronic filling was developed by Southwestern State University. We have indeed made the world's first nanosatellite, the body of which is printed on a 3D printer. The device turned out to be small: 30 cm long, 11 cm wide and deep, weighing about 4 kg.

The idea to create a satellite named after TPU came to Rector Petr Chubik. He suggested that the aircraft be a secret and transmit a sound signal to Earth in different languages, and radio amateurs from all over the world could catch this signal. The project was completed in less than a year. The electronic filling was developed by Southwestern State University. We have indeed made the world's first nanosatellite, the body of which is printed on a 3D printer. The device turned out to be small: 30 cm long, 11 cm wide and deep, weighing about 4 kg.

It took a long time to select a material capable of withstanding low and high temperatures, ± 100 ° C, ordinary plastic did not meet these parameters. We had to select raw materials from the list of materials allowed for use on the ISS and refine them. Batteries that power on-board equipment do not like temperature changes; we printed special protective blocks for them. The satellite was sent to the ISS on March 31, 2016 aboard the Progress MS-02 transport cargo spacecraft from the Baikonur cosmodrome. But he got into space only the second time.

But he got into space only the second time.

— Why?

Oh, that was history! When we sent the satellite to Baikonur and he was already waiting for his turn to be packed in the transport ship, the ballistics came to the conclusion with a ban on departure. Experts calculated that if an astronaut unsuccessfully launches our satellite, then on the second orbit he will fly back to the ISS and crash into the American sector. There will be an international scandal. We were all on our toes! We were given two days to finalize the design. To change the trajectory of movement, it was necessary to make a special braking element, a small detail in the shape of a bow tie. We barely made it. The astronauts launched the satellite into orbit at an altitude of about 400 km. He spoke with the voices of 12 foreign TPU students. At the same time, it transmitted telemetry - information about the operation parameters of all systems. For about three months, we and Roskosmos controlled him, he flew along a given trajectory, then entered the dense layers of the atmosphere and burned out. While he was flying, radio amateurs spotted him and wrote to us about it. And an exact copy of the satellite is in the Moscow Museum of Cosmonautics, we are the first university to receive such an honor.

While he was flying, radio amateurs spotted him and wrote to us about it. And an exact copy of the satellite is in the Moscow Museum of Cosmonautics, we are the first university to receive such an honor.

Swarm of nanosatellites

- Now your work is being used to create a series of spacecraft that can swarm and interact with each other. How is this project developing?

— Swarm of Small Spacecraft is a large project, a team of more than 15 organizations is working on it, also under the leadership of RSC Energia. Our university is responsible for the buildings, Tomsk State University of Control Systems and Radioelectronics is responsible for inter-satellite communication systems, the Research Institute of Nuclear Physics of Moscow State University is making a gamma-ray burst detector, Skoltech is developing an on-board computer and attitude control and stabilization systems using the Concurrent Engineering and Design Laboratory (CEDL).

From 2020, we must launch 10 satellites a year for three years. At the first stage, they must exchange information with each other, at the second, they should broadcast data to the ISS, and at the third, final stage, they should become a positioning system, united like a swarm of bees.

— Why are such satellites needed?

- Outwardly, the satellites are similar, but their on-board equipment is different. Each device has its own purpose: to study forests for the balance of cuttings and new plantings, to monitor the behavior of insects, climate change, to control crop yields in agricultural areas, to probe the soil, to explore outer space, to record the volume of garbage flying in the orbit of the planet. And this is only part of the tasks. Let me give you an example: some time ago in Kyrgyzstan, brown clouds appeared over Lake Issyk-Kul. No one can understand what this phenomenon is. All hope is that our satellite systems, using optical control methods, will determine what we are dealing with.

3D printing in zero gravity

— At what stage is the project to create a layout of a space 3D printer for printing with composite materials on board the ISS?

- The design documentation is ready, the contract with the customer is signed, we are making a layout. A prototype printer will appear in 2021. After we test it and make sure that all the calculations are correct, we will begin to build a flight version.

— What is the difference between a space 3D printer and ordinary ones?

— There are many differences, because it will work in zero gravity, the security system must be carefully thought out. In a laboratory on Earth, you put a printer on a table and it prints. If suddenly there is a smell from the plastic or particles of dust fly, we will simply open the window and ventilate. There are no air vents on the ISS. We need good filters and protective devices, a ventilation system so that nothing threatens the atmosphere at the station. Due to these features, the printer will be larger and heavier than traditional models. We have to foresee all the nuances of working without gravity, so that all materials adhere to each other as they should, the material is strong and the details of the desired shape. It is not so easy. On Earth, gravity often helps us out, and we immediately have to do without it. There will be an original configuration of the nodes associated with the supply of material, the ability to position the substrate and the print head. In parallel, software for the printer is being developed.

Due to these features, the printer will be larger and heavier than traditional models. We have to foresee all the nuances of working without gravity, so that all materials adhere to each other as they should, the material is strong and the details of the desired shape. It is not so easy. On Earth, gravity often helps us out, and we immediately have to do without it. There will be an original configuration of the nodes associated with the supply of material, the ability to position the substrate and the print head. In parallel, software for the printer is being developed.

— And what exactly will the astronauts print on it?

- Anything. They have a lot of technological connectors there, they often need plastic plugs, and in zero gravity they constantly fly apart. Without plugs, there may be leakage of electricity, current may strike. The printer will help out in such a situation: turn it on and print. You can make any parts to replace those that failed. Sometimes some non-standard tools are needed, they can be designed on a computer or you can request a drawing from the Earth and also print and use it. Depending on the tasks, cosmonauts themselves will be able to change the composition of composite materials, add fiberglass, carbon fiber, metals to the polymer matrix - this will change the properties of the resulting parts. The lightness will remain, but the products will become harder and will be able to withstand extremely low or, conversely, high temperatures. Astronauts will appreciate. Our printer can become a prototype of the standard equipment of orbital stations, as well as Martian and lunar complexes.

Sometimes some non-standard tools are needed, they can be designed on a computer or you can request a drawing from the Earth and also print and use it. Depending on the tasks, cosmonauts themselves will be able to change the composition of composite materials, add fiberglass, carbon fiber, metals to the polymer matrix - this will change the properties of the resulting parts. The lightness will remain, but the products will become harder and will be able to withstand extremely low or, conversely, high temperatures. Astronauts will appreciate. Our printer can become a prototype of the standard equipment of orbital stations, as well as Martian and lunar complexes.

Orbit view

— Tell us more about the Peresvet project, within which TPU develops a protective coating for windows.

- As part of the Peresvet experiment, a multilayer nanocomposite coating will be applied to the ISS windows to protect the glass from space debris, micrometeorites and cosmic dust. Coatings have passed all tests, received a patent. At the end of the summer we have to sign a contract and we will immediately start making equipment for coating in space.

Coatings have passed all tests, received a patent. At the end of the summer we have to sign a contract and we will immediately start making equipment for coating in space.

Cosmic dust accumulates on the windows over time, they lose their transparency, and plaque forms. Plus mechanical damage. A few years ago, an emergency occurred in the American sector. They have a large glass dome to admire space landscapes, its radius is 60 cm. A meteorite flew into it and damaged the glass, leaving a two-centimeter scratch. Astronauts are now afraid that the crack will go further and depressurization will occur. The hatch had to be closed with a metal screen. Now they go to look into space from our windows - they are almost three times smaller, but more reliable. Our technology will help not only to take preventive measures, but also to repair already damaged areas, it will be like “healing” a chip on the windshield of a car.

— Will the new coating be used anywhere else?

— We plan to use this technology for protective coatings on photoelectronic converters. Now space batteries are covered with glass without sputtering, and when they are folded, they seem to be nothing, but when they unfold, they have a large square and turn into a space dust collector. They break down faster and give less energy. Our spraying will help solve the problem.

Now space batteries are covered with glass without sputtering, and when they are folded, they seem to be nothing, but when they unfold, they have a large square and turn into a space dust collector. They break down faster and give less energy. Our spraying will help solve the problem.

— What is the essence of your autonomous orbital greenhouse project?

— This year we plan to submit an application to Roskosmos in order to enter the long-term program of experiments on the ISS and receive funding. In the greenhouse, we will grow different plants in space. We use smart lighting that accelerates plant growth, special hydroponic installations, automatic watering and harvesting, and nutrient gel instead of soil. The project team includes scientists from TPU and Tomsk State University, as well as Tomsk State University of Control Systems and Radioelectronics, the Institute of Petroleum Chemistry of the Siberian Branch of the Russian Academy of Sciences and the Siberian Research Institute of Agriculture and Peat. There have been many experiments on growing crops in microgravity, but they have all been conducted in the living quarters of orbital stations. We are developing a specialized autonomous module capable of supplying food for astronauts and, if necessary, docking to the ISS through a gateway. Someday it could be used on the Moon or Mars.

There have been many experiments on growing crops in microgravity, but they have all been conducted in the living quarters of orbital stations. We are developing a specialized autonomous module capable of supplying food for astronauts and, if necessary, docking to the ISS through a gateway. Someday it could be used on the Moon or Mars.

- In your opinion, are the colonization of the Moon and Mars viable projects?

“It’s all very relevant and viable. I can well imagine how we flew to the moon, dug a trench, printed on 3D printers all the structures necessary for life, put up greenhouses. I think that the colony is a prospect for the next 10 years.

— Can a person be happy not on Earth?

- Why not? Of course it can. I think that in 15 years we will not be walking freely along the street, it will be entertainment for extreme people, and most people will move in sealed capsules equipped with everything that is needed for happiness.