Hoberman sphere 3d print

▷ hoberman sphere 3d models 【 STLFinder 】

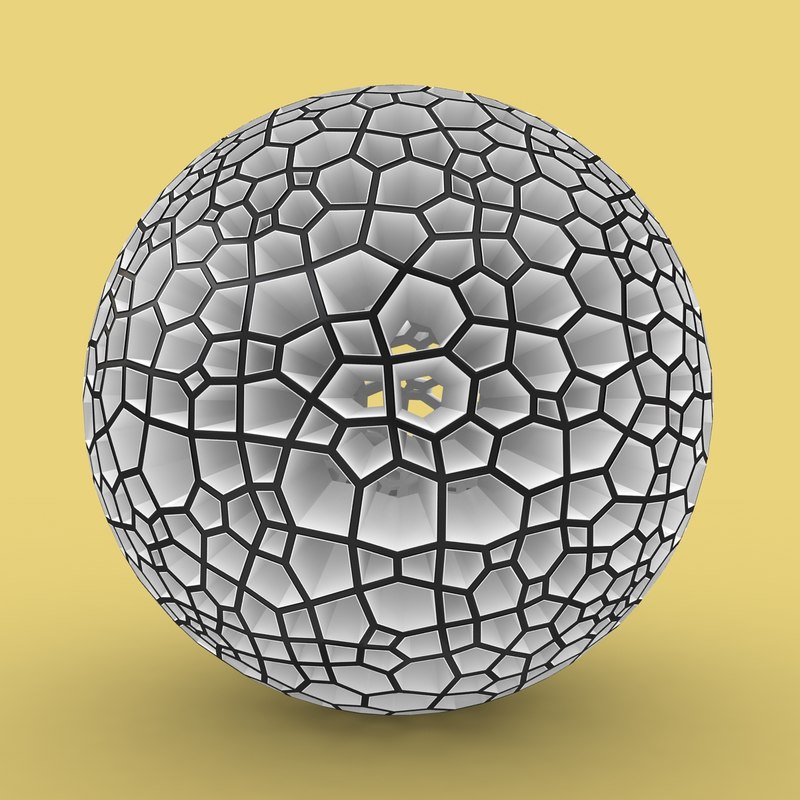

Hoberman Sphere

thingiverse

I was looking to build a NautilusX model http://en.wikipedia.org/wiki/Nautilus-X and realized that Thingiverse didn't even have a Hoberman sphere library. It uses one-way snaps might be useful for other projects too. I'm not nearly clever enough to...

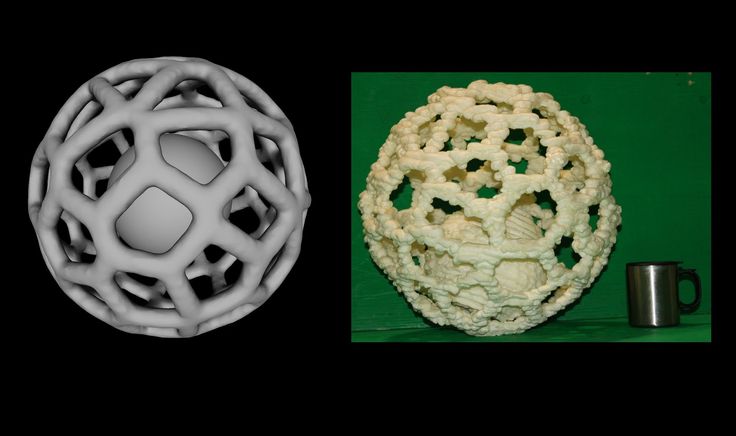

Hoberman Sphere

thingiverse

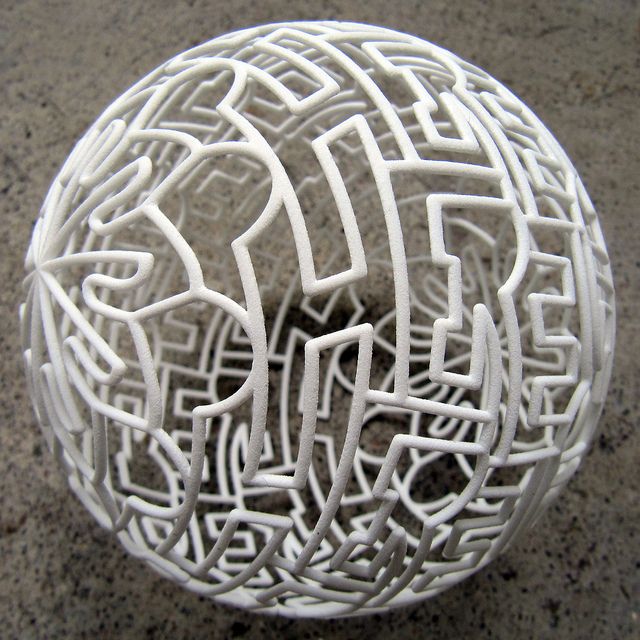

As a final year project at The University of Sheffield I successfully replicated Hoberman's Sphere using the EOS Formiga P100. The build comprises of 132 individual parts assembled on Solidworks. The entire piece came out assembled and required a...

Hoberman Sphere

thingiverse

When building the sphere, note that the hubs have lines engraved on them. These lines should be facing TOWARDS the other hub (check the picture). ...Start with the piece shown in the picture on the table, and work on from that, always forming hexagons...

Hoberman Sphere

thingiverse

... two joining parts and trying this out, so I can modify the files. They work on my printer. I'm currently working on a larger sphere, with diagonal lines as well. It will require patience during assembly. . Have fun making this thingie! ...:D

hoberman sphere (3 ring)

grabcad

hoberman sphere made up of 3 rings.

Hoberman sphere ( Cuboctahedron )

thingiverse

Hoberman sphere ( Cuboctahedron 150mm - 220mm, 65gramm). Need: 96 segments, 24 cross.

For link use 1.75 filament. Pins melted with a soldering iron.

...

Need: 96 segments, 24 cross.

For link use 1.75 filament. Pins melted with a soldering iron.

...

Hoberman Sphere

thingiverse

https://www.youtube.com/watch?v=6l8F_rbPgKA Please see the video if you're having trouble with assembly. Everything is done out in blender with the array modifier. If anyone is upset that there are no stl files then leave a comment and I'll do...

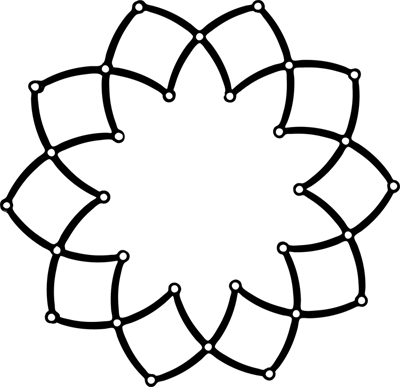

Hoberman Sphere - "Expanding Circle"

thingiverse

Part was derived from a video I saw while youtube browsing. Instructions Print appr. 20 pieces, tie joints together or use Brass Fasteners "Brads" http://en. wikipedia.org/wiki/Brass_fastener. Works...

wikipedia.org/wiki/Brass_fastener. Works...

Make Sense of the Hoberman Sphere / Circle, Linkage

cults3d

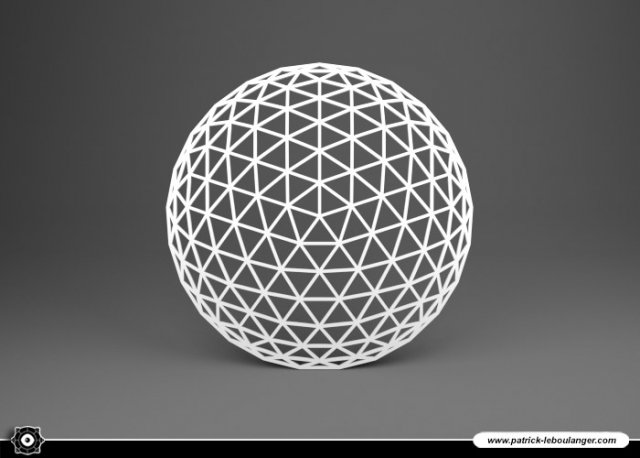

####Make Sense of the Hoberman Sphere/Circle The Hoberman sphere is a beautiful structure (Hoberman, 1990, 1991), appealing to children and grownups alike. Mathematically, it is an extension of the traditional linkages. Taking two bars of the same...

Make Sense of the Hoberman Sphere / Circle, Linkage

thingiverse

The Hoberman sphere is a beautiful structure (Hoberman, 1990, 1991), appealing to children and grownups alike. Mathematically, it is an extension of the traditional linkages. Taking two bars of the same length and connecting them in the middle, we...

Mathematically, it is an extension of the traditional linkages. Taking two bars of the same length and connecting them in the middle, we...

Hoberman Wheel Prototype

grabcad

A prototype of Hoberman wheel

Hoberman Circle Segments

thingiverse

Scissor-lift/Hoberman style ciclce segments Instructions Untested design. The scad is parametric so you can change the number of segments. In theory, you can 3D print ten of each segment, and assemble. ...The construction fails at 6 segments, though it...

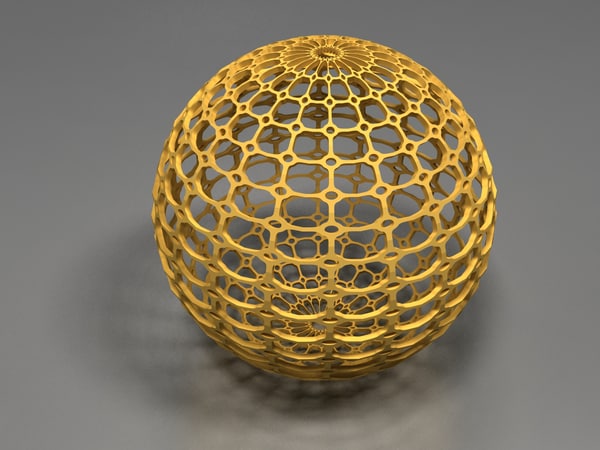

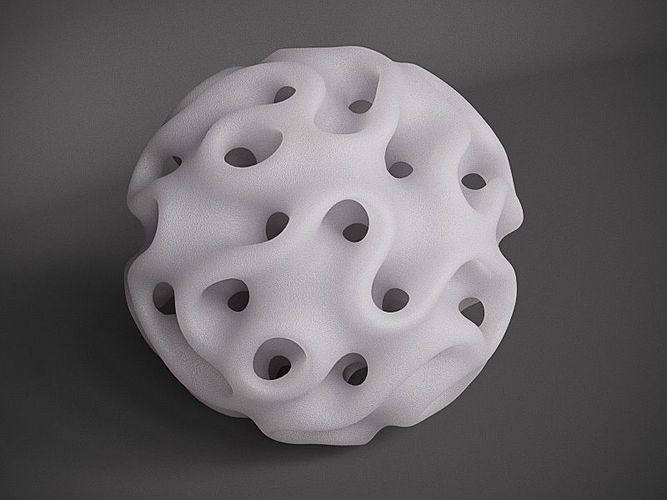

sphere

grabcad

sphere

sphere

sketchfab

sphere

Sphere

thingiverse

Sphere

sphere

thingiverse

sphere

sphere

thingiverse

sphere

sphere

grabcad

sphere

Sphere

cults3d

Sphere

sphere

sketchfab

sphere

Sphere

thingiverse

Sphere

Sphere

thingiverse

Sphere

Sphere

grabcad

Sphere

Sphere

thingiverse

sphere

sphere

thingiverse

sphere

SPHERE

thingiverse

SPHERE

Sphere

thingiverse

SPhere

Sphere

grabcad

Sphere, sfera

Sphere

thingiverse

New Sphere

Sphere

thingiverse

Hollow Sphere

Transformable/ Deployable Structures: Caroline Yanson Video: https://youtu.

be/AtUbnL-QS8c

be/AtUbnL-QS8cNext Story

from 'Mind and Medium 2021'

Parametric Design Jacky Yan Video

TRANSFORMABLE/ DEPLOYABLE STRUCTURES

CAROLINE YANSON

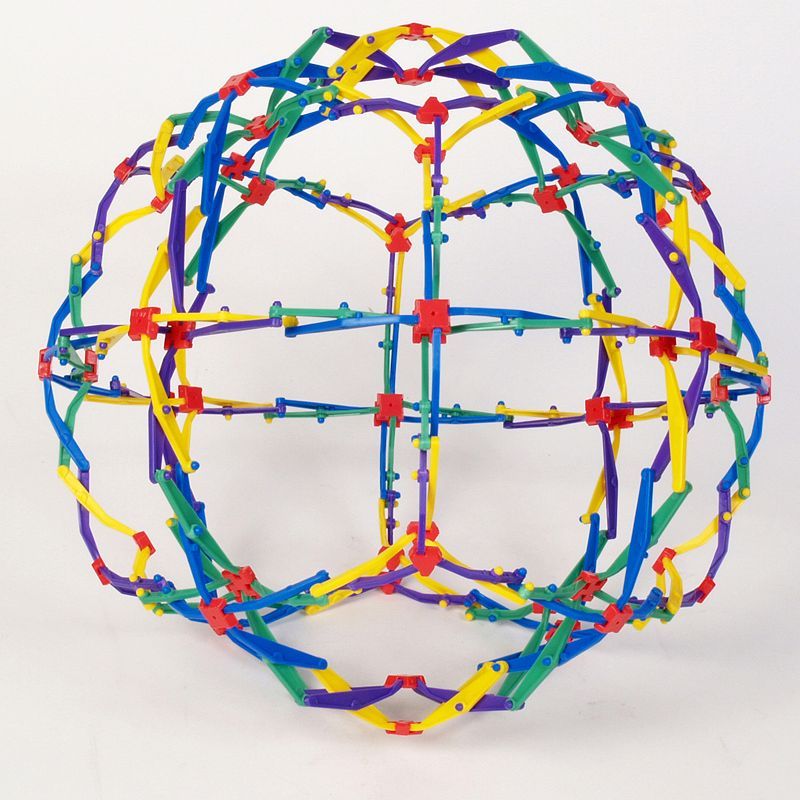

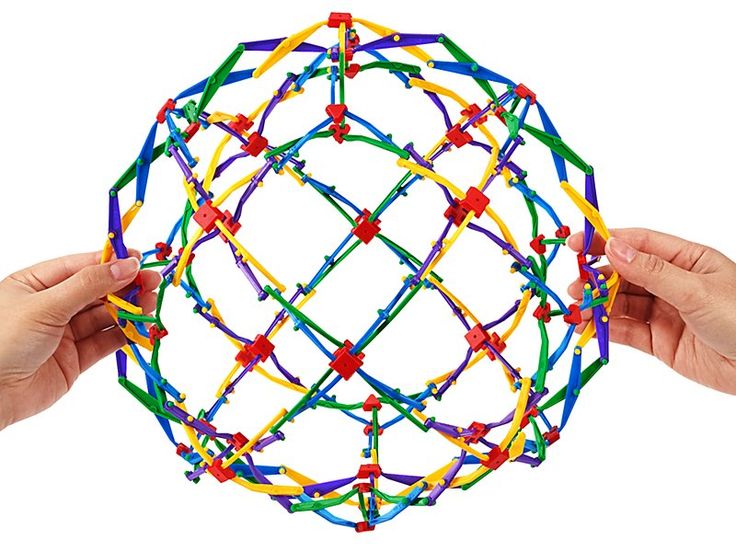

INTRODUCTION I am exploring the design of Transformable/ deployable structures by building a model of a Hoberman Sphere & 3D printing my own joints with the goal of understanding how these structures work via the “scissor hinge”. Transformable/deployable structures are expandable & contractable for storage, transportation, reuse, & adaptability (DeTemmerman, Roovers, Mira, Vergauwen, Koumar, Brancart, Mollaert, 2014). They evolved in history starting from their use as Egyptian hunter chairs & Mongolian nomadic yurts (mira, 2014) (Figure A). Today, applications of transformable/deployable structures are widely used in everyday objects: umbrellas, store gratings, tents, foldable furniture, & more (Figure B). Designer, Chuck Hoberman, increased the popularity of these structures from his creation of the Hoberman Sphere (Figure C). His work, among other designers’ work, have inspired more interpretations & developments of these structures.

His work, among other designers’ work, have inspired more interpretations & developments of these structures.

FIGURE A: Transformable/ Deployable Structures in Historic Applications

Egyptian Hunting Chair (Pamperin, (n.d). Mongolian Yurts (Arneill, 2017).

FIGURE B: Everyday Applications FIGURE C: Designer, Chuck Hoberman Transformable/deployable structures apply today in many fields: the military uses them as shelters, NASA uses them in space exploration, the medical field uses them as temporary care units in disasters, etc (Merchan, 1987). The possibilities of such structures are endless! These, though complex & intricate, can be designed & produced in an easier manner via AEC technology, such as softwares, Rhinoceros & Grasshopper Plug-in, Karamba . AEC programs perform simulations, model structures, & calculate algorithms ensuring stability, geometry, & effectiveness. AEC allows the architect, engineer, or contractor to understand the structure & assembly. Then, they can either manually assemble or digitally fabricate the structure. Because transformable/ deployable structures have little available/ easy softwares for the general public (DeTemmerman, Roovers, Mira, Vergauwen, Koumar, Brancart, Mollaert, 2014)., I predict that there will be a future trend of easy-to-use software development aiming accessibility to a wider audience (Figure D). I also predict that transformable/deployable parts will be designed for mass production to make assembly more efficient.

Then, they can either manually assemble or digitally fabricate the structure. Because transformable/ deployable structures have little available/ easy softwares for the general public (DeTemmerman, Roovers, Mira, Vergauwen, Koumar, Brancart, Mollaert, 2014)., I predict that there will be a future trend of easy-to-use software development aiming accessibility to a wider audience (Figure D). I also predict that transformable/deployable parts will be designed for mass production to make assembly more efficient.

FIGURE D: GARTNER HYPE CYCLE FOR AEC TECHNOLOGY

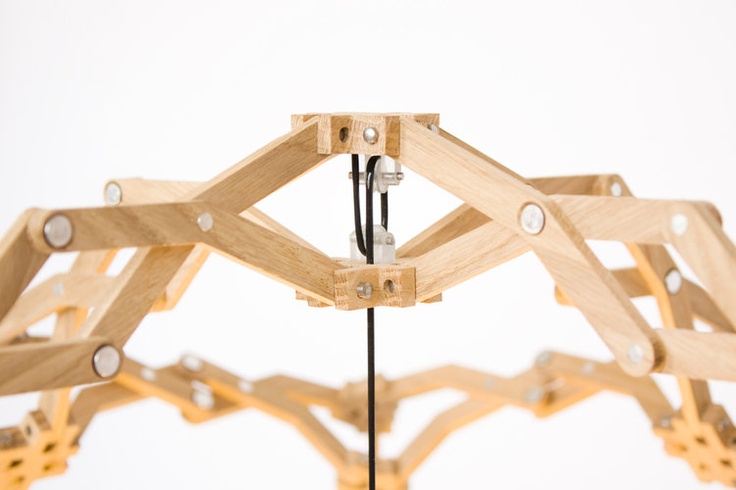

CASE STUDY 1: Universal Scissor Component, Workshop Led by Niels De Temmerman, London, 2011 (Mira, 2014) This is the development of a universal scissor component (USC) used in an icosahedron scissor dome made of wood. They used Rhino to create a parametric model & Karamba for structural analysis & mathematic algorithms. The parts were laser cut MDF boards manually connected to wooden struts by bolts. This design is reducing the number of materials, & therefore, waste, by designing for adaptability & structural reuse of the USC. In theory, scissor components in transformable/ deployable structures, are complex & generally designed for a single purpose. By creating the USC, it makes it simpler to design a transformable/deployable structure because the scissor component can be mass produced & applied to different shapes & sizes of such structures. The adaptability of a uniformed component will ultimately lower the production cost & make it easier & faster to set up & take down.

In theory, scissor components in transformable/ deployable structures, are complex & generally designed for a single purpose. By creating the USC, it makes it simpler to design a transformable/deployable structure because the scissor component can be mass produced & applied to different shapes & sizes of such structures. The adaptability of a uniformed component will ultimately lower the production cost & make it easier & faster to set up & take down.

CASE STUDY 1: WOOD DOME ICOSAHEDRON

Full Scale Icosahedron Dome with the Universal Scissor Component (Mira, 2014).

Assembly of Universal Scissor Component - Contracted (Mira, 2014). Assembly of Universal Scissor Component - Expanded (Mira, 2014).

CASE STUDY 2: The Hoberman Arch, Chuck Hoberman, Salt Lake City Utah, 2002, ( Hoberman Arch, 2020). This structure is a motor operated aluminum arch with rigid covers that acts as a stage. It expands & contracts like an “iris of a human eye”. Hoberman employs his prior design of a scissor-hinge mechanism, but adapts it by angling the hinges in a ring & attaching 2 of the same angulated bars to a revolute joint. As a result, he created the largest transformable structure of the time. By attaching the rigid covers to the parts of his structure with angles, the covers did not get in the way of the motion of this structure. Hoberman’s use of rigid covers provided safety and shelter from weather conditions & avoided many of the problems that membrane covers had for other designers in the past.

As a result, he created the largest transformable structure of the time. By attaching the rigid covers to the parts of his structure with angles, the covers did not get in the way of the motion of this structure. Hoberman’s use of rigid covers provided safety and shelter from weather conditions & avoided many of the problems that membrane covers had for other designers in the past.

CASE STUDY 2: WINTER OLYMPICS HOBERMAN ARCH

The Hoberman Arch at the Winter Olympics (Yenal, 2010).

Hoberman Arch’s Motorized Structure with Rigid Covers (Hoberman Arch, n.d).

CASE STUDY 3: Transformable Dome, Iran, Maziar Asefi & Soheila Aram, 2017 (Asefi, Aram, 2018). This design is a transformable dome that uses rigid covering panels to cover the space when expanded. The rigid covers are attached to the interior of this surface, giving the benefit of extra warmth in cold places. It is smart to use detached rigid covers for it allows the installation to act as unitized modules. That way if one of the cover panels needs repair, they can do it without having to dissemble the whole thing. They designed this model through the computer model of Rhino, then manually assembled the pieces. Overall, they created a great precedent from which others can 76 learn stability, weather protection, & more.

That way if one of the cover panels needs repair, they can do it without having to dissemble the whole thing. They designed this model through the computer model of Rhino, then manually assembled the pieces. Overall, they created a great precedent from which others can 76 learn stability, weather protection, & more.

CASE STUDY 3: TRANFORMABLE DOME WITH KINETIC ELEMENTS

Rhino Model of Transformable Dome Using Kinetic Elements (Asefi, Aram, 2018).

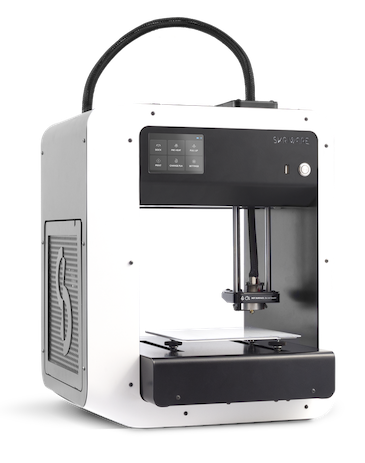

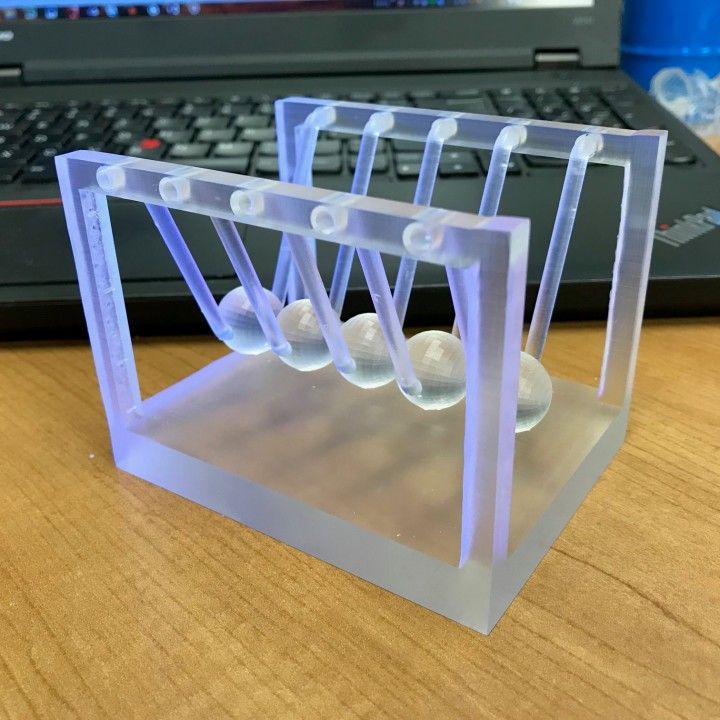

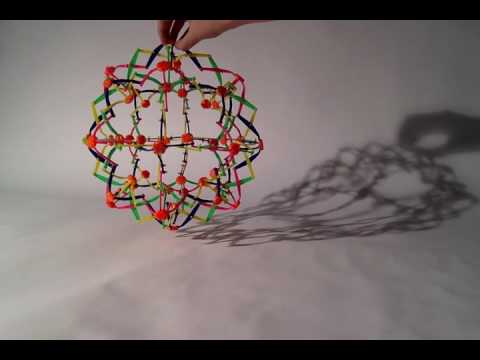

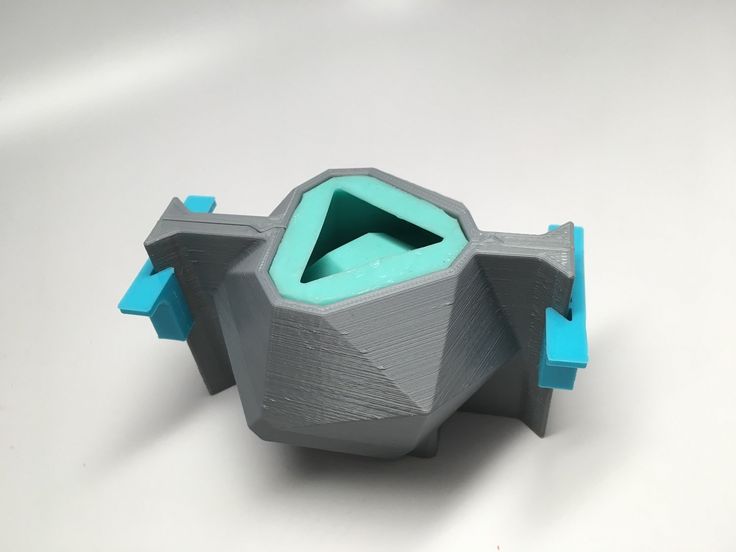

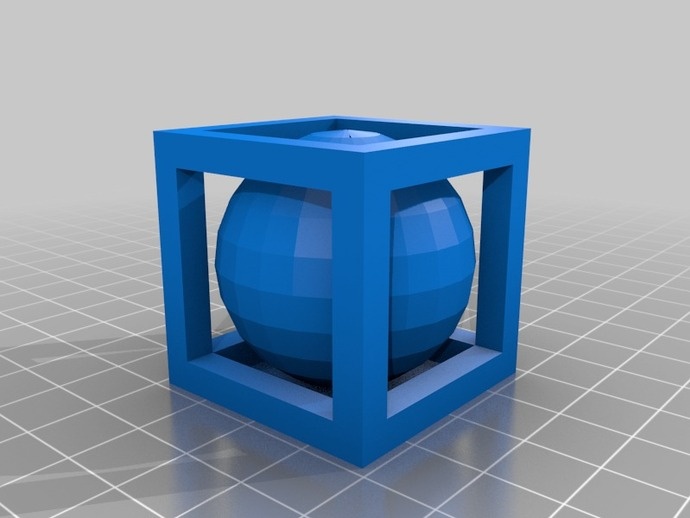

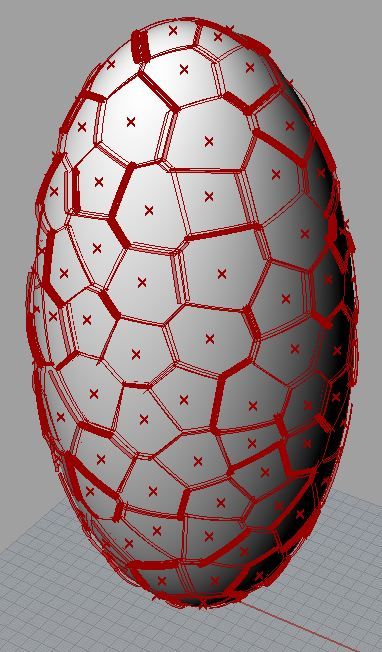

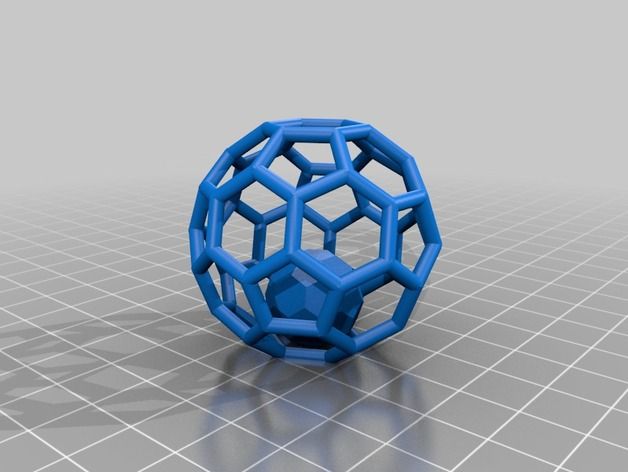

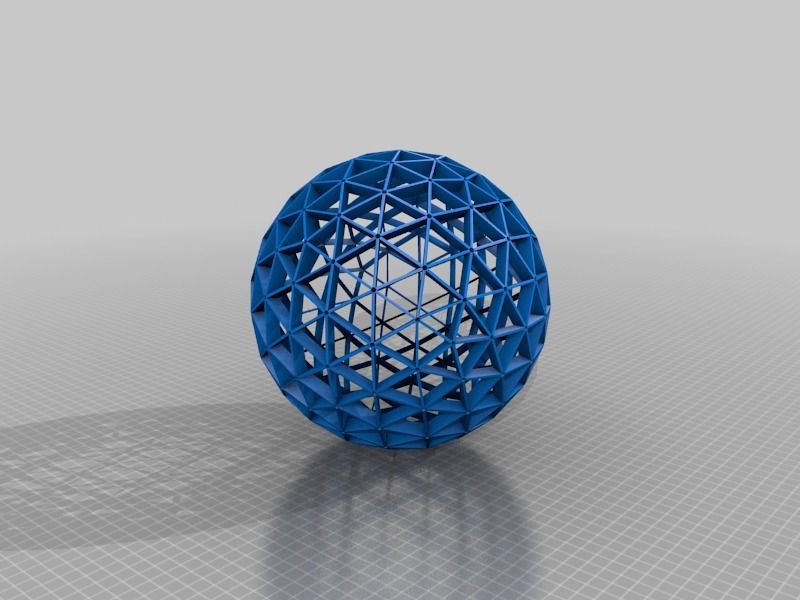

HYPOTHESIS If I learn possibilities of transformable/deployable structures, model 1 out of K’nex pieces, & finally, 3D print scissor hinges, than I will have a comprehensive understanding of how these structures work in regard to the AEC industry PROCESS I am exploring how transformable/deployable structures are assembled & how they expand & contract in different forms. I completed my project in 3 parts: PART 1: WOLFRAM SOFTWARE SIMULATIONS I logged into the Wolfram software & visited “Scissor Hinge Simulation” (Berczi, 2007) , “Expanding Fence Simulation” (Kabai, 2007), “Expanding Tower Simulation”(Kabai, 2008), & “Deployable Shelter Simulation”(Kabai, 2020). I experimented by changing the control variables that go into making the components of such structures. PART 3: 3D PRINTING SCISSOR JOINTS I wanted to learn how to 3D print, so I am 3D printing a 3D & 2D scissor hinge. The first step was finding a computer model of a Hoberman Sphere so that I could extract the 2 forms of scissor hinges to 3D print. I found a model that was already made on Thingiverse (Badro, 2014)- a website of shared, 3D models that the public can use to 3D print.

I experimented by changing the control variables that go into making the components of such structures. PART 3: 3D PRINTING SCISSOR JOINTS I wanted to learn how to 3D print, so I am 3D printing a 3D & 2D scissor hinge. The first step was finding a computer model of a Hoberman Sphere so that I could extract the 2 forms of scissor hinges to 3D print. I found a model that was already made on Thingiverse (Badro, 2014)- a website of shared, 3D models that the public can use to 3D print.

WOLFRAM SIMULATIONS Scissor Expandable Fence Expandable Tower Deployable Shelter ORIGINAL MODEL 3D PARTS I AM PRINTING MY ASSEMBLY GOAL

3D Model from which I extracted the parts (Badro, 2014). 3D Connector One Pin Arm Two Pin Arm Cap 2D Scissor Hinge 3D Scissor Hinge

I downloaded my files to Cura (Cura, 2017), where I rotated & arranged each piece on the bed & set the 3D printing settings. s se ettings sg . CURA 3D PRINTING SOFTWARE

3D printer settings prep (Cura, 2017). How I arranged & rotated my parts on the 3D printing bed (Cura, 2017).

I saved the Cura file to a USB, plugged it into the 3D printer, added the PLA blue filament & selected “print”. I printed each different piece as a separate print. In total, the actual time it took to 3D print was only 3 hours. t to oo ok k to o 3D D p 3 ho ou urs sr .t t wa aw s s on o ly ly 3D PRINTING PARTS PRINTED- NOT ASSEMBLED

Exploration of how the number of scissors determines the expansion & contraction of the computer model (Berczi, 2007).

Screenshots of my exploration of different heights of the scissors & how they can be formed into a closed circle (Kabai, 2007). Screenshots of my exploration of how the scissors bending angles can be manipulated to form a closed structure (Kabai, 2008). Screenshots of my exploration of how the scissors can form a shelter (Kabai, 2020).

PART 2: MODELING A HOBERMAN SPHERE OUT OF K’NEX TOY PIECES To model a Hoberman Sphere, I followed a tutorial (Mosely, 2017). To begin, I collected the K’nex pieces I needed to build the model. K’NEX INVENTORY 48- short green rods 96- grey 2 prong connectors 96- grey 1 prong connectors 96- red 3 prong connectors 96- blue spacers 192- yellow long rods 12- white 8 prong connectors

K’NEX INVENTORY 48- short green rods 96- grey 2 prong connectors 96- grey 1 prong connectors 96- red 3 prong connectors 96- blue spacers 192- yellow long rods 12- white 8 prong connectors

DOCUMENTATION AND INSTRUCTIONS

My infographic 3D printer in King Library’s Makerspace. Caps Printed 3D Connectors

One Pin Arms Caps

Two Pin Arms

I assembled the 2 scissor hinge types. I had some difficulties fitting some of the pieces together, so I took an Xacto knife & cut out excess material that resulted from the 3D printing process. I also printed cap pieces, but it turned out that I did not need them. Overall, the process was educational & I accomplished my goal of showing the 2D & 3D scissor hinges. ASSEMBLED 2D SCISSOR HINGE ASSEMBLED 3D SCISSOR HINGE

Expanded How 2D arms connect to the 3D hinge Contracted

DISCUSSION REFERANCES Arneill, P. (2017). My Shot. Retrieved April 6, 2021, from https:// www.nationalgeographic.orgencyclopedia/ yurt/ Asefi, M. , & Aram, S. (2018). Flexibility in Architecture: An Innovative Design-Covering of Transformable Dome Using Kinetic Elements,41-52. Retrieved April 6, 2021, from http://soij.qiau.ac.ir/ article_545 286_9b62172367beefe52344cca1d9bcfcea.pdf Badro, A. (2014). STL. Thingiverse MakerBot Industries, LLC. Bérczi, S. (2007). “Nuremberg Scissor” http:// demonstrations. wolfram.com/NurembergScissors/ WolframDem onstrations Cura LulzBot: Quick Start Guide. (2017, November 22). I achieved my hypothesis by successfully learning about different forms of transformable/deployable structures Retrieved April 06, 2021, from https://www. lulzbo t.com/cura-lulzbot-edition-quick-start-guidethrough the demonstrated simulations, physically modeling my own Hoberman Sphere, & by 3D printing Delivering Differently: Emerging Technologies. Retrieved March26, 2021, from https://www.my own scissor hinges. Through my demonstrated newcivilengin simulations, I learned that by using a scissor hinge type, eer.com/archive/delivering-differently-emerging I can create numerous forms of transformable structures.

, & Aram, S. (2018). Flexibility in Architecture: An Innovative Design-Covering of Transformable Dome Using Kinetic Elements,41-52. Retrieved April 6, 2021, from http://soij.qiau.ac.ir/ article_545 286_9b62172367beefe52344cca1d9bcfcea.pdf Badro, A. (2014). STL. Thingiverse MakerBot Industries, LLC. Bérczi, S. (2007). “Nuremberg Scissor” http:// demonstrations. wolfram.com/NurembergScissors/ WolframDem onstrations Cura LulzBot: Quick Start Guide. (2017, November 22). I achieved my hypothesis by successfully learning about different forms of transformable/deployable structures Retrieved April 06, 2021, from https://www. lulzbo t.com/cura-lulzbot-edition-quick-start-guidethrough the demonstrated simulations, physically modeling my own Hoberman Sphere, & by 3D printing Delivering Differently: Emerging Technologies. Retrieved March26, 2021, from https://www.my own scissor hinges. Through my demonstrated newcivilengin simulations, I learned that by using a scissor hinge type, eer.com/archive/delivering-differently-emerging I can create numerous forms of transformable structures. technologies-18-01-2016/ This visualization gave me clarity to how a scissor hinge De Temmerman, N., Roovers, K., Mira, L. A.,Vergauwen, A., actually works & that using the least amount of sides/ bars, gives me a more lightweight & compressed Koumar, A., Brancart, S., Mollaert,M(2014). Lightweight Transformable Structures IV. doi:10.2495/mar140011 structure that will be easier to store & transport. Through my K’nex Hoberman Sphere, I gained knowledge in how scissor hinges can join together in order for Folding Gate Installation. (n.d.). Retrieved April 6, 2021, from https://www.acfoldinggates.com/maxguard them to expand & contract in 2D & 3D. I learned Hoberman Arch.(2020). Retrieved April 06, 2021, from that there are much more pieces involved in creating https://en.wikipedia.org/wiki/Hoberman_ Archa deployable structure than I thought. However, these pieces could be mass fabricated, for there are only Hoberman Arch. (n.d.). Retrieved March 10, 2021, from http a couple different type of parts needed.

technologies-18-01-2016/ This visualization gave me clarity to how a scissor hinge De Temmerman, N., Roovers, K., Mira, L. A.,Vergauwen, A., actually works & that using the least amount of sides/ bars, gives me a more lightweight & compressed Koumar, A., Brancart, S., Mollaert,M(2014). Lightweight Transformable Structures IV. doi:10.2495/mar140011 structure that will be easier to store & transport. Through my K’nex Hoberman Sphere, I gained knowledge in how scissor hinges can join together in order for Folding Gate Installation. (n.d.). Retrieved April 6, 2021, from https://www.acfoldinggates.com/maxguard them to expand & contract in 2D & 3D. I learned Hoberman Arch.(2020). Retrieved April 06, 2021, from that there are much more pieces involved in creating https://en.wikipedia.org/wiki/Hoberman_ Archa deployable structure than I thought. However, these pieces could be mass fabricated, for there are only Hoberman Arch. (n.d.). Retrieved March 10, 2021, from http a couple different type of parts needed. Lastly, through s://www.hoberman.com/portfolio/olympicarch/my 3D printing of scissor hinges,I learned how to bring the 3D model into Cura & how to control the actual 3D printer. In the end, I got a glimpse of how Kabai, S. (2007). “Extendable Frame” http://demonstrations. wolfram.com/Extendable Frame/ WolframDem- onstrations easy it would be to large-scale manufacture parts of deployable/transformable structures. I can design Kabai , S. ( 2008) “Extendable Tower” http://demonstrations. wolfram.com ExtendableTower/ Wolfram Demo-my own transformable/deployable structures in my nstrations future. Because I want to specialize in humanitarian architecture & social infrastructure, I could use my Kabai , S. (2020) .“Frame for a Deployable Shelter” http:// demonstrations.wolfram.com/FrameForAnew gained knowledge to create flexible, portable, DeployableShelter/ Wolfram Demonstrations & easy-to-erect structures that are sustainable, leaving no permanent damage to their sites. Some practical Merchan, C.

Lastly, through s://www.hoberman.com/portfolio/olympicarch/my 3D printing of scissor hinges,I learned how to bring the 3D model into Cura & how to control the actual 3D printer. In the end, I got a glimpse of how Kabai, S. (2007). “Extendable Frame” http://demonstrations. wolfram.com/Extendable Frame/ WolframDem- onstrations easy it would be to large-scale manufacture parts of deployable/transformable structures. I can design Kabai , S. ( 2008) “Extendable Tower” http://demonstrations. wolfram.com ExtendableTower/ Wolfram Demo-my own transformable/deployable structures in my nstrations future. Because I want to specialize in humanitarian architecture & social infrastructure, I could use my Kabai , S. (2020) .“Frame for a Deployable Shelter” http:// demonstrations.wolfram.com/FrameForAnew gained knowledge to create flexible, portable, DeployableShelter/ Wolfram Demonstrations & easy-to-erect structures that are sustainable, leaving no permanent damage to their sites. Some practical Merchan, C. (1987). Deployable Structures (ii-83, Rep). Cambridge: MIT.implementations of what I could design from my new knowledge could be Covid-19 vaccination hubs, social Mira, L. A. (2014). Parametric Structural Assessment of Deployable Scissor Systems: Optimizing the distancing igloos, shelters in natural disasters, refugee USC. Brussels: Uitgeverij University Press. rooming, etc. More temporary spaces are needed in our built environment because in times of crisis, these Mosely, J. (2017, October 22). K’nex Expanding Sphere. Retrieved March 10, 2021, from https://www. structures can quickly serve an essential purpose. I feel instructables.com/Knex-Expanding-Sphere/ more prepared going into the architecture field because I learned the importance of testing simulations under Pamperin, N. (n.d.). Bronze Age Folding Chair Found in N. Germany & Now in Helms Museum different conditions, making physical models, learning [Photograph]. new AEC computer programs, & the characteristics Archäologisches, Helm’s Museum, Hamburg.

(1987). Deployable Structures (ii-83, Rep). Cambridge: MIT.implementations of what I could design from my new knowledge could be Covid-19 vaccination hubs, social Mira, L. A. (2014). Parametric Structural Assessment of Deployable Scissor Systems: Optimizing the distancing igloos, shelters in natural disasters, refugee USC. Brussels: Uitgeverij University Press. rooming, etc. More temporary spaces are needed in our built environment because in times of crisis, these Mosely, J. (2017, October 22). K’nex Expanding Sphere. Retrieved March 10, 2021, from https://www. structures can quickly serve an essential purpose. I feel instructables.com/Knex-Expanding-Sphere/ more prepared going into the architecture field because I learned the importance of testing simulations under Pamperin, N. (n.d.). Bronze Age Folding Chair Found in N. Germany & Now in Helms Museum different conditions, making physical models, learning [Photograph]. new AEC computer programs, & the characteristics Archäologisches, Helm’s Museum, Hamburg. of flexibility, adaptability, reuse, & transformability in a 78 sustainable context.

of flexibility, adaptability, reuse, & transformability in a 78 sustainable context.

SHUAILANG YAN (JACKY)

1998

JUNIOR

ARCHITECTURE MAJOR

ABOUT ME

JACKY YAN

ARCHITECTURE IS ABOUT TRYING YO MAKE THE

WORLD A LITTLE BIT MORE LIKE OUR DREAM

BACKGROUND

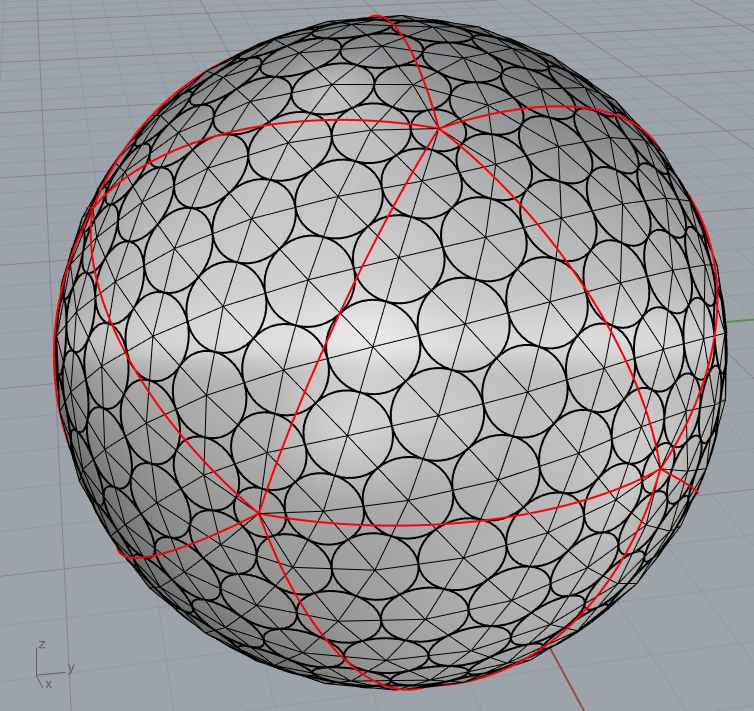

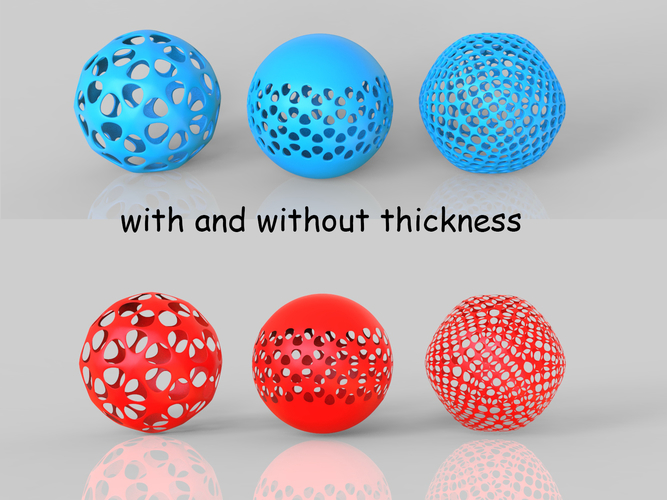

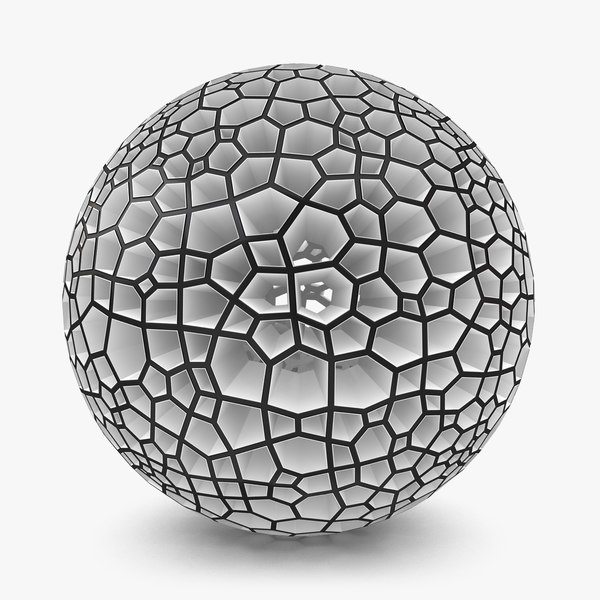

After I started learning architecture, I came into contact with a lot of new things, started to touch some computer modeling software AutoCAD, Sketchup, and also learned that Photoshop, InDesign, Illustrator is not only used to make posters, but also to modify and type our drawings. What makes me feel most incredible is parametric modeling. By learning and consulting, we know that many things in life are inseparable from numbers, like big data, finance, design, and many of the most basic things in software are numbers. Digital has influenced the development and future of cities, like digital cities, digital modeling. Parametric modeling is one of the representatives of digital modeling, parametric modeling is free modeling through numbers, formulas, and software. Why free modeling is because you can build whatever arc you want, whatever shape you want. Model production in a purely digital space is simply a transformation of ideas for designers, allowing designers to greatly enhance their designs, diverge their thinking, and create different buildings. Rhino is the most representative software because it is a parametric modeling software that was molded earlier and contains very functional software Grasshopper. In the process of learning this software, I found that the biggest difficulty is that it has too many functions, there are many small functions in each big function, you need to spend a lot of time to practice in order to better master this software. But I really enjoy the process since Rhino is more like a game software than a model software, it lets you think of design as an interest, love a favorite thing to do, you don’t think it’s boring, because you can find more inspiration here.

Why free modeling is because you can build whatever arc you want, whatever shape you want. Model production in a purely digital space is simply a transformation of ideas for designers, allowing designers to greatly enhance their designs, diverge their thinking, and create different buildings. Rhino is the most representative software because it is a parametric modeling software that was molded earlier and contains very functional software Grasshopper. In the process of learning this software, I found that the biggest difficulty is that it has too many functions, there are many small functions in each big function, you need to spend a lot of time to practice in order to better master this software. But I really enjoy the process since Rhino is more like a game software than a model software, it lets you think of design as an interest, love a favorite thing to do, you don’t think it’s boring, because you can find more inspiration here.

More stories from this publisher:

from 'Mind and Medium 2021'

Parametric Design Jacky Yan Video

from 'Mind and Medium 2021'

Grasshopper Modeling: Ruiqi Ba.

..

..from 'Mind and Medium 2021'

Generative/ Algorithmic Design...

from 'Mind and Medium 2021'

Technology and Music: Julia M....

from 'Mind and Medium 2021'

AI in Film Industry: Chuqi Wan...

from 'Mind and Medium 2021'

Advanced 3D Printing: Anna Hen...

from 'Mind and Medium 2021'

Dynamo Training: Kiara Clark V...

from 'Mind and Medium 2021'

Parametric City Analysis: Mary...

from 'Mind and Medium 2021'

UX & AI: Tia Phillips Video: h...

from 'Mind and Medium 2021'

Generative Design: Saumyabrata...

from 'Mind and Medium 2021'

ARchitecture: Brandon Dalessan...

from 'Mind and Medium 2021'

AR in Advertizement: Jiayi Zha...

from 'Mind and Medium 2021'

Animal Friendly Virtual Realit...

from 'Mind and Medium 2021'

Empathy in Immersion: Kendra S...

from 'Mind and Medium 2021'

UX/WEB Design Kylie Blovits Vi.

..

..from 'Mind and Medium 2021'

Augmented Reality in an Interi...

from 'Mind and Medium 2021'

Advancements in Photogrammetry...

from 'Mind and Medium 2021'

3D Printing in the Medical Ind...

from 'Mind and Medium 2021'

3D Printed Fidgets: Marissa An...

3D printing, 3D scanning and 3D modeling applications

Loading

3D printing is increasingly entering our lives, turning into an indispensable assistant for specialists in various fields of activity. The availability of 3D printing allows for bold experiments in architecture, medicine, education, dentistry, jewelry, small-scale production, advertising and souvenirs.

3D printing, 3D scanning, 3D modeling applications

1

LOW SERIES PRINTING

Small batch 3D printed parts

2

3D LAYOUT PRINTING

Professional production of all kinds of models

3

PRODUCT DESIGN

Lamps, vases, shelves, coasters, figurines, interior decorations

4

3D SCANNING OF SCULPTURES

Small batch 3D printed parts

5

CT MRI 3D PRINTING

Professional production of all kinds of layouts

6

SHOPPING

Lamps, vases, shelves, coasters, figurines, interior decorations

7

3D PRINTING OF HUMAN FIGURES

Exact mini copies created by scanning and printing on a 3D printer

8

3D PRINTING IN EDUCATION

Printing visual aids for the educational process.

9

PACKAGING DESIGN

3D printing of packaging mock-ups, vials and bottles in original shape

10

3D PRINTING OF ARM LANGETS

3D printing allows you to create splints, orthoses and any other fixations

11

3D MODELS FROM PHOTOGRAPHY

We provide services for creating 3D models from photographs

12

YOUR THESE PROJECT

You can order 3D printing of various products for graduation projects

13

PROTECTIVE VISERS

14

3D PRINTING MASK

Printing a protective maxim on a 3D printer. Protect yourself and loved ones

15

RAPID PROTOTYPE

3D printing of parts and accessories for medical equipment

16

ORTHODONTAL aligners

3D printing of aligners on Formlabs Form 3 printer

17

SLS 3D PRINTING

Selective laser powder sintering

18

3D PRINT COSPLAY

3D Print Game, Movie, Comic Character Costumes

19

PROFIDE CAPS

3D printed profile caps

20

Heroes from Minecraft

3D printing of Minecraft models

21

3D printing of church models

We make models of churches, church cathedrals using 3D printing

22

3D scanning of goods

Digitization of goods to add to the site. Texture overlay.

Texture overlay.

23

3D printing materials

Plastics ABS, PLA, Nylon, PC, PET-G, FLEX, Rubber, ASA, Formax, Aerotex, Wax Base

24

Car 3D scanning

We provide services for 3D scanning of cars and individual elements

25

3D scanning of casts

We provide services for 3D scanning of dental plaster casts

26

3D printed molds

3D printed molds for molding fast food boxes

27

Burn-out photopolymer

3D printed jewelry casting

28

PEEK, PEKK & ULTEM Plastics

High Performance 3D Printing Plastics

29

Food grade plastic PET-G

3D printing with safe materials

30

Button 3D printing

Custom 3D printing

31

Trade show products

3D printing for trade shows

32

3D model libraries

List of sites where you can download models for 3D printing

33

Resin post-processing

Post-processing of products after 3D printing with photopolymer

34

3D models of implants

Creation of 3D models of implants to reshape the chin

35

3D printing of three-dimensional paintings

A harmonious interior is a system of many parts and elements

36

3D printing of life figures

New possibilities in the implementation of ideas in the field of design with 3D printing

37

Appliance Repair

3D Printing and 3D Scanning for Appliance Repair

38

Agribusiness and 3D printing

Agricultural efficiencies of 3D printing

39

Manufacture of conductors

Manufacture of conductors by 3D printing

40

Military 3D

Military 3D printing

41

Plastic Composite

Composite 3D Printing

42

Large-scale printing

3D printing of large models on a 3D printer

43

3D printing and climbing

3D printing of ledges for climbing walls

How to place an order? You will receive a letter with the calculation of the cost of your order, which will include - cost, material of manufacture, deadlines.

After confirmation and payment, the order will be sent for production. When ready, the order will be sent to you by courier service at the specified address.

3D technologies have become a part of modern life. They are used almost everywhere, helping to solve both domestic and professional, including industrial-scale tasks. This is due to the advantages that 3D printing, in particular, gives, which is increasingly being called a great helper that can become an excellent alternative even to a production conveyor.

Advantages of 3D printing:

- high precision;

- wide range of materials;

- speed - a minimum of time costs in comparison with the production process;

- practically no restrictions;

- variety of technologies and their continuous improvement.

In fact, there are practically no restrictions in the scope of 3D printing. It is used both in production and in high-precision areas. Increasingly, you can find 3D printers in everyday life. However, the main areas of application are:

However, the main areas of application are:

- design;

- layout;

- architecture;

- small-scale production;

- creation of master models;

- education and research activities;

- souvenirs, bijouterie;

- modeling and engineering;

- jewelry sphere;

- medicine and dentistry, etc.

In any of these industries, 3D printing can be a great help, helping to effectively solve the most complex problems.

Do you want to order 3D printing, 3D scanning or 3D modeling? Please contact our company. We print on printers that print using different technologies FDM, SLA, DLP, SLS, SLM. Our own fleet of modern equipment allows us to solve problems of any complexity.

We guarantee the shortest lead time and high quality.

We use cookies. Learn more in our 3D Services 9 personal data processing policy0010

Capabilities and Applications of 3D Printing

Whereas massive industrial machinery in special workshops used to produce parts, today 3D printing helps. Using this technology, it is possible to print parts of different complexity, which are not inferior in quality and characteristics to those produced by traditional methods.

Using this technology, it is possible to print parts of different complexity, which are not inferior in quality and characteristics to those produced by traditional methods.

3D printing technology

Printing on a 3D printer consists in the layer-by-layer formation of the structure of the future part from its graphic representation compiled on a computer in the form of files with three-dimensional graphic structures. They are created manually using specialized software, or obtained by scanning a real prototype.

Printers are capable of recreating parts from sheet, liquid or powder material. The possibilities of a 3D printer in terms of the use of material for printing are very wide - it can be:

- plastic;

- nylon;

- glass powder;

- metallic powder;

- building mixtures;

- other materials.

The future details are obtained by fusing layer upon layer in such a way that their shape corresponds to her digital prototype.

Techniques used

3D printing can be done using different techniques.

- Extrusion printing consists in heating the base material to the melting temperature and extruding it through the extruder nozzle, forming fragments of the future part. Various polymeric compounds act as the starting material;

- The powder technique involves inkjet printing, in which binders are applied to a thin powder layer, followed by impregnation with wax or a polymer composition. Next, sintering of adjacent powder layers is performed. For this, direct or selective fusion with a laser or cathode ray tube is used;

- Laminating opens up wide possibilities for 3D printing. Using this method, you can significantly reduce the cost of manufactured spare parts. This technology involves the use of paper, sheets of thin plastic and metal as the base raw material.

Applications

Since 3D printers can create parts of a wide variety of shapes, 3D printing has become used in various industries. Most often it is used in:

Most often it is used in:

- industry;

- medicine;

- construction;

- automotive industry;

- aviation.

Advances in technology and declining prices for 3D printers are driving their widespread adoption at the consumer level. Anyone who is at least a little versed in technology and has free financial resources can start home production of the necessary things and parts.

3D printing at home

If earlier everyone wanted to have a regular printer for printing documents, photos, presentations at home, today desires have switched to a 3D printer. Why might it be needed at home? Given the almost unlimited possibilities of 3D printing, a printer at home will become not just another high-tech toy for technology lovers, but an essential tool for the home. With it, it will be possible to print-produce:

- elements of furniture fittings;

- Christmas tree decorations;

- stands for office supplies;

- clothespins;

- Kids toys;

- chessmen;

- original protective cases for tablets and phones.

Having a 3D printer at home will eliminate the unnecessary waste of time searching in stores and the market for some small detail that you can now make yourself.

Medicine

An important point in the development of 3D printing technologies is that they can be used in medicine. The most common use of 3D printers is in dentistry. They help to quickly make jaw implants and temporary crowns, which are necessary for a full life of the patient. The manufacture of jaw implants on a printer greatly simplifies the work of a dental surgeon.

In addition to jaw implants, other complex elements necessary for the restoration of the human skeleton can be made. For example, a modeled and then printed human skull implant made it possible to restore its integrity after a serious injury.

3D printing in medicine is actively used in prosthetics. Thanks to this technology, it is possible to produce prostheses that take into account the individual characteristics of the physical structure of the patient's body. By forming special microcavities in the prosthetic element, the possibilities of normal functioning of healthy tissue cells in contact with the material of the prosthesis are opened. This speeds up the process of human adaptation to the prosthesis.

By forming special microcavities in the prosthetic element, the possibilities of normal functioning of healthy tissue cells in contact with the material of the prosthesis are opened. This speeds up the process of human adaptation to the prosthesis.

Another successful example of 3D printing in medicine is the fact that scientists were able to grow a fragment of liver tissue using healthy liver cells. These samples are used to test and validate drugs on them. It is too early to talk about their transplantation to a person, but this is only for now.

Construction

In addition to printing parts used in the construction process, scientists are trying to create a printer that could be used to construct various buildings. Already today, the first construction 3D printers are being produced that can print-build houses with a total volume of 100-145m3. So far, it has not been possible to find the optimal solution that would satisfy civil engineers, but work on the introduction of 3D printing into the construction of houses is very active. Basically, they are aimed at creating a universal technique that can work with different building materials.

Basically, they are aimed at creating a universal technique that can work with different building materials.

3D printing in construction will reduce human labor costs and injuries of builders, reduce the cost of building materials, and reduce the time required to build houses. At the exit, it is planned to receive a house ready for laying engineering communications, installing plumbing, electrical wiring, etc.

Industry

The purpose of 3D printing in industry is the manufacture of spare parts that are needed to restore the integrity or performance of components and mechanisms. The use of reverse engineering technology will allow you to restore the part in the presence of its whole or damaged prototype. Using 3D modeling, you can reconstruct the structure of a part and then print it on a printer.

If you need to change the functionality of the product, it is easy to make adjustments to its structure. To do this, you need to make the appropriate changes in the 3D model and then print the improved part. Thanks to different printing technologies and a wide choice of base materials, it is possible to produce parts with the required parameters. You can change their elasticity, strength, surface texture, color, etc.

Thanks to different printing technologies and a wide choice of base materials, it is possible to produce parts with the required parameters. You can change their elasticity, strength, surface texture, color, etc.

Industrial 3D printing allows you to prototype future parts, print one-offs or start small-scale production.

Engineering Solutions has long introduced 3D printing technology and is ready to print products of any complexity.

The future of 3D printing

The prospects for the development and implementation of 3D printing technologies in various industries are very huge. If today 3D printers are used in several industries, then tomorrow it will be dozens of different industries. The most anticipated emergence of 3D printing in the following industries:

- electronics - in the near future it is expected that with the help of a printer it will be possible to print not just a separate part, but finished digital devices and devices;

- Pharmaceuticals - already now there are several drugs manufactured using 3D printers, in the future, almost a large part of the pharmaceutical industry will be able to be served by 3D printing equipment;

- food industry - no matter how strange it sounds, the printer can also print food; this technology is still at the development stage, but it also has a future, so soon it will be possible to order a dessert that will be prepared by a 3D printer.

Learn more