Glowforge 3d printer price

Your At-Home 3D Laser Printer

For a limited time: Get 0% APR with Affirm. Ends 8/31

Learn More ➔

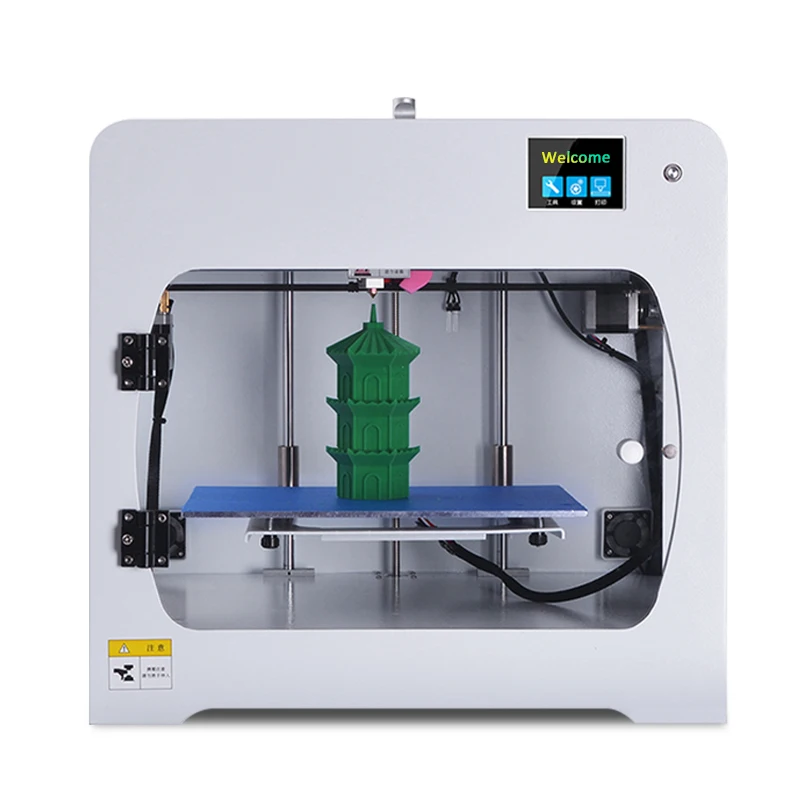

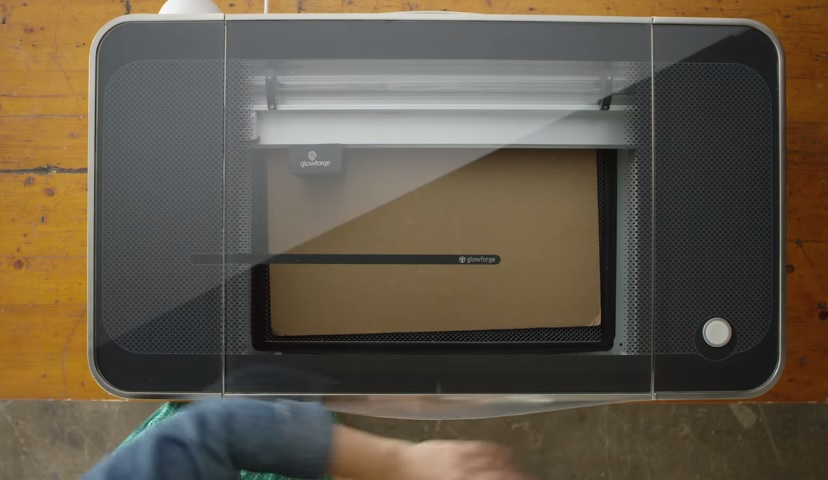

Glowforge 3D Laser Printer.

We believe in a future where anyone can create anything. That's why we made Glowforge, the 3D Laser Printer that cuts, engraves, & scores hundreds of materials.

Learn MoreBuy NowWhat will you create with your Glowforge?

What will you create with your Glowforge?

See what people are making

Your Glowforge works with hundreds of materials.

Built on laser cutter & engraver technology, Glowforge uses a beam of light the width of a human hair to cut, engrave, and shape designs from a variety of materials.

Features that set Glowforge apart

Live Camera Preview

3D Autofocus

3D Hi-Res Engraving

Laser Precision

Design with just a pen

Cloud simplicity

Automatic Setup

Live Camera Preview

See your design take shape before you print. Onboard cameras show you a preview of your design on whatever material you choose. Place your design with your mouse or finger and position it exactly where you want.

Need something outstanding, fast? Catalog designs are the perfect gift.

Print jewelry, toys, leather goods, lighting, containers, art, and more. Designs are thoroughly tested and guaranteed to print perfectly every time. Each comes with detailed photo instructions to make them a snap to finish.

Browse Catalog Designs“…the next wave of computer-aided creativity.”

New York Times

Real people, real magic.

Discover what’s possible.

Discover what’s possible.Buy today - every US Glowforge Pro & Plus printer ships in 3 days.

Glowforge 3D Laser Printer.

We believe in a future where anyone can create anything. That's why we made Glowforge, the 3D Laser Printer that cuts, engraves, & scores hundreds of materials.

Learn MoreBuy NowFor a limited time: Get 0% APR with Affirm. Ends 8/31

Learn More ➔

What will you create with your Glowforge?

What will you create with your Glowforge?

See what people are making

Your Glowforge works with hundreds of materials.

Built on laser cutter & engraver technology, Glowforge uses a beam of light the width of a human hair to cut, engrave, and shape designs from a variety of materials.

Features that set Glowforge apart

Live Camera Preview

3D Autofocus

3D Hi-Res Engraving

Laser Precision

Design with just a pen

Cloud simplicity

Automatic Setup

Live Camera Preview

See your design take shape before you print. Onboard cameras show you a preview of your design on whatever material you choose. Place your design with your mouse or finger and position it exactly where you want.

Need something outstanding, fast? Catalog designs are the perfect gift.

Print jewelry, toys, leather goods, lighting, containers, art, and more. Designs are thoroughly tested and guaranteed to print perfectly every time. Each comes with detailed photo instructions to make them a snap to finish.

Browse Catalog Designs“…the next wave of computer-aided creativity.”

New York Times

Real people, real magic.

Discover what’s possible.

Discover what’s possible.Glowforge

3D Laser Printer

Glowforge’s powerful desktop laser cuts, engraves, & scores hundreds of materials.

Learn more“…the next wave of computer-aided creativity.”

“…the next wave of computer-aided creativity.”

What will you create with Glowforge?

Swipe to see more ⭤

What will you create with Glowforge?

Craft with leather

Design home goods

Make custom signs & maps

Create intricate art

Personalize gifts

Start a side hustle

Customize anything

Bring your ideas to life.

Watch the magic happen.

Customize your prints.

Create with hundreds of materials.

Swipe to see more ⟷

Let's make something together.

Schedule a free virtual demo with a Glowforge Expert & experience the magic of Glowforge in real time.

Schedule a demoMade by creators like you.

Swipe to see more ⟷

Dear Glowforge,

Meet Glowforge | Glowforge

Great news! You can use your Glowforge from a Mac, PC, tablet, and smartphone, using our simple, powerful, and free web interface. To prepare your project, you can choose to use any software that saves a PDF (Adobe Illustrator, Inkscape, CorelDraw, Adobe Photoshop, GIMP, Autodesk 360, and Sketchup and more) Glowforge can print JPG, PNG, SVG, PDF, and other file formats. To print a file, just drag-and-drop it directly on our app, and then adjust the preview to your liking.

To prepare your project, you can choose to use any software that saves a PDF (Adobe Illustrator, Inkscape, CorelDraw, Adobe Photoshop, GIMP, Autodesk 360, and Sketchup and more) Glowforge can print JPG, PNG, SVG, PDF, and other file formats. To print a file, just drag-and-drop it directly on our app, and then adjust the preview to your liking.

Your Glowforge is yours to use, free of charge! The Glowforge cloud service gives you unlimited monthly prints, including all the features you see in our video. And don’t worry, there’s no paid subscription required.

Believe it or not - most of our customers tell us it takes them less than 30 minutes to get their printer out of the box, plug it in, set it up, and finish their first print!

Glowforge uses a beam of light the width of a human hair to cut and engrave with incredible accuracy within a thousandth of an inch. Further, your Glowforge can engrave images in stunning high-resolution - comparable to what you see on your phone or computer screen now. You can learn more, here.

Further, your Glowforge can engrave images in stunning high-resolution - comparable to what you see on your phone or computer screen now. You can learn more, here.

Glowforge opens up a world of materials. While traditional 3D printers are confined to layers of plastic, Glowforge is completely different. Delve into hundreds of beautiful materials like leather, acrylic, hardwood, fabric - even chocolate! Glowforge can cut wood, fabric, leather, paper, Plexiglas (acrylic), Delrin (acetal), mylar, rubber, Corian, foods, and more. Glowforge can also engrave all of the above plus glass, coated metal, marble, anodized aluminum, titanium, some phones, tablets, and laptops, and more laser safe materials. For a by-the-minute update on what folks are printing: check out #glowforge on Instagram.

No matter which Glowforge you choose, you’ll be able to use materials measuring 12 x 20. 4” The Glowforge Pro has a Passthrough slot which accommodates material up to 20.4” wide, 1/4" thick, and as long as you want. Want to work with a thicker material? Simply remove the stainless steel crumb tray in the bottom of your Glowforge and print with materials up to 2” thick.

4” The Glowforge Pro has a Passthrough slot which accommodates material up to 20.4” wide, 1/4" thick, and as long as you want. Want to work with a thicker material? Simply remove the stainless steel crumb tray in the bottom of your Glowforge and print with materials up to 2” thick.

The Glowforge has a compact 3’ x 2’ footprint and fits well in any craft space, workshop, or family area.

Whichever Glowforge model you choose, you can be sure your Glowforge will be easy to set up and use, and will allow you to work with hundreds of materials. It comes will free printing software, everything you need to get started, and a free supply of premium materials to get you started. But there are some differences between our three models.

Not sure which model is right for you?

- The Glowforge Basic is our introductory model, perfect for moderate home use.

- The Glowforge Plus is a great solution for people who want to print frequently and quickly.

- The Glowforge Pro is our most powerful and capable model, ideal for a small business, or when more than one person will be using it.

Here are a few more details to help you decide:

Speed (Pro is fastest): The Glowforge Pro top engraving speed is 3x as fast as the Glowforge Basic, and cutting is 1.2x as fast. The Glowforge Plus top engraving speed is 2x as fast as the Glowforge Basic.

Warranty (Plus and Pro have 12 months): The Glowforge Basic has 6 months of warranty coverage, while the Plus and Pro offer a double warranty of a full 12 months warranty.

Material Size (Pro has Passthrough): All Glowforge printers can accommodate materials measuring up to 18” deep, 20.4” wide, and 2” tall. The maximum printable area is about 11 x 19.5”. The Glowforge Pro allows you to make enormous oversized prints.

The Pro Passthrough slot in the front and back allows for materials that are 20” wide, up to ¼” thick, and as long as you want. That means you can create huge, dramatic products like furniture. To use the passthrough, you print the first 10 inches (25.4 cm), then slide the material through the slot, and repeat.

The Pro Passthrough slot in the front and back allows for materials that are 20” wide, up to ¼” thick, and as long as you want. That means you can create huge, dramatic products like furniture. To use the passthrough, you print the first 10 inches (25.4 cm), then slide the material through the slot, and repeat.Laser Class: The Plus and Basic models are a Class 1 laser (like a DVD player). The Passthrough slot makes the Pro model a Class 4 laser which requires the person using it to have laser safety training (included with your purchase). You should not use the Pro in public or around kids without installing Pro Shields, which are included with your purchase.

Temperatures (Pro prints up to 81°F (27°C)): The Pro is designed for printing all day in temperatures up to 81°F (27°C). The Basic and Plus will pause periodically to cool if used continually in warm temperatures; they’re designed for environments up to 75°F (24°C).

Technology. The Glowforge Plus has an upgraded linear system to support faster motor speeds. The Glowforge Pro adds a solid state cooling unit and an upgraded 45 watt laser for the fastest possible prints.

KingPrint.ru, about 3d printers

The rapid advance of 3D printers has created an incredible demand for machines that can create quality products right in your home. Glowforge is another representative of this popular trend. Here is a laser 3D printer, cutter and engraver in one bottle. Read more →

Posted by in the heading News, 0 comments. An integral part of the coffee table is a single module that the designers from WertelOberfell-Platform have developed especially for .MGX. This module is printed using Stratasys FDM (Fused Deposition Modeling) machines. The table itself is a fractal (a fractal is a figure whose small parts, when enlarged, are similar to itself), created from tree trunks and designed in such a way as to take up space as usefully as possible. The peculiarity of this product is that you yourself can vary the number of small modules to create a table of exactly the size you need. Read more →

The peculiarity of this product is that you yourself can vary the number of small modules to create a table of exactly the size you need. Read more →

Thanks to the work of Alexander Pelikan (Alexander Pelikan) from PeLiDesign, such wonderful things were born. A few years ago, Peli (you can call him Alexander, but he prefers Peli himself) worked with TNO and Studio Ludens on his Machine's Perception project. The aim of the project was to observe how a machine "sees" things and to define the limits of 3D scanning possibilities on the example of numerous everyday objects, including doorknobs. Now his project has evolved into a line of door handles, which he presented at the International Furniture Fair in Milan.

Read more →

Posted by under Articles, 0 comments.

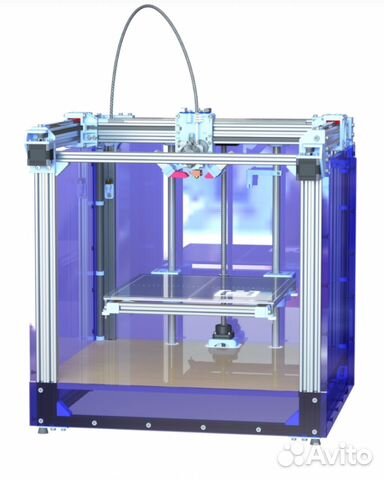

Since its launch in 2013, the Ultimaker 2 3D printer has become a favorite among users due to its high print resolution, eye-catching design and attractive price. In addition, this 3D printer can print items larger than the average size, 203x203x305mm, and is very popular in schools and medical institutions. Now the company has released a couple of new models: Ultimaker2+ and Ultimaker2 Extended+ for printing extra large items. The company's CEO Jos Burger said that during the redesign process, users were "closely collaborated and collected valuable feedback." Read more →

In addition, this 3D printer can print items larger than the average size, 203x203x305mm, and is very popular in schools and medical institutions. Now the company has released a couple of new models: Ultimaker2+ and Ultimaker2 Extended+ for printing extra large items. The company's CEO Jos Burger said that during the redesign process, users were "closely collaborated and collected valuable feedback." Read more →

Since 3D printed objects are usually not very functional, their use was previously limited mainly to prototyping. That may change in the near future, however, with devices like the MIT-developed MultiFab printer capable of printing ten materials simultaneously. However, the design of such complex materials is still a big problem. This is where the Foundry program, created by the Computer Science and Artificial Intelligence Laboratory (CSAIL) at MIT, enters the scene. Read more →

Read more →

Adidas is never far behind its competitors, especially when it comes to fooling the public. In June of this year, Adidas introduced shoes made almost entirely from recycled waste washed ashore from the ocean. This event marked the conclusion of a partnership between the German concern and the organization Parley, leading the fight against pollution of the world's oceans. Read more →

Posted by in the heading News, 0 comments.

Following in the footsteps of rival Adidas, New Balance has unveiled its own 3D printed athletic shoe with the support of 3D printing equipment supplier 3DSystems. The interlayer between the insole and outsole of the New Balance shoes is made from a new highly elastic powder and DuraForm Flex TPU. According to the company, the use of these materials results in an "optimal" balance of responsiveness, durability, wear and weight, making the shoe very comfortable for everyday walking. Read more →

Read more →

Introducing the world's first fully 3D printed robotic doll with smartphone control. The smart doll is 60 cm tall and is based on Mirai Suenaga, Culture Japan's symbol and mascot. Read more →

Posted under Articles, 0 comments.

Kanye West has a peculiar relationship with his vocal apparatus. Frankly, he rarely (if the word is applicable here at all) restrains the flow of thoughts that arise in his head. On a recent episode of the reality show Keeping Up with the Kardashians, our self-proclaimed musician-designer had something interesting to say about 3D printers: According to Kanye, they will destroy the fashion industry. While visiting the TUMO Center for Creative Technologies in Yerevan, West was introduced to a 3D printer, after which he said:

“3D printing is what I fear.

The Internet has destroyed the music industry, and now this device is threatening the textile industry." The guide tried to say a few words in defense of the device, noting that a 3D printer cannot create a design, and a person is needed who first comes up with what will then be printed. “Yes,” Kanye replied, “but I just want to say that the time will come when people will print their own shoes at home.”

Continue reading →

Posted in the heading News, 0 comments.

Researchers at the Massachusetts Institute of Technology have unveiled a new 3D printing technology that uses transparent glass instead of conventional plastic. The new method, dubbed 3DGP, works in much the same way as conventional 3D printing, but it also has the ability to vary glass properties such as light transmission, reflectivity, and light refraction by changing the thickness of the print. Read more →

Posted by in the heading News, 0 comments.

How much does a 3D printer cost?

3D printing is a one-stop solution for a wide range of applications, from high-resolution model production to rapid prototyping, rapid tooling for traditional manufacturing processes, production of aids and end-use models.

However, when you consider investing in a 3D printer, the viability of a solution usually boils down to a simple question: Is it cost-effective for your business? How much does a 3D printer cost and how much time and money can it save your business?

3D printer prices range from $200 to $500,000 depending on the printing process, materials, and complexity of the solution.

In this guide, we'll break down 3D printing costs by technology, compare outsourcing versus in-house manufacturing, list factors to consider when calculating the cost of each model, and look at what else to look for when comparing different solutions. for 3D printing and other production methods.

Interactive

This interactive ROI tool will help you find out how much time and money you can save by 3D printing with a Formlabs 3D printer.

Calculate Your Costs

The three best-known plastic 3D printing technologies today are Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS).

Each technology has its advantages and disadvantages - take a look at the infographic:

Download this high resolution infographic here. Interested in learning more about FDM, SLA and SLS 3D printing technologies? Check out our detailed guide.

Prices for 3D printers have dropped significantly in recent years, and today all three technologies are available in compact, low cost systems.

FDM generally produces models at a lower cost if you only print relatively simple prototypes in limited numbers. SLA technology offers higher resolution and quality, as well as a wide choice of 3D printing materials at a slightly higher price. But this difference is quickly offset when you print complex designs or larger batches due to the less labor-intensive post-processing process. Finally, SLS technology is the most cost effective for medium to high volume production of high quality functional models.

Finally, SLS technology is the most cost effective for medium to high volume production of high quality functional models.

Comparing the total cost of different 3D printers by price tags alone will not give you a complete picture of how the cost of a 3D printer and a printed model will compare. The cost of 3D printing materials and labor significantly affects the cost of a model, depending on the application and your production needs.

Let's look at the different factors and costs for each process.

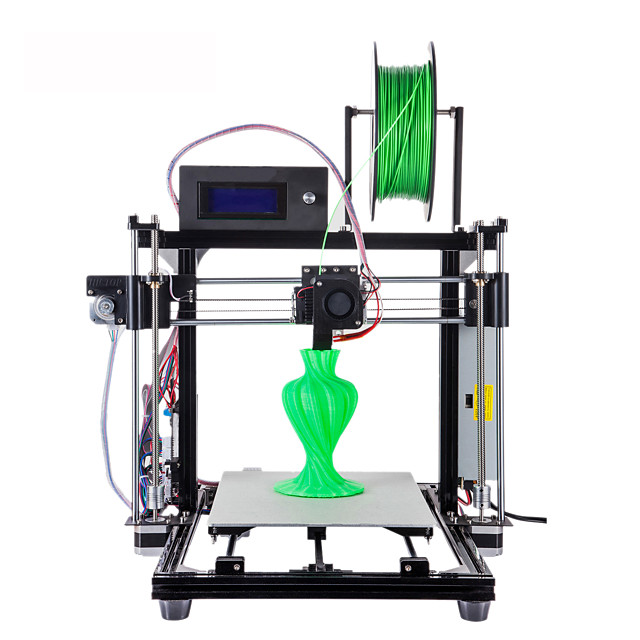

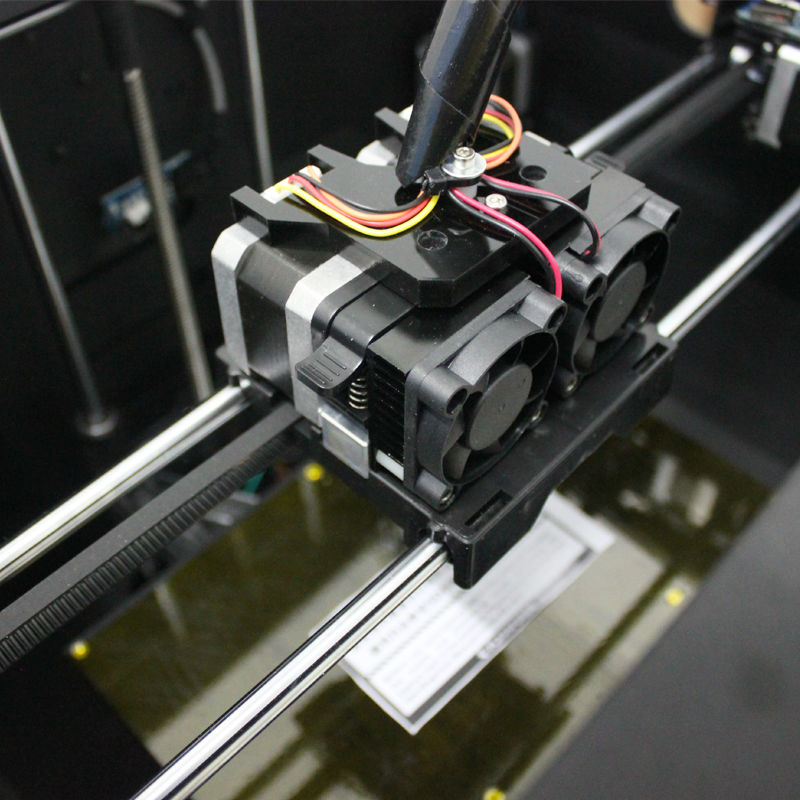

FDM, also known as Fused Filament Manufacturing (FFF), is a printing method where the parts of a model are made by melting and extruding a thermoplastic filament, which the printer's nozzle applies layer by layer onto the model being made.

FDM is the most popular form of consumer grade 3D printing, fueled by the proliferation of hobbyist 3D printers. However, professional and industrial FDM printers are also popular among professionals.

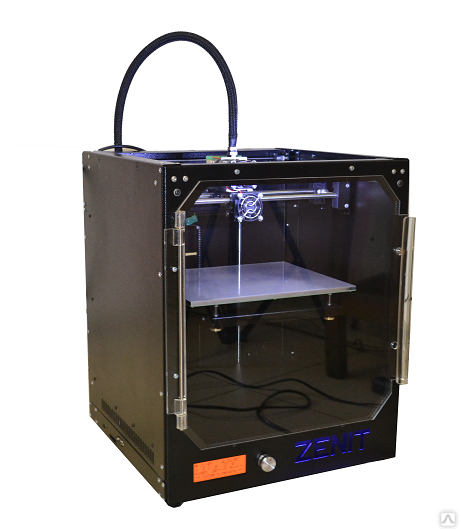

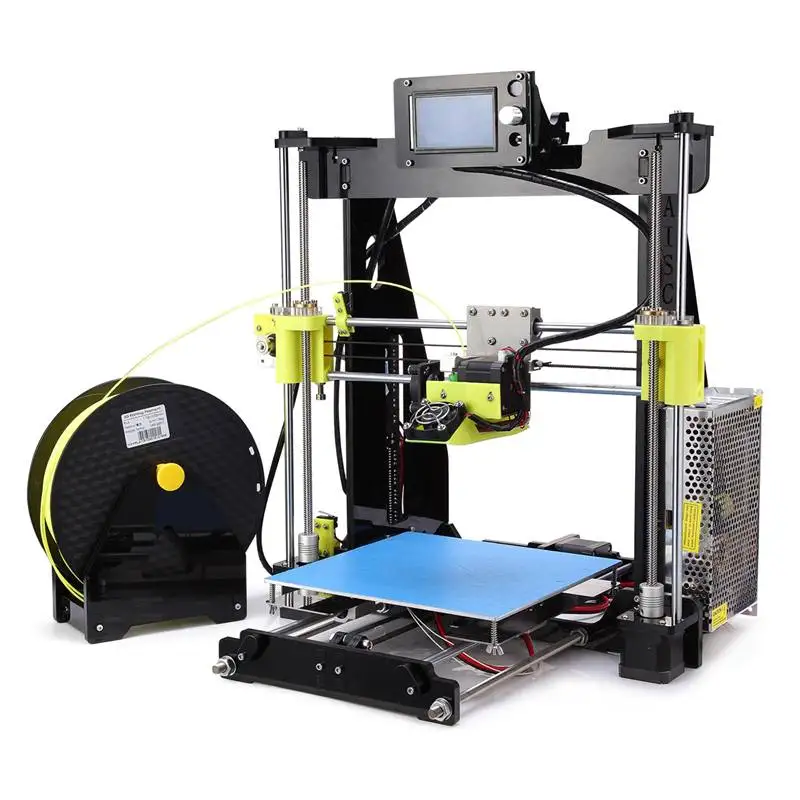

The cheapest 3D printers are FDM printers. DIY kits for FDM 3D printers start at $200. However, most of these models are more like toys or DIY projects that require a significant amount of time to build, set up and calibrate. The quality of the print largely depends on the success of these operations. In addition, machines require repairs and regular maintenance to keep them working, so they are more suitable for people with a higher engineering education who have a lot of time and patience.

DIY kits for FDM 3D printers start at $200. However, most of these models are more like toys or DIY projects that require a significant amount of time to build, set up and calibrate. The quality of the print largely depends on the success of these operations. In addition, machines require repairs and regular maintenance to keep them working, so they are more suitable for people with a higher engineering education who have a lot of time and patience.

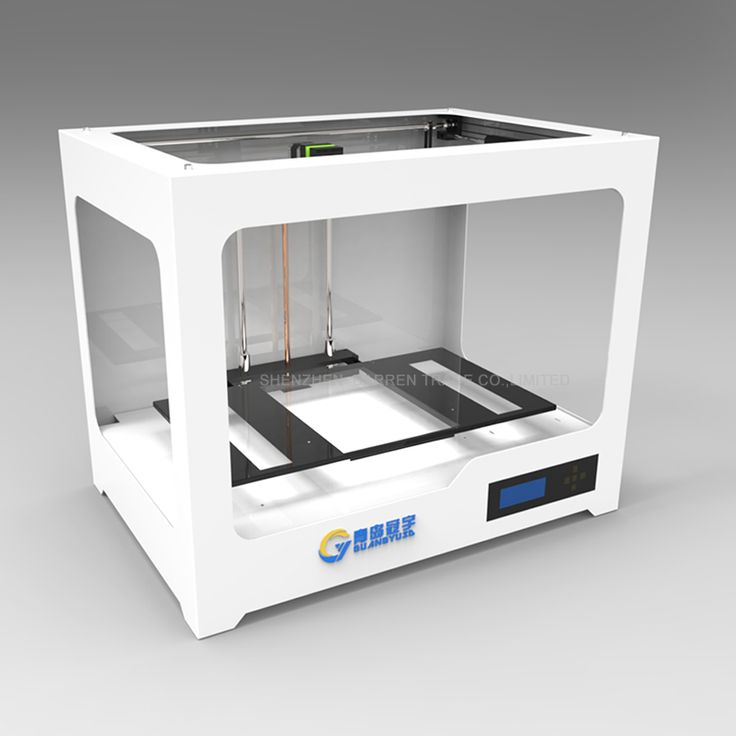

Hobbyist FDM 3D printers cost between $500 and $1,500, come pre-assembled or unassembled, require less setup, but have the same disadvantages as the cheapest 3D printers. More expensive models are capable of large print volumes and work with a wide variety of materials besides low temperature ones such as PLA.

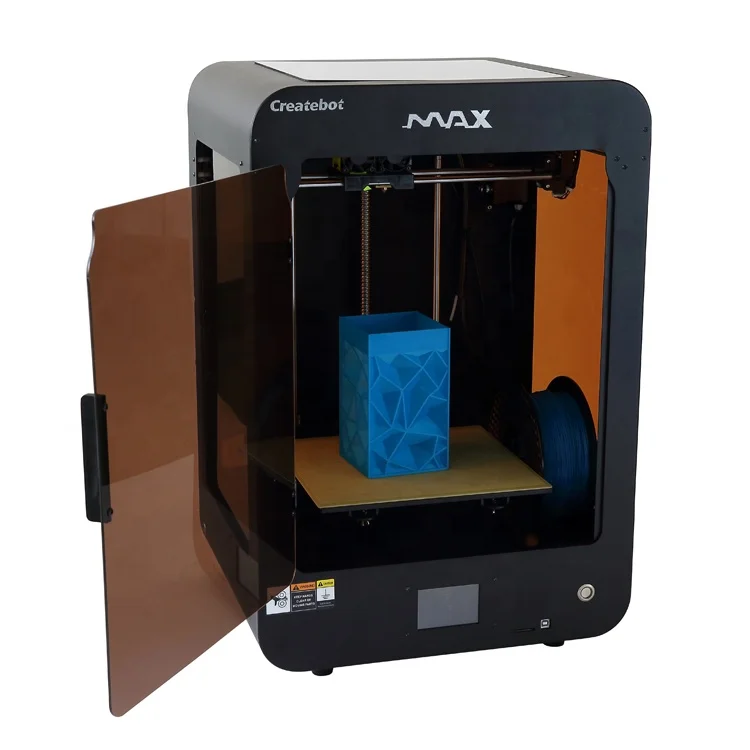

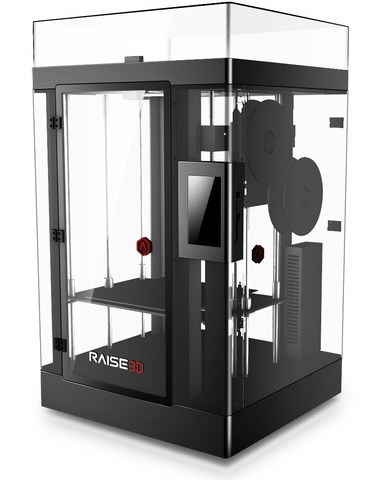

Professional 3D FDM printers start at $2,500 and large format professional FDM printers are available from $4,000. The cost of the most modern industrial FDM printers can exceed 10,000 US dollars. Most of these printers come pre-assembled and calibrated in the box, or they can be automatically calibrated. Printers in this category offer better print quality, a wider range of media, higher print volumes, improved reliability, and ease of use and maintenance. In addition, professional 3D printer manufacturers offer customer support services for troubleshooting.

Printers in this category offer better print quality, a wider range of media, higher print volumes, improved reliability, and ease of use and maintenance. In addition, professional 3D printer manufacturers offer customer support services for troubleshooting.

Material costs for FDM 3D printing range from $50 to $150/kg for most standard and engineering filaments, and $100 to $200/kg for auxiliary materials. There are also cheaper alternatives, but they are of lower quality.

In addition, FDM printing can be very labor intensive. Successful printing of complex models requires support structures that must be removed manually or dissolved in water. To obtain a high quality surface and remove layer lines, lengthy manual post-processing of models, such as sanding, is necessary.

SLA 3D printers use the process of photopolymerization, that is, the conversion of liquid polymers into hardened plastic using a laser. SLA is one of the most popular processes among professionals due to its high resolution, accuracy and material versatility.

Models printed on SLA printers have the highest precision, sharpest detail and smoothest surface possible of any plastic 3D printing technology. But the main advantage of the SLA method is its versatility. SLA polymers have a wide range of optical, mechanical and thermal properties that match those of standard, engineering and industrial thermoplastics.

SLA 3D printers can handle a wide range of resin materials for a wide variety of applications.

SLA used to be used only in large and complex industrial 3D printers costing over $200,000, but the process is now much more affordable. With the Formlabs Form 3+ Printer, businesses can now use industrial quality SLA printing for as little as $3,750. With Form 3L, large format SLA printing starts at just $11,000.

Stereolithographic 3D printers will be shipped in a box assembled and calibrated. These are professional tools that are highly reliable and require virtually no maintenance. Technical support is also always available. It provides troubleshooting in a critical situation (but its probability is extremely small).

It provides troubleshooting in a critical situation (but its probability is extremely small).

Most standard and engineered polymers for SLA technology cost between $149 and $200 per liter.

SLA printers are easy to use and many workflow steps such as rinsing and final curing can be automated to reduce labor costs. Printed models have a high quality surface immediately after printing and require only simple post-processing to remove supporting structures.

Selective Laser Sintering (SLS) 3D printers use a high power laser to sinter fine polymer powder particles. The unsprayed powder supports the model during printing and eliminates the need for special support structures. This makes SLS ideal for complex geometries, including internal features, grooves, thin walls, and negative taper.

Models produced using SLS printing have excellent mechanical characteristics - their strength can be compared with the strength of injection molded parts. As a result, SLS technology is the most popular plastic 3D printing process for industrial applications.

SLS printed nylon models are ideal for a range of functional applications, from consumer product design to healthcare applications.

Like SLA, SLS was previously only available in large format, complex 3D printing systems costing $200,000 or more. With the Formlabs Fuse 1 stereolithography printer, businesses can now solve industrial-scale tasks with SLS technology starting at $18,500. The complete kit, which includes the post-processing and powder recovery system, costs $31,845.

As with SLA printers, stereolithographic printers are shipped assembled and calibrated in the box. They are reliable and can operate 24/7. The package includes in-depth training and fast technical support.

SLS nylon print materials cost about US$100/kg. SLS does not require supporting structures and unused powder can be reused, reducing material costs.

SLS is the least labor-intensive plastic 3D printing process in the production environment, because the printed models are of high quality right away, and to remove excess powder, they simply need to be cleaned.

There are several processes for 3D printing not only plastics but also metals.

Metal FDM printers are similar in design to traditional FDM printers, but use extruded metal rods held together by a resin binder. The finished parts of the model are sintered in an oven to remove the binder.

SLM and DMLS printers are similar to SLS printers, but instead of polymer powders, they fuse metal powder particles layer by layer using a laser. 3D printers based on SLM and DMLS technologies can create strong, precise and complex metal products, making this process ideal for the aerospace, automotive and medical industries.

Prices for metal 3D printers have also begun to decline, ranging from $100,000 to $1 million today. However, these systems are still out of reach for most businesses.

SLA 3D printing is available as an alternative for casting workflows that allow metal models to be produced cheaper and faster than traditional methods and provide greater design freedom.

Technical report

Get design guides for 3D printing samples, see the step-by-step direct investment casting process, and study guides for indirect investment casting and sand casting.

Download white paper

Different plastic and metal 3D printing processes have unique qualities that make them suitable for different applications. Below is a comparison of different printing technologies.

| Fused Deposition Modeling (FDM) | Stereolithography (SLA) | Selective Laser Sintering (SLS) | Metal FDM Printing | Selective Laser Melting (SLM4) and Metal Direct | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Permission | ★ venti ☆☆☆ | ★ opa | ★ opa | ★cle | 90ARO | 9017ARE COMMUNITURE | ★☆ | ★ opa ★ ution | ★ opa | ★cle | ★ opa ★ ution | |||||

| 7 ☆☆☆ ☆☆☆ ingu | 7 ★ opa ☆ | ★cle | ☆ | ★ opa | ||||||||||||

| Simplicity of use | ★ opa | ★ Look | ★cle | ★ opa | x 300 x 600 mm (Desktop and Workshop 3D printers) | Up to ~300 x 335 x 200 mm (Desktop and Workshop 3D printers) | Up to 165 x 165 x 300 mm (3D - workshop printers) | Up to 300 x 200 x 200 mm | Up to 400 x 400 x 400 mm | |||||||

| Price range | DIY kits for 3D printers start at $200, while hobby printers cost $500-1500. Professional 3D FDM printers start at $2,500, while large format professional FDM printers are available from $4,000. Professional 3D FDM printers start at $2,500, while large format professional FDM printers are available from $4,000. | Professional desktop printers start at $3,750, while high-volume large format desktop printers are available from $11,000. | Workshop industrial printers start at $18,500 and traditional industrial printers start at $100,000. | Metal FDM printers start at $100,000, but complete solutions including an oven are much more expensive. | DMLS/SLM solutions start at around $200,000. These printers require special infrastructure conditions, which can further increase costs. | |||||||||||

| Cost of materials | US$50-150/kg for most standard and engineering yarns and US$100-200/kg for auxiliary materials. | US$50-150/L for most standard and engineering polymers. | $100/kg for nylon. SLS does not require supporting structures and unused powder can be reused, reducing material costs. | Depends on material and technology. Significantly higher than plastic. Significantly higher than plastic. | Depends on material and technology. Significantly higher than plastic. | |||||||||||

| Labor | Manual removal of support structures (soluble support structures may be used in some cases). Long post-processing is required to obtain a high quality surface. | Washing and final polymerization (both can be automated). Simple post-processing to remove supporting structures. | Easy cleaning to remove excess powder. | Washing and sintering (both can be automated). It is possible to use mechanical processing and other types of surface treatment. | Stress relief, support structure removal, heat treatment, and mechanical and other surface treatments. | |||||||||||

| Materials | Standard thermoplastics such as ABS, PLA and their various blends. | Various polymers (thermosetting plastics). Standard, engineering (similar to ABS and PP, similar to silicone, flexible, heat resistant, rigid), injection molding, dental and medical (biocompatible). | Engineering thermoplastics - typically nylon and its composites (nylon 12 biocompatible + sterilizable). | Stainless steel, tool steel, inconel, copper, titanium. | Stainless steel, tool steel, titanium, cobalt-chromium, copper, aluminium, nickel alloys. | |||||||||||

| Applications | Basic experimental models, low cost rapid prototyping of simple parts. | Prototypes with a high level of detail requiring close tolerances and smooth surfaces: molds, tooling, templates, medical models and functional parts. | Complex geometries, functional prototypes, low volume production or limited trial production. | Strong and durable models, tools and production aids. | Strong and durable models with complex geometries; ideal for the aerospace, automotive and medical industries. |

When calculating the cost of one model, the cost of ownership of equipment, material costs and labor costs are usually taken into account. It is important to understand the factors that affect each of these cost components, as well as the questions to ask in order to evaluate alternative production methods and uncover hidden costs.

It is important to understand the factors that affect each of these cost components, as well as the questions to ask in order to evaluate alternative production methods and uncover hidden costs.

Hardware ownership costs are fixed costs: 3D printer price, service contracts, installation and maintenance. These amounts must be paid whether your printer is idle or produces dozens of models per week.

Add up all projected fixed costs over the lifetime of the equipment, then divide by the number of models you plan to make. As a rule, the higher the performance and efficiency of your 3D printer, the lower the cost of ownership of equipment per model.

In recent years, desktop 3D printers have shown excellent results in reducing the cost of ownership of equipment. With a price 10 to 100 times lower than traditional industrial 3D printers and the ability to produce thousands of models over a lifetime, the cost of ownership can be negligible.

Questions:

-

Are there installation, training or additional initial costs other than the cost of the machine itself?

-

Do I need to sign a (mandatory) service contract? What does it include?

-

What accessories and tools are needed to make the final models?

-

What kind of maintenance is required for the machine to function properly? What is the expected annual maintenance cost? Will it change with an increase in production volumes?

The 3D printing raw materials and consumables you need to create models at an affordable price. These costs largely depend on the number of models you produce.

These costs largely depend on the number of models you produce.

When calculating the cost of materials, determine how much material is required to create one model, and multiply this figure by the cost of the material. Count the amount of waste and any other consumables. As production grows, the cost of ownership of equipment decreases, and the cost of 3D printing materials tends to become more balanced.

Be sure to check what materials you need to create specific models, as the cost of 3D printing consumables can vary greatly. Please note that some 3D printers only work with their proprietary materials and thus limit your ability to use third party materials.

Questions:

-

What is the cost of each type of 3D printing material?

-

How much material is required to create one particular model, including waste?

-

What is the shelf life of the materials?

-

Do I need other consumables to create models?

-

Can the machine work with third-party materials?

While 3D printing can replace complex traditional manufacturing methods and provide significant time savings, depending on the 3D printing technology, it can still be quite labor intensive.

Professional desktop 3D printers are generally optimized for ease of use. DIY kits for 3D printers and hobby printers often require additional effort to adjust settings, while regular maintenance or material changes on traditional industrial machines can involve time-consuming tasks that require the assistance of a skilled operator.

Post-processing workflows vary depending on the 3D printing process, but in most cases include cleaning up models and removing support structures or excess material. However, there are solutions to automate some specific tasks. For example, Formlabs Form Wash and Form Cure simplify the wash and finish process for Formlabs SLA 3D printers, while Fuse Sift offers a turnkey post-processing and powder recovery system for the Fuse 1 SLS printer.

More complex processes such as SLA and SLS do not take long to achieve high quality models, while FDM models require lengthy manual post-processing to improve quality and remove layer lines.

Questions:

-

What is the whole model production workflow? What specific steps are required to set up printing, change materials, and post-process models?

-

How long does it take to post-process one particular model?

-

Are there any tools or devices available to automate some of these tasks?

Outsource production orders to third-party service bureaus or labs if you use 3D printing only occasionally or to produce large models in non-standard materials. Typically, the bureau has several in-house 3D printing processes such as SLA, SLS, FDM, as well as metal 3D printers. They can also provide advice on a variety of materials and offer additional services such as design or improved finishes.

Typically, the bureau has several in-house 3D printing processes such as SLA, SLS, FDM, as well as metal 3D printers. They can also provide advice on a variety of materials and offer additional services such as design or improved finishes.

The main disadvantages of outsourcing are the high cost and duration of production. One of the main advantages of 3D printing is its speed compared to traditional production methods. But it is noticeably reduced if the delivery of the model produced by the involved organization takes several days or even weeks. And as demand and capacity grow, the costs of outsourcing are rising rapidly.

Desktop 3D printers are the perfect solution for fast model production. Depending on the number of parts needed and the volume of prints, the investment in a professional 3D printer can pay for itself in just a few months.

With desktop and workshop printers, you can pay for the capacity that matches your business needs and scale your production by adding more devices as demand grows, without the heavy investment of a large format 3D printer. Using multiple 3D printers also allows you to print models from different materials at the same time. But if there is a need for the production of large parts or the use of non-standard materials, service bureaus can come to the rescue.

Using multiple 3D printers also allows you to print models from different materials at the same time. But if there is a need for the production of large parts or the use of non-standard materials, service bureaus can come to the rescue.

Investment, material and labor costs are relatively easy to calculate. But what about indirect costs and hard-to-calculate factors that affect your business? Let's look at some of the main considerations when comparing a desktop 3D printer to outsourcing or other manufacturing methods.

Save time: What if you could get products to market a few months faster? Or reduce the delivery time of your products by a few days or weeks? 3D printing simplifies traditional prototyping and manufacturing workflows, helping you save time and stay ahead of the competition.

Best results: 3D printing allows you to create more iterations, overcome failures faster and produce better end products. Troubleshooting a design early on also helps avoid costly redesign and the use of additional tools.