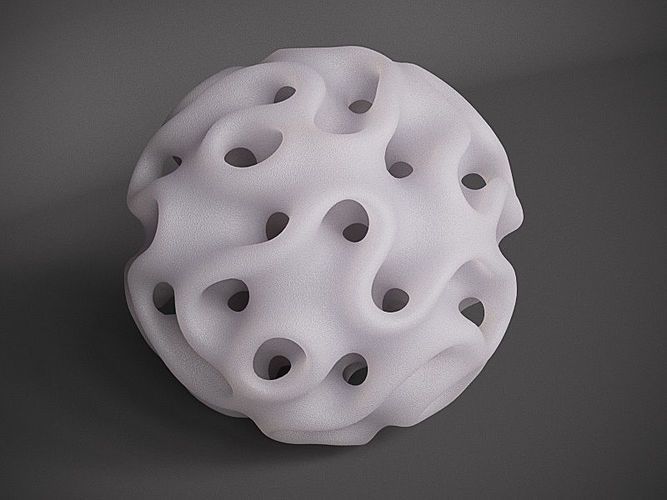

3D printed pop socket

▷ pop socket 3d models 【 STLFinder 】

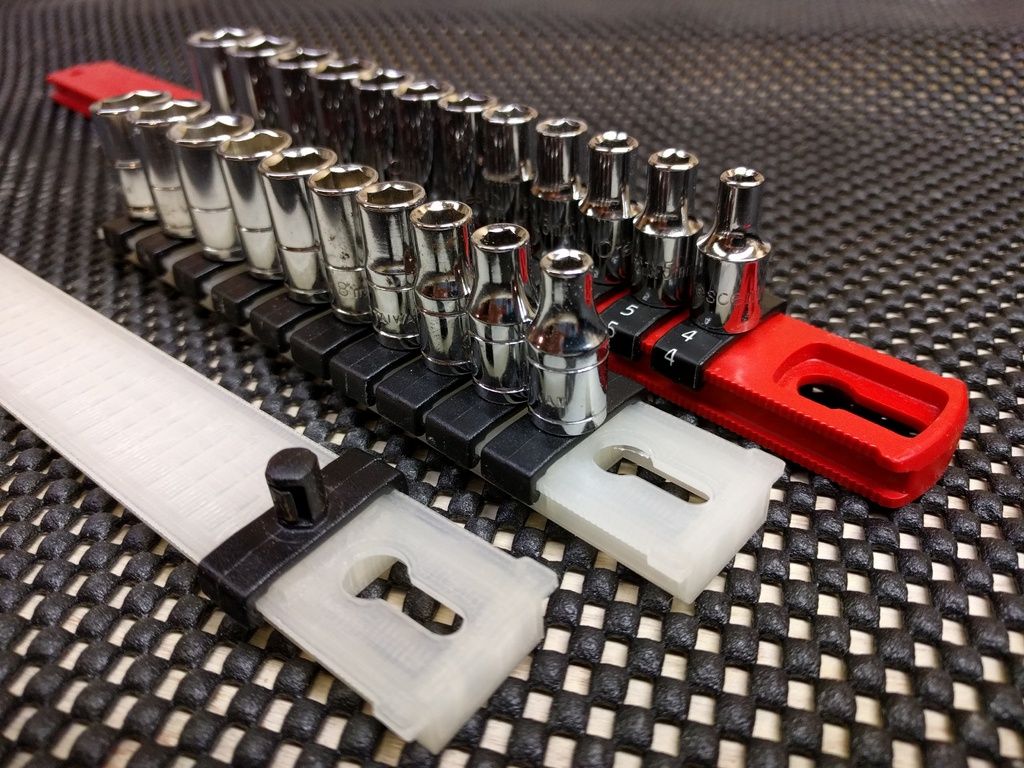

POP SOCKET

grabcad

POP SOCKET

Pop socket

thingiverse

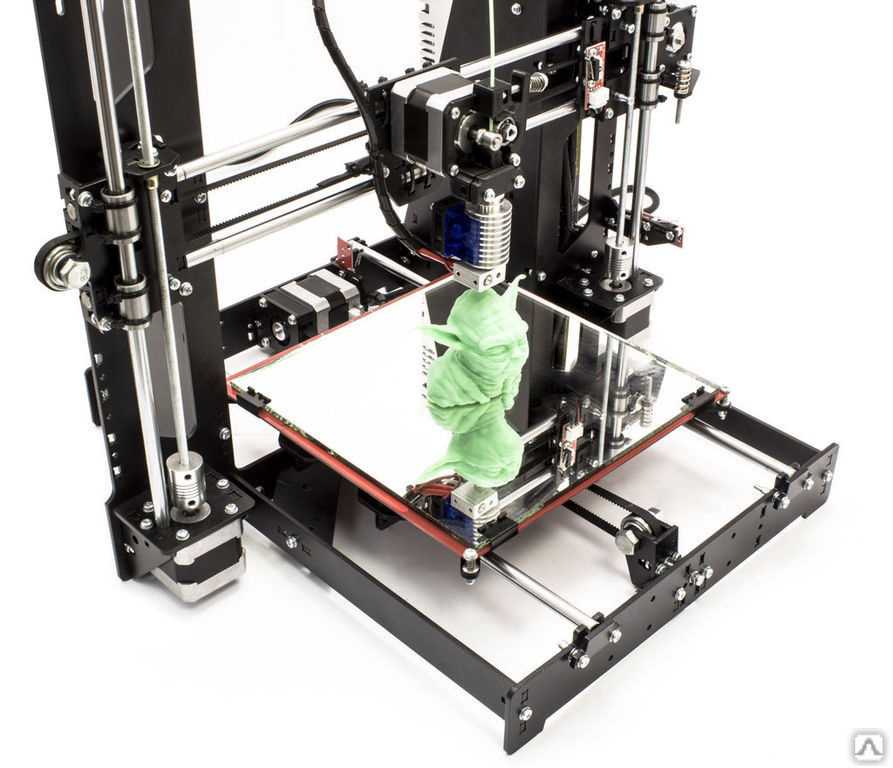

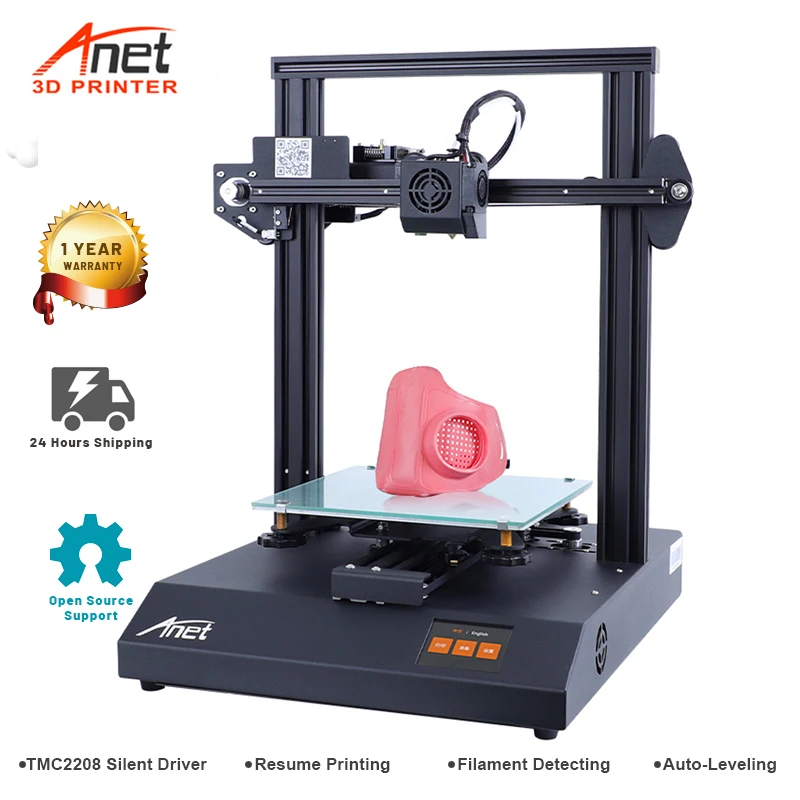

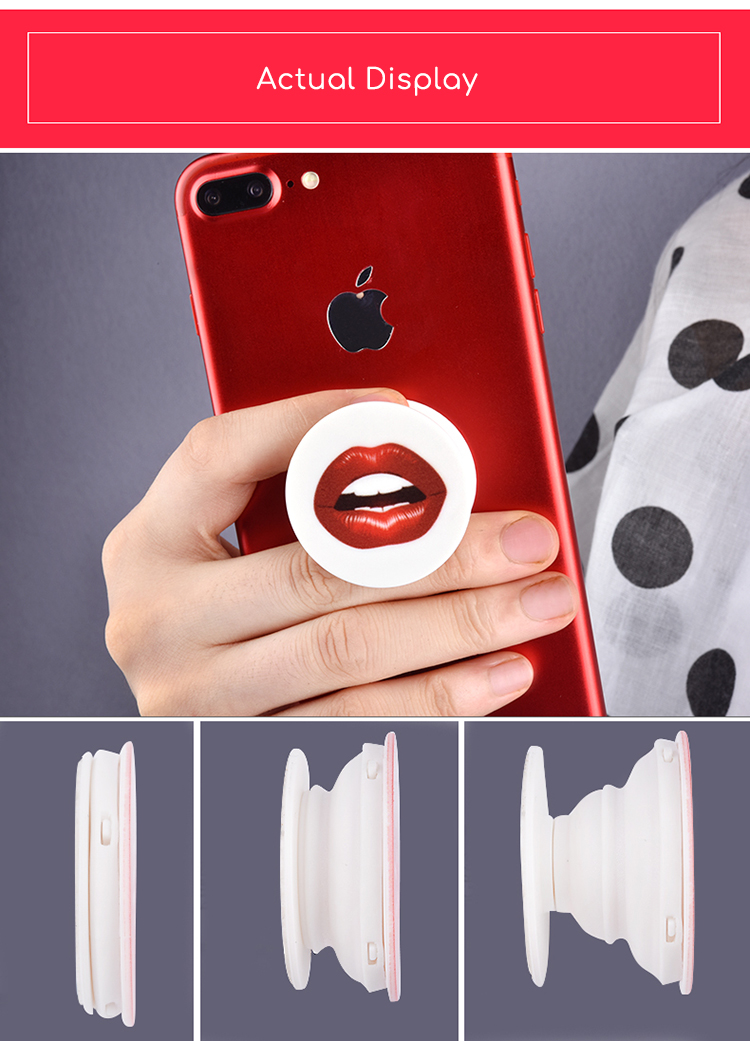

A pop socket is something that you can print or buy.A pop socket is something you atatch to your phone.It helps you hold your phone.

Pop-Socket

thingiverse

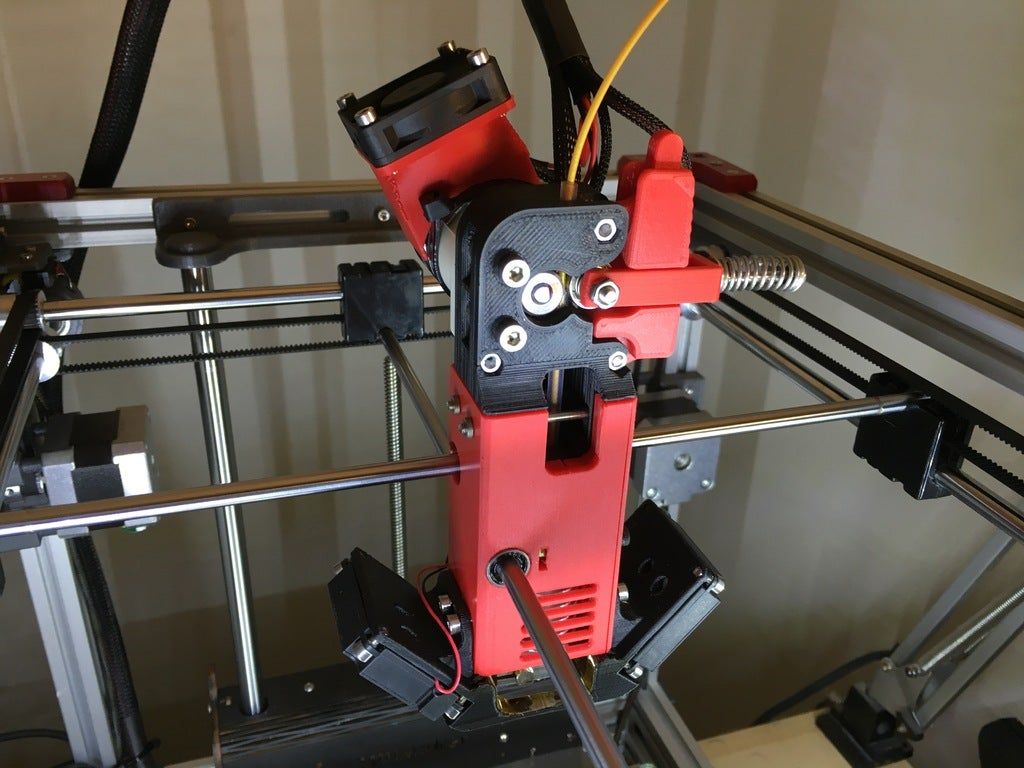

A working pop-socket designed for printing.

No supports needed.

Print the top and bottom parts with your regular filament (ABS, PLA etc).

Print the middle with flexible filament (TPU).

...

I used some super-glue to keep everything together.

Pop Socket

thingiverse

Update 12/14/18: I made some minor changes to the models that should help the retention flanges not wear out as fast from repeated opening and closing of the pop socket. Update 12/21/18: I just uploaded an updated file called "Pop Socket Round." It...

Pop Socket (Pop Clip)

thingiverse

... mine in regular PLA and around 30% infill, which fits my needs. You can either use 3M's double side adhesive or you can purchase the official pop socket sticky pad replacements which can be found on either Ebay or Amazon for just a few dollars.

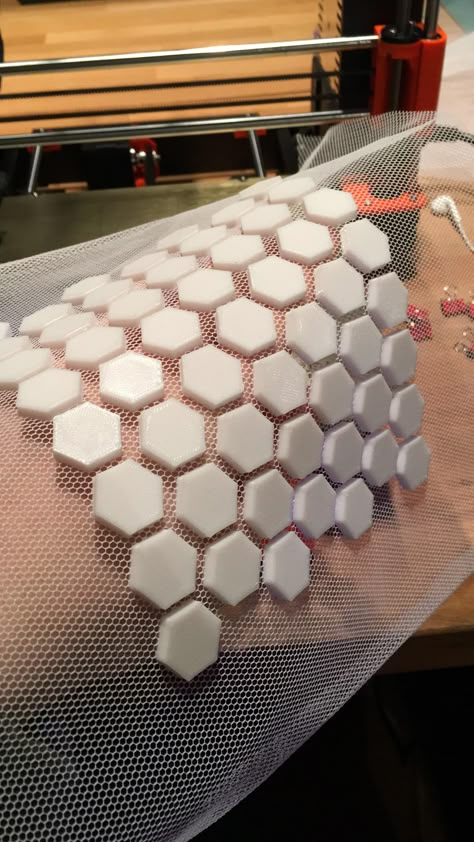

Hexagon Pop Socket

thingiverse

Hexagon Pop Socket Cover

pop socket car holder

cults3d

pop socket car holder

Mandalorian Pop Socket

thingiverse

Mandalorian Pop Socket

dragon pop socket cover

thingiverse

made a dragon pop socket

Mobile Pop Socket

grabcad

Modular Pop Socket Designwith more textures

Pop Socket Back

thingiverse

A simple Pop Socket back with impossible triangle design.

Quadlock Pop Socket

thingiverse

Pop Socket to connect with your Quad Lock case

Supreme Pop Socket

thingiverse

Supreme Pop Socket Cover. ... Print the pop socket base with supports touching the build plate. ... Use super glue or model glue to glue all the pieces together.

Dodge Charger Pop Socket

thingiverse

Dodge Charger Pop Socket Cover. ... Base needs support touching the build plate.

Pop socket car holder

thingiverse

Attach to dash and hold your phone up if equipped with pop socket.

pop socket mount

thingiverse

This fits very well with the twist lock pop sockets, better than the original mounts.

Punisher Logo Pop Socket

thingiverse

Punisher Logo Pop Socket cover. ... Needed a replacement for my original.

Quadlock Pop Socket adapter

thingiverse

Make your Pop Socket removable. ... Print a Quadlock female for your phone.

Pop Socket Replacement

thingiverse

Simple Pop Socket replacement that should be a bit stronger. ...Step file is included.

...Step file is included.

Pop Socket Collection

thingiverse

These are meant to replace the plastic cap on a Pop Socket Phone stand. ... These do need supports.

Pop Socket (assembly required)

thingiverse

DIY Pop Socket (made by a 10 year old). Prints 4 disks - 2 outer (solid), 2 inner (with holes). ...

Ariel Pop Socket

thingiverse

This is a remix of the blank pop socket cover I made for friend that has ariel on it.

Pop Socket Vent Clip

thingiverse

Hang your pop socket enabled phone from your car vent. ... Also another style clip for universal vents remixed from "Wider vent clip for universal car mount by abrokadabra"

Pop Socket Adapter

myminifactory

... once applied, can't be removed. This interface solves that problem. Attach pop socket to this thing and snap it around your phone. It's easily removed and added back after charging is complete. ...Edge_Clip_04 is an alternate attachment method.

Pop Socket Stand

thingiverse

Do you like the idea of the Pop Socket but don't want it on your phone. ...Or maybe just need a phone stand for watching movies or YouTube.

Simple design. Print 0.2 layer heights There are cuts in the design to help with placing the Pop Socket

...Or maybe just need a phone stand for watching movies or YouTube.

Simple design. Print 0.2 layer heights There are cuts in the design to help with placing the Pop Socket

Blank Pop Socket

thingiverse

I needed a pop socket for my phone so I made one. ...its really easy to carve in your own design and then print it out. it costs like a few cents a pop socket. ...I really like them I hope you do too.

Traverse_Pop_Socket_Mount

thingiverse

... ... I found the Phone Mount by camolito and the Pop Socket Vent Clip by Rocketman_47. I merged the two to make this mount. I am very new to 3D printing. I used Blender to do the merging. It is my first project using any CAD type program. ...

I used Blender to do the merging. It is my first project using any CAD type program. ...

Oreo Pop Socket remix

thingiverse

Oreo Pop Socket remixed from https://www.thingiverse.com/thing:3391808 - Oreo https://www.thingiverse.com/thing:2353984 - pop socket Reduced the sized to a standard pop socket, added positive locator to filling and gave the split attachment ring a...

Pop Socket Mount

thingiverse

Designed to fit a pop socket and angled specifically for a Nissan Frontier dash board. Will need double sided sticky tape to mount the mount..

Printing:

Basic settings for PLA, no supports, nothing special. ...Print flat on back.

...Print flat on back.

Ipega Pop Socket Mount

thingiverse

This replaces the controller holder on an Ipega PG-9021 controller to accept a pop socket style holder. ...The mount is based on a go pro mount so you can create different attachments if need be

Buy Panda Print 3D Cases With Pop Socket online from Caseteria

Mobile Number +91

+91

Resend code in

Didn't get the code? See other options

Verify

Similar Products

View all

Free Delivery (above ₹100) Delivery happens within 3-5 days

Payment Options Cash on Delivery

Customer Support +91-7666651252

Store Details Caseteria

Sai Shakti Tower, Bhayandar, Jesal Park, Bhayandar East, Mira Bhayandar, Maharashtra 401105, IndiaText

Add More

Recent Searches Clear all

Bestsellers

Select options

Select size *

Select color *

SEE ALL PRODUCTS

Size chart

CUSTOMER RATINGS

SORT BY

Newest First

Newest First

Oldest First

Highest Rated

Lowest Rated

RATINGS

All Ratings

All Ratings

5 Stars

4 Stars

3 Stars

2 Stars

1 Star

VERIFIED PURCHASE

Panda Print 3D Cases With Pop Socket

Hated it

Didn't like it

Just OK

Liked it

Loved it

Your name*

Add photos (optional)

Write a review (optional)

0/500

VERIFIED PURCHASE

VERIFIED PURCHASE

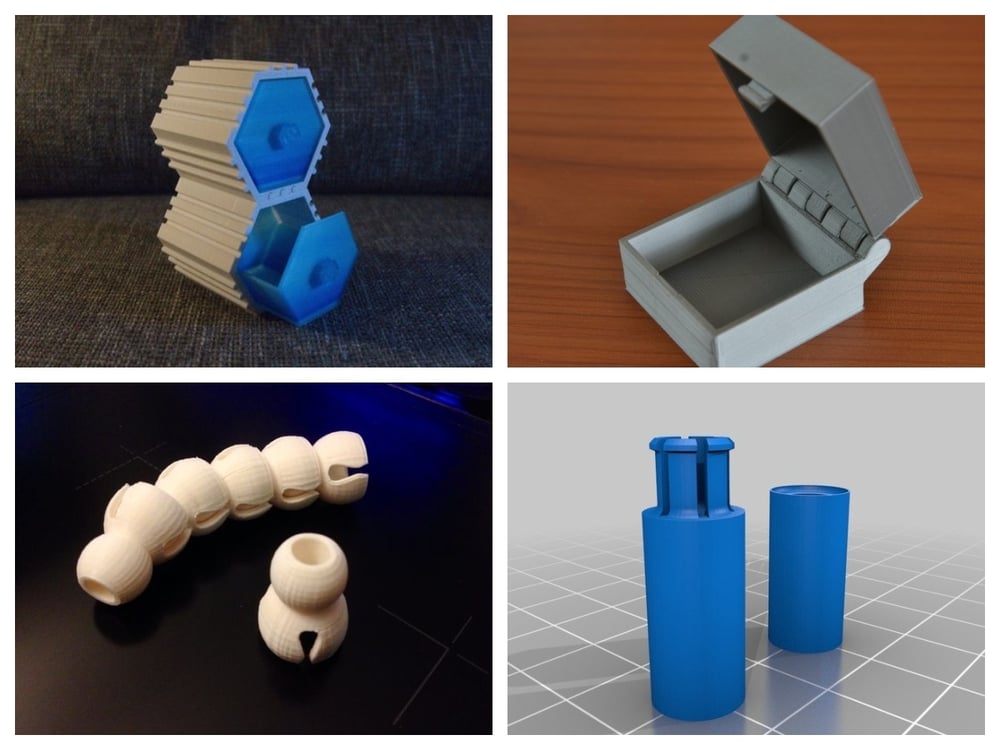

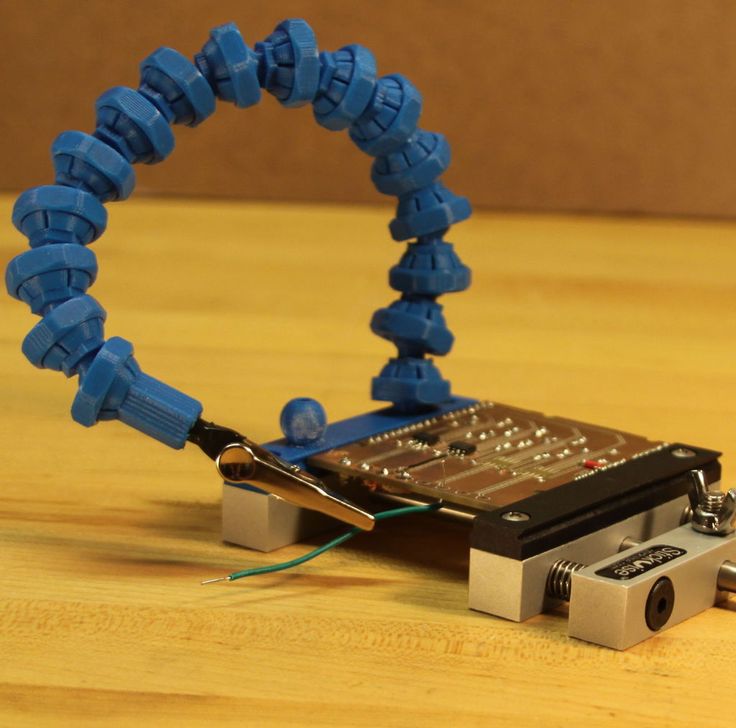

50 3D Printing Ideas

It looks like we'll soon be drowning in useless stuff made for 3D printing projects. But you can do something that will really be useful! If you're running out of ideas, here's a list of 50 3D printable items you're unlikely to throw away.

But you can do something that will really be useful! If you're running out of ideas, here's a list of 50 3D printable items you're unlikely to throw away.

Bag clip with screw cap

Now the bag clip will have a new feature - a hole with a lid for quick access, as in the photo. This clip is easy to print and convenient to use. Strange that no one thought of this before.

Author: Minkix

Download: Thingiverse

Modular Furniture Connector

This connector allows you to quickly assemble modular furniture. The default model is designed for 17×17 mm wood, but the size and material can be changed to suit your needs using a parametric file for customization.

Author: LeFabShop

Where to download: Cults

Sealant cap

No more throwing open sealant tubes away. The screw cap for the nozzle presses the o-ring tightly against the body of the tube and closes the access of air to the solvents inside.

Author: The-Mechanic

Where to download: Thingiverse

Laptop niche

Now the laptop will always be at hand, but hidden from prying eyes in a special niche that is attached to the bottom of any coffee table.

Author: Too Snide

Download: Thingiverse

Phone holder - Candice

Elegant and simple, perhaps the easiest thing you can print on a 3D printer.

Author: Clem.C2

Where to download: Cults

Polypanels

The idea for Polypanels came from Devin Montes. A polypanel is a series of three-dimensional building blocks. The individual elements of a Polypanel look simple, but if you print a lot of them and different types, you can create all sorts of complex designs. Something like LEGO where you can design each brick.

Author: MakeAnything

Where to download: MyMiniFactory

Coat Hook

This coat hook is designed as an E3D attachment and can be printed multiple times to fit all your clothes.

Author: Filar3D

Where to download: Cults

Plant Pot

This anatomical brain flower pot is easier to print than it looks, creator DrFemPop says. For assembly, it is only necessary to glue the parts after printing. It turns out an original house for plants.

Author: DrFemPop

Where to download: Cults

Door Holder

This is a simple solution for holding a door. Double-sided adhesive tape is sufficient for surface mounting.

Author: Akiraraiser

Where to download: Thingiverse

Piggy bank

A simple piggy bank for beginners, no complicated settings.

Author: lecaramel

Where to download: Thingiverse

Cable ties

This tie is perhaps the simplest and most ingenious of all devices. Clips are printed as a whole sheet at once, and then the required amount can be cut off from it.

Author: Sunshine

Where to download: Cults

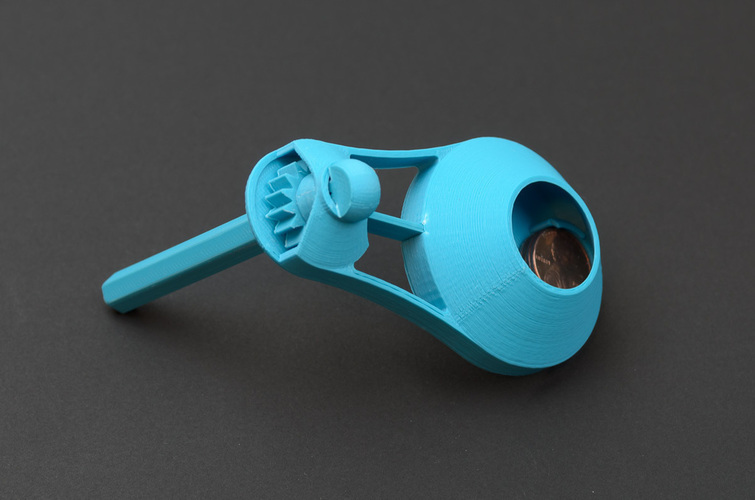

Roller ruler

An indispensable device if you need to measure the length of something non-linear: a piece of rope, a curved line, a perimeter with bends, etc. The ruler is called Geneva and has step 5 mm.

The ruler is called Geneva and has step 5 mm.

Author: MechEngineerMike

Where to download: Thingiverse

Pliers

This small, solid piece of plastic can easily replace your pliers / pliers. These forceps take the force to the handles and redistribute it at the end of the grip. It's definitely pliers. Just smarter.

Author: BYU CMR

Where to download: Thingiverse

Cylindrical textured box

Beautiful tube from Syboulette decorated with hexagons. Well suited as a kitchen utensil for storing oatmeal, rice and other crumbly substances.

Author: Syboulette

Where to download: Cults

Door stopper

This stopper is modeled after the Guyer Anderson cat statue in the British Museum. The design is hollow, which allows you to fill the limiter with something for additional weight.

Author: Duaneindeed

Where to download: Cults

Plague Doctor Mask

Not exactly the most useful item on the list since bubonic plague is a thing of the past. But a mask can come in handy, for example, when you need to clean up after your pet. And you can also go to the carnival in it.

But a mask can come in handy, for example, when you need to clean up after your pet. And you can also go to the carnival in it.

Author: Odrivious

Download: Cults

Universal Spool Holder

This adjustable spool holder uses a spring and an adjustable rewind clutch. It's the perfect place to store those pesky wires.

Who made it: Vincent Goenhuis

Where to download: Thingiverse

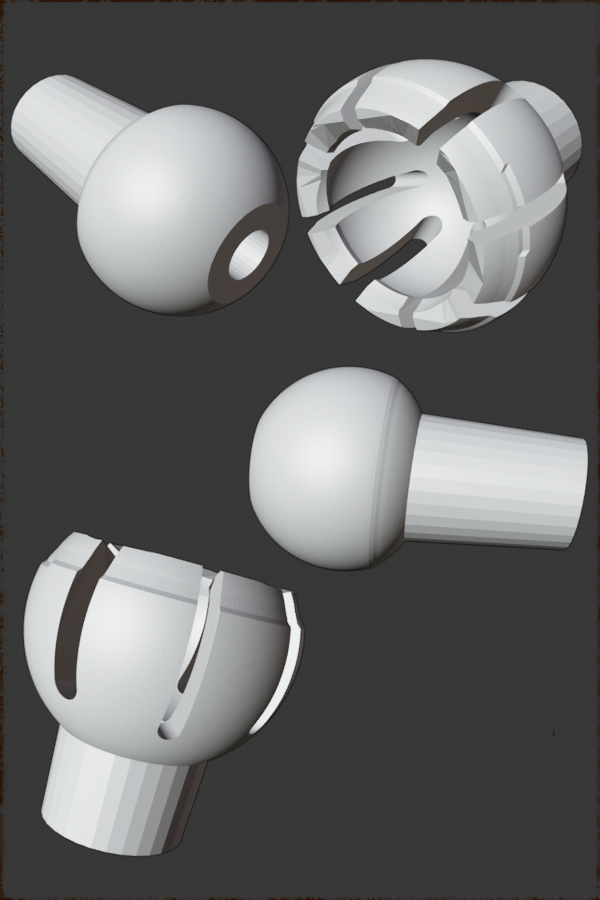

Sturdy waterproof box

This tight-fitting box will keep things from getting wet. Print it in PLA or PETG, add a flexible TPU seal and M3 screws for the spring hinge, and you're done.

Author: ZX82

Where to download: Cults

Dice

This dice is suitable for flat 3D printing and has a face size of 16mm.

Author: Devin Montes (MakeAnything)

Where to download: MyMiniFactory

Collapsible Coat Rack

Really cool coat rack. That's all there is to say about her.

Author: Komaru

Where to download: Thingiverse

Business Card Holder

Great for showing off your new business cards to your Wall Street friends. What could be more delightful than this Zippo card holder with flip-top lid.

Author: PentlandDesigns

Where to download: Cults

Pencil and pen holder

Iceberg or melting beehive? Be that as it may, this is a handy pen and pencil holder that is cheaper to print than to buy.

Author: BeeVeryCreative

Where to download: Cults

Groovi Monster Audio Amplifier

This is a passive smartphone audio amplifier that looks stylish and does the job well. It's called Groovi Monster for a reason.

Author: 3DShook

Where to download: Cults

Cup holder

Can be used not only as a cup holder, but also as a coaster for hot dishes. The dimensions of the template are easily adjusted to suit any size cookware.

Author: jmdbcool

Where to download: Thingiverse

Clamp

Designed for fixing various materials, including the ends of the wire in the coil. Also great as a clothespin replacement.

Author: Med

Where to download: Cults

Pencil Box

Suitable for storing all your desk trivia and trinkets (memory cards, rubber bands, pencils, paper clips, etc.).

Author: Monkey3D

Where to download: Cults

Headphone holder

This is a duck. Yes, you can hang headphones on it.

Author: Toshi_TNE

Download: Thingiverse

Polyhedral Succulent Pot

Unusual geometric pots for your growing succulent collection. These small pots can be configured to be connected together.

Author: PrintFutura

Download: Cults

Survival Whistle

This is a survival whistle with original design. It is durable, easy to make and very loud (118 dB is more than enough to be heard in an emergency).

Author: Joe Zisa

Where to download: Thingiverse

Measuring Cube

Simple and original measuring cube for the kitchen. On each side there are recesses for measuring the volume of ingredients (in cups - according to the American system, and in metric units for everyone else). It is best to print with PETG material, it is the safest for products.

Author: iomaa

Download: Thingiverse

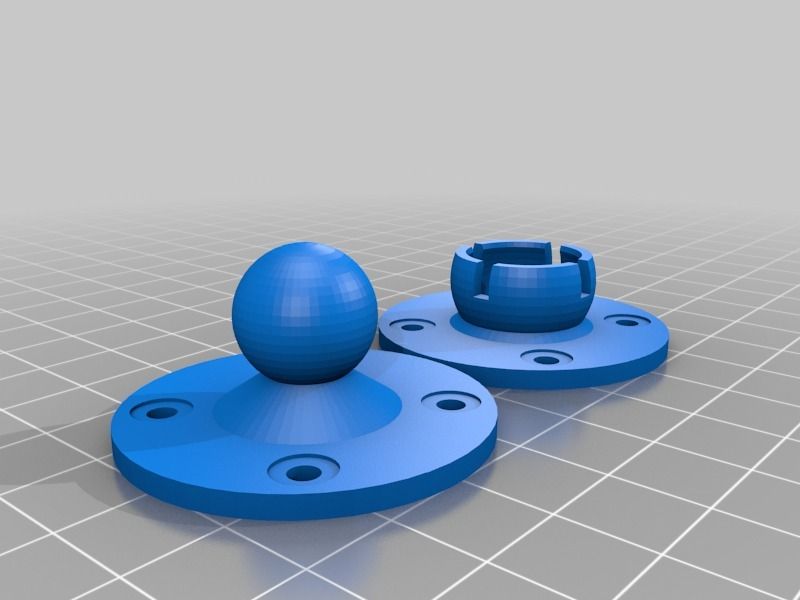

Hinge

This is a parametric hinge that can be sized to fit your needs.

Written by Rohin Gosling

Download: Thingiverse

Car Eyeglass Holder

Attaches to your car's sun visor. Glasses will always be at hand.

Author: Trevor Long

Download: Thingiverse

Opener

The simplest things are usually the most useful. Convenient and easy to print opener. Covers the sharp edges of the cork as much as possible, protecting you from injury.

Author: Jeremy Peterson

Download: Thingiverse

Superhero Keychains

Sometimes you need to remind yourself of your hidden superpowers. Stylish and cool keyrings are well suited as a small gift.

Stylish and cool keyrings are well suited as a small gift.

Author: Formbyte

Where to download: Cults

Headphone stand

It will be useful for music lovers and gamers who use headphones a lot and often. After all, now they will no longer roll around anywhere.

Author: MakerBot

Where to download: Thingiverse

Bag Clip

The model consists of two printed parts. Allows you to keep packages closed and keep food fresh longer.

Author: Walter Hsiao

Download: Thingiverse

Plastic wrench

Handy wrench, but don't choose soft plastic to make it.

Author: Daniel Noree

Where to download: Cults

Sliding Decal

No more worrying about whether cups are clean or dirty right now in the dishwasher! With the help of a special mechanism, the slider easily changes the inscription on the plate.

Who made it: MiddleFingerBoss

Where to download: Thingiverse

Collapsible basket

Cool picnic item. A folding square basket with five sections is printed from several parts and then glued together. For product safety, it is recommended to use PETG plastic.

A folding square basket with five sections is printed from several parts and then glued together. For product safety, it is recommended to use PETG plastic.

Author: PatternToPrint

Where to download: Cults

Self-watering plant pot

Houseplants are dying from your forgetfulness? This will not happen again! This pot will water them by itself, and your conscience will be clear.

Author: Parallel Goods

Where to download: Cults

Maze Gift Box

Cash is not the most original gift. But if you present them in such a gift box, your friend will surely like it. The lucky recipient will have to work hard to get to the prize, because there is only one right way.

Author: Robert

Download: Thingiverse

Wired headphone holder

The headphones will now be protected from tangling and breakage.

Author: Robert

Where to download: Thingiverse

Tube Squeezer

Will help squeeze out the contents of the tube to the last drop. Wide enough to fit most tubes on the market. Printed in three separate parts.

Wide enough to fit most tubes on the market. Printed in three separate parts.

Author: Justin Otten

Where to download: Thingiverse

Webcam Shutter

The best thing for the paranoid and just for those who are uncomfortable being under the gun of a webcam. Instead of sticking tape or sticky tape over the lens, attach a slider shutter to the body and open it when you need a video call.

Author: Horizon Lab

Where to download: Cults

Hexagonal Prefabricated Drawers

Useful to free your desk from the noodles of cables, wires and just every little thing. The design can be easily expanded if necessary.

Created by Dan O'Connell

Where to download: Cults

Wall Phone Shelf

Attach the shelf to a power outlet and place your phone on it while charging. The model also has a corner slot that holds your smartphone or tablet upright for watching videos.

Author: Tosh Sayama

Where to download: Cults

Card Shuffle Machine

Awesome item for poker lovers. This device will help to shuffle the cards and deal them during the game.

This device will help to shuffle the cards and deal them during the game.

Author: LarsRb

Where to download: MyMiniFactory

Box with a secret lock

Box for storing things in a place inaccessible to prying eyes with a secret multi-stage opening mechanism.

Author: 3DPrintingWorld

Where to download: Thingiverse

Digital Sundial

Yes, your eyes don't deceive you. This is a digital sundial and it really works. They are designed to pass only the right beams at the right time and at the right angle to display the actual time in 20-minute intervals. Only works during daylight hours, of course.

Author: Mojoptix

Where to download: Thingiverse

Keyring

Designed in the shape of a stylish Swiss Army knife, it looks amazing. Printed from two plates and the keys are held in place with standard hex nuts and bolts.

Author: Craig Blanchette

Download: Thingiverse

Translation of the article "50 Cool Things to 3D Print in June 2019"

- Remove supports

- Remove Soluble Supports

- Sanding

- Cold welding

- Filling voids

- Polishing

- Priming and painting

- Pair smoothing

- Epoxy coating

- Metallization

Introduction

FDM technology is best suited for rapid, low-budget prototyping. Layer lines are usually visible in FDM prints, so post-processing is essential if a smooth surface is to be achieved. Some post-processing techniques can also make a print more durable by changing the degree of its elastic properties, density, structural and textural features.

Layer lines are usually visible in FDM prints, so post-processing is essential if a smooth surface is to be achieved. Some post-processing techniques can also make a print more durable by changing the degree of its elastic properties, density, structural and textural features.

In this article, we will discuss the most common post-processing techniques in FDM.

Post-processed FDM prints (left to right): cold welded, void filled, raw, sanded, polished, painted and epoxy coated. photo 3dhubs.com

Support removal

Support removal is usually the first step in post-processing for any 3D printing technology that uses them. In general, props can be divided into two categories: standard and soluble. Unlike other post-processing methods discussed in this article, the removal of props is mandatory and does not result in improved surface quality.

Initial printout with props, poor prop removal, good prop removal. photo 3dhubs. com

com

Removal of standard supports

Tools

- Nippers, needle nose pliers, tongs

- Toothbrush, brush

| Finishing | ★ ☆ ☆ ☆ ☆ |

| Approvals | ★ ★ ☆ ☆ ☆ |

| Speed | ★ ★ ★ ★ ☆ |

| Suitable for | all thermoplastics FDM |

Process

Normally the backups come off the printout without problems, and hard-to-reach places (such as holes or cavities) can be removed from the backup material with an old toothbrush. Proper placement of support structures and correct print orientation can significantly reduce the negative impact of supports on how the final printout will look.

Pluses

- Does not change the overall geometry of the part.

- The process is very fast.

Cons

- Does not remove layer lines, scratches or other surface defects.

- If excess material or marks remain from the support structure, print accuracy and appearance suffer.

Soluble Support Removal

Instrumentation

- Solvent resistant container

- Thinner

- Ultrasonic cleaner (optional)

| Finishing | ★ ★ ★ ☆ ☆ |

| Approvals | ★ ★ ☆ ☆ ☆ |

| Speed | ★ ★ ★ ★ ☆ |

| Suitable for | all thermoplastics FDM |

Process

Soluble support standard materials are removed from the printout by immersing it in a reservoir of the appropriate solvent. Supports are usually printed:

Supports are usually printed:

- HIPS (usually with ABS)

- PVA (usually with PLA)

A glass container like a preservation jar is fine. Any non-porous vessel is suitable for water treatment. To quickly remove props from HIPS/ABS printouts, you will need a solution of equal parts D-limonene and isopropyl alcohol. Many other support structure materials such as PVA (with PLA) dissolve in normal water.

Pro Tricks

Shorten the solution time by using an ultrasonic cleaner and changing the solvent as it becomes saturated. A warm (not hot) solution works faster - heating is useful if there is no cleaner.

Pluses

- Complex geometry is allowed for which the standard method of removing props is not possible.

- Smooth surface at the support points.

Cons

- Improper dissolution of the props can cause discoloration and skewed printouts.

- Does not remove layer lines, scratches or other surface imperfections.

- May cause small holes or holes if soluble material seeps into the object during printing.

Cleaning with a skin

Screenshot Gray ABS ABS ABS PROBECTION

Instrumentation

- EVERTICAL PREASE with grain

on 150, 220, 400, 600, 1000 and 200 2222 - Wiping cloth

- Toothbrush

- Soap

- Face mask

| Finishing | ★ ★ ★ ★ ☆ |

| Approvals | ★ ★ ★ ☆ ☆ |

| Speed | ★ ★ ☆ ☆ ☆ |

| Suitable for | all thermoplastics FDM |

Process

Once the props have been removed or dissolved, sanding can be done to smooth the part and remove any obvious defects such as blots or prop marks. Which sandpaper to start with depends on the thickness of the layer and the quality of the print: for layers of 200 microns or less, or for prints without blotches, you can start with sandpaper at P150. If there are blobs visible to the naked eye, or the object is printed with a layer thickness of 300 microns or more, stripping should begin with P100.

Which sandpaper to start with depends on the thickness of the layer and the quality of the print: for layers of 200 microns or less, or for prints without blotches, you can start with sandpaper at P150. If there are blobs visible to the naked eye, or the object is printed with a layer thickness of 300 microns or more, stripping should begin with P100.

The process can be continued up to P2000 grit (one approach is to go to 220, then 400, 600, 1000 and finally 2000). Wet sanding is recommended from the very beginning to the very end - this will avoid excessive friction, which can lead to an increase in temperature and damage the object, as well as contaminate the sandpaper itself. Between sanding, the printout should be cleaned with a toothbrush and washed with soapy water, then wiped with a cloth to remove dust and prevent it from sticking together. Even P5000 can be sanded to achieve a smooth, shiny FDM part.

Pro Tricks

Always sand in small circular motions - evenly over the entire surface of the part. It may be tempting to sand perpendicular to the layers, or even parallel, but this can lead to gouges. If the part is discolored or has a lot of scratches after sanding, it can be heated a little to soften the surface and allow some defects to smooth out.

It may be tempting to sand perpendicular to the layers, or even parallel, but this can lead to gouges. If the part is discolored or has a lot of scratches after sanding, it can be heated a little to soften the surface and allow some defects to smooth out.

Pros

- An exceptionally smooth surface is obtained.

- Further post-processing (painting, polishing, smoothing and epoxy coating) is greatly facilitated.

Cons

- Not recommended for double or single shell parts as sanding may damage the printout.

- The process is difficult in the case of sophisticated surfaces and the presence of small details in the object.

- Grinding too aggressively and removing too much material can affect the appearance of the part. Acetone for ABS. Dichloromethane for PLA, ABS

- Foam applicator

| Finishing | ★ ★ ☆ ☆ ☆ |

| Approvals | ★ ★ ☆ ☆ ☆ |

| Speed | ★ ★ ★ ★ ★ |

| Suitable for | all thermoplastics FDM |

Process

If the object is larger than the printer's capacity, the object is printed in parts and then assembled. In the case of PLA and some other materials, assembly can be done with Dichloromethane or a suitable adhesive (the choice of adhesive depends on the plastic). In the case of ABS, it is possible to "weld" with acetone. The mating surfaces should be slightly moistened with acetone and squeezed tightly or clamped and held until most of the acetone has evaporated. So the parts will be held together by chemical bonds.

In the case of PLA and some other materials, assembly can be done with Dichloromethane or a suitable adhesive (the choice of adhesive depends on the plastic). In the case of ABS, it is possible to "weld" with acetone. The mating surfaces should be slightly moistened with acetone and squeezed tightly or clamped and held until most of the acetone has evaporated. So the parts will be held together by chemical bonds.

Pro Tricks

Increasing the surface area of the acetone contact increases bond strength. Tongue-and-groove to help.

Pros

- Acetone does not change surface color as much as most adhesives.

- After drying, the compound acquires the properties of ABS, which makes further processing easier and more uniform.

Cons

- The bonding of ABS parts by cold acetone "welding" is not as strong as if the part were printed as a whole.

- Excessive use of acetone can dissolve the part and affect final appearance and tolerances.

Void Fill

Black ABS Print, Filled and Sanded

Tool Kit

- Epoxy (for small voids only)

- Automotive body filler (for large voids and joints)

- ABS filament and acetone (only for small voids in ABS printouts)

| Finishing | ★ ★ ☆ ☆ ☆ |

| Approvals | ★ ★ ★ ☆ ☆ |

| Speed | ★ ★ ★ ☆ ☆ |

| Suitable for | all thermoplastics FDM |

Process

Unusual voids may come out after the part has been ground or the soluble props have been dissolved. These voids are formed during printing when the layers are incomplete due to any restrictions on the trajectory of the print head, which is often inevitable. Small gaps and voids can be easily filled with epoxy and no additional treatment is required in this case. Larger gaps or voids left by assembling a multi-part object can be filled with automotive bodywork filler, but the printout will then need to be re-sanded. Putty works great, is easy to process with sandpaper and can be painted. Moreover, the parts connected by such a filler, or voids filled with it, turn out to be stronger than the original plastic.

Small gaps and voids can be easily filled with epoxy and no additional treatment is required in this case. Larger gaps or voids left by assembling a multi-part object can be filled with automotive bodywork filler, but the printout will then need to be re-sanded. Putty works great, is easy to process with sandpaper and can be painted. Moreover, the parts connected by such a filler, or voids filled with it, turn out to be stronger than the original plastic.

Slots in ABS printouts can also be filled with ABS thinned with acetone, which reacts chemically with the ABS object and seeps into existing voids. It is recommended to make such a putty from 1 part ABS and 2 parts acetone, then it will not spoil the surface if used correctly.

Dichloromethane works on all plastics: ABS, PLA, HIPS, SBS, etc.

Epoxy is also useful if you want to make your 3D printed part more durable

Pros

- Epoxy filler is easy to sand and prime, resulting in an excellent surface for painting.

- ABS solution of the same filament will give the same color, so nothing will show up on the surface.

Cons

- Auto body filler or other polyester epoxy adhesive is opaque when dry and will leave discolored areas on the printout.

- Additional processing required to achieve a uniform surface.

- Grinding too aggressively and removing too much material can affect the appearance of the part.

Polished

PLA model, polished. Photo rigid.ink

Tool kit

- Plastic polishing compound

- Sandpaper for P2000

- Wiping cloth

- Toothbrush

- Polishing pad or microfiber cloth

| Finishing | ★ ★ ★ ★ ★ |

| Approvals | ★ ★ ★ ☆ ☆ |

| Speed | ★ ★ ☆ ☆ ☆ |

| Suitable for | all thermoplastics FDM |

Process

Once the part has been cleaned, a plastic polish can be applied to the part to give a standard ABS or PLA object a mirror finish. After the part has been sanded for 2000, it is necessary to remove dust from the printout with a cloth and rinse the printout under warm water using a toothbrush. When the object is completely dry, buff it on a buffing pad or microfiber cloth, adding a polishing compound as you go, such as polishing jewelry. They are designed specifically for plastics and synthetics and give a long-lasting shine. Other plastic polishes, such as those used to polish car headlights, also work well, but some of them contain chemicals that can damage the printout.

After the part has been sanded for 2000, it is necessary to remove dust from the printout with a cloth and rinse the printout under warm water using a toothbrush. When the object is completely dry, buff it on a buffing pad or microfiber cloth, adding a polishing compound as you go, such as polishing jewelry. They are designed specifically for plastics and synthetics and give a long-lasting shine. Other plastic polishes, such as those used to polish car headlights, also work well, but some of them contain chemicals that can damage the printout.

Pro Tricks

To polish small parts, place the polishing wheel on your Dremel (or other rotary tool such as a power drill). For larger and stronger parts, you can use a grinder, just make sure that the part does not stay in one place for too long, otherwise the plastic may melt from friction.

Pros

- The part is polished without solvents that can warp it or change its tolerances.

- When properly ground and polished, a mirror-smooth surface is obtained, very similar to cast.

- Polishing and deburring plastics is extremely economical, making this a very cost-effective method of achieving a quality finish.

Cons

- If you want to achieve a mirror-smooth surface, the part must be carefully ground before polishing, which may affect tolerances.

- After polishing, the primer or paint no longer sticks.

Primer and paint

Gray PLA FDM print spray painted black. 3dhubs.com

Tools

- Cleaning cloth

- Toothbrush

- 150, 220, 400 and 600 grit sandpaper

- Aerosol Primer for Plastics

- Finish paint

- Polishing sticks

- Polishing paper

- Masking tape (only if multiple colors are expected)

- Nitrile gloves and matching face mask

| Finishing | ★ ★ ★ ★ ★ |

| Approvals | ★ ★ ★ ☆ ☆ |

| Speed | ★ ☆ ☆ ☆ ☆ |

| Suitable for | all thermoplastics FDM |

Process

Once the printout has been properly sanded (up to P600 when painting), it can be primed. Aerosol plastic primer should be applied in two coats. This primer is intended for subsequent painting of models, provides an even coating and at the same time thin enough not to hide small elements. Thick primer, which is sold in hardware stores, can clump, and then you have to seriously work with sandpaper. Apply the first spray coat with short pressures from a distance of 15-20 cm from the object, trying to do it evenly. Let the primer dry and smooth out the unevenness with 600 grit sandpaper. Apply a second coat of spray with light, quick pressures, also very gently and evenly.

Aerosol plastic primer should be applied in two coats. This primer is intended for subsequent painting of models, provides an even coating and at the same time thin enough not to hide small elements. Thick primer, which is sold in hardware stores, can clump, and then you have to seriously work with sandpaper. Apply the first spray coat with short pressures from a distance of 15-20 cm from the object, trying to do it evenly. Let the primer dry and smooth out the unevenness with 600 grit sandpaper. Apply a second coat of spray with light, quick pressures, also very gently and evenly.

When the priming is completed, you can start painting. You can paint with artistic acrylic paints and brushes, but a spray gun will provide a smoother surface. Hardware store spray paints are thick and viscous and difficult to control, so use paints that are designed specifically for modeling. The primed surface must be sanded and polished (sanding and polishing sticks, which are used in nail salons, can be purchased online, they are great for our task), and then wiped with a cloth. The paint should be applied to the model in very thin layers, the first layers should be transparent. When the paint finish becomes opaque (usually 2-4 coats), let the model rest for 30 minutes to allow the paint to dry completely. Carefully polish the paint layer with manicure sticks, repeat the procedure for each of the colors (between each applied paint).

The paint should be applied to the model in very thin layers, the first layers should be transparent. When the paint finish becomes opaque (usually 2-4 coats), let the model rest for 30 minutes to allow the paint to dry completely. Carefully polish the paint layer with manicure sticks, repeat the procedure for each of the colors (between each applied paint).

Separate parts of the model can be covered with masking tape so that the colors, if there are several, do not mix. When painting is complete, remove the masking tape and polish the object with polishing paper. Polishing paper, such as 3M or Zona, comes in a variety of grits and is a relatively new product. It is sold in packs in various online stores, and after processing with this paper, the ink layer or topcoat will literally shine - and nothing else can achieve this effect. Apply 1-2 coats of top coat to protect the paint and let it dry completely. The top coat is selected in accordance with the recommendations of the paint manufacturer. If the topcoat and paint are incompatible, it can render your entire painting job meaningless, so compatibility is very important here.

If the topcoat and paint are incompatible, it can render your entire painting job meaningless, so compatibility is very important here.

Pro Tips

Don't shake the can when spraying! It is important not to mix the pigment or primer with the propellant (propellant gas), which will cause bubbles to form in the spray. Instead, the can must be rotated for 2-3 minutes so that the mixing ball rolls like a pearl, and does not strum.

Pros

- Excellent result, if you take into account all the nuances of the process and practice.

- You can do anything with the final look of the object, no matter what material it is printed on.

Cons

- Primer and paint increase the volume of the model, which affects tolerances and can be a problem when it comes to a part of a larger object.

- High quality spray paint or spray gun increases costs.

Vapor smoothed

Vapor smoothed black ABS printed hemisphere

Tools

- Cleaning cloth

- Solvent resistant sealed container

- Thinner

- Paper towels

- Aluminum foil (or other solvent resistant material)

- Face mask and chemical resistant gloves

| Finishing | ★ ★ ★ ★ ☆ |

| Approvals | ★ ★ ☆ ☆ ☆ |

| Speed | ★ ★ ★ ☆ ☆ |

| Suitable for | all thermoplastics FDM |

Process

Line the bottom of the container with paper towels, if possible along the sides. It is critical that the vapors cannot damage the container and that the container itself is sealed. It is recommended to use a glass or metal container. Apply enough thinner to the paper towels so that they are wet but not soaked - this will also help them adhere better to the walls. Acetone is famous for its ability to smooth out ABS. PLA can be smoothed with a variety of other solvents (dichloromethane works well), but this plastic tends to be much harder to smooth than ABS. When working with any solvents, please follow the safety precautions for handling chemicals and always take appropriate precautions. Place a small "raft" of aluminum foil or other solvent-resistant material in the center of the paper towel-lined container. Place the printout on the "raft" (either side of your choice) and close the lid of the container. Steam polishing can take varying amounts of time, so check your printout periodically. To increase the speed of polishing, the container can be heated, but this must be done carefully so as not to cause an explosion.

It is critical that the vapors cannot damage the container and that the container itself is sealed. It is recommended to use a glass or metal container. Apply enough thinner to the paper towels so that they are wet but not soaked - this will also help them adhere better to the walls. Acetone is famous for its ability to smooth out ABS. PLA can be smoothed with a variety of other solvents (dichloromethane works well), but this plastic tends to be much harder to smooth than ABS. When working with any solvents, please follow the safety precautions for handling chemicals and always take appropriate precautions. Place a small "raft" of aluminum foil or other solvent-resistant material in the center of the paper towel-lined container. Place the printout on the "raft" (either side of your choice) and close the lid of the container. Steam polishing can take varying amounts of time, so check your printout periodically. To increase the speed of polishing, the container can be heated, but this must be done carefully so as not to cause an explosion.

When removing the printout from the container, try not to touch it in any way, leave it on the “raft”, take them out together. In all those places where the printout has come into contact with something, there will be defects, since the outer layer will be under-dissolved. Before working with it, let the printout completely “breathe” so that all solvent vapors have evaporated.

Many aerosols and/or solvent sprays are flammable or explosive and their vapors can be harmful to humans. Be extremely careful when heating solvents, always handle them and store them in a well ventilated area.

Pluses

- Many small blotches, as well as many layer lines, are smoothed out without additional processing.

- The printout surface becomes exceptionally smooth.

- The procedure is very fast and can be performed using widely available materials.

Cons

- Does not “heal” gaps, does not completely hide layer lines.

- During the smoothing process, the outer layer of the printout dissolves, which greatly affects the tolerances.

- Negatively affects the strength of the printout due to changes in the properties of its material.

Immersion

PLA model immersed in dichloromethane. Photo 3dpt.ru

Tools

- Solvent resistant container

- Thinner

- Eye hook or cog

- Heavy wire for sculpture or landscaping

- Dryer or drying frame

- Face mask and chemical resistant gloves

| Finishing | ★ ★ ★ ★ ☆ |

| Approvals | ★ ☆ ☆ ☆ ☆ |

| Speed | ★ ★ ★ ★ ☆ |

| Suitable for | all thermoplastics FDM |

Process

Make sure the container you are using is wide and deep enough to completely submerge the printout in the solution. Fill the container with the appropriate amount of solvent - be careful not to splash. As with vapor smoothing, ABS dip smoothing can be done with acetone, which is easy to find in the store, and for PLA, dichloromethane can also work well with ABS, HIPS, SBS, PETG, and many other materials. PLA is quite resistant to solvent smoothing, so it may take several passes to achieve the desired result. Prepare the printout for dipping by screwing a hook or eye screw into it in an inconspicuous place. Pass the wire through the eyelet or wrap the wire around the screw so that the printout can be immersed in the solvent. If the wire is too thin, it will not be able to withstand the buoyant force on the printout, and it will be difficult to sink the object.

Fill the container with the appropriate amount of solvent - be careful not to splash. As with vapor smoothing, ABS dip smoothing can be done with acetone, which is easy to find in the store, and for PLA, dichloromethane can also work well with ABS, HIPS, SBS, PETG, and many other materials. PLA is quite resistant to solvent smoothing, so it may take several passes to achieve the desired result. Prepare the printout for dipping by screwing a hook or eye screw into it in an inconspicuous place. Pass the wire through the eyelet or wrap the wire around the screw so that the printout can be immersed in the solvent. If the wire is too thin, it will not be able to withstand the buoyant force on the printout, and it will be difficult to sink the object.

Once the printout is ready, use a wire to completely immerse it in the solvent for a few seconds. Remove the printout and hang it by the wire in a dryer or on a drying frame to allow the solvent to completely evaporate from the surface. After ejection, the printout can be gently shaken to facilitate the drying process and ensure that no solvent has accumulated in the depressions.

After ejection, the printout can be gently shaken to facilitate the drying process and ensure that no solvent has accumulated in the depressions.

Pro Tricks

If an opaque whitish coating appears on the print after drying, this can be corrected by holding the object over a solvent bath for a while so that its vapor slightly dissolves the surface. This restores the original color of the printout and achieves a shiny outer layer.

Pros

- The printed surface is smoothed much faster than steam polishing.

- Significantly less fumes are generated than other solvent polishing methods, so this method is less hazardous.

Cons

- The surface is smoothed very aggressively, so you can forget about tolerances.

- Immersion for too long can result in complete deformation of the object and a significant change in material properties.

Epoxy

Black ABS printout, half epoxy coated, half uncoated

Toolbox

- two part epoxy resin

- Foam applicator

- Mixing container

- Sandpaper P1000 or finer

| Finishing | ★ ★ ★ ★ ☆ |

| Approvals | ★ ☆ ☆ ☆ ☆ |

| Speed | ★ ★ ★ ★ ☆ |

| Suitable for | all thermoplastics FDM |

Process

After the printout has been cleaned (preliminary cleaning gives the best end result), wipe it thoroughly with a cloth. Mix the resin and hardener in the proportion indicated in the instructions, accurately measuring all volumes. The curing process of epoxy resin is exothermic, so glass containers and containers made of materials with a low melting point should be avoided. It is recommended to use containers that are specifically designed for mixing epoxy resins. Incorrect ratio of resin and hardener can result in longer curing time or no curing at all and result in a permanently sticky substance. Mix the resin and thinner as directed in the instructions - carefully, in smooth movements to minimize the amount of air bubbles remaining inside the mixture. Very little epoxy is needed, and most of these resins only work for 10-15 minutes, so plan accordingly.

Mix the resin and hardener in the proportion indicated in the instructions, accurately measuring all volumes. The curing process of epoxy resin is exothermic, so glass containers and containers made of materials with a low melting point should be avoided. It is recommended to use containers that are specifically designed for mixing epoxy resins. Incorrect ratio of resin and hardener can result in longer curing time or no curing at all and result in a permanently sticky substance. Mix the resin and thinner as directed in the instructions - carefully, in smooth movements to minimize the amount of air bubbles remaining inside the mixture. Very little epoxy is needed, and most of these resins only work for 10-15 minutes, so plan accordingly.

Apply the first coat of epoxy with a sponge applicator, being careful not to build up in crevices and small parts. When the printout is sufficiently coated, allow the resin to fully cure - as described in the instructions that came with it. One coat may be sufficient, but for optimum results it is best to lightly sand the printout with fine sandpaper (on P1000 and above) to eliminate any imperfections. Wipe off the dust with a cloth and, in the same way as before, apply a second layer of epoxy.

Wipe off the dust with a cloth and, in the same way as before, apply a second layer of epoxy.

Pros

- A very thin coat of epoxy won't affect tolerance too much (unless the printout has been sanded too hard beforehand).

- A protective shell forms around the object.

Cons

- The layer lines will remain visible, they will only be covered by a smooth shell.

- If too much epoxy is used, it can flood parts and edges, and the surface can appear greasy.

Plating

FDM printed structural element nickel plated with Repliform RepliKote technology

Tools (for home use)

- Electroplating solution can be obtained by mixing a metal salt, acid and water, but if the proportions are inaccurate and the substances are of insufficient quality, one cannot count on a professional result.

If you buy a ready-made solution (as in Midas kits), you can be sure that the problems with plating are not caused by the solution.

If you buy a ready-made solution (as in Midas kits), you can be sure that the problems with plating are not caused by the solution.  The rectifier is safer in the sense that it can simply be turned off and thus cut off the current during the galvanization process.

The rectifier is safer in the sense that it can simply be turned off and thus cut off the current during the galvanization process. | Finishing | ★ ★ ★ ★ ☆ |

| Approvals | ★ ★ ★ ☆ ☆ |

| Speed | ★ ★ ★ ★ ☆ |

| Suitable for | all thermoplastics FDM |

Process

Electroplating can be carried out at home or in a professional workshop. To do everything right, you need to be well versed in the materials, in what is actually happening - and at home these opportunities are usually limited. In order to achieve excellent surface quality and to have more plating options, including chrome plating, it is best to use the services of professional workshops. The copper galvanization process will be described below as an example.

To do everything right, you need to be well versed in the materials, in what is actually happening - and at home these opportunities are usually limited. In order to achieve excellent surface quality and to have more plating options, including chrome plating, it is best to use the services of professional workshops. The copper galvanization process will be described below as an example.

At home, you can galvanize with copper or nickel, and this coating will then serve as the basis for galvanizing with other metals. It is critically important that the printout surface be as smooth as possible before it is galvanized. Any bumps and lines in the layers will be enhanced as a result of the process. Prepare the sanded and cleaned object for plating by coating the plastic with a thin coat of high quality conductive paint, or with a graphite and acetone solution for ABS printouts. Allow the conductive coating to dry completely, sand if necessary to ensure a smooth surface. At this stage, it is extremely important not to touch the printout with bare hands or to wear gloves, because sweat marks on the object will certainly affect the quality of the galvanization.

Insert a screw or eyelet in an inconspicuous place on the printout and connect it to the negative terminal of the rectifier. This will be the cathode. Connect the copper anode to the positive contact of the rectifier. Fill the container with enough copper plating solution so that the printout is completely covered with it. Immerse the anode in the container and turn on the power. After the rectifier is turned on, immerse the printout in the container, making sure that it does not touch the anode anywhere. Beware! When the object is already in the bath, the galvanization system is active, and contact with the solution, cathode or anode can be traumatic. Set the voltage on the rectifier to 1-3 Volts, and the process will go to full metallization. To speed things up, the voltage can be increased, but not more than 5 volts. When enough metal has deposited on the printout, simply turn off the power and dry the object with microfiber towels. When it's dry, varnish the object to protect it from corrosion.