3D printer idler pulley

Gates belts, pulleys and idlers now available! – E3D Online

Written by Sam Tumilty

As a community, we need to care more about the rigidity of the belts positioning our printers. As you’re probably aware, one of the most effective methods to increase the stiffness of a belt is to increase its size and width. It’s for this reason, that we at E3D are offering belts in greater sizes than the puny 6mm standard used as the current market standard across 3D printers.

If you just want to go ahead and buy them then click here, if you fancy finding out some more then carry on reading!

Because who doesn’t like it stiffer, wider and longer?.. Product Title | Size | Internal Diameters | Pitch Circle Diameter | |

|---|---|---|---|---|

Belts | Gates 2GT Belt | 6mm | n/a | n/a |

| Gates 2GT Belt | 9mm | n/a | n/a | |

| Gates 2GT Belt | 12mm | n/a | n/a | |

Pulleys | Gates Pulley with 16 Teeth | 6mm | 5mm | 10. |

| Gates Pulley with 18 Teeth | 6mm | 5mm | 11.46mm | |

| Gates Pulley with 20 Teeth | 6mm | 5mm | 12.73mm | |

| Gates Pulley with 20 Teeth | 9mm | 5mm | 12.73mm | |

| Gates Pulley with 20 Teeth | 12mm | 5mm | 12.73mm | |

Idlers*all idlers are 20-tooth equivalent | Gates Toothed Idler | 6mm | 5mm | 12.73mm |

| Gates Toothed Idler | 9mm | 5mm | 12.73mm | |

| Gates Toothed Idler | 12mm | 5mm | 12.73mm | |

| Gates Smoothed Idler | 6mm | 5mm | 12.73mm | |

| Gates Smoothed Idler | 9mm | 5mm | 12.73mm | |

| Gates Smoothed Idler | 12mm | 5mm | 12.73mm |

Even if you don't opt for a wider belt, these genuine Gates belts offer significant benefits over other no-name belts.

Genuine Gates 2GT belts have notably better stiffness than clone belts on the market. This is due to the inclusion of a generous helping of glass-fibre reinforcement, which carries the tensile or stretching loads of the belt. More reinforcement, more stiffness. Additionally the construction of these belts results in better damping, meaning that despite being stiff they are also less prone to ringing as vibrations settle quickly. Overall this results in less overshoot at corners and reduced ringing or ‘ghosting’.

Stiffer, wider, longer.We’re happy to be offering our belts in the very common 6mm width as a direct drop-in for most machines out there. However for the more enthusiast machine designer or modder we’re also carrying these in 9mm and 12mm widths. These extra wide belts means more fibreglass, more tooth engaged with the pulley and therefore a much more impressive stiffness. We expect these wider belts to be very beneficial to those designing machines that operate at higher speeds, carry heavier loads, or need to traverse longer distances.

We expect these wider belts to be very beneficial to those designing machines that operate at higher speeds, carry heavier loads, or need to traverse longer distances.

We’re also carrying pulleys and idlers to match, (see below).

A truly superior gripThese bad boys are fitted with a nylon fabric tooth facing, giving them their distinctive red teeth. This tooth facing material protects the tooth from wear, eliminating that classic black dust that builds up at pulleys. An additional benefit is that the tooth facing increases the stiffness of the tooth, increasing the overall stiffness and control authority of your linear motion. The facing also results in smoother running with less friction and noise.

Perfectly profiled teethGates are the inventors and experts in GT tooth profiled belts, their tooth profile having undergone multiple subtle iterations improving grip and registration over the years.

The convex profile is purposely designed to engage the grooves on the pulley with a firm grip that eliminates backlash. This is achieved by making the teeth ever so slightly longer than the pulley’s groove they fit into. The design is intentional: the belt’s tooth actively deforms into and fills the pulley’s tooth-groove locking it into place with a perfect interference fit which markedly reduces unsavoury backlash which would otherwise sully your prints.

Design improvements

Pulleys & Idlers

But for this system to work properly the Gates belts need to be paired with Gates pulleys and idlers which are precisely machined to fit with these teeth. Using ill-matched belts and pulleys can introduce error which can, in turn, introduce backlash or cause tooth deformation and wear of the belts.

PulleysThese come in standard 5mm bore, with dual grub-screw holes. Suitable for attaching to most NEMA17 motors with a 5mm shaft.

It’s fairly common practice to simply use bearings instead of toothed idlers. No wonder: they’re difficult to find online. But this should not be the case. Quite simply put, the tension of the belt when combined with the flat surface of a bearing crushes the teeth of your belt! This reduces registration accuracy and significantly shortens the life of the belt. Whereas, a toothed idler allows the belt to glide freely and gently cups its teeth as it traverses around the curve.

Smooth IdlersSmooth idlers complete our offering by providing idlers with precisely and carefully matched diameters that coincide with the belt's pitch circle diameter, allowing for easy design of parallel belt paths. This ensures that the tension of the belt remains constant throughout the stroke of the belt. Refer to Gates' Design Guide for more info.

Not only this, but Gates’ smoothed idlers have correct flanges, clearance and are super concentric, meaning the diameter and positioning of the centreline is precisely aligned to keep the belt straight and true.

We Needed These Belts in Our Life

We're sure you’ve heard of our recent endeavours into the magical world of ‘ToolChanging’. Well, when considering which belts (and pulleys) to use in the E3D Tool-Changer all of our engineers were in unanimous agreement that the tool changer needs to have genuine Gates Belts. These belts are widely known to be the finest belts out there- running smoother, and with more accuracy than any other belt on the market. It was then that one of the team jestingly pointed out that we don’t even sell these belts to our customers. Well why the hell don’t we!?

Verdict

We at E3D are both delighted and proud to be stocking Genuine Gates belts for our customers at long last. The effort that goes into their production and quality control really pays off. Gates offer a standard other belt providers just can’t reach. If you’re interested in purchasing official Gates Powergrip® belts please click here.

Timing pulleys and idler pulleys in the 3D industry – MISUMI

Timing pulleys, synchronous timing pulleys and idler pulleys

Timing belts run on timing pulleys and synchronous timing pulleys. Together with idler pulleys, teeth and a motor, they form the basis of a toothed belt drive. Due to their versatility and high efficiency, toothed belt drives are very important in industry.

Together with idler pulleys, teeth and a motor, they form the basis of a toothed belt drive. Due to their versatility and high efficiency, toothed belt drives are very important in industry.

Timing pulleys

The range of applications for toothed belt drives includes power drives, linear drives and transport drives. Timing pulleys perform various functions in a toothed belt drive. They are are divided into driving, output, securing and tensioning pulleys.

Synchronous timing pulleys

Synchronous timing pulleys are distinguished according to drive and output pulleys. Drive pulleys transmit the rotational forces of the motor to the belt and set it in motion. Output pulleys are the non-driven counterpart of the drive pulleys.

Toothed pulleys

Toothed pulleys ensure that the belt runs straight and tracks sideways from the timing pulleys. Depending on the engagement side of the pulley onto the belt, the running surface of the pulley can be either toothed or smooth.

Idler pulleys

Idler pulleys tension the belt in order to ensure smooth running without flutter due to the relieved slack strand. The optimum tension of a toothed belt drive is significantly lower than that of a frictionally engaged belt drives. Both toothed and smooth idler pulleys are used, depending on the engagement side of the idler pulley on the belt.

The MISUMI online shop for timing pulleys and synchronous timing pulleys offers you the following configuration options:

- Freely selectable number of teeth: 10 to 192 teeth

- Freely selectable disc width: 3 to 125 mm

- Various surface treatments: burnished, clear or black anodised and nickel-plated

- Various metric profile shapes available: T2.5, T5 ,T10

- Various imperial profile shapes available: MXL, XL, L, H, GT, YU, T and AT

- Selectable drive form: clamping screw, keyway or conical clamping sleeve

- Selectable materials: aluminium, plastic, normal and stainless steel

- Flanged Idlers with Teeth - Center Bearing

- Idler Pulleys

- Timing Pulleys T10 Type

- Timing Pulleys / Width Configurable

- Timing Pulley Star Quick

- Timing Pulley Flange

spacer

You can rely on MISUMI

Trust and reliability are playing an even greater role in working life now more than ever. Precisely these two values have always had top priority at MISUMI – even now in difficult times! That’s why you can rely on us, as you can be certain that you’ll get the usual service quality.

Precisely these two values have always had top priority at MISUMI – even now in difficult times! That’s why you can rely on us, as you can be certain that you’ll get the usual service quality.

Timing pulleys and synchronous timing pulleys in the 3D printing industry

The timing belt originally comes from the automotive sector. Later developments of belt shapes resulted from the use of timing belts in scanners. Today, the 3D printer sector is able to benefit particularly from these developments. Toothed belt drives are a very common drive element for positioning in the 3D printer industry due to their high positioning accuracy and the small installation space required. Additional advantages include their low maintenance requirements and long service life.

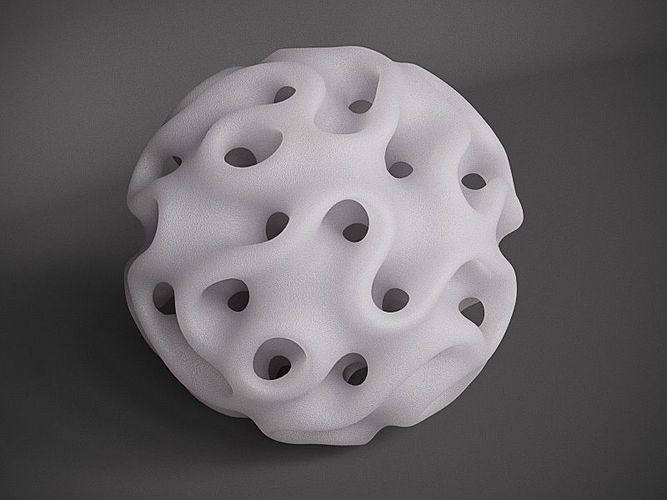

Example application – 3D printer

A project from the practice of additive manufacturing where these parts were used was implemented by our partner Christian Reil. Here the toothed belt drive drives a ball screw via a timing pulley. The timing pulley in turn raises and lowers a machine table in a vertical direction in order to position it. In addition, it is also possible to move the print head of a 3D printer in a horizontal direction using a toothed belt drive.

The timing pulley in turn raises and lowers a machine table in a vertical direction in order to position it. In addition, it is also possible to move the print head of a 3D printer in a horizontal direction using a toothed belt drive.

3D printer by Christian Reil using MISUMI parts

Description of 3D printer by Christian Reil

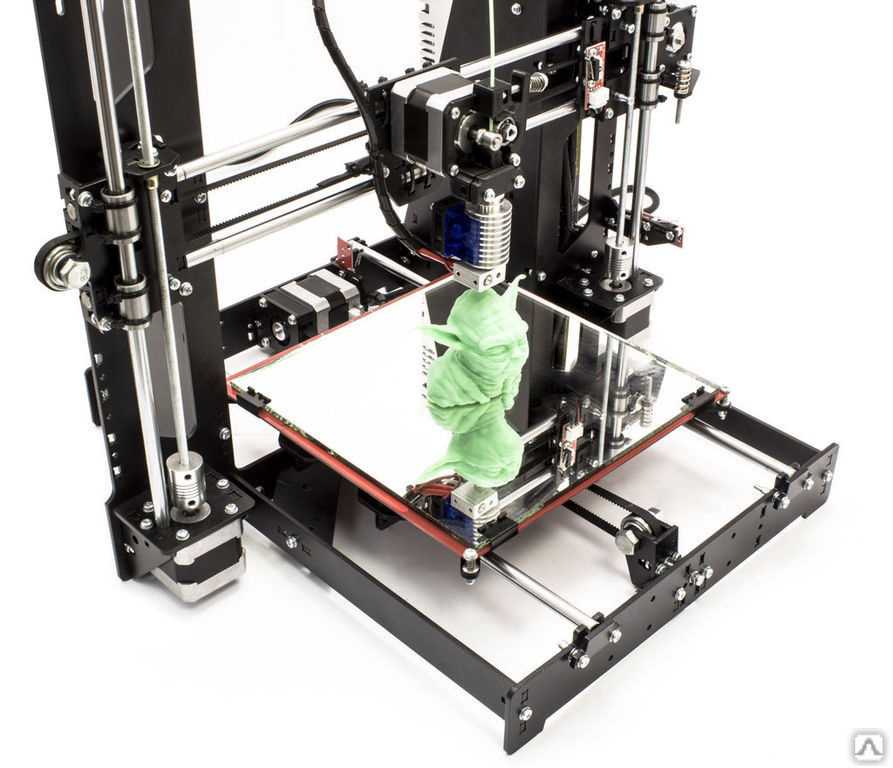

The 3D printer C1 from CR-3D is a Fused Filament Fabrication (FFF) 3D printer for the highest demands.

The C-Series stands for a compact design and ultra fast printing speeds in a space of 320x250x350mm. The state-of-the-art CoreXY MotionSystem ensures low moving mass and low vibration movements of the dual print head. The weight of the printhead has been further reduced by the Bowden extruder system. The user interface is a 7-inch touch display, which provides intuitive operation, uncomplicated setup and detailed status information to the user. In terms of user-friendliness, the device has also been equipped with a filament sensor and automatic print bed measurement before printing, so that nothing stands in the way of high process safety and reliability.

Part list download

Download the part list here.

Switching power supplies by OMRON

| OMRON offers the complete portfolio for the required switching power supplies for 3D printers: whether DIN rail power supplies in control systems for large 3D printers or 24V open-frame power supplies for the small private 3D printer. A wide range of performance categories is also offered within the individual series. |

OMRON offers the complete portfolio for the required switching power supplies for 3D printers: whether DIN rail power supplies in control systems for large 3D printers or 24V open-frame power supplies for the small private 3D printer. A wide range of performance categories is also offered within the individual series.

During the design process, engineers will often opt for a more powerful heating bed for the 3D printer so as to shorten the warm-up time of the device. In this case, OMRON offers the simple option of selecting a different power supply with more power – so there’s no need to go back to the drawing board.

Maintenance is a major issue for large 3D printers as operating hours and remaining life expectancy are becoming increasingly important. Many OMRON power supplies have displays of this kind. For example, the S8VS Series Type A has a function that displays the remaining life of the device in service years. This supports unit maintenance, enabling replacement before product life finishes. Type B provides a total life monitoring function to help the user to plan maintenance properly.

Desgining easier and faster with MISUMI RAPiD Design

My struggle with vertical stripes. Smooth, toothed rollers or something else?

Technician

Subscribe to the author

Subscribe

Don't want

27

From the very beginning of printing, I noticed these bands and read the Internet on the topic of who is struggling with this.

Here it should be noted that these two types of bands. Some are wider - with the frequency of the belt, in the event of resonant bands - the frequencies approximately coincide. Others are smaller. They are not so noticeable, but on large vertical planes at certain angles they can be seen very well. Perhaps this is the same thing, but at different speeds it manifests itself in different ways. Didn't go into details. In the picture, the speed changes from 30mm/s at the bottom to 120mm/s at the top.

Some are wider - with the frequency of the belt, in the event of resonant bands - the frequencies approximately coincide. Others are smaller. They are not so noticeable, but on large vertical planes at certain angles they can be seen very well. Perhaps this is the same thing, but at different speeds it manifests itself in different ways. Didn't go into details. In the picture, the speed changes from 30mm/s at the bottom to 120mm/s at the top.

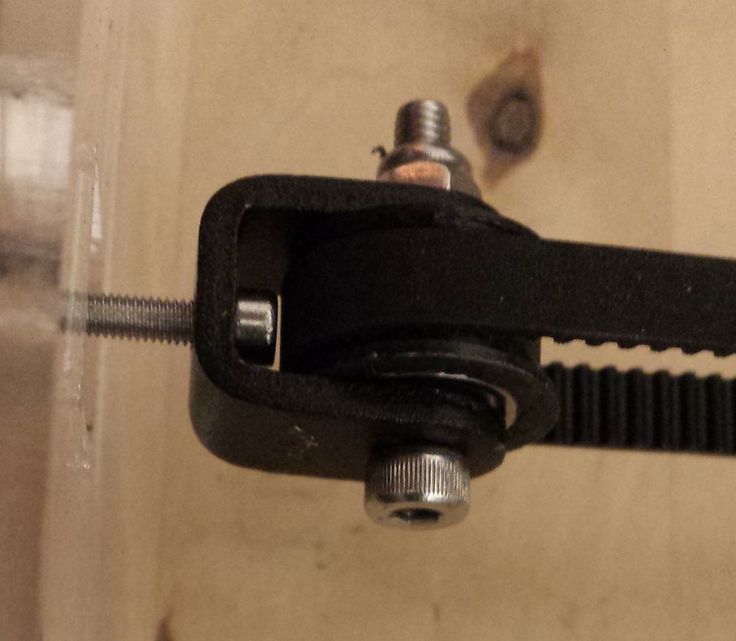

One solution was to replace smooth rollers with toothed ones. For this decision, they drown with the arguments “smooth on smooth, teeth on jagged”. But then we were in the army, there we clearly learned the rule "Round to carry, square - to roll." Therefore, you need to check everything yourself.

Ended up buying the "correct" 20T rollers from Powge. In order to completely beat off all possible problems, pulleys were also taken there, because. "Otherwise, there will be no correct effect." I also took the LL strap there, so that everything was from one manufacturer. In addition, a belt type with reduced vibration. Well, in order to kill all the arguments on the spot, stepped screws with an outer diameter of 4mm were taken to install the rollers.

In addition, a belt type with reduced vibration. Well, in order to kill all the arguments on the spot, stepped screws with an outer diameter of 4mm were taken to install the rollers.

And what happened as a result:

On the left - jagged, on the right - smooth.

Sadly noted that things only got worse with toothed rollers. Thought it might be the new belt. Returned smooth rollers. And with the new LL belt, the picture was no different from what it was with the old belt.

I don't know how to interpret this. Perhaps there is a difference in that flanged bearings are used as smooth rollers. Perhaps if you compare smooth 20T with gear 20T, everything will really be in favor of gear. But for now, a fact has remained for me, confirmed by experiment - smooth flanged bearings give better results than gear rollers.

Second part (Marlison Ballet)

All this was interesting and informative, but I had another upgrade ready on this topic, namely, the replacement of motors with 0. 9 degree ones. Moreover, the motors arrived earlier, but I decided to finish the topic of roller belts first, so that all this was more visual. Actually, we look at what happened in the end:

9 degree ones. Moreover, the motors arrived earlier, but I decided to finish the topic of roller belts first, so that all this was more visual. Actually, we look at what happened in the end:

All pictures are signed, we look and draw conclusions.

Here it is only necessary to add that in order to make it easier to see, gray PET-G with glitter was taken, the light was selected and the contrast was enhanced in Photoshop.

In real life, we can say that the new motors have an almost perfect surface. Small stripes disappeared completely. More precisely, they just became even smaller, and it is much more difficult to notice them. Large stripes have decreased in number, and where they remain, they have become smoother.

On the plus side, replacing motors is a fairly simple operation, if there is a setting of steps and current through EEPROM, then even a flashing is not required. Even replacing the rollers with gear ones required significantly more action and effort.

The relative minuses include the fact that the echo has become clearer. Apparently not extinguished by interference with small waves. But here's how to look, as a result, complex shapers may not be required to eliminate all vibrations.

But this is the next step. In the meantime, a number of other upgrades are already in the queue.

Rollers ender 3 pro vibration

Follow author

Follow

Don't want

27

More interesting articles

43

Subscribe to the author

Subscribe

Don't want

All health!

I have already assembled and set up a machine for broaching PET tape from a bottle. ..

..

Read more

3

Follow author

Subscribe

Don't want

Spoiler - M25 saves us

Preamble

Owners of consumer ...

Read more

168

Subscribe to the author

Subscribe

Don't want

Quite recently PRUSIA announced its product MMU2, which is a system...

Read more

Rollers for 3d printer in Ukraine. Prices for rollers for a 3d printer at Prom.ua 9Filament for ABS 1.75 mm, purple

in a warehouse in Vyshgorod

Delivery in Ukraine

360 UAH

324 UAH

Buy

3DPLAST - Producer of Plastic for 3D Press

ABS (ABS) Plastic for 3D printer, 1.75 mm, red

in a warehouse in Vyshgorod

Delivery in Ukraine

360 UAH

324 UAH

Buy

3DPLAST - Plastic Printing Printing Plastic ABS (ABS) Plastic for 3D Printer, 1. 75 mm, Blue

75 mm, Blue

In stock in Vyshhorod

Delivery across Ukraine

360 UAH

324 UAH

Buy

0003

in a warehouse in Vyshgorod

Delivery in Ukraine

360 UAH

324 UAH

Buy

3DPLAST - Plastic Printing Printing Plastic ABS (ABS) Plastic for 3D Printer, 1.75 mm, colorless

In a warehouse in Vyshgorod

Delivery in Ukraine

360 UAH

324 UAH

Buy

3DPLAST - Plastic Production manufacturer

Tozhtubnik rivet 20, diameter 8 mm, pulley GT2 6mm 3D printer RT 9Ol000 Toothed roller 60, diameter 8mm, GT2 pulley 6mm for 3D printer RT

Delivery across UkraineOl000 166.04 UAH

83.02 UAH

Buy

Karamell Online Store

Toothed roller 60, diameter 5mm, GT2 pulley 6mm 3D printer KR

Delivery across Ukraine

8 0003

252.09 UAH

Buy

Online store Karamell

Tough video 60, diameter 8 mm, pulley GT2 6mm 3D printer KR

504. 18 UAH

18 UAH

252.09 GRN

Buy

online store Karamell

PLA (PLA) plastic for 3D printer White 1.75mm 0.75kg

In stock

Delivery across Ukraine

365 UAH

0003

Tough video 20, diameter 8 mm, pulp GT2 6mm 3D printer WL

Delivery in Ukraine

188.43 UAH

94.21 UAH

Webline

See also Tough roller 60, diameter 5mm, scroll GT2, ShKIV GT2 6mm 3D printer WL

Delivery in Ukraine

526.57 UAH

263.28 UAH

Buy

Webline

Tough roller 60, diameter 8mm, 3D 3D printer WL

Delivery 9000

003

526.57 UAH

263.28 UAH

Buy

Webline

Tough Rider Pip 2GT 20 teeth 8MM for 3D printer (17100)

Delivery

28 UAH

Buy

Beegreen 9000 , belt pulley GT2 5mm 20 teeth for 3D printer

In stock

Delivery across Ukraine

printer 9Ol000 hryvnia

Buy

Ardi online store

Roller 20 teeth belt GT2, shaft 5 mm for 3D printer

In stock

Delivery across Ukraine

50.