Full 3d printed gun

The real 3D printed guns

Stay up to date with everything that is happening in the wonderful world of AM via our LinkedIn community.

Is it possible to almost entirely 3D print a functioning firearm? It may be. But only if your name is Beretta and you have been pioneering manufacturing processes in the firearms industry for five centuries. Beretta, the oldest industrial dynasty in the world, recorded its first transaction on October 3, 1526, when master gun-barrel maker Bartolomeo Beretta sold 185 arquebus barrels to the Republic of Venice for 296 ducats.

Fast forward to the 21st century. Beretta Holding has a global presence, spanning 14 different brands and generating yearly revenues of nearly $1 billion, with the US as its largest market. The Beretta factory near Brescia, Italy, produces some of the most precise and trusted firearms for law enforcement, military, and security around the world. Precision is key: Beretta has been forging hunters for 500 years and is a leader in shooting sports. At the last two editions of the Olympic Games, Beretta’s athletes took 10 out of 15 medals in 2016 (as many as the 20th placed nation) and 9 out of 10 in 2020.

Over the past century, starting with Pietro Beretta in 1903, Beretta’s Presidents have invested in modernizing, digitizing and automating their production processes. The latest initiative, under the current President and CEO of Beretta and VP of Beretta Holdings, Franco Gussalli Beretta, is the additive manufacturing laboratory, featuring both metal and polymer additive manufacturing capabilities. We had the unique opportunity to visit this laboratory and learn from Marco Bassoli, Firearm Research & Product Development Director, and Gianmarco Chiari, Process Engineer, how 3D printing is used to make models and functional prototypes, with the sight set on serial production of final parts.

The Beretta factory is adjacent to the magnificent Villa Beretta, connecting past and future.A truly digital workflow

Attached to the beautiful, centuries-old Villa Beretta, the factory is a state-of-the-art, highly automated facility with capacity of up to 1,000 handguns and several hundred shotguns per day. Because of the scale, the tight tolerances and the high-quality materials involved, manufacturing is carried out via formative and advanced subtractive processes. The Machining Department houses lines of dozens of 5-axis CNC systems that churn out parts day and night, with minimal human operators.

Because of the scale, the tight tolerances and the high-quality materials involved, manufacturing is carried out via formative and advanced subtractive processes. The Machining Department houses lines of dozens of 5-axis CNC systems that churn out parts day and night, with minimal human operators.

Mr. Bassoli’s team works on digitalizing these workflows, from FEM analysis of models all the way to ERP and PLM implementation. “We apply these tools to all products and workflows, from the very beginning of a new product’s development all the way to production and beyond,” Mr. Bassoli explains, “we are working towards implementing a full digital twin of the value chain, so that we can simulate every aspect of the workflow.”

Today all these advanced digital capabilities are implemented in digital subtractive workflows – to a degree that only few companies around the world have achieved – however additive manufacturing already plays a part by enabling much faster and more cost-effective development cycles. With such advanced levels of digitalization, it should come as no surprise that Beretta began implementing AM processes for prototyping very early, both through external suppliers and an internal machine.

With such advanced levels of digitalization, it should come as no surprise that Beretta began implementing AM processes for prototyping very early, both through external suppliers and an internal machine.

Functional gun prototypes

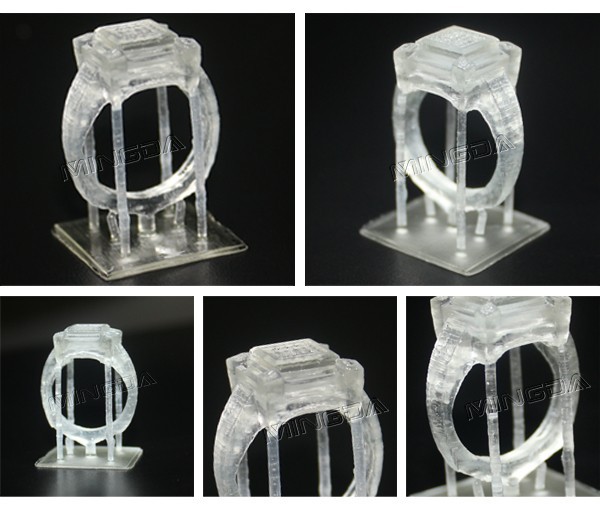

“We got our first SLA 3D printer from 3D Systems in 2004,” Bassoli says, “and we used it to start making non-functional models. It was helpful but we what we really needed was the ability to make prototypes that we could test so we used 3D printing to produce silicone molds, to then make the functional prototypes in polyurethane.”

The mold to manufacture a Beretta final product can cost several tens of thousands of dollars. Producing such a mold early in the development cycle to test a part is simply not feasible but the company needs functional test parts. “The silicone molds offered us an initial solution but the introduction of SLS technology in 2014 changed everything,” Bassoli says. “Using a glass-fiber-reinforced nylon powder we are now able to produce hundreds of polymer components for prototypes that we can test for form, function and stress resistance. It was a game changer.” It should be highlighted that parts made through this technology are not parts that can withstand the direct force of the shot, such as the gun barrel.

“Using a glass-fiber-reinforced nylon powder we are now able to produce hundreds of polymer components for prototypes that we can test for form, function and stress resistance. It was a game changer.” It should be highlighted that parts made through this technology are not parts that can withstand the direct force of the shot, such as the gun barrel.

As Bassoli explained, reinforced nylon is an ideal material for many gun and rifle final parts, even for parts produced by traditional means (i.e. injection molding). It is sufficiently strong and at the same time sufficiently elastic to withstand the stresses generated by the forces due to a projectile’s explosion. It’s even better than other high-performance plastics such as PEEK, which are commonly used for metal replacement but are too stiff to be used in firearms.

In the additive lair

The additive manufacturing laboratory at Beretta today houses the large SLS system with a post-processing station for functional models and a material jetting system for rapid production of visual models. It also has a large, single laser metal PBF 3D printer. It is located inside the larger section dedicated to R&D and small series production. These are getting increasingly larger and can reach a few thousand pieces. In some cases, they are used for bridge manufacturing and are mostly produced using subtractive processes.

It also has a large, single laser metal PBF 3D printer. It is located inside the larger section dedicated to R&D and small series production. These are getting increasingly larger and can reach a few thousand pieces. In some cases, they are used for bridge manufacturing and are mostly produced using subtractive processes.

But AM is also increasingly playing a role in providing functional parts as delivery times get shorter and shorter. “We usually get requests to deliver parts or products yesterday,” Bassoli jokes. “With AM we can now at least deliver them on the same day.” To further prove this point, Gianmarco Chiari showed us a largely 3D printed automatic submachine gun that was delivered to the Italian Carabinieri, in over 30 units that were in use for testing purposes, while awaiting delivery of the final stock.

The state-of-the-art additive manufacturing lab is located in the area dedicated to the production of small series and R&D.The importance of rapid functional prototyping at a company like Beretta should not be underestimated as firearms production revolves around dozens of different product models that are optimized for ergonomics, portability, weight, and comfort and can be highly customized. These include sporting and hunting rifles and shotguns all the way to fully automatic, assault weapons for the armed forces and police of many countries around the world. Beretta offers these products along with accessories and clothing. Rifle customization and luxury collector items are also significant businesses where AM could play a part. Serial production of gun and rifle parts using AM is still far away for both metal and polymers, although some applications could start being envisioned.

These include sporting and hunting rifles and shotguns all the way to fully automatic, assault weapons for the armed forces and police of many countries around the world. Beretta offers these products along with accessories and clothing. Rifle customization and luxury collector items are also significant businesses where AM could play a part. Serial production of gun and rifle parts using AM is still far away for both metal and polymers, although some applications could start being envisioned.

Setting sights on production

“Costs are just prohibitive at this time to think that we could use AM for larger productions,” says Bassoli, “Productivity is too low,” he adds, referring to metal parts and components. “In addition, every material needs to be validated for every single new part and the process can take a long time.” To date Beretta has validated different kinds of metals alloys for use with AM. More materials are on the way, but they cannot compare to some of the alloys used for the gun barrels: their quality is a distinguishing element of all Beretta products. The process and materials have been fine-tuned for centuries.

The process and materials have been fine-tuned for centuries.

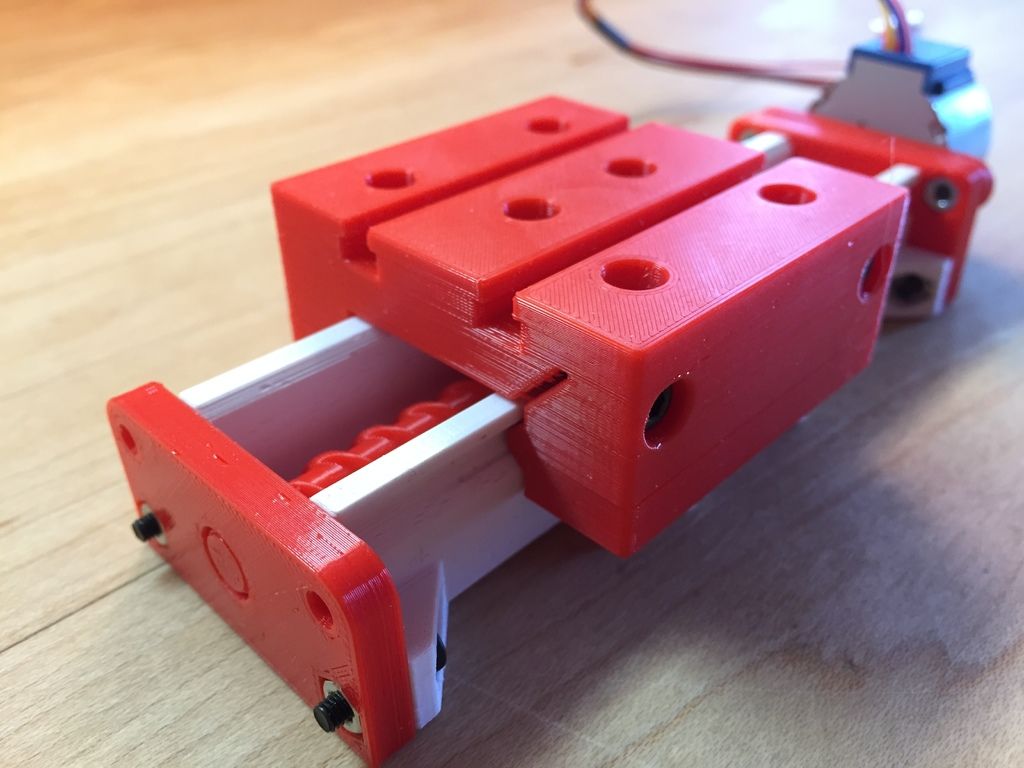

Many of the smaller metal components require extremely tight tolerances which means that not only they have to withstand forces and ensure the utmost levels of reliability and repeatability, but also, they must be finished subtractively when they come out of the 3D printer. “Designing the parts for additive manufacturing can reduce the amount of finishing required but not eliminate it completely and that contributes to drive up costs,” Bassoli explains.

Production of customized, collectible items has been explored as a possibility and also as a way to introduce DfAM concepts.To implement metal AM into production – which is still the final objective – it became necessary for Bassoli and his team to implement some serious lateral thinking. “When we decided to bring the metal 3D printer in-house in 2018, we leveraged a regional fund and worked to re-imagine a rifle through the new geometric possibilities offered by additive manufacturing, reviewing completely the classical design mindset,” Bassoli says. The first result was a highly customized rifle with a generatively designed stock 3D and a customized handle, all 3D printed in metal.

The first result was a highly customized rifle with a generatively designed stock 3D and a customized handle, all 3D printed in metal.

“It was an exercise to understand the capabilities of this technology and it has helped our team understand many aspects of using metal AM, Bassoli says. “We understood is that costs are currently still too high for serial production. While it could make sense to use AM to make certain collector and unique items, it remains to be seen how many requests we would receive for the items featuring the unique geometries that AM can create.”

Bassoli and his team are at the same time very optimistic about future the possibilities of AM and they are convinced that adoption will continue to grow. “We realize that it is necessary to begin working with, and understanding, the technology now. If you wait until it’s widely adopted it will be too late,” he recognizes: “it’s a matter of identifying the applications where it makes sense to use it.”

A silent transition

This brings us to one of the highlights of our visit: Beretta already has identified the first key application for direct metal additive production: silencers. This is where AM’s capability to build highly complex geometries as single parts can provide significant added value. Silencers are used to reduce the noise and blast of the firearm. They are usually made of multiple “ring-like” parts that are screwed and then bonded or welded together. Each one of these parts provides a layer that reduces and contains the noise and gases released by firing.

This is where AM’s capability to build highly complex geometries as single parts can provide significant added value. Silencers are used to reduce the noise and blast of the firearm. They are usually made of multiple “ring-like” parts that are screwed and then bonded or welded together. Each one of these parts provides a layer that reduces and contains the noise and gases released by firing.

“With additive manufacturing, we can make these as single parts, with a complex internal structure that does not require supports if it’s properly designed,” Bassoli explains. This makes them extremely effective in dispersing the gases that accumulate and can be detrimental to both the operator and the weapon itself. But even more importantly, from a manufacturing point of view, is that this is an additive manufacturing application that has already been validated both technically and commercially. “We are able to assess the exact productivity of our metal 3D printer for this product – Bassoli says – and that means we can define both the price and our ability to deliver these to our customers. ” The product is already available on the market (where allowed by local laws) and can be ordered. Beretta is already envisioning a distributed manufacturing network where these are produced on location by Beretta partners.

” The product is already available on the market (where allowed by local laws) and can be ordered. Beretta is already envisioning a distributed manufacturing network where these are produced on location by Beretta partners.

That’s the beauty of digital, additive manufacturing. Once an application and its workflow has been shown to be profitable and sustainable, making more of them comes down to adding more 3D printers. Seeing by the number of CNC machines already working full time at Beretta, that should not be difficult.

DEFCAD

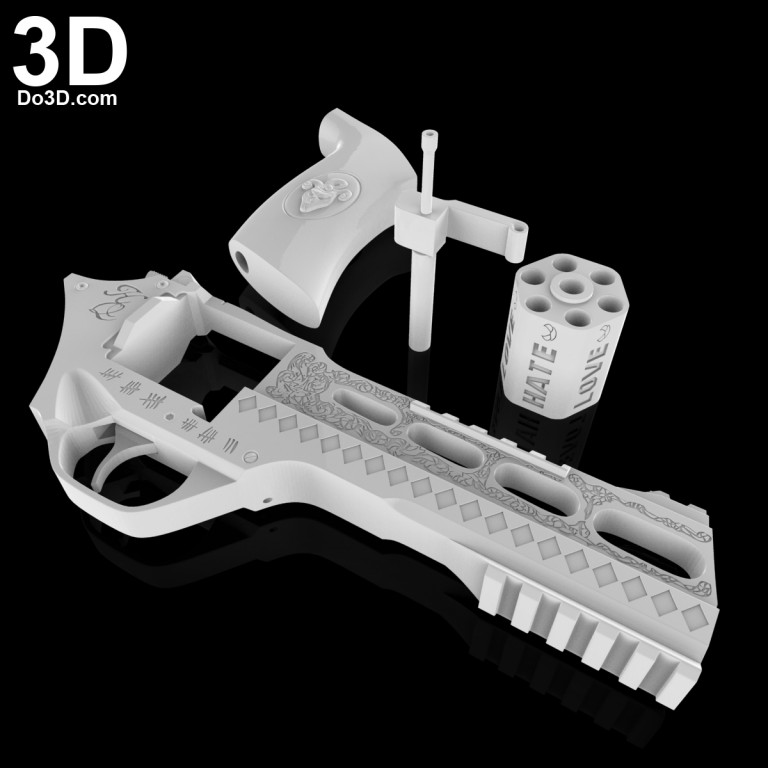

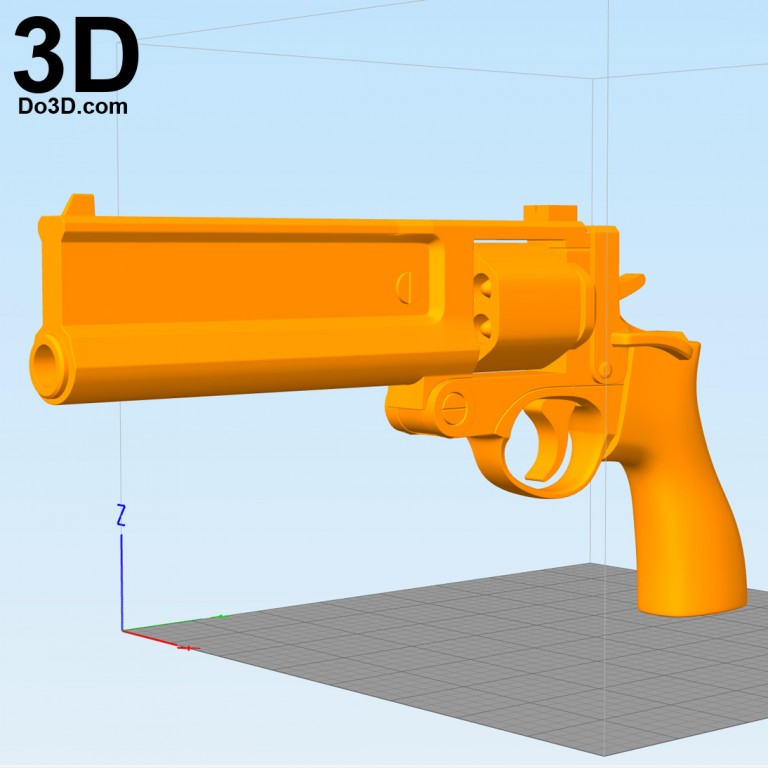

King Cobra 9

Newest release from Derwood and Mussy - the world's most advanced 3D-printed gun

Access Today

4.44

Rating based on 46 reviews.

4.22

Rating based on 100 reviews.

4.52

Rating based on 69 reviews.

3.91

Rating based on 56 reviews.

4.59

Rating based on 29 reviews.

4.29

Rating based on 73 reviews.

4.39

Rating based on 13 reviews.

5

Rating based on 10 reviews.

5

Rating based on 9 reviews.

3.84

Rating based on 25 reviews.

4.78

Rating based on 9 reviews.

4.50

Rating based on 2 reviews.

4.86

Rating based on 14 reviews.

5

Rating based on 2 reviews.

4.25

Rating based on 4 reviews.

4.24

Rating based on 86 reviews.

2.75

Rating based on 12 reviews.

3.74

Rating based on 72 reviews.

3.96

Rating based on 22 reviews.

4.25

Rating based on 20 reviews.

4.73

Rating based on 15 reviews.

4.35

Rating based on 43 reviews.

4

Rating based on 4 reviews.

4.48

Rating based on 25 reviews.

4. 08

08

Rating based on 13 reviews.

5

Rating based on 6 reviews.

5

Rating based on 1 reviews.

4.50

Rating based on 4 reviews.

4.04

Rating based on 196 reviews.

5

Rating based on 18 reviews.

4.67

Rating based on 6 reviews.

3.93

Rating based on 15 reviews.

3.85

Rating based on 13 reviews.

4.23

Rating based on 13 reviews.

4.50

Rating based on 2 reviews.

4.92

Rating based on 12 reviews.

4.44

Rating based on 46 reviews.

4.22

Rating based on 100 reviews.

4.52

Rating based on 69 reviews.

3.91

Rating based on 56 reviews.

4.59

Rating based on 29 reviews.

4.39

Rating based on 13 reviews.

5

Rating based on 10 reviews.

5

Rating based on 9 reviews.

4.50

Rating based on 2 reviews.

4.86

Rating based on 14 reviews.

3.96

Rating based on 22 reviews.

4.25

Rating based on 20 reviews.

4.73

Rating based on 15 reviews.

4.35

Rating based on 43 reviews.

4

Rating based on 4 reviews.

5

Rating based on 18 reviews.

4.67

Rating based on 6 reviews.

3.93

Rating based on 15 reviews.

3.85

Rating based on 13 reviews.

4.23

Rating based on 13 reviews.

4.50

Rating based on 2 reviews.

4.92

Rating based on 12 reviews.

4.71

Rating based on 7 reviews.

4.14

Rating based on 29 reviews.

4.11

Rating based on 9 reviews.

4. 33

33

Rating based on 82 reviews.

4.42

Rating based on 36 reviews.

3.81

Rating based on 41 reviews.

4.29

Rating based on 17 reviews.

4.05

Rating based on 22 reviews.

3.86

Rating based on 14 reviews.

3.63

Rating based on 38 reviews.

3.67

Rating based on 21 reviews.

5

Rating based on 2 reviews.

3.70

Rating based on 27 reviews.

5

Rating based on 2 reviews.

4.25

Rating based on 4 reviews.

4.24

Rating based on 86 reviews.

2.75

Rating based on 12 reviews.

3.74

Rating based on 72 reviews.

4.48

Rating based on 25 reviews.

4.08

Rating based on 13 reviews.

5

Rating based on 6 reviews.

5

Rating based on 1 reviews.

4.50

Rating based on 4 reviews.

4.04

Rating based on 196 reviews.

4.90

Rating based on 10 reviews.

4.42

Rating based on 26 reviews.

4.33

Rating based on 3 reviews.

5

Rating based on 2 reviews.

4.67

Rating based on 3 reviews.

5

Rating based on 2 reviews.

4.67

Rating based on 3 reviews.

2

Rating based on 1 reviews.

4.50

Rating based on 2 reviews.

3.78

Rating based on 18 reviews.

5

Rating based on 1 reviews.

4.04

Rating based on 52 reviews.

5

Rating based on 8 reviews.

2.89

Rating based on 63 reviews.

2.40

Rating based on 15 reviews.

3.90

Rating based on 20 reviews.

5

Rating based on 2 reviews.

4.67

Rating based on 21 reviews.

4.90

Rating based on 10 reviews.

5

Rating based on 2 reviews.

3.84

Rating based on 25 reviews.

4.78

Rating based on 9 reviews.

4.75

Rating based on 4 reviews.

5

Rating based on 4 reviews.

4

Rating based on 4 reviews.

3.75

Rating based on 4 reviews.

4.25

Rating based on 8 reviews.

4.82

Rating based on 11 reviews.

5

Rating based on 1 reviews.

4.71

Rating based on 7 reviews.

3.33

Rating based on 6 reviews.

4.25

Rating based on 4 reviews.

4.67

Rating based on 3 reviews.

4

Rating based on 1 reviews.

5

Rating based on 2 reviews.

4.17

Rating based on 6 reviews.

3.67

Rating based on 3 reviews.

3.20

Rating based on 10 reviews.

4.50

Rating based on 2 reviews.

4.33

Rating based on 3 reviews.

4

Rating based on 1 reviews.

5

Rating based on 3 reviews.

5

Rating based on 4 reviews.

1.60

Rating based on 5 reviews.

2.83

Rating based on 12 reviews.

5

Rating based on 1 reviews.

3.50

Rating based on 8 reviews.

5

Rating based on 2 reviews.

5

Rating based on 2 reviews.

4.67

Rating based on 3 reviews.

3.17

Rating based on 24 reviews.

4.78

Rating based on 9 reviews.

5

Rating based on 5 reviews.

2.33

Rating based on 24 reviews.

4

Rating based on 1 reviews.

5

Rating based on 2 reviews.

4.46

Rating based on 80 reviews.

2.43

Rating based on 7 reviews.

2.75

Rating based on 4 reviews.

4.46

Rating based on 13 reviews.

5

Rating based on 2 reviews.

5

Rating based on 4 reviews.

4.86

Rating based on 7 reviews.

4.60

Rating based on 5 reviews.

5

Rating based on 2 reviews.

4.25

Rating based on 4 reviews.

5

Rating based on 1 reviews.

5

Rating based on 1 reviews.

5

Rating based on 4 reviews.

2

Rating based on 7 reviews.

3.11

Rating based on 9 reviews.

5

Rating based on 1 reviews.

3.40

Rating based on 5 reviews.

3.40

Rating based on 5 reviews.

4.29

Rating based on 7 reviews.

1.64

Rating based on 11 reviews.

4

Rating based on 7 reviews.

4.29

Rating based on 73 reviews.

5

Rating based on 15 reviews.

5

Rating based on 6 reviews.

4.50

Rating based on 2 reviews.

4.50

Rating based on 2 reviews.

5

Rating based on 2 reviews.

4.67

Rating based on 3 reviews.

4

Rating based on 4 reviews.

5

Rating based on 2 reviews.

5

Rating based on 2 reviews.

5

Rating based on 4 reviews.

5

Rating based on 1 reviews.

5

Rating based on 2 reviews.

5

Rating based on 3 reviews.

4.67

Rating based on 3 reviews.

4.50

Rating based on 2 reviews.

4.50

Rating based on 4 reviews.

5

Rating based on 1 reviews.

5

Rating based on 1 reviews.

4.50

Rating based on 2 reviews.

5

Rating based on 1 reviews.

5

Rating based on 1 reviews.

3.40

Rating based on 5 reviews.

4.50

Rating based on 2 reviews.

1.80

Rating based on 5 reviews.

4.50

Rating based on 2 reviews.

5

Rating based on 2 reviews.

5

Rating based on 2 reviews.

5

Rating based on 2 reviews.

1

Rating based on 3 reviews.

1.80

Rating based on 5 reviews.

5

Rating based on 2 reviews.

4.67

Rating based on 3 reviews.

4.33

Rating based on 3 reviews.

1

Rating based on 1 reviews.

2

Rating based on 4 reviews.

2

Rating based on 4 reviews.

2

Rating based on 4 reviews.

2

Rating based on 4 reviews.

3.33

Rating based on 3 reviews.

1

Rating based on 1 reviews.

1

Rating based on 3 reviews.

5

Rating based on 2 reviews.

4.33

Rating based on 3 reviews.

2

Rating based on 4 reviews.

2

Rating based on 4 reviews.

2

Rating based on 4 reviews.

1

Rating based on 1 reviews.

5

Rating based on 1 reviews.

3.50

Rating based on 2 reviews.

5

Rating based on 1 reviews.

3

Rating based on 2 reviews.

4.67

Rating based on 3 reviews.

4.59

Rating based on 29 reviews.

1.80

Rating based on 5 reviews.

4.67

Rating based on 3 reviews.

1

Rating based on 1 reviews.

3.33

Rating based on 3 reviews.

4.67

Rating based on 3 reviews.

4.33

Rating based on 3 reviews.

1.80

Rating based on 5 reviews.

2

Rating based on 4 reviews.

1.80

Rating based on 5 reviews.

2

Rating based on 4 reviews.

2

Rating based on 4 reviews.

2

Rating based on 4 reviews.

2

Rating based on 4 reviews.

2

Rating based on 4 reviews.

2

Rating based on 4 reviews.

1.80

Rating based on 5 reviews.

2

Rating based on 4 reviews.

2

Rating based on 4 reviews.

1.80

Rating based on 5 reviews.

5

Rating based on 1 reviews.

2.20

Rating based on 5 reviews.

4.50

Rating based on 2 reviews.

2

Rating based on 4 reviews.

4.50

Rating based on 4 reviews.

3.50

Rating based on 8 reviews.

1

Rating based on 1 reviews.

2.33

Rating based on 3 reviews.

2.33

Rating based on 3 reviews.

3.25

Rating based on 4 reviews.

2

Rating based on 4 reviews.

4.67

Rating based on 3 reviews.

5

Rating based on 2 reviews.

2

Rating based on 4 reviews.

3.20

Rating based on 5 reviews.

2.33

Rating based on 3 reviews.

5

Rating based on 1 reviews.

5

Rating based on 2 reviews.

2.33

Rating based on 3 reviews.

2.33

Rating based on 3 reviews.

3.67

Rating based on 3 reviews.

4.67

Rating based on 3 reviews.

5

Rating based on 2 reviews.

4.71

Rating based on 7 reviews.

2.83

Rating based on 12 reviews.

5

Rating based on 2 reviews.

5

Rating based on 2 reviews.

4.67

Rating based on 3 reviews.

4.50

Rating based on 2 reviews.

3

Rating based on 3 reviews.

5

Rating based on 2 reviews.

4.50

Rating based on 2 reviews.

4.50

Rating based on 2 reviews.

5

Rating based on 1 reviews.

4

Rating based on 4 reviews.

3.67

Rating based on 3 reviews.

5

Rating based on 2 reviews.

5

Rating based on 1 reviews.

5

Rating based on 1 reviews.

5

Rating based on 1 reviews.

4.67

Rating based on 3 reviews.

4

Rating based on 4 reviews.

5

Rating based on 1 reviews.

5

Rating based on 1 reviews.

4.50

Rating based on 4 reviews.

4.50

Rating based on 2 reviews.

5

Rating based on 2 reviews.

4.50

Rating based on 2 reviews.

5

Rating based on 2 reviews.

4.67

Rating based on 3 reviews.

5

Rating based on 2 reviews.

4.50

Rating based on 2 reviews.

4.50

Rating based on 2 reviews.

5

Rating based on 2 reviews.

5

Rating based on 4 reviews.

5

Rating based on 6 reviews.

5

Rating based on 1 reviews.

5

Rating based on 3 reviews.

DEFCAD Newsletter:

Subscribe to the DEFCAD newsletter

×Defects in the structure of a 3D printed object issued by the printer that created it

3D printing

Complexity 3.7

Zhengxiong Li et al. / CCS 2018

American researchers have learned to identify the 3D printer on which it was printed by the microstructure of a 3D printed object. The principle of operation of the system is based on the fact that each specific 3D printer, when printing, creates small defects in the structure of an object that are specific to it and act as "fingerprints". In the future, this technology could be used to track the provenance of 3D printed weapons, according to a paper presented at CCS 2018.

In the future, this technology could be used to track the provenance of 3D printed weapons, according to a paper presented at CCS 2018.

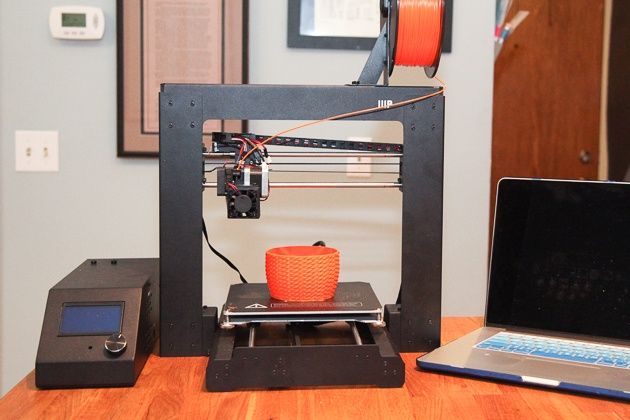

3D printing has many advantages over other production methods. Initially, it was considered mainly as a faster way to create intermediate prototypes. Subsequently, thanks to the development of 3D printers, it began to be used as an independent production method that allows you to create parts of a very complex shape. In addition, 3D printing allows people not to depend on other organizations and create the items they need on their own. For example, in 2013, an American enthusiastic gunsmith Cody Wilson printed a working pistol for the first time and showed that a full-fledged weapon could be created in this way. This caused great concern among the US authorities due to the inability to track the creation and circulation of such weapons, and as a result, the court banned the creation of a library of 3D printed weapons. You can read more about the history of the development of printed weapons in the United States in our material “Freedom to Print Weapons”.

Liberator

3D Printed PistolVvzvlad / Wikimedia Commons

Share

Engineers led by Wenyao Xu of the State University of New York at Buffalo set out to develop a technology that could identify the origin of a weapon, even if it was made with a home 3D printer. In their work, they proceeded from the fact that during the production of 3D printers, inevitable imperfections are formed in their parts that affect the printing process. In particular, due to the unevenness of the filament supply discs, the volume of material passing through the extruder changes periodically. Also, uneven material supply and uneven sintering are caused by imperfections in the algorithms that regulate the heating of the thread. In addition, imperfections in the motors and gears cause the print head to move slightly less than ideal. Engineers conducted initial tests to test the hypothesis and found that the periodic pattern of stripes created during printing does indeed have a non-uniform structure depending on the printer used.

Structure of the same model printed on different printers

Zhengxiong Li et al. / CCS 2018

Share

The system created by the researchers works as follows. First you need to get pictures of the surface of the object, and for this a regular office scanner is enough. The surface images are processed by an algorithm that analyzes the texture and calculates 20 texture element distribution parameters. After that, these parameters are passed to the classifier, which, based on the support vector machine and the k-nearest neighbor method, assigns the texture to a known 3D printer from the database, or indicates that the object was printed on a printer that is not in the database.

Method diagram

Zhengxiong Li et al. / CCS 2018

Share

To test the system, engineers used 14 printers in six different models, using popular printing methods such as FDM and SLA, and popular materials such as ABS, PLA, and photopolymer. The developers used 2100 images to train the classifier and 1400 other images to test. As a result, the accuracy of printer identification by the texture of the printed object turned out to be 92 percent.

The developers used 2100 images to train the classifier and 1400 other images to test. As a result, the accuracy of printer identification by the texture of the printed object turned out to be 92 percent.

Previously, engineers have repeatedly studied 3D printing defects and suggested ways to eliminate or exploit them. For example, recently American specialists taught a 3D printer to periodically evaluate print quality and detect deviations from the program, and last year, another group of engineers, on the contrary, proposed introducing deliberate defects in 3D models to protect against piracy.

Grigory Kopiev

Weapons and 3D printing: nothing is impossible

In recent years, 3D printing has reached a qualitatively new level in its development. The equipment, which was initially positioned as purely industrial, smoothly migrated to the desktop for ordinary users. Today, a desktop 3D printer can handle complex mechanical prototyping with ease. In addition to flower pots and jewelry, modern additive printers make it possible to produce designer shoes, engineering tools, and even quadcopters at home.

In addition to flower pots and jewelry, modern additive printers make it possible to produce designer shoes, engineering tools, and even quadcopters at home.

Use our services

It was only a matter of time before 3D printed weapons. It has now become available to everyone. You can talk a lot about how dangerous it is that anyone, armed with an inexpensive FDM printer and a spool of plastic filament, can print military firearms in a matter of hours. We will leave this topic to be eaten up by journalists, while we ourselves will focus on the achievements of additive technologies.

Liberator

It is believed to be the first 3D printed firearm. Compact pistol, for which you will need cartridges of 9x17 millimeters (US marking). Most of the structure is created using additive technology. In this case, the instructions can be found in the public domain. It was posted by the author of the product, Cody Wilson.

The original pistol could only fire one shot. After that, the weapon became unusable. During the tests, it was found that Liberator, alas, gives a lot of misfires (almost half the time).

After that, the weapon became unusable. During the tests, it was found that Liberator, alas, gives a lot of misfires (almost half the time).

The updated version of the Lulz Liberator is free from the above disadvantages. It is characterized by an increased margin of safety (up to 8 shots).

Сolt M1911

3 years ago Solid Сoncepts presented to the world community one more model of quite effective 3D printed weapon. The main difference between the Solt M1911 and the Liberator was that it looked more like a conventional firearm. From the name it is clear that the developers used the original Colt M19 model as the basis11.

A 3D printed version of the pistol was made from Inconel 625. It is a chromium/nickel/molybdenum metal alloy. Thanks to this, about 2000 shots can be fired from the weapon with a minimum number of misfires. The model is characterized by a high level of operational safety.

The model is characterized by a high level of operational safety.

Feinstein for the AR-15 and AK-47

Defense Distributed, the company that made the Liberator didn't stop there. She set about creating functional horns for the Kalashnov and R-15 automatic weapons. Feinstein showed itself perfectly in fire tests.

New rifle horns feature a smooth texture and light weight. True, due to the relatively high cost, it is not yet possible to launch mass production of these products.

The design of such elements is the first step towards the development of mass production of 3D weapons, including automatic ones.

Michael Gaslick and his experiments

This American designer managed to quite successfully print several parts for the AR-15 self-loading rifle on a regular Stretasus:

- frame;

- stock;

- lower receiver.

The use of such elements made it possible to turn the submachine gun into an ordinary pistol. If the legislature did not restrict the activities of makers in this direction, Michael would have been able to make a full-fledged rifle.

Shutu-MP1

An interesting example of a 3D printed weapon was posted on YouTube. A certain "derwoodvw" made a video in which tests were carried out on this firearm. It looks like a mini pistol / machine gun, although, apparently, the weapon does not have an automatic fire mode.

Almost all parts of the product were printed using additive technology. Only 5% are original items:

- springs;

- bolts;

- barrel.

Of course, they could also be created on a 3D printer. But then the safety of the operation of weapons would be a big question. Deformation of the pistol/machine gun occurs after the 18th shot.

Despite the functionality of the Shutu-MP1, its author does not want to publish instructions for its manufacture on the net.

Parts from Stankoprom

The printing of weapons, as it turned out, is a priority area for Russia as well. Domestic holding "Stankoprom", for example, launched the printing of parts for machine guns / pistols. The company wants to establish close cooperation with the TsNIItochmash and Kalashnikov concerns.

For this, specialists are already working on the production of elements from metal powder. Also considered are options for the production of products from polymer consumables. It is planned that the details will be used as testing of certain design solutions. Although the possibility of their full use in the process of assembling firearms is not excluded.

Good or bad?

The network does not stop arguing about what the printing of three-dimensional weapons entails? Supporters of such progress argue that there is nothing wrong with this, and everyone will be able to create means for personal protection at home.

On the other hand, this is an uncontrolled production of firearms that can be used to kill people.