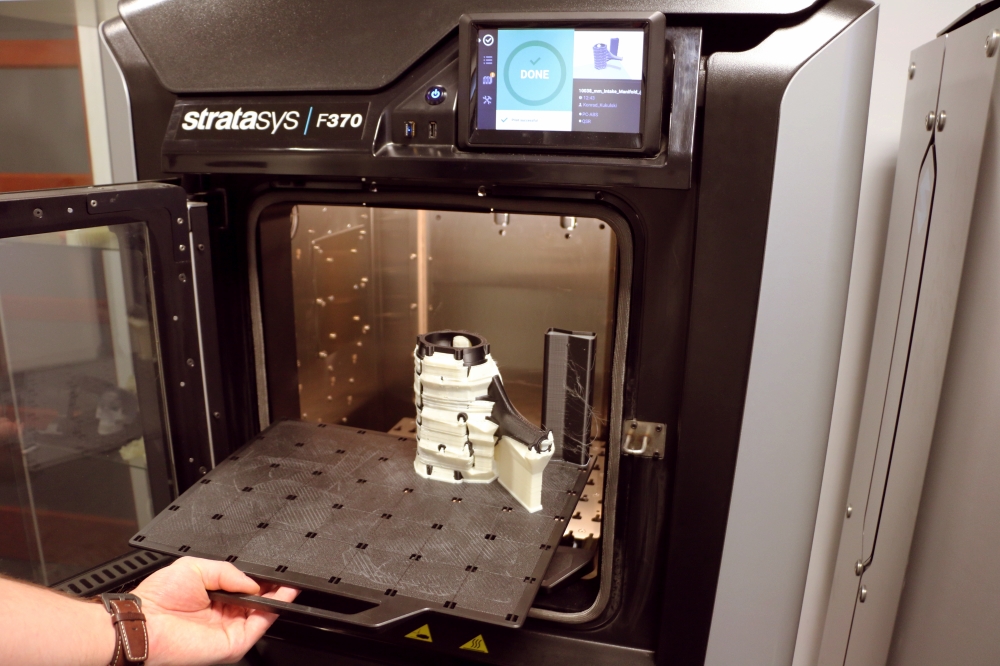

3D printer with dissolvable support

Which 3D Printer Under $1,000 Works Best With Soluble Supports?

Comprehensive guide to 5 low-cost dual-material FFF printing technologies in 2021/2022This story was originally published on www.fabbaloo.com (see Part 1 and Part 2).

“I don’t care about multi-color, I just want soluble supports,” writes a 3D printer user in a forum on dual-material 3D printing.

Sure, a model of a four-colored amazon rainforest frog would look great in your 3D printed collection. But enough users would agree that the true potential of dual-head printers lies in their ability to print soluble supports rather than a palette of colors.

A quick search on Google reveals dozens of soluble support filaments on the market. Most of them are based on well-known water-soluble polymers PVA and BVOH. But there are also new contestants coming out such as VXL from Xioneer that provide superior performance to PVA.

But printing a support-material combination is not the same as printing two colors of the same filament. So, which dual extrusion 3D printer is up to the task?

In general, multi-material FFF technologies can be classified into five categories – each with its own pros and contras when it comes to printing soluble supports.

Depending on how often you print, what support material you use, and how much you are willing to invest, you might even find the perfect match for your needs.

The good news: you can get a decent 3D printer in any of these categories for under $ 1,000. So read on.

1. Mixer 3D Printers: Lowest Price-Tag But Probably Not the Best Choice for PVA

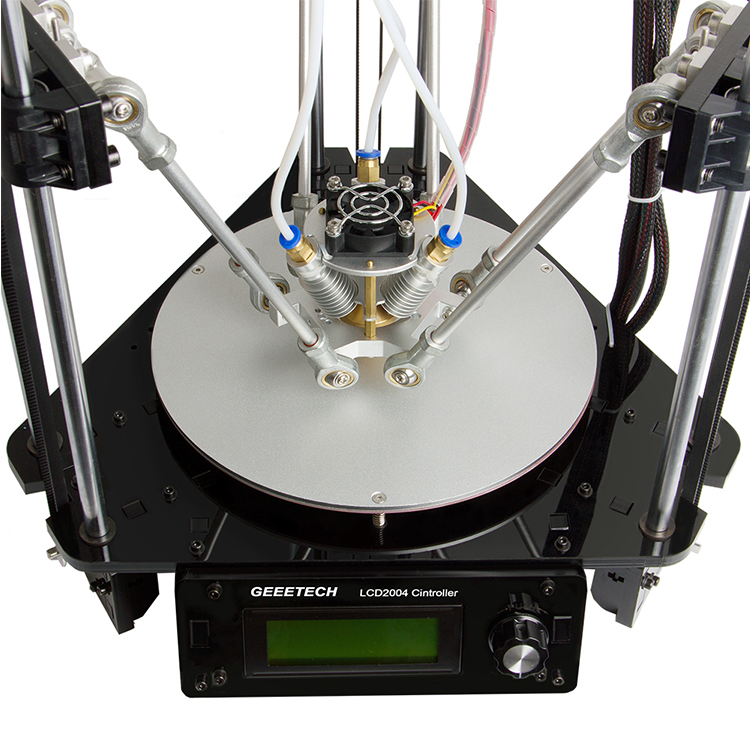

Mixer Hotend (Illustration by Xioneer)In 2014, the legendary 3D printer component manufacturer E3D came out with its “Cyclops” hot-end. The name says it all: It is a hot-end with two inlets, but only one outlet: the “eye.”

This mystical creature takes two filaments in, melts them inside, and extrudes a single strand of mixed material. It’s great for mixing colors and creating stunning color gradients in your parts using just two filaments.

But can it also print supports?

The mixer hot-end acts as a Y-splitter – letting you extrude either support or model material from a single nozzle – without mixing them together. So yes, it can print supports too.

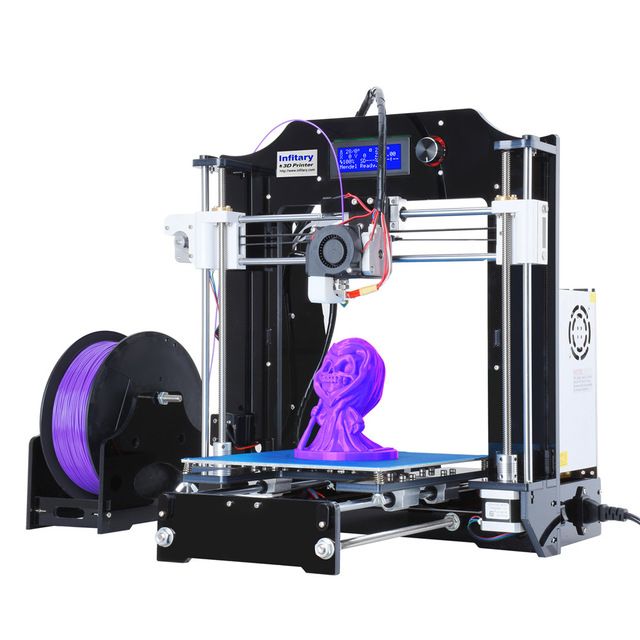

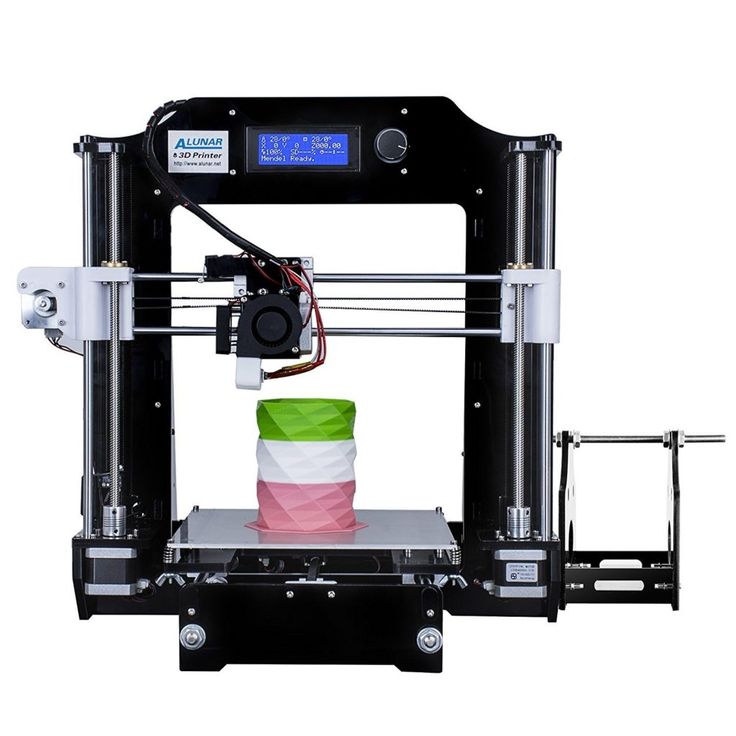

3D printers with a mixer hot-end like the Geeetech A10M sell from USD 230. This price tag is really hard to beat when it comes to something as sophisticated as dual-material 3D printing.

Nozzle calibration on these machines is straightforward because they use only one nozzle. No need to fiddle with extruder offsets, which are notorious in systems with two separate nozzles. So with a device like A10M you could start churning your complex models with supports soon after unboxing.

But before you grab your credit card to order an A10M, you might want to keep learning about some of the drawbacks.

Mixer hot-ends require you to print a purge tower with every print job. It is a way to clean the nozzle before switching materials and avoid material bleed in your parts.

But getting the right amount to purge can be tricky. Purge too much and you needlessly waste precious filament. Purge too little, and the residues of support filament will contaminate your model affecting part stability and surface quality in the end.

But one way or another: mixer hot-ends will always produce waste.

Besides, using PVA with a mixer hot-end is a challenge on its own.

PVA and similar water-soluble materials are very sensitive to heat. If you leave them lingering for too long in a hot nozzle, they will degrade and turn into a crusty mess – clogging your extruder.

So, with mixer hot-ends, you want to keep PVA flowing through your nozzle as much as possible. This means shorten time window to print model materials. In practice, you will print only smaller models to avoid a clogged nozzle when using a mixer hot-end.

One trick is to use more temperature-stable support material such as VXL from Xioneer. But if you absolutely need to stick to PVA, the only remedy seems to use two separate nozzles – each with its own temperature control.

2. Traditional Dual-Extruders: Work With PVA But Are a Challenge to Calibrate

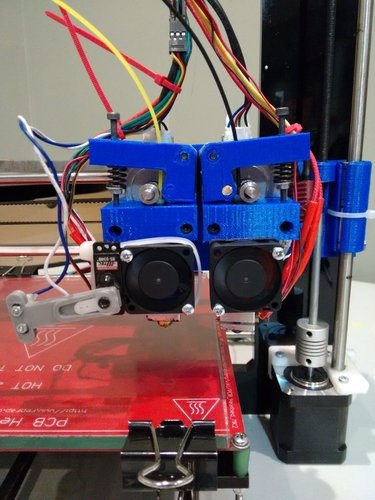

Traditional Dual Extruders (Illustration by Xioneer)What’s the benefit of using two nozzles (for model and support materials respectively) versus a single alá “Cyclops” nozzle?

Using two nozzles lets you cool PVA inside your support nozzle while you print your model material with another nozzle. This helps prevent PVA from overheating and eventually clogging your extruder.

But this requires some tweaking to get it right.

However, PVA will need at least a 20°C-50°C temperature drop to keep the material from degrading too quickly. This leads to long heat-up times for every layer, adding to hours of unproductive time throughout the entire print job.

One solution is to use a temperature-stable support material such as VXL instead. The material does not degrade as quickly as PVA inside a hot-end saving you the need to cool down your support nozzles.

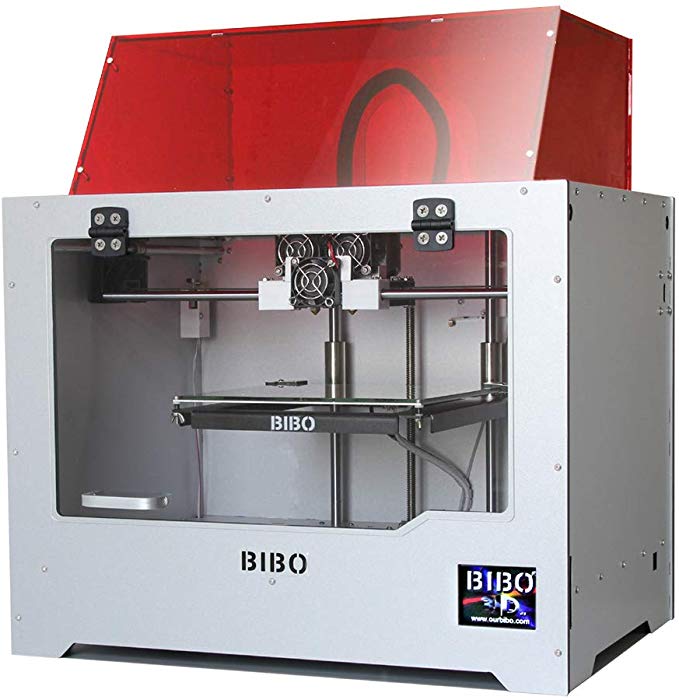

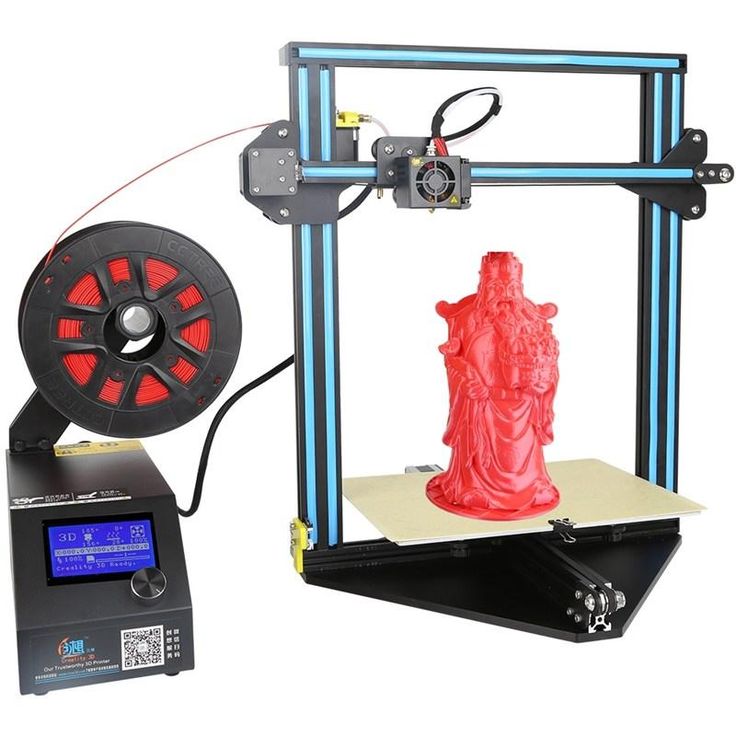

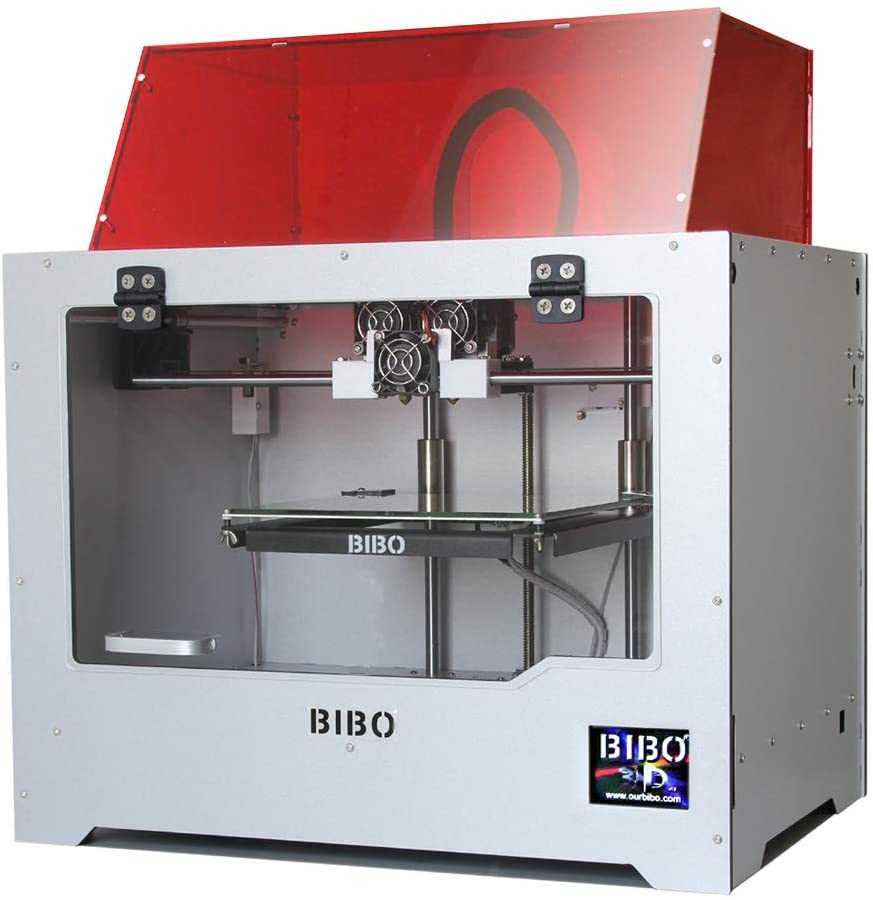

The two low-cost dual-printhead 3d printer models often found in reviews are the X-Pro from Qidi Technology and the Bibo Dual Extruder 3D Printer. These printers seem to be popular due to their low prices of $482 and $650 respectively.

These printers seem to be popular due to their low prices of $482 and $650 respectively.

A decent 3D printer model comes from Prusa with its I3 MK3S+ together with the dual head upgrade. This kit would burden your wallet with around 890 euros. However, the reputation of Prusa and its supportive community, this investment may pay itself off quickly.

But despite their advantages over mixer hot-ends, dual-printhead models do not always sell well. I once asked one of our resellers why.

The problem wasn’t the higher price. It was the complexity of getting these systems calibrated. This reseller required its users to undergo rigorous mandatory training to learn how to use dual-head machines (probably to save hours of support calls later on).

Imagine holding two pens in your hand and trying to write something with both of them at the same time. One of them will always try to lift up, while the other will be pushing too hard against the paper. It’s really tricky.

The same problem happens when printing with two nozzles mounted on a single print-head. If one is too low, it may kick your part off the build plate. If it is too far, the layers will not bond well.

If one is too low, it may kick your part off the build plate. If it is too far, the layers will not bond well.

So calibrating the height of two nozzles in a sub-millimeter range will take time and experience to get it right before every print job.

Actually, this problem was one of the reasons 3d printing companies came up with another solution: place both nozzles on separate print-heads: each with its own temperature and motion control.

3. IDEX: Most Likely Your Top Choice For Support Materials

IDEX Multi-material 3D printing (Illustration by Xioneer)IDEX stands for an independent extruder 3d printer. These systems use two extruders that alternate in the printing process.

So instead of trying to hold two pens in one hand, you take one pen in each hand – and write with each of them individually. Now, most of us aren’t ambidextrous (able to write with left and right hand equally well) – the machines do a great job printing with a pair of independent print-heads.

The first benefit of two independent nozzles: they are typically easier to calibrate than two nozzles mounted on a single print-head.

Another benefit of IDEX systems: they park unused nozzles outside of the build area, where they can leak material without oozing over your part.

Oozing is indeed a big issue not only in multicolor 3D printing but in printing model-support combinations. The smeared support may leave blemishes and holes inside your model undermining its aesthetics and surface finish.

So using IDEX 3D printers typically results in more reliable printing, prevents scraping of nozzles over the parts, and creates smoother surfaces. Such systems come very close to being the top choice for printing with support materials.

One of the lowest cost IDEX machines is the Tenlog Hands 2 Pro which retails at $430. The machine encompasses an impressive build volume of 235 x 235 x 250 mm. If you need to print larger parts, Tenlog offers its TL-D3 Pro with 310 x 310 x 350 mm build volume with a price tag of $ 560.

Another popular IDEX model appearing in 2021 reviews is the Creator Pro 2 from FlashForge. It is available for USD 700 and comes with a number of useful features such as an enclosed build-area to reduce the warping of parts. The Creator Pro 2 has a build space of 200 x 148 x 150 mm.

When it comes to printing support materials (VXL or PVA), machines with independent extruders offer the best price-performance ratio in my opinion.

4. Tool Changers: Smooth Parts But Comes With a High Price-Tag

Tool changer (Illustration by Xioneer)Tool changers are nothing new in the world of CNC machining. But in 3D printing, they are considered an exotic species. Although priced above a thousand dollars, it would be unfair to leave them out of this review.

In our pen and paper example, tool changing is the equivalent of picking a pen from a cup whenever you need it. When you are done writing with one pen, drop it back into a cup, and simply pick another one. In fact, this is what we (humans) naturally do when we want to use two pens.

For a machine, this approach has a few benefits.

A machine with a tool-changer only needs a single set of motors. So overall, these systems typically exhibit fewer moving masses, letting you reach smoother surfaces on your parts. This is clearly an advantage when printing intricate models with lots of supports.

But this solution is generally the most expensive choice. This is bad news if you are looking for a 3d printer with a tool-changer under one thousand bucks: we didn’t find any as of this day.

The option that comes to mind is to build a tool-changing dual extruder 3D printer yourself. You can get a head-start with a $ 2,105 (excl. VAT) Tool Changer & Motion System Bundle from E3D that provides all the mechanics you need to create such a beast.

5. Filament Switchers: Great for PVA But Produce Waste

Filament Switcher (Illustration by Xioneer)The Canadian company Mosaic Manufacturing came up with a multi-material 3D printing solution that is truly out of the box.

Mosaic Palette 3 is a device that cuts different filaments and welds them together in a single multi-material filament strand. Depending on the amount of model and support material for each layer, the device will precisely chop the filaments in lengths as needed – and deliver a welded strand to your 3D printer.

The device is an add-on. This means a great deal if you already own a single-extruder 3d printer. No need to buy a new dual-extruder machine and calibrate its two nozzles. You can keep using your single-extruder 3D printer and fit the Palette post factum.

Agreed, a price tag of $599 is more than double what you pay for a Geeetech A10M, but the Palette 3 seems to offer a unique benefit when it comes to printing with support materials.

Switching filament before the melt-zone on Palette makes sure that PVA is delivered to the nozzle only when it is needed. So PVA does not have a chance to linger in a hot nozzle eventually clogging it. This should drastically improve printing reliability.

Another – less expensive option – is the Prusa’s MMU2S Upgrade that retails for USD 300, but it was designed specifically for upgrading Prusa printers in mind.

However, both products seem to have a major drawback: they produce lots of waste when switching from one material to another.

On the mosaic website, the manufacturer states: “In order to create clean, high-quality multi-color/material prints, Palette uses a Transition Tower. This allows your extruder to purge the filament in between transitions, creating precise breaks in your model. Without these towers, the quality of the print would be reduced due to filament bleed and other print issues.”

They recommend purging 130mm of filament for its transition tower on each layer. Now, for a 1000-layer object, this amounts to 130 meters of wasted material or about a half of a 750g spool! This may not seem like a big deal when using cheap PLA or ABS. But you may consider accounting for so much waste when using expensive support materials such as PVA and VXL.

Mosaic and Prusa do provide tips and tricks on how to reduce material waste. For example, printing multiple objects at once, or using your model infill as a purge/transition area. But clearly, the material waste remains one of the key issues of filament switchers.

SummaryPrinting model and support is no longer a luxury of high-end expensive FFF machines. You can get a decent dual-material system well under $1,000.

The table below gives a summary of the low-cost options available on the market today.

If you are aiming for the lowest price and plan to use VXL instead of PVA as your support material, then you may seriously consider getting the Geeetech A10M. The device comes with the added benefit of simpler calibration due to a single-nozzle setup.

But if you look for a more reliable printing experience with PVA and less material waste, you should be looking into an IDEX machine like the TenLog Hands 2 Pro or the Creator Pro 2 from FlashForge. The nozzle calibration is a bit trickier than on A10M, but not as challenging as on traditional dual-nozzle machines.

The nozzle calibration is a bit trickier than on A10M, but not as challenging as on traditional dual-nozzle machines.

For the highest reliability when printing with PVA, and if you don’t mind the notable material waste, you might find a filament switcher like the Mosaic Palette 3 or Prusa’s MMU2S as an attractive option. The system gives PVA the least chances to burn and clog in your nozzle. The device is an add-on you can fit onto an existing single-head 3d printer.

Summary: 5 dual-material technologies for printing soluble supports.3D Printing - Truths and Myths of 3D Printing with Support Material

Our knowledge of FDM additive manufacturing is mostly derived from the past 25+ years of industrial-style 3D printing. Over this time period, we’ve tended to print small (less than 8”x8”) parts and it’s become commonplace to create “dissolvable” support structures from a second extrusion head.

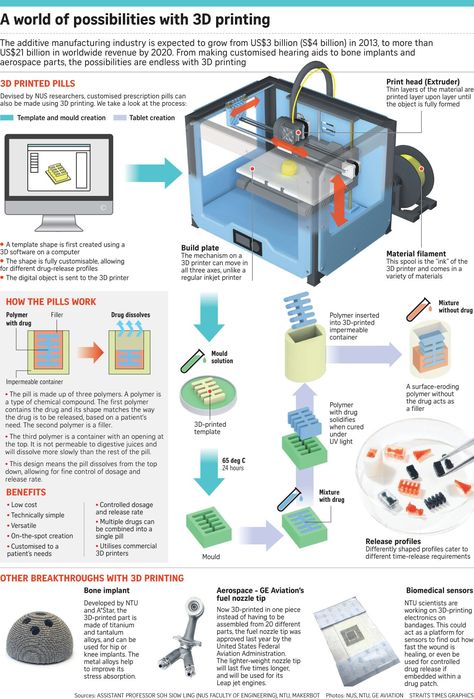

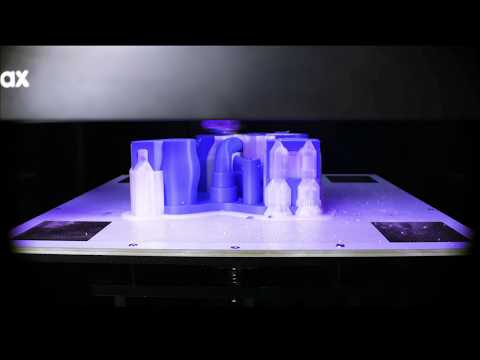

Before and after: HydroFill provides support for a wider range of materials, making it easy to 3D print parts with steep angles and overhangs.

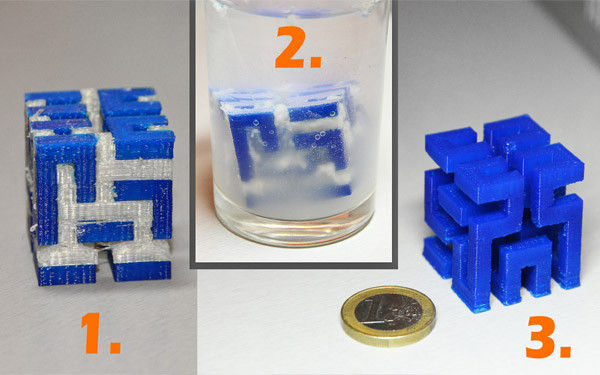

The support structures are designed to hold up “overhangs” so that the part does not collapse as it is being layered. Afterward, the support material is dissolved, usually in a caustic sodium-hydroxide mixture in a circulating heated tank, leaving the main material forming the desired part.

Today, we are tending to print larger parts (up to 12”x12”x 22.75” in the case of the EVO) for not only prototyping purposes, but also for applications such as jigs and fixtures. In other words, these parts must not only look good, they should also be large and functional. As large prints can take significantly more time, machine reliability and print repeatability is coming into sharp focus in the next cycle of additive manufacturing.

While we still use support structures for overhanging model geometry, support generation has matured significantly. It is now possible to use one material for both print and support material. Today’s same-material supports, such as those generated in Apex software, are easily removable from the main part and leave little to clean up after the print. This tends to play a significant role in the generation of larger models where fine details (less than .5mm) are not as critical as overall appearance, print time, and functionality

This tends to play a significant role in the generation of larger models where fine details (less than .5mm) are not as critical as overall appearance, print time, and functionality

Dissolvable support has also matured with the advent of materials such as Hydrofill. This type of support dissolves in warm water rather than by using chemicals. As with traditional additive manufacturing, these dissolvable supports are extruded from a secondary nozzle. The advantage over less user-friendly support materials of the past is that Hydrofill is safe to work with, environmentally friendly, and compatible with most printers.

When and Where to Use Soluble Support MaterialCases where soluble support material like Hydrofill really shine are with prints that feature internal geometry or extremely delicate features. Since single-head support material must be taken out by hand (usually using a set of pliers, etc.), there may be internal features that are completely inaccessible with a hand tool, and thus unsuitable for single-head support.

Conversely, as long as there is an entry point for water, soluble support may be dissolved out, without the use of hand tools. For delicate models (ie characters, architectural, etc), you may have features — such as fingers — that are extremely gentle and can be easily broken if too much force is used with a hand tool. Models that are suspended within each other, have internal threading, and moving models can also be more easily printed with a soluble support structure, and some models can only be printed this way.

With the introduction of this water-soluble support material, the process of creating soluble support has become easier than ever before. The cost of the extra equipment needed to dissolve the material is eliminated, and the safety is no longer a factor as these materials (like Hydrofill), are usually completely non-toxic and safe for the environment.

However, keep in mind that soluble support is usually more costly than printing with a single material. The cost of dedicated support materials is usually 1-2 times that of the main printed material (i.e., ABS). Those of us familiar with 3D printing understand that models are frequently iterated at least 2-3 times and as such, consideration must be given to the cost of using this more expensive material in your workflow, at least during the initial stages. Accordingly, it is wise to make sure your print will benefit from using soluble support material.

Ease of UseWhile a few desktop 3D printers, such as the EVO and Axiom, utilize soluble support material well, adding a second material of any type to a 3D printer introduces another layer of complexity to the print. With more complexity comes more possibility of error. Specifically, two heads now have to work together to build the part correctly (vs. a single-head print). If either head jams, it can cause the entire print to fail. Failures in dual-head prints are frequently more costly than single-head failures because of the added cost of the secondary support material. In addition, by using two heads most of the time, a prime or wipe tower will be used to create a purge for one head when the other is printing. Creating the prime tower adds complexity and significant time to the print.

Failures in dual-head prints are frequently more costly than single-head failures because of the added cost of the secondary support material. In addition, by using two heads most of the time, a prime or wipe tower will be used to create a purge for one head when the other is printing. Creating the prime tower adds complexity and significant time to the print.

A job that may take only 3 hours in single-head printing mode, may take twice as long using primary and secondary extruders. In addition to adding prime towers as set forth above, soluble support material is generally more delicate than conventional materials and therefore tends to be printed at a slower speed. Also, it will frequently be printed at thicker infill rates requiring further time. Build time will also increase because the dual print heads will need to switch for most every layer, such switching including prime cycles for both nozzles. Conversely, harder and more easily workable base materials such as ABS can usually be printed with single-head support quickly because the settings for Airwolf printers are optimized to print ABS as fast as possible in a reliable fashion.

If the objective is a final prototype for a presentation to potential investors or upper management, soluble support may be beneficial, at least for the final iteration, as you will have a cleaner surface where the primary material is mated with the support structures. However, when using materials such as ABS, a bit of light support sanding could make nearly as nice of a part in far less time. Further, it must be remembered that the dual-head print will still need at least a small bit of post-processing to optimize the clean mating surfaces.

StorageSoluble support material such as Hydrofill, usually dissolves by soaking the part in hot water for several hours. Agitation and heat will generally speed up the process. Since these materials are developed to work this way, they are susceptible to moisture from the surrounding air and can degrade if not properly re-packaged after use. This can be a costly mistake with a $100+ roll of material. Proper handling and storage techniques are needed when using these materials. However, with single-head printing, no extra material is needed. This eliminates the issues that can arise during storage, the cost of storing filament correctly, and the space it takes up in the workplace. Generally with either material, if it kept inside an enclosed printer like the EVO, the filament will tend to stay dry as the chamber is heated.

However, with single-head printing, no extra material is needed. This eliminates the issues that can arise during storage, the cost of storing filament correctly, and the space it takes up in the workplace. Generally with either material, if it kept inside an enclosed printer like the EVO, the filament will tend to stay dry as the chamber is heated.

While dual-head prints have reached a level of quality that is accepted in the industry, a single-head print, using intelligent single-head support structures, such as those generated in Apex, can also achieve very high quality. Things like chamber temperature and bed temperature can be optimized for that one material, rather than possibly compromised for two different types of materials. Any time a second head is introduced, it is usually using a different material and will need different, or slightly different settings to work properly. This complexity can lead to poor quality prints if settings are not correct.

Many machines have complex dual-head systems that tilt or close up an inactive nozzle to prevent it from dripping filament. While these methods try to prevent the two print heads from contaminating each other, they also add more complexity to the hardware, and in most cases can cause reliability issues. The best way to prevent material contamination within a dual print is to work with the correct settings, especially if the manufacturer provides software with presets for their machine (Airwolf 3D has many dual-head presets written into APEX).

Single-Head Support StructuresAs a general rule, single-head support structures come with more benefits than drawbacks. Our experience is that most users who purchase a dual-head printer don’t often use the second head for support. However, dual-head printers are very useful for optimizing workflow by printing with different settings for primary and secondary nozzles. For example, with the EVO and Axiom Dual Direct, users can place different size nozzles on different print heads and use optimized settings for each. Apex allows users to select nozzle sizes and thus allows one printer to print a part in two completely different ways from primary and secondary heads (i.e., fast with a 1.0mm nozzle on one head, and slower and more precise with a .35mm nozzle on the other).

Apex allows users to select nozzle sizes and thus allows one printer to print a part in two completely different ways from primary and secondary heads (i.e., fast with a 1.0mm nozzle on one head, and slower and more precise with a .35mm nozzle on the other).

Single-head support structures have also greatly improved over the past few years, mostly due to software development. For these supports to be broken off easily, but also have the ability to leave somewhat clean surfaces, the software has to be able to not only create the support where needed but also set the spacing correctly for it to be broken off with little effort. When printing large models, single material support tends to work well as most imperfections arising from support material tend to be overshadowed by overall part appearance.

Having the ability to use different support patterns is also becoming common practice. In this case, for example, the single-head support structures utilized in APEX printing software use the “line” pattern. This only lays support structures down in one direction — enabling the user to more easily remove the structure. For soluble printing, the “Grid” pattern is used in order to provide more support for the print (since it will not be removed by hand).

This only lays support structures down in one direction — enabling the user to more easily remove the structure. For soluble printing, the “Grid” pattern is used in order to provide more support for the print (since it will not be removed by hand).

The ability to use a secondary head for creating soluble support structures remains a powerful tool in the belt of the creator. Featuring the ability to support inaccessible part geometry and to minimize post-processing time, dual soluble support will continue to be a staple of FDM additive manufacturing. However, single-head support needs to be factored into more purchasing, design, and manufacturing considerations. When it comes to repetitive iteration, experimentation, and large part making, the cost and time efficiencies associated with same-material support are worthy of consideration.

Download our white paper "Support Material, Truths and Myths"This white paper discusses the options and process involved in the use of support material in FDM additive manufacturing. Read this white paper to learn:

Read this white paper to learn:

- When and where to use soluble support material

- The pros and cons of same material support

- The pros and cons of soluble support

Reading time: 15 minutes

Related Video: HydroFill Water Soluble Filament

Related Equipment: EVO 22 PRINTER

Related Materials: HYDROFILL SOLUBLE SUPPORT

Original Article: 3D PRINTING WITH SUPPORT MATERIAL

Using Dissolvable Filament to Create Supports

Using Dissolvable 3D Printing Filament is an easy and effective way to create support structures for your 3D printed part. In this article, we'll take a look at the different types of dissolvable filaments on offer, the benefits of using them over insoluble filaments, and tips and tricks for the smoothest possible printing process.

FDM 3D printing is a manufacturing technology that allows you to create parts with complex geometries that are usually impossible to obtain using traditional methods. However, when using this technology, each layer of the part requires supports, either on the structure of the part itself or on an additional supporting structure.

However, when using this technology, each layer of the part requires supports, either on the structure of the part itself or on an additional supporting structure.

With a single extruder 3D printer, you are limited to using the base material of the printed part to create the support structure. Things are different with dual-extruder printers, since dissolvable filaments can be used to create support structures.

Soluble 3D Printing Filament Types

Water Soluble 3D Printing Filaments

Such materials are known for their solubility in ordinary water without any aggregates. This makes them an excellent option, as their dissolution does not pose any danger, and also does not cause any reaction to the base material of the product.

One of these materials is PVA, which is the most commonly used support material in 3D printing. BVOH is another widely used material with better material compatibility than PVA as well as faster dissolution time.

Water Soluble Chemical 3D Printer Filaments

Some industrial grade materials are not compatible with filaments such as PVA or BVO due to their chemical properties and/or heat resistance. For this reason, materials like BVOH or PVA have been designed with additional properties to make them compatible with high temperature materials such as PEEK, PEKK, PPSU, PP and others.

In order to dissolve these supports, the pH of the water must be acidic in order to break down the sugar that this type of material normally contains, as this is less dangerous than the use of solvents.

Soluble 3D Printer Filaments with Organic Solvents

These are the least used materials due to the difficulty of using organic solvents with polymers most used in 3D printing as the solvent can react with the print material and damage it.

The advantage of using these materials is their high compatibility with the construction material. The most common example is HIPS as a support material for ABS.

Insoluble and dissolvable filaments for 3D printers

Soluble filaments for support structures have advantages and disadvantages compared to using insoluble filaments:

- Easy to remove supports

- Since the supports are soluble, simply dip the model in the appropriate solvent and wait until the supports are gone. This is very useful for parts with a very complex structure.

- Improved contact surface quality

- This advantage is related to the first point; since the material is easily removed, a strong base can be created in the area where supports are required, resulting in a smooth surface without filament residue.

- Less need for post-processing of the model

- The ability to print complex 3D models with high surface quality using dissolvable filaments also reduces the need for post-processing tasks such as polishing, sanding, gluing, etc.

- Longer print times in increasing the time of 3D printing, since materials need to be changed in the process.

However, there are techniques for optimizing the support structure to reduce this problem.

However, there are techniques for optimizing the support structure to reduce this problem.

Tips for creating support structures with dissolvable filaments

By changing some settings in your slicer, you can get solid supports to improve the quality of your 3D model.

Strengthening the Supports

It is quite common to create thin supports for very thin parts of a model, however they are not strong and tend to break during the printing process. To increase their durability, you can adjust the following support configuration options:

Horizontal Support Extension: Increases the overall thickness of the support, allowing the tower to be thicker and stronger.

Avoid breakage of supports during printing

The thickness of supports is equal to the diameter of the hot end, so they are usually quite fragile and can break during printing. By changing the pattern and other parameters, the strength can be increased:

- Support pattern: Patterns such as grid and triangle are quite resistant to tearing during printing.

It is recommended to print such patterns only on soluble material, as they are quite difficult to remove.

It is recommended to print such patterns only on soluble material, as they are quite difficult to remove. - Supports printing speed: If the supports are printed too fast, there is a risk of breaking the structure. Reducing the speed avoids vibration or damage to the structure as the head passes.

Improving the quality of the surface of the model

The quality of the contact surface depends on the distance Z from the support pattern, the direction of the upper and lower perimeter lines and the amount of material holding the base of the model. Changing these parameters can improve the quality of the surface, but will complicate the process of extracting supports.

- Density of supports: The higher the density, the better the model will hold and therefore the surface finish will improve.

- Top/Bottom Line Direction: Changing the direction of the perimeter pattern helps hold the bottom layer of the model, as it allows the support and the perimeter pattern to intersect better.

- Support Pattern and Top/Bottom Pattern: The support and perimeter patterns affect how the support model attaches, ideally the patterns should overlap as often as possible to better secure the first layer.

Always remember that it is important to keep filaments in a dry environment, as soluble materials readily absorb moisture and can cause printing problems. Materials such as PVA and BVOH can be dissolved in plain water. This water can also be heated to shorten the removal time of supports.

We hope you follow our advice and recommendations to improve the surface quality of your 3D printed parts and make the process faster and more efficient.

We will keep you updated with the latest news!

Your team IGO3D Russia

Our groups on social networks:

Vkontakte

Telegram

YouTube

Best 3D-printer and updating 2022 9000 3D-dimenships . 3D printing using multiple colors, multiple materials to reinforce specific areas, or using dissolvable filaments such as PVA or HIPS to achieve a smooth finish.

We've been lucky enough to try a few dual extruder 3D printers first hand and have come up with our recommendations for the best dual extruder printers available in 2022. We also explain the differences between different types of dual extruders (IDEX, mixed color 3D printing, dual extruder upgrade) and whether you should upgrade your printer.

Contents

- What are the advantages of a dual extruder 3D printer?

- What is the best dual extruder 3D printer?

- Budget Dual Extruder 3D Printers (under $1,000)

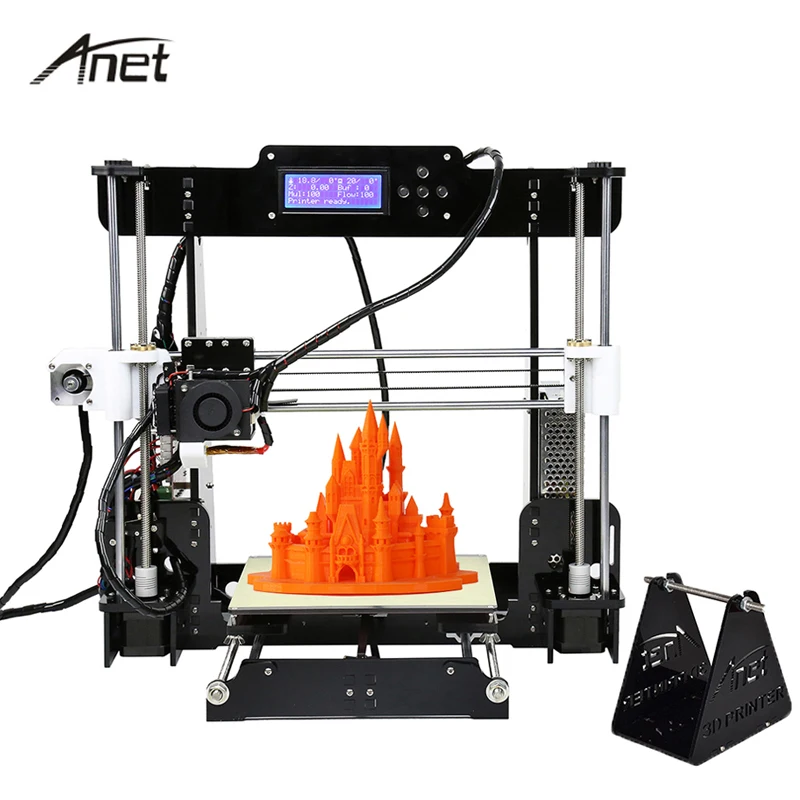

- 1. Geeetech A20M / A10M - Best Budget Dual Extruder 3D Printers

- 2. BIBO 3D Printer (Touch Laser if purchased with laser engraver)

- 3. Flashforge Creator Pro 2 - Affordable IDEX

- 3D Printer 4. BCN3D Sigma D25 - IDEX

- 3D Printer 5. Ultimaker S3 - Highly Accurate Dual Extruder 3D Printer

- 6. Raise3D Pro2 / Pro2 Plus

- 7. Ultimaker S5

- Best Dual Extruder Upgrades

- 8.

Mosaic Palette 2S / 2S Pro - Best Dual Extrusion Filament Splicer Upgrades

Mosaic Palette 2S / 2S Pro - Best Dual Extrusion Filament Splicer Upgrades - - Prusa Material Upgrade 9. Prusa Material Upgrade 9. Prusa Material Upgrade Upgrade Kit

- Dual Extruder 3D Printer Q&A

What are the advantages of a dual extruder 3D printer?

The main advantages of the dual extruder 3D printer include:

Better for supports: one extruder prints your material of choice, such as ABS or PLA, while a second extruder prints water-soluble supports, such as PVA filament. These supports dissolve easily in water and produce smoother prints without having to manually remove them.

Multiple colors: Dual filament 3D printers can print multiple colors of the same filament type, such as PLA, for stunning multi-color details.

Multiple parts at the same time (IDEX): IDEX 3D printers such as the BCN3D Sigma D25 have two extruders that work completely separately and can print different parts at the same time.

What is the best dual extruder 3D printer?

That's why we've ranked the best dual extruder 3D printers on the market. We rated these printers for value for money, reliability, build volume, ease of use, and various other features.

Budget Dual Extruder 3D Printers (under $1000)

These amazing 3D printers break the rules of the definition of "dual extruder 3D printing". To be clear, they can be loaded with two separate filaments, such as red and yellow PLA, but they will come out of the same nozzle, mixing the two colors during the printing process. Some call it dual nozzle 3D printing.

The results are amazing. Connect red, orange and yellow threads and watch your printed vase look like an exotic cocktail. The printers offer four dual 3D printing modes: single color, dual color, gradient and mixed. This provides a huge selection of print designs for such an inexpensive dual extruder 3D printer.

In terms of specifications, the A20M has a good working volume of 255 x 255 x 255 mm, while the A10M is only slightly smaller. The A20M also boasts improved stability as it is better anchored. Overall, this is an accurate (layer resolution down to 0.1 mm), interesting and inexpensive two-color 3D printer that combines colors and filaments through a single nozzle.

single nozzle geeetech a20m filament mixer.

2. BIBO 3D printer (touch laser if purchased with laser engraver)

- Dual extruder 3D printer cost: $599

- Assembly volume: 214 x 180 x 160

How do we get started with the BIBO eccentric printer? Well, the most important thing is that it also performs another function. It can be used as a laser engraver! The engraver can permanently carve your favorite designs on wood, as well as cut paper or felt materials - and print in 3D!

You can purchase BIBO as a 3D printer kit or pre-assembled, with or without a laser engraver. And if he performs another function, this does not mean that he cannot succeed in both. In fact, this is a very efficient multi-extruder 3D printer with a minimum layer height of 0.05 mm and stable printing in a closed working chamber.

And if he performs another function, this does not mean that he cannot succeed in both. In fact, this is a very efficient multi-extruder 3D printer with a minimum layer height of 0.05 mm and stable printing in a closed working chamber.

This is a great printer, crazy and ambitious. Even the product images on Amazon showcase the machine's character and personality. We love it.

3. Flashforge Creator Pro 2 - affordable 3D printer IDEX

- Creator Pro 2 price: $649

- Assembly volume: 200 x 148 x 150 mm

The popular and beloved Flashforge Creator Pro has started to show its age since it was released in 2016, so Flashforge followed it up with the vastly improved Creator Pro 2. assembly volume on the x-axis. It retained a minimum resolution of 100 microns and a Teflon tube extruder for 3D printing of PLA, ABS and nylon in a closed working chamber.

However, the main change that makes this printer so profitable is undoubtedly the IDEX upgrade. In the IDEX 3D printer, the nozzles work independently, unlike the dependent, attached nozzles on the original Creator Pro, with different modes such as Mirror Mode for 3D printing multiple identical models at the same time - a big time saver, trust me.

In the IDEX 3D printer, the nozzles work independently, unlike the dependent, attached nozzles on the original Creator Pro, with different modes such as Mirror Mode for 3D printing multiple identical models at the same time - a big time saver, trust me.

Other quality-of-life improvements include an improved touch screen interface, as well as important nozzle updates that prevent unused nozzles from oozing out and messing up the print bed or even causing errors. You won't find a more affordable IDEX printer.

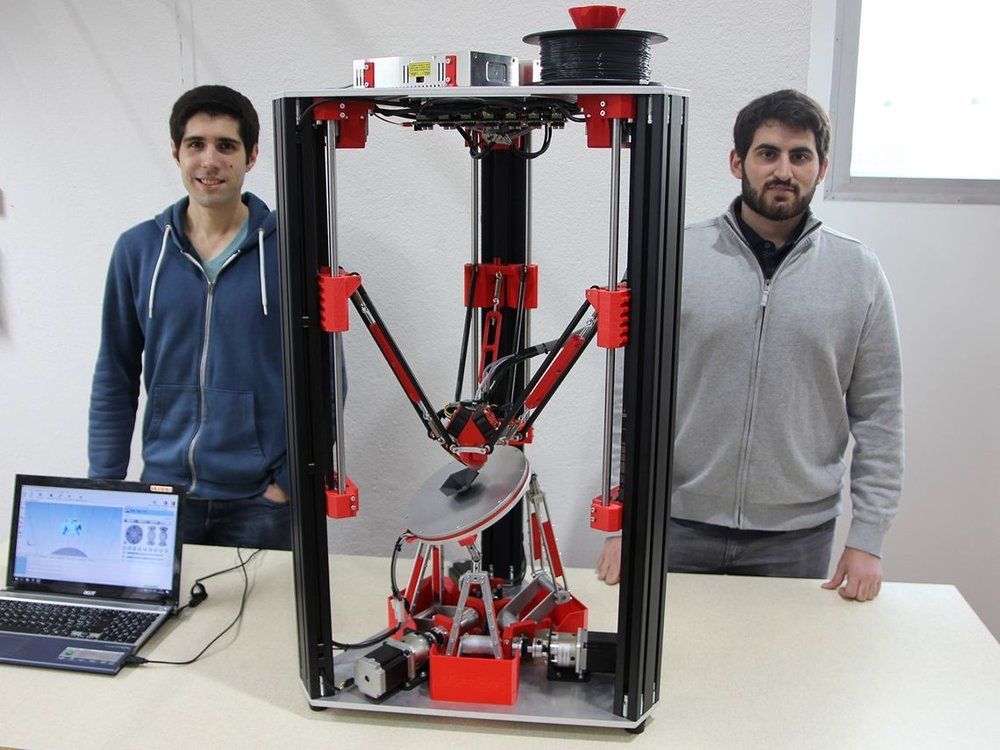

4. BCN3D Sigma D25 — IDEX 3D printer

- Manufacturer: Spain

- Price: $3,995

- Assembly volume: 210 x 297 x 210 mm

Spanish 3D printer manufacturer BCN3D has made a name for itself with reliable dual extruder 3D printers. All of their printers, including the Sigma and Epsilon series, use BCN3D's IDEX (Independent Dual Extruder System) 3D printing technology, a unique and key advantage.

IDEX 3D printing allows each extruder to move completely independently, not limited to working on the same model at the same time as in other 3D printers. Two different parts can be created at the same time, cutting the time required to create several small parts in half. The Sigma D25 also features high quality E3D hot ends for quality printing on a variety of materials, including stiffer filaments, and a filament low sensor informs you when the filament has run out.

Two different parts can be created at the same time, cutting the time required to create several small parts in half. The Sigma D25 also features high quality E3D hot ends for quality printing on a variety of materials, including stiffer filaments, and a filament low sensor informs you when the filament has run out.

For those who need a 3D printer for rapid prototyping, being able to print multiple parts for testing at the same time is a huge advantage. The BCN3D Sigma D25 uses 2.85mm filaments instead of the standard 1.75mm so be aware of this, but is compatible with any 2.85mm filament. You can use a variety of 3D printer nozzle sizes, from 0.3mm to 1.0mm, and a clear and easy-to-navigate touch screen interface.

Interestingly, Sigma D25 is also an open source 3D printer: printer firmware, workflow, software and other files are available on BCN3D GitHub. It works seamlessly with the Cura 3D slicer and is easy to set up and use right from the start. Overall this is a great, reliable and efficient dual extruder 3D printer. With a resolution of 50 microns, this is a high quality, high resolution 3D printer for accurate rapid prototyping.

With a resolution of 50 microns, this is a high quality, high resolution 3D printer for accurate rapid prototyping.

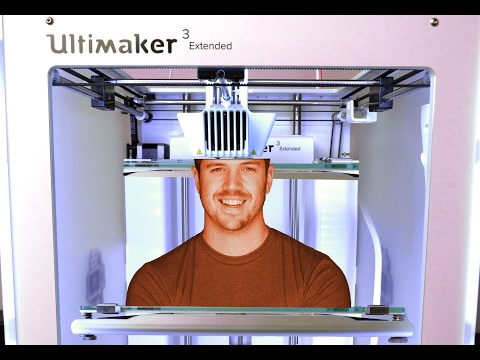

5. Ultimaker S3 - very precise dual extruder 3D printer

- Manufacturer company Holland

- Ultimaker S3 price: $3,850

- Assembly volume: 230 x 190 x 200 mm

Ultimaker is another behemoth of desktop 3D printing that has created award-winning deposition modeling printers. With a dual extruder and incredible precision down to 20 microns, the Ultimaker S3 is a fantastic option for small businesses, manufacturers and prosumers.

For precision multi-material 3D printing, nothing beats the Ultimaker S3. It is widely used to create accurate architectural models as building design prototypes, to create accurate industrial and engineering prototypes, and in many other industries. Upon release, it won dozens of awards and is still one of the best dual extruder 3D printers.

With a print volume of 230 x 190 x 200 mm, the Ultimaker S3 can handle most printing needs. It also has a built-in camera that allows you to monitor the printing process remotely.

It also has a built-in camera that allows you to monitor the printing process remotely.

Connected via WiFi, Ethernet or USB stick, the Ultimaker S3 is designed to be easy to use. While the Ultimaker 3 doesn't come cheap at $3,850, it's accurate, fast, reliable, and easy to use. This makes it overall one of the best dual extruder 3D printers on the market today.

6. Raise3D Pro2 / Pro2 Plus

- Price: $3,999

- Assembly volume: 305 x 305 x 300 mm

Also featured in our overall ranking of the best 3D printers, the Raise3D Pro2 series impresses with its reliability, size and range of printable materials. In addition to standard PLA, ABS, and PETG printing, the Pro2 and Pro2 Plus 3D print with nylon, polycarbonate, carbon fiber, ASA, and metal-filled filaments on either of the two extruders.

Its big brother, the Raise3D Pro2 Plus, costs $5,999

The Raise3D Pro2 also boasts a fantastic build volume of 305 x 305 x 300mm, enough for everyday and industrial printing. The printer is also very accurate, with a minimum layer height of 0.01mm, and is equipped with a 7-inch touch screen for easy printer control. The Raise3D Pro2 costs just under $4,000 and overall is a fantastic dual-extruder printer for the price.

The printer is also very accurate, with a minimum layer height of 0.01mm, and is equipped with a 7-inch touch screen for easy printer control. The Raise3D Pro2 costs just under $4,000 and overall is a fantastic dual-extruder printer for the price.

7. Ultimaker S5

- Price: $5,995 - Available at Dynamism Store

- Assembly volume: 330 x 240 x 300 mm

Ultimaker is highly regarded, and for good reason - the company can't go wrong. After the Ultimaker 3, the Ultimaker S5 is an updated, improved and slightly more expensive dual extruder 3D printer that will compete with the Makerbot Method.

A 330 x 250 x 300mm large-format 3D printer built for more scalable production, the Ultimaker S5 already has satisfied customers at Volkswagen, Decathlon and many more. It features a very advanced print leveling system, an improved touch screen, and can be connected to a phone via the Ultimaker app, which notifies you when a print is complete. The Ultimaker S5 is undoubtedly a great dual extruder 3D printer.

The Ultimaker S5 is undoubtedly a great dual extruder 3D printer.

Best Dual Extruder Upgrades

8. Mosaic Palette 2S / 2S Pro - Best Upgrades for Dual Extrusion Filament Splicer

- Palette 2S Price: $599

- Palette 2S Pro Price: $799

If you want to print multiple colors without a dual extruder, consider Palette as well. Instead of 3D printing with two multi-colored filaments from separate extruders, the Palette 2S and 2S Pro fuse up to four multi-colored filaments - or different materials - together during printing to create multi-color or multi-material parts.

They work by running your model through specially designed software - CANVAS for Palette - to assign different colors to different areas of your model before printing. When a particular area needs to be printed, the Palette software splices the colored filaments to print that particular area in the material or color you choose.

This makes Palette ideal for creating architectural models for construction projects, colorful desktop models of your favorite designs or D&D models, and multicolor prototyping businesses. The standard Palette 2S model includes all of these features, while the Palette 2S Pro can also splice up to 20% faster and comes with an extended 2-year warranty and replacement parts.

The standard Palette 2S model includes all of these features, while the Palette 2S Pro can also splice up to 20% faster and comes with an extended 2-year warranty and replacement parts.

Palette is compatible with hundreds of 3D printers, including almost all of the most popular options. For more information, you can check your printer's compatibility here, and as for choosing between the Palette 2S and 2S Pro: The 2S Pro cuts filament 20% faster and comes with a longer warranty - so if that's important to you, spend the extra money on 2S Pro.

9. Prusa Multi Material Upgrade 2S - Prusa Upgrade Kit

- Price: $299

While you can upgrade the palette for most 3D printers, Prusa printer owners can purchase a similar Multi Material Upgrade kit that allows you to print up to 5 different materials at once. Prusa printers are some of the best 3D printers under $1,000 and this upgrade turns your Prusa into a multi-color or multi-material 3D printer.

MMU2S is an improvement over the previous version of the Multi Material Upgrade Kit 2.0, key changes include a material feed sensor, buffer and a much improved overall calibration process.

The Filament Sensor goes further, checking not only for the presence of filament, but also to see if it has reached the Bondtech gears for printing. This provides much more reliable extrusion and makes filament calibration and loading easier.

The filament buffer also saves you the hassle because each of your filaments (especially if you're using all 5!) won't get tangled or tangled. Organizing and separating each filament also saves space on your desk or 3D printer table.

Q&A for Dual Extruder 3D Printers

What is a dual extruder 3D printer?

Dual extruder 3D printers have two print heads or nozzles instead of one print head like standard FDM 3D printers. Dual printing frees you from the limitations of using only one type of 3D printer filament and allows you to create multicolored parts with ease.

Dual Head 3D printing improves printing with soluble supports such as HIPS and PVA and also allows multi-color parts to be printed.

Most budget dual extruder 3D printers are dual nozzle printers, meaning they have two nozzles but extrude from a single head, but we also include more advanced printers. These advanced options include IDEX 3D printers with two printheads that move completely independently for efficient and versatile printing.

What are the main types of dual extruder 3D printers?

The main types are:

1. Dependent Dual Extruder 3D Printers - Most low-cost multi-extrusion 3D printers are dependent, that is, two nozzles that extrude separate filaments are attached to one print head. They follow the same path, filling areas (such as a support or main part) in turn.

2. Dual Extruder Independent 3D Printers (IDEX 3D Printers) - IDEX extruders use two printheads independently, doubling productivity when printing multiple parts at the same time.

3. Dual Extruder Printer Upgrades - These upgrade kits, such as the Palette 2S series and Prusa Multi Material Upgrade 2.0, transform a single extruder 3D printer into a printer that can print up to 5 colors simultaneously using splicing systems and dedicated software and plans for filling 3D models.

4. Mixed color 3D printers are some of the cheapest dual extruder 3D printers, and maybe not even dual extruders. They use one printhead and one nozzle, but two filaments to mix the colors while melting. You can print models in half color, or mix colors like red and blue to create a purple hue.

Can the 3D printer be upgraded with a dual extruder?

Yes, you can. Dual extruder upgrades such as Palette 2S (compatible with most popular 3D printers) and Prusa Multi Material Upgrade 2.0 (for Prusa 3D printers) will turn your standard FDM printer into a multi-color 3D printer.

However, manually modifying a 3D printer and adding a second extruder is more difficult.