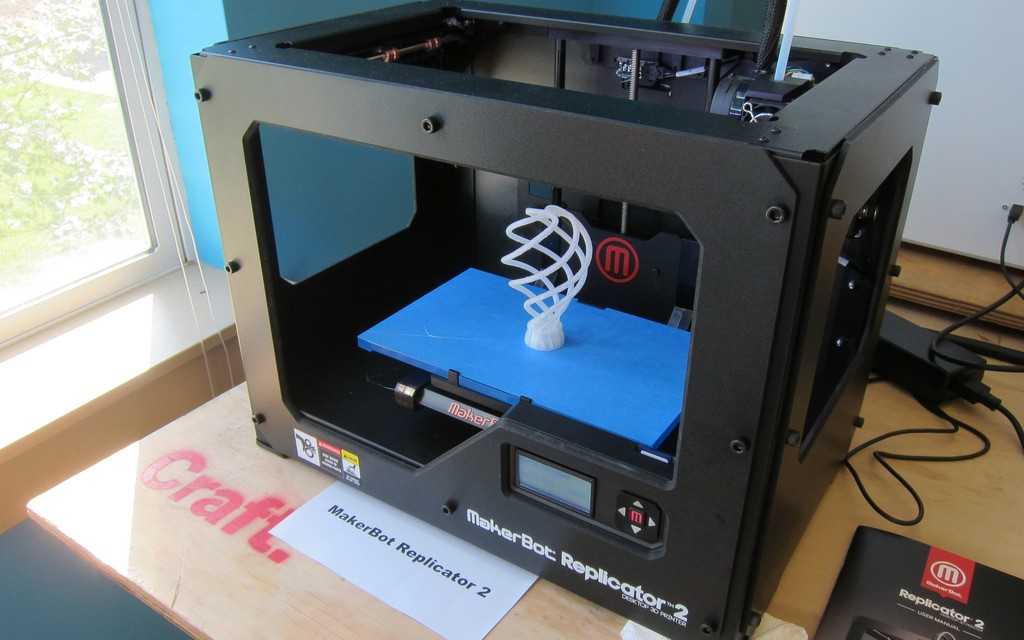

Envisiontec perfactory 3d printer

3D Printers | Desktop, Professional and Industrial

ETEC offers a variety of 3D printing systems with the ability to mass produce polymer parts with the speed and quality needed for demanding end-use applications. ETEC printers deliver parts with exceptional accuracy, superior part properties, fine feature detail, and smooth surface finish at a scale and cost that is competitive with traditional manufacturing techniques like injection molding.

·

Printers

From desktop production of small parts to 24/7, lights-out manufacturing to large, production-grade printers, ETEC solutions address a wide range of production scales.

Materials

With more than 190 materials, from hard plastics to high-performance elastomers to high-temperature materials, ETEC’s material portfolio can address a huge range of applications.

High Accuracy + Feature Detail Smooth Surface Finish High Throughput Superior Part Properties Quality Materials Ease of Use

High Accuracy + Feature Detail

ETEC’s advanced DLP printing process delivers best-in-class part accuracy and feature detail down to the micron level.

Smooth Surface Finish

ETEC DLP parts deliver best-in-class surface finish with less than 1um Ra. This exceptional smoothness is critical to compete with plastic injection molding and is the result of more than 10 years of research & development devoted to perfecting the DLP process.

High Throughput

ETEC printers enable throughput [up to 100x legacy FFF 3D printing processes] to deliver parts at volumes and costs competitive with traditional manufacturing techniques like injection molding.

Superior Part Properties

ETEC combines advanced hardware features such as high-powered projectors and custom-designed optics with materials that leverage long-chain chemistry to deliver truly isotropic material properties critical for end-use applications.

High-performance Materials

With a wide array of materials, including both proprietary and third-party qualified resins, ETEC materials deliver mechanical properties required for for end-use parts across a range of industries and applications.

Easy To Use

ETEC solutions are designed for ease of use from the ground up, with intuitive software that simplifies the process of setting up and starting a print and the ability to switch between materials in just minutes, users can produce end-use parts tailored to their application with ease.

Trusted By Industry

· Systems

Our Systems

- Printer technology

- Build envelope

- Models

- XY Resolution

- Z Resolution

- Printer technology

- Build envelope

- Models

- XY Resolution

- Z Resolution

- Printer technology

- Build envelope

- Models

- XY Resolution

- Z Resolution

- Printer technology

- Build envelope

- Models

- XY Resolution

- Z Resolution

- Printer technology

- Build envelope

- Models

- XY Resolution

- Z Resolution

· Case Studies

3D Composites

Additive manufacturing service bureau using 3D printing to create parts for 747 jets, satellites, medical devices and more.

Shapeways

Industrial service bureau creating prototype parts for everything from consumer goods to medical devices.

Products - ETEC

Skip to content

Team DM

Platforms

Metal and composites 3D printing 3D printing solutions for health care Industrial-grade polymer 3D printing™

Sand and tooling 3D printing solutions 3D printers for sheet metalMaterials

Breakthrough photopolymer development Advancing 3D printed upcycled woodApps & More

The hydraulic additive manufacturing experts Multi-material powder recoating technology Driving digital transformation in dentistry· Systems

Our Systems

- Printer technology

- Build envelope

- Models

- XY Resolution

- Z Resolution

- Printer technology

- Build envelope

- Models

- XY Resolution

- Z Resolution

- Printer technology

- Build envelope

- Models

- XY Resolution

- Z Resolution

- Printer technology

- Build envelope

- Models

- XY Resolution

- Z Resolution

- Printer technology

- Build envelope

- Models

- XY Resolution

- Z Resolution

· Key Features

Why ETEC?

High Accuracy + Feature Detail

High-resolution printing with Industrial DLP Chips

DLP chips come in a variety of configurations, from industrial chips designed for 3D printing to less expensive chips intended for video projectors found in many offices. While some DLP print technologies choose to use these inexpensive chips to reduce costs, ETEC only uses true industrial DLP chips, which allow for higher contrast ratios, resulting in finer part details.

While some DLP print technologies choose to use these inexpensive chips to reduce costs, ETEC only uses true industrial DLP chips, which allow for higher contrast ratios, resulting in finer part details.

High-resolution printing with CDLM Domeless Printing

https://etec.desktopmetal.com/wp-content/uploads/2022/01/MS_DM_EnvisionTec_E1_CDLM_320.mp4

To print continuously (without peeling) requires flowing oxygen through a permeable film just above the print bed to create a “dead zone”. Within this ‘dead zone’ the polymerization process is inhibited ensuring the layer being printed adheres to the layer above and not the printing bed film. This ‘dead zone’ is what enables continuous printing, where the build plate can continually move in the Z axis, leading to faster, more reliable prints.

On competitor “dead zone” printers, by comparison, air pressure from the flowing oxygen causes the film to dome up. Printing parts on that domed surface greatly impacts resolution along the Z axis, as well as the ability to print flat parts on the build plate.

ETEC’s CLDM technology uses over 200,000 pillars to hold the film perfectly flat, resulting in significantly better Z-axis resolution and allowing for the printing of flat parts straight to the bed with no supports.

Smooth Surface Finish

Smooth surface finish with Pixel Shifting

Projectors deliver light in square-shaped pixels, which creates volumetric pixels, or voxels, as resin cures.

Along curved edges, however, square pixels create a jagged edge – what the industry often refers to as “stair stepping.”

As the size of printed objects and build volumes increase, stair stepping becomes more pronounced.

ETEC printers use patented pixel-shifting technology to move pixels at the edge of parts half a pixel in both the X and Y directions, cutting stair-stepping by half and delivering significantly improved surface finish.

Smooth surface finish with Pixel Tuning

Anti-aliasing technologies are ubiquitous today — used virtually everywhere digital images appear, from cell phones to TV screens and more.

ETEC brings the same technology to the 3D realm by using anti-aliasing techniques at the edge of print layers to improve surface finish. Since voxels grow from the center of a part to the edges, applying less power to these outside pixels ensures they only grow to the desired edge of the part and not beyond. (Less power = slower polymerization growth)

Called pixel tuning, that process dramatically reduces pixelation on the edges of parts, resulting in a surface finish that requires little to no post-processing.

Smooth surface finish with CDLM and Top-down Printing

https://etec.desktopmetal.com/wp-content/uploads/2022/02/top-down-1-1-1.mp4

Most forms of DLP require each layer to be peeled off the film between each layer as the build plate moves up. As each layer is peeled, a small lip is formed on the part, which roughens the surface finish.

The patented CDLM process of the Envision One and top-down printing of the Xtreme 8K eliminate the need for peeling. With no peeling, lipping does not occur, resulting in a significantly better surface finish than other DLP processes.

With no peeling, lipping does not occur, resulting in a significantly better surface finish than other DLP processes.

During top-down printing, parts are fully submerged in the resin. With the parts supported by the resin, fewer support structures are needed, ultimately resulting in a better final surface finish.

High Throughput

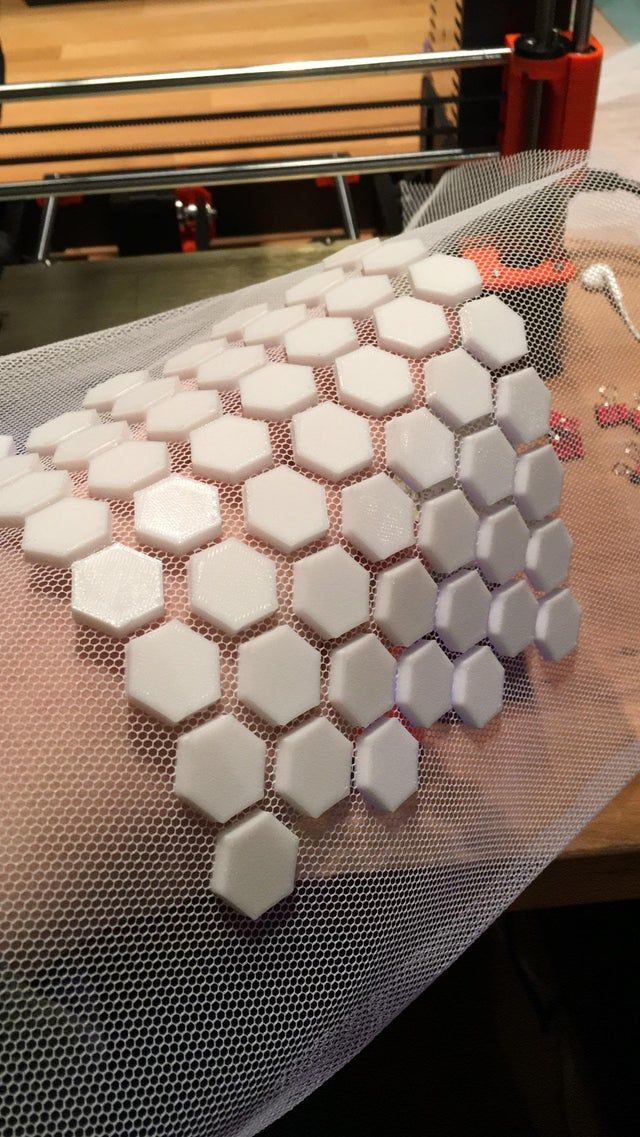

High throughput via Large Build Volumes

With a variety of build volumes, ETEC DLP printers are capable of printing a wide variety of part sizes, from large single parts to high volumes of smaller parts in a single build.

Since build times are entirely dependent on Z-axis height, having large build volumes in the X- and Y-axes allow for potentially thousands of parts to be printed at once, in the same time required to print one part.

High throughput via Faster Polymerization

DLP build times are determined by Z-axis height because much of the print time is related to the time it takes to cure, or polymerize, each layer.

ETEC’s DLP technology enables the fastest layer polymerization through the use of the highest-power projectors and a highly efficient optical train.

By allowing for shorter exposure times per layer, ETEC systems ultimately deliver shorter print times and higher throughput.

High throughput via CDLM or Top-Down Printing

https://etec.desktopmetal.com/wp-content/uploads/2022/02/MS_DM_EnvisionTec_E1_CDLM_1080-1.mp4

Many forms of DLP require each layer to be peeled off the film as the build plate moves up between layers. This peeling takes time and must be done slowly to ensure parts are not damaged.

The patented CDLM process of the Envision One and top-down printing of the Xtreme 8K eliminate the need for peeling, reducing the time needed to print each layer and overall print times.

High throughput via Lights-Out Manufacturing

https://etec.desktopmetal.com/wp-content/uploads/2022/01/MS_DM_EnvisionTec_X8K_320_v043. mp4

mp4

Get the most out of your ETEC DLP system with high throughput, 24/7 manufacturing designed to rival the volumes of traditionally-manufactured plastic parts.

An automated system for lights-out manufacturing and a dashboard for monitoring all operations and remote control of each machine, further increase uptime for each system.

Superior Part Properties

Superior part properties with New Backbone Chemistry

For decades, polymer 3D printing has been used for prototyping and tooling applications, but the technology hasn’t been widely adopted for the production of end-use parts.

One key to unlocking those end-use applications is the ability to create long-chain molecules in printed parts, resulting in significantly improved material properties, including isotropic strength – a key factor for many end-use parts.

ETEC printers and the DLP process include a number of hardware features – including high-powered projectors, custom-designed optics that minimize power loss– ensuring the creation of those long-chain molecules.

Superior part properties with Isotropic Material Properties

Isotropic material properties are essential for end-use components, but until recently have rarely been achievable with polymer 3D printing.

With FDM printing, very weak mechanical – not chemical – bonds form between each layer, resulting in anisotropic properties, or greater weakness along the Z axis than on the X or Y axes. This lack of uniformity has long kept FDM parts from being used as end-use parts.

With DLP printing, by comparison, each layer is left in a slightly uncured state, allowing it to chemically bond with the next layer as it prints. That bonding helps to create long chain polymers throughout parts, resulting in truly isotropic parts which are strong enough for end-use applications, and rival the properties of injection molded parts.

Superior part properties with 385nm Wavelength

All UV-curable resins require the addition of photoinitiators to start the polymerization process. Resins cured with 385-nm wavelength light require significantly less than many other materials, because the 385-nm wavelength is where absorption peaks for most common photoinitiators. Limiting the amount of photoinitiator in a part is particularly important for clear materials, because higher concentrations of photoinitiator result in parts with a yellow tint.

Resins cured with 385-nm wavelength light require significantly less than many other materials, because the 385-nm wavelength is where absorption peaks for most common photoinitiators. Limiting the amount of photoinitiator in a part is particularly important for clear materials, because higher concentrations of photoinitiator result in parts with a yellow tint.

Quality Materials

Quality materials via Industry-Leading Material Suppliers

ETEC is determined to provide its customers with the best materials in the 3D printing industry. To do it, they utilize a world-class material science team to produce ETEC-exclusive materials, and partner with world-leading material suppliers. The printer systems are designed to be selectively open, giving users flexibility.

Quality materials via 190+ qualified materials

With more than 190 materials, from hard plastics to high-performance elastomers to high-temperature materials, ETEC’s material portfolio can address the widest range of applications.

Quality materials that break the stigma of resins

Though they have been available to print for decades, resins have long been stigmatized as brittle and possessing mechanical properties that deteriorate quickly. A new generation of resins is emerging to erase that stigma, and open the door to a host of new applications.

The superior properties delivered by this new generation of resins includes vital features for end use parts, including mechanical properties that remain stable over time, highly ceramic-filled materials for added toughness and improved surface finishes, and high-temperature materials without brittleness, which are ideal for demanding environments.

In addition to those materials, ETEC offers resins with high wax content, making them ideal for casting jewelry and other products.

Easy To Use

Easy to use Software-Controlled Workflow

https://etec.desktopmetal.com/wp-content/uploads/2022/02/2022-01-24_15-55-16-3.mp4

The software that powers all ETEC printers, Envision One Rapid Prototype (RP) simplifies the process of setting up and starting a print.

With optimized support strategies for every material and automatic part orientation calculation, Envision One RP helps ensure printing success. For users who want more control over prints, the software allows for manual editing of a range of support parameters, including tip thickness, beam thickness, beam spacing and more.

To help increase productivity, prints can even be started remotely.

Easy to use Fast Material Switching

https://etec.desktopmetal.com/wp-content/uploads/2022/02/materiial-switch-1.mp4

With the ability to swap between any of ETEC’s 190-plus materials in just minutes, users can tailor their material choice to each specific application.

All ETEC materials come in a single pot, with no two-pot mixing required, simplifying the process of adding resin to the printer.

While the short shelf life of many competitor resins means they must be used within hours of being opened, all ETEC materials feature shelf lives of more than a year, ensuring no material ever goes to waste.

Out of stock 3D equipment and consumables, page 7

Up to 10% DISCOUNT on plastics and polymers with the purchase of a 3D printer

Displaying 145–168 of 777

In selected

Complete View 9000 request

4.5 out of 5

(2 reviews)

Out of production

- Manufacturer - BQ

- Country of origin - Spain

Price on request

is not released

Number

Number

In the favorites

Compare

Quick View

Condor

3D Condor SCAN

Price for

9000 9000 9002 of 5(3 reviews)

Out of production

- Manufacturer - Condor

- Country of origin - France

Price on request

is not released

number

Number

in the chosen

Complete

Quick View

Request KP

Carbon

3D Printer Carbon M1

Price for

0 OOT OOT OFOM 5,000 ( 0 reviews)

Out of stock

- Manufacturer - Carbon

Price on request

Out of stock

Quantity

Quantity

In the favorites

Compare

Fast view

KP

Cyberon

3D Printer Cybermicro Plus

Price on request

5 OUT of 5

(2 reviews)

9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 Producer - CyberonPrice on request

Out of stock

Quantity

Quantity

Add to favorites

Compare

Quick View

Request Lab DWS XFAB

Price on request

4 out of 5

(1 review)

Out of production

- Manufacturer - DWS Lab

- Country Country - Italy

Price on request

is not available

number

Number

In the favorites

Complete view 9000 028J Plus

Price on request

3 out of 5

(2 reviews)

Out of production

- Manufacturer - DWS Lab

- Country of origin - Italy

Price on request

is not released

number

Number

In the favorites

Compare

Quick View

KP

DWS Lab 9000 5 out of 5

(1 review)

Out of production

- Manufacturer - DWS Lab

- Country of origin - Italy

Price on request

is not released

number

Number

In the favorites

Compare

Quick View

KP

DWS Lab

3D DWS Lab DWS 008J

Price on request

9000 5 OUT(1 review)

Out of stock

- Manufacturer - DWS Lab

- Country of origin - Italy

Price on request

Out of stock

quantity

Number

In the chosen

Compare

Quick View

Request KP

EnvisionTec

3D EnvisionTec Vector 3SP

Price for

4 OF

Out of stock

- Manufacturer - EnvisionTEC

- Country of origin - Germany

Price on request

Out of stock

Number

Number

In the Favorite

Compare

Quick View

9000Out of stock

- Manufacturer - EnvisionTEC

- Country of origin - Germany

Price on request

Out of stock

Quantity

Number

In the favorites

Compare

Quick View

Request EnvisionTEC

EnvisionTEC ULTRA 3SP 3D Printer

Price on request

5 out of 5

(1 review)

is not released

- Manufacturer - EnvisionTec

- Country Country - Germany

Price on request

A number

Number

In the favorites

Complete

References

Price on request

Out of stock

Quantity

Quantity

Wishlist

Compare

Quick view 9Ol000

Add to Wishlist

Compare

Quick View

Inquire CP

Hori

0055

Price on request

5 Out of 5

(1 Review)

A

- manufacturer is not produced - Hori

- Country

Price for

A

Number Number Number

Quantity

Add to Wishlist

Compare

Quick view

Inquire CP

Hori

Hori Titan 3D printer

Price on request

0002 0 OUT of 5(1 Review)

A

- Manufacturer - HORI

- Country Country - China

Price at the request of

A number

9000Number

V. favorite

favorite

Compare

Quick view

Inquire CP

Hori

Hori Pluto 3D printer

Ask price

5 out0 of 5

(1 review)

A

- manufacturer - Hori

- Country Country - China

Price for

A number

Number

In the favorites

Compare

Quick viewing

Inquiry KP

Hori

3D printer Hori Gold

Price on request

0 out of 5

(0 reviews)

Out of stock

- Manufacturer - Hori

- Country Country - China

Price on request

is not produced

number

V -chosen

Compare

Fast View 9000 3D printer Hori Fobos

Price on request

5 out of 5

(1 review)

Not available

- Manufacturer - Hori

- Country Country - China

Price on request

is not produced

number

Number

In the favorites

Compare

Quick View

9000 Price on request4 out of 5

(1 review)

Not available

- Manufacturer - Hori

- Country of origin - China

Price on request

is not released

number

Number

In the favorites

Compare

Quick View 9000 out of 5

(1 review)

Out of production

- Manufacturer - Kevvox

- Country of origin - Singapore

Price on request

is not released

number

Number

In the favorites

Compare

Quick View

KP

Kevvox

3D Printer Kevvox SP 4300

Price for

22 5 5 5 5 5 5 5 5 5 5 5 5 5 (1 review)

Out of stock

- Manufacturer - Kevvox

- Country of origin - Singapore

Price on request

Out of stock

Quantity

Quantity

Manufacturers regularly update their product lines. The result is goods that are no longer produced. They can be found in residual quantities in warehouses in retail chains, but even there they disappear very quickly, and their search becomes meaningless.

The result is goods that are no longer produced. They can be found in residual quantities in warehouses in retail chains, but even there they disappear very quickly, and their search becomes meaningless.

Read more…

This section presents products discontinued due to product line renewal or liquidation of the company. This section is purely informational, and you can always find current models, improved analogues in our catalog.

For any questions, you can contact our staff.

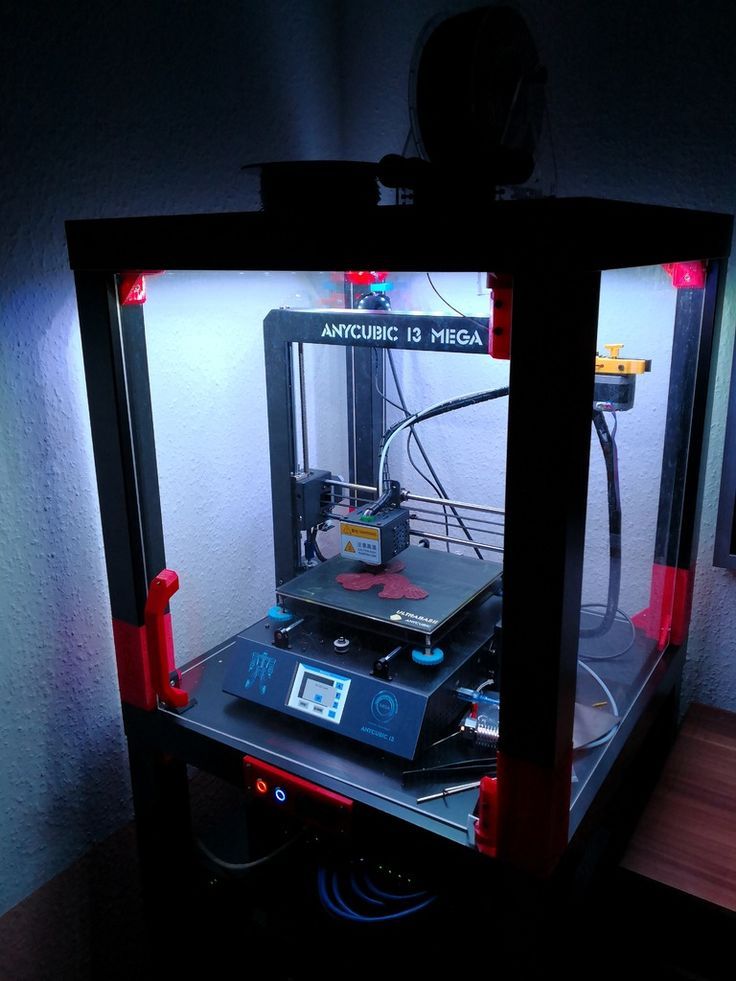

Perfactory P4K - high precision industrial DLP 3D printer

Perfactory P4K - professional solution

Designed for 24/7 production.

Allows you to take control of your production workflow with an automated job queue controlled by the built-in processor and automatic job completion alerts to help minimize printer downtime.

Designed for ease of use, with intuitive software and easy material changes, users can focus more on creating optimized parts and less time managing their equipment.

User-friendly Envision One RP software automates all steps of the print process, including support creation and part orientation, while a fully integrated file recovery tool fixes mesh holes and prepares parts for printing.

A simple material change in less than two minutes allows users to produce a wide range of parts with properties tailored to different applications, and excess material can be stored for months, helping users achieve additional cost efficiencies.

With few moving parts and easy access to optics and electronics, the printer is easy to maintain, helping to maximize efficiency by reducing or eliminating downtime.

Excellent reliability and designed for trouble free operation.

Excellent print quality

Hover over image

Applications

Dentistry

DLP technology is great for printing: implants and surgical guides; aligners; demonstration and collapsible models of the upper and lower jaws in bite; ash-free burnout structures, caps, bases for crowns and bridges, clasp prostheses; surgical templates for implantation, individual caps, guides for maxillofacial surgery and other technological materials.

The minimum layer thickness ensures perfect printing of small details and the highest detail of the main structural elements. The surface remains perfectly smooth.

Various dental materials can be used. Burn-out and non-burn-out, high precision biocompatible polymers. Any shades of polymers and transparent options.

Expand text

Jewelery

3D modeling and 3D printing technology allows in the shortest possible time to create products of increased complexity, including small and very detailed elements of the product.

The main advantage is the speed of obtaining the finished master model, in contrast to the CNC machine. For artists, this process allows the creation of unique product models, with complex geometries, thus opening up endless possibilities for creativity and experimentation.

Possibility of preliminary accurate calculation of the weight of the future product and, accordingly, the possibility of its adjustment to the required values.

The 3D printer platform accommodates a large number of models, allowing many prototypes to be produced in a single print cycle.

Expand text

Modeling

Modelers print matrices that are poured into silicone molds to make molds. Then they get scale copies of the necessary elements and assemblies required for each model. Subsequently, all these elements are brought together.

Also in radio modeling, sometimes there is a need to print the desired body of the future model from plastic, in order to subsequently produce body elements by molding.

3D printing plays an important role in modeling aviation. Growing aircraft bodies, propellers and propellers, quadrocopter bodies. In all these cases, printing significantly facilitates and speeds up the creation of a future model for testing.

Expand text

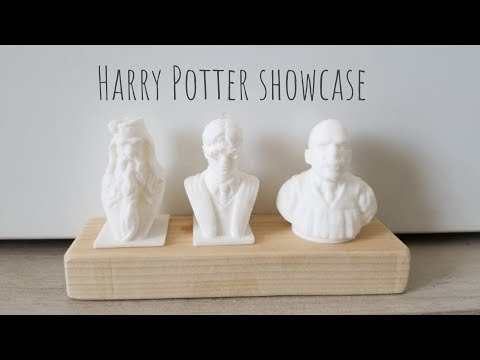

Miniatures and action figures

Miniatures and action figures are also quite popular in 3D modeling. For example, when creating layouts where human figures or miniature trees and other elements are required, as well as in game collecting or games. All this can be quickly created and printed on a DLP printer. Making such elements manually takes much more time and resources.

For example, when creating layouts where human figures or miniature trees and other elements are required, as well as in game collecting or games. All this can be quickly created and printed on a DLP printer. Making such elements manually takes much more time and resources.

3D printing can capture even the smallest elements of your action figures or miniatures, such as clothing, faces, shapes and reliefs. The model will have a perfect surface, ready for further painting and creating your work of art.

Expand text

Modeling

With the advent of modern design CAD systems and 3D printing complexes, architects began to use and use them with pleasure, which greatly simplified their lives. To speed up and be productive when working on a project, it is possible to print, for example, a certain segment of the layout with all the details, and immediately make the necessary adjustments on the computer.

3D printing allows you to create and demonstrate architectural and other models to the customer at the early stages of project approval, quickly making the necessary changes. It is also possible to simultaneously make several copies of an object for demonstration to several people, at different scales and environments. All these tools allow you to save time on model development, significantly reducing production time.

It is also possible to simultaneously make several copies of an object for demonstration to several people, at different scales and environments. All these tools allow you to save time on model development, significantly reducing production time.

Expand text

Engineering

When manufacturing a product that consists of different types of materials, such as an electronic board and a case, there is a need for more complex specialized equipment that can automate and simplify the manufacturing process as much as possible. Such products and their parts can be produced using three-dimensional printing.

Classic SLA/DLP printing methods are used for the production of cases and mechanical equipment. Engineering software allows you to achieve a perfect fit of the printed circuit board in the case of the future product printed on a 3D printer.

For a designer, printing instrument cases is a unique opportunity to make the necessary adjustments, evaluating the ergonomics and convenience of a future instrument based on a printed prototype.

Expand text

Price and payment

Check the availability and exact cost of the Perfactory P4K printer with our specialists on request via , by calling +7 (921) 907-46-35 or by writing to [email protected]. Payment is made according to the terms of the contract in cash or by bank transfer.

Leasing

It is possible to lease new equipment for your business and pay in convenient monthly payments. All details can be clarified with our specialists upon request via , by calling +7 (921) 907-46-35 or by writing to [email protected].

Warranty

1 year manufacturer's warranty. Warranty service, you can get in the city of Moscow and St. Petersburg.

Shipping

Delivery of equipment is carried out by transport companies the next day after payment.

Delivery to customer's address free of charge.

By providing his personal data, the User agrees to the processing, storage and use of his personal data on the basis of Federal Law No. 152-FZ "On Personal Data" dated July 27, 2006 for the following purposes:

• Providing customer support

Personal data means any personal information that allows you to identify the User / Buyer, such as:

• Last name, First name, Patronymic

• Date of birth

• Contact phone

• Email address

• Postal address

Users' personal data is stored exclusively on electronic media and processed using automated systems, except when non-automated processing of personal data is necessary in connection with the fulfillment of legal requirements.

The Company undertakes not to transfer the received personal data to third parties, except in the following cases:

• At the request of the authorized state authorities of the Russian Federation only on the grounds and in the manner established by the legislation of the Russian Federation

• Strategic partners who work with the Company to provide products and services, or those who help the Company sell products and services to consumers.