3D printing design considerations

What are the key design elements for 3D printing?

Are you new to designing parts for 3D print manufacturing or need a refresher on essential design elements? This article provides the key design elements for creating digital models for 3D printing, no matter the additive manufacturing process.

Every 3D printing technology comes with a distinct set of capabilities and its own design freedoms and restrictions. Whether you are a seasoned engineer who’s well-versed in designing for 3D printing or you are new to the field, it’s always a good idea to go over the most essential factors that make or break a design.

This article covers the key design considerations that apply to 3D printing in general, regardless of the printer you choose for manufacturing your custom parts.

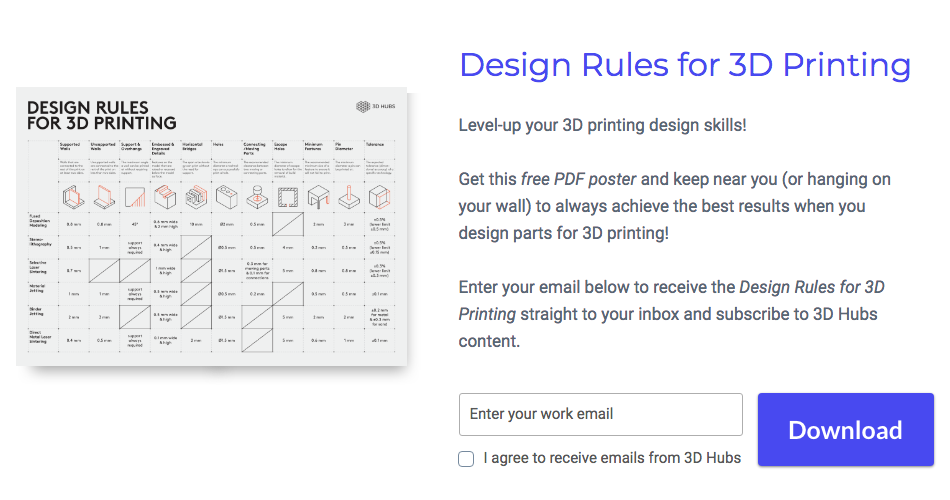

Check out this handy infographic for quick access to every essential design element you may need while creating digital models to 3D print.

Each 3D printing process has its own design advantages as well as some limitations. Let’s break down the key design considerations that apply to every 3D printing technology to keep in mind when designing your next custom parts.

All 3D printing processes build parts layer-by-layer. New layers can’t be deposited onto thin air, so every layer must be printed over some underlining material.

Overhangs are areas of a model that are either partially supported by the layer below or not supported at all. There is a limit on the angle every printer can produce without the need for support material. For example, if you’re printing with an FDM and SLA machine, this angle is approximately 45 degrees .

We recommend limiting your model’s overhangs, as layers printed over support structures usually come out with a rougher surface finish.

This image shows the effect of increasing angle on overhang quality for FDM printingWall thickness for 3D printing

The second thing to keep in mind when designing a part to be 3D printed is wall thickness. Every 3D printing process has its own level of precision. FDM, for instance, is the least accurate, while SLA has the tightest tolerances. In terms of part stability, every 3D printing process has a lower limit regarding wall thickness and feature size.

Every 3D printing process has its own level of precision. FDM, for instance, is the least accurate, while SLA has the tightest tolerances. In terms of part stability, every 3D printing process has a lower limit regarding wall thickness and feature size.

For example, imagine you are an engineer designing a new generation of hang gliders. You’ve chosen to 3D print a scaled-down version of the product to test its efficacy. 3D modeling programs allow you to model the sailcloth of the wing, for instance, but you then encounter problems when you would try to 3D print it. This is because the model’s wall thickness is less than the minimum required for successful printing.

It’s essential to make sure that your 3D designs have walls that meet the minimum required thickness for the printing process you choose. All 3D printers can successfully print components with wall thicknesses greater than 0.8 mm.

What is warping and how can you avoid it?

Something that is often easily overlooked while designing a 3D model is the fact that the materials used for 3D printing undertake physical change: they are melted, sintered or scanned with a laser and solidified. The heating and cooling of material can cause the parts to warp while printing.

The heating and cooling of material can cause the parts to warp while printing.

Large, flat surfaces can be especially prone to warping. Warping can typically be avoided by using correct machine calibration and having adequate surface adhesion between your part and the print bed. A good practice is to avoid large flat surfaces and add rounded corners to your 3D models.

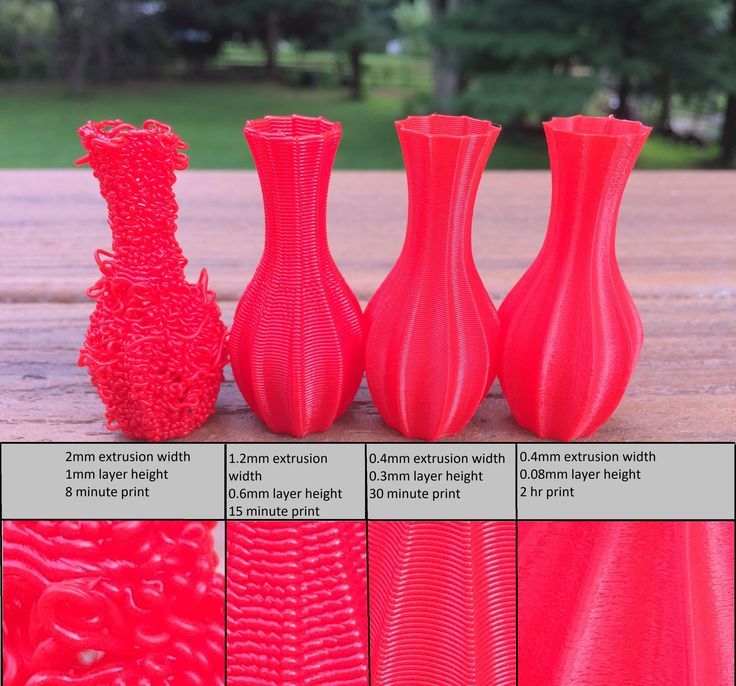

When you are creating a 3D model with intricate details, it is important to keep in mind the minimum feature size each 3D printing process can handle. The minimum level of detail is connected to the capabilities and mechanics of each 3D printing process and to the selected layer height .

The process and materials used will have an impact on the speed and cost of your print, so determining whether smaller details are critical to your model is an important design decision.

The most important thing to remember while designing for 3D printing is the fact that your digital design will become a physical object. In the digital design environment, there are no laws of physics to adhere to, such as gravity.

In the digital design environment, there are no laws of physics to adhere to, such as gravity.

Anything can be "drawn" in 3D on a digital canvas, but not everything can be 3D printed. Knowing the key factors that go into designing 3D models will ensure that you produce digital designs that can be successfully printed.

Want to learn the key design elements for every 3D printing technology?

Design parts for FDM Design parts for SLA Design parts for SLS

Ready to transform your CAD file into a custom part? Upload your designs for a free, instant quote.

Get an instant quoteDesign Considerations for 3D printing

When creating a model for 3D printing, there are several things you must keep in mind in order to be able to print successfully, especially when using a desktop printer. This article highlights some of the things to look out for.

As in any type of manufacturing, there are certain limitations to the materials and manufacturing processes that dictate how you must design a product. 3D printing is no different. Characteristics of hardware, software, temperature, and filament and many other factors play into how your digital model translates into a printed object.

3D printing is no different. Characteristics of hardware, software, temperature, and filament and many other factors play into how your digital model translates into a printed object.

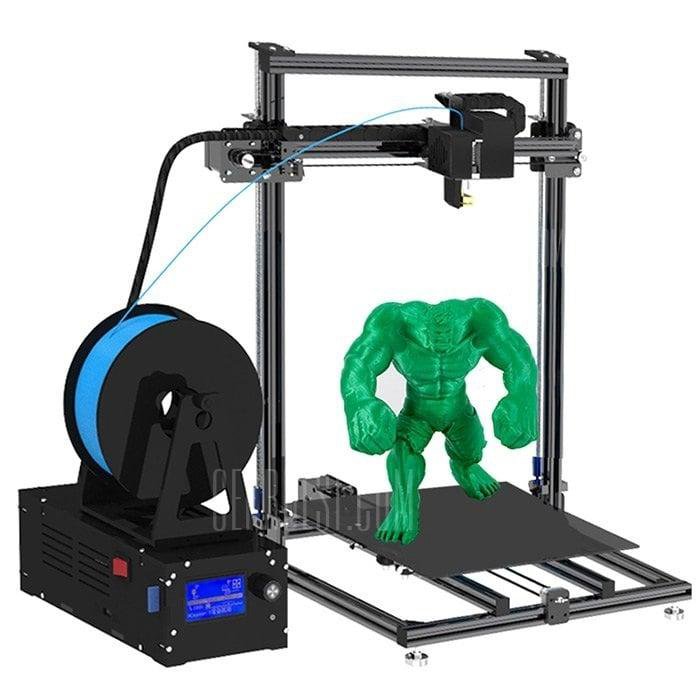

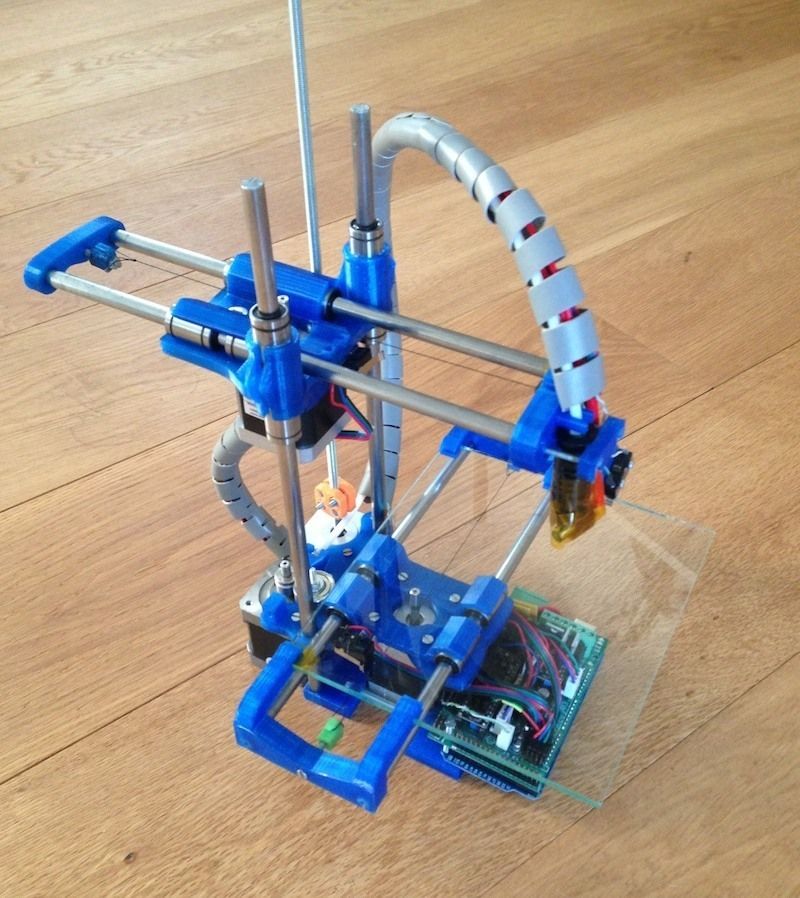

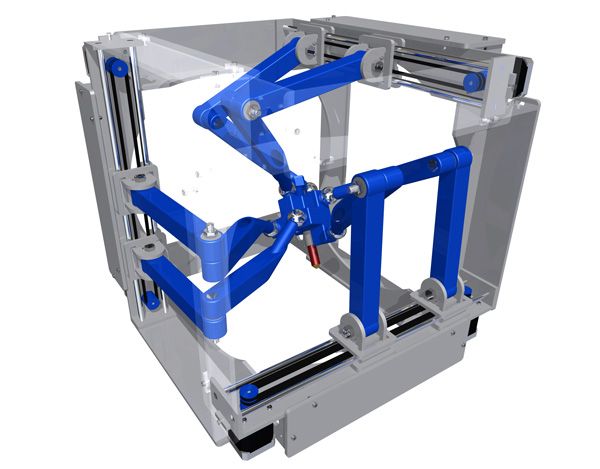

The following tips are for desktop style printers, also known as FDM (Fused Deposition modeling), such as the MakerBot, Ultimaker, Afinia, or any RepRap style printer. (I built a MendelMax 1.5 3D printer last year, which I’ve been having a lot of fun with.)

(UPDATE: 4/4/15 – I’m now printing on a MendelMax 3, which I’m really happy with. You can check out my full review of the MendelMax 3 right here.)

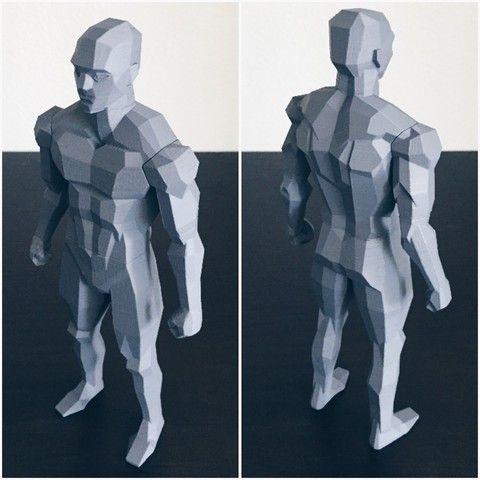

I have mostly been printing structural parts with my 3D printer, so some of the following tips won’t apply as much for purely sculpture type models.

Design a strong base

With typical desktop 3D printers, the model is printed out one layer at a time. The plastic filament (typically PLA or ABS) is melted and extruded onto a surface, called a bed, and it is absolutely critical that this first layer adheres to the bed for the duration of the print. If the model loses adhesion during the print, game over.

If the model loses adhesion during the print, game over.

Most of the times, prints will fail during the first layer due to lack of adhesion. I have a lot of experience with this…

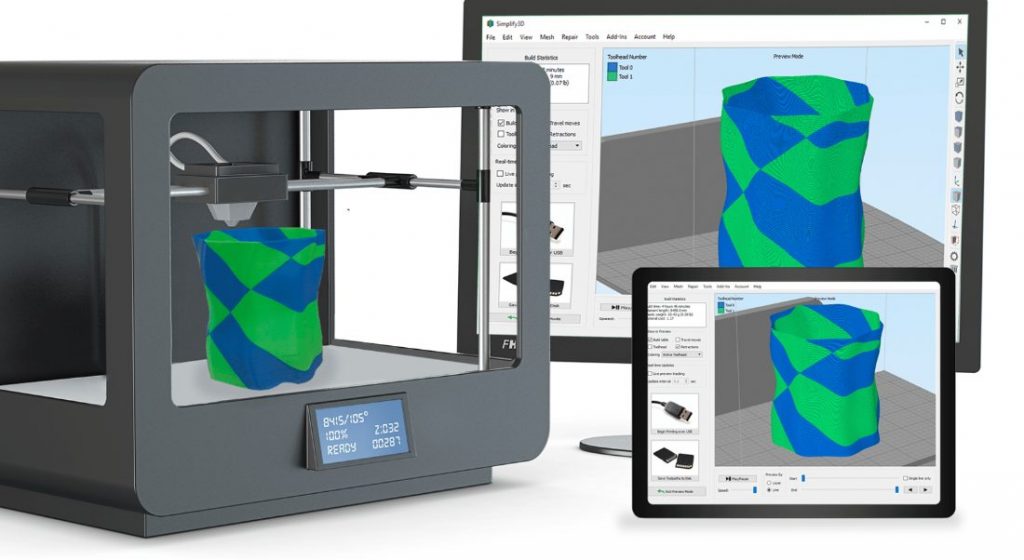

There is a lot of fine tuning that needs to be done to the printer and the printing software in order for the first layer to print successfully. (I happen to use Cura to interface with my printer, there are a few different free programs out there you can use.) You need to physically “level the bed” using adjustment screws so the end of the extruder is perfectly parallel with the entire surface of the bed. You can also do things in the software like add a brim or raft, increase the first layer extrusion thickness, turn off fans for the first layer, etc.

You can have a perfectly configured printer, but it won’t help you if your model isn’t designed to support itself and stick to the bed during the printing process. You need to make sure you have a strong enough base designed into your model with the following characteristics:

- Enough surface area to create positive adhesion to the printer bed.

(Adding a raft in your printing software can help with this.)

(Adding a raft in your printing software can help with this.) - Wide enough to support model and resist tipping over during the printing process.

- Strong enough to resist warping caused by different cooling rates.

Grain Direction

3D printed objects have a grain direction, since each layer is extruded one layer at a time. Each layer is adhered to the next, and the joints between layers are susceptible to delamination. If your model is designed for a structural application, these layer joints can become a weak point in your model if your model is not oriented correctly.

A way to overcome this potential problem is to simply orient your model so that the X/Y axis plane is where you need the most strength. Layers print in the Z axis direction. Continuous extrusion happens along the X/Y axis plane, so they are stronger.

Overhangs/Holes

Since each layer builds on top of the next, if you have parts of your model that are supported by thin air, there’s a good chance that the print will fail. Most printing software has the ability to add support material automatically to your model that can be broken away once the print is completed. However, there are many gaps that can be bridged by a printer without the use of support material.

Most printing software has the ability to add support material automatically to your model that can be broken away once the print is completed. However, there are many gaps that can be bridged by a printer without the use of support material.

These objects were printed without any support material. Pretty amazing, right?

Most small holes will print just fine. Also, as a rule of thumb, anything less than 45° overhang will print as well without the use of automated support material.

Wall Thickness

When you import your model into your printing software, you most likely have the ability to control many variables, including wall thickness. The wall thickness defines the number of times the extruder will lay filament around the perimeter of your model before switching to your infill factor. (Infill is defined separately as a percentage. Typically, 10% or 20% works well for infill.)

Your wall thickness should be defined as a multiple of your nozzle diameter, so a . 4mm nozzle with a .8mm wall thickness would result in the printer laying a perimeter two thicknesses wide for each layer.

4mm nozzle with a .8mm wall thickness would result in the printer laying a perimeter two thicknesses wide for each layer.

It is most important to keep this in mind when you are drawing very thin walls. When parts of your model are thin, the perimeter walls are so close together that it doesn’t leave much room for infill in between them. Sometimes, it may not properly fuse the walls to each other, leaving a hollow gap between the walls on the inside of the model.

When you have thin walls like this, think about your defined wall thickness (.8mm), and either leave plenty of space for good infill in between, or have the walls touching so they fuse together by making the wall 1.6mm thick.

Rounded Corners

SketchUp is really great at making objects with flat faces and square edges using the Push/Pull tool. It get’s a little bit tricky when you want to round off corners.

But round corners, from a structural point of view, are stronger. They also apply less wear and tear on your printer because changes in direction are gradual instead of sudden.

I love using the RoundCorner Plugin to add round corners to my models.

Tolerances

If you’re designing parts that need to fit one another, you need to take that into account. For example, a 10mm peg won’t fit into a 10mm hole. You need to make the hole slightly larger.

Another thing that comes into play is the segmentation of curves in your SketchUp model. Smoothed/Softened edges are irrelevant once you export your model to STL.

- Leave enough clearance for parts to fit.

- Make sure segmented curves are aligned with each other where they need to fit together.

- Consider increasing the number of segments on your curves to make the model more smooth.

Mock-ups

When designing parts that have critical tolerances, see if you can isolate that part of your model and print it out separately. This will allow you to test fit that shape alone, without worrying about the rest of the model.

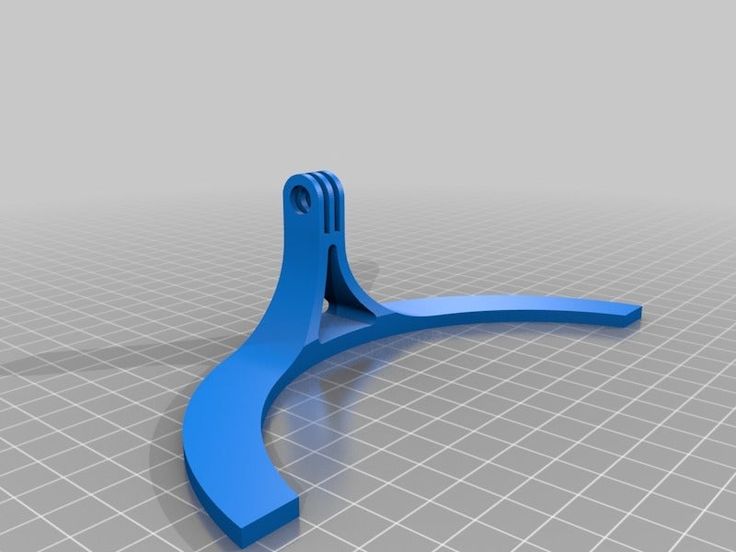

In the image below you’ll see the dashboard clip I’m designing for my truck. (I want to mount my cell phone to my dash, work in progress…) I printed out the top and bottom parts of the clip separately in order to confirm I had modeled the profiles of the dash correctly. Once I confirmed they were correct (after many iterations), I reincorporated those shapes back into the main model.

(I want to mount my cell phone to my dash, work in progress…) I printed out the top and bottom parts of the clip separately in order to confirm I had modeled the profiles of the dash correctly. Once I confirmed they were correct (after many iterations), I reincorporated those shapes back into the main model.

You’ll likely have to make numerous iterations in order to get the fit just right, but once you’ve figured it out, just incorporate that shape back into your main model.

Unique Properties

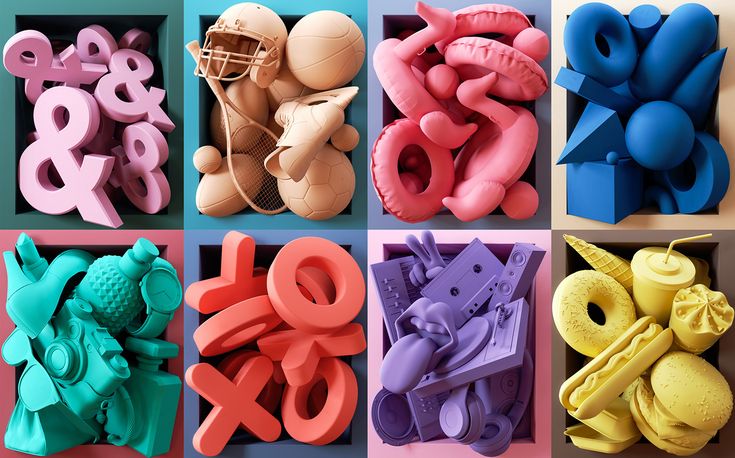

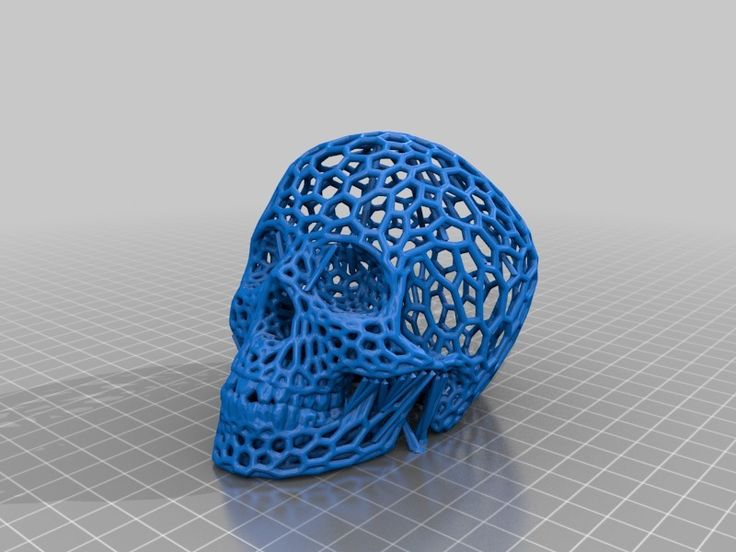

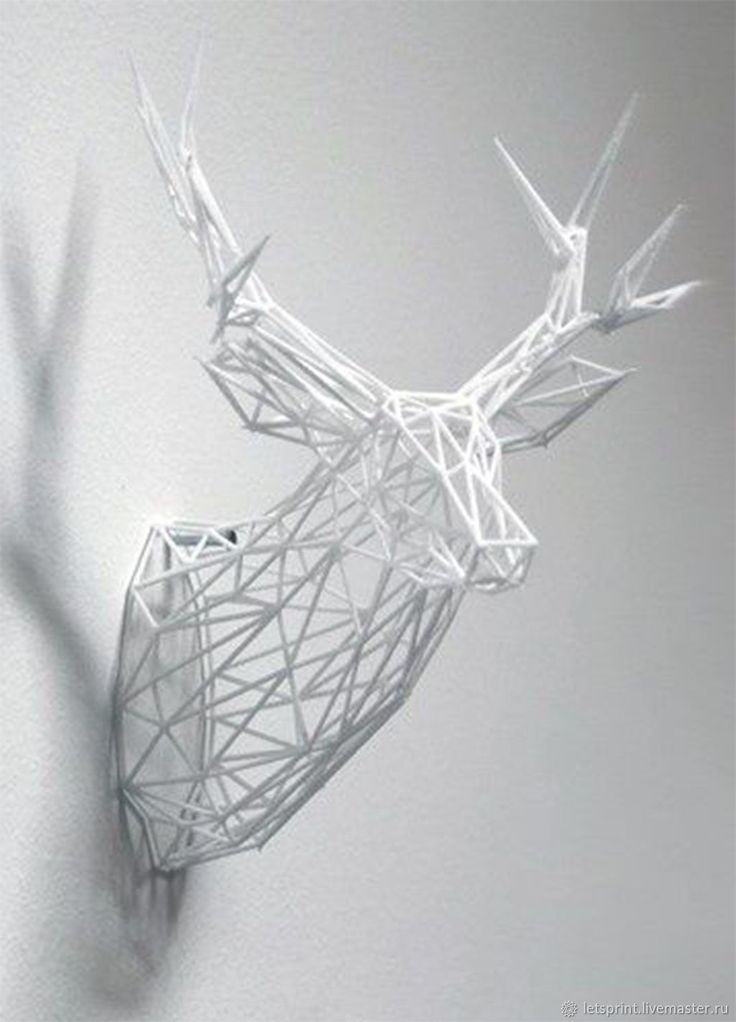

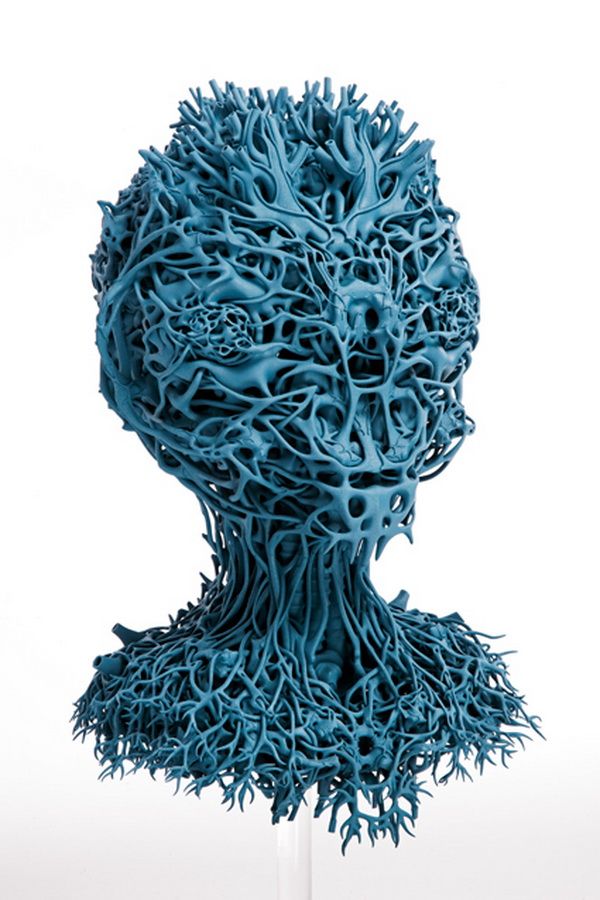

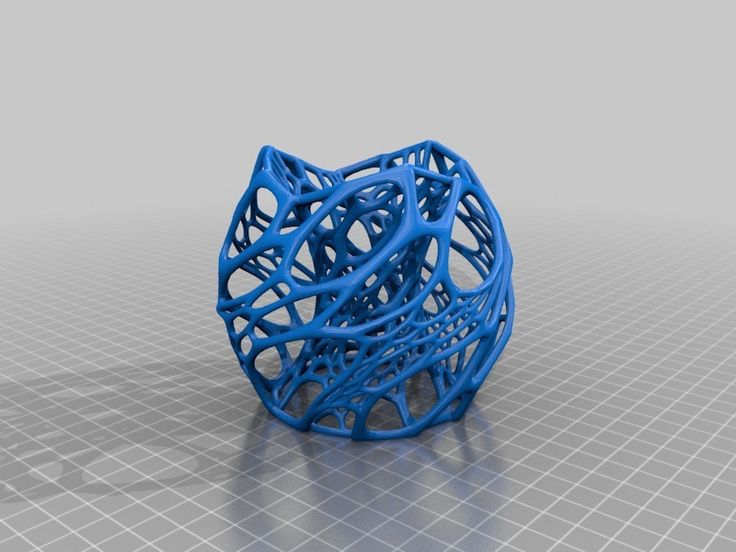

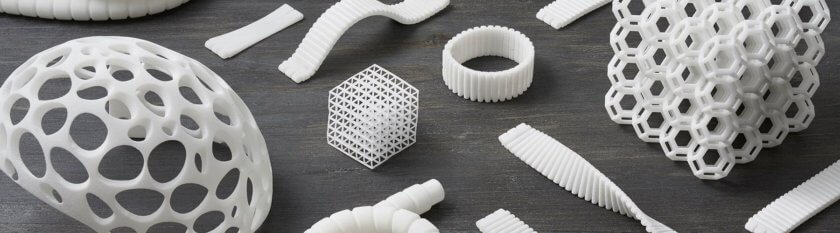

You’re not limited to designing a rigid, solid object. Experiment with the unique properties of the material and the printer to exploit their characteristics. Here are some examples of models that take advantage of unique properties of the material or the printer.

- This Jellyfish model uses the natural drooping effect caused by printing over thin air to create the tentacles of a jellyfish.

- A stretchy bracelet design is printed with a single wall thickness, and its squiggly shape lends to its flexibility.

- Taking advantage of the way a 3D printer prints layer by layer, this fully enclosed gear bearing uses careful tolerances to create a usable bearing straight off the printer. (I had some trouble printing this one, personally. I think I was printing too hot, everything was stuck together, lol)

- NinjaFlex is a special type of filament that creates a flexible “rubber ducky” style model. I’ve seen this stuff in person, it’s really awesome!

Check your GCode

One thing I always like to do when I’m getting ready to print, is to look at a visualization of the GCode, before sending it to my printer. The GCode is the set of computer instructions that are generated to tell your printer step by step, how to print your model. A visualization will show what your model will look like, layer by layer, as it will be printed by your printer.

There are many things that can go wrong with a model, (for example, if your model isn’t “solid”) and if you didn’t change the mistake yet, looking at your GCode visualization will be your last chance to catch anything before it goes to the printer. See below for an animation of a GCode visualization from Cura.

See below for an animation of a GCode visualization from Cura.

Most 3D printing software has visualizers built in, but if yours doesn’t, you can view it right in your browser at http://gcode.ws/ Some of the things I’ve been able to catch by looking at a visualization have been:

- I realized I didn’t have a raft, when I thought I had checked that option.

- I saw the generated support material, and decided to make changes to the model to reduce the amount of support material needed.

- The model wasn’t sitting flat on the bed, because I had accidentally rotated the model a few degrees.

- My infill was set too high.

- Major errors caused by model not being solid.

Do you have some design tips for 3D printing? Leave a comment below!

3D Modeling Basics for 3D Printing / Habr

KolianM

Working with 3D graphics *Prototyping *DIY or DIY 3D printers

casting or milling. This is due to the technical features of the 3D printer, from which you need to either squeeze the maximum benefit, or adjust to the disadvantages of printing.

This is due to the technical features of the 3D printer, from which you need to either squeeze the maximum benefit, or adjust to the disadvantages of printing.

From the reservations, I note that these recommendations relate mainly to the FDM (FFF) 3D printing method, in which a plastic rod is heated by a moving extruder that forms the part layer by layer.

3D model development starts with a sketch. It can be a drawing on paper, a material prototype, a mental image, etc. What is important to pay attention to when creating such a sketch and the model itself, we will analyze in detail.

Part strength

Here and further down the text there are several sub-points that must be taken into account at the same time, kept in mind from the very beginning.

- Be aware of the layering or anisotropy of the material: it is much easier to break a part in layers than across. This must be taken into account in advance, given the location of the 3D model on the 3D printer table.

- Add fillets. The leg of the stool and the tabletop at the junction should have a rounded corner. At the same time, the larger the radius of curvature, the stronger the leg will be fixed on the tabletop. Similarly for various body parts. Modeling a box All right angles are rounded. It doesn't matter what plane they are in. Even where a right angle is needed, we make a radius of 0.5 mm. The printer will pass through such a section more easily than an unrounded one, there will be no impact from a sharp stop of the extruder, the part will not sway, and other pluses.

- Wall thickness and filling. The maximum strength at 100% infill is a fact, but if you need to lighten the part or save plastic, you can make a much larger wall thickness in the print settings, while setting the infill much lower. This works with parts that have holes for fasteners. When creating machine code for a printer, absolutely all the outer walls are thick, so the fastener will be surrounded by a reliable thick layer of plastic of your part.

- Support. This element affects the strength in that the layers supported by the support are not always ideal in structure. This can be solved by increasing the wall thickness, filling, but it is better not to do support at all. Support is added by the slicer depending on the angle between the part wall and the table plane. Often the default is 60 degrees, sometimes 45. This setting is selected experimentally for each 3D printer. You can check this with the help of special test parts. For example, https://www.thingiverse.com/thing:2806295 - do not forget to turn off support to check the real quality of 3D printing in its absence. For example, you need to print a T-piece for tubes. Cast products are made in a T-shape. 3D printing makes the product L or even Λ-shaped. In the second case, support can even be avoided, and the part will be stronger due to the layers located at an angle of 45 degrees to the tubes. We, in the workshop, set up slicers for each machine and ask the client about the strength requirements, and, depending on this, choose a 3D printer to print.

Geometric restrictions

- The wall thickness is limited from below by the size of the 3D printer nozzle. Its diameter is constant and in the vast majority of cases it is 0.4 mm. Smaller thickness - long 3D printing for most parts. The larger the nozzle, the bonds between the layers are less strong, the steps between the layers are more visible. And in general, the wall thickness should be a multiple of 0.4 mm, then the 3D printer will be able to accurately make the wall in two passes (0.8 mm), in 3 passes (1.2 mm), etc. Other thicknesses will cause the 3D printer to leave a gap or overflow, which negatively affects the strength and appearance of the printed part.

- 3D printing of thin cylinders and "needles". For 3D printing of such products, special 3D printer settings are needed: low 3D printing speed, allow time for cooling, otherwise such a structure will bend. Vertically standing thin elements are best avoided at all costs.

Even if they are printed, they will be very fragile. It makes sense to leave them only for decorative purposes, but you must be prepared that their quality will be worse than the quality of other elements of the 3D part.

Even if they are printed, they will be very fragile. It makes sense to leave them only for decorative purposes, but you must be prepared that their quality will be worse than the quality of other elements of the 3D part.

- 3D printed holes. I note that if the hole is straight and through, then it can be drilled, if it is curved and requires support, then it may turn out that it will be impossible to get support.

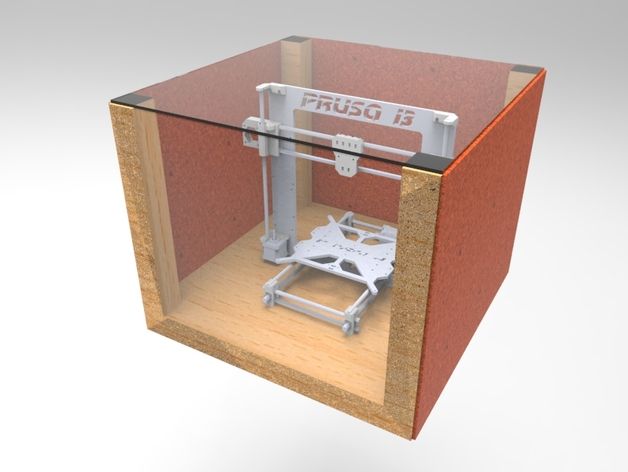

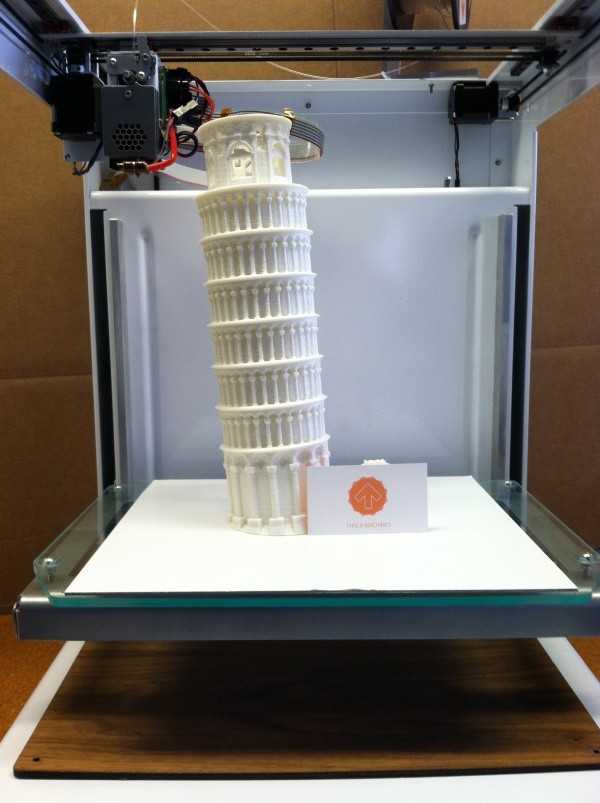

- When 3D modeling, it is important to consider the overall dimensions of the 3D printer. We use convenient 3D printers, table 250x250 mm, diagonal 353 mm. This is where you need to enter the dimensions, if possible. Otherwise, you need to order either an industrial 3D printer with a large print area, or use gluing, but assembly is better, so the assembly process will be controlled by the developer, and not by the 3D printing master.

- Large footprint may cause edges to peel off the table. We use special glue, but this does not always help.

We are periodically approached with a complaint about colleagues in the shop that for them such “minor” defects as a folded edge are not a reason to restart 3D printing, take it as it is. But an engineer who 3D models a part can take this into account in his work and make either assemblies or thin-walled flat 3D parts that “do not have enough strength” to compress the outer contour and, as a result, raise the edge.

We are periodically approached with a complaint about colleagues in the shop that for them such “minor” defects as a folded edge are not a reason to restart 3D printing, take it as it is. But an engineer who 3D models a part can take this into account in his work and make either assemblies or thin-walled flat 3D parts that “do not have enough strength” to compress the outer contour and, as a result, raise the edge.

- Tall and thin "towers" may not work well due to vibrations that occur when the 3D printer is running closer to the top, and layer shifts are also possible.

Dimensional stability, accuracy

- Precise 3D printing is quite rare. I don’t want to speak in engineering terms here, but the likelihood that a complex composite structure will assemble the first time is very low. Here, rather, you need to take into account the fact that you can then mechanically refine the details.

- Holes for fasteners are best done with a margin of 0.

5 mm in diameter. This will not reduce strength, the fasteners will also not dangle due to tightening forces, but if you do it without a margin, you will definitely have to drill it out. Reducing the size of a large shaft, >10mm sandpaper is much easier than making a hole, which requires a huge drill that cuts into the plastic walls and breaks the part, or gets stuck in it. It is also important to consider that when drilling, the plastic melts and the drill can melt into it so that it cannot be removed. There have been cases.

5 mm in diameter. This will not reduce strength, the fasteners will also not dangle due to tightening forces, but if you do it without a margin, you will definitely have to drill it out. Reducing the size of a large shaft, >10mm sandpaper is much easier than making a hole, which requires a huge drill that cuts into the plastic walls and breaks the part, or gets stuck in it. It is also important to consider that when drilling, the plastic melts and the drill can melt into it so that it cannot be removed. There have been cases.

- Heat shrinkage is not always compensated, more precisely, it is very difficult to catch it, it is not the same in different directions, so it is extremely difficult to take it into account. It's easier to print a test version, and then make adjustments.

When appearance matters

- Think about how the craftsman will orient the part on the 3D printer table. 3D printing proceeds in layers, which is clearly manifested when printing surfaces that are at a small angle from the horizontal of the table.

Skinning will be long and painful, because you will have to cut this "ladder" to the deepest depressions of the "steps". It is better to place such surfaces either horizontally, for example, put on a table, or increase the angle. In some cases, even adding support that spoils the wrong side of the wrong side saves time and effort on post-processing.

Skinning will be long and painful, because you will have to cut this "ladder" to the deepest depressions of the "steps". It is better to place such surfaces either horizontally, for example, put on a table, or increase the angle. In some cases, even adding support that spoils the wrong side of the wrong side saves time and effort on post-processing.

- Support. First, the surface it supports has significantly more defects than without it. Secondly, thin and high support is weak, wobbly, which leads to the fact that the supporting part may have serious defects, or not work at all.

- First layer quality improvement. You need to add a bevel. Even where a sharp corner is not needed, I recommend adding a chamfer of 0.5 mm. It will not be clearly visible, but the edge will be neat.

What you need to know in order not to make a mistake when ordering 3D printing

If appearance is important

- Placement of the part on the table.

Remember about anisotropy.

Remember about anisotropy.

- Wall thickness and filling. What you can run into here: the filling is 20% cells, which are either visible through a thin outer wall, or the filling slightly tightens the outer wall during shrinkage, but at the same time it is visually easy to determine that there is support inside. Here, first of all, an increase in the thickness of the outer wall, or an increase in the filling density, helps. Please take this into account when ordering.

Postprocessing

The elimination of stepping is achieved by mechanical and chemical methods. It is possible to use putty. Acrylic paint available. If the part has a complex color structure, then we use the ProJet 4500 printer, which works on a different technology. He glues the powder particles together with colored ink glue. It turns out well.

Morality

In conclusion, I would like to note that these recommendations and the accumulated experience will make it possible to produce parts by 3D printing, which in their properties will not be inferior to cast ones, which makes it possible to save significant funds in the presence of a customized printer and small production volumes. From my own experience, I note that fiddling with the printer, debugging it, knowing “all the cracks” is a separate topic, which I will talk about later. And in conclusion, I would like to ask the reader to express their opinion in the survey.

From my own experience, I note that fiddling with the printer, debugging it, knowing “all the cracks” is a separate topic, which I will talk about later. And in conclusion, I would like to ask the reader to express their opinion in the survey.

Only registered users can participate in the survey. Come in, please.

Do I need to buy a 3D printer, or should I outsource it?

66.67% It is better to control everything yourself, modeling and printing 60

21.11% I model, and let those who live it print 19

10% I prefer designing and printing to narrow-profile specialists 9

14.44% I don't believe in 3D printing, I try to avoid it altogether 13

90 users voted. 24 users abstained.

Tags:

- 3D-modeling

- 3D -ip

Habs:

- Work with 3D graphics

- Prototyping

- 3D 3D

- DIY or do

- Building information model (Revit, ArchiCAD)

- Surface modeling (Rhino, SketchUp)

- Compound

- Finishing

- Build Volume Limitations: Printers with large build volumes are either expensive or compromise on surface quality. Form 2 build volume is 57 x 57 x 69 inches (145 x 145 x 175 mm)

- Need to show interior details or materiality : Some models require components to be separated to show more design information.

- Need to show internal or external parts

- Easy Split (You want to split the model by the least complex part of the model)

- Least heavy use of CAD

- Greater tolerance for prints that warp or have a higher degree of dimensional change

- Assembly requires manually leveling each piece and fixing it in place until the adhesive is fully bonded

- Easy alignment Parts that are not accurate

- Easy to assemble (mating parts help create a large surface area for adhesion)

- High precision SLA allows tight fit with high tolerance and can be used without adhesive

- Parts that are not true to size will not fit well. High fine details are often less accurate.

Modeling Strategy and Software Usage Guide

At a Glance

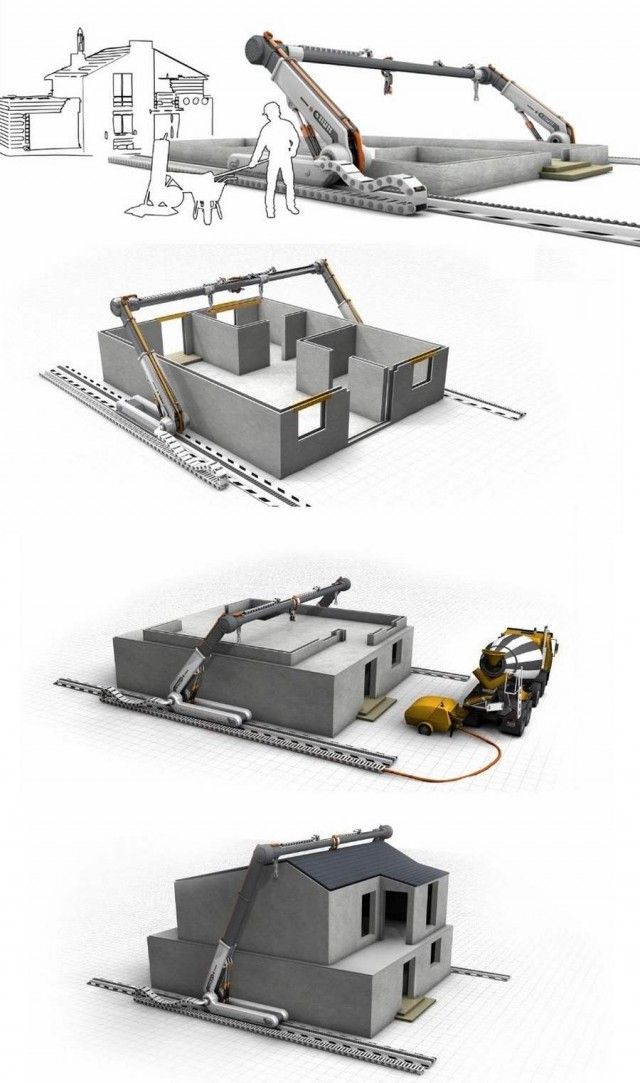

3D printing provides tremendous benefits to the conventional architectural workflow. You can print complex designs without the need for skilled craftsmen, and quickly modify these designs without too much difficulty. Stereolithographic (SLA) 3D printing delivers incredibly high surface quality and detail, making it suitable for architectural applications. This paper explores modeling strategies and software workflows that enable architects and designers to easily integrate 3D printing into existing design methodology, create best practices based on internal testing by Formlabs and architecture firms, successfully using Form 2 to create 9 models0005

You can print complex designs without the need for skilled craftsmen, and quickly modify these designs without too much difficulty. Stereolithographic (SLA) 3D printing delivers incredibly high surface quality and detail, making it suitable for architectural applications. This paper explores modeling strategies and software workflows that enable architects and designers to easily integrate 3D printing into existing design methodology, create best practices based on internal testing by Formlabs and architecture firms, successfully using Form 2 to create 9 models0005

WHAT YOU WILL LEARN:

Strategies for designing 3D printed architectural models

Tips for improving workflow Pre-print processing software

Good post-processing techniques

Introduction

The 3D printing market today offers affordable options in both price and scale. While professional-grade technology used to be costly, desktop stereolithography 3D printers allow architects, designers, and model makers to offer high-quality, in-house fabricated parts.

While professional-grade technology used to be costly, desktop stereolithography 3D printers allow architects, designers, and model makers to offer high-quality, in-house fabricated parts.

Most models cost less than $10 per part.

3D printing opens the door to creating complex designs with less effort and fewer materials, but the successful transition from a CAD model to a printable file is based on a basic understanding of design for 3D printing. This document will help you understand how standard modeling constraints relate to preparing a file for 3D printing, as well as approaches and decision making for intelligent modeling - from scale selection to design and assembly for post-processing.

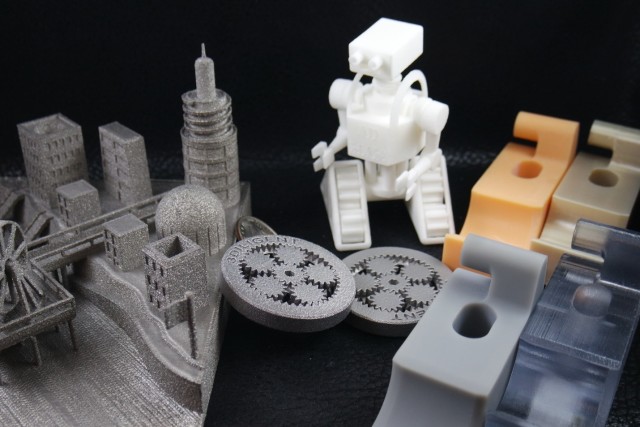

To integrate these strategies into existing workflows, this booklet explores ways to approach modeling strategies tactically by examining three of the most common software ecosystems: allows you to include small details even on the smallest models. This example of a small city model is 1/32″ = 1’ scale and is 3D printed entirely on a Form 2. Many small details and parts of this design will take significantly longer if cut and assembled by hand. Model from LaneyLA Inc.

Many small details and parts of this design will take significantly longer if cut and assembled by hand. Model from LaneyLA Inc.

This auditorium section was 3D printed as one piece on a black resin Form 2. Model from DLR Group.

Modeling strategy

Architectural models are usually assembled using various materials and components. 3D printers help combine these components into as few separate parts as possible, but assembly manipulation is still necessary for two reasons:

DESIGN FOR ASSEMBLY

All 3D models require preparation before they can be sent to the 3D printer. In the case of architectural models for the Form 2, this often involves splitting the model into smaller parts to fit the scope of the Form 2 build. The parts can then be easily joined together by chemical adhesive or mechanical assembly; high precision printing ensures that the parts fit together.

In the case of architectural models for the Form 2, this often involves splitting the model into smaller parts to fit the scope of the Form 2 build. The parts can then be easily joined together by chemical adhesive or mechanical assembly; high precision printing ensures that the parts fit together.

Dimensioning for parts to be separated must take into account the final orientation of the model. Most architectural prints need to be oriented at a 45 degree angle due to floor slabs being considered large horizontal projections. Dividing the model into long, thin parts helps maximize the diagonal length of the build volume while achieving perfect orientation

Strategy Overview

There are several strategies for assembling 3D printed models. Your strategy will depend on what you hope to represent with the design, as well as the scale and geometry of the model. Consider the following parameters:

It is necessary to show a certain part of the program: typology, structure, floor layout

| Seam separation | Separation by component |

| Section model | Program separation |

| Straight cut | Separation by structure |

| Aligners |

Splitting at a seam

STRAIGHT CUT

The easiest way to split a model is with a straight cut. This is a simple command to execute in most CAD software. The bridge model is divided lengthwise using straight cuts into four parts, one of which is shown above. Each support post is inserted into

This is a simple command to execute in most CAD software. The bridge model is divided lengthwise using straight cuts into four parts, one of which is shown above. Each support post is inserted into

mating hole that does not require glue. Regardless of which method you choose, if you have a large number of parts (more than 10), it can be helpful to add a unique identifier for each part to help solve the puzzle during assembly.

Pros:

Cons:

Try to print all components in the same orientation so that the layer lines and subsequent dimensional inaccuracies follow the same pattern.

ALIGNMENT TOOLS

Another approach is to add features to the design that will allow the prints to align. When adding mate fixtures, try to subdivide the model in areas with the least complex geometry. Use the CAD tool of your choice to split your model and add basic alignment fixtures such as slots, pins, grooves, recesses and flanges, or more complex fixtures such as dovetails and cuts that follow existing model curves. In addition, it is important to create a design with ~0.25 mm tolerance between mating parts to prevent additional sanding at the post-printing stage.

When adding mate fixtures, try to subdivide the model in areas with the least complex geometry. Use the CAD tool of your choice to split your model and add basic alignment fixtures such as slots, pins, grooves, recesses and flanges, or more complex fixtures such as dovetails and cuts that follow existing model curves. In addition, it is important to create a design with ~0.25 mm tolerance between mating parts to prevent additional sanding at the post-printing stage.

Pros:

Cons:

SECTION MODEL

The separation of the model with a seam has the additional task of showing the section model for structures with irresistible interior details. Initially, the model can be presented as a whole to the client, and then disassembled to reveal interior details as desired. These LaneyLA examples show how the same model conveys different types of information based on open and closed configurations

Initially, the model can be presented as a whole to the client, and then disassembled to reveal interior details as desired. These LaneyLA examples show how the same model conveys different types of information based on open and closed configurations

This LaneyLA model was printed on Form 2 white resin.

Using devices for combining: Methods component

SOFTWARE SPLITTING

By breaking down a building with software, you can represent the building as a set of parts, providing a clear understanding of all design components without a plan and section drawings. You can print each floor slab separately and then assemble using mates, or just print one component of the entire building separately from the rest. A good example is the model from Stanley Sitetowitz | Natoma Architects Inc (SSNAI), who used the Form 2 to model the residential complex.

Model by Stanley Sitetowitz | Natoma Architects Inc.

Since each body block followed the same pattern, it makes sense to simply print one removable block that will allow the customer to understand the typology of the typical device to print as a single block or separate along the seam.

This method usually works for models that do not have straight lines, such as typical building blocks, but complex structures, such as detailed building sections, bridges, pavilions, or airports.

First, break these models down into components that can be 3D printed with minimal supports. This saves post-processing time (removing supports for delicate models can be tedious) and reduces material costs and print times.

This bridge example demonstrates multiple partitioning methods. First, the model is divided into several parts (Figure a). Although they fit the

Form 2 build platform, they require painstaking removal of supports around more delicate areas such as cables and railings.

To solve this problem, each part is broken down into three sub-components: base plate and railing, vertical tensile cables and solar panels on top (figure b). They can be printed with significantly fewer supports, making it easier to finish,

They can be printed with significantly fewer supports, making it easier to finish,

Once completed, the components simply need to be assembled using the alignment functions that were included in the design phase. Smaller parts are also easier to place on a single build platform, with the entire bridge being printed from five 100ml parts.

Model from T.Y. Lin Architects

This playground model was created using laser-cut fiberboard. The primary building was 3D printed from clear and white resin. Model by Schwarz Silver Architects

Materials

Materials play an important role in conveying the basic design concept. It is not always necessary to model the exact color and texture of a material, but it can help separate different materials. Dividing a model into its components allows for the display of materiality, as parts can be printed in different materials or individually dyed in different colors.

The transparent façade is illuminated from within, simulating the visual conditions of this site at night.

Formlabs Matte Resins

Black, White and Gray out of the printer have a smooth, opaque finish and provide an excellent neutral palette for architectural models. Gray and white resins are also easy to process and can be finished with just a few coats of paint, as discussed further in the finishing section of this document.

Formlabs Clear Resin is excellent for printing features that mimic translucent materials. If your model requires more transparency, you can simply dip the printed part in clear resin and let it dry evenly, as described in this article on making clear resin parts. You can also spray any clear coats on the model to increase the transparency and glossiness of the surface.

3D PRINTING AND TRADITIONAL MATERIALS

This model uses Form 2 to print very fine details such as the cornice, clock and railing. Model by Miles Burke Architectural Models Inc.

Model by Miles Burke Architectural Models Inc.

Instead of 3D printing an entire building, sometimes it's better to print only complex components. Complex facades, slings and cornice details are excellent candidates for SLA 3D printing. Flat walls, floor slabs and topography can be laser cut or even hand-drawn

This complex façade is parametrically designed based on solar trajectory analysis and would be incredibly difficult to fabricate in any other way at this scale.

Software workflow

Good printing comes from a well-designed 3D model. This section will cover modeling best practices and workflows for printing in some of the most common CAD environments:

Revit, SketchUp and Rhino

CAD software is typically the bottleneck in the transition from drawing to 3D printed model

General workflows

IMZ workflow

902 PreForm

Although BIM (Building Information Model) software is popular with architecture firms, it is not always used for direct 3D printing models. There are some high level steps that you can take

There are some high level steps that you can take

take to create a 3D printed model from these programs. This workflow is widely applied to Autodesk Revit or Graphisoft ArchiCAD software, both of which are IMZ parametric modeling programs.

PREPARE THE FILE

STEP 1: Prepare a stand-alone file

STEP 2: Component Management: remove ducts, double glazing, HVAC units and internal parts that will not be visible in model

STEP 3: Select all components to be sealed (eg doors, windows, walls, slabs). The parametric nature of the model allows you to simultaneously compact the dimensions of several objects.

EXPORT FILE

Select the scale at which you want to export the file. Select the export options depending on the needs of your model:

EXPORT AS STL

Exporting the file as a mesh is very difficult to manipulate, so this is only useful if you don't want to edit any geometry after this step. You can then use your software to correct the mesh of your choice, as well as subdivide the mesh along the main Cartesian planes.

You can then use your software to correct the mesh of your choice, as well as subdivide the mesh along the main Cartesian planes.

EXPORT AS 3D DWG

Export as surfaces allows you to easily manage and edit geometry in Rhino or SketchUp. This step is recommended for those who want to split the model programmatically or by component, or split by a seam that is not on the normal Cartesian plane. You can then export the STL file from Rhino or from SketchUp using the plug-in

EXPORT USING ARCHICAD

Perform geometry conversion to Morphs and "consistency check" before exporting the model as STL. When printing in parts, use tool

"Divide" to cut the model for multiple print platforms if needed. This operation basically creates printable files, but a quick check in mesh repair/analysis software never hurts.

USING STL REVIT EXPORTER

This method automatically removes smaller details such as doorknobs and railings. However, it is not reliable and still often requires some post-processing in other CAD environments before being sent to print.

However, it is not reliable and still often requires some post-processing in other CAD environments before being sent to print.

Surface Modeling Workflow

AutoCAD → Rhino/SketchUp → Model Diagnostics → PreForm

This workflow is often an easier approach and starts with 2D drawings solely for the purpose of 3D printing

FILE PREPARATION

STEP 1: Hide unwanted layersSTEP 2: Identify and remove unnecessary elements such as furniture, trees, etc.

EXPORT FILE

STEP 1: Export simplified drawing from Rhino as DWG

STEP 2: Import into Rhino

STEP 4: Start extruding and trimming until you get the outer shell.

STEP 5: Export as STL STEP 6: Mesh Analysis/Correction STEP 7: Import to PreForm

Note: If the model will be printed in several parts, split it before exporting as STL

THICKNESS WITH RHINO

Instead of parametrically controlling the thickness of components directly in the BIM file, you can also use the BoxEdit component in Rhino.

This allows you to simultaneously scale a number of elements in relation to their center lines. BoxEdit is ideal for models that need to be scaled parallel to three Cartesian axes. Non-uniform scaling is a little trickier.

For non-rectilinear geometries, we suggest converting the part to a mesh and then using the Weaverbird thicken command, which simply shifts any non-standard mesh geometry outwards by a given distance. Alternatively, it is possible to "split" complex parts into surfaces and then offset them instead of importing volumes from Revit.

SELECTING SMALL GEOMETRIES WITH RHINO

Another valuable feature of Rhino is the SelSmall command, which allows you to select all elements in the Stage that are smaller than a custom bounding box. You can then select those objects and use

BoxEdit for individual scaling or just remove them. This is useful when you are dealing with a file that does not have a well organized layer system.

Although performing a logical connection on all geometries is ideal, often the problem can be solved with simple overlapping geometries. PreForm will interpret them as one closed geometry in most cases, but be sure to check printability with the "slicer" tool in the right pane in PreForm

. CONTINUOUS / LOGICAL CONNECTION GEOMETRY

Note : PreForm is Formlabs free software that prepares your 3D model for printing in Form 2. Once the part is set up, you can save it as a FORM file for future use in preform.

COMPUTATION WORKFLOW

Although a less common workflow, computational design is slowly being introduced into mainstream architectural workflows. Software such as Grasshopper and Dynamo are used to create parametrically generated geometries that are often so complex that they can only be created with 3D printing.

Since geometries are already easy to manipulate, it's usually best to create a separate component that allows you to easily control the basic dimensions of all thin objects. In this case, it's a simple matter of trial and error; running the exported geometries with a print test (PreForm,

In this case, it's a simple matter of trial and error; running the exported geometries with a print test (PreForm,

MeshMixer) and resizing until you arrive at a printable file.

Model Diagnosis

All workflows described below share a potential "generic diagnosis". This is an optional (but often necessary) step to ensure that the model is fully printable. Free programs such as Autodesk's MeshMixer and Netfabb are tools that allow you to repair, smooth, cavity, and split 3D print files.

MESH FIX

Formlabs PreForm software uses Netfabb's built-in mesh fix, so NetFabb and MeshMixer must be used for custom fix or to preview problem spots in print. Materialize Magics is a great proprietary tool that covers the entire preprint workflow for a wide range of printer types. The mesh patching software part is most important to the Form 2 print workflow and can save you a decent amount of preparation time. Netfabb has a beautiful built-in model cutter that allows you to effectively split and restore large files along any Cartesian plane.

SPLITTING THE MODEL

It is also possible to split the model in NetFabb, which splits and fixes the split parts into printable volumes. In Rhino, you will need to close open volumes. Be sure to leave a tolerance of ~0.25mm between adjacent parts, this will allow them to be inserted without friction.

See our white paper for tolerances.

PREFORM SLICER

Architectural models are very detailed and it is often difficult to isolate each print issue. A combination of the above practices and mesh repair software is usually used for almost all problems, but it's always wise to use the PreForm Slicer tool to make sure there are no thin unsupported areas and enclosed volumes (such as rooms with no doors, elevator shafts, and parking spaces) .

“Building and architecture structures are not meant to be 3D printed, they are meant to be built. This creates problems of scale and complex geometry. By combining Netfabb's powerful mesh repair tools with the precision of the Form 2, you can prototype and visualize designs faster and in more detail, benefiting more for your business and speeding up your project's design review process. ”

”

Matt Lemay. Lead Enterprise Solutions Provider, Autodesk Customer Service

Post-Processing

Joining

The modeling strategy section of this booklet covers some ways of splitting and aligning parts together, but glue is always needed for a secure connection. Architectural parts are bonded in two main ways:

CYANOACRYLATE

Cyanoacrylate (CA or Super Glue) creates a fast, strong enough bond, ideal for small to medium sized parts. CA does not bond dirty surfaces well, so be sure to thoroughly clean the part before applying adhesive to the surface of the model.

POLYMER

For smaller prints, you can use liquid resin as a binder. Dispense a small amount of resin into the tray from a bottle or cartridge, use a dropper or syringe to lift it up, and place it on the surface of the part to be bonded.

Join parts and wipe off any excess resin that may be spilling around the edges. To cure the resin and bond the parts, use a 5 mW laser pen at 405 nm and point it at the bonding area around the parts.

To cure the resin and bond the parts, use a 5 mW laser pen at 405 nm and point it at the bonding area around the parts.

This method creates a chemical bond, just as if the part had been printed on your SLA 3D printer, but only applies to small bonding surfaces because a low power laser pen cannot penetrate the model deep enough to create a strong bond .

FINISHING

Parts printed on Form 2, especially matte standard resins, have a smooth surface immediately after exiting the printer. However, visible areas with supports almost always require sanding. In addition, you can prime and paint parts in any desired color.

GRINDING

Sanding will help you remove the support marks and any remaining inaccuracies from your model. Start by carefully dry sanding the surface of the part using ~150 grit sandpaper to remove large support marks and smooth out the edges of the joint. Once the surface of the part is smooth, wet sand with 320mm sandpaper to remove any remaining layer lines. Move the sandpaper randomly to avoid grain formation.

Move the sandpaper randomly to avoid grain formation.

In most cases these two steps will create a fairly even finish, but you can continue to increase the grit size of the sanding paper by a factor of 2 and use wet sanding on the entire piece until the surface is the desired smoothness.

Once you have finished sanding your model, wash the model in soapy water to remove any dust or debris and dry thoroughly before proceeding to the last step.

The architectural models are very detailed and it is quite difficult to access certain areas with only sandpaper. You can use different sizes of nail files to get to problem areas of the model.

PRIMER AND PAINTING

Priming is required before parts are painted to ensure the paint adheres to the surface. Priming can also make it easier to find areas that require additional finishing. A quick spray of primer over the model makes the support marks very visible, so you can instantly identify areas that need additional sanding.