Boston 3d printing company

Advanced Additive Manufacturing Solutions - Micro 3D Printers : BMF Boston Micro Fabrication

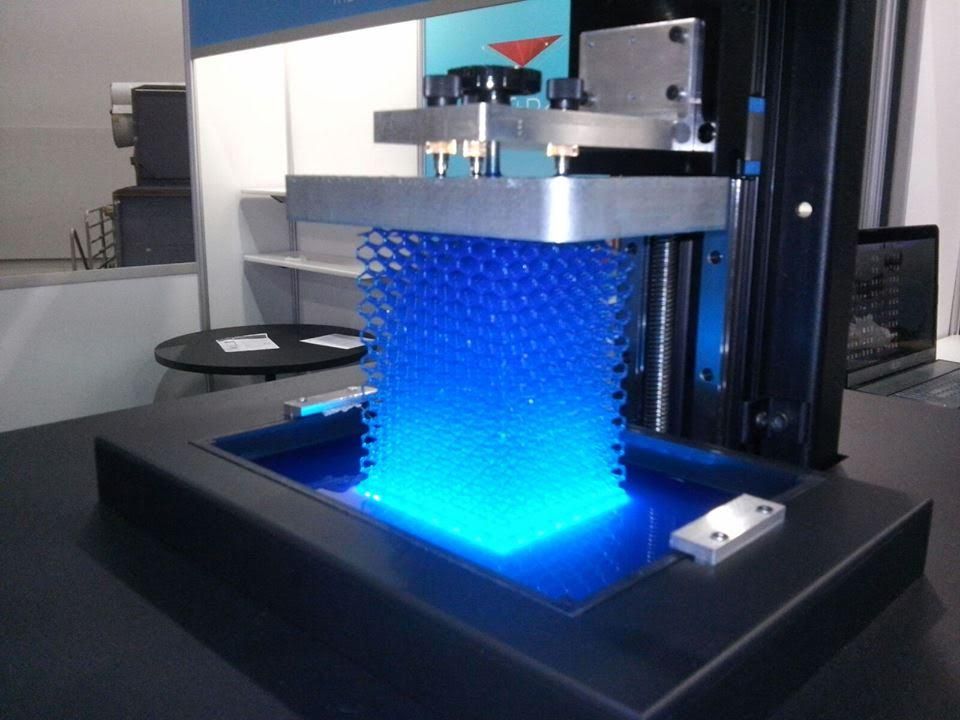

ULTRA-HIGH RESOLUTION, ACCURACY, AND PRECISION

Boston Micro Fabrication is the world leader in advanced additive manufacturing solutions based on Projection Micro Stereolithography (PµSL) technology. Many leading companies worldwide are adopting PµSL to 3D print true microstructures with ultra-high printing resolution (2µm~50µm) and printing tolerance (+/- 10µm ~ +/- 25µm).

Micro-precision 3D printing is the optimal manufacturing process for various use cases across a wide variety of industries. BMF empowers companies with complete design freedom to enable the creation of geometries that can be manufactured no other way. The combination of ultra-high resolution, accuracy, and precision allows for more intricate, exact, and replicable parts, at scale and tolerances that match those of micro injection molded parts.

Learn More

Our Capabilities

News

Accelerating Prototyping and Design Testing with Micro 3D Printing

Learn how Tessy Plastics uses Projection Micro Stereolithography to optimize the design on a minimally invasive surgical tool for one of their largest customers.

Read More

Our Products

Build Size

- 100 × 100 × 75mm

- 100 x 100 x 50mm

- 19.2 × 10.8 × 45mm

- 3.

84 × 2.16 × 10mm

84 × 2.16 × 10mm - 48 × 27 × 50mm

- 50 × 50 × 10mm

- 50 x 50 x 50mm

- 94 × 52 × 45mm

Layer Thickness

- 10μm~40μm

- 10μm~50μm

- 5μm~20μm

Optical Resolution

- 10μm

- 25μm

- 2μm

Printing Material

- Ceramic

- Photosensitive Resin

Clear Filters

Request a Benchmark Part

We’d be happy to manufacture a benchmark part so you can assess our quality.

Request a Benchmark part

News • November 29, 2022

BMF CEO John Kawola on the new microArch S350, the company's new 25µm resolution printer

“Really good surface finish and really good performance, which we believe, from a part quality point of view, is better than the rest of the market.” John Kawola, CEO of BMF, told TCT at Formnext 2022 in Frankfurt.

The company’s new system, the microArch S350, is the latest addition to the line-up of industrial grade micro-precision 3D printers. The S350 offers a 25µm resolution and has the highest throughput in the BMF portfolio.

Read More

The quality and accuracy of BMF PµSL parts is very unique, and truly mimic expensive micro molded parts, and now we can have parts ready for test within 1-2 days rather than 1-2 months, as well as reducing the huge costs associated with tooling manufacture and reworking as the new products evolve.

We can also explore designs previously out of reach due to manufacturing limitations. Our main focus is to lift our prototyping capabilities to the highest possible level, both in quality and speed. BMF will help us accomplish that.

– Sally van der Most, DSS Manager, Sonion NL

We chose BMF’s microArch 3D Printer due to its ability to replicate critical micro features. Their unique Projection Micro Stereolithography (PµSL) technology prints 3D parts with ultra-high resolution and accuracy, which is key to our business. This is the first 3D printer we’ve encountered that can print micro-precision parts, with the dimensional accuracy and precision that our customers require at this stage of product development. We have put the BMF parts through the same rigorous CT scanning inspection process of our micro molded components and were amazed that dimensionally the parts fell within the tolerances required.

Our customers have been equally amazed.

– Donna Bibber, VP of Business Development, Isometric Micro Molding, Inc.

We have been looking for some time for a machine that can reliably produce parts in this size range as we were at the limits of other machines or would have to sink cost into other manufacturing methods- typical micro injection molding or other micro machining activity that can be expensive and prohibitive to R&D iterations. The ability to rapidly produce these types of parts combined with an open ecosystem is unmatched.

– Sam Wilson, STORM Lab UK, Institute of Robotics and Autonomous Sensing, University of Leeds

The parts say it all. The first time you see a part from a BMF printer you will be amazed. 3D printing, until now, has never been able to produce parts of such precision, and accuracy.

Being able to capture thin walls and fine features at this scale and resolution, with unmatched reliability, is unprecedented from any 3D printing technology. This will absolutely usher in new industries, that have previously ignored 3D printing, to the world of rapid design iteration.

– James Grimm, Senior Business Development Manager, Empire Group

December 6, 2022 • Additive Manufacturing

Read MoreJanuary 3, 2023 • 3DPrint.com

Read More3D Printing Service for Boston, Massachusetts

CapabilitiesCustom Online 3D Printing ServiceMassachusettsBoston

High Quality Boston, Massachusetts 3D Printing | 60+ Materials Available

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

Quality Assurance

Our number one job at Xometry is making your custom parts to your specifications.

Your Boston, Massachusetts 3D Printing Service: 3D Prototypes and Production Parts

A Global Leader in Industrial-Grade 3D Printing

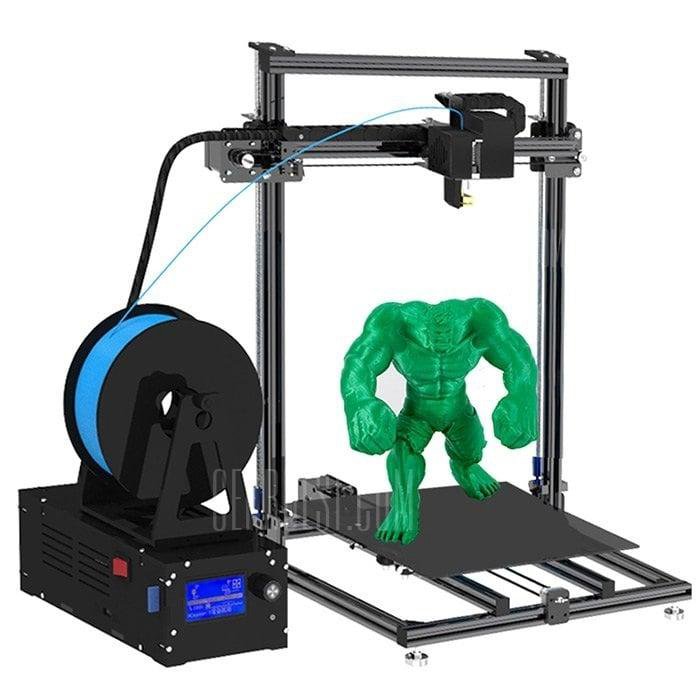

Xometry is an industry-leading 3D printing service. Whether you need prototypes or production parts, we can make them for you in as fast as a day. We are your one-stop-shop for accurate, precise custom 3D printed parts at a low cost. Upload your 3D CAD file to get a quote and lead time within seconds. We use the latest additive manufacturing processes to build affordable functional prototypes & end-use parts in over 60 metals and plastics.

We offer eight high-quality 3D printing processes including selective laser sintering, fused deposition modeling, stereolithography, direct metal laser sintering, polyjet, Carbon DLS, binder jet metal, and HP Multi Jet Fusion. We use commercial and industrial-grade printers such as Stratasys Fortus 900mc and Fortus 450 FDM, EOS Polymer Laser Sintering (SLS) and DMLS, Concept Laser, SLM Solutions, 3D Systems, ExOne, and more.

We use commercial and industrial-grade printers such as Stratasys Fortus 900mc and Fortus 450 FDM, EOS Polymer Laser Sintering (SLS) and DMLS, Concept Laser, SLM Solutions, 3D Systems, ExOne, and more.

Xometry's High Quality 3D Printing Services

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) is a powerful 3D printing technology that produces highly accurate and durable parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping.

An additive manufacturing layer technology, SLS involves the use of a high power laser (for example, a carbon dioxide laser) to fuse small particles of plastic powders into a mass that has a desired three-dimensional shape. The laser selectively fuses powdered material by scanning cross-sections generated from a 3-D digital description of the part (for example from a CAD file or scan data) on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness, a new layer of material is applied on top, and the process is repeated until the part is completed.

Download the SLS Design Guide.

Stereolithography (SLA)

Stereolithography (SLA) is a robust 3D printing technology that produces extremely accurate and high-resolution parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping.

SLA is an additive manufacturing process that focuses an ultraviolet (UV) light on a vat of photopolymer resin. It offers higher resolution printing than many other 3D printing technologies, allowing customers to print parts with fine details and surface finishes. SLA 3D printing is a highly-versatile platform for making custom parts in prototype and production settings; often acting as a stand-in for injection-molded plastic parts.

Xometry offers both standard and high-resolution options for fine detail parts, and can also print larger sized parts and products, with some materials offering up to a 58" inch build area. In addition, Xometry's manufacturing partner network allows us to offer a larger variety of materials than other 3D printing companies - we offer a wide range of both Accura and Somos brand materials.

Download the SLA Design Guide.

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is a 3D printing technology widely known for its speed, accuracy, and competitive cost. A machine precisely extrudes melted plastic filament to create a part. Parts are very rigid, especially compared to Selective Laser Sintering (SLS), which makes them a great fit for projects with a rigidity requirement. Xometry's FDM solution offers large build volumes up to 24″ x 36″ x 36″, a variety of colors, and a diverse selection of production-grade thermoplastics — from ABS to Polycarbonate to Ultem.

Download the FDM Design Guide.

HP Multi Jet Fusion (HP MJF)

HP Multi Jet Fusion is a new 3D printing technology that produces highly accurate and durable parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping. Since the process uses well-established 2D printing ink-jetting, it has remarkably fast layer times compared to other powder bed fusion technologies.

Download the HP Multi Jet Fusion Design Guide.

PolyJet 3D (PJ3D)

PolyJet 3D is a 3D printing technology known for its customizable material properties and excellent surface finish. It works by jetting UV curable resin onto a build tray in a process that is somewhat similar to inkjet printing. PolyJet 3D printing offers one of the most advanced industrial 3D printing solutions available, producing parts with incredible precision and speed. It also supports a wide variety of build materials including rigid and rubber-like plastics. Xometry's PolyJet solution has a maximum build envelope of 19.3 × 15.4 × 7.9 in. (490 × 390 × 200 mm) in a variety of colors and materials.

Download the PolyJet 3D Design Guide.

Direct Metal Laser Sintering (DMLS)

Direct Metal Laser Sintering (DMLS) is an 3D metal printing technology that builds prototype and production metal parts from a CAD file using a laser to selectively fuse a fine metal powder in either stainless steel or aluminum materials. A DMLS machine is capable of producing highly complex features and all-in-one assemblies using metal materials that would be difficult to achieve with subtractive manufacturing techniques.

A DMLS machine is capable of producing highly complex features and all-in-one assemblies using metal materials that would be difficult to achieve with subtractive manufacturing techniques.

Our DMLS metal 3D printing service typically offers build volumes up to 250 x 250 x 325 mm, but we may be able to accommodate larger part volumes upon request in the quote. (See our Manufacturing Standards for more details) A good first step is to find out the cost of the parts you need using DMLS and compare them to other 3D printing processes and CNC machining.

Download the DMLS Design Guide.

Carbon DLS™

Carbon DLS™ uses digital light projection, oxygen-permeable optics, and programmable liquid resins to produce products with end-use durability, resolution and surface finish. This 3D printing technology is called Digital Light Synthesis™, or DLS for short. Another legacy term for the process is Continuous Liquid Interface Production (CLIP). Along with Carbon’s custom liquid resins, DLS unlocks new business opportunities and product designs previously impossible, including mass customization and on-demand inventory of end-use products.

Carbon bridges, and sometimes substitutes, for processes like Urethane Casting and Injection Molding service production, because the materials are urethane-based or epoxy-based, giving excellent mechanical properties. There are even elastomer and silicone resins that outperform most additive manufactured rubber-like materials.

The typical build area is 7.4” x 4.6” x 12.8”. Parts with dimensions exceeding 4” x 4” x 6” will require manual review.

Download the Carbon DLS Design Guide.

Metal Binder Jetting

With binder jetting, an inkjet print head quickly deposits a bonding agent onto a thin layer of powdered particles -- either metal, sand, ceramics or composites. This process is repeated, layer-by-layer, using a map from a digital design file, until the object is complete. Binder jetting is offered through our Digital RFQ Marketplace through Xometry's partnership with ExOne.

Download the Binder Jetting Design Guide.

Locations near Boston, Massachusetts

Cambridge

MassachusettsWorcester

MassachusettsProvidence

Rhode IslandManchester

New HampshireNewport

Rhode IslandSpringfield

MassachusettsNew London

ConnecticutHartford

ConnecticutNew Haven

ConnecticutBridgeport

ConnecticutAlbany

New YorkSchenectady

New YorkStamford

ConnecticutYonkers

New YorkBurlington

VermontQueens

New YorkNew York City

New YorkBrooklyn

New YorkJersey City

New JerseyNewark

New Jersey

Ready to start making custom 3D printed parts?

NEW PALITRA TO OFFER AVAILABLE FULL COLOR 3D PRINTING INSTEAD OF RISE

You are here

Home

THE BOSTONON RIZE COMPANY, THAT DEVELOPED THE FULL COLOR 3D PRINTING PROCESS AND IMPLEMENTED IT IN THEIR XRIZE SYSTEM, IS SUBJECTLY CLOSING OPERATIONS.

Kerry Stevenson, founder of the popular online 3D printing publication Fabbaloo, announced this in his article "The Demise of RIZE?" yesterday.

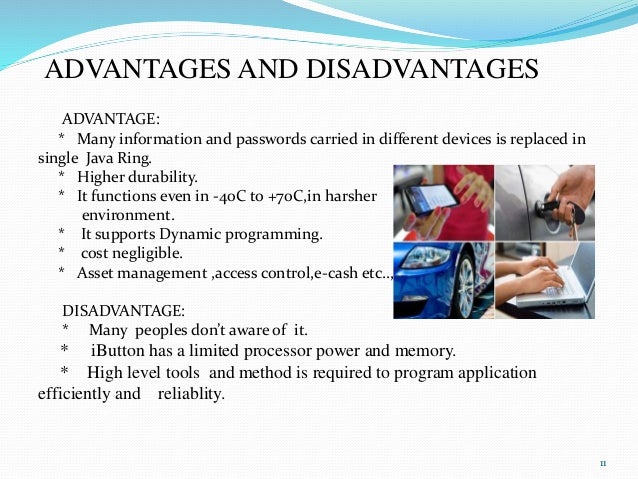

Recall that RIZE has developed an innovative approach to 3D printing that combines FFF and inkjet technologies. This made it possible to use special inks for easy separation of models and supports, the ability to apply serial numbers and various markings to products during the printing process, print color products, etc.

During his investigation, Kerry Stevenson contacted Eugene Giller, co-founder of RIZE, and learned that the company was experiencing financial difficulties in 2021, which led to the departure of employees. Apparently, the $40,000 XRIZE system was priced too high for the market.

In the fall, the company auctioned off its intellectual property portfolio and other assets, which were purchased by Eugene Giller himself for his new company, Palitra.

. But the most interesting thing is that with Palitra it is planned to bring RIZE full color technology to the market at a much lower price - less than 10 thousand US dollars, and possibly less than 5 thousand if there are enough orders.

The explanation is that the RIZE full color system was simply too expensive. Its cost largely depended on the use of extremely expensive components, which were the only ones available at the time the machine was developed. Meanwhile, today there are many alternative components that can significantly reduce the cost of developing a similar full-color 3D printing system.

For example, according to Giller, each printhead in the XRIZE system cost about $1,500, and the system required THREE of them. Whereas now it is possible to purchase equivalent printheads almost an order of magnitude cheaper.

Palitra isn't quite ready to launch yet, Giller says, but it's expected to be visible on the company's website in February.

Source

Other materials:

- A 3D printer that prints from metal and ceramics has been developed in Novosibirsk

- Fleet Space has developed satellites completely printed on a 3D printer

- The Rosseti group began testing Rostec exoskeletons at power facilities

- Israeli company launches plant-based 3D printing of hamburgers

- German engineers mastered nanoscale 3D printing

Attention!

We accept news, articles or press releases

with links and images. [email protected]

[email protected]

3D printers - All about 3D printers and 3D printing technology / Sudo Null IT News0001

All about 3D printers and 3D printing technology

Articles Authors Companies

Show first

Rating threshold

Biotechnology 3D printers

Scientists from the Australian University of Wollongong have developed a new device that may well become an indispensable tool for a surgeon. The device, BioPen, is a portable bioprinter (3D, how else), with which a doctor can print patient tissue by applying it to an injured area. At the same time, bone, muscle or nervous tissue is not “printed”, no. BioPen "ink" is a mixture of stem cells + protective polymer.

BioPen "ink" is a mixture of stem cells + protective polymer.

Read more →

Total votes 42: ↑39 and ↓3 +36

Views47K

Comments 59

GoldSerg

3D printers

This post is a kind of warning to those who are planning to buy a 3D printer. This seemingly simple process for civilized countries can be shattered by the harsh Russian realities. I, not expecting it myself, managed to go through all the possible rakes, and on my own skin I was convinced how things really are on the “other side of the screen”. So, I invite you to learn from the mistakes of others.

Read more →

Total votes 350: ↑342 and ↓8 +334

Views872K

Comments 487

MagisterLudi

3D printers

The Home Office has tightened firearms laws and now the manufacture, sale, purchase and possession of 3D printed weapons is completely illegal.

The offender will be imprisoned for 10 years old .

Would you buy a Liberator?

Read more →

Total votes 47: ↑36 and ↓11 +25

Views70K

Comments 145

marks

Smartphones 3D printers from an IT company

Not so long ago, Habré published news about a modular smartphone from Motorola, in which it will be possible to upgrade individual modules by adding RAM, replacing the processor, etc. instead of replacing the whole device..jpg) So, company

So, company Google Motorola has announced a partnership with 3D Systems, maker of Cube 3D printers, to develop "modular smartphones with customization capabilities that allow users to create the gadget of their choice."

Read more →

Total votes 40: ↑33 and ↓7 +26

Views50K

Comments 18

tedbeer

3D printers

On November 15-16, a 3D print show was held in Paris (at the beginning of the month it was held in London). I went to look at this case and share my impressions. In the Netherlands, the format of a similar show has changed, the event was stretched out over several days and the price was raised to the highest possible. You have to go to Paris.

want more. ..

Total votes 21: ↑21 and ↓0 +21

Views40K

Comments 7

alizar

Soft 3D printers

Microsoft has released a 3D Builder program with which you can quickly prepare a 3D model for printing.

The kit comes with a large library of ready-made objects and components.

Read more →

Total votes 80: ↑74 and ↓6 +68

Views66K

Comments 39

marks

3D printers

The Smithsonian Institution has a huge number of exhibits, something like 137 million. Of course, most of the exhibits are in the museum's vaults, and the average visitor sees only the "tip of the iceberg". Actually, this is a problem for many museums, and some of them are trying to solve the problem by digitizing their treasures (both literally and figuratively). Someone photographs the exhibits, someone scans. And the Smithsonian Institution decided to digitize some of the exhibits in the form of 3D models.

Read more →

Total votes 29: ↑29 and ↓0 +29

Views28K

Comments 23

jeston

3D printers

The already well-known Liberator pistol, which can be printed on a 3D printer, has been recognized by the US Bureau of Alcohol, Tobacco, Firearms and Explosives (ATF) as a lethal weapon.

The Bureau's experts did a simple job of downloading the pistol's CAD files freely available on the Internet, printing the required number of weapons and testing. In the end, it turned out that a .38 caliber bullet fired from a Liberator is able to penetrate several inches of human flesh, causing damage to vital organs and even piercing the skull - however, the distance to the target and how clothes affect the effectiveness of the shot are not indicated. .

Learn more

Total votes 63: ↑60 and ↓3 +57

Views115K

Comments 271

exeditor

3D printers

Industrial metal 3D printers that can print a rocket engine or gun cost tens of thousands of dollars. Printers available to a mere mortal costing up to $ 1,000 so far only know how to work with plastic. American engineer and entrepreneur David Hartkop intends to change this. His Mini Metal Maker printer will cost just $750 as a kit and parts, and $1,000 as a complete kit.

Read more →

Total votes 66: ↑63 and ↓3 +60

Views128K

Comments 52

alizar

Robotics Astronautics 3D printers

Only in the Milky Way, scientists estimate the number of planets suitable for life at 60 billion (according to the latest extended estimates). It is clear that with modern engines, the flight will take millions of years, but in the perspective of the fading of the Sun, the colonization of other M-class planets seems to be the only possible way for the development of civilization.

One way or another, before settling in other systems, you have to master your own system well: for starters, the Moon and Mars. It is necessary to create permanent bases. According to experts, 3D printing should become a key technology along this path. With the help of 3D printers and robots, we will be able to create any objects on the lunar and Martian bases, successfully develop colonies, controlling the process from Earth. With the help of 3D printing, we can assemble interstellar ships directly on the lunar and Martian bases, fitting consumables there.

Read more →

Total votes 28: ↑21 and ↓7 +14

Views26K

Comments 16

impwx

Gadgets Crowdsourcing 3D printers

This past February, Boston-based WobbleWorks launched a pen-shaped 3D printer project on Kickstarter called the 3Doodler. The campaign ended with a resounding success - instead of the expected 30 thousand dollars, more than 2 million were collected. The project was written several times on Habré - in fact, from this article I learned about it and managed to order one of the first.

The device was finally delivered today. Under the cut - a few photos and subjective sensations obtained in half an hour of use.

Read more →

Total votes 45: ↑39 and ↓6 +33

Views65K

Comments 25

alizar

Gadgets 3D printers

A working replica of the M1911 self-loading pistol designed by John Browning. The pistol has been in service with the US Army since 1911 to 1985

Engineers from Texas-based Solid Concepts printed the world's first metal gun. They did this to demonstrate the possibilities of modern industrial 3D printing and do not aim to make the technology available in every home. Although, sooner or later it will inevitably happen.

Read more →

Total votes 58: ↑54 and ↓4 +50

Views156K

Comments 76

marks

Biotechnology 3D printers

Of course, it is too early to talk about printing a whole liver as an organ ready for transplantation. But scientists and engineers are getting closer to solving this problem. For example, the startup Organovo, which deals with just such issues, was able to show an excellent result: samples of the liver “printed” using a 3D bioprinter functioned normally for 40 days.

Read more →

Total votes 54: ↑53 and ↓1 +52

Views77K

Comments 71

Bernodot

3D printers

These are not one but two very similar stories. In fact, there are already many such cases and there are additional links at the end of the article. With the advent of 3D printers in the consumer market, these stories are becoming mainstream.

Leon was born without fingers on his left hand, he has been living without a prosthesis for 12 years. Doctors say that the cause of the injury was the limited circulation in this limb, when the baby was still in the mother's womb ...

Read more →

Total votes 82: ↑79 and ↓3 +76

Views126K

Comments 51

marks

3D printers

Sometimes the achievements of the police in the pursuit of businessmen of the criminal world turn out to be just curiosities. So, the other day, the British police proudly announced that its employees seized the components of a firearm printed on a 3D printer (as the police said, “the first such weapon in the UK”). The seized parts were photographed and posted online, along with a police report. Its experts claimed that these parts are the magazine and the trigger.

Read more →

Total votes 47: ↑39 and ↓8 +31

Views68K

Comments 35

marks

Astronautics 3D printers

Recently, the European Space Agency announced the start of work on the Amaze project. The goal of this project is to "bring 3D printing into the Iron Age". In other words, the project participants are going to create a technology for 3D printing of metal parts (and even entire devices). This project is not some small initiative. There are already 28 large organizations as participants.

Read more →

Total votes 32: ↑31 and ↓1 +30

Views36K

Comments 27

exeditor

Robotics Biotechnology 3D printers

A typical palm prosthesis costs between £7,000 and £70,000 ($10,000 - $100,000) in the UK. Expensive materials, lack of mass demand, low competition, the need for individual fitting of each product make a full-fledged prosthesis very expensive. That is why 3D printing for the manufacture of prostheses has huge potential, according to British roboticist Joel Gibbard. A few hours ago, his IndieGoGo crowdfunding campaign to create Dextrus, an open and affordable palm prosthesis, successfully completed. Most of it is 3D printed. Dextrus has independent drives for each of the fingers, haptic feedback that allows you to automatically adjust the grip force and is controlled by a bioelectric method, reading signals through the skin. At the same time, it will cost several tens of times cheaper than commercial analogues, and all specifications, models and drawings will be freely available.

Read more →

Total votes 70: ↑67 and ↓3 +64

Views40K

Comments 19

MagisterLudi

Gadgets Crowdsourcing 3D printers

In February, there was a post "3Doodler pen can draw three-dimensional objects directly in the air", which raised a hype in the Russian-speaking Internet.

But there was also "Our answer", in which the "analogue" was assembled in 20 minutes "on the knee" (although the cost of the prototype was about $ 1000).

Recall that the 3Doodler project raised the declared amount of $ 1 million in an hour after the launch on Kickstarter.

They raised $2.3 million in total.

And now the moment has come when 30,000 customers will ship their order.

Daniel Cowen, co-founder of the project, comments: “We've been pushing ourselves to stay on schedule to start shipping this month and we're looking forward to people getting creative with the 3Doodler pen.

Clone details and overview

Total votes 43: ↑36 and ↓7 +29

Views76K

Comments thirty

malan 3D Printers 36 BanzaiTokyo

3D printers

Another project of a personal 3D printer Zim has appeared on kickstarter.