Cost of stratasys 3d printer

Stratasys F770 Large Format FDM 3D Printer

SEE CURRENT 3D PRINTING PROMOTIONS

800-688-3234

ACCESSIBLE LARGE FORMAT FDM 3D PRINTING

The Stratasys F770 allows you to print on larger scale, without breaking your budget. A reliable and simple way to print large, complex parts.

STRAIGHTFORWARD OPERATION

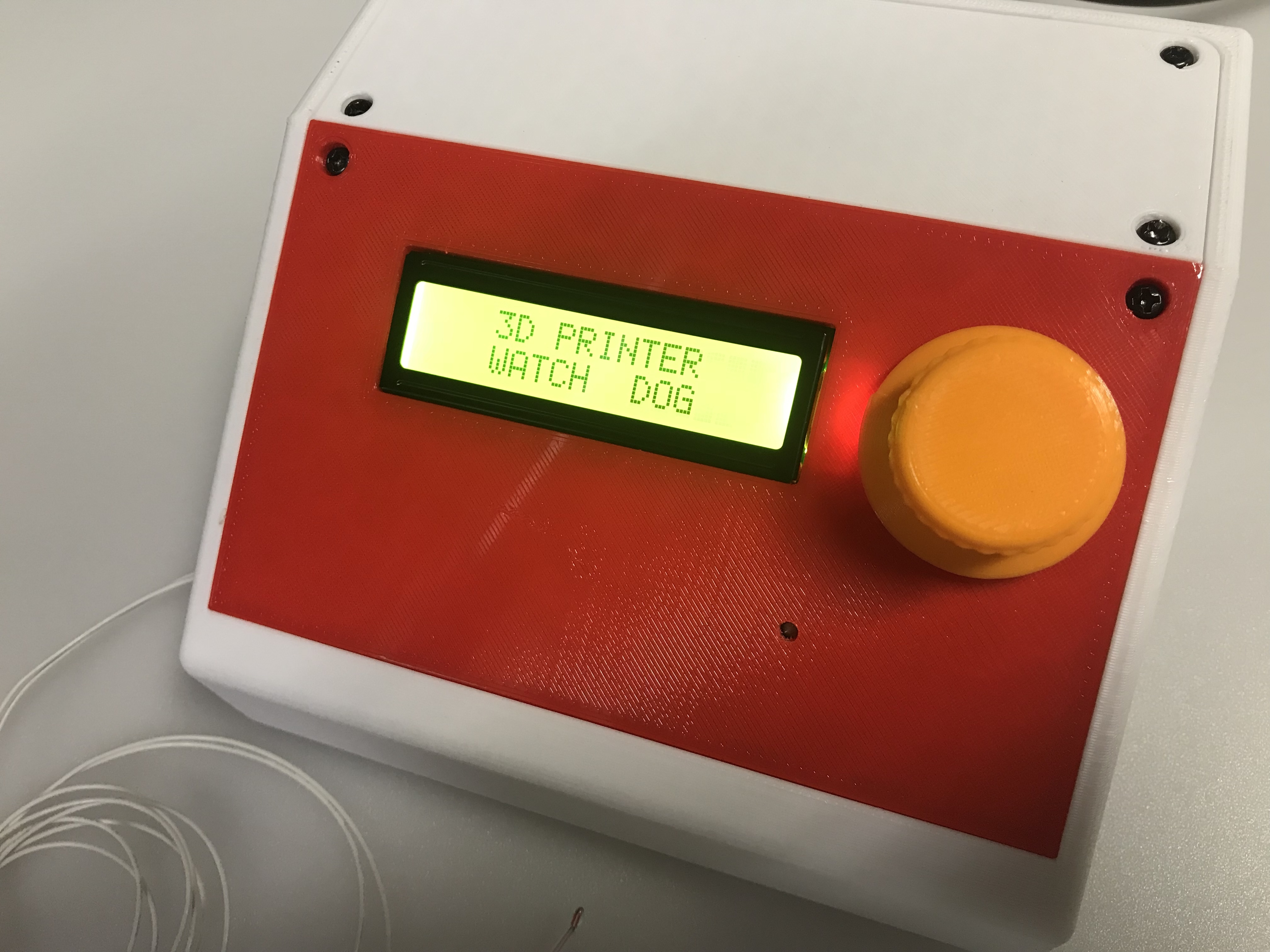

Printing with the Stratasys F770 requires no special training. It is engineered with plug-and-print simplicity that allows any team member to print large parts with ease. No need to constantly monitor the F770 either, material canisters enable up to 140 hours of unattended printing. Prints can be monitored 24/7 with the F770's built in camera, and viewed on your mobile device via the GrabCAD print app.

Industrial Scale meets affordable

Large format 3D printing doesn't have to be a large investment. The Stratasys F770 achieves affordability by focusing on widely used engineering-grade materials, instead of niche high performance alternatives, and building off of the extremely reliable Stratasys FDM platform.

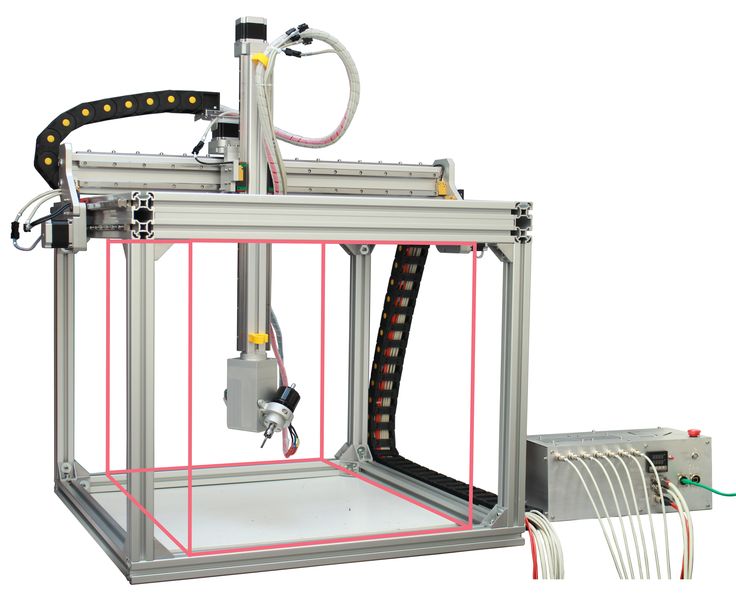

Print large, or Print many

With the longest heated chamber on the market, you can print over 48 inches long on a diagonal, or take advantage of the space to make multiple parts simultaneously. Achieve quantity as well as quality, thanks to soluble support structures that ensure you'll never have to compromise on the complexity of your parts.

ASA

Acrylonitrile styrene acrylate

– New Standard material for all-purpose prototyping

– UV-stabilized for outdoor production parts

– Superior aesthetics and 10 color options

– All-around average mechanical performance

Potential applications:

– Conceptual models

– Functional prototypes

– Manufacturing tools

– Production parts

LEARN MORE

ABS-M30

Acrylonitrile Butadiene styrene

– High performing ABS blend 25-70% stronger than standard

– Versatile, well-understood material

Potential applications:

– Conceptual models

– Functional prototypes

– Manufacturing tools

– Production parts

LEARN MORE

SR-30

DISSOLVABLE SUPPORT

– SR-30 works seamlessly with ABS, ASA. Thanks to focused development SR-30 can yield impressive ABS and ASA prints not possible with PVA.

Thanks to focused development SR-30 can yield impressive ABS and ASA prints not possible with PVA.

Potential applications:

– Conceptual models

– Functional prototypes

– Manufacturing tools

– Production parts

Request More Information on the Stratasys F770 3D Printer and Materials

System Size and Weight

-

175 x 124 x 196 cm (69 x 49 x 77 in.

)

)

- 658 kg (1450 lbs.)

BUILD ENVELOPE

- 1000 x 610 x 610 mm / 372,000 cm 3 (39.4 x 24 x 24 in. / 22,677 in 3 )

-

Maximum length on the diagonal – 1,320mm (51.9 in.)

MATERIALS

- ASA – Ivory

- ABS-M30™ – Black

- SR-30™ soluble support material

MATERIAL DELIVERY

- 200 in 3 coil box (3277 cm 3 )

ACHIEVABLE ACCURACY

-

XY part accuracy = +/- 0.

254 mm (+/- 0.010 in.) or +/- 0.002 mm/mm (+/- 0.002 in./in.), whichever is greater

254 mm (+/- 0.010 in.) or +/- 0.002 mm/mm (+/- 0.002 in./in.), whichever is greater

- Z part accuracy = +/- 0.200 mm (+/- 0.008 in.) or +/- 0.002 mm/mm (+/- 0.002 in./in.), plus 1 layer height

SOFTWARE

WORKSTATION COMPATIBILITY

- Wired and wireless (with USB dongle) network interfaces using standard TCP/IP protocols at 100 MBPS minimum

OPERATING CONDITIONS

- Operating temperature 15 °C to 30 °C (59 °F to 86 °F)

- Operating Humidity 30-70% - 39 in. clearance on each side of printer

POWER REQUIREMENTS

- 3 phase, 208V, 30A, 5 wire, 47-63 Hz frequency

Audible Noise/AcousticS

- 54 dBA

Regulatory Compliance

- 3 phase, 208V, 30A, 5 wire, 47-63 Hz frequency

Wireless Network Connectivity

- IEEE 802.

11n-2009

11n-2009 - IEEE 802.11g-2003

- IEEE 802.11b-1999

Request More Information on the Stratasys F770 3D Printer Specifications

GrabCAD Print

make 3D printing easy, with thoughtful features:

- Automatically corrects files and reduces print time with automatic tray arrangement.

- Calculates the time and material resources needed for production before printing.

- 3MF file supported – significantly simplifies color assignment in your workflow.

- New feature alerts the user if there has been cross-contamination with a biocompatible material.

- Schedule and monitor the print job remotely from your mobile device or browser.

- Get automatic alerts remotely when the job is printing and finished.

LEARN MORE

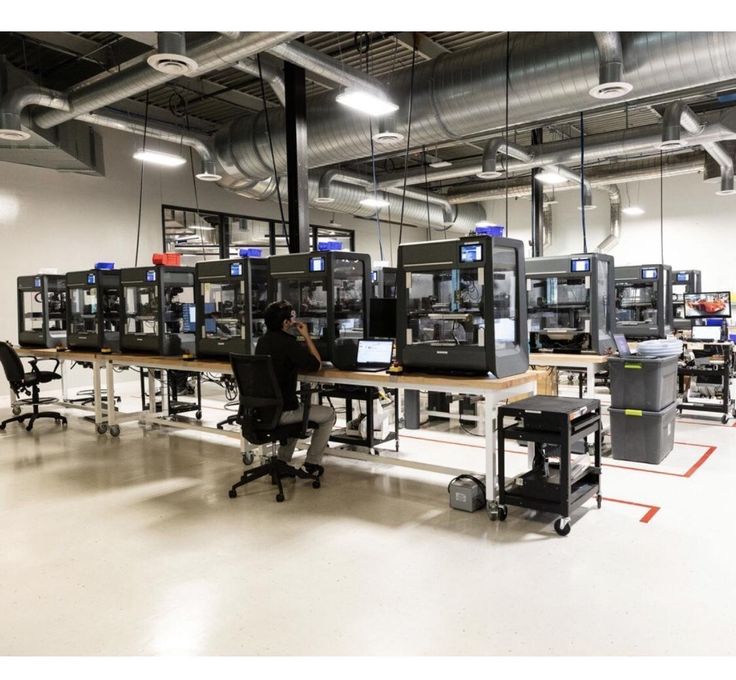

3D Printing Services

AWARD WINNING TECHNICAL SUPPORT

GoEngineer’s extensive technical knowledge can assist with your additive manufacturing needs. Our Award winning team is ready to help. Reach out and see why GoEngineer is the #1 reseller of SOLIDWORKS and Stratasys systems in the world!

Our Award winning team is ready to help. Reach out and see why GoEngineer is the #1 reseller of SOLIDWORKS and Stratasys systems in the world!

LEARN MORE

ADDITIVE MANUFACTURING TRAINING

Learn to utilize all features and tools of Stratasys commercial 3D printers with GoEngineer additive manufacturing on-boarding training. Take advantage of our 3D printing team of experts to help launch all your 3D printing capabilities.

LEARN MORE

3D Print and Part Design

No matter your size, quantity or complexity of part(s) needed, GoEngineer can help you! Take advantage of our 3D Printing and Part Design Services to help your organization produce the best parts and prototypes available on the market.

LEARN MORE

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom.

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store.

FREE SOLIDWORKS Tools

Enjoy this collection of small ‘macros’ that were tailored to help our customers. These free SOLIDWORKS tools are for you to use, review, and modify. SOLIDWORKS Automation Tools

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet, SL, or Metal 3D printers.Stratasys F123 FDM 3D Printer Series

SEE CURRENT 3D PRINTING PROMOTIONS

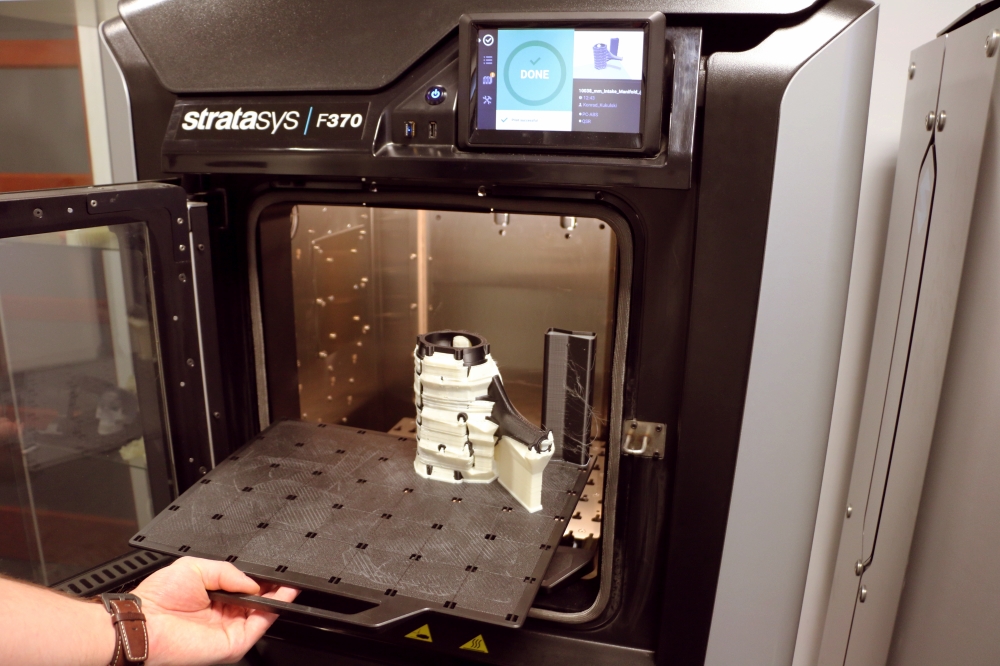

Featuring the F170, F370, and Composite Ready FDM 3D Printers

888-559-6167

Precision 3D Printing

Now there’s a more capable, more affordable professional rapid prototyping solution for your entire office — from the leader in 3D printing. The Stratasys F123 Series combines powerful FDM technology with design-to-print

GrabCAD Print

software for the most versatile and intelligent solution available. Produce fast, effective prototypes for concept development, as well as highly accurate and robust parts for design validation and functional performance. Share projects between multiple users, get your new product designs to market faster and do it all without the need for dedicated expert staffing. It’s just one more way we shape what’s next.

More Speed More Productivity

F123 Series 3D printers give designers, engineers, and educators access to affordable, industrial-grade 3D printing. Work faster through concept iterations and component verification. Increase productivity and reach your goals sooner with repeatable results.

Smoother Workflow Quieter RUN

F123 3D printers are designed for supreme ease of use and a more streamlined workflow, working seamlessly with the design-to-print GrabCAD Print software. They provide the reliability and simplicity needed to refine designs. This can be done within the workspace, thanks to safety-certified printers that are the quietest on the market.

More Choices More POSSIBILITIES

From the affordable F170 through the versatile F370, the choices available with F123 Series printers are unmatched. Work with a wide range of materials including elastomer.* Achieve complex geometries and interlocking components with our unique soluble support material.

30 Years of Expertise

For companies and schools new to 3D printing and established users alike, Stratasys F123 3D printers are the game-changing choice, with the highest levels of plug-and-print reliability and repeatable accuracy.

F-Series 3D Printers

-

ABS-CF10

- Available with: F170 / F190CR / F370 / F370CR

- Potential Applications:

– Tooling

– Jigs and fixtures

– Production and assembly

– Drill guides -

ABS-CF10 Combines standard ABS material with 10% carbon fiber by weight .

This makes for a 50% stiffer than standard ABS 3D printing material and 15% stronger than standard ABS 3D printing materials.

- Learn More >

-

ABS-ESD7

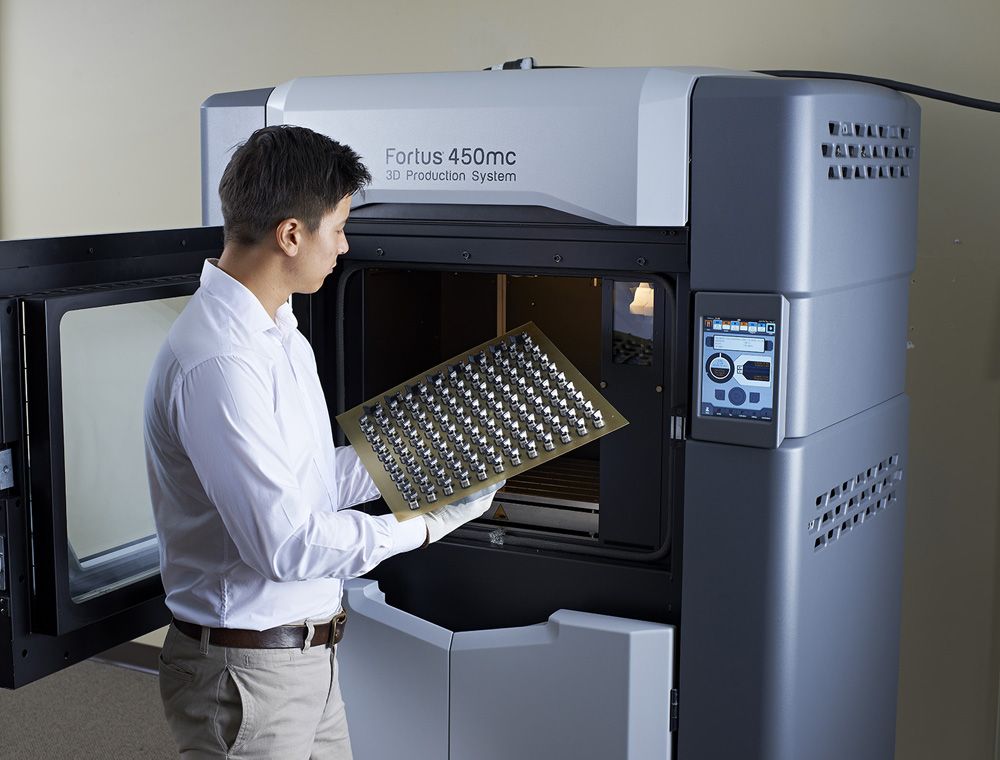

- Available with: F370 / F370CR / Fortus 450mc / F900

- Potential Applications:

– End-use components

– Electronic products

– Industrial equipment

– Jigs & fixtures

-

ABS-ESD7 standard FDM thermoplastic works with soluble support technology, so support removal is hands-free and complex parts require no extra effort.

- Learn More >

-

ABS-M30

- Available with: F170 / F190CR / F370 / F370CR / F770 / Fortus 450mc / F900

- Potential Applications:

– Conceptual models

– Functional prototypes

– Manufacturing tools

– Production parts -

ABS-M30 FDM material enables you to prototype quickly and efficiently.

This strong, familiar material lets you explore more ideas, test frequently, work iteratively – and ultimately take better products to market faster.

- Learn More >

-

ASA

- Available with: F170 / F190CR / F370 / F370CR / F770 / Fortus 450mc / F900

- Potential Applications:

– Conceptual models

– Functional prototypes

– Manufacturing tools

– Production parts -

Mechanical strength and UV stability make ASA a great choice for functional prototyping. Ease of use makes it a top pick for iterative design. Outstanding aesthetics and ten fade-resistant colors make it an all-around favorite, even for end-use parts.

- Learn More >

-

Diran

- Available with: F370 / F370CR

- Potential Applications:

– Tooling

– Jigs & fixtures -

Displaying functional properties of chemical resistance, high-impact strength, and a low coefficient of friction this material is well-suited for jigs and fixturing applications where non-marring robust tooling is desired.

- Learn More >

-

nylon CF10

- Available with: F190CR / F370CR

- Potential Applications:

– Metal forming dies

– Press brakes

– End effectors

– Alignment and assembly fixtures -

3D printing with carbon fiber material lets you build strong, stiff, lightweight tools and parts.

FDM Nylon CF10 combines nylon and carbon fibers to achieve a high flexural strength and stiffness-to-weight ratio.

- Learn More >

-

FDM TPU 92A

- Available with: F170 / F190CR / F370 / F370CR

- Potential Applications:

– Hoses, tubes, air ducts

– Protective covers & seals

– Vibration dampeners

– Prototype and end-use parts -

Thermoplastic polyurethanes otherwise known as TPU’s are flexible elastomers found in products that require a soft touch, shock absorption, or a comforting grip. They are commonly co-molded or over-molded onto ABS and Polycarbonate substrates in sunglasses and phone/tablet cases.

- Learn More >

-

pc-abs

- Available with: F370 / F370CR / Fortus 450mc / F900

- Potential Applications:

– Conceptual models

– Functional prototypes

– Manufacturing tools

– Production parts -

For functional prototyping, tooling, and low-volume manufacturing that requires superior impact strength, FDM Technology works with PC-ABS thermoplastic.

PC-ABS also exhibits excellent feature definition and surface finish.

- Learn More >

-

PLA

- Available with: F170 / F370

- Potential Applications:

– Low-cost iterations

– Conceptual prototypes -

Polylactic Acid otherwise known as PLA is an entry-level grade of thermoplastic material commonly associated with the ‘hobbyist’ FFF based printers because it builds well in systems that do not have closed-loop thermal control of the build chamber.

- Learn More >

Request More Information about FDM Materials

GrabCAD Print

Professional 3D Printing Made Easy and Accessible

GrabCAD Print is the most complete solution for Stratasys 3D printers on the planet. The intuitive, easy-to-use software allows for simplified preparation, scheduling, monitoring, and reporting of print jobs. With the ability to read and understand CAD files natively, GrabCAD Print offers an efficient workflow that streamlines job management in shared office and model shop environments.

LEARN MORE

INSIGHT SOFTWARE

OPTIMIZE BUILD OUTPUT FOR 3D PRINTING

(ONLY AVAILABLE ON F370)

Insight software prepares your CAD program’s STL output for 3D manufacturing on a Fortus machine by automatically slicing and generating support structures and material extrusion paths. For maximum control, users can manually edit parameters that determine the look, strength, and precision of parts as well as the speed and material use of the FDM process.

- Optimize build orientation for maximum strength and smoothest surface finish

- Customize supports for fast, easy removal and best use of materials

- Program pauses into the build for any reason, such as to embed hardware or circuitry

- Manipulate tool paths for advanced control over part properties

Included with Insight is Control Center. This sophisticated software application communicates with user workstations and Fortus systems, to manage jobs and monitor production status. Design, engineering, and manufacturing teams can network and share 3D manufacturing capacity to maximize efficiency and throughput.

*Compatible with GrabCAD Print for use with job reports, scheduling, and remote monitoring.

Request More Information on Insight 3D Printing Software

3D Printing Services

AWARD WINNING TECHNICAL SUPPORT

GoEngineer’s extensive technical knowledge can assist with your additive manufacturing needs. Our Award winning team is ready to help. Reach out and see why GoEngineer is the #1 reseller of SOLIDWORKS and Stratasys systems in the world!

LEARN MORE

ADDITIVE MANUFACTURING TRAINING

Learn to utilize all features and tools of Stratasys commercial 3D printers with GoEngineer additive manufacturing on-boarding training. Take advantage of our 3D printing team of experts to help launch all your 3D printing capabilities.

LEARN MORE

3D Print and Part Design

No matter your size, quantity or complexity of part(s) needed, GoEngineer can help you! Take advantage of our 3D Printing and Part Design Services to help your organization produce the best parts and prototypes available on the market.

LEARN MORE

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions.

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services.

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

FREE SOLIDWORKS Tools

Enjoy this collection of small ‘macros’ that were tailored to help our customers. These free SOLIDWORKS tools are for you to use, review, and modify. SOLIDWORKS Automation Tools

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry.

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet, SL, or Metal 3D printers. 3D Printing ServicesStratasys Launches Three New 3D Printers

News

-printer h450 and large-format FDM-system F770 with a 372-liter usable volume.

“We are accelerating into the era of Additive Manufacturing 2.0, in which industry leaders are moving beyond prototyping and are beginning to take full advantage of the manufacturing flexibility of 3D printing technologies. The failures that we are seeing today in global supply chains speak clearly of the incapacity of the status quo. Additive manufacturing gives businesses the flexibility to decide when, where and how to produce parts. That is why we strive to be a complete global solution provider for resin 3D printing,” said Yoav Zeif, CEO of Stratasys. nine0003

Stratasys Origin One

The first system was developed by California startup Origin, acquired by Stratasys in December last year. The Origin One 3D printer relies on its own variant of projector stereolithography called P3 ( P rogrammabale p hoto p olymerization) with automatic adjustment of backlight brightness, temperature and other parameters, as well as the integration of machine vision for quality control and adjustment in real time mode. nine0003

Another interesting point is the pneumatic system for lifting and lowering the flexible bottom of the cuvette, which helps to reduce the effect of vacuum force on fresh layers during platform lifting (something similar is implemented on third-generation laser stereolithographic 3D printers from Formlabs). Origin One uses a 4K resolution illumination module with a wavelength of 385 nm, the size of the construction area reaches 192x108x350 mm. The start of accepting orders is scheduled for May this year. nine0003

Stratasys h450

This 3D printer is intended to compete directly with HP Inc.'s Multi Jet Fusion additive systems. and relies on HSS (High Speed Sintering) polymer powder thermal sintering technology by Xaar, a well-known manufacturer of inkjet heads for printing equipment. The h450 3D printer was developed jointly by Stratasys and Xaar, and the technology was renamed SAF (Selective Absorption Fusion). The essence is the same: a layer pattern is applied to the powder with dark ink, which increases the absorption coefficient of thermal radiation, then a movable head with IR emitters sinters the layer, and the process is repeated until the model is completely built. nine0003

The h450 additive system is designed for high productivity and applications not only in rapid prototyping, but also in serial additive manufacturing with volumes of thousands of units. The designers are so confident in the quality of the printed products that they equipped their own 3D printers with them: for every h450 there are about a dozen 3D printed parts. So yes, this is RepRap, industrial grade only. The same goes for Multi Jet Fusion systems.

Beta testing of h450 systems launched at the beginning of this year, the new 3D printers will go on public sale in the third quarter of this year. The systems are designed to use certified third party materials. The first was a biopolymer powder of polyamide-11 from castor oil, the range will expand.

The third novelty is an industrial-grade FDM system more familiar to Stratasys, distinguished by a large working area of 372 liters (1000x610x610 mm) and an active thermal chamber with background temperature control. The exact cost, as usual, is not indicated, but the selling price will not exceed one hundred thousand dollars. nine0003

The standard consumables for this 3D printer are ABS-M30 (industrial version of ABS with higher strength) and ASA (similar to ABS, more UV resistant and therefore better suited for outdoor use). For the construction of support structures, SR-30 filament based on water-soluble polyvinyl alcohol is used.

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at [email protected]. nine0069

Stratasys DLP fdm SAF origin one F770 h450

Subscribe to the author

Subscribe

Don't want

8

History of 3D printing

In this section, we wanted to trace the history of 3D printing from its inception to the present day, as well as give a forecast regarding the future development of technology.

The first 3d printer was invented by the American Charles Hull, he worked on the technology of stereolithography (SLA), the patent for the technology was filed in 1986. The printer was a fairly large industrial installation. The installation "grew" a three-dimensional model by applying a photopolymerizable material to a moving platform. The basis was a digital model pre-modeled on a computer (3D model). This 3d printer created three-dimensional objects, rising by 0.1-0.2 mm - the height of the layer. Despite the fact that the first device had many disadvantages, the technology has received its application. Charles Hull is also the co-founder of 3dsystems, one of the world's leading manufacturers of industrial 3D printers. nine0003

Charles Hull was not the only one to experiment with 3D printing technology, as in 1986 Carl Deckard invented Selective Laser Sintering (SLS). You can learn more about the method in another article, briefly: a laser beam sinters a powder (plastic, metal, etc. ), while the mass of the powder is heated in the working chamber to a temperature close to the melting point. The basis is also a digital model pre-modeled on a computer (3D model). After the laser passes through the horizontal layer, the chamber is lowered to the layer height (usually 0.1-0.2 mm), the powder mass is leveled with a special device and a new layer is applied. nine0003

However, the most famous and widespread 3D printing method today is layer-by-layer direction (FDM). The idea of technology belongs to Scott Crump (Scott Crump), the patent dates back to 1988. You can learn more about the method in another article, in short: material (usually plastic) is fed from the heated nozzle of the print head using a stepper motor, the print head moves on linear guides along 1 or two axes, and the platform moves along 1 or 2 axes . The basis of the movement is also a 3D model. The molten plastic is laid on the platform along the established contour, after which the head or platform is moved and a new layer is applied on top of the old one. Scott Crump is one of the founders of Stratasys, which is also one of the leaders in the production of industrial 3D printers. nine0003

All the devices described above belonged to the class of industrial devices and were quite expensive, so one of the first 3d Dimension printers from Stratasys in 1991 cost from 50 to 220 thousand US dollars (depending on the model and configuration). Printers based on the technologies described above cost even more and until very recently, only a narrow circle of interested specialists knew about these devices.

Everything began to change since 2006, when the RepRap project (from the English Replicating Rapid Prototyper - a self-replicating mechanism for rapid prototyping) was founded, with the goal of creating a self-copying device, which was a 3D printer working on technology FDM (layer by layer deposition). Only, unlike expensive industrial devices, it looked like a clumsy invention made from improvised means. Metal shafts serve as a frame, they also serve as guides for the print head. driven by simple stepper motors. The software is open source. Almost all connecting parts are printed from plastic on the 3D printer itself. This idea originated among English scientists and aimed at spreading available additive technologies so that users can download 3D models on the Internet and create the necessary products, thus minimizing the production chain. nine0003

Leaving aside the ideological component, the community (which exists and develops to this day) managed to create a 3d printer accessible to the "ordinary person". So a set of unprinted parts can cost around a couple of hundred US dollars and a finished device from $500. And even though these devices looked unsightly and were significantly inferior in quality to their industrial counterparts, all this was an incredible impetus for the development of 3D printing technology.

As the RepRap project developed, 3D printers began to appear, taking as a basis the base laid down by the movement in technical and, sometimes, ideological terms (for example, commitment to the concept of open source - OpenSource). The companies that made printers tried to make them better both in terms of performance, design and user experience. The first RepRap printers cannot be called a commercial product, since it is not so easy to manage (and even more so to assemble) and it is not always possible to achieve stable work results. Nevertheless, companies tried to close the more than significant gap in quality, leaving a significant gap in cost whenever possible. nine0003

First of all, it is worth mentioning the MakerBot company, which started as a startup, took RepRap ideas as a basis and gradually turned them into a product of a new quality.

Their flagship product (and in our opinion the best to this day) remains the MakerBot Replicator 2 3D printer. The model was released in 2012 and later discontinued, but remains one of the most popular 3D printer models to this day " personal" segment (according to 3dhubs). The word "personal" is in brackets because this printer, which cost $2,200 at the time of release, was (and is) primarily used for business purposes, but falls into the personal segment due to its cost. This model differs from its progenitors (RepRap), being, in fact, a finished commercial product. Manufacturers abandoned the concept of OpenSource, closing all sources and software codes. nine0003

In parallel with the release of equipment, the company actively developed the Thingiverse resource, which contains many models for 3d printing, available for download for free. During the development of the first printer and beyond, the community has helped the company a lot, testing the product and offering various upgrades. After the release of the Replicator 2 (and the closure of development), the situation has changed. You can learn more about the history of MakerBot and other companies and people associated with 3d printing by watching the film Print the legend. nine0003

This film also highlights the history of Formlabs, one of the first companies to launch an affordable 3D printer based on SLA (Strereolithography) technology. The company raised funds for the first FORM 1 model through crowdfunding, encountered production difficulties, but eventually released an affordable and productive 3D printer, closing the quality gap described above.

And although the 3D printers described above were far from perfect, they laid the foundation for the development of affordable 3D printing technology, which continues to this day. At the moment, the quality of FDM and SLA printers is increasing, but there is no significant price reduction, rather, on the contrary, it is growing slightly. Along with FDM and SLA, many companies are developing in the field of powder sintering (SLS), as well as metal printing. Despite the fact that such printers cannot be called affordable, their price is much lower in comparison with analogues from the professional segment. It is also worth noting the development of the line of materials, in addition to the standard ABS and PLA plastics, today many different materials are used, including nylon, carbon fiber and other durable and refractory materials. nine0003

Personal 3d printers of today are very close to professional devices, the development of which also does not stop. In addition to the "founders" of the technology (Stratasys, 3dsystems), many small companies specializing in industrial 3D printing technologies (metal in particular) have emerged. 3D printing is also attracting the attention of large corporations, which, with varying degrees of success, are striving to take their place in a growing market. Here it is worth highlighting HP, which recently released the HP Jet Fusion 3D 4200 model, which has gained popularity among 3d printing professionals (as of 2018, it is at the top of the ranking of professional 3D printers in the quarterly reports of the 3dhubs portal). nine0003

However, 3D printing technologies are developing not only in breadth, but also in depth. One of the main disadvantages of 3D printing, compared to other production methods, is the low speed of creating models. A significant advance in terms of accelerating 3D printing was the invention of CLIP technology by CARBON, printers operating on this technology can produce models 100 times faster than classic SLA technology.

There is also a constant expansion of the range, properties and quality of materials and post-processing of products. All this accelerates the transition to the use of 3d printers in production, and not just as prototyping devices. Today, many large and not only companies and organizations are closely using a 3D printer in their production chain: from consumer goods manufacturers NIKE and PUMA to BOEING and SPACE X (the latter prints engine parts for its rockets that could not be made in any other way) . nine0003

In addition to the "classic" scope of 3D printing, today more and more often you can see news about how a house or some organ (or rather, a small part of it) was printed on a 3D printer from bio-material. And this is true, several companies around the world are testing or already partially using 3D printing in the construction of buildings and structures. This mainly concerns the contour pouring of walls (similar to the FDM method) with a special composite concrete mixture. And in Amsterdam there is a 3D printed bridge project and this list will only expand over time, since the use of 3D printing in construction can significantly reduce costs and increase the speed of work at certain stages. nine0087 With regards to medicine, here 3D printing also finds application, but at the moment it is not printing organs, but rather the use of technology in prosthetics (of various kinds) and bone replacement. Also, 3D printing technology is widely used in dentistry (SLA technology). Regarding the printing of organs, this is still far in the future, at the moment bio-3D printers are experimental facilities in the early stages, the success of which is limited to printing a few limited-viable cells. nine0003

Looking to the future, it is safe to say that 3D printing technology will expand both in breadth and depth, improving technology, speeding up processes, improving quality and improving material properties. 3D printers will increasingly replace old methods in production chains of various scales, and world production, due to this, will move towards the “on demand” scheme of work, increasing the degree of product customization. Perhaps someday, 3D printers will be widely used at the household level for the production of necessary things (the dream and goal of the RepRap movement), but this requires not only the development of technology, but also a paradigm shift in social thinking, as well as the development of a powerful design ecosystem ( 3d modeling) products (which is often forgotten).