Best 3d printer for farm

5 Best 3D Printers For Print Farm In 2023

- Last Updated: January 19, 2023

- Jackson O'Connell

Ever wanted to start your own 3D printing business? Or just want to sell sick 3D prints online? Well, for mass manufacturing 3D printed parts, you’ll need a print farm!

Just like a real farm has tons of animals, print farms are made up of many 3D printers to pump out as many models as possible. While print farms can be pretty large investments, costing anywhere from $5,000 to over $100,000, they can yield significant returns depending on how you wield their manufacturing power.

Etsy shops, online on-demand printing services, and contract small-scale manufacturing are just a few ways you can profit from a print farm.

But for a good print farm, you’ll need machines that don’t just print high-quality models but are also extremely reliable. In the sections below, I’ve reviewed what I believe to be the best 3D printers to include in your print farm.

I’ve also gone over everything I’ve learned from building and operating my own print farm.

Enjoy!

Elegoo Neptune 2S

Build volume: 220 x 220 x 250 mm

Get Discount Now

Check Latest Price

Creality Ender 3 (Pro/V2)

Build volume: 220 x 220 x 250 mm

Get Discount Now

Check Latest Price

Prusa i3 MK3S+

Build volume: 250 x 210 x 200 mm

Check Official Website

Check Latest Price

Check Kit Price

Table of Contents

- Product Reviews:

- Best 3D Printers for Print Farm At A Glance

- 1. Creality Ender 3 (Pro/V2) (Best Choice)

- 2. Prusa i3 MK3S+ (Premium Choice)

- 3. Elegoo Neptune 2S (Best Value)

- 4.

Creality CR-10 (Best for Advanced Users)

Creality CR-10 (Best for Advanced Users) - 5. Prusa Mini+ (Easy to Use)

- What Is A Print Farm?

- What It Takes To Start A Print Farm?

- 3D Printers

- Materials

- Target Market

- Storage

- Spare Parts

- 3D Print Farm Software

- Considerations for Print Farm Printers

- Reliability

- Print Quality

- Material Compatibility

- Build Volume

- Price

- Automatic Bed Leveling

- Power Loss Recovery

- Conclusion

Product Reviews:

Let’s get into the best 3D printers for a print farm. In each of the sections below, we’ll go over a different printer, discussing its features, pros, cons, and more.

Best 3D Printers for Print Farm At A Glance

1. Creality Ender 3 (Pro/V2) (Best Choice)

2. Prusa i3 MK3S+ (Premium Choice)

3. Elegoo Neptune 2S (Best Value)

4. Creality CR-10 (Best for Advanced Users)

5. Prusa Mini+ (Easy to Use)

Prusa Mini+ (Easy to Use)

3D Printer Type: FDM | Materials: PLA, ABS, TPU & PETG | Build Volume: 220 x 220 x 250 mm

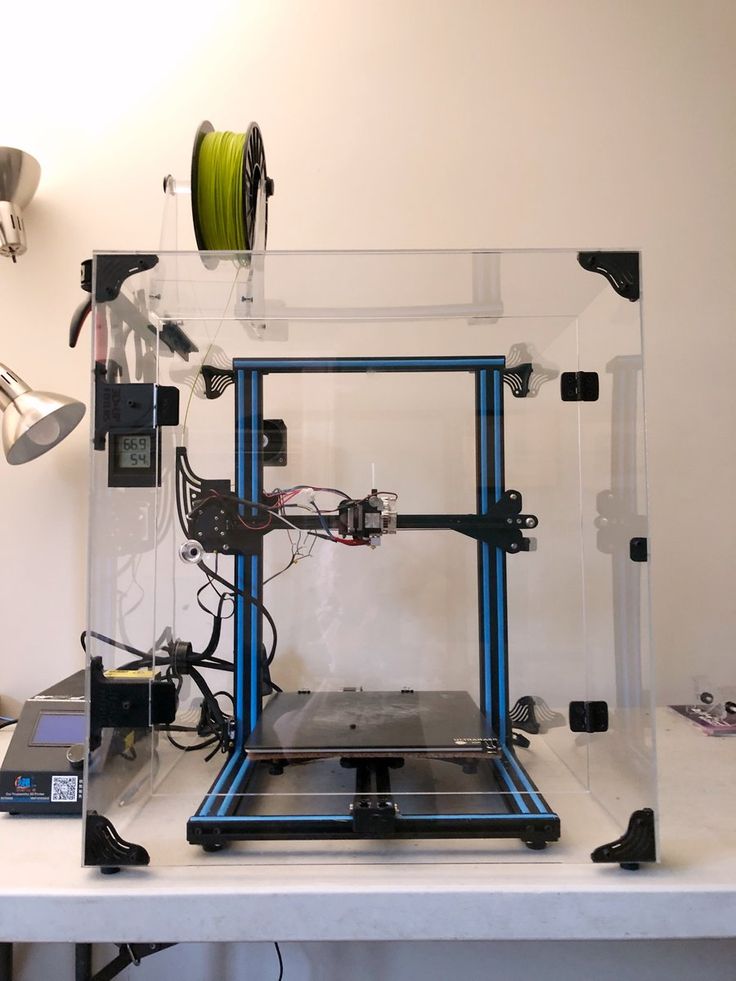

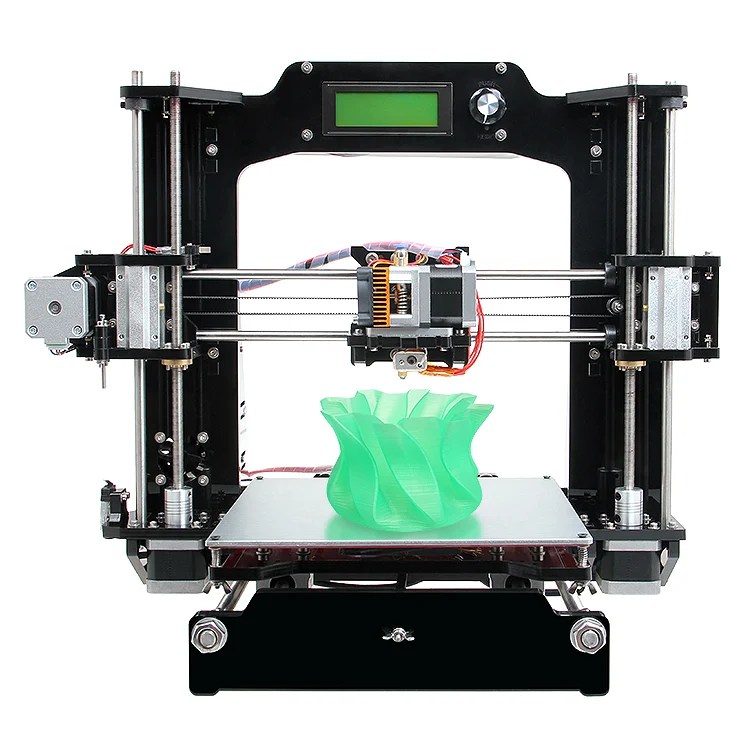

Our first printer to discuss is the Creality Ender 3, which comes in three four versions: the Original, Pro, V2, and the new S1. All four are great options for a print farm and are a great bang for your buck.

The Original Ender 3 costs under $200 and can put out prints that look better than ones made on a $1,000 printer. And the other versions of the Ender 3 (the Pro, V2, and S1) cost just a bit more but can print even better models. Note: the S1 can print with flexible filament with its direct drive extruder so if you’re looking to print phone cases, this is Ender to get

But the best part about the Ender 3 (Pro/V2) is its mod-ability. While the Ender 3 (Pro/V2) is decently dependable, you can make it even more reliable by adding some of the many available upgrades to the machine. For the Ender 3s in my print farm, I’ve added rubber feet, an E3D nozzle (more long-lasting), and a metal extruder, which has improved their consistency drastically.

For the Ender 3s in my print farm, I’ve added rubber feet, an E3D nozzle (more long-lasting), and a metal extruder, which has improved their consistency drastically.

Overall, the Ender 3, whether you get the Original, Pro, or V2, is my personal favorite choice for a machine on a print farm. It’s pretty reliable right out of the box, especially the V2, but once you add in the upgrades, it gets a whole lot better. And its low price makes it fit into any print farm budget!

- Good bang for your buck

- Comes in a few versions, each with different features

- Many optional upgrades exist

- Not super reliable in pure stock form (especially for the Original and Pro)

Get Discount (Official Store)

Check Latest Price

3D Printer Type: FDM | Materials: PLA, PETG, ASA, ABS, PC, HIPS, Flex, Nylon, Carbon filled & Woodfill | Build Volume: 250 x 210 x 210 mm

If you’re looking for the best print quality for an FDM 3D printer, you can’t beat the Prusa i3 MK3S+. Developed by the expert team at Prusa Research, the i3 MK3S+ has every detail of a 3D printer right.

Developed by the expert team at Prusa Research, the i3 MK3S+ has every detail of a 3D printer right.

With a great build plate, automatic bed leveling sensor, touchscreen interface, high-temperature hot end, and so much more, it’s the perfect machine for a print farm. Just be prepared to spend a little on the higher side because each one of these bad boys goes for just under $1,000 a pop.

And if you look at the thousands of reviews for the printer, the one thing that basically all users can agree on is that the MK3S+ is super reliable. For the two years I’ve had the printer, I don’t think I can recall more than a few failed prints. And it only takes a simple search on Prusa’s large forum and Q/A section to figure out the issue and solve it!

The Prusa i3 MK3S+ isn’t as upgradeable as the Ender 3, but it really doesn’t need to be, considering how many features are already on the machine. As for the build volume, it’s just the right size, boasting a 210 x 210 x 250 mm build volume that will fit basically any regular print job.

While you can’t print ABS on the MK3S+ because it lacks an enclosure, it has a direct drive extruder and a high-temperature hot end. These features mean basically every other filament material, including flexibles, can be printed on the MK3S+.

It’s also worth noting that power loss recovery is a feature on the MK3S+!

As long as the budget isn’t an issue with you, I’d say the MK3S+ is the most premium choice to include in your print farm. It prints super high-quality models (decently fast, too) and almost never fails.

- Very high-quality prints

- Direct-drive extruder

- Decently large build volume

- Extremely reliable; almost never fails

- Prints fast

- Sturdy frame design

- Expensive

Check For Official Website

Check Latest Price

Check For Kit Price

3D Printer Type: FDM | Materials: PLA, ABS, PETG & TPU | Build Volume: 220 x 220 x 250 mm

Elegoo is a popular 3D printer company, mainly known for its excellent resin (SLA) printers. However, their Neptune 2S is definitely a notable FDM printer that’s worthy of consideration for your print farm.

However, their Neptune 2S is definitely a notable FDM printer that’s worthy of consideration for your print farm.

At first glance, the Neptune 2S looks a lot like the Creality Ender 3. But, unlike the Original and Pro versions of the Ender 3, the Neptune is decked-out with features that make the detail in prints exceptional.

For example, though there isn’t an automatic bed leveling sensor, the Neptune 2S comes with strong leveling springs. These will keep the bed level longer than usual, so you don’t have to redo the manual leveling process as frequently.

Additionally, the printer comes with a 32-bit motherboard that’s fast and powerful enough to handle the latest firmware releases with the most features. The touchscreen, full-color LCD interface also helps as it makes using the printer very easy.

But my favorite part about the Neptune 2S is its stock metal extruder. The metal construction makes the extruder super accurate and reliable, and I’ve yet to have an extrusion issue with my Neptune printer.

I also love the magnetic metal build plate that makes it easy to remove parts. All you have to do is take the bed off the printer, bend it, and your prints pop right off.

The downsides of the printer, however, are that you can’t print flexibles due to the Bowden-drive extruder configuration. Additionally, a fair amount of users, including myself, have found that layer shifting is common, so you’ll have to tighten the axis belts every so often.

But if you’re okay with that issue and want a solid FDM printer that won’t have extrusion issues, definitely add the Neptune 2S to your cart!

- Very reliable

- Sturdy build

- Flexible magnetic build plate for easy print removal

- Stock strong bed leveling springs

- Metal extruder

- Manual bed leveling is required

- No belt tensioners

Click For Discount (Official Website)

Check Latest Price

3D Printer Type: FDM | Materials: PLA, TPU & ABS | Build Volume: 300 x 300 x 400 mm

Creality really nailed it with the Ender 3, but the CR-10 is another great option. Its strong suit is its size. The Original Creality CR-10 offers a build volume of 300 x 300 x 400 mm, which is extremely large considering the sub-$300 price point of the machine.

Its strong suit is its size. The Original Creality CR-10 offers a build volume of 300 x 300 x 400 mm, which is extremely large considering the sub-$300 price point of the machine.

This much space on a print farm-ready machine will allow you to mass-produce large 3D models. I love using my Original CR-10 to print large models, like a Batman mask or shoe rack. But the extra space is also convenient if you’re just printing smaller models because you can’t print more at once.

And, if you want to go even bigger, you can opt to get the CR-10 S5 which gives you an extra 200 mm on the X and Y axes.

As for the other features on the Original CR-10, it’s pretty limited. The machine rocks an older 8-bit Creality motherboard with no automatic bed leveling or filament runout sensor. However, don’t let the simplicity of the machine fool you, as it’s still very reliable.

As long as the bed is level and the nozzle is unclogged, you’ll likely run into very few issues. And the quality of the prints from the Original CR-10 is still decent and good enough for most print farm jobs.

If you want the most print space per dollar, the CR-10 is my recommendation. While it lacks the features of the newer 3D printers, it’s one hell of a reliable and consistent machine. Plus, if you really want those extra bells and whistles, like auto-leveling or a runout sensor, you can choose one of the later versions of the CR-10, like the CR-10 Smart Pro.

- Other variations exist with more features

- Inexpensive; a good bang for your buck

- Large build space

- Somewhat outdated features

- Manual bed leveling

- Bowden-drive extruder (can’t print flexibles)

Get Discount (Official Store)

Check Latest Price

3D Printer Type: FDM | Materials: PLA, PETG, ASA, ABS, Polycarbonate, CPE, PVA/BVOH, PVB, HIPS, Polypropylene, Flex, nGen, Nylon & Woodfill | Build Volume: 180 x 180 x 180 mm

Lastly, the Prusa Mini+ is another printer from Prusa Research and is like a younger brother to the Prusa i3 MK3S+. The Mini+ is meant to be a more value-efficient printer for farms than the MK3S+. That’s because, with two Mini+ printers, you can print more parts than with one MK3S+, and the cost is about the same.

The Mini+ is meant to be a more value-efficient printer for farms than the MK3S+. That’s because, with two Mini+ printers, you can print more parts than with one MK3S+, and the cost is about the same.

The Prusa Mini+ is a lot like the MK3S+, with exceptional build quality and thousands of happy users who reiterate the machine’s reliability. But, there are a few differences.

For one, the Mini+ is Bowden-drive, so printing flexibles won’t be as easy as on the direct drive MK3S+. Additionally, as indicated by the name, the build volume on the Mini+ is a little smaller, at 180 x 180 x 180 mm. While smaller than you might want for a print farm machine, it’s still enough space to print more than a few prints at once or midsized parts.

The print quality on the Mini+ is also something worth mentioning. If I had to print a miniature model on an FDM printer, the Mini+ would have to be my go-to. The E3D hot end lays out the filament so smoothly that the resulting models look just spectacular.

While the printer is decently pricey for its size, I promise the quality won’t let you down. So if you like the quality and reliability of Prusa printers but want a more cost-efficient machine than the MK3S+, the Prusa Mini+ is your guy.

- Spectacular print quality

- High-quality E3D hot end

- Automatic bed leveling sensor

- PEI Spring Steel build plate

- Bowden drive extruder (can’t print flexibles)

- Smaller build plate

Check Latest Price

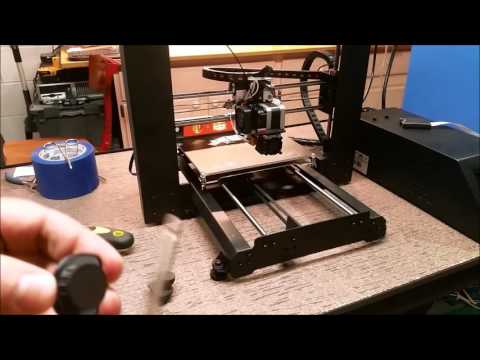

What Is A Print Farm?

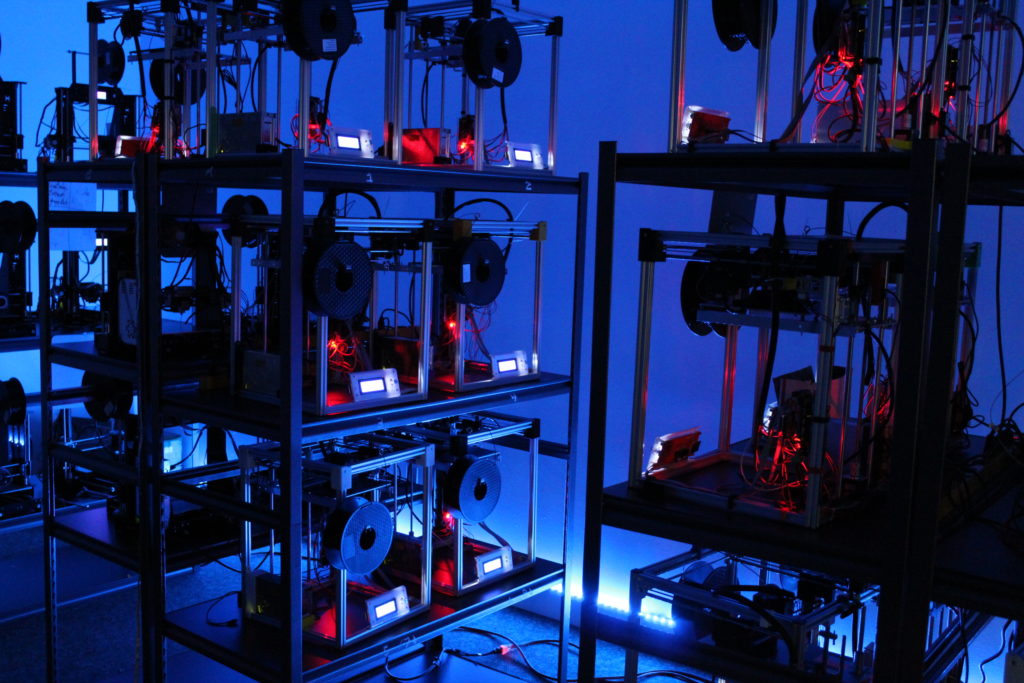

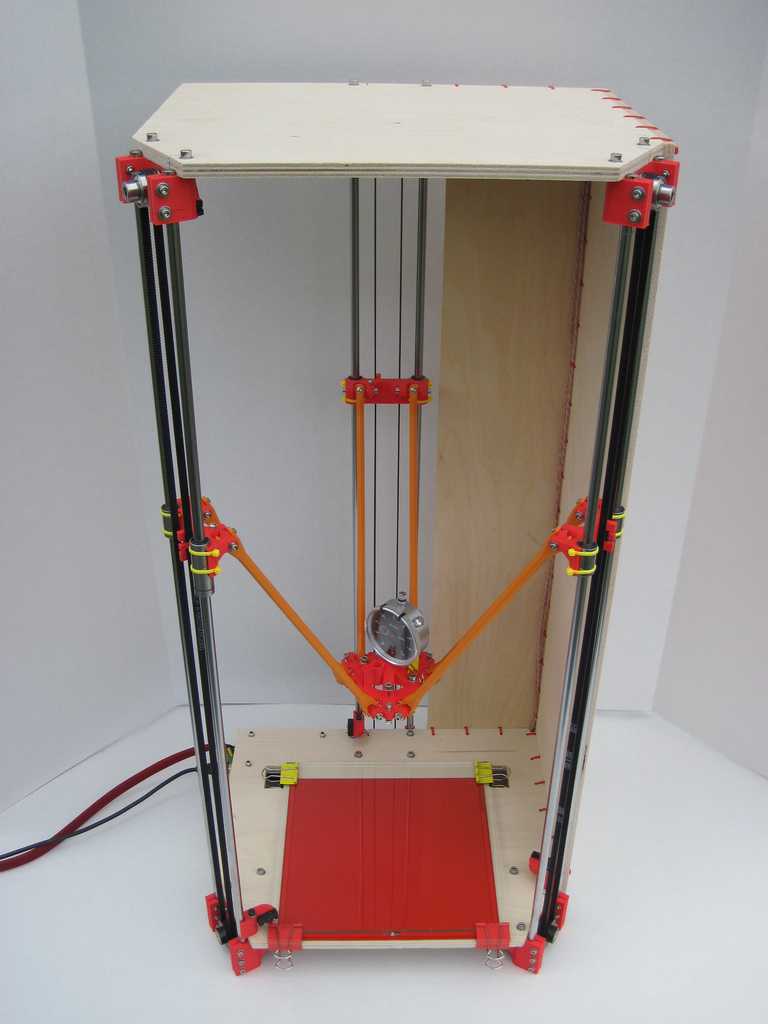

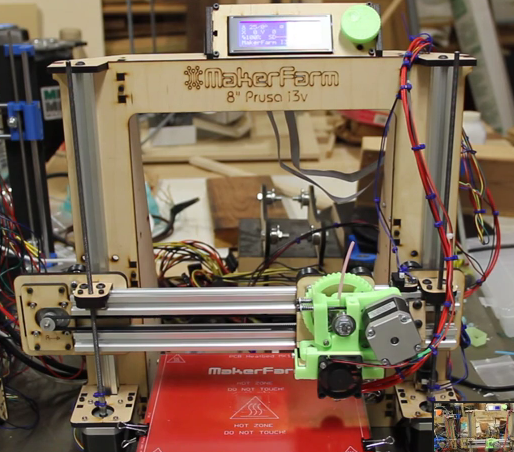

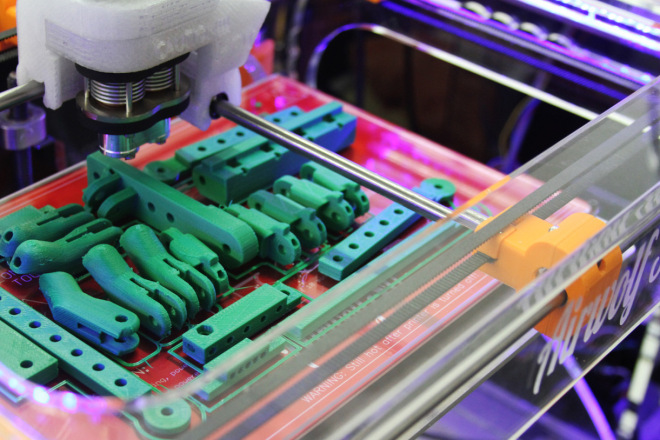

Source: Youtube 3D Printing NerdA print farm is a large collection of 3D printers that work to produce parts efficiently and consistently. There’s no official number of 3D printers that you must have to call your set up a “print farm”, but I’d say above 10 is the minimum.

There’s no official number of 3D printers that you must have to call your set up a “print farm”, but I’d say above 10 is the minimum.

Every print farm varies depending on the machines included, the filament/resin used, the environment around the printers, the software used, etc. But they all are or should be pretty reliable, being able to push out 3D prints day-in and day-out.

What It Takes To Start A Print Farm?

It probably comes as no surprise that it takes a lot to start a print farm. In the mini-sections below, I’ve briefly reviewed the main components of any print farm, including the hardware and other things you need to make your print farm worth it (or profitable):

3D Printers

Obviously, for a print farm, you need 3D printers. How many you get is up to you, but definitely above 10 so that you can still operate your business if a few machines break down.

As for the actual machines, we’ll go over the best printers for a print farm in the later sections, but the Ender 3 V2, Prusa Mini+, and CR-10 are my three favorites because they’re all good bang for your buck.

Materials

Just like a gun needs ammunition, 3D printers need filament or resin, depending on the type of printer, to actually print models. For FDM 3D printers (e.g. Ender 3), you’ll need a lot of filament.

I recommend buying the filament in bulk to save money, and you should also look for jumbo spools that are larger than 1 kg. This will save you time because you won’t have to replace the filament spool as often if each spool is bigger.

You also need to offer a diverse range of filament materials. Having the top 3 filament materials – PLA, ABS, and PETG – is 100% necessary, but it’s also a smart move to offer some exotic materials too, like Nylon, Carbon Fiber composite, and polycarbonate, as this will attract more customers.

Lastly, don’t forget to get some different colors of filament too! Nobody wants all-red 3D prints, even if that’s the cheapest color. Trust me when I say that offering some extra colors will go a long way in growing your customer base!

Target Market

And, on this note of customer base, you need a target market when proposing your 3D print farm. While on-demand 3D print services can still be profitable with your own print farm, you need to focus on one specific audience.

While on-demand 3D print services can still be profitable with your own print farm, you need to focus on one specific audience.

For example, instead of making your service for all people who want 3D printed parts, focus it on people looking for cosplay items. Making your 3D print farm business more niche will narrow the audience as a whole but attract more actual customers (and you’ll be an expert for your audience).

Storage

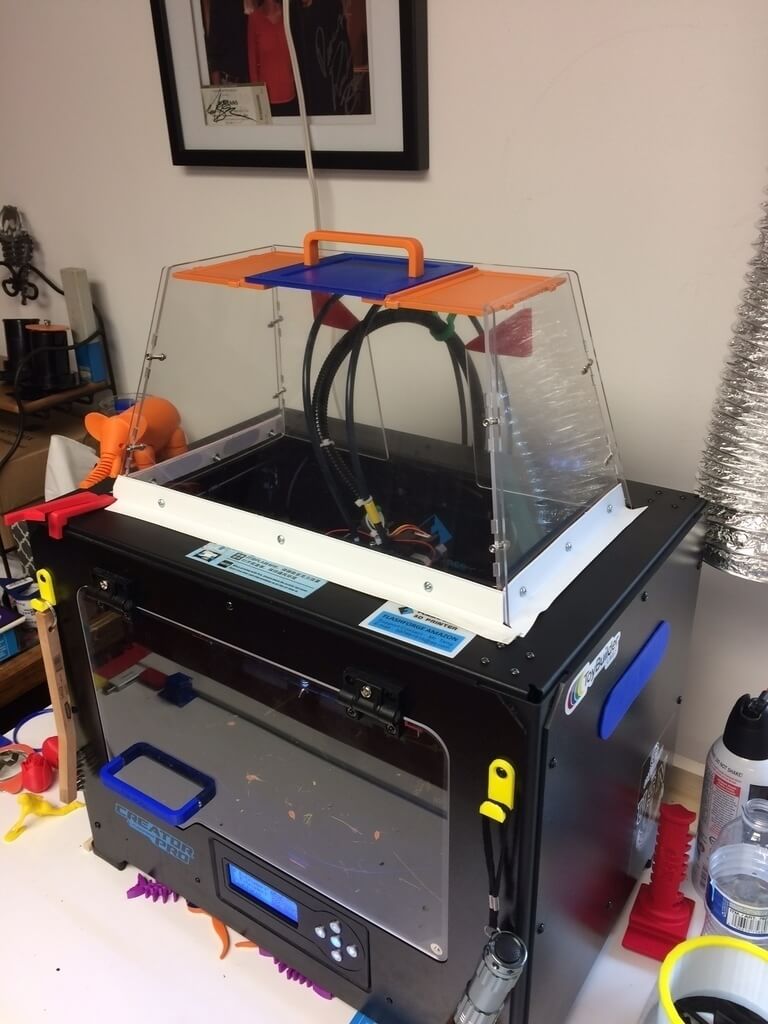

Source: Youtube Modern HobbyistSurprisingly, storage is also a pretty major component of any print farm.

On top of the space required by the printers themselves, take into account the space required for all the tools and extra materials (filament spools) too. And because filament can degrade in quality when exposed to moisture, dust, and other substances, you might want to make a special storage area for filament spools. Filament dry boxes and heated containers are perfect for this!

I also strongly recommend reserving one area of your print farm for a small workshop. This way you can repair printers on your farm and have the printer back up and running in no time.

This way you can repair printers on your farm and have the printer back up and running in no time.

Spare Parts

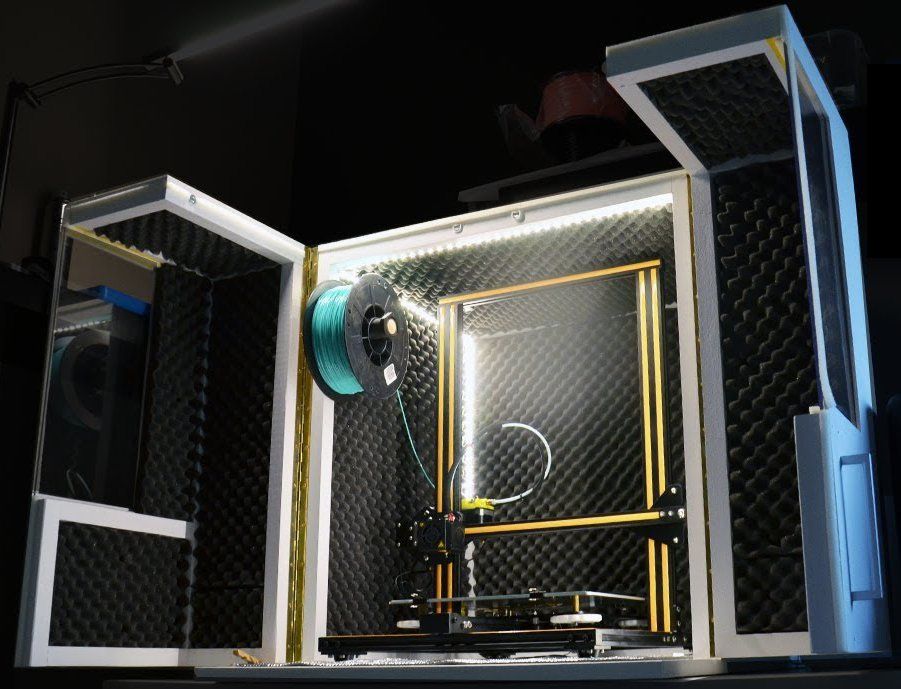

Source: Youtube ModBotWhether you like it or not, your 3D printers will break. No matter the quality of the 3D printers on your farm, something will eventually break when they’re pumping out prints for days on end. That’s why it’s essential to have some spare parts lying around.

Now you don’t need to keep spares of every single part on your 3D printers, but having some extras on the parts that break the most, like the nozzle, is smart. For my print farm of Ender 3s, I have a box of extra nozzles, hot ends, and extruder gears just in case some break.

3D Print Farm Software

Source: Youtube Thomas SanladererLastly, automation is the key to an efficient and consistent 3D print farm. Ideally, you won’t have to be in your print farm all day to make sure everything is running smoothly. A 3D print farm software helps with this by automating your printers.

There are a handful of different software options, including OctoPrint, Buildbee, 3DPrinterOS, Slant3D, and Authentise. Each software works differently, but they all require some form of computer (e.g. Raspberry Pi board) attachment for the printers. The computer hosts a server that you can remotely access and use to control your printers, set up a print queue, and more.

My personal favorite software is OctoPrint, though, because I love the control it gives me. While it doesn’t natively support control over multiple printers, you can use an app container (e.g. Docker) or just have an OctoPrint server for each printer. For a more cohesive experience, 3DPrinterOS is a great option, though it does cost money.

Check out our article on how to set up OctoPrint on your 3D printer here.

Considerations for Print Farm Printers

When looking for a 3D printer to fill your print farm with, there are a few aspects of the machine to keep in mind.

Reliability

The single most important aspect of a machine for your print farm is its reliability. You want a 3D printer that can consistently print models without failure.

While there’s no one way to rate a printer’s reliability, the better the machine’s build quality, the more reliable it is. That’s why the more expensive machines are typically more reliable, but this isn’t always the case, as we’ll talk about later.

The best way you can rate the reliability of a 3D printer is by checking the reviews of the machine. Reddit is also an amazing source!

Print Quality

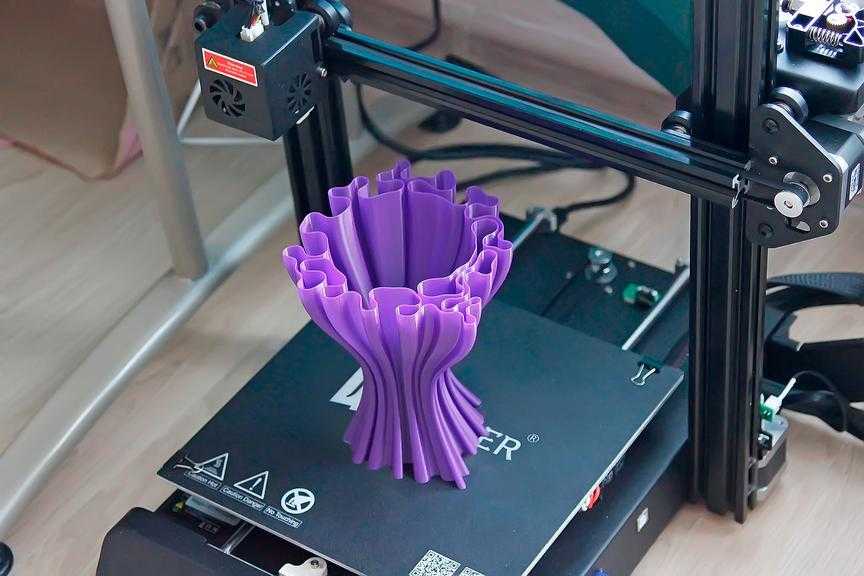

No matter how reliable your print farm is, if the prints suck, no one will want 3D prints from your business. That’s why the quality of prints is also extremely important for the machines in your print farm.

Like with reliability, there isn’t really a good way to rate the quality of prints by a specific machine. You can get an idea of how nicely the prints will turn out based on the build plate material, hot end type, and motion system. But, just like with reliability, checking the reviews helps the most.

But, just like with reliability, checking the reviews helps the most.

Material Compatibility

The material compatibility of the 3D printer regulates which filament (or resin) materials you can print on the machine and which you can’t. Most printers can handle PLA and PETG.

However, if you want to print ABS, you’ll need a printer with an enclosure and a high-temperature bed (minimum 100 °C). And for printing flexible materials like TPU and TPE, you’ll want a printer with a direct drive extruder.

And for the more industrial materials, like Nylon and PC, you’ll want a high-temperature hot end.

Build Volume

Build volume is also extremely important because the more space you have, the more items you can print at once. A typical volume you want for a print farm printer is 200 x 200 x 200 mm or higher. But this isn’t a hard requirement, and you can use a printer with a smaller volume if the machine makes up for it in other areas.

Price

Of course, price is probably the first aspect of a printer you look at. And it’s very important!

And it’s very important!

You shouldn’t overpay for a printer that doesn’t put out its worth. As you want ten or more printers in your farm, picking out a machine that will make your budget work is important, so don’t break the bank for only a few high-quality printers!

Automatic Bed Leveling

Automatic bed leveling is an increasingly popular feature on 3D printers that makes the whole printing experience much easier. All you have to do is click a button, and your printer will level itself rather than having to manually rotate the bed knobs to get a level bed.

You should keep an eye out for printers with an automatic bed leveling sensor, but it’s not totally necessary, so don’t rule out machines just because they don’t have ABL.

Check out our article on the best auto-leveling 3D printers here.

Power Loss Recovery

The last consideration for a print farm machine is a small but vital one: power loss recovery. If the power goes out on your print farm, you wouldn’t want all of the ongoing print jobs to be wasted. Power loss recovery is a feature in the firmware of your printer’s motherboard that will ensure your 3D printer resumes any ongoing prin jobs once the power is back.

Power loss recovery is a feature in the firmware of your printer’s motherboard that will ensure your 3D printer resumes any ongoing prin jobs once the power is back.

Conclusion

Though it’s no small investment (with money, time, and effort), building a 3D print farm can help you start your own 3D printing business or fill your manufacturing needs. But if you build one, do it right! Make sure you’ve got a 3D printer that won’t disappoint you even after hundreds of high-quality prints.

If you’re deciding which machine to fill your print farm with, my first suggestion would have to go to the Ender 3 V2. It’s a bit more expensive than the Original or Pro versions of the Ender 3 but its extra features, like belt tensioners and a glass build plate, allow for exceptional quality prints. And the machine has a very low failure rate.

But if the print quality is your #1 concern, you definitely need to check out both the Prusa i3 MK3S+ and Mini+. These printers cost a bit extra, but with the premium price comes premium features, like automatic bed leveling, a smooth motion system, and a powerful, never-failing metal extruder.

Top 3D Printers for 3D Printing Farms

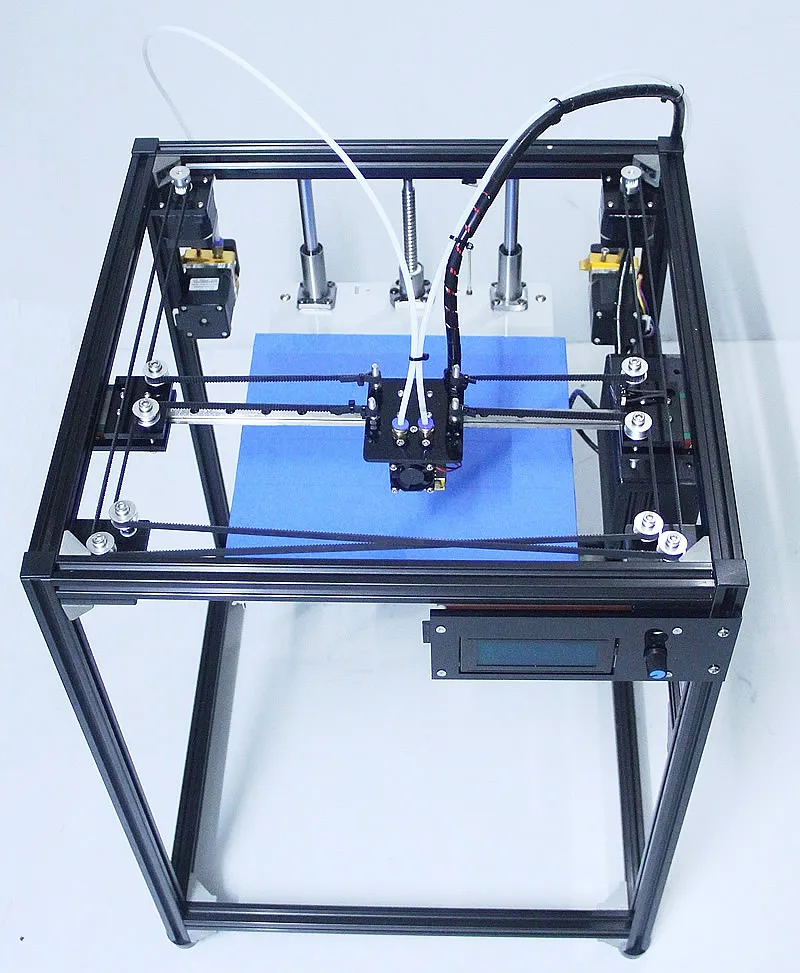

| 10/10/2020 0 Comments

3D Printing farms are a becoming a critical part of manufacturing and small businesses in the creation of prototypes and tooling and actual finished products. But what are good printers to deploy in fleets? In this post we will discuss printers with proven track records of being used in 3D Printing farms. The Mason 3D Printer is the machine used in all Slant 3D Printing farms. The Mason was originally never intended as a commercially saleable product. It was developed internally to be optimized for production. This mean high reliability and simple maintenance since they were meant to be deployed by the thousands the way data centers deploy servers. Versions of the Mason are the predominant machine used in Print Farm Beta being built in Boise Idaho, which will house 800 3D Printers when complete, producing hundreds of thousands of parts. The Mason was made commercially available in 2019, 2 years after the original versions were created and put into use in Slant 3D. They were made for clients that needed ready access to prototyping. Having a Mason allowed them to iterate on a prototype until they were satisfied and then immediately start production with Slant 3D printing services without lengthy sampling and verification. Any part made on a Mason 3D Printer is identical to what comes out of Slant 3D Printing farms, which are composed of Masons. That means a product can go from prototype to full scale production with no steps in between. The Mason is a machine for experienced users. Since it was designed for production it does not have many of the trendy bells and whistles of other machines. It is workhorse machine not a beginner trainer. It is meant to be a reliable and sturdy and last a few years without being a headache. A popular machine among the 3D Printing community because of its user friendliness and reliability, the Prusa i3 was originally produced in 2018 and has been going strong since. Manufactured in Prague and based on the original RepRap project, the Prusa i3 was developed by Prusa Research. While the i3 is considered a consumer/hobbyist machine Prusa does use a fleet of 300-500 3D Printers at its factory in Prague to produce the 3D Printed parts for the printers that it sells. This does give them the credibility of "eating their own cooking." The Prusa i3 is recognized for its removable lined build-plate and auto bed leveling. Both of these features can make it simpler to operate. The downside is that it is a moving bed Cartesian design which limits the height of certain parts because the foundation of the part moving under it can lead to rippling at the the stop of the part. UltimakerUltimaker is one of the leading brands of 3D Printers. Manufactured in Denmark Ultimaker focuses on making professional desktop printers. While Ultimaker does not use 3D Printing to make any of their machines the reliability and integration of their machines makes them ideal for many manufacturing settings where many personnel will be sharing the machines. Companies such as Gantri utilize a 3D Printing farm of Ultimaker machines to manufacture custom Lamps. And companies such as Jabil use the machines within their factories for prototyping and jigs. The Ultimaker machines are nearly second to none in print quality and ease of integration in a professional setting. But that also means that they are one of the most expensive options in creating a 3D Printing farm. These are the machines that we consider viable for creating reliable 3D Printing farms. Lower cost machines, while easy to setup, often only have a usable life of less than a year with heavy use in a 3D Printing farm. Many of them also have defects or lack of consistency that just makes them a pain to work with. The machines in this post are all battle hardened and have a proven track record of actually working successfully in 3D Printing Farms. 0 Comments | Categories All Archives January 2023 RSS Feed |

Best Small Business 3D Printer 2022: The Best Professional-Grade Printers

Whether you're looking to jump into professional 3D printing for the first time or upgrade an existing print farm, we're ready to push you in the right direction with our guide to the best 3D printers for business. small business.

small business.

Nowadays, a business-ready printer must not only create affordable, high-quality parts and prototypes; it should actively increase productivity and optimize workflows. Below you'll find a selection of the most reliable and user-friendly mid-range printers on the market today, for start-ups and established businesses alike. nine0003

We have selected proven working machines suitable for applications ranging from rapid prototyping to end-use parts and everything in between. Let's dive in.

Contents

- Best Small Business 3D Printers

- Formlabs Form 3+ / 3L - Professional Resin Printer

- Ultimaker S5 / S5 Pro Bundle

- Raise3D Pro2 / Pro2 Plus Prusa3-MK+ - Best Inexpensive small business printer

- Desktop Metal Studio System - Best small business metal 3D printer

- Things to consider when buying a small business 3D printer

- Software and workflow

- Materials

- Resolution

- Workpiece size and volume Sphere

- Applications

- Small Business 3D Printer FAQ

Best Small Business 3D Printers

Formlabs Form 3+ / 3L - Professional Resin Printer

The Formlabs 3+ and Formlabs 3L resin printers are designed from the ground up for the fast-paced, productivity-oriented small business that wants to go without outsourcing. They allow companies to easily implement streamlined, affordable prototyping and in-house manufacturing of functional end-use parts.

They allow companies to easily implement streamlined, affordable prototyping and in-house manufacturing of functional end-use parts.

Print quality is nothing short of industrial quality with fast, accurate printing that features rich features and a flawless surface. These printers excel in areas where highly precise and functional parts are required, such as jewelry making, hybrid visual effects, mechanical engineering, medical, and miniature/figure making. nine0003

The two printers are basically the same, except that the FormLab 3L offers a larger build volume of 335 x 200 x 300 cm and two light processing units to compensate for the larger build platform. If your job involves large models or prototypes, or if you need to batch print large quantities of small parts, we recommend FormLab 3L. Otherwise, FormLab 3+ offers the same reliable accuracy and speed at a more affordable price.

Formlabs Form 3+ and 3L's focus on productivity extends to the surrounding ecosystem to ensure a seamless end-to-end workflow. You can switch between 30 different types of resins, each with different characteristics and properties, in seconds with the easy-to-change Formlab cartridges. Formlabs Form Wash and Form Cure accessories fully automate resin print post-processing with a “set it and forget it” feature. nine0003

You can switch between 30 different types of resins, each with different characteristics and properties, in seconds with the easy-to-change Formlab cartridges. Formlabs Form Wash and Form Cure accessories fully automate resin print post-processing with a “set it and forget it” feature. nine0003

Formlabs PreForm SLA software is equipped with automated features such as adaptive layer thickness, mesh recovery and one-click support generation for true printing. The cloud-based print monitoring and management panel also means you can scale up with multiple printers or queue multiple prints from anywhere without much hassle.

Investing in a complete Formlabs ecosystem is expensive, which can be prohibitive for some businesses. In this case the Prusa SL1S Speed is a great low cost alternative. Since it bears the Prusa name, you are buying 3D printing royalties. It's fast, easy to use, delivers professional-quality prints and keeps running costs low. nine0003

Ultimaker S5 / S5 Pro Bundle

The Ultimaker S5 and S5 Pro are working FDM printers for high precision rapid prototyping of functional parts for the arts, medicine, mechanical engineering, automotive, consumer goods and architecture industries.

Like consumer-grade Ultimaker printers, the S5 and S5 Pro are designed with ease of use in mind to increase productivity without the hassle while reducing costs. At the heart of this is a dual extrusion system, compatibility with a wide range of materials, easy network printer management, and near-zero one-click printing speed with Ultimaker Digital Factory software. nine0003

With desirable and identical specifications, the Ultimaker S5 and S5 Pro produce industrial-grade prints with a level of detail and smoothness that conventional FDM printers rarely achieve. The Ultimaker S5 and S5 Pro allow you to produce durable and precise parts such as mock-ups, prototypes, functional parts, tools and proof samples.

The Ultimaker S5 Pro is an S5 with an enclosed, temperature controlled material feed station. The station filters out toxic fumes and maintains a dust and moisture free environment with a reliable air filtration system to keep materials in optimum condition. nine0003

In addition, the station can simultaneously hold up to six different front-loading spools of thread. Automatic media handling manages spool changes and runtime switching to ensure trouble-free printing. It really is a handless seal.

Automatic media handling manages spool changes and runtime switching to ensure trouble-free printing. It really is a handless seal.

Although smaller in footprint and build volume than its S5 sibling, the Ultimaker S3's more affordable price, smaller footprint and identical specifications make it a great choice for smaller businesses with less cash to spare. nine0003

Raise3D Pro2 / Pro2 Plus

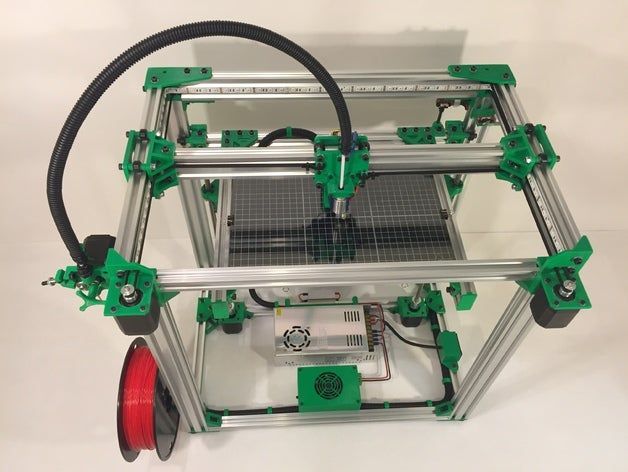

Raise 3D calls the Raise3D Pro2 and its more expensive Pro2 Plus counterpart the "best industrial-grade 3D printers" under the sun, delivering fast, highly detailed prints backed by a durable and strong frame. Both will make a solid addition for performance-oriented small businesses looking for a reliable and versatile solution for manufacturing and rapid prototyping.

Features include dual extruders, a comprehensive HEPA air filtration system, and end-to-end control of the entire print process with RaiseCloud software, making it easy to manage a flock of printers remotely. nine0003

nine0003

Raise3D Pro2 and Pro2 Plus material compatibility is extensive: PLA, ABS, HIPS, PC, TPU, TPE, PETG, ASA, PP, PVA, nylon, as well as fiberglass, carbon fiber, metal-filled, wood-filled and filled are supported.

With the same basic hardware and specifications as the Raise3D Pro2, the Raise3D Pro2 Plus differs in build volume. It increases the build volume with single extrusion to 305 x 305 x 605mm and dual extrusion to 280 x 305 x 605mm, adding verticality for taller prints. nine0003

Raise3D E2 should also be mentioned in passing. With a smaller footprint and build volume, combined with the IDEX system, the Raise3D E2 takes on the form of a desktop printer. It's a great choice for small design studios that don't need as much print area as the industrial-strength Pro2 machines.

Prusa i3 MK3S+ is the best low cost 3D printer for small businesses

A favorite of hobby makers around the world, the Prusa i3 MK3S+ makes our list as a low cost savior for the smallest businesses that are put off by the exorbitant prices of the Form 3+ and Ultimaker S5. nine0003

nine0003

While the Prusa i3 MK3S+ is a workhorse of its kind, it's not a production tool or design powerhouse like the other best small business 3D printers we've rounded up. Its footprint is significantly smaller than most professional grade printers for business use. If you're working from home, the Prusa i3 MK3S+ won't take up an entire room.

More compact and less ambitious, it is a reliable companion for companies that want to produce one high-quality prototype quickly or focus on producing small, highly detailed, limited-edition parts. nine0003

The Prusa i3 MK3S+ does just that without compromising the quality of the finished product. Print results come close to what you'd expect from other printers on our list, but at a fraction of the cost. Multiple built-in failsafes and sensors ensure easy printing with high hardware quality and decent media compatibility, including PLA, PETG, ASA, PC, HIPS and more.

Easy printing and software equally appeal to aspiring entrepreneurs getting into 3D printing for the first time. You won't get tired of managing your printer fleet with a cloud-based management system. nine0003

You won't get tired of managing your printer fleet with a cloud-based management system. nine0003

Desktop Metal Studio System - the best metal 3D printer for small businesses

Despite the ridiculous name, Desktop Metal Studio System is a reliable, advanced metal printing solution suitable for prototyping, manufacturing, automotive design , consumer products and even small disposable parts designed for heavy industry applications.

As the name suggests, this is a desktop-friendly solution with the same approach as the native Fabricate software. The software covers all aspects of part creation, reducing the complex, often confusing, not to say intimidating, metallurgy into a well-managed, step-by-step process. Like the other printers on our list, Fabricate is workflow aware and you can easily manage and control multiple printers for consistent and productive printing. nine0003

It's amazing how it makes it easy to create difficult-to-machine parts with a high level of geometric complexity. The results often surpass traditional casting in terms of density and accuracy, while still allowing fine undercuts and internal channels to be produced, resulting in superior surface finish in every print.

The results often surpass traditional casting in terms of density and accuracy, while still allowing fine undercuts and internal channels to be produced, resulting in superior surface finish in every print.

Desktop Metal Studio System comes with a sintering oven in an office-friendly package. The latter has temperature profiles that match the type of material and design, ensuring industrial sintering strength with every print. In addition, the print is much less messy than most powder-based metal systems and has many safety features, not least a fully enclosed chamber. nine0003

Things to Consider When Buying a Small Business 3D Printer

Software and Workflow

Time is money, as the old saying goes, and the software installed on a 3D printer plays a huge role in determining workflow and efficiency . Whether you're looking to scale up production, quickly complete an order, or reduce manual steps to improve productivity, look to robust software suites that allow you to monitor and manage multiple printers via the cloud. nine0003

nine0003

One-click printing, Wi-Fi connectivity, automated slicing processes - all worth considering if productivity is your number one priority. An intuitive user interface and ease of use are also important to efficiency.

Materials

When choosing a small business 3D printer, look for material compatibility, especially if your application requires more exotic and abrasive filament types. Generally, professional printers offer wider compatibility than hobbyist printers: PLA, ABS, PETG, and flex materials come standard. nine0003

You may also want to consider purchasing a dedicated metal or resin printer if these materials are in your printing plans. Dedicated machines tend to produce better results with selected media than general purpose printers.

Resolution

Resolution, often referred to as layer height, is a measurement in mm (or microns) that determines the thickness of each printed layer. The lower the resolution, the better the details and textures. nine0003

nine0003

For small businesses, 20 to 100 microns is sufficient in most cases. If you want the most accurate results, look to resin printers, high-resolution machines that excel at printing richly detailed parts.

Stock size and volume

Print volume refers to the available printable area, or in other words, the maximum print size. The best small business 3D printers have a higher build volume than standard consumer printers, but it's worth checking if they have a high enough build volume if you're planning on making large prototypes or if you plan on mass printing. nine0003

The physical footprint of the printer is probably not that important, but it's worth considering if you're planning to set up a print farm and have limited space in your workshop, lab, or office.

Applications

While most professional 3D printers are suitable for a variety of applications, we recommend that you find out if a particular machine is suitable for your preferred use case. A compact printer like the Prusa i3 MK3S+ is well suited for printing small prototypes and limited edition parts in a small home office environment. nine0003

A compact printer like the Prusa i3 MK3S+ is well suited for printing small prototypes and limited edition parts in a small home office environment. nine0003

The Metal Studio System is ideal for making disposable metal parts for heavy industry. The Ultimaker S5 Pro makes it easy to print with multiple filament types, automatically switching between them as needed to create complex, detailed parts. You got the idea; make sure the printer meets your needs.

Small Business 3D Printer FAQ

What is the best 3D printer for starting a small business at home? nine0003

Although 3D printers, even professional-grade ones, have shrunk considerably since the early days of the technology, they are still bulky machines. To save space and reduce costs, we recommend the Prusa i3 MK3S+ as the best 3D printer for starting a small business at home. The print quality of the Prusa i3 MK3S+ approaches that of three times the price of printers, and its compact size, along with its elegant orange and black color scheme, fits perfectly into a home office environment. nine0003

nine0003

What is the best small business metal 3D printer?

Several printers on our list allow metal 3D printing, but one printer stands out above the rest, the Desktop Metal Studio System. The printer is designed from the ground up to work exclusively with metal for a variety of professional applications. The results are excellent and the Fabricate software greatly simplifies the normally complex art of metallurgy. The printer also comes with an industrial-grade perfect sintering oven. nine0003

What is the best resin 3D printer for small businesses?

We recommend Formlabs Form 3+ and Formlab Form 3L for small businesses that want to work exclusively with resin. As ecosystem printers, they have everything you need from design to post-processing to help you set up a reliable, productivity-focused workflow. The print results are excellent, replete with fine detail and a smooth surface. Choose the Formlab Form 3L if you need more build volume to print larger parts or for faster batch printing. nine0003

nine0003

Complete 3D Printing Solution - 3D Farms

Home

Complete solution for 3D printing - 3D farms

What is a 3D farm

A 3D farm is a set of 3D printers, usually of the same type and performing standard tasks, within one enterprise.

A well-managed 3D printing farm can be a strong addition to an existing business or stand alone. Creating a cell from several 3D printers will increase production capacity, allow simultaneous production in several materials and offer 3D printing to customers as a paid service. nine0003

The use of 3D printing in production allows you to shorten the production cycle, reduce overhead costs and reduce the time needed to translate projects into a finished product.

3D printer farms are the best solution for starting or expanding your business. Their advantages:

- Easy scalability – from small workshop to factory

- Quick installation and start nine0011 Ideal for fast turnarounds

Why you need a 3D farm

For a large team

A 3D farm increases the efficiency of a team of engineers or designers - having several 3D printers will allow you to print models at the same time, without taking up a queue for printing and without waiting for several hours or days.

By dedicating one specialist to maintain the farm, you free the rest from the need to fill printers with material and control printing, which allows them to focus on their work. nine0003

For more productivity

Regardless of the field of activity, the production cell of several 3D printers allows you to increase production volumes.

The Formlabs farm, for example, which includes fifty Form 2 printers, produces about 650 models per week in different types of polymer, and only seven people work there. When printers are bundled together, there is no need for an operator for each device. nine0003

Multi-material

Most 3D printers print one material at a time. There are models of FDM printers with two or even three extruders, but such printers are also limited in the number of plastics used at the same time. This forces you to wait for the end of printing to create the next model from a different material, which stretches the process for many hours. With the help of a 3D farm, you can print parts from any number of materials at the same time, limited only by the number of printers in your farm. nine0003

With the help of a 3D farm, you can print parts from any number of materials at the same time, limited only by the number of printers in your farm. nine0003

Custom print

3D print shop websites and 3D hubs accept 3D printing orders over the Internet, converting printer life into profit. Users who print too little to buy a 3D printer send them their models in .STL or .OBJ format and receive finished prints. This industry is growing, the service is gaining popularity. If you are interested in getting into this field and capturing your piece of the market, then it's time to get a small 3D farm, which can then be easily scaled up by adding new printers. nine0003

For Guaranteed Success

Even with the most reliable 3D printer, there is always the possibility of a breakdown, operator error, or mishap due to unforeseen circumstances. If you have only one 3D printer, this situation can slow down the entire organization while it is being repaired, causing production delays and customer dissatisfaction. Having a farm of 3D printers, you are protected from suddenly being left without a 3D printing tool, and especially important orders can be duplicated by printing at the same time to ensure that force majeure is avoided. nine0003

Having a farm of 3D printers, you are protected from suddenly being left without a 3D printing tool, and especially important orders can be duplicated by printing at the same time to ensure that force majeure is avoided. nine0003

Options for execution

Fermlabs

Fermlabs Form 2 Farm Ferts are equipped with high-precision stereolithographic 3D-sprinters, which have well proven themselves in the quality of the quality of the quality in the soil.

Buy Formlabs Form 2

- High resolution and quality

- Reliable printing process - ultra low reject rate

- An assortment of advanced photopolymers designed specifically for this printer, for any purpose

- Ideal for jewelry and dental applications

Ultimaker Farm

Ultimaker builds some of the most accurate and high quality FDM printers in the world. This solution is perfect for prototyping or custom 3D printing. The farm is equipped with Ultimaker 3 Extended 3D printers, which print simultaneously with two filaments in a working area of 215 x 215 x 305 mm. nine0003

Buy Ultimaker 3 Extended

- High quality printing from a renowned manufacturer

- Possibility of remote control via WEB

- Inexpensive and proven, familiar materials - Nylon, ABS, PLA, CPE

- Ideal for prototyping, small batch production of finished products

Makerbot Farm

The MakerBot Farm is a centralized, scalable 3D printing center consisting of MakerBot Replicator + 3D printers.