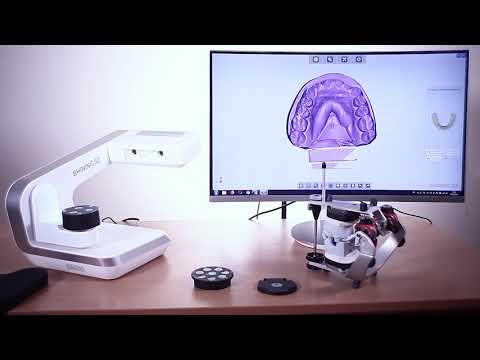

Biodegradable filament for 3d printer

Fillamentum unveils first fully biodegradable filament NonOilen for 3D printing

0Shares

Czech 3D printing filament producer Fillamentum has launched its first 100 percent biodegradable filament for 3D printing, NonOilen.

The biobased filament is made from a blend of polylactic acid (PLA) and polyhydroxy butyrate (PHB) to yield improved toughness and temperature-resistant properties. It can be reused time and again to adhere to the principles of a circular economy.

Once an object printed with NonOilen reaches the end of its lifecycle, it can be fully degraded to biomass, water, and carbon dioxide (CO2) in compost or food waste disposal or sent back to Fillamentum for recycling. The company has also joined the DHL GoGreen program to neutralize its carbon footprint with each NonOilen parcel sent via the delivery service.

According to the company, the driving force behind creating NonOilen was to reduce the use of fossil resources, such as oil, to make its 3D printable filaments and reduce the firm’s environmental footprint on the planet.

Developing a fully biobased and biodegradable filament

Previous attempts to improve the biodegradability of plastics include the creation of oxo-bioplastics, where standard polymers were modified by adding substances that cause degradation in the presence of oxygen. However, these oxo-bioplastics can not be sufficiently degraded in compost as secondary microplastics, created as the plastic decays, can have harmful effects on the surrounding environment, such as soil or oceans.

To solve this problem, Fillamentum states that new ways to degrade such polymers need to be discovered, in addition to finding new sources to replace fossil resources in creating biodegradable polymers with high-value use and improvements in waste handling.

To this end, the company’s latest 3D printing filament, NonOilen, has emerged out of a long-term partnership with the research team of Professor Pavol Alexy from the Slovak Technical University in Bratislava, Slovakia. The filament is 100 percent biodegradable and all polymers used in its production are fully biobased.

The filament is 100 percent biodegradable and all polymers used in its production are fully biobased.

Once an object reaches the end of its lifetime, it can be placed in industrial or home food waste composters where degradation takes place around three times faster than standard PLA. The PHB in NonOilen acts as an initiator for the breakdown process, allowing bacteria to depolymerize and metabolize the polymer quicker.

Alternatively, if sent back to Fillamentum the material will be recycled and reused several more times while retaining its mechanical properties.

The principle of a circular economy. Image via Fillamentum.Mechanical properties of NonOilen

In addition to its biodegradable credentials, NonOilen also possesses improved toughness, hardness, and strength properties when compared to standard PLA, as a result of its PHB content.

One of the main advantages of the filament is its temperature resistance up to 110 degrees celsius after 3D printing, meaning there is no need for annealing. NonOilen is easily printed, reportedly comparable to the ease of printing with standard PLA, with parts featuring a smooth surface with a natural silk look that is translucent when printed in a thin layer.

NonOilen is easily printed, reportedly comparable to the ease of printing with standard PLA, with parts featuring a smooth surface with a natural silk look that is translucent when printed in a thin layer.

Objects printed with NonOilen showcase long-term durability and are safe for food contact applications. The filament can also be used for the production of 3D printed electrical components and electronic equipment.

According to Fillamentum, NonOilen can retain its mechanical properties even after being recycled “many times”, an improvement on the firm’s other biodegradable filaments PLA Extrafill and PLA Crystal Clear, which both experience at least some loss of mechanical properties when recycled. What’s more, the material performs significantly better than the firm’s Timberfill filament which, while biodegradable, cannot be recycled.

NonOilen also has a substantially higher temperature resistance than the company’s other biodegradable filaments and boasts a considerably shorter biodegrading timeframe.

“Green prototyping” of NonOilen by Fremach

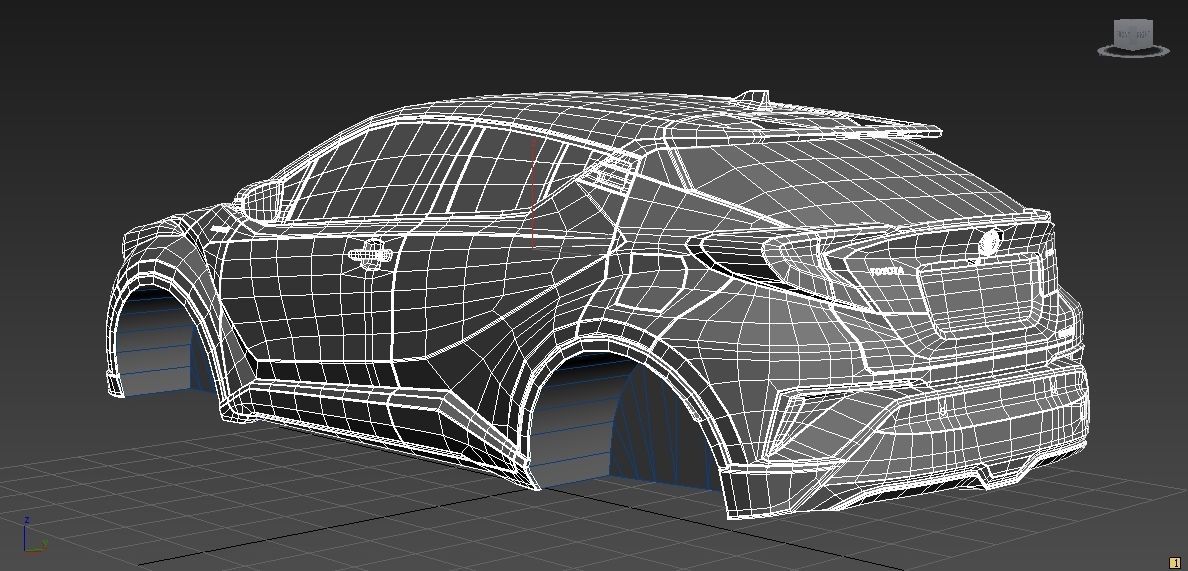

Fremach, a global supplier of complex plastic components to the automotive market, has tested Fillamentum’s NonOilen filament in the production of control gauges and gears. The firm chose the material for its ability to resist high temperatures and for its complete recyclability, which is a welcome benefit when printing large numbers of these components.

The gauges are used to check the positions of symbols on decorative parts, which then go unused once their purpose has been served. The recyclability of NonOilen is therefore a huge benefit to the company and enables Fremach to significantly reduce waste. The 3D printed gears form part of a rotating system for painting cylindrical parts, and here Fremach hails the filament’s ability to resist the high temperatures that the gears are exposed to in the pant shop furnace without deforming.

“The benefits of 3D printing are obvious and are increasingly important to our business,” said Miroslava Pribylova, Process Engineer for Fremach. “Furthermore, Fillamentum’s ecological thinking motivates us to take our own steps closer to nature.”

In cooperation with Fillamentum, Fremach will regularly collect and recycle unused parts made of NonOilen materials for use in its own production. As of today, Fillamentum is available for purchase and shipping.

NonOilen retains its mechanical properties even after being recycled many times. Photo via Fillamentum.Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

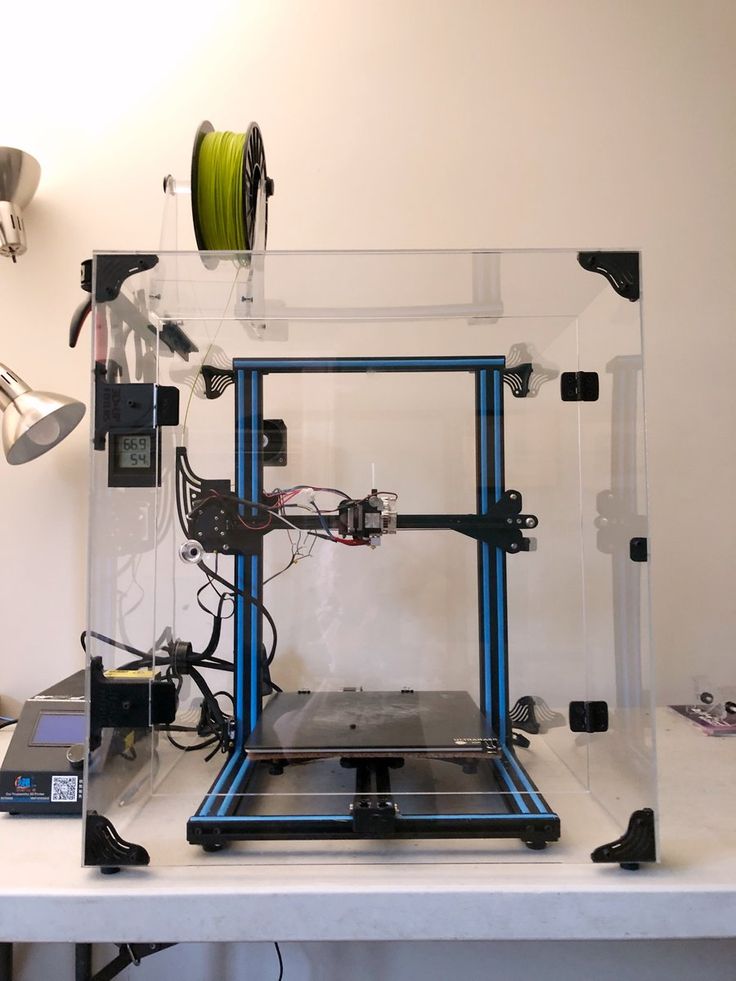

Featured image shows Fillamentum NonOilen filament is biobased and fully biodegradable. Photo via Fillamentum.

Photo via Fillamentum.

Tags DHL GoGreen Fillamentum Fremach NonOilen PLA Crystal Clear PLA Extrafill Slovak Technical University Timberfill

Hayley Everett

Hayley is a Technology Journalist for 3DPI and has a background in B2B publications spanning manufacturing, tools and cycling. Writing news and features, she holds a keen interest in emerging technologies which are impacting the world we live in.

Biodegradable 3D Printer Filaments - A Guide to Going Green with 3D Printing

Environmental concerns are more of a priority than ever, and a lot of us are doing our bit to lower our carbon footprint.

With rising concerns about plastic use, it’s only natural that the largely plastic-based 3D printer filaments are being looked at more carefully.

Biodegradable 3D printer filaments are more common than you’d think, and there are a lot of ways to make your 3D printing a much greener process.

As we’ll see today, plastic waste is avoidable, and there are plenty of biodegradable filaments to make 3D printing more eco-friendly.

Depending on how you want to cut down on plastic waste, and your budget, what kind of biodegradable filament you chose will vary.

Here we’re going to look at which 3D printer filaments biodegrade at what rates, and which you should go for depending on your priorities.

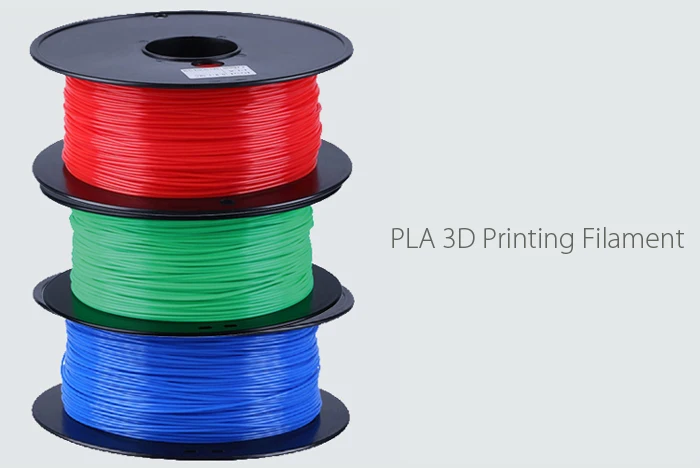

PLA

- Primary Ingredient: Cornstarch and other plant-based sugars

- Price: $20 – $50/kg

- Suitable for Home Composting: Yes

- Toxic: No

- Best Used For: Standard 3D printing projects, medical and dental tools, and kitchenware.

Beginning with a standard filament that you may have already used before, PLA is a bioplastic, which means that it is 100% biodegradable.

That is not to say that it won’t do some damage if disposed of incorrectly, however.

For PLA to live up to its 100% biodegradability, it needs to be done commercially. Properly recycling any wasted materials or failed PLA projects is the best way to keep it green. But you can also take care of it at home if you happen to have a home composting setup.

But you can also take care of it at home if you happen to have a home composting setup.

This is because PLA is only fully recyclable using very high temperatures and will need to be treated in a plant to be reused with any real efficiency. But it can still be composted at home.

It may interest you to know that there is ongoing research to make standard thermoplastics suitable for at-home composting too.

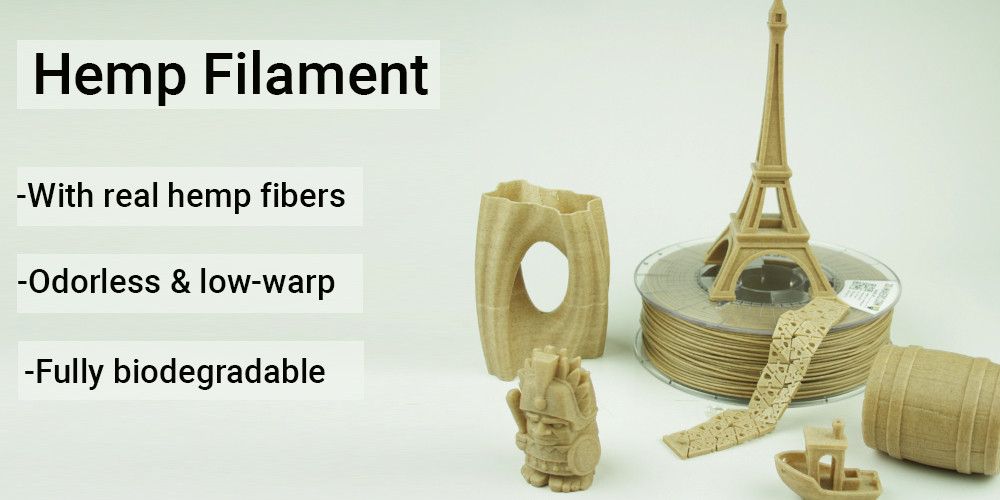

Wood

- Primary Ingredient: PLA and wood

- Price: $50/kg

- Suitable for Home Composting: Yes

- Toxic: No

- Best Used For: Puppets, sculptures, and anything else that would look better with a wooden veneer.

Despite how cool it sounds and the fact that you can alter the shade by changing the extrusion temperature, wood filament isn’t just made of wood.

Fortunately, the base for most wood filaments is made from PLA, meaning the filament’s natural biodegradability is left untouched.

Fillamentum’s Timberfill is one such PLA-based wood filament that is 100% biodegradable as well as a highly reliable filament.

You’re also not limited to only plywood when 3D printing, and you can find a host of different kinds like bamboo and cork to suit your printing needs. All of these filaments are biodegradable, non-toxic, and very eco-friendly.

Wood filaments are suitable for home composting and can be recycled just like any other good plastics, just don’t make the mistake of throwing them in with your garden waste.

It may look like wood, but the recycling plant won’t be too happy with that.

Paper

- Primary Ingredient: Paper Pulp

- Price: N/A

- Suitable for Home Composting: Yes

- Toxic: No

- Best Used For: Soft decorative items like pots and centerpieces.

It may seem like an unorthodox 3D printing material, but in an effort to help reduce paper waste, Dutch engineer Beer Holthuis developed a way to 3D print with paper.

This paved the way for a much greener way to 3D print using a famously biodegradable material.

If you’d like to learn more about the science and techniques behind 3D printing with paper, you can check out our in-depth guide here.

With a process similar to laminating, CleanGreen 3D created a method that glues paper pieces together to make 3D printed objects.

The process wasn’t entirely green, though, as it did use some plastics to help the paper retain its shape. Though it was still much cleaner than a lot of other fully plastic-based methods.

While not as tough as standard materials, using paper as a biodegradable filament is a lot greener as it’s suitable for home composting, and works out quite a bit cheaper too.

Unfortunately, CleanGreen has gone out of business, but Beer Holthuis has continued his research in 3D printing directly with paper pulp, the details of which can be found on his blog here.

While not currently available to the public, continued research into 3D printing with paper will make for a much greener 3D printing experience for us all.

Coffee

- Primary Ingredient: PLA and coffee grounds

- Price: $20 – $50/KG + Your favorite coffee brand

- Suitable for Home Composting: Yes

- Toxic: Yes

- Best Used For: Decorative ornaments that you want to smell like coffee.

One of the more surprising additions to biodegradable filament development is coffee.

As an easily manipulatable substance that reacts well and predictably with heat, coffee makes for an excellent 3D printer filament that’s a lot easier to use than you’d think.

Like wood filament, coffee filament is PLA based, meaning it’s fully biodegradable.

It’s not only a cool way to get 3D prints with very satisfying colors (the prints even smell like coffee!) but it helps buff out your filament to give you more bang for your buck.

Coffee filament can be made at home with some simple PLA and store-bought coffee grounds.

This is simple to do. Using a filament customizer like a Felifil Evo extruder, you can easily make some fun and great 3D prints with coffee that are compostable and eco-friendly.

The only important thing to note here is that, despite its base ingredients, coffee filaments are toxic.

Because of its reaction to heat, the plastic will fray and seep into anything too hot in contact with it, so it’s not recommended to use coffee filaments for kitchen utensils.

If you’d like to know which 3D filaments are suitable for your kitchen, you can check out our full guide to food-safe filaments here.

Beer

- Primary Ingredient: Cereals and grains

- Price: ~$80/kg

- Suitable for Home Composting: No

- Toxic: No

- Best Used For: Decorative pieces with easily smooth finishes

Okay, so this one got me excited.

The brewing process for all kinds of beer involves some byproducts that generally don’t or can’t be reused. Fortunately, most of these byproducts are all-natural like grains and cereals and can be composted without issue.

Fortunately, most of these byproducts are all-natural like grains and cereals and can be composted without issue.

However, C2Renew, a company specializing in eco-friendly 3D printing solutions, found another use for these byproducts; 3D printer filament!

By turning these waste products into biodegradable filaments, they created a special filament called ‘Buzzed’ (clever, right?) that’s pretty much letting you 3D print with beer.

This is not only a very eco-friendly alternative to more harmful plastics but also gives unique finishes and ever-changing hues.

Traditional brewing processes are more random than one would think, and each batch will have a slightly different color to it.

While this does mean you can’t expect specific colors for your 3D printing needs, it does make each batch unique and makes for a different experience each time.

You can print the same project with each variety you get and compare them for some subtly different decorations.

Potatoes

- Primary Ingredient: Starch

- Price: N/A

- Suitable for Home Composting: Yes

- Toxic: No

- Best Used For: Kitchen utensils and decorative items.

Similar to the above example, potato processing produces a lot of compostable byproducts that can be turned into biodegradable 3D printer filament.

Like PLA, the main ingredient in these filaments is the starch that comes from potatoes and yams that would otherwise end up in a compost heap at best.

With a faster printing time than PLA, but lacking the general durability, potato and yam-based filaments are a much greener way to print. It’s also non-toxic, so imagine eating potatoes off a plate you made from potatoes! Trippy, right?

While not yet widely available for sale, more starch-based filaments are on their way and should enter the mainstream before too long.

Eco-Friendly 3D Printing Solutions

As well as using biodegradable 3D printer filaments, there are other ways to keep your 3D printing adventures eco-friendly and green as it gets.

Here are a couple of options you can apply to keep your environmentally friendly conscience clear while you print.

Recycle at Home

Home recycling and composting are good practices for eco-conscious people, and there are a lot of ways to do it.

Machines like the ProtoCycler+ are desktop extruders that let you recycle old filament and even experiment with your own additives.

You will need this equipment if you plan on making your own coffee filament.

Keep in mind that you will also need a grinder or shredder to get your 3D filaments ready for recycling. All-in-all, this is by far one of the best ways to keep your 3D printing green as it basically makes wasted filament a thing of the past.

Buy and Use Already Recycled Materials

With just a little research, you’ll find there are plenty of companies out there that deal exclusively in recycled 3D printer filaments.

Reflow is one such company that specializes in sustainable 3D printing solutions, including recycled PETG 3D printer filament.

Because PETG is oil-based and therefore non-biodegradable, using recycled PETG is the best way to use it in an eco-friendly way.

Refilament also focuses on recycling otherwise non-biodegradable filaments like ABS and provides greener solutions to those of you who want something tougher than PLA but are still environmentally conscious.

Biodegradable 3D Printer Filaments FAQs

What filament is biodegradable?

PLAs are the most common biodegradable 3D printer filaments, but other materials like wood, paper, coffee, and hemp are being used as eco-friendly 3D alternatives to non-biodegradable filaments like ABS.

There have also been some innovations in biodegradable 3D printer resins that are currently available.

Is PLA filament actually biodegradable?

Yes. PLA is a fully biodegradable 3D printer filament but is best reused via a recycling plant.

Through home composting, PLA can take a very long time to degrade, whereas it takes a maximum of twelve weeks if done professionally.

Is wood filament biodegradable?

Yes. Being PLA-based, wood filament is fully biodegradable and suitable for home composting.

Given both its eco-friendliness and its awesome-looking results, wood is an ideal filament for 3D printing enthusiasts who want to go greener.

Is there environmentally friendly 3D printing?

By avoiding non-biodegradable filaments like ABS, 3D printing can be very environmentally friendly.

With proper recycling and composting, the carbon footprint of 3D printing is easily minimized. Industries that use 3D printing to create parts in-house are also more eco-friendly as it cuts down on importation and wasted material.

Other articles you may be interested in:

- The Complete Best 3D Printer Filament Guide

- Recyclable 3D printer filaments

- PLA 3D Printing Filament

- Metal Filaments: The Complete 3D Printing Guide

- PVA Filament: The Complete 3D Printing Guide

- PLA vs ABS: Which is Best for your 3D Printing Needs?

- PLA vs PLA+: Is PLA Plus Filament better for 3D printing?

- Best ABS Filament: Top Brands & 3D Printing Guide

3D Printer Filament Buyer's Guide

- home

- 3D printing technologies

- Weld FDM, FFF and FGF material

- 3D Printer Plastic Filament Buyer's Guide - Part 4 nine0011

-

Plus: aesthetically, ideal for visual models

-

minuses: Non -consumed mechanical properties, requires enhanced nozzles with increased diameter (from 0.5 mm)

9000

19 — Wood (Wooden)

WHAT IS A WOODEN FILAMENT?

Thinking of printing an object that looks and feels like wood? And you can make it happen! But of course it won't be wood - it's PLA filled with wood fiber.

USER NOTE

There are many Wood-PLA 3D printer filaments on the market today. These include standard woods such as pine, birch, cedar, ebony and willow, but the range also extends to less common bamboo, cherry, coconut, cork and olive. nine0014

As with other types of 3D printer filament, wood filaments also have a reverse side. In this case, aesthetic and tactile appeal is achieved by reducing flexibility and strength.

Be careful with the temperature at which you print the wood, as too much heat can result in a charred or caramelized appearance. On the other hand, the look of your wooden creations can be greatly improved with a little post-printing treatment. Wood filament can also wear out your 3D printer's nozzle, so use steel or reinforced nozzles. nine0014

WHEN SHOULD WOOD FILAMENT BE USED?

Wood is popular for printing items that are valued not for their functionality, but more for their natural appearance. When printing interior and decor items, wood filament for a 3D printer is often used, for example, for printing bowls, figurines and awards. One really creative use of wood as a 3D printer filament is to create scale models used in architectural models. nine0014

When printing interior and decor items, wood filament for a 3D printer is often used, for example, for printing bowls, figurines and awards. One really creative use of wood as a 3D printer filament is to create scale models used in architectural models. nine0014

Summary

WHAT IS A METAL FILATION?

Maybe you're looking for a different type of aesthetic in your prints - something more voluminous and shiny. To do this, you can use "live" metal. Like wood 3D printer filament, metal filament is not entirely made of metal. It is actually a mixture of metal powder and PLA or ABS. But this does not prevent the results from having the appearance of metal. nine0014

Even the weight is metal-like as blends tend to be several times denser than pure PLA or ABS.

USER NOTES

Bronze, brass, copper, aluminum and even stainless steel filaments are just some of the "metallic" 3D printer filaments available on the market. And if you need to get a special look for your product, don't be afraid to polish, tumble or matt products after printing with these filaments - even a little post-processing can have a huge visual impact. nine0014

However, please note that you will have to replace the nozzle sooner after printing with "metal", as the metal powder in such filaments is highly abrasive and will cause increased nozzle wear.

The most common metal-filled 3D printer filaments typically contain around 50% metal powder and 50% PLA or ABS, but there are also composites containing up to 85% metal.

WHEN SHOULD METAL FILAMENT BE USED?

Metal-filled filament is used to solve a wide range of tasks: both for aesthetics and to achieve certain functionality. Figurines, models, toys, and dog tags can all look great with metal 3D printing. And as long as the printed objects don't have to deal with undue stress, feel free to use metallic 3D printer filament to create functional prints such as tools, grills, or finishing components.

And as long as the printed objects don't have to deal with undue stress, feel free to use metallic 3D printer filament to create functional prints such as tools, grills, or finishing components.

SUMMARY

-

Pros: mimics a metallic look, ideal for both aesthetic and functional models mm)

21 — BIOFILA (Biodegradable)

WHAT IS A BIODEGRADABLE FILAMENT?

Biodegradable 3D printer filaments constitute a unique category because their most valuable characteristics are independent of their technical parameters. As most 3D printing enthusiasts can attest, not every print comes out the way you intended, and that results in a lot of plastic being thrown away. Biodegradable threads seek to negate the negative environmental impact that plastic waste has. nine0014

USER NOTE

As mentioned earlier in this article, PLA is actually a biodegradable filament, but also includes the BioFila lines from TwoBears and Biome3D from Biome Bioplastics.

WHEN SHOULD BIODEGRADABLE FILAMENT BE USED?

Regardless of their primary purpose of being environmentally friendly, biodegradable filaments can still be printed with good physical properties. Use them when you do not have high requirements for strength, flexibility or wear resistance of the printed product. And if you really want to take advantage of the waste-free printing of biodegradable filaments, try using them in your prototyping projects. nine0014

Summary

-

Plus: Ecological safety

-

disadvantages: meager mechanical properties, limited choice and, as a rule, increased cost on the market

22 - decorative types of PLA - marmal, marmot sparkling, silk and colored glass

It would seem that all the advantages of the ease of use and variety of types of PLA filament have already been described earlier in this article in the first section. Does it make sense to allocate decorative grades of PLA to a special additional section? Yes, it does, and more than that. All the variety of colors and additives that increase strength and elasticity will not convey the advantages of specialized decorative grades of PLA. These wonderful filaments allow you to create great visual effects in the professional field for creating special ways of decorating interiors and furniture or imitating handicrafts at no significant cost. They can also be useful for personal use, such as printing colorful children's toys. Many decorative varieties of various materials already exist and will still be created. As an example, we will consider marble, Marble, sparkling, Twinkling, and colored glass, Transparent Glass, which are already widely represented on the market thanks to enthusiastic manufacturers from the Celestial Empire. nine0014

All the variety of colors and additives that increase strength and elasticity will not convey the advantages of specialized decorative grades of PLA. These wonderful filaments allow you to create great visual effects in the professional field for creating special ways of decorating interiors and furniture or imitating handicrafts at no significant cost. They can also be useful for personal use, such as printing colorful children's toys. Many decorative varieties of various materials already exist and will still be created. As an example, we will consider marble, Marble, sparkling, Twinkling, and colored glass, Transparent Glass, which are already widely represented on the market thanks to enthusiastic manufacturers from the Celestial Empire. nine0014

USER NOTES

eMarble Marble Filament

Based on PLA with the addition of colored particles that visually imitate a stone surface. Of course, about any properties of stone strength or density, heat capacity, etc. there is no question - the imitation is only visual. However, with proper use, this material will reveal its full potential and allow you to imitate from sculptures to elements of marble decoration of furniture and / or interiors. Remarkable Feature Marble is low shrinkage due to the base used. This will help you immediately get into the dimensions laid down when modeling "stone" prototypes and easily mount the printed decorative element into the main product or interior.

there is no question - the imitation is only visual. However, with proper use, this material will reveal its full potential and allow you to imitate from sculptures to elements of marble decoration of furniture and / or interiors. Remarkable Feature Marble is low shrinkage due to the base used. This will help you immediately get into the dimensions laid down when modeling "stone" prototypes and easily mount the printed decorative element into the main product or interior.

Shimmer eTwinkling

Able to delight both a child and a professional graphic designer. Multi-colored bright colors and splashes of sparkles create the illusion of complex painting with tinsel on the printed product. The biggest misconception is to classify this material as "only for children's toys." This filament is indispensable for creating prototypes, bright indoor signs (but not for outdoor use!), advertising structures, Christmas decorations and anything that is designed to attract attention with a strong visual effect, especially in the case of backlighting (most materials are translucent). nine0014

nine0014

Silk thread (eSilk)

Features a high-gloss bright surface, visually reminiscent of silk fabric. Of course, this plastic does not have any properties of real silk, only a visual effect. However, its use in prototyping furniture finishing elements, decor items, Christmas toys and other decorative accessories can give a significant gain both in the cost and speed of manufacturing a prototype, and in the ability to reproduce a product of a very complex shape. Try silk upholstering a model of the Eiffel Tower or a wicker chair? A 3D printer using eSilk can do this in exactly the same time as printing these prototypes with regular PLA filament. Agree - this is a unique opportunity that, if used skillfully, can become a strong competitive advantage. nine0014

Colored glass (Transparent Glass)

The filament, unlike the basic grades of PLA, is transparent in mass - as if made from tinted glass due to the high degree of purification of raw materials and additional chemical processing.

The product printed with it can be visually confused with the PETG product, but transparent PLA is easier to print and is much cheaper on the market. Orange, yellow, red, blue and green colors, which are often used in household appliances and radio engineering, are chosen as the main tints, which immediately outlines the scope of application - backlight indicators, translucent tinted buttons, prototypes of backlight elements, automotive parts, and, of course, lighting elements. advertising structures. nine0014

WHEN SHOULD PLA DECORATIVE FILAMENT BE USED?

Decorative PLA is indispensable for the tasks of quickly and accurately creating design elements for decorative elements, advertising structures and backlit product prototypes. Very much in demand for the development of children's creativity.

SUMMARY

-

Pros: ease of printing and post-processing, low cost, visual impact

-

Cons: increased abrasiveness of filaments with additives due to the effect of the filler on the nozzle.

PLA-based materials are not suitable for outdoor use due to the biodegradable base

PLA-based materials are not suitable for outdoor use due to the biodegradable base

23 - Fluorescent Glow in the Dark

Luminescent Glow in the Dark 3D Printer Filament - very impressive! Leave your imprint in the light for a while, then flip the switch and there's that ominous green light. nine0014

Of course, it doesn't have to be green. There are also other colors of the luminescent thread: blue, red, pink, yellow or orange. But green is perhaps the most popular and echoes the classic night glow style.

NOTE TO THE USER

So how does it work? It all comes down to phosphorescent materials mixed with a PLA or ABS base. Thanks to these added materials, the 3D printer filament is able to absorb in the light and then emit photons in the dark, which resemble tiny particles of light. This is why your prints will only glow when exposed to light - they must store energy before they can release it. nine0014

For best results, we recommend printing with thick walls and little infill. The thicker your walls, the stronger the glow!

The thicker your walls, the stronger the glow!

WHEN SHOULD I USE LUMINESCENT FILAMENT?

Mostly PLA or ABS based luminescent materials are used in decorative applications such as Halloween installations, lanterns, window decorations. You can print wearable items (jewelry), toys, and figurines.

SUMMARY

-

Pros: visually bright (we mean, it glows in the dark!) 5 mm)

24 — Color changing

Remember those 80s T-shirts that changed color depending on body temperature? Or what about chameleon rings? Well, it's the same idea here, because color-changing 3D printer filaments also change color based on changes in temperature or UV light. nine0014

USER NOTE

Threads in this category have a gradient between two colors, such as purple to pink, blue to green, or yellow to green.

As with other exotic 3D printer filaments, the color changing filament is based on PLA or ABS.

WHEN SHOULD COLOR-CHANGING FILATION BE USED?

This type of 3D printer filament has no special physical, tactile or functional characteristics and is intended solely for aesthetic purposes. Use it whenever you normally use PLA or ABS but need an extra visual boost. Good potential projects include phone cases, children's toys, and containers. nine0014

Summary

-

pluses : aesthetically pleasant, can be used to detect heat and other environmental elements

-

Minutes : limited mechanical properties

9000

Share article:

Best 3D Printer Filaments (Review 2021)

Once you've chosen your 3D printer, you need to select the type of filament you'll need for your project. Filament is a raw material used in 3D printers that will be heated to a high temperature to turn it into a semi-solid state. At this point, the printer can easily create the appropriate design layers and print the entire 3D CAD model onto the plate. nine0014

nine0014

However, when researching different 3D printer filaments, you will hear about numerous materials that can only make it harder to choose the right one for you. This is especially true for people who are just starting to explore the world of the 3D printing process.

Although most of us are not new to PLA and ABS, there are other fiber materials you should be aware of such as HIPS, PET, PETG, TPE, TPU, TPC and a few others. And to get a better idea of them, here are some of the more typical types of 3D printer filaments available on the market. nine0014

3D Printer Filament Types

PLA Filament

Polylactic acid (PLA) reigns supreme in the industrial 3D printing world. 3D printing with PLA is so easy. It has a lower plate temperature, so it doesn't need a heating bed and therefore has fewer warping issues.

It is widely used in prototyping, such as printing low-wear toys, prototype parts and containers. Please note that it cannot be used for anything that has a temperature rating of 60°C or higher as it warps at 60°C. For all other purposes, PLA is suitable for a general 3D printer. nine0014

Please note that it cannot be used for anything that has a temperature rating of 60°C or higher as it warps at 60°C. For all other purposes, PLA is suitable for a general 3D printer. nine0014

ABS Filament

ABS (also known as Acrylonitrile Butadiene Styrene) is the second most popular 3D printing filament. In general, ABS withstands high loads and high temperatures. Thus, it is suitable for most applications. It is great for items that are frequently handled, dropped or heated. For example, mobile phone cases, high-wear items, automotive trim parts, and electronic houses.

Nylon thread

Nylon is the preferred family of synthetic polymers for many industries, professional 3D printing being one of them. As for other forms of filament, they have better performance, efficiency, versatility and durability. Given the strength and versatility of nylon, this type of 3D printer filament can be used to make loops, buckles or gears, as well as working prototypes.

PET (G) thread

The most widely used plastic in the world is polyethylene terephthalate (PET). It is best known as water bottle thread, but it is also used in clothing fibers as well as food containers. Although PET is commonly used in 3D printing, its modified version PETG is becoming more common. nine0014

The G in PET stands for glycol, resulting in a more transparent filament that is less prone to cracking and easier to use. PETG is versatile but surpasses many forms of 3D printer filament in its strength and inability to reach high temperatures or withstand strong impacts. The fulfillment of the following conditions makes it an excellent choice for 3D printing filament for practical parts such as mechanical parts, printer parts, and protective materials. nine0014

TPE, TPU, TPC filament

Thermoplastic polyurethane (TPE) is a flexible and durable plastic similar to rubber. In addition, TPE is mainly used for the production of auto parts and household appliances.

TPU (Thermoplastic Polyester E) is a special form of TPE that is very common among high end 3D printers. Compared to conventional TPE, TPU is significantly more flexible, hence allowing more control during printing.

What's more, TPC (Thermoplastic Copolyester) is also another form of TPE that is not as widely used as TPU. The key advantage of TPC over TPE is its greater resistance to chemical and UV attack, as well as heat (up to 150°C). nine0014

If you need to create items that require a lot of wear, use TPE or TPU because these filaments use 3D printed filaments that are vulnerable to deformation. Products such as toys, mobile phone cases, or wearable items such as wristbands can be some examples of its application. On the other hand, TPC performs well for comparable applications, but outperforms it in harsher environments, including outdoors. nine0014

Wood filament

Technically not wood because it contains wood fiber in enhanced PLA. Generally speaking, wood products are valued for their natural beauty rather than their practical utility. When printing items for tables, tables or shelves, it is recommended to use wood 3D printing media. Any of the application examples include chalices, figurines, and trophies. What's more, it's a truly innovative application for 3D printers, which are often used to model real buildings, structures, or trees. nine0014

Generally speaking, wood products are valued for their natural beauty rather than their practical utility. When printing items for tables, tables or shelves, it is recommended to use wood 3D printing media. Any of the application examples include chalices, figurines, and trophies. What's more, it's a truly innovative application for 3D printers, which are often used to model real buildings, structures, or trees. nine0014

Metal thread

Like wood thread, it is not 100% metal. Specifically, it is composed of metal powder, and one of the following materials is PLA or ABS. However, the effects also have a metal-like aesthetic appeal. Metal Infused can be printed for both decorative and practical purposes. Figures, prototypes, toys, including tokens, can be 3D printed from metal and give them a great look. You can also use metallic 3D printer filament to make parts such as tools or finishing components in light applications. nine0014

Biodegradable (biophila) filament

This biodegradable 3D printer filament aims to reduce the impact of all plastic waste into the atmosphere. Although biodegradable 3D filament was originally environmentally friendly, it can still produce quality printed products. Choose this biophile if you don't have special requirements for strength, versatility or endurance. For projects that require prototyping, you can also benefit from these flawless fiber prints that can be biodegraded responsibly. nine0014

Although biodegradable 3D filament was originally environmentally friendly, it can still produce quality printed products. Choose this biophile if you don't have special requirements for strength, versatility or endurance. For projects that require prototyping, you can also benefit from these flawless fiber prints that can be biodegraded responsibly. nine0014

Conductive thread

This is a kind of three-dimensional material with conductive carbon particles in it. It is ideal for Arduino-based open source businesses. You'll want to look into this filament if you want to make circuits, LEDs, sensors, and other low voltage projects.

Magnetic filament

Magnetic PLA iron filament is as magnetic as the name suggests. This one-of-a-kind filament is made from PLA material impregnated with powdered iron. It is ideal for making fridge magnets and other custom-made decorative items. Also, it can be used to create multiple DIY structures, sensors, educational resources, etc.