Dinosaur 3d print file

🦖 Best STL files of dinosaurs to make with a 3D printer・Cults

🦖 Best STL files of dinosaurs to make with a 3D printer

Download free Dinosaurs 3D files

Makers and 3D printer owners around the world are often also science fans and any good science fan necessarily loves dinosaurs. To revive these mysterious animals that have disappeared from the face of the Earth, simply download these beautiful 3D models and 3D print them!

Dean the Dino

Free

T-Rex Skeleton

Free

Ceratosaurus dinosaurus

Free

T-Rex Skeleton - Leo Burton Mount

Free

Alioramus dinosaurus

Free

Ceratosaurus

Free

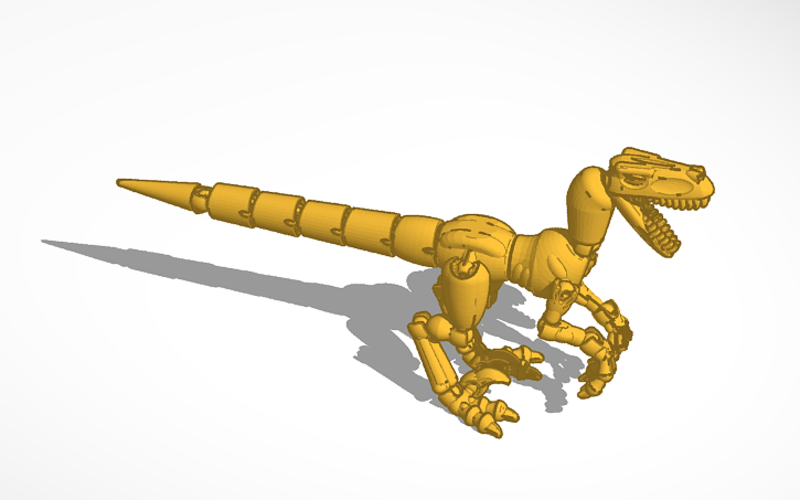

Flexi Raptor (Dual Extrusion)

Free

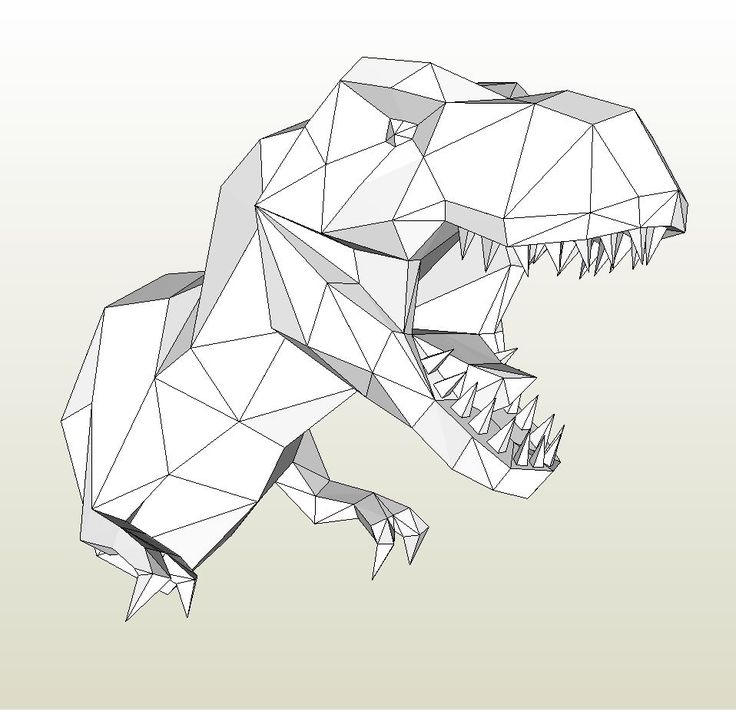

Low Poly T-rex

Free

Baby T-rex Flexy Keychain

Free

Full size Velociraptor skeleton Part05/05

€4

Velociraptor (Easy print no support)

€0. 50

Stegosaurus Skeleton

Free

Dino Flintstone

Free

Stegosaurus (Easy print no support)

€0.50

Allosaurus (Easy print no support)

€1.50

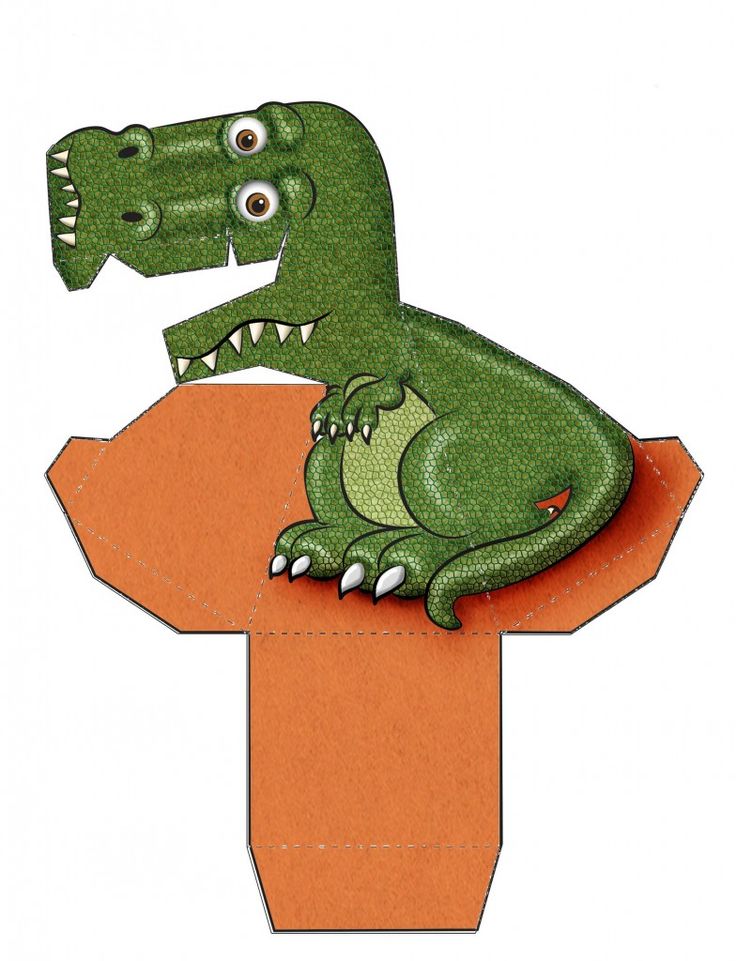

Dinosaur gluttonous pencil holder

€1.58

Reptar [Rugrats]

Free

dinosaur t-rex

Free

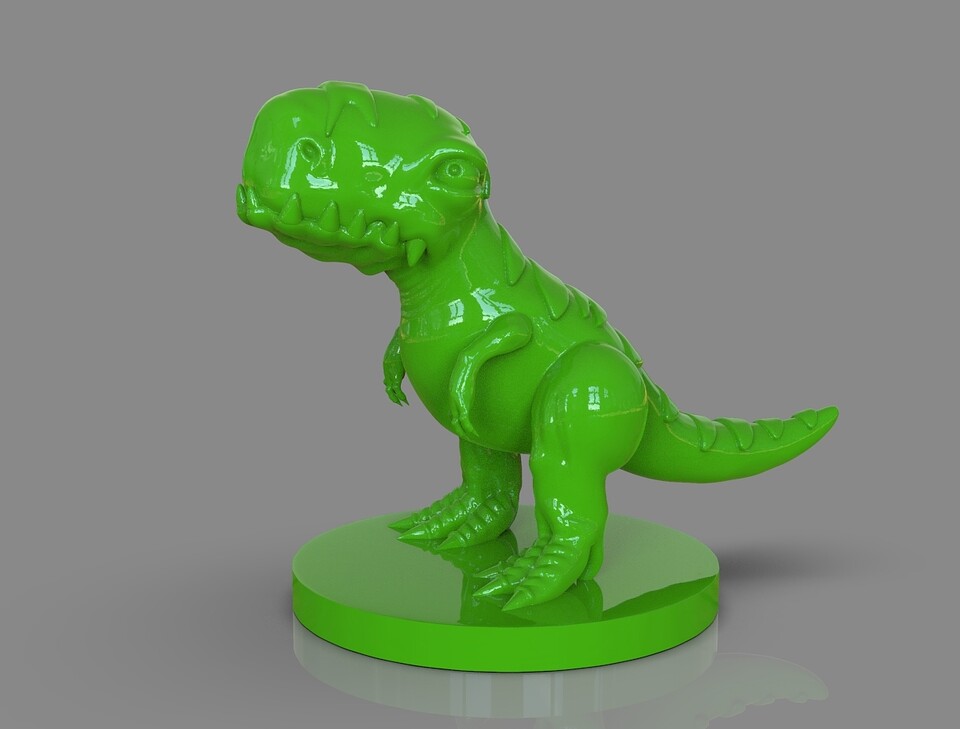

Cute Dinosaur Rex Flexi

€1.77

T-rex

Free

Allosaurus 3D Puzzle Construction Kit

€0.50

Dinosaur Skull

Free

Flying Dinosaur Skull

Free

dinosaur dino cookie cutter

Free

Flexi Rex with Scales

Free

T-Rex Footprint Cookie Cutter

Free

Triceratops

Free

Friendly Dinosaur Skull

Free

T-Rex Dinosaur

Free

Grumpy T Rex

Free

T-Rex

Free

Rex from the makers of Dr Fluff

Free

Tristan-Otto

Free

Arti-Brachi

€3. 68

68

3Dino Puzzle Museum DX Set

Free

Spinosaurus (Easy print no support)

€1.50

Stegosaurus Dinosaur

Free

Clap T Rex

Free

High resolution tyrannosaurus

Free

Multi-Color Dinosaur Toothbrush Holder

Free

ankylosaurus

Free

Triceratops Dinosaur

Free

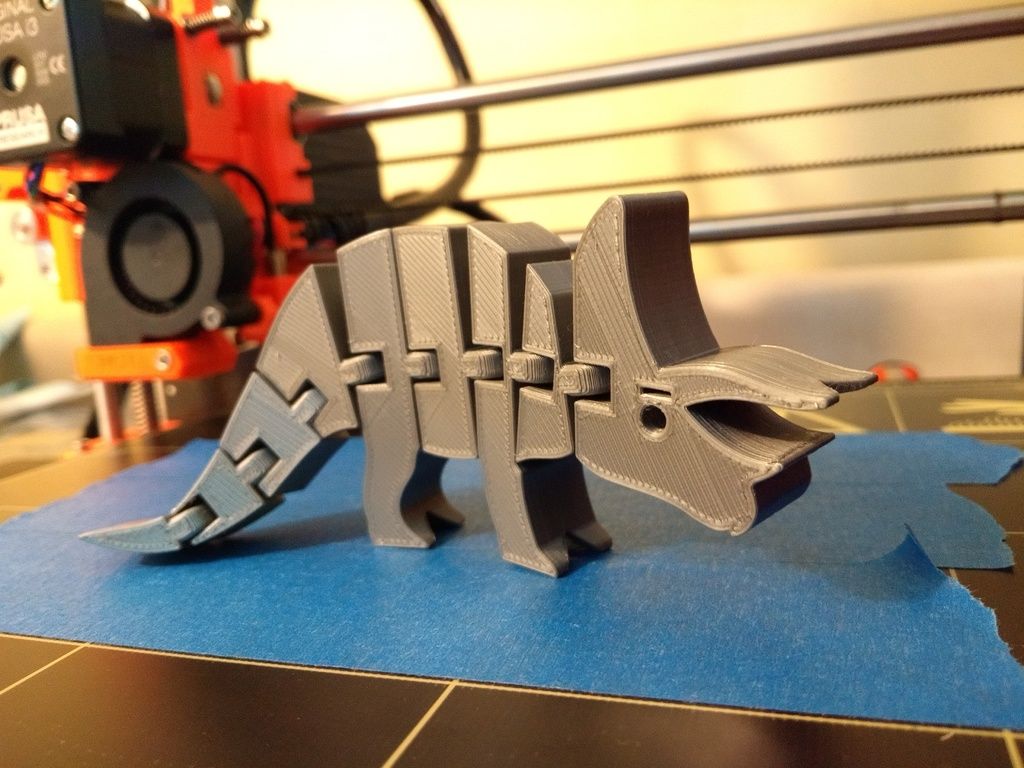

Triceratops 3D Puzzle Construction Kit

€0.50

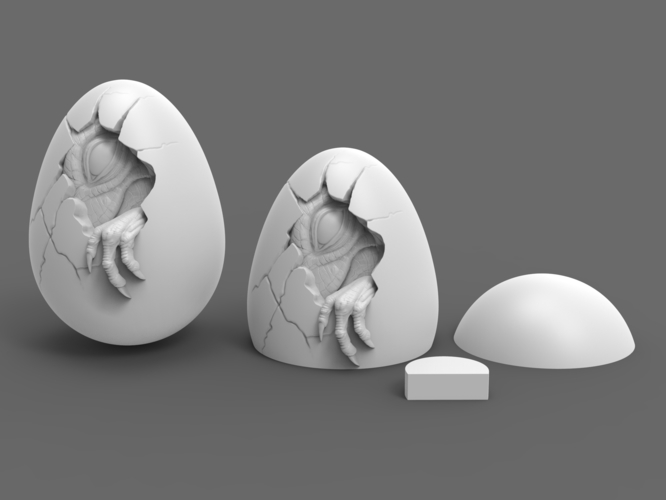

BabyDino

Free

Mr.&Mrs. Flexi Rex

Free

Stegosaurus 3D Puzzle Construction Kit

€0. 50

50

T-Rex Hanger

Free

velociraptor

Free

Low Poly T-rex

Dinosaur gluttonous pencil holder

PLACA DINOSAURIO 3D

Alioramus dinosaurus

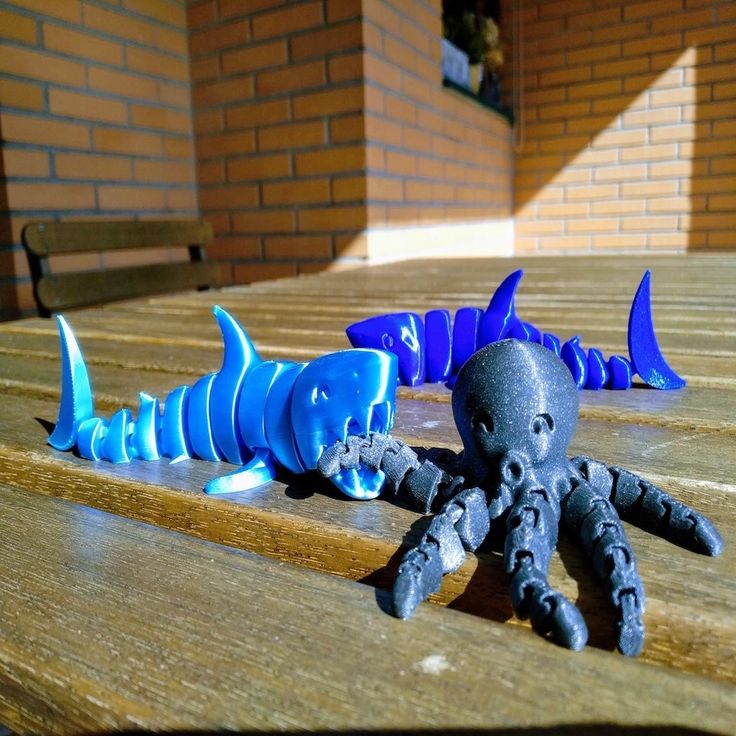

Here is our selection of the best dinosaur STL files, all these magnificent creatures come from the 3D file library Cults and are perfectly 3D printable.

This collection includes many free and paid 3D files that will allow you to 3D print at home many variations of these extinct animals. Each Cults 3D Designer has its own vision of the dinosaur. So you will find both very realistic versions of animals reproduced identically or freer versions expressing the artist's creativity.

A dinosaur STL file is composed of many items that will necessarily challenge your 3D printer. For some creations representing dinosaur skeletons, it will also be a challenge for you because you will have to manage the 3D printing perfectly, but also do the puzzle work to recreate the skeleton. Whether you are a fan of Velociraptor, Diplodocus, Triceratops, Pterodactylus or even the great Tyrannosaurus, you will necessarily find something to satisfy your passion with this collection.

Free STL file T-Rex Skeleton・Design to download and 3D print・Cults

Human Skull

Free

Ram Skull

Free

Saber-Toothed Cat Skull

Free

Dragon Skull

Free

Stegosaurus Skeleton

Free

The Capitol - Legislative

Free

Jet Engine

Free

The Endeavor

Free

Best 3D printer files of the Game category

Aspide 2000 rocket

Free

Playmobil System X hospital elevator ramp

Free

SmallToys - Tow truck

€0. 83

83

Cigarette Magic Box

€1.90

Among Us Cheese/ support free!

€1.32

Mareep Pokemon

Free

Deactivated

Bust T-Rex Articulated (Easy print and Easy Assembly)

€3

Best sellers of the category Game

Snake and Rattlesnake

€3.68

Nintendo Switch Crystal Dock - Classic and OLED version

€3.10

Voidwalker Exosuits Truescale

€14.85

Eagle Armor Space Troopers - Truescale

€6

Train-Snake compatible with IKEA/BRIO easy to assemble

€2. 10

10

Enourmous Imperial Heavy Tank

€10

Army Jeep

€2

Nekhron melee pack

€7

3RD GENERATION POWER ARMOR BODIES, TORSOS, LEGS

€8.50

Strange rocket launcher upgrade pack

€3

Nintendo Switch Japanese Cloud Dock - Classic and OLED version

€3.10

Derelict damaged space ship compatible Murder team or small corridor games

€13.77

Nice Flexi Dragon

€1.77

Marine montando Marine

€1

Chopper Motorcycle Print-In-Place

€1

Batman Crossbow Gun / Print in Place

€2. 50

50

Would you like to support Cults?

You like Cults and you want to help us continue the adventure independently? Please note that we are a small team of 3 people, therefore it is very simple to support us to maintain the activity and create future developments. Here are 4 solutions accessible to all:

ADVERTISING: Disable your AdBlock banner blocker and click on our banner ads.

AFFILIATION: Make your purchases online by clicking on our affiliate links here Amazon.

DONATE: If you want, you can make a donation via PayPal.

WORD OF MOUTH: Invite your friends to come, discover the platform and the magnificent 3D files shared by the community!

🦖 Best Dinosaur STL Files to 3D Printer・Cults

🦖 Best Dinosaur STL Files to 3D Printer

Free Download Dinosaur

3D Files 3D printer creators and owners around the world are often also science fans, and any good science fan is bound to love dinosaurs. To bring these mysterious vanished animals to life, simply download these beautiful 3D models and 3D print them! nine0007

To bring these mysterious vanished animals to life, simply download these beautiful 3D models and 3D print them! nine0007

Dean Dino

Free

T-Rex Skeleton

Free

Ceratosaurus dinosaur

Free

T-Rex Skeleton - Leo Burton Mount

Free

Alioramus dinosaurus

Free

nine0008 CeratosaurusFree

Flexi Raptor (Dual Extrusion)

Free

Low Poly T-rex

Free

Baby T-rex Flexy Keychain

Free

Full size Velociraptor skeleton Part05/05

4 €

nine0008 Velociraptor (light seal without support) 0. 50 €

50 €

Stegosaurus Skeleton

Free

Dino Flintstone

Free

Stegosaurus (easy printing without support)

0,50 €

Allosaurus (light seal without support)

1,50 €

nine0008 Pencil with dinosaur gluttony1.58 €

Reptar [Rugrats]

Free

dinosaur t-rex

Free

Cute dinosaur Rex Flexi

1,77 €

T-rex

Free

nine0008 Allosaurus 3D Puzzle Construction Kit0,50 €

Dinosaur Skull

Free

Flying Dinosaur Skull

Free

dinosaur dino cookie cutter

Free

Flexi Rex with Scales

Free

nine0008 T-Rex Footprint Cookie CutterFree

Triceratops

Free

Friendly Dinosaur Skull

Free

T-Rex Dinosaur

Free

Grumpy T Rex

Free

T-Rex

Free

Rex from the makers of Dr Fluff

Free

Tristan-Otto

Free

Arti-Brachi

3. 68 €

68 €

3Dino Puzzle Museum DX Set

Free

Spinosaurus (light seal without support)

€1.50

Stegosaurus Dinosaur

Free

Clap T Rex

Free

High resolution tyrannosaurus

Free

Multi-Color Dinosaur Toothbrush Holder

Free

ankylosaurus

Free

Triceratops Dinosaur

Free

Triceratops 3D Puzzle Construction Kit

0,50 €

BabyDino

Free

Mr.

&Mrs. Flexi Rex

&Mrs. Flexi Rex Free

Stegosaurus 3D Puzzle Construction Kit

€0.50

T-Rex Hanger

Free

velociraptor

Free

Low Poly T-rex

Dinosaur Gluttony Pencil

PLACA DINOSAURIO 3D

Alioramus dinosaurus

Here is our selection of best dinosaur stl files, all of these gorgeous creatures are taken from Cults 3d file library and are perfectly 3d printable .

This collection includes many free and commercial 3D files that allow you to 3D print at home with many variations of these extinct animals. Each 3D designer of Cults has their own vision of a dinosaur. Therefore, you will find both very realistic versions of the animals, reproduced identically, and freer versions expressing the artist's creativity. nine0007

Therefore, you will find both very realistic versions of the animals, reproduced identically, and freer versions expressing the artist's creativity. nine0007

STL file dinosaur consists of many elements that are sure to cause problems for your 3D printer . For some creations representing dinosaur skeletons, this will also be a challenge for you, because you will not only have to perfectly control the 3D printing, but also do the puzzle work of recreating the skeleton. Whether you're a fan of Velociraptor, Diplodocus, Triceratops, Pterodactyl or even the great Tyrannosaurus Rex , you're sure to find something to satisfy your passion in this collection. nine0007

3D printed anatomical models for preoperative planning and enhanced patient consent

Introduction

3D printed models are becoming increasingly useful tools in the modern practice of personalized, precision medicine. As case histories become more complex and treatments become truly unique, visual and tactile anatomical models can improve understanding and communication in the process of creating a solution for a particular patient. nine0007

nine0007

Health care professionals, institutions and organizations around the world use 3D printed anatomical models as reference tools for preoperative planning, intraoperative imaging and calibration or pre-positioning of medical equipment for routine and high complexity procedures, which has been documented in hundreds of publications1. Physicians often save time preparing and performing surgeries, resulting in significant reductions in operating costs while reducing patient risk, anxiety, and recovery time. nine0007

This guide provides practical step-by-step guidance for physicians and technologists to move from patient scans to 3D printed models by learning how to set up a CT/MRI scan, segment datasets, and convert files to 3D printable format.

“The unique advantage of image-based 3D printing is the ability to demonstrate anatomical spatial relationships with sub-millimeter accuracy.”

Jeffrey D. Hirsch, MD

Associate Professor, Director of Community Radiology, Department of Diagnostic Radiology University of Maryland Medicine

Formlabs-printed anatomical models are already used by several subspecialists in surgery, including but not limited to orthopedic, cardiothoracic, vascular surgery, oral and maxillofacial surgery, oncology, plastic and reconstructive surgery, urology and pediatrics. This handbook provides an overview of the steps that can be applied to any Digital Imaging and Communications in Medicine (DICOM) dataset, which is the standard format for storing images in any modern Image Archiving and Communication Systems (PACS)

This handbook provides an overview of the steps that can be applied to any Digital Imaging and Communications in Medicine (DICOM) dataset, which is the standard format for storing images in any modern Image Archiving and Communication Systems (PACS)

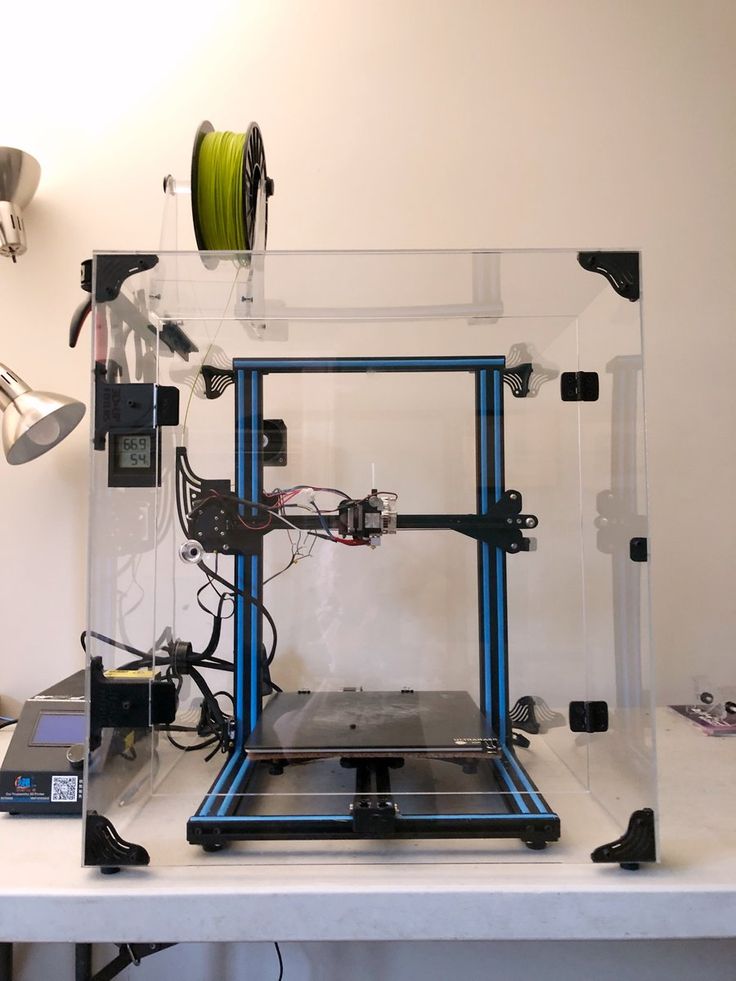

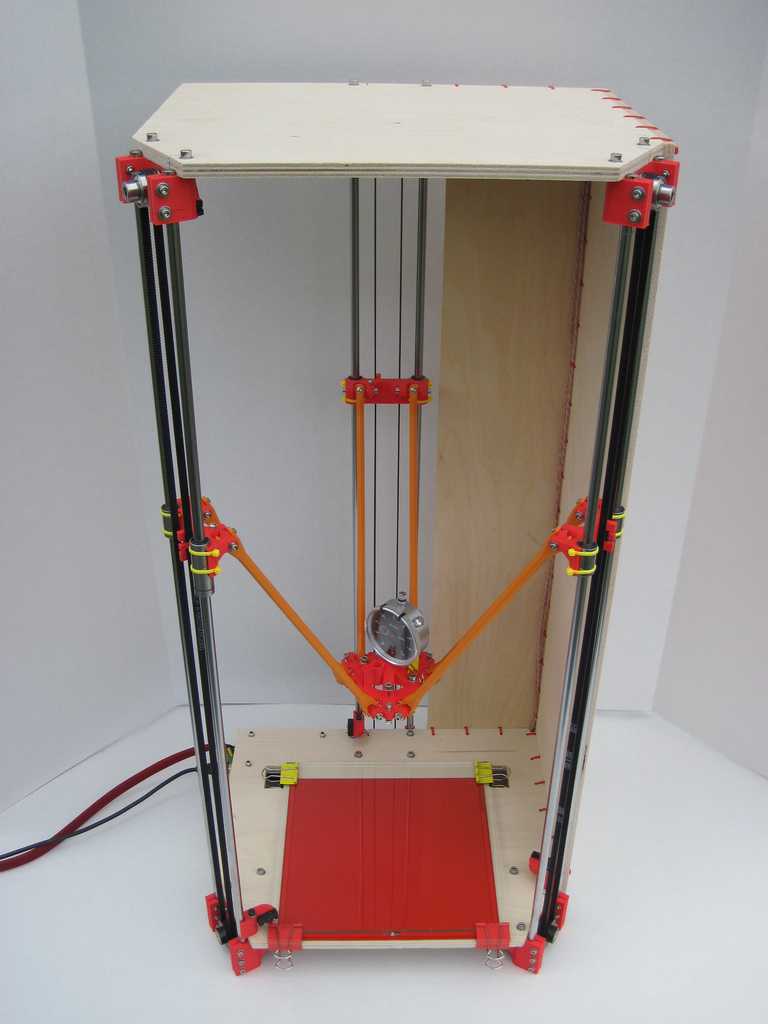

WHAT YOU NEED FOR IN-HOUSE 3D PRINTING

CT or MRI scan and associated DICOM file

- Recommended slice thickness: 0.25mm-1.25mm2

Computer with imaging software for segmentation or using an outsourced segmentation service

Form 2 3D printer and resin, e.g.:

- Orthopedic white resin or OMFS

- Transparent polymer for cardiovascular or urological surgery

- SG Dental Resin for Surgical Guides (for approved applications only)

Form Wash and Form Cure for 3D post-processing (recommended for medical models)

Applications and benefits of 3D printed anatomical models

medicine. Please consider your intended use, local regulations, medical imaging approvals, material specifications, biocompatibility requirements, protected medical information, and institutional standards before 3D printing or using anatomical modelsDepending on your institution, anatomical models may be used for patient or pathological purposes:

- Preoperative planning and intraoperative reference models for surgeons

- Device calibration (e.

g. mandibular plates) and surgical instrument design*

g. mandibular plates) and surgical instrument design* - Molds for implant material or prostheses*

- Teaching and simulation laboratories

- Patient Education and Enhanced Informed Consent

* May be regulated and/or require institutional approval

Numerous published case studies and ongoing efforts have demonstrated the potential of 3D printing in clinical settings. Public use cases include preoperative planning3, intraoperative use4, patient-centric instrument kits5, customized implants6, bone cement molds or polymethyl methacrylate (PMMA) implants8, prostheses9and trays

These use cases have demonstrated success in a variety of fields and surgical specialties, including orthopedic, cardiac, oral and maxillofacial (OMFS), vascular, neurological, cardiothoracic, musculoskeletal, plastic and reconstructive surgery, oncology, pediatrics, interventional radiology, etc.

“While I would like to think that my brain can reconstruct a 3D interpretation from a 2D CT scan, I was surprised by the relative inaccuracy of the approach I have been using for 20 years. 3D models are invaluable in planning, especially when using the daVinci robot.” nine0253

3D models are invaluable in planning, especially when using the daVinci robot.” nine0253

Dr. Ronald Hrebinko

Urologist and Associate Professor of Urology

University of Pittsburgh Department of Medicine

3D printed models can also provide significant benefits for the education of residents, fellows and students10. Individual models are particularly attractive when compared to the cost of cadaveric specimens and animal testing and the associated requirements for laboratory space, surgical instruments, and disposal

5 leading medical disciplines on the use of 3D printing technology

Chepelev et al.

Image sourced from http://www.materialise.com/en/blog/3d-printing-us-hospitals

how Formlabs printers and supplies are being used in healthcare. nine0253

The widespread use of advanced imaging in radiology has become a key factor in diagnosis and communication between physicians. While these visualizations have traditionally been used in the 2D plane as CT or MRI scans as DICOM files, software developers have recently created tools to reconstruct diagnostic images as 3D anatomical imaging.

While these visualizations have traditionally been used in the 2D plane as CT or MRI scans as DICOM files, software developers have recently created tools to reconstruct diagnostic images as 3D anatomical imaging.

3D printed models are a natural extension of these various 3D rendering options and offer many additional benefits such as tactile feedback and other tangible information that visualizations cannot provide. nine0007

When a patient's severe foot deformity could not be fully represented with 2D images, surgeons used a 3D printed model to plan how to correct gait with preoperative equipment and work with clinical staff and receptionists.

For example, research on a custom 3D printed model allowed a UK orthopedic surgeon to find a solution with a lower risk of abnormal injury to a boy's forearm

“Access to the model has changed standard CT-indicated therapy from a four-hour complex osteotomy to a simple, much less invasive 30-minute soft tissue procedure,” says Dr. Michael Eames

Michael Eames

A successful operation was completed in just 30 minutes — reduction of more than three hours from the originally scheduled time in the operating room, saving the hospital an estimated $5,500. Subsequently, the patient spent less time on post-operative care and recovered more quickly

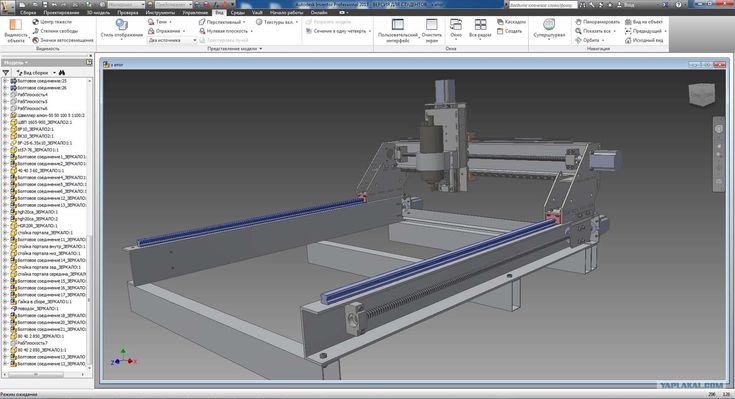

Workflows from scan to 3D model

Creating 3D printed files and 3D printed models requires special considerations and minor changes to the medical imaging workflow

The tailored workflow can be divided into three steps: image acquisition, image segmentation and 3D printing

IMAGE ACQUISITION

Image acquisition is the first step and is already integrated into the workflow. The most common imaging techniques suitable for 3D printing are CT and MRI. In general, 3D models can be printed from any volumetric image dataset (slices) with sufficient contrast to differentiate tissues. nine0007

Cone-beam CT is also widely used for dental and otolaryngological imaging of teeth, but contrast may be worse than conventional CT, making segmentation more difficult. See recommendations for setting up patient scans for 3D models in the second part of this booklet

See recommendations for setting up patient scans for 3D models in the second part of this booklet

IMAGE SEGMENTATION

The main goal of this step is to reduce the complexity of the original image while leaving the necessary characteristics unchanged and isolated. Once the radiographer has received the DICOM, they must perform Regions of Interest (ROI) processing, which will be rendered as a 3D printed object. The process of identifying and separating tissues and other areas of interest is called segmentation. Depending on the complexity of the model, it is performed by a radiologist-technician under the guidance of a radiologist or directly by a radiologist. Once the segmentation is completed, it is reviewed by the surgeon for final approval13

A number of commercial and open source software products can be used for the segmentation process (see the list at the end of this section). Before choosing a software solution, consider your intended use, regulatory requirements in your area, and recommendations at your institution.

ROI segmentation steps can include automatic methods (eg thresholding, edge detection and region enlargement) or manual selection and adjustments. Thresholding uses parameters that can be identified and associated with a particular ROI, such as bones with higher Hounsfield values relative to their surroundings. nine0007

Thresholds may need to be dynamic and include more sophisticated algorithms to account for factors such as CT noise and beam hardening that can create artifacts and other unwanted results.

Another option is to use the growth region to automate segmentation, where the algorithm assigns voxels as belonging to one part or another based on similarity or difference to surrounding voxels. This may require additional adjustments and clarifications. nine0007

After segmentation is complete, convert the segmented objects to a file type that can be used by the 3D printer. This file type is usually an STL or OBJ file format.

After conversion, make any necessary physical adjustments that are more common in 3D modeling, such as smoothing surfaces, filling holes, and fixing other minor features. These adjustments can be made by a specialist in various CAD or CAM programs and should always include review by a physician to ensure that the result is clinically useful. nine0007

These adjustments can be made by a specialist in various CAD or CAM programs and should always include review by a physician to ensure that the result is clinically useful. nine0007

Once the radiographer has received DICOM, they must determine the regions of interest (ROI) that will be displayed as a 3D printed object. Source: ITK-Snap

In-house 3D printing enables healthcare providers to rapidly create high resolution medical models.

3D PRINT

Once the final file is ready, it can be exported and sent to a 3D printer for production. There are several key factors to consider when choosing the right 3D printing technology, including: the cost of the printer, software, and materials; print speed, accuracy and resolution; ease of use and access to customer service; the type of printed materials, including biocompatibility and sterilization for certain uses. nine0007

After printing, parts should be rinsed with isopropyl alcohol (IPA) to remove excess resin and, depending on the material and application, post-cured in a curing chamber. All biocompatible resins require post-cure prior to use, while standard Formlabs resins such as White and Clear Resin increase post-cure strength and stability.

All biocompatible resins require post-cure prior to use, while standard Formlabs resins such as White and Clear Resin increase post-cure strength and stability.

Learn more about print options

Visit our Software Support and Resources pages for more information on how to set up print files and learn more about specifications such as internal supports and minimum wall thickness

POTENTIAL FIELD 3D PRINTING SOFTWARE AND HARDWARE

Note: Each section requires only one kind of software that completes the workflow steps. This list is for ease of reference and research and does not constitute an endorsement of any particular software or vendor. If you require anatomical models without segmentation or printing in situ, specialized service providers offer conversion, segmentation and/or printing services for a fee (e.g. Anatomage, Armor Bionics, Axial3D and Materialize)

Check your local regulations and intended use before choosing a software solution.

Transform + Segmentation

| Materialise Mimics* | ITK-SNAP |

| 3D Slicer | 4DICOM |

| Axial3D | Seg3D |

| Osirix | Embodi3D (DICOM - STL conversion, no segmentation) |

| Ossa 3D | Vitrea Vital Images |

| Anatomage Medical Design Studio |

Preparation for editing + File management, smoothing and identification

| Blender | Materialize 3matic | Autodesk Meshmixer |

Support Generation + Print Orientation

| Formlabs PreForm | nine0442 Materialize e-Stage Note: Cardiac cases may require advanced removal of supports from within the valves (PreForm video tutorial)

Printer

| Formlabs Form 2 or Form Cell system | Formlabs Fuse 1 |

Post-print

| Formlabs finishing kit | Form Wash and Form Cure | nine0446

Ultrasonic cleaner (e. g. GT Sonic) g. GT Sonic) | CUREBox CB-4051 |

* Formlabs and Materialize have partnered to offer a comprehensive package of services in the US, Europe and Japan. Mimics inPrint is a specialized software solution for creating accurate virtual anatomical models from medical images and preparing files for 3D printing. Integrated into Clinical Environments (PACS), Mimics inPrint includes predefined workflows with direct link to Formlabs 3D printers. nine0007

Patient Scan Setup for 3D Models

Some conventional medical imaging scans cannot be converted to high quality 3D models for clear and accurate anatomical structures. Plain radiographs (X-rays) and ultrasounds are not commonly used for 3D printing and these imaging techniques are not recommended.

The most commonly used imaging modalities for evaluating internal structures are computed tomography and MRI imaging. These rendering methods generate a DICOM file. DICOM is a standard for storing and transmitting medical images and can be thought of as a series of slices. nine0007

nine0007

DICOM images cannot be edited in 3D design software or sent directly to a printer. To convert a DICOM file to a format suitable for 3D printing, such as an STL or OBJ file, separate software is required to calculate the surface area of interest. This surface will become a 3D model.

Almost any DICOM file with sufficiently fine detail (eg thin slices) can be converted to a format that supports 3D printing of the structure of interest. nine0007

The following articles may be helpful in preparing, printing and post-processing anatomy models:

Design models for print support

Design features and geometry recommendations 9 cleaning internal canals

Post-curing printing

Post-processing basics

Criteria for creating a printable scan

The first consideration when converting a CT or MRI to a 3D model is what needs to be shown; bones, vessels, and whole organs are all modeled differently. A model with outdated structures not only detracts from the focus of the model, but it will also be harder to produce. Scanning at the right specifications makes it easy to create a 3D printable model. The main features are intravenous contrast and slice thickness.

A model with outdated structures not only detracts from the focus of the model, but it will also be harder to produce. Scanning at the right specifications makes it easy to create a 3D printable model. The main features are intravenous contrast and slice thickness.

For 3D models of bone structures, low contrast images are likely to be sufficient for accurate and detailed printing. Models containing solid organs, tumors, or vascular structures almost always require contrast magnification scans

Introductory contrast information

CT brightness variation allows the segmentation software to highlight different structures, allowing you to print an area or organ of interest. Some structures, such as bones, are inherently bright on CT scans. This makes it easier to 3D print when started from a non-contrast CT. However, intravenous

(IV) contrast is needed when you want to 3D print a blood vessel, tumor, or most organs. A contrast agent is injected into the patient just before the scan. With IV contrast, blood vessels (arteries and veins) and solid organs (such as the liver, kidneys, spleen, heart, and brain) become brighter when scanned, allowing the segmentation software to accurately separate them from surrounding tissues. See images below for a comparison of non-contrast and contrast-enhanced CT scans of the abdomen. nine0007

With IV contrast, blood vessels (arteries and veins) and solid organs (such as the liver, kidneys, spleen, heart, and brain) become brighter when scanned, allowing the segmentation software to accurately separate them from surrounding tissues. See images below for a comparison of non-contrast and contrast-enhanced CT scans of the abdomen. nine0007

The effect of intravenous contrast is shown with two axial (transverse) CT scans of the upper abdomen. On a right scan, the aorta is enhanced, whereas on a left scan, the aorta appears very similar to the adjacent soft tissue. The contrast allows you to isolate the desired structures in post-processing. Source: Embodi 3D

In addition to enhancing contrast, slice thickness and resolution are equally important for planning when creating a 3D model. Most clinically useful scans were obtained at adequate resolution for 3D printing. However, if you try to 3D print an anatomical model while scanning with thick sections, your

model will have a rough surface. According to numerous sources, when creating a model for 3D printing, it is very important to use scans with slices less than 1.25 mm.

According to numerous sources, when creating a model for 3D printing, it is very important to use scans with slices less than 1.25 mm.

Two CT scans of the chest. The image on the left shows a frontal view constructed from 5 mm thick slices, while the high resolution scan shows a similar view of the chest using only 1 mm thick slices. Thick slices in the left image create rough textures that will result in a lower quality print. Source: Embodi 3D

The thickness of sections obtained from CT or MRI scans are converted directly into details generated from 3D scans. Depending on the focus object, areas of the image should be reconstructed with isotropic voxels of 1.25 mm or less15. According to a Mayo Clinic presentation in March 2016, 1 to 5 mm slices can be used for large structures, while 0.75 mm can be used for thin bone16. Thicker regions may degrade model accuracy, while very thin regions (e.g. <0.25 mm) may require extensive segmentation and STL enhancement, especially in the presence of image artifact. Cardiac models show sufficient accuracy with 0.5 mm patches, but thinner targets may be required for thin objects such as the inferior wall of the orbit17. Generally, thicker areas can create fuzzy or less accurate prints. However, unnecessarily thin areas can lead to significantly more work in the post-processing step. nine0007

Cardiac models show sufficient accuracy with 0.5 mm patches, but thinner targets may be required for thin objects such as the inferior wall of the orbit17. Generally, thicker areas can create fuzzy or less accurate prints. However, unnecessarily thin areas can lead to significantly more work in the post-processing step. nine0007

Regulatory Issues

Please check local regulations, material data, patient information, and institutional requirements before 3D printing or using anatomical models. If you work in the US, please refer to the latest FDA presentation which outlines its guidance document18 Please note that these documents and recommendations are subject to change. Make sure you are using the latest guidelines. nine0007

Formlabs is the industry's leading manufacturer of 3D printers and materials used by healthcare providers to support the practice of medicine

Conclusion

Barriers to the transition to personalized precision medicine are fast disappearing. The advent of affordable, professional-grade 3D printers has enabled healthcare providers to produce anatomy models for specific patients and specialties with inspiring results. In some cases, the initial cost of a high quality printer has been covered by the time saved in the operating room after the surgeon used the 3D printed model to prepare for one complex procedure.19

The advent of affordable, professional-grade 3D printers has enabled healthcare providers to produce anatomy models for specific patients and specialties with inspiring results. In some cases, the initial cost of a high quality printer has been covered by the time saved in the operating room after the surgeon used the 3D printed model to prepare for one complex procedure.19

“Medicine is not a one-size-fits-all solution, and when a tool like desktop 3D printing comes along that allows you to create personalized medical solutions, there is no doubt that it needs to be used to its full potential.”

Todd Goldstein

Instructor, Institute for Medical Research. Feinstein Director, 3D Printing Lab, Northwell Ventures, Northwell Health

Understanding the workflow required to integrate 3D printing is key to success. nine0007

This tutorial covers everything you need to get started, popular workflows and tools and techniques to ease the transition from patient scanning to 3D printing

Contact us to learn more about 3D printing in Your institution and join the community of innovators in precision medicine

REFERENCES

- Chepelev, Leonid, Andreas Giannopoulos, Anzhi Tan, Dimitrios Mitsouras and Frank J.

Rybicki Medical 3D Printing: Terminology Standardization Techniques and Report Trends 3D- printing in medicine 3, no. 1 (2017) doi:101186/s41205-017-0012-5

Rybicki Medical 3D Printing: Terminology Standardization Techniques and Report Trends 3D- printing in medicine 3, no. 1 (2017) doi:101186/s41205-017-0012-5 - Mitsworth, Dimitris, Peter Lakouras, Amir Imanzade, Andreas A Giannopoulos, Tianrun Kai, Kanako K. Kumamaru, Elizabeth George, et al. "3D Medical Printing for the Radiologist" RadioGraphics 35, no. 7 (November 2015): 1965–88 https http://doi.org/101148/rg2015140320

- Kerr, William, Philip Rowe, and Steven Gareth Pierce "Accurate 3D Bone Reconstruction Using Ultrasonic Synthetic Aperture Techniques for Robotic Knee Arthroplasty" Computerized Medical Imaging and Graphics 58 (June 2017): 23–32 https://doi org/101016/j compmedimag 201703 002

- Chen, Xing, Jesse K Possel, Katherine Waconne, Ann F van Ham, P. Christian Klink, and Peter R. Roelfsema "3D printing and modeling of customized implants and surgical guides for lower primates" Journal of Neuroscience Methods 286 (July 2017 ): 38–55 https://doi org/101016/jjneumeth 201705 013

- Wong, K.

S., S.M. Kumta, N. V. Geel and J. Demol "One-stage reconstruction with a 3D printed, biomechanically assessed custom implant after complex resection of pelvic tumors" Computer Surgery 20, no. 1 (January 2, 2015): 14–23 https:// doi org/10 3109/1092908820151076039

S., S.M. Kumta, N. V. Geel and J. Demol "One-stage reconstruction with a 3D printed, biomechanically assessed custom implant after complex resection of pelvic tumors" Computer Surgery 20, no. 1 (January 2, 2015): 14–23 https:// doi org/10 3109/1092908820151076039 - Tan, Eddie T.W., Ji Ming Lin, and Shri Kumar Dinesh “Creating Acrylic Patient Cranioplasty Implants with an Inexpensive 3D Printer” Journal of Neurosurgery 124, no. 5 (May 2016): 1531–37 https://doi org/10 3171/2015 5 jns15119

- Tan, Eddie T.W., Ji Ming Lin, and Shri Kumar Dinesh “Creating Acrylic Patient Cranioplasty Implants with an Inexpensive 3D Printer” Journal of Neurosurgery 124, no. 5 (May 2016): 1531–37 https://doi org/10 3171/2015 5 jns15119

- Abdel Hey, Joe, Tarek Smyra, and Ronald Moussa "Customized Implants with Polymethyl Methacrylate Cranioplasty Using 3D Polylactic Acid Printing Plates: Technical Note with 2 Illustrative Examples" World Neurosurgery 105 (September 2017): 971–979 e1 https http://doi.

org/101016/j wneu 201705 00

org/101016/j wneu 201705 00 - Keith, Jelleten, Gerwyn Smith, and Paul Bredveld, 3D Printed Upper Limb Prosthesis: A Review of Disability and Rehabilitation: Rehabilitation Techniques 12, no. 3 (February 2, 2017): 300–314 https://doi org/ 101080/1748310720161253117

- Azer, Sami A., and Sarah Azer, “3D Anatomical Models and Impact on Learning: A Review of Quality in the Literature,” Health Professions Education 2, no. 2 (December 2016): 80–98 https://doi org/101016 /j hpe 2016 05 002

- Preoperative-planning-with-custom-3d-printed-surgical-model-reduces-theater-time by 88 percent Formlabs Accessed November 22, 2017 https://formlabs com/preoperative-planning-with-custom-3d-printed-surgical-model-reduces-theater-time/ nine0268 Christensen, Andy "Medical Imaging Software" 3D printing | Wohlers Associates Accessed November 22, 2017 http://www.wohlersassociates com/

- Matsumoto, Jane S., Jonathan M. Morris, Thomas Foley, Eric E. Williamson, Shuai Leng, Ciarán P McGay, Joel L.

Kuhlmann, Linda E. Nesberg, and Terry J. Vrtiska 3D Physical Modeling: Applications and Experiences in Mayo Clinic RadioGraphics 35, No. 7 (2015): 1989-2006 doi:101148/rg 2015140260

Kuhlmann, Linda E. Nesberg, and Terry J. Vrtiska 3D Physical Modeling: Applications and Experiences in Mayo Clinic RadioGraphics 35, No. 7 (2015): 1989-2006 doi:101148/rg 2015140260 - Kikinis R, Pieper SD, Vosburg K (2014) 3D Slicer: a platform for subject image analysis, visualization and clinical support. Intraoperative image processing. Imaging Therapy, Ferenc A. Jolez, Editor 3 (19): 277-289 ISBN : 978-1-4614-7656-6 (Print) 978-1-4614-7657-3 (Online) https://www slicerorg/wiki/ CitingSlicer

- Mitsworth, Dimitris, Peter Lakouras, Amir Imanzade, Andreas A Giannopoulos, Tianrun Kai, Kanako K. Kumamaru, Elizabeth George, et al. "3D Medical Printing for the Radiologist" RadioGraphics 35, no. 7 (November 2015): 1965–88 https http://doi.org/101148/rg2015140320

- T. J. Vrtiska, MD, Jane Matsumoto, MD, Jay Morris, MD, Imaging: The Role of the Radiologist. A Key First Step” Mayo Clinic (March 4, 2016)

- Mitsworth, Dimitris, Peter Lakouras, Amir Imanzade, Andreas A Giannopoulos, Tianrun Kai, Kanako K.

Kumamaru, Elizabeth George, et al. "3D Medical Printing for the Radiologist" RadioGraphics 35, no. 7 (November 2015): 1965–88 https http://doi.org/101148/rg2015140320

Kumamaru, Elizabeth George, et al. "3D Medical Printing for the Radiologist" RadioGraphics 35, no. 7 (November 2015): 1965–88 https http://doi.org/101148/rg2015140320 - Nooshin Kiarashi, PhD, FDA/CDRH/Department of Radiological Medicine, "FDA Current Practice and Regulations, FDA/CDRH-RSNA SIG Joint Meeting on Customized 3D Printed Anatomical Models", excerpted from https://www fda gov/ downloads/MedicalDevices/NewsEvents/WorkshopsConferences/ UCM575723 pdf

- Preoperative-planning-with-custom-3d-printed-surgical-model-reduces-theater-time by 88 percent Formlabs Accessed November 22, 2017

ADDITIONAL RESOURCES AND LINKS

1531–37 https://doi org/10 3171/2015 5 jns15119 Kikinis R., Pieper S. D., Vosburg K. (2014) 3D Slicer: a platform for object-based image analysis , imaging and clinical support. Intraoperative image processing. Imaging Therapy, Ferenc A. Jolez, Editor 3 (19): 277-289 ISBN : 978-1-4614-7656-6 (Print) 978-1-4614-7657-3 (Online)

Rybicki F.