Carbon liquid 3d printer

Who We Are - Carbon

Carbon’s Mission

Light and Oxygen

The Carbon DLS™ process combines versatile printers, advanced software, and best-in-class materials to deliver functional parts with end-use performance and aesthetics, helping engineers and designers to create products that outperform. From prototyping and low-volume production to production-at-scale, hundreds of global organizations, including adidas, Ford, and Becton Dickinson, use the Carbon process to create a wide range of functional end-use parts and print them reliably wherever and whenever they need them through our production network partners.

Learn about DLS

Latticed Bike Saddle

Read our customer stories

TED Talks

The talk that introduced us to the world

Science Magazine

The science behind Carbon technology, on the cover of Science

Our Leadership Team

With senior leaders from Silicon Valley, scientific, and business communities, we’re bringing together the best in hardware and software engineering, molecular science and service.

Craig Carlson

Office of the CEO

Craig is a member of the Office of the CEO, and most recently the CTO responsible for short and long term technology needs of the company as it scales and continues to introduce industry-leading software and hardware capabilities. He joined Carbon in 2014 from Tesla Motors, where he was VP of Software and Electrical Integration, with responsibility for all low-voltage electronics and all software that powers the Model S – from battery and motor control firmware, to the hardware and software that run the Model S in-car displays, to the Tesla mobile apps and server-based systems that connect to Teslas on the road. Craig joined Tesla in 2007 to lead the firmware organization, beginning with delivery of the first Tesla Roadsters in 2008. Before Tesla, Craig spent 15 years at Intuit, joining when Intuit acquired his small startup to start and lead development of QuickBooks. Craig was VP of Software Development for QuickBooks and then started, built, and launched QuickBooks Online. Craig received his BS in Electrical Engineering and Computer Science from Stanford University.

Craig received his BS in Electrical Engineering and Computer Science from Stanford University.

Philip DeSimone

Office of the CEO

Phil is a member of the Office of the CEO. He was part of the founding team at Carbon in 2013, and most recently the Chief Product and Business Development officer responsible for Carbon’s product strategy and strategic partnerships. Most recently, Phil led the go-to-market strategy and managed Carbon’s most strategic partnerships and customer relationships. Prior to Carbon, Phil co-founded and was the VP of Business Development at Buystand, an ecommerce company. Phil received his BA in business and econometrics from Ursinus College.

Ellen J. Kullman

Executive Chair

Ellen is the Executive Chair of Carbon, previously serving as President & CEO. Prior to joining Carbon, Ellen was Chairman and CEO of DuPont. She was the nineteenth executive, and the first woman to lead the company in its 212-year history. As a business leader, Ellen led double-digit growth of the company’s Safety and Protection business portfolio, started two successful high-growth businesses known today as DuPont Industrial Biosciences and DuPont Sustainable Solutions. During her seven years as CEO, Ellen led the company’s focus on growth in emerging international markets and championed the power of DuPont science and global market knowledge to transform industries. She decisively positioned the company for its next generation of growth, executing a strong plan that is delivering results today while positioning DuPont for future growth.

During her seven years as CEO, Ellen led the company’s focus on growth in emerging international markets and championed the power of DuPont science and global market knowledge to transform industries. She decisively positioned the company for its next generation of growth, executing a strong plan that is delivering results today while positioning DuPont for future growth.

Ellen is co-chair of the Paradigm for Parity coalition and a board director of Dell Technologies, Amgen, and Goldman Sachs. She is a member of the National Academy of Engineering and past president of the U.S. China Business Council. She serves on the board of trustees of Northwestern University. Ellen has been named as one of the “50 Most Powerful Women in Business” by Fortune and one of the “World’s Most Powerful Women” by Forbes. Ellen holds a B.S. in mechanical engineering from Tufts University and an MBA from the Kellogg School of Management of Northwestern University.

Barb Cadigan

Chief People Officer

Barb Cadigan is Chief People Officer, and she is responsible for spearheading the company’s organization and culture by empowering employees to fulfill the company’s mission. With over 25 years of experience, she is adept at developing strategies and processes for attracting and developing a world-class team of people. Previously, Barb worked as SVP of People for Talend, a leading cloud integration solutions company, and VP of Human Resources at Electronic Arts, one of the world’s largest video game companies. Barb holds a BA degree in Psychology and Economics from UC Santa Cruz.

With over 25 years of experience, she is adept at developing strategies and processes for attracting and developing a world-class team of people. Previously, Barb worked as SVP of People for Talend, a leading cloud integration solutions company, and VP of Human Resources at Electronic Arts, one of the world’s largest video game companies. Barb holds a BA degree in Psychology and Economics from UC Santa Cruz.

Anirma Gupta

Chief Legal Officer

Anirma is the Chief Legal Officer, responsible for leading the Carbon legal team. Prior to Carbon, Anirma was General Counsel at Tanium where she advised on company business strategy, managing global compliance and a variety of legal issues associated with a high growth stage company. Prior to joining Tanium, Anirma was Vice President and Deputy General Counsel at Intuit, Inc., and held a number of roles during her 11-year tenure. Anirma has a Juris Doctorate degree from Georgetown University Law Center and earned a Bachelor of Science degree in Electrical Engineering from University of Maryland College Park.

Jason Rolland, PhD

SVP of Materials

As SVP of Materials, Jason is tasked with creating the broadest possible range of materials for growing 3D objects with Carbon DLS technology. Previously, he was Senior Director of Research at Diagnostics for All, and co-founded Liquidia Technologies. Jason holds a BS in chemistry from Virginia Tech, a PhD in chemistry from UNC Chapel Hill, and has over 25 current and pending patents.

Chris Van Wert

SVP of Operations

Chris is the Senior Vice President of Operations at Carbon. He leads the supply chain, operations engineering, facilities, environmental health and safety, planning, and inventory functions, building infrastructure and processes to redefine digital manufacturing. Chris brings more than 20 years of experience leading cross-functional teams at companies including Stryker and Berkeley Process Control. Prior to Carbon, Chris was Director of Product Excellence at Tesla, where he managed all aspects of product excellence teams, including Quality Engineering, Supplier Quality, and Inspections. Chris received his MSc in Mechanical Engineering from Stanford University and his BSc from the University of California, Davis.

Chris received his MSc in Mechanical Engineering from Stanford University and his BSc from the University of California, Davis.

Vincent Rerolle

SVP of Corporate Development

Vincent is the Senior Vice President of Corporate Development at Carbon. He brings over 30 years of software and technology experience in startups and public companies. Vincent is responsible for corporate strategy, mergers and acquisitions, innovation, and strategic alliances. He was recently Chief Commercial Officer at Nauto. Prior to Nauto, he served as a strategic advisor to several technology start-ups and previously held senior corporate development and general management roles at Lunera, Acquia, Cavium, Wind River (acquired by Intel), and Mercury Interactive (acquired by HP). Vincent received his MBA from INSEAD and his Masters in Electrical Engineering from and Computer Science from Télécom Paris.

Tim Avila

SVP of Marketing

Tim is the Senior Vice President of Marketing at Carbon. He leads the marketing, communications and product marketing, and customer education functions building Carbon’s brand and driving growth. Tim brings more than 25 years of experience leading growth-focused marketing teams at companies including Yahoo!, BrightRoll and United Business Media. Prior to Carbon, Tim was Vice President of Marketing and Business Development at Intellimize, the pioneer in machine learning-based website optimization. Tim received his MBA from Santa Clara University with Beta Gamma Sigma honors.

He leads the marketing, communications and product marketing, and customer education functions building Carbon’s brand and driving growth. Tim brings more than 25 years of experience leading growth-focused marketing teams at companies including Yahoo!, BrightRoll and United Business Media. Prior to Carbon, Tim was Vice President of Marketing and Business Development at Intellimize, the pioneer in machine learning-based website optimization. Tim received his MBA from Santa Clara University with Beta Gamma Sigma honors.

Colleen Martin-Garcia

SVP of Finance

Colleen Martin-Garcia is the SVP of Finance, responsible for Carbon’s overall financial activities and global finance organization, including accounting and controllership, financial planning and analysis (F,P&A), reporting, tax, treasury, and sales operations. Leading into this role, Colleen was VP, Corporate Controller for more than three years at Carbon. Colleen is an experienced financial leader with more than 25 years of experience in Accounting and Finance. Colleen worked as the VP, Corporate Controller at Polycom, a global communications company and the Corporate Controller at Plantronics, a maker of audio solutions. She also spent nearly 10 years in the assurance practice at KPMG LLP. Colleen is a CPA and holds a BS degree in Economics from UC Santa Cruz and a Masters in Accounting from San Jose State University.

Colleen worked as the VP, Corporate Controller at Polycom, a global communications company and the Corporate Controller at Plantronics, a maker of audio solutions. She also spent nearly 10 years in the assurance practice at KPMG LLP. Colleen is a CPA and holds a BS degree in Economics from UC Santa Cruz and a Masters in Accounting from San Jose State University.

Board of Directors

Executive Chair

Ellen J. Kullman

Member, Board of Directors & Co-Founder at Carbon

Joseph DeSimone, PhD

Former CEO, Ford Motor Company

Alan Mulally

Partner, Sequoia Capital

Jim Goetz

Managing Director, Silver lake

Bryce Lee

Former KPMG Managing Partner

Deborah M. Messemer

Group CIO, Adidas

Andreas Hubert

Granville Capital

Bobby Long

Executive VP and GM of the Client Computing Group at Intel Corporation

Michelle Johnston Holthaus

Founders

Member, Board of Directors & Co-Founder at Carbon

Joseph DeSimone, PhD

Office of the CEO, Carbon

Philip DeSimone

Launch CEO & Co-founder

Steve Nelson

Advisor & Co-founder, Carbon

Ed Samulski, PhD

Chief Innovation Officer & Co-founder, Carbon

Alex Ermoshkin, PhD

Co-founder

Nikita Ermoshkin

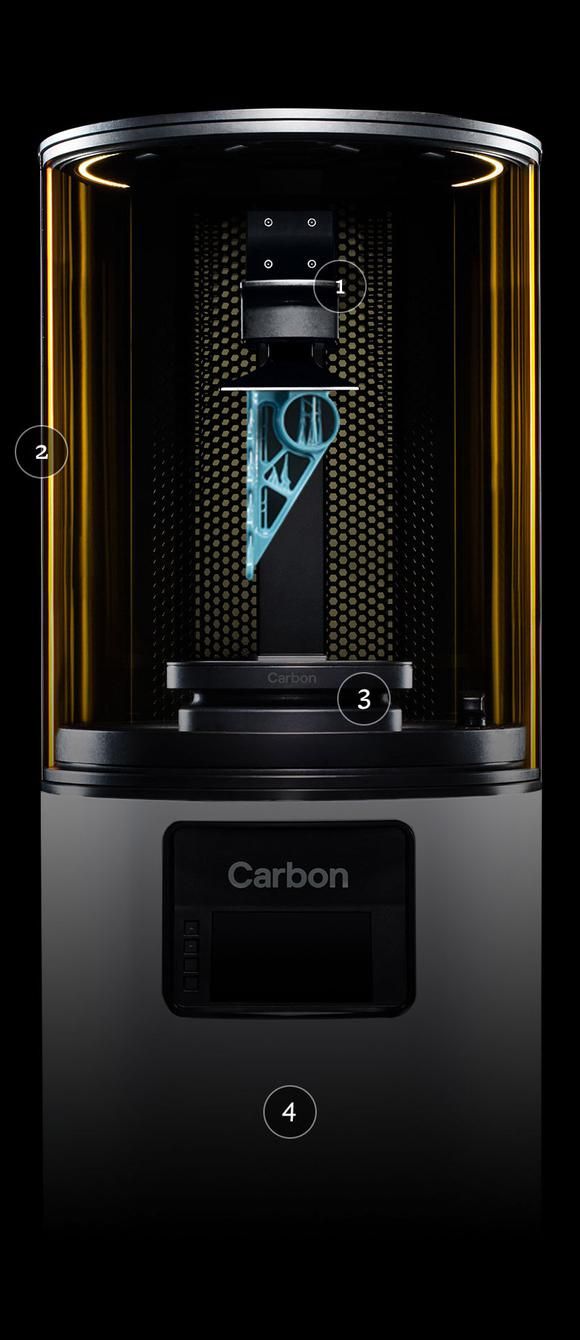

DLS 3D Printing Technology - Carbon

The Carbon DLS™ Process

Digital Light Projection: UV Light Shapes the Part

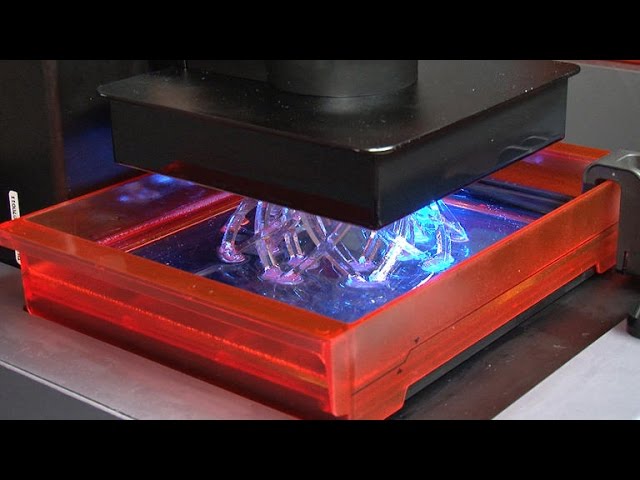

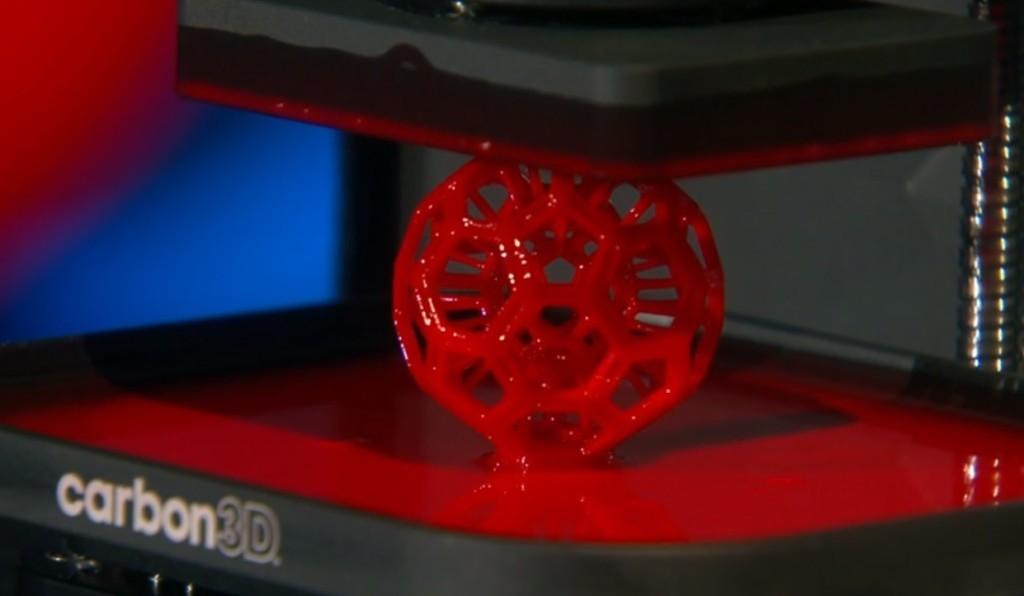

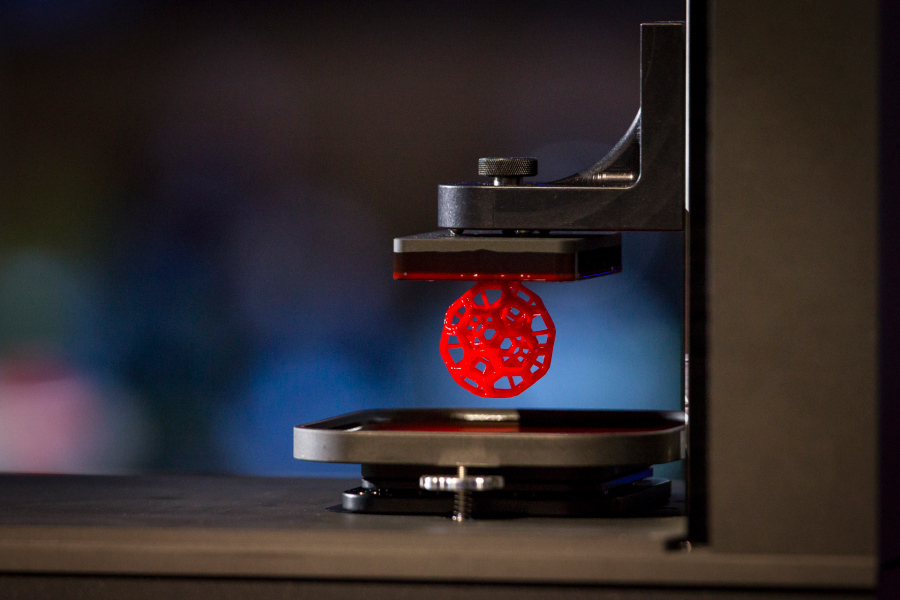

The Digital Light Synthesis process is driven by Carbon’s groundbreaking Continuous Liquid Interface Production™, or CLIP™. CLIP is a photochemical process that cures liquid plastic resin into solid parts using ultraviolet light. It works by projecting light through an oxygen-permeable window into a reservoir of UV-curable resin. As a sequence of UV images is projected, the part solidifies and the build platform rises.

CLIP is a photochemical process that cures liquid plastic resin into solid parts using ultraviolet light. It works by projecting light through an oxygen-permeable window into a reservoir of UV-curable resin. As a sequence of UV images is projected, the part solidifies and the build platform rises.

Oxygen-Permeable Optics: Fast Printing via the “Dead Zone”

The heart of the CLIP process is the “dead zone”—a thin, liquid interface of uncured resin between the window and the printing part. Light passes through the dead zone, curing the resin above it to form a solid part without curing the part onto the window. Resin flows beneath the curing part as the print progresses, maintaining the “continuous liquid interface” that powers CLIP and avoiding the slow and forceful peeling process that is inherent to many other resin-based printers.

Dual-Cure Materials: Mechanical Properties Set by Heat

Traditional resin-based 3D printing processes produce weak, brittle parts. Carbon overcomes this by embedding a second heat-activated programmable chemistry in our materials. Once a part is printed on a Carbon printer, it’s baked in an oven. Heat sets off a secondary chemical reaction that causes the materials to adapt and strengthen, taking on exceptionally strong characteristics. This produces high-resolution parts with engineering-grade mechanical properties.

Carbon overcomes this by embedding a second heat-activated programmable chemistry in our materials. Once a part is printed on a Carbon printer, it’s baked in an oven. Heat sets off a secondary chemical reaction that causes the materials to adapt and strengthen, taking on exceptionally strong characteristics. This produces high-resolution parts with engineering-grade mechanical properties.

The Results? Isotropic Parts with Exceptional Surface Finish

3D printed parts are notoriously inconsistent. Because of a layer-by-layer process, conventional 3D printed materials often exhibit variable strength and mechanical properties depending on the direction in which they were printed.

The Carbon DLS™ process, on the other hand, produces parts with predictable isotropic mechanical properties. These printed parts are solid on the inside like injection-molded parts and behave consistently in all directions. The resolution and gentleness of our process—where parts aren’t harshly repositioned with every slice—make it possible to leverage a broad range of materials that meet the surface finish and detail requirements needed for end-use parts.

The Carbon Isotropic Difference

Carbon’s isotropic properties are a feature of our dual-cure materials technology. Each stage in the process contributes to the mechanical integrity of every printed part.

Stage 01: Print

The isotropic difference of parts printed on the Carbon platform is due in part to the dead zone. In this small region, a thin layer of oxygen prohibits curing closest to the window with its effect falling off to zero at ~20 µm from the surface of the window.

Liquid resin begins to intersect and cure along the z-axis as light escapes the oxygen layer of the dead zone.

Stage 02: Bake

The isotropy of each printed part is reinforced with a thermal curing stage. Here, a secondary reaction creates a molecular weaving, adding strength in all directions.

Fully Dense Parts with End-Use Quality

Unlike powder-bed fusion 3D printing technologies, Carbon technology produces fully dense parts.

Why the Carbon DLS™ Process?

Accelerate Every Step of Product Development

Rapid Design Iterations

Test dozens of designs in the time it used to take to try one.

Functional and Rapid Prototyping

Don’t settle for fragile prototypes. Bring your designs to life with the industry’s best materials, then start testing and iterating immediately.

Scale to Production

Seamlessly transition into production, while still having the ability to revise your designs immediately and without retooling. Scaling has already been done by leading brands like adidas, Specialized, and fizik.

Find the Perfect Design for Your Application, Not the Mold

Undercuts and Undrafted Walls

Moldability constraints don’t apply here. Enjoy the freedom of designing with undercuts and perfectly straight walls without sacrificing manufacturability.

Performance-oriented Lattices

Lattices allow you to specify your required characteristics at every millimeter. Determine your product’s ideal mechanical response and leverage Carbon Design Engine™ software to generate the right lattice for it.

Consolidated Parts

A single printed part frequently offers better overall mechanical performance than an assembled part. Streamline production with reduced SKUs and less labor by consolidating assemblies.

Streamline production with reduced SKUs and less labor by consolidating assemblies.

Discover New Aesthetics

Customization

With no tooling costs, you’re free to make every unit unique. Offer personalized designs, or build entire products around individuals.

Surface Design and Textures

Enhance your parts by applying textures to complex curved surfaces like grips and enclosures with Carbon design software.

Perfecting Product Design with the Carbon DLS™ Process

3D printing sends modern design soaring, giving designers and engineers the freedom to bring their most inspired ideas to life without the constraints of molding or machining.

Learn about how the Carbon DLS™ process unlocks a new world of design.

Read more

Ready to Get Started?

Contact us to see if the Carbon DLS™ process is the right fit for your production needs.

Contact us

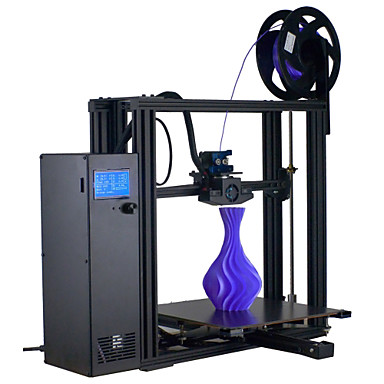

Carbon 3D Printers

The L and M Series printers and Smart Part Washer offer versatility and enable scalable manufacturing.

Learn More

Materials

Find the right material for your project, from consumer product elastomers to high-temperature automotive materials.

Learn More

Carbon Design Engine

Design high-performance conformal lattices to improve product performance and speed up print time.

Learn More

3D as It’s Meant to Be

Carbon fiber 3D printing

Researchers at the National Laboratory. Lawrence Livermore claim they are the world's first 3D printed carbon fiber aerospace composites and may be paving the way for sophisticated new printouts.

Carbon fiber is a material that is stronger than steel and at the same time very light. Because of this, it is ideal for the manufacture of parts for the aerospace and automotive industries. However, when creating complex shapes from the material using traditional methods, it is extremely difficult to control.

Researchers at Lawrence Livermore National Laboratory (LLNL) may have found a way to change that. The Explorers are the world's first 3D printed carbon fiber aerospace composites. And they believe that because of this work, they will be able to control and optimize the use of high specification material.

The Explorers are the world's first 3D printed carbon fiber aerospace composites. And they believe that because of this work, they will be able to control and optimize the use of high specification material.

This is not the first time carbon fiber has been 3D printed. There are many PLA derivatives that can do the same on a regular home printer. However, it is important to note that the difference is that LLNLs have printed aerospace composites.

Previous problems with carbon fiber composites have included the complex techniques required to create parts and overcompensate material due to "performance issues". However, the researchers at LLNL were able to achieve the same material properties as two-thirds through a new 3D printing method.

To achieve this goal, LLNL created its own Direct Ink Printer (DIW) using its own carbon fiber composite "ink". The researchers also patented a method to cure extruded material in seconds, not hours.

They used the computational model shown in the video above to develop models for the flow of carbon fiber filaments in their inks. Julia Kanarska, Analyst, explains:

Julia Kanarska, Analyst, explains:

“We have developed a numerical code to simulate a non-Newtonian liquid polymer resin with a dispersion of carbon fibers. With this code, we can simulate the evolution of fiber orientation in 3D under different printing conditions. We've managed to find the optimal fiber length and optimal performance, but it's still a work in progress. Current efforts are to achieve even better fiber alignment by applying magnetic forces to stabilize them.”

Since the material is conductive, it allows the control of thermal channeling. The use could be in the manufacture of satellite components that - printed in their design - are insulated on one side. That is, they do not require rotation in space.

The next challenge for the research team is to optimize the process. They demonstrated the benefits achieved with this method. But to understand this further, it will mean determining the best way to stack carbon fiber.

Source: Lawrence Livermore National Laboratory

Carbon Fiber 3D Printing Guide: Printers and Materials

Bicycles, race cars, drones and tennis rackets all have a variety of applications and require high strength and durability without added weight. This combination of properties is typical of carbon fiber composites, which are used in everything from Formula 1 racing car chassis to lightweight road bike frames.

This combination of properties is typical of carbon fiber composites, which are used in everything from Formula 1 racing car chassis to lightweight road bike frames.

Since many 3D printers usually use polymer-based materials, including various composites, many people ask the question: "Can a 3D printer print carbon fiber?".

Indeed, there are two methods by which 3D printing can be used to create carbon fiber parts: supporting traditional fabrication methods with 3D printed molds, or direct 3D printing of carbon fiber composites. In this article, we'll look at traditional fabrication methods as well as new workflows for 3D printed carbon fiber molds and direct 3D printed carbon fiber composite parts.

Combining traditional carbon fiber parts with 3D printing

Carbon fiber is a composite material traditionally made by weaving long strands of carbon fibers together and then bonding them with a polymer. The yarns can be woven strategically so that the strength is directed along one specific vector, or so that the final product has multiple strengths in all directions. The resulting material is then molded into the desired end product using one of three processes: wet laid, pre-laminated, or resin transfer molding (RTM).

The resulting material is then molded into the desired end product using one of three processes: wet laid, pre-laminated, or resin transfer molding (RTM).

Wet Laid

Wet laid carbon fiber sheets are cut and pressed in a mould, then dyed with a liquid resin that cures to bind the sheets into the desired final shape. This method requires the least equipment and is the easiest to master for a beginner. Because most of the work can be done by hand, this is one of the cheapest methods, but the trade-off is that the resulting parts are less accurate to the master mold than parts made by other methods.

Prepreg lamination

In this method, the carbon fiber is already impregnated with resin and then placed in a mold that uses pressure and heat to form the final shape. This method is the most expensive due to the need for specialized equipment to store and process the pre-impregnated sheets, as well as a heated and pressurized forming machine. These factors also make it the most repeatable and consistent, and thus the most suitable for serial production of carbon fiber parts.

These factors also make it the most repeatable and consistent, and thus the most suitable for serial production of carbon fiber parts.

Resin transfer molding (RTM)

In RTM molding, the dry fiber is inserted into a two-part mold. The mold is clamped, after which high-pressure resin is injected into the cavity. This method is usually automated and is used to produce large volumes of products.

3D printed carbon fiber parts

For each of the three previous methods, 3D printing can be used to reduce costs and improve production times. All three traditional manufacturing methods require the use of a mold or multiple molds, which are traditionally created through labour-intensive subtractive processes such as wood, foam, metal, plastic or wax. 3D printing offers an alternative way to make molds. 3D printed molds are customizable and are more efficient and cost effective for small batch or custom production.

For applications requiring live prototypes, such as the automotive and aerospace industries, the iterative process can require hundreds of different shapes. Producing such iterations with traditional manufacturing methods can be costly and time consuming, so 3D printing provides an efficient way to produce small batches. Although 3D printed molds are not as suitable for high-volume production as metal molds, they can be created in-house, reducing costs, speeding up product development and validation, and short-term production.

Carbon fiber molds can be made in a variety of ways, but the smooth surface and wide choice of materials for SLA 3D printers make them a common choice for mold making in the factory. SLA-created parts have virtually no layer lines or porosity, so carbon fiber sheets can be pressed tightly into the mold without the fear of creating a textured surface.

Panoz, a manufacturer of racing and sports cars, needed a custom race car cabin duct to bleed the air out of the cabin and cool the temperature inside. In collaboration with DeltaWing Manufacturing, they used a Formlabs SLA 3D printer to print a high temperature resin part and then manually molded that printed part using high temperature epoxy for tooling. By using 3D printing, DeltaWing avoided outsourcing the costly metal mold for this custom carbon fiber part, reducing overall costs and delivery times.

In collaboration with DeltaWing Manufacturing, they used a Formlabs SLA 3D printer to print a high temperature resin part and then manually molded that printed part using high temperature epoxy for tooling. By using 3D printing, DeltaWing avoided outsourcing the costly metal mold for this custom carbon fiber part, reducing overall costs and delivery times.

Carbon fiber wing duct next to two piece mold printed with High Temp Resin made by DeltaWing Manufacturing.

Direct Carbon Fiber 3D Printing

Looking for the best carbon fiber 3D printer? There is a strong demand for workflows that combine the strength, durability and wear resistance of traditional carbon fiber parts with the maneuverability, geometric capabilities and cycling of 3D printing. Therefore, it is not surprising that there are many companies offering 3D printing using carbon fiber, with two methods currently available: printing using chopped or continuous fibers.

Chopped Carbon Fiber 3D Printing

Chopped Fiber refers to 3D printing composite plastic materials that are impregnated with small pieces of carbon fibers. These crushed fibers add strength to the composite, which can be carbon fiber filament for FDM modeling or nylon powder for SLS 3D printing.

The main advantages of chopped carbon fiber reinforced materials over other types based on polymers are that they are strong, light, heat resistant and less prone to deformation. Compared to traditionally molded carbon fiber parts, chopped fiber 3D printing provides increased geometric flexibility in part design, especially in SLS 3D printing, potentially eliminating the labor involved with traditional molding or opening up innovative new opportunities for users to incorporate this material into the working process.

The Formlabs Fuse 1+ 30W SLS 3D Printer enables this type of carbon fiber 3D printing with Nylon 11 CF Powder, the strongest material in the Formlabs SLS material library. Fuse 1+ 30W is the most affordable high performance SLS printing option for shredded carbon fibers. Although traditional industrial SLS machines also offer some carbon fiber materials, the initial implementation costs negate much of the added value of 3D printing carbon fiber parts over RTM or prepreg lamination methods.

Fuse 1+ 30W is the most affordable high performance SLS printing option for shredded carbon fibers. Although traditional industrial SLS machines also offer some carbon fiber materials, the initial implementation costs negate much of the added value of 3D printing carbon fiber parts over RTM or prepreg lamination methods.

Formlabs Nylon 11 CF Powder is strong, lightweight and heat resistant making it ideal for the automotive, aerospace and manufacturing industries .

Many FDM 3D printers can handle carbon fiber filaments, but these materials are more difficult to print than standard ABS or PLA filaments, resulting in more clogs and more maintenance as the brass nozzles wear out. FDM 3D printers specifically designed to grind carbon fiber filaments are also available but are more expensive.

The main limitation of chopped-fiber printed parts using both SLS and FDM technologies is that they should be considered as more durable 3D printed parts, rather than a true alternative to traditional woven and continuous carbon fiber parts. fibers. They also provide the greatest increase in strength by positioning them in the X-plane direction for SLS printing, and in the XY-plane direction for FDM printing. Traditional methods of creating carbon fiber parts provide multidirectional strength through careful planning and placement of different carbon fiber sheets in a preform.

fibers. They also provide the greatest increase in strength by positioning them in the X-plane direction for SLS printing, and in the XY-plane direction for FDM printing. Traditional methods of creating carbon fiber parts provide multidirectional strength through careful planning and placement of different carbon fiber sheets in a preform.

Carbon Fiber Continuous 3D Printing

Carbon Fiber Continuous 3D Printing is available on some dedicated FDM 3D printers, and the resulting parts are close in strength to traditional carbon fiber parts, but similar to chopped fiber printers FDM, only in the XY plane. In such printers, continuous filaments of carbon fiber are mixed with a thermoplastic and the filaments can be applied strategically to selectively pressurize certain planes or axes. This method can use either a dual extruder nozzle to lay down a combination of carbon fiber and polymer filaments, or a 2-in-1 in which one nozzle lays down the carbon fiber filaments and the other heats and extrudes the filament.

Continuous carbon fiber 3D printing offers an alternative comparable to traditional molded carbon fiber parts, albeit with limited design freedom. While these parts are incredibly strong, strength only appears in the XY planes and the models must be oriented so that their strength matches the direction of the applied force. In designs where possible, this method can be used to replace aluminum parts, as well as to create durable manufacturing aids or end-use parts.

Applications for 3D printed carbon fiber parts

The high strength, light weight, and impact, heat and chemical resistance of carbon fiber printed parts make them ideal for a variety of applications where 3D printing has never been before. was not considered. Now, these plastic and carbon fiber composite parts can withstand the heat generated by automotive or aerospace engine components, be used as a replacement for machined aluminum parts and manufacturing fixtures, and produce durable and impact-resistant equipment.

3D printed carbon fiber parts are ideal for rapid prototyping, the production of wear-resistant and durable manufacturing fixtures such as tooling and fixtures, and for low-volume production of durable end-use parts with complex geometries.

3D printing technology has opened up new possibilities in design and manufacturing, and 3D printing of carbon fiber composites has further expanded these possibilities, allowing users in the automotive, aerospace, defense, and manufacturing industries to quickly and efficiently produce high-strength, heat-resistant, geometrically flexibility. By bypassing traditional machining or molding processes, these users can more easily create custom parts, replacement parts and functional prototypes. Although carbon fiber printed parts are not a complete replacement for traditional technologies due to the single plane of added strength, they are still stronger than almost all other plastics, making them exceptionally useful in many applications.