3D printer 3 extruder

Triple and Quad Extruder 3D Printing: How to Print with More Colors

3D Insider is ad supported and earns money from clicks, commissions from sales, and other ways.

A triple extruder setup is one of the less popular methods for producing multi-color and multi-material prints, and it’s not that difficult to figure out why. A dual extruder setup is already complicated enough to deal with, even for some of the more experienced tinkerers. Introducing another variable to an already complicated equation is pushing it.

Like all-in-one 3D printers, triple extrusion is a real thing and not just one of those outrageous concepts people often put up on Kickstarter, Indiegogo, and other crowdfunding platforms. The now-abandoned RepRapPro Tricolour Mendel build was one of the more notable products to come out and served as solid proof that triple extrusion can be done.

Considering the complications it brings to the table, triple extrusion is not as widely adopted as single and dual extrusion. Few companies commit to such a mechanical setup, and the ones that did in the past flopped hard, with 3D Systems and its discontinued Cubify CubePro Trio being a good example of that.

For those interested in triple-color printing, there’s still a sliver of hope. In this piece, we’ll introduce you to a couple of triple extruder 3D printers that might be worth a shot, along with other methods that will allow you to print with three colors for more vibrant models.

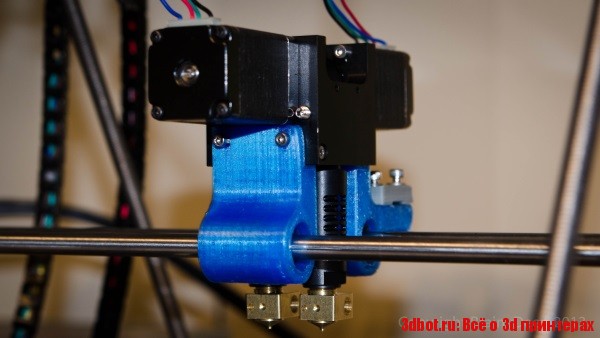

On the surface, the He3D EI3-Tricolor appears to be a rebranded Tevo Tarantula, one of the more recognizable budget 3D printers on the market. Obviously, the triple extruder setup separates it from that product. It comes in a kit and sells for less than $500, which immediately raises questions about its overall quality, especially with regard to the core components.

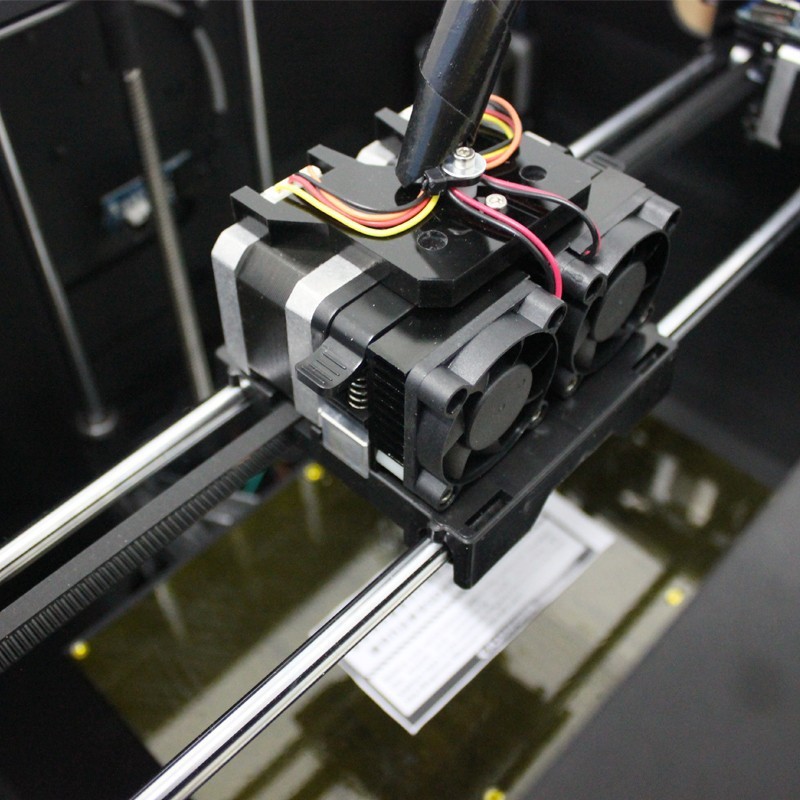

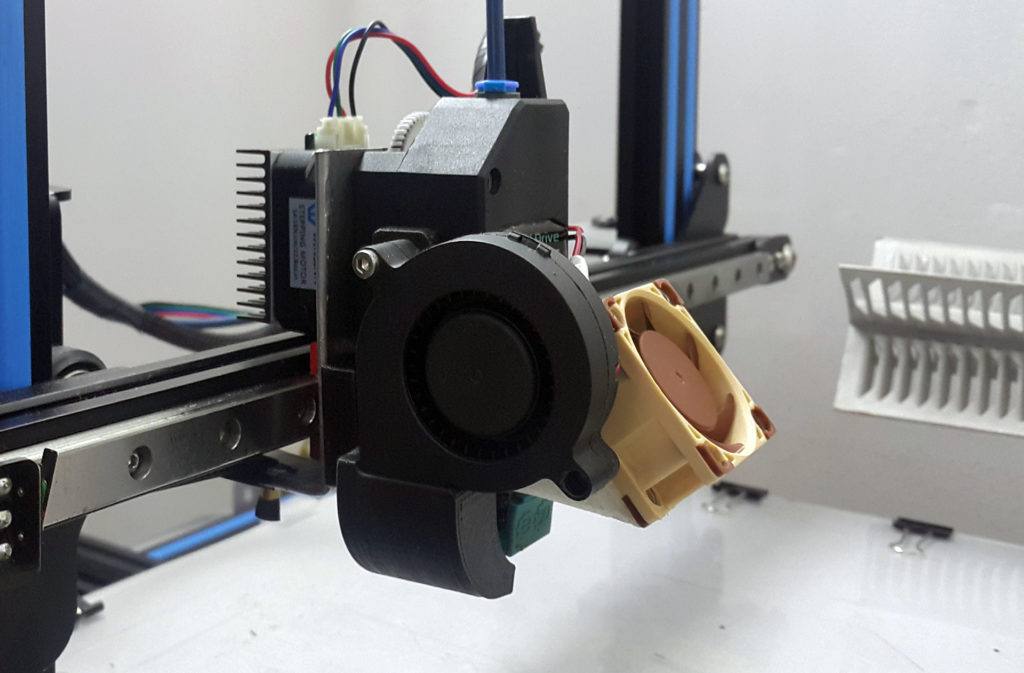

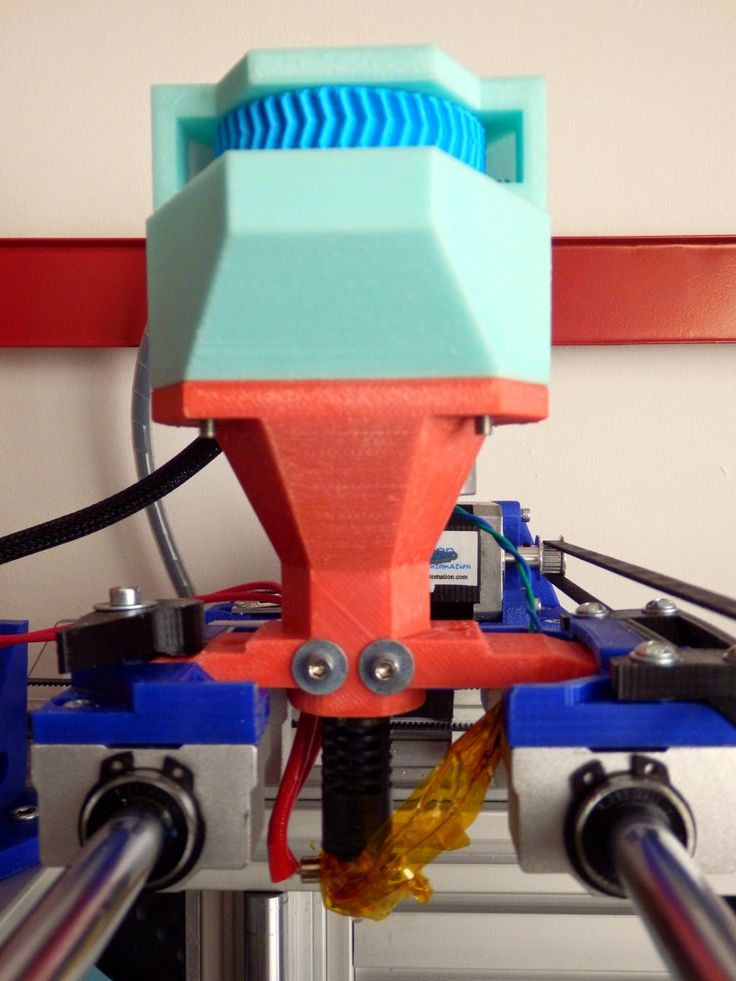

An open-structured machine with an aluminum frame, the EI3-Tricolor comes with a trio of extruders, each equipped with a filament tube and all of which are mounted on one side of the frame, along with the main electronics. It can print in either a “three in, three out” setup or a “three in, one out” setup.

It can print in either a “three in, three out” setup or a “three in, one out” setup.

In the former setup, the filament tubes are connected to individual hotends, similar to a regular dual extruder setup but with three nozzles. In the latter setup, there’s only one nozzle for the output, with the three filament tubes converging on the single hotend.

The EI3-Tricolor has a large build volume, featuring a lengthy heated print bed. It uses Repetier and can connect via SD card and USB, the standard connection options for most 3D printers. It has an open material system and, according to the manufacturer, can print with ABS, PLA, PETG, PVA, and Wood-filled materials.

While all of those specifications and features look neat on paper, it’s difficult to confirm whether or not the EI3-Tricolor can actually deliver on the promise. There’s not much coverage from both customers and professional reviewers, not counting unverified customer feedback seen at online stores. Well, at least He3D has videos of the EI3-Tricolor in action, which might be good enough to convince some people.

Considering the lack of information, especially in-depth reviews, about the EI3-Tricolor, giving it a shot is a huge gamble, so think hard before parting with that $500. At the very least, expect the kind of issues often associated with China-made budget 3D printers, such as less-than-stellar documentation and poor quality control. And remember, it comes in a DIY kit, so be prepared for a significant amount of assembly.

The CreatBot DX is another product with roots in China. But compared to the above product, this one appears to be made of better components, featuring a steel frame that boosts its durability. CreatBot offers an upsized model in the form of the DX Plus, one more reason the DX series comes off as an Ultimaker 3 clone. (Ultimaker also offers an upsized Ultimaker 3.)

The DX boasts a large build area, with the DX Plus featuring an even larger one. It’s one of the three most notable things separating it from the Ultimaker 3. The other ones would be the all-black finish and, most importantly, the ability to equip a triple extruder setup. It has a semi-enclosed frame with a 4.3-inch touchscreen interface and comes with a heated glass-ceramic build plate. It can print with a wide range of materials, including ABS, HIPS, PVA, and Nylon.

It has a semi-enclosed frame with a 4.3-inch touchscreen interface and comes with a heated glass-ceramic build plate. It can print with a wide range of materials, including ABS, HIPS, PVA, and Nylon.

When it comes to features, the DX has a good list, which includes a filament sensor, automatic shutdown upon print completion, and power loss recovery. Sadly, the build platform has a manual bed leveling system, which is a turn-off for many people. But at least the build plate isn’t prone to misalignment after just a few prints, courtesy of the stable mechanical arrangement.

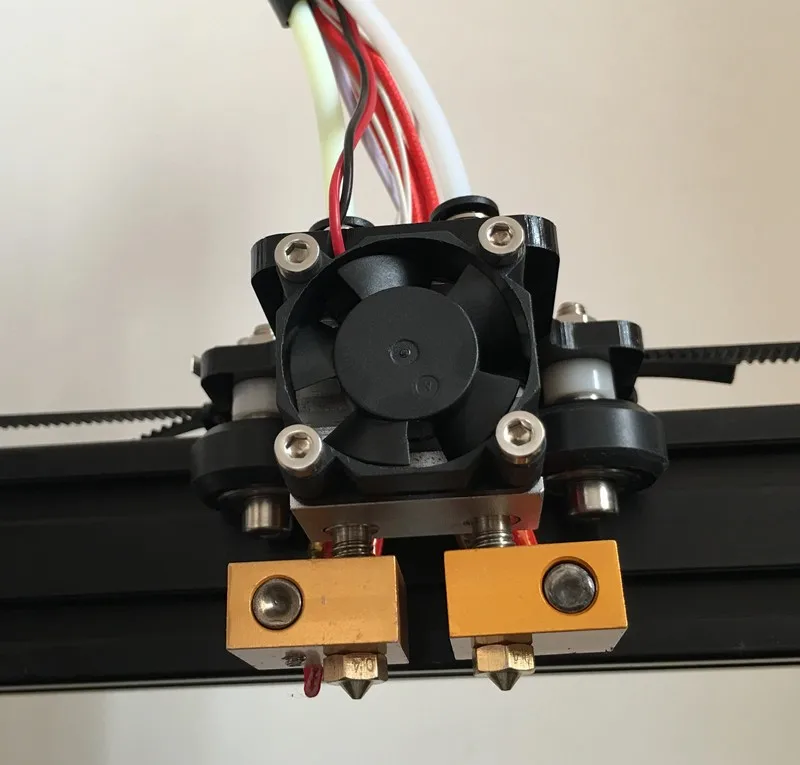

Unlike with the He3D EI3-Tricolor, CreatBot only offers one triple extruder configuration for the DX, which comes in the form of a triple nozzle configuration – or the “three in, three out” setup. But as with the EI3-Tricolor, it’s difficult to ascertain whether or not the entire thing works as advertised, considering the lack of in-depth info on the internet, not counting the unverified customer feedback at online stores.

There are a couple of short videos showing the DX printing with triple extruders, which at least shows it’s not a complete scam. Outside of that, you’re pretty much in the dark about the overall performance, especially with regard to the triple extruder setup. Keep this in mind before you commit to buying this 3D printer.

Other Options

It’s disappointing there aren’t more triple extruder 3D printers on the market, much less in-depth info about the ones available. On the bright side, there are other methods to produce triple-color prints. No, we’re not talking about the mid-print filament change on a single extruder setup, which is what some people do to create more colorful prints. What we’re talking about are add-ons and components built specifically for printing multi-color models. Instead of spending a lot of time digging around for viable triple extruder 3D printers, check out the following methods.

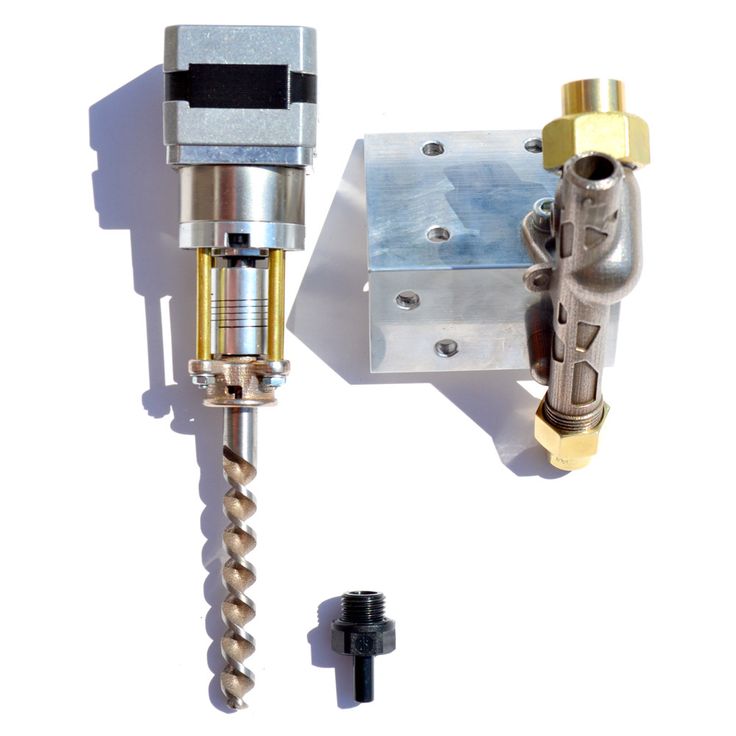

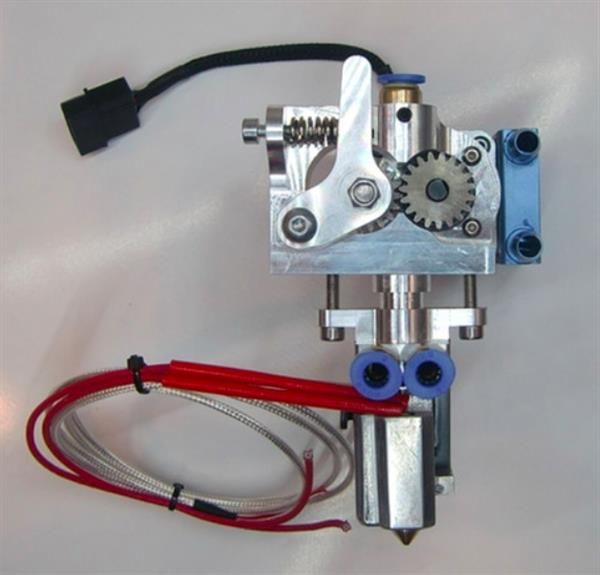

For tinkerers, one interesting option is to build a triple extruder setup centered on the Diamond Hotend. Created and sold by RepRap.me, the Diamond Hotend is a massive, boss-looking hotend built for multi-material printing. It can use up to three different filaments to produce colorful prints.

Created and sold by RepRap.me, the Diamond Hotend is a massive, boss-looking hotend built for multi-material printing. It can use up to three different filaments to produce colorful prints.

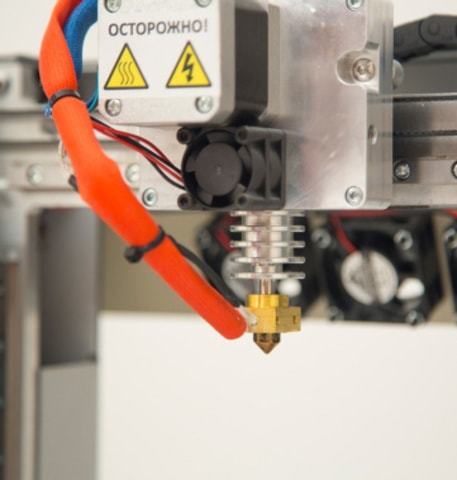

The Diamond Hotend includes three separate heat sinks and a single diamond-shaped nozzle with a standard 0.4-millimeter opening. It mixes colors directly in the hotend. The mixing chamber is optimized for faster color shifting and reduced filament waste, according to the creators.

The Diamond Hotend’s biggest problem is its heavy structure, which translates to reduced print speeds. Just looking at that massive hotend will be enough to scare away those who value print speed more than anything else. Although it’s been out for a while, the Diamond Hotend is still far from a polished product, especially with regard to the color-switching operation.

Take note that the Diamond Hotend requires a significant amount of tinkering. You need to install it on your own. It requires a very specific setup, especially on the electronics side, considering most regular mainboards are not built for triple extrusion.

For those who are interested, the manufacturer offers a customizable purchase for the Diamond Hotend kit, offering different choices in several areas, such as the heat sink, the temperature sensor, and the cooling fan. For the full Diamond Hotend kit, expect to cough up at least $100.

When it comes to extruders and hotends, UK-based E3D is one of the most popular names in the business. The company is best known for the V6 hotend and the Titan extruder. Considering E3D’s expertise with hotends, it’s not surprising the company also has contenders in the multi-material department, one of which is the Kraken, which you can use as the centerpiece in a custom 3D printer built for triple-color and multi-material printing.

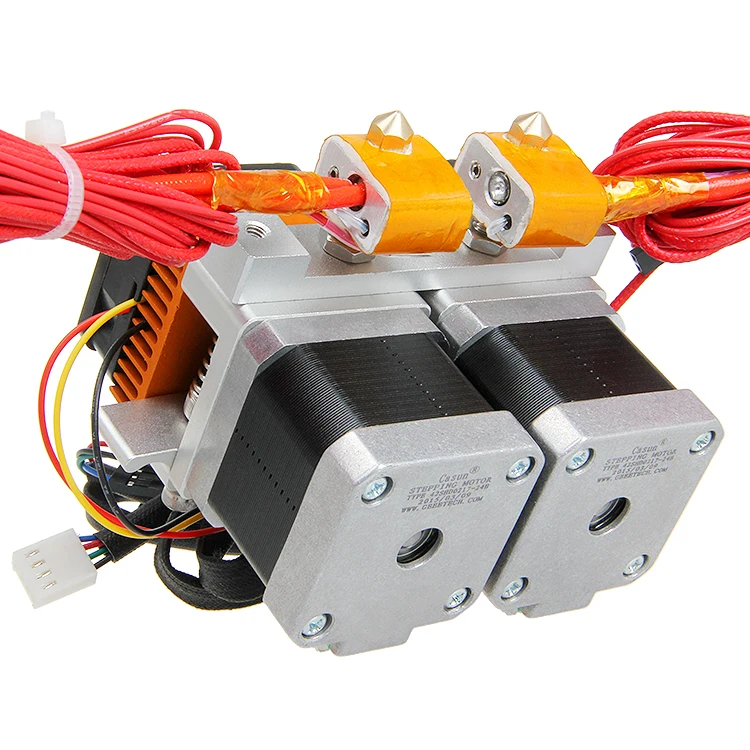

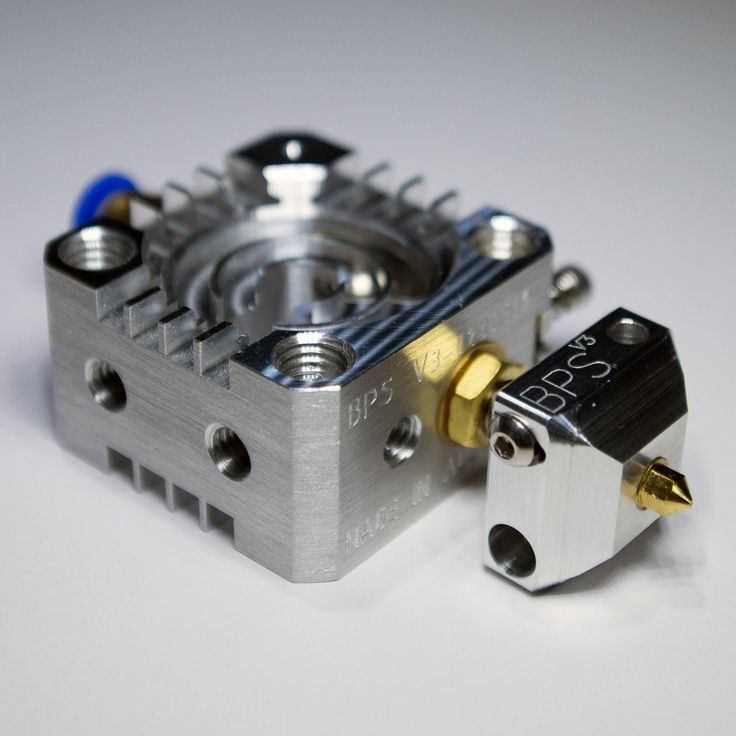

The Kraken is a water-cooled hotend system equipped with four nozzles, which sets it apart from the single-nozzle Diamond Hotend. Each nozzle is a separate entity; the temperature and height of each nozzle can be adjusted individually. While considered more developed than the Diamond Hotend, the Kraken is still far from reaching its full potential as a multi-material tool.

Like the Diamond Hotend, the Kraken requires a significant amount of tinkering, especially with regard to the electronics because, as mentioned previously, not all mainboards are built to accommodate a multi-material setup with three or more outputs. It’s not a plug-and-play equipment that you can install on just any 3D printer.

Considering E3D is known for its high prices, it’s not surprising the Kraken sells for over $200, including taxes. This price point places it close to Prusa Research’s multi-material kit, which is already a fully formed system out of the box, complete with electronics and a frame mount. On the plus side, the Kraken, like other E3D hotends, has the entire E3D ecosystem behind it, making it easy to replace the parts in the future.

The Mosaic Manufacturing Palette 2 is an external accessory that allows a single extruder setup to print with up to four different materials. It serves as the follow-up to the successful Palette+, the upgraded version of the original Palette, which got off the ground thanks to a crowdfunding campaign.

It sells for around $600, with its big brother, the Palette 2 Pro, going for about $800. In regard to performance difference, the more expensive model has a more optimized cooling system and boasts a 20 percent increase in splicing speeds, according to Mosaic Manufacturing.

The Palette 2 is a neat tool equipped with its own built-in touchscreen interface. Inside, it’s got a series of stepper motors for pushing the loaded filaments and a cutting mechanism, which is the heart of the operation. The Palette 2 cuts and splices the filaments together, forming a single filament strand with different colors. Since there’s no need to switch to a different filament mid-print – unless the filament runs out – this method makes for smoother and hassle-free multi-material printing, whether in three colors or four colors.

Keep in mind that the Palette 2 doesn’t actually mix the filaments to produce full-color prints. It simply splices them together into a single strand, with the color sequence depending on the model being printed. It’s an effective way to produce multi-color prints, one that’s definitely worth that expensive price tag.

It’s an effective way to produce multi-color prints, one that’s definitely worth that expensive price tag.

What makes the Palette 2 even better is that it’s compatible with some of the most popular 3D printers on the market. It can work with the Creality CR-10, the Monoprice Maker Select v2, the Robo R2, and even the Original Prusa i3 series, though for the latter, Prusa Research’s own multi-material upgrade kit is more ideal (more on this in the next section).

Compatible with PLA, PETG, flexibles, and dissolvable materials, the Palette 2 is rated for 1.75-millimeter filaments and can connect via SD card and USB. While it doesn’t give you the chance to watch a triple extruder setup in action, the Palette 2 is a great tool to use for triple-color printing. It can turn a regular single extruder 3D printer into a multi-material machine capable of producing colorful models.

On the other side of the fence is the significantly cheaper Multi-Material Upgrade (MMU) 2.0 kit from Prusa Research, the company behind the popular Original Prusa i3 series. It’s another tool that allows a single extruder 3D printer to print with multiple materials in a single session. At around $300, the MMU 2.0 is half the Mosaic Manufacturing Palette 2’s price.

It’s another tool that allows a single extruder 3D printer to print with multiple materials in a single session. At around $300, the MMU 2.0 is half the Mosaic Manufacturing Palette 2’s price.

Here’s the catch: Out of the box, the MMU 2.0 only works with the Original Prusa i3 series. Or more specifically, the MK2.5 and MK3 models. The Palette 2, on the other hand, has a longer list of compatible 3D printers it can work with right out of the gate.

Other than the price, another easily noticeable difference between the MMU 2.0 and the Palette 2 is the former’s ability to print with up to five materials. That’s sure to make printing not only even more colorful but also more exciting. Compared to the older MMU, this redesigned model offers a more simplified and cleaner operation, featuring just a single main filament tube instead of one for each material.

Like its predecessor, the MMU 2.0 is mounted on the frame. It boasts better electronics and has a filament sensor and a power loss recovery system. It’s got a smart wiping system, too, which reduces the amount of wasted filament, a major concern when printing with multiple materials.

It’s got a smart wiping system, too, which reduces the amount of wasted filament, a major concern when printing with multiple materials.

While the MMU 2.0 uses a different operation to produce colorful prints, it has one notable thing in common with the Palette 2: it can’t mix colors for full-color printing. It simply switches between different filaments during the entire operation, which eliminates the need to manually swap out filaments mid-print. But that’s more than good enough, except maybe for those who want full-color printing badly.

For those who own or plan to buy an MK2.5 or MK3, it’s worth the money to get Prusa Research’s new multi-material system as well. It’s a cool piece of equipment that makes printing more fun and colorful. And, as mentioned, it’s a lot more affordable than the Palette 2, which will cost you at least $600.

Warning; 3D printers should never be left unattended. They can pose a firesafety hazard.

3D Printer Extruders - 3DJake International

Sort byRelevanceBestsellersCustomer ReviewsPrice, Low to HighPrice, High to LowNew arrivalsHighest Discount

-

Creality Metal Extruder Upgrade Kit- High-quality aluminium alloy

- Easy installation

- Adjustable pressure on the filament

-

Micro-Swiss Direct Drive Extruder for Creality CR-10 & Ender 3 2 Model types- Dual drive gear

- Easy filament loading

- For flexible filaments

-

Micro-Swiss Direct Drive Extruder for Creality Ender 5 2 Model types- Dual drive gear

- Easy filament loading

- Perfect for flexible filaments

-

BondTech Extruder BMG right- Dual-Drive

- Adjustable tension

- Versatile use

-

Micro-Swiss Bowden Dual Gear Extruder- Reliable and firm filament grip

- More accurate extrusion movements

- CNC precision gears

-

Micro-Swiss Extension Cable for Direct Drive Extruders- 67 cm long

- Inexpensive replacement

-

Micro-Swiss NG Direct Drive Extruder for Creality CR-10 and Ender 3 series- 3:1 gear ratio

- Hardened steel dual gear drive

- Short filament path

-

Artillery Direct Drive Extruder Assembly 2 Model types- Original spare part

-

E3D Hemera Direct Drive Kit - 1.75mm 2 Model types- Practical assembly

- Reliable extruder

- Unique heat sink

-

Creality Drive Gear- Original spare part

- Drivegear

-

E3D Revo Hemera 2 Model types- Including a 0.

4 mm nozzle

4 mm nozzle

- Dual gear extrusion

- Ideal for flexible materials

- Including a 0.

-

BondTech LGX Lite Large Gear Extruder- For 1.75 mm filament

- Raised filament handle

- Easy maintenance

-

Qidi Tech Extruder 5 Model types- Original spare part

- Available for different printers

-

BondTech Drivegear Kit 1.75 mm 2 Model types- CNC machined

- Made of hardened steel

-

BIQU h3 Extruder 500°C- Temperatures up to 500 °C

- Fast, efficient cooling

- Accurate printing

-

BondTech IFS Extruder for the Prusa Mini- Compatible with the filament sensor

- Hardened drive gears

- Adjustable tension

-

BIQU h3 Extruder- Reduced weight

- Premium brass nozzle

- Unique cooling system

-

BondTech Prusa i3 MK2.5S / MK3S extruder upgrade- Better quality

- Lower weight

- Optimized geometry

-

BondTech LGX Extruder 1 set- Larger drive wheels

- Multifunction interface socket

- Light and symmetrical design

-

Creality Titan Extruder Upgrade Kit 3 Model types- Constant extrusion

- Efficient heat dissipation

- No clogging

-

BondTech LGX B for Anycubic Mega X 1 set- Easy installation

- Strong filament grip

- Compact and light

-

E3D Hemera Bowden Kit - 1.75mm- Practical assembly

- Reliable extruder

- Unique heat sink

-

BondTech DDX V3 extruder for Creality- High precision

- Dual drive extruder

- More choice of print materials

-

BondTech LGX for the MK3S & Mosquito- Easy installation

- Strong filament handle

- Maintenance window

All prices incl. VAT.

VAT.

Content

-

- EXTRUSION MOUSICIZY

- Heating module and channel for heating the Philment

- COLLICATION

- SOMPLS

in TIERTIME was a lot for all materials, but, alas, this was not possible, because plastics differ greatly in their properties from each other.

Tiertime has been focusing on ABS for many years, so extruders have been optimized for this material or similar styrene-based materials such as ASA, PC-ABS, HIPS, etc.

But when people start experimenting and using different materials, a single extruder design cannot provide equally good reliability for all of them.

Therefore, we classified 3 main types of plastic extrusion behavior and designed 2 more extruders: for PLA and TPU.

Below we will explain why these 3 extruders will work better.

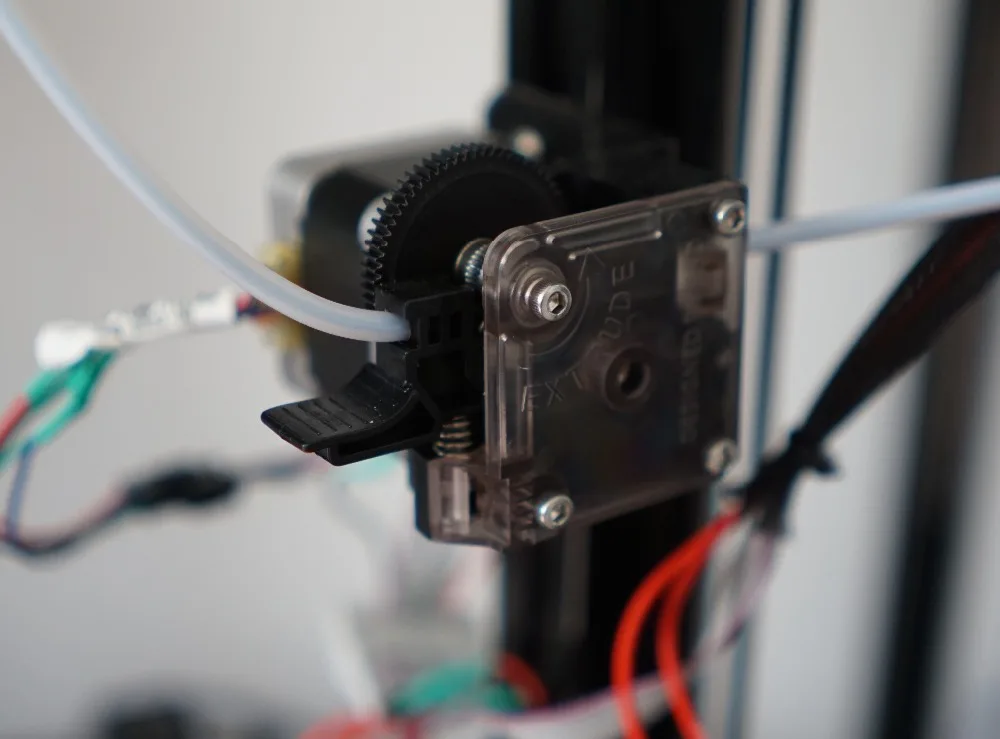

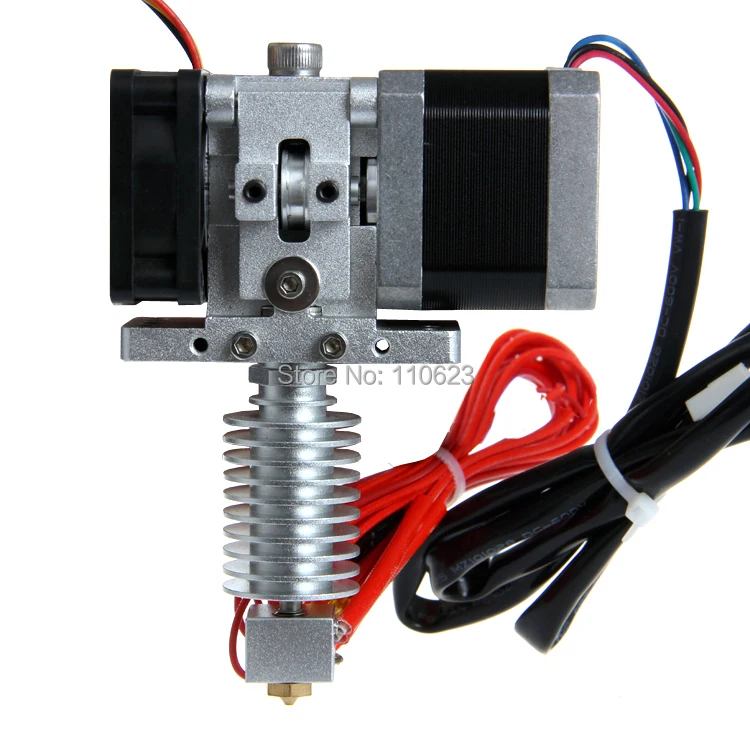

Extrusion mechanism

Extrusion mechanism for ABS and PLA is the same. The thread is fed through a fixed width gap between the feed gear and the bearing. This mechanism is well tested, very reliable and provides excellent results, provided that the diameter and hardness of the filament are controlled.

For the TPU extruder, the extrusion mechanism is spring-loaded and the feed gear is grooved because TPU or other soft material will change the diameter of the filament under pressure. These designs can effectively prevent slippage and apply maximum extrusion force.

Heating module and filament heating channel

The heating module for all 3 extruders is similar, but with slight differences.

All 3 extruders have 80W 24V heating tube and Pt100 temperature sensor. All are equipped with silver plated wires and PTFE tubing for maximum reliability.

In fact, the only difference is in the heating channel.

The heater for ABS uses a stainless steel tube, while for PLA and TPU a PTFE surface is used inside the stainless steel tube.

This is because PLA and TPU have more friction against steel, but can be effectively lubricated by PTFE.

For the TPU extruder, the extrusion channel is also completely limited, so that the soft filament will not be squeezed out of the channel when a large extrusion force is applied.

However, PTFE is a material that can only work stably at temperatures around 280 degrees. Therefore, if you print with ABS or other high temperature materials, the PTFE surface will degrade over time and reduce print reliability.

Therefore, the all-metal body ABS extruder is a good choice for long-term high-temperature operations and should also be considered for printing materials such as PA, PC, PP, etc.

Cooling

Cooling of the extruder is also a very important factor influencing print quality and reliability.

High shrinkage material such as ABS requires little or no cooling. If too much cooling is applied, the model will warp or distort, resulting in a negative result.

However, for materials with little shrinkage and a lower melting point, such as PLA, proper nozzle cooling will improve print quality sufficiently.

The temperature gradient between cold end and hot end is also critical for materials with lower melting points. When the temperature rises to the cold end, the filament may soften before entering the nozzle and cause clogging.

Given these features, Tiertime was done as follows:

- The ABS extruder uses the least amount of cooling and usually requires the door to be closed to achieve a perfect result.

- PLA requires the most cooling for the nozzle, and additional cooling is provided to the heatsink and extruder motor to prevent premature filament softening.

- Extruder cooling for TPU should be less than for PLA, but more than for ABS.

Nozzles

Tiertime produces several nozzle options, as using the right extruder nozzle can also improve print quality.

According to the company's experience, the universal nozzle diameter of 0.4mm is too small for flexible filaments, so a 0.5mm nozzle was designed for the TPU extruder, which provides better material flow, as well as perfect print quality and reliability.

For PLA and ABS, the user can choose between 0.2, 0.4 or 0.6 mm nozzles.

The 0.4mm nozzle has the widest working range, it provides good print quality for layers from 0.1mm to 0.3mm, so it can be considered as an all-rounder.

The 0.2mm nozzle is designed for high resolution precision printing and is best suited for layer thicknesses between 0.1mm and 0.05mm.

Nozzle 0.6 mm , on the contrary, is designed for printing in thick layers, starting from 0. 3 mm and above. It provides the best filament flow and maximum print speed. Some users also find that thick layers increase overall print strength, so a 0.6mm nozzle is better for support structure parts.

3 mm and above. It provides the best filament flow and maximum print speed. Some users also find that thick layers increase overall print strength, so a 0.6mm nozzle is better for support structure parts.

Also available in 0.4mm and 0.6mm hardened steel nozzle options to maintain accuracy even when printing with abrasive materials such as carbon fiber or glass fiber materials.

Techno Print 3D Company

This is our first review of the most popular and inexpensive 3D printers for 2020. The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The Chinese company Dazz3D announces the launch of the project on KickStarter and accepts pre-orders for Dazz3D Basic and Dazz3D Pro 3D printers. These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

Read more→

We all know that precise calibration of the 3D printer desktop is the foundation and the key to successful printing on any FDM printer. In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

It's hard to go through a day today without hearing about 3D printing technology, which is bursting into our lives at an incredible speed. More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

The FormLabs Form 2 and Ultimaker 3 are perhaps the most popular 3D printers today, capable of high quality printing with incredible surface detail. Moreover, these two devices use completely different technologies, and therefore, there are a lot of differences between them.