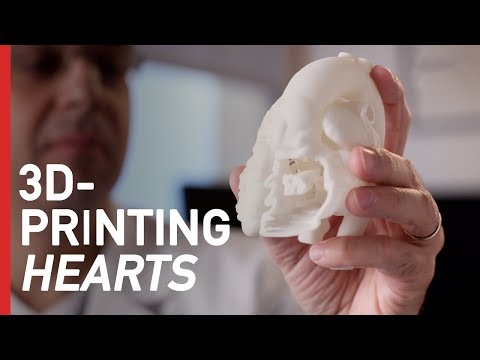

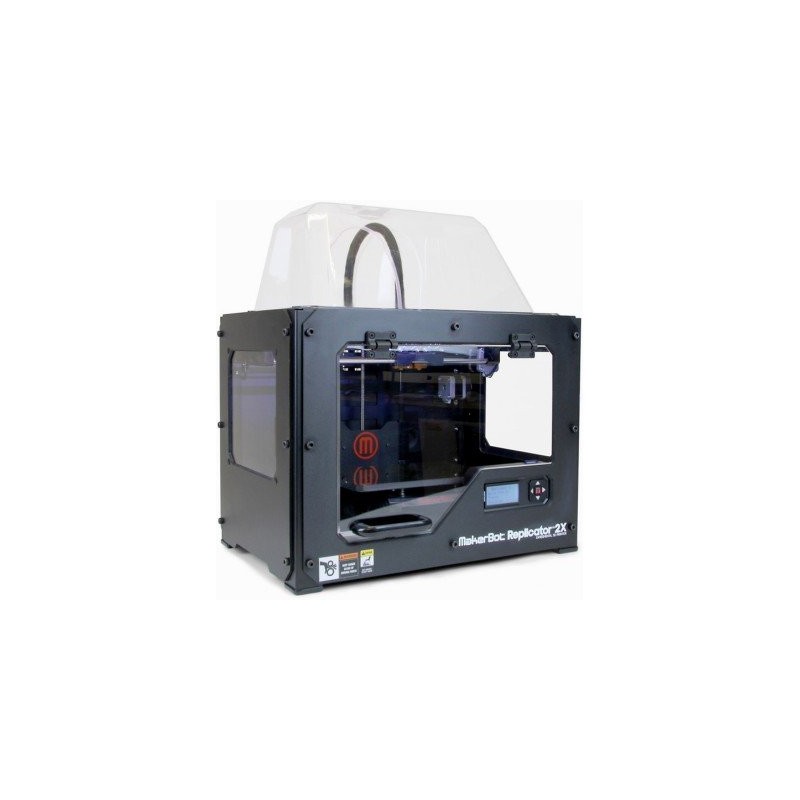

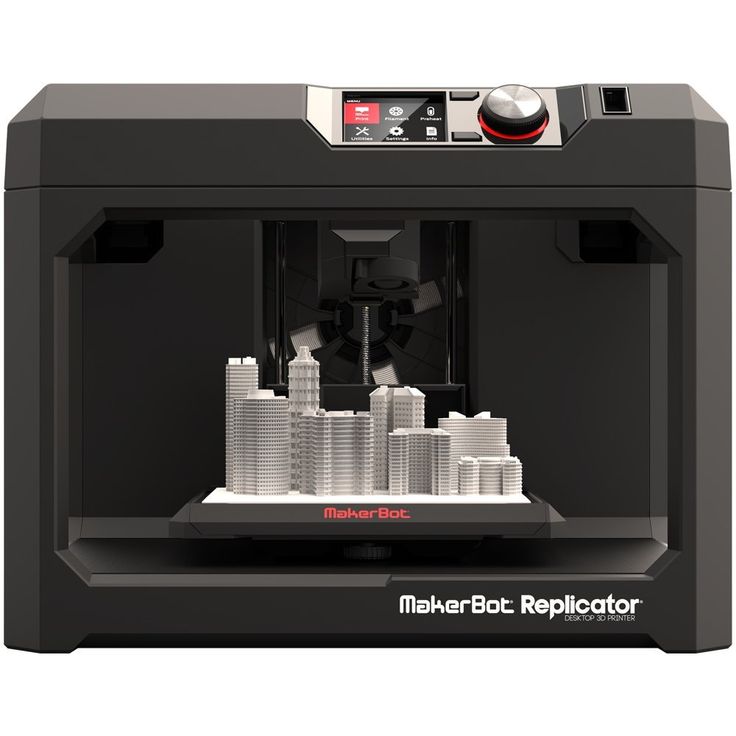

Makerbot 3d printer demo

Learn 3D Printing - Get Started With 3D Printing

Scroll down for more information about how to use your MakerBot 3D Printer and MakerBot software. For MakerBot set-up questions, go to www.makerbot.com/getstarted.

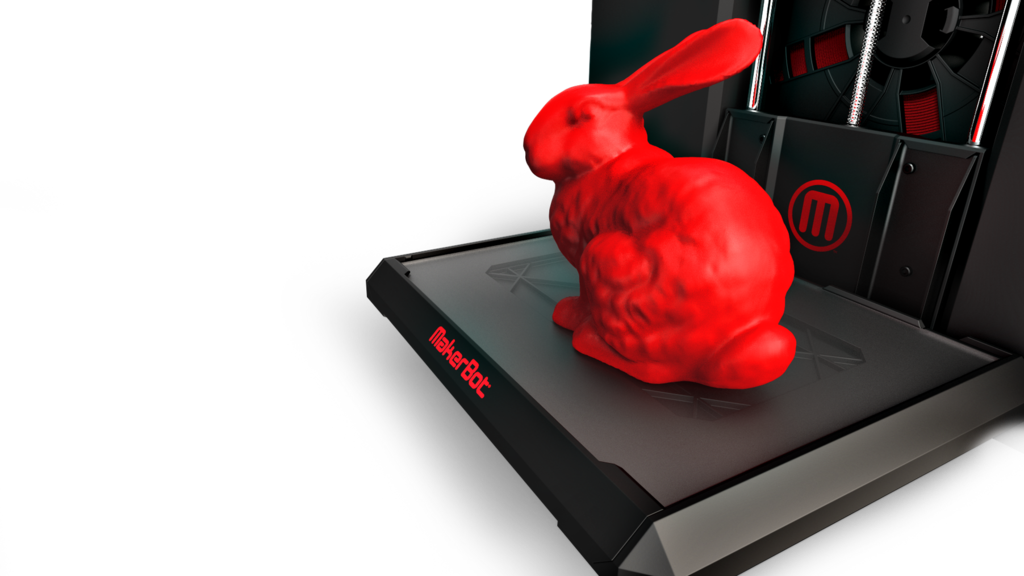

Explore the key technologies that work together to make MakerBot 3D Printers possible.

FDM or Fused Deposition Modeling

MakerBot's 3D Printers rely on a technology called Fused Deposition Modeling or FDM. It uses an extruder, which acts similar to a hot glue gun. Plastic filament is fed in through the top, is melted at 215℃, and finally is “extruded” out of a small nozzle into the layers that build a 3D print.

Cartesian Coordinates

MakerBot 3D Printers know where to move using a three dimensional cartesian coordinate system which defines every point of a 3D model with a unique position along the X, Y, and Z axes. The coordinates are fed to the printer from MakerBot Print and MakerBot Mobile.

MakerBot PLA Filament

MakerBot PLA Filament is the best and most consistent filament optimized for use in MakerBot 3D Printers. Safe for the classroom, office, or home, this filament is non-toxic and easy-to-print with minimal warping or curling.

MakerBot Tough Filament

Created for engineers and designers, MakerBot Tough Filament allows you to print durable, high-impact strength prototypes and fixtures. This filament is tested and optimized to print reliably and easily with the Tough Smart Extruder+.

To print on a MakerBot 3D Printer, you must obtain a 3D file, prepare it in MakerBot Print, and send it to your MakerBot 3D printer.

Step 1: 3D File

In order to 3D print, you must have a 3D file. Here are a few ways to get a file:

Design an object to print in a 3D modeling or CAD program.

Scan an existing object with a 3D scanner.

Find a file online from websites like thingiverse.com

Step 2: Prepare

Before sending a 3D file to your MakerBot, you must prepare the file. Preparing an object in our softwares translates your objects into a language the 3D printer can understand. This is referred to as slicing.

This is referred to as slicing.

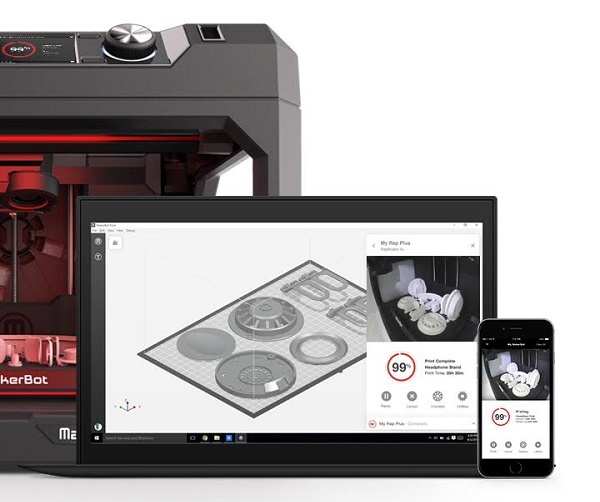

MakerBot Print

MakerBot Print is free software that optimizes and streamlines the 3D printing process. It allows you to discover, prepare, manage, and share 3D prints.

MakerBot Mobile

MakerBot Mobile is a free app that gives you the power to wirelessly set up, monitor, and control all of your network-enabled MakerBot 3D Printers over the Cloud.

Rafts and Supports

Print with Overhangs

An overhang is when a layer extends outward, potentially unsupported, over the previous layer.

If your models have overhangs greater than 68 degrees (measured from the vertical axis) for MakerBot PLA Printers, then you will need to print with support material.

What Are Rafts & Supports?

Supports are printed scaffolding for overhangs. You can turn on supports in MakerBot Print.

A Raft helps with adhesion to the build plate by laying down an even flat foundation. Rafts are turned on by default in MakerBot Print.

Rafts are turned on by default in MakerBot Print.

Completed Print

Both rafts and supports are physically removed after the print is finished. Once rafts and supports are removed, your model is complete!

Infill Percentage

Infill is the support structure inside your object. Changing Infill affects your print’s density. A higher percentage will result in a more solid object, while 0% infill will make your object hollow.

0% infill

10% infill

40% infill

Number of Shells

Shells are the outer layers that make up the surface of your prints. Adding more shells does not affect its external dimensions, but can make your object stronger.

1 Shell

2 Shells

5 Shells

Layer Height and Print Resolution

Layer Height, also known as Print Resolution, changes the surface quality of a 3D print. Low resolution means the layers are thicker, objects print faster, and the surface quality is rougher. High resolution means the layers are thinner, objects print slower, and the surface is smoother. We suggest printing at our standard print quality.

High resolution means the layers are thinner, objects print slower, and the surface is smoother. We suggest printing at our standard print quality.

Low 0.3mm (300 microns)

Standard 0.2mm (200 microns)

High 0.1mm (100 microns)

Step 3: Print

Follow these steps before printing: Attach your extruder and build plate to your MakerBot 3D Printer, then load the filament. If you have any questions about your specific model MakerBot 3D printer, please refer to the manuals at support.makerbot.com/learn

Remote Monitoring

Once a print has begun, you can monitor its progress from MakerBot Print or MakerBot Mobile. Your MakerBot 3D Printer will need to be connected to a network over Wi-Fi or Ethernet to monitor remotely.

Sanding

Learn how to sand your 3D prints to create an amazing surface finish, or prepare them for painting or silicone molding.

Painting

Learn how to create a nearly automotive quality paint job on any of your 3D prints.

MakerBot NYC Training

Get scaled up on your MakerBot 3D Printers faster with hands-on, education-specific sessions taught by MakerBot's knowledgeable, friendly experts.

MakerBot Certified Trainers

Your teachers, team, or staff can quickly learn about our products and solutions in The MakerBot Fundamentals Workshop. It's a 3-hour session conducted by a MakerBot Certified Trainer near you.

Free 3D Design Program Overview

Learn all about how 3D files are created in this overview that covers 3D scanning, popular 3D design programs, and popular websites for downloading 3D files, like MakerBot Thingiverse.

3D Design Tips and Tricks

In this webinar, Drew Lentz, a 3D design expert on the MakerBot Learning Team, offers tips on topics like overhangs, build plate orientation, print-in-place assemblies, and more.

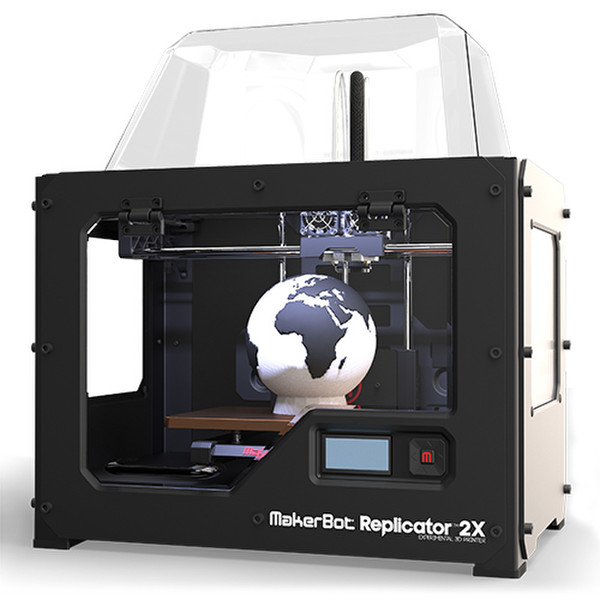

MakerBot Replicator 3D test print gallery

I attempted about 30 prints during my review of the MakerBot Replicator 3D printer. These are their stories.

These are their stories.

Rich Brown

See full bio

1 of 15 Sarah Tew/CNET

In order to print an object from a 3D printer you need a 3D model file, generally an .STL file. Where can you find .STL files? Three places. You can make one yourself, using 3D modeling software like AutoCAD or Google Sketchup. You can scan an object in the real world and convert it into a 3D model (I hope to try this soon). Lastly, you can download an .STL file someone else has made.

Following are the majority of the designs I printed (or tried to print) during the course of reviewing the MakerBot Replicator. Most I obtained through Thingiverse, MakerBot's community-driven repository of 3D object design files, all of which are available to download for free. With 15,000-plus design available on Thingiverse, I barely scratched the surface of its content.

Of the files I pulled from Thingiverse, this is the most impressive item I printed successfully. The cube-shape and the ball come out in a single print thanks to the Replicator's dual-extruder printer head (or "dualstrustion," as MakerBot likes to call it). Design by etrohn at Thingiverse.com. This would make a great cat toy.

2 of 15 Sarah Tew/CNET

The well-known geometric oddity the Klein Bottle, designed by Thingiverse user richgain.

3 of 15 Sarah Tew/CNET

I taught myself the basics of Google Sketchup with this model. I'd like to refine it so that the white lettering stands out more prominently.

4 of 15 Sarah Tew/CNET

These printed just perfectly. Designed by Thingiverse user SSS.

5 of 15 Sarah Tew/CNET

These designs came on the SD card that ships with the MakerBot. I also used these for a power drill test, as evidenced by the holes in the black and red sharks. The drill bit went into each shark well enough, but it punched through the opposite side rather roughly.

The inside of each shark is only filled 10 percent of the way to save on plastic. I'm interested to know if the bit would come out more cleanly with a denser infill.

6 of 15 Sarah Tew/CNET

MakerBot uses this design to confirm that each printer can print straight lines. You can still see some rough edges on these test samples.

7 of 15 Sarah Tew/CNET

This design, by Thingiverse user tbuser, is one of the more exciting experiments I've seen with dual extrusion. Playing with gradations like this shows how Thingiverse users are still finding new ways to explore the Replicator's creative potential.

8 of 15 Sarah Tew/CNET

Just because it looks like a duck...

9 of 15 Sarah Tew/CNET

...doesn't mean it can't also be a box. (design by Thingiverse user Ushanka)

10 of 15 Sarah Tew/CNET

High school geometry teacher (and Thingiverse user) mazels uses the MakerBot and the 3D modeling program OpenSCAD in his class to teach the concept of the z-axis, as well as some code. One of masels' students made this design.

One of masels' students made this design.

11 of 15 Sarah Tew/CNET

Another sample design on the Replicator's SD card, the Spiral Box, however neat-looking, also shows the potential for a less than perfect print. The black marks are from residue on the idle extruder that was loaded with black plastic. Let that be a lesson: clean your extruders!

12 of 15 Sarah Tew/CNET

I really wanted this chair to print well, but failed after several attempts. You can see the front leg on the left didn't form up properly. Worse, the extruder went through the motion of printing the upper rungs, but it didn't lay down any material. I'm not sure why. Still, this print shows the printer's impressive ability to string plastic across small gaps without support material. This is called "bridging."

I hope to figure out how to print this chair eventually. Its design, by Thingiverse user PrettySmallThings, is beautiful.

13 of 15 Sarah Tew/CNET

I tried and failed three times to print a workable iPhone case from a design by Thingiverse user nickfabb. I fixed the stringy print by turning up the heat on the build platform, thus making sure the base would stay in position during the print. I still can't figure how to get the sides to stick to the base.

I fixed the stringy print by turning up the heat on the build platform, thus making sure the base would stay in position during the print. I still can't figure how to get the sides to stick to the base.

14 of 15 Sarah Tew/CNET

I'm not giving up on this one. Look at this design on Thingiverse (by user bathsheba grossman) and you'll see how intricate it is.

Like some prints with large overhanging portions, the Metatron requires that you print it with a support structure, which you then break away after the print. Thankfully, the ReplicatorG software calculates the support layout for you when you have the option selected.

15 of 15 Sarah Tew/CNET

While the Metratron did print successfully, it didn't not survive my attempt to remove the support material. I suspect the fact that I reduced the size of the print by half made it more brittle. A full-size Metratron print would take over 10 hours, according to the Replicator software's estimate. I'll have to come in to work early one day.

I'll have to come in to work early one day.

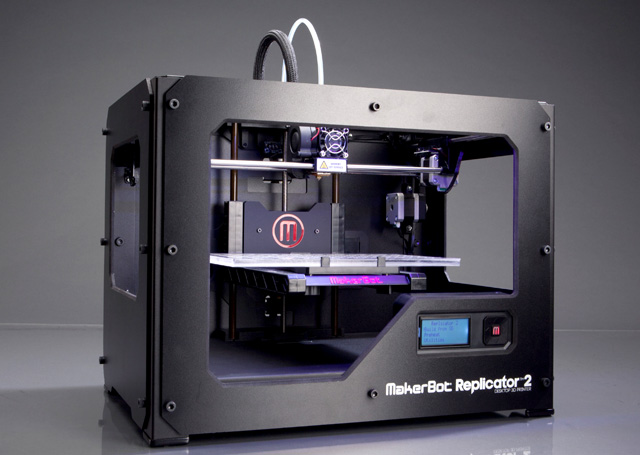

MakerBot Introduces Three New Replicator Series 3D Printers

Today November 21, 2022

About Advertising Newsletter Contacts

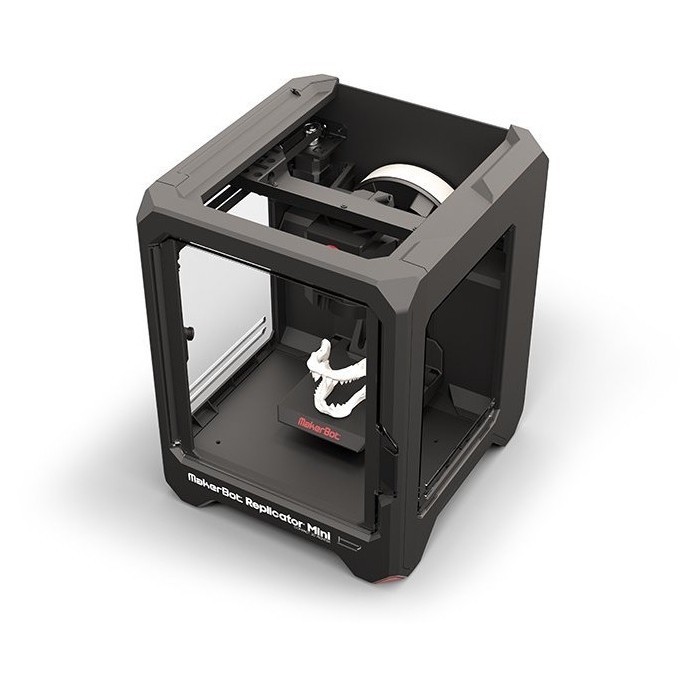

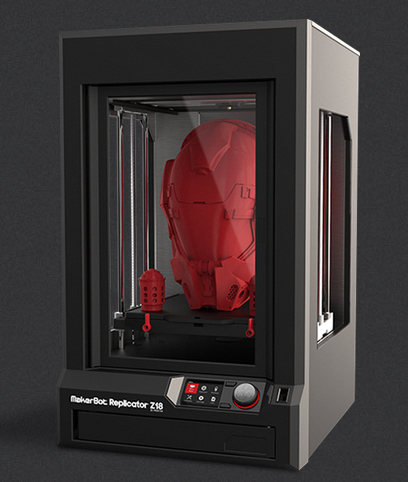

| 3DNews Technologies and IT market. CES 2014 3D Technology News: MakerBot Unveils Three New... The most interesting in the reviews 01/09/2014 [13:45], Dmitry Prikhodko Perhaps the most famous representative of the 3D printing industry and all the equipment associated with it, MakerBot also did not stand aside from the ongoing CES 2014 exhibition, presenting an updated line of its products. We have repeatedly mentioned 3D printers and scanners of this manufacturer in the news of our site. www.makerbot.com During the press conference, MakerBot representatives announced as many as three desktop 3D printers: an updated version of the MakerBot Replicator, well-known to fans of this technology, a new model - Replicator Z18 and, which is typical for all modern devices, is a miniaturized version of the Replicator Mini. “With the latest generation of Replicator 3D printers, now you won’t have to wonder whether to buy such a device or not. Now the question should be – which MakerBot printer is best for you?” commented during a press conference at CES General Director of the company Mr. Bre Pettis (Bre Pettis). www.techradar.com All three devices are equipped with wireless modules that will send a notification to the owner's mobile phone, say, when a print job has finished or the printer is running out of consumables. Also, all Replicators are equipped with a built-in camera to capture the process of creating an object and a new "smart" extruder. It is worth paying attention to each of the presented models in more detail. Replicator Mini: making 3D printing accessible to everyone This device is the entry level printer in the MakerBot line. Updated MakerBot Replicator: we develop the idea in the same vein The next novelty, if you build a new model range according to its overall parameters, is an improved version of the popular Replicator 2. Now every next updated version of the "average" representative of the 3D printer from MakerBot will not receive the next index, but will simply be supplemented with the prefix "next generation" in the model name. The 3D printer takes all the best features from the previous model and adds a 3.5-inch display to show information about the current print, such as the predicted end time of the process. Replicator Z18: 3D technology for business purposes. The last representative of the "Replicator" family was the most massive model - Z18. It is able to print a part with dimensions of 30.48 x 30.48 x 45.72 cm, which looks like a truly impressive achievement for the company. To showcase the Replicator Z18's capabilities, Mr. Pettis showed off a printer-printed Star Wars stormtrooper helmet. www.usatoday.com The main purpose of the top device from the new line will be mainly commercial. The printer can be used for prototyping large components by industrial companies like the aircraft manufacturer Lockheed Martin or even the space agency NASA. At least that's what Bre Pettis hopes. In addition, the Replicator Z18's list of features includes the ability to print multiple things at once. Thanks to the closed and heated compartment where the process of creating 3D objects takes place, the models will not be subject to deformation and will be able to maintain their exact dimensions. The price of the largest Replicator will be $6499 and will be available in Spring 2014. Companion applications for computers and mobile devices have also been announced that will be able to send a report on the printing process while you are away from home, as well as provide data on consumables and other useful information. This software is free and will be available for users of Mac, Windows and Linux platforms. As for the mobile version of the programs, they will appear for iOS this spring, and for Android a little later. www.techradar.com There was also a digital store. The company introduced MakerBot Entertainment to the public, where everyone can purchase complete models of toys that are rather complex in design. www.techradar.com By expanding its lineup, creating convenient applications for remote print monitoring and opening its online store, MakerBot demonstrates its determination to make 3D printing technology not only accessible to the public, but also as easy to understand technically. sides. Source: If you notice an error, select it with the mouse and press CTRL+ENTER. Related materials Permanent URL: https://3dnews.ru/793226 Headings: News Hardware, 3D technologies, Tags: hardware, 3d printer, makerbot replicator 2, makerbot, ces 2012, printer ← В past To the future → |

Demo

As part of the 3D Print Expo exhibition, which was held in Moscow in Sokolniki Exhibition and Convention Center in October, the editors asked what new and interesting things in the field of 3D printing and 3D scanning are offered to the consumer on the Russian market. What did the visitors see?

What did the visitors see?

3D printers

When asked about the most interesting, most of the exhibitors readily demonstrated the equipment and materials presented at the stands, including novelties from the domestic manufacturer.

The Vortex company from Surgut showed 3D printers of its own design and production: DUAL and GIANT models ( fig. 1 ). The presence of two printheads makes it possible to produce two-color parts or parts with complex supports on them, when the supports are printed with a water-soluble material, and the product is the main one. The small DUAL has a diameter of 320 mm and a print height of up to 55 cm, the large GIANT has a diameter of 55 cm and a print height of up to 95 cm. As innovative components for delta printers were identified: a fairly light head, head height switching system and a fully automated calibration system .

Fig. 1.

3D printers also with two extruders: Pro2 and Pro + 2 by the well-known Chinese developer RAISE3D - were demonstrated at the booth of Tsvetnoy Mir LLC (construction area, respectively, 305 × 305 × 300 mm and 305 × 305 × 605 mm, resolution printing - 0. 01 mm). The printers are distinguished by high productivity, as well as a wide range of materials used, which is achieved due to the special design of the extruder and its heating up to 300°C.

01 mm). The printers are distinguished by high productivity, as well as a wide range of materials used, which is achieved due to the special design of the extruder and its heating up to 300°C.

The capabilities of the Her-cules STRONG DUO printer with a new dual-extruder printhead manufactured by IMPRINTA demonstrated a unique motorcycle from Vizuit lab (a motorcycle customization company). Vizui Lab uses printing for two purposes: prototyping and testing parts before final production from metal and for printing parts that are not under load: electronics cases, decorative covers, overlays, etc. As for this printer model, it has new systems automatic calibration from nozzle height position to table plane calibration, increased positioning accuracy, plastic control system in the coil.

In the new product from Cyber, the Dragon 3D printer, the benchmark was taken for speed and quality. Printing is implemented by two independent extruders on the same X-axis. In addition to the fast switching of materials, this gave an additional function of parallel printing - two parts in the time of printing one. The closed case with a space frame provides good rigidity and allows printing with structural materials with shrinkage.

The closed case with a space frame provides good rigidity and allows printing with structural materials with shrinkage.

Two new models were presented at the Maestro booth. The goal of the little Honey printer was to make it affordable for the home, but like the base Maestro Classic, it has a filament motion sensor and table adjustment. The future flagship with two printheads was also presented. In addition to the technologies mentioned, the model provides a power backup system, a new control controller, a color screen, USB support, and a built-in Wi-Fi module. In the process of developing a remote monitoring and control system via the Internet, it is planned to install a camera to receive slides from a printed table.

New from Picasso - VC Picasso machine has a large print area of 360×360×610 mm, automatic table level, automated profile system, like all X-series printers. So far, printing is carried out with one material, but a two-nozzle version is being prepared.

The new Magnum Creative 2 printer ( fig. 2 ) has improved and simplified the process of printing with two nozzles, the switching time between which is no more than 0.5 s. For ease of use, semi-automatic calibration of the height and distance between the nozzles has been added. The updated software gives you faster speed and better print quality than the PRO model. The size of the construction area is 245×170×170 mm.

2 ) has improved and simplified the process of printing with two nozzles, the switching time between which is no more than 0.5 s. For ease of use, semi-automatic calibration of the height and distance between the nozzles has been added. The updated software gives you faster speed and better print quality than the PRO model. The size of the construction area is 245×170×170 mm.

Fig. 2.

The key feature of the new PrintBox3D White 3D printer is the fully enclosed forced draft chamber. Thus, the best temperature balance is created in the 3D printer chamber for printing with high-temperature plastics. For this model, a new extruder was developed, which has become much lighter than its predecessor. Easier cleaning process. There is a filament sensor. Working chamber size: 220×210×230 mm.

Elektroprivod presented a SkyOne 3D printer based on Koskar's mechanics ( fig. 3 ). To date, no one in the world produces such printers..jpg) What is the main advantage? The printer turned out to be quite compact with standard print settings. Removing the table, you can achieve a minimum dimension for storage. The printer has no components subject to temporary deformation.

What is the main advantage? The printer turned out to be quite compact with standard print settings. Removing the table, you can achieve a minimum dimension for storage. The printer has no components subject to temporary deformation.

Fig. 3 .

A new product on the market - a 3D printer that prints with clay, was presented by the company "Robokinetics". The company also offers Delta 3D printers with a Mixing extruder, which allows you to mix two or three filaments of the same material of different base colors in the required proportions during the printing process. Thus, shades of these colors and new colors can be obtained in the product.

At the booth of AM-KOR LLC, the official representative of XYZprinting (Taiwan), they showed the world's first affordable 3D printer with the ability to print in full color daVinci Color ( fig. 4 ), combining the processes of inkjet and 3D printing based on technology FFF (Fused Filament Fabrication). The principle of operation is as follows: an inkjet printhead applies CMYK ink to a special CPLA absorbent filament, allowing you to create products with millions of shades. The print area of this model has dimensions of 200 × 200 × 150 mm, positioning accuracy along the Z axis is 0.4 μm, along the X and Y axes is 12.5 μm, the layer thickness is 100–400 μm, which allows you to create quite voluminous and accurate full-color 3D models.

The principle of operation is as follows: an inkjet printhead applies CMYK ink to a special CPLA absorbent filament, allowing you to create products with millions of shades. The print area of this model has dimensions of 200 × 200 × 150 mm, positioning accuracy along the Z axis is 0.4 μm, along the X and Y axes is 12.5 μm, the layer thickness is 100–400 μm, which allows you to create quite voluminous and accurate full-color 3D models.

Fig. 4 .

Industrial 3D printers using FDM technology were presented by two companies Nissa Digispace — a dealer of Stratasys (the Srtatasys F370 model with a working area of 356 × 254 × 355 mm was demonstrated at the booth) and the Russian manufacturer Total Z (the model was demonstrated at the booth). ANYFORM 450 PRO with working area 450×450 mm - fig. 5 ). In addition, Maker Bot FDM printers, the Replicatior+ and Replicator 9 models, were shown at the Nissa Digispace booth.0105 Mini+ with working areas 295×195×165 mm and 101×126×126 mm, respectively.

Fig. 5.

The only SLM printer for metal printing at the exhibition was demonstrated by the domestic company OOO Exclusive Solutions (3DSLA.RU). According to the manufacturer, the platform of its own design allows you to quickly manufacture printers with any reasonable build zones (up to 900 × 900 × 1000 mm), install laser sources of different powers and create solutions with several synchronously operating scanners. These machines work not only with spherical powders, but also with non-spherical ones, which are 2-4 times cheaper. Triangulatica's own software allows you to prepare printing tables, arrange support structures in automatic mode, create printing strategies for various materials, etc.

The ISL group of companies, together with the Moscow State University of Food Production, is developing innovative 3D food printers. Various materials, modes of their supply, temperature parameters are investigated. A concept model was demonstrated at the exhibition, the first 3D printer is expected to be released within a year. Among the materials used: chocolate, icing, dough, puree.

Among the materials used: chocolate, icing, dough, puree.

And at the stand of the 3D ARTEL online store, one could already see the results of printing on coffee foam, cocktails and desserts.

And of course, there were other exhibits and exhibitors, including online stores offering Chinese equipment.

Scanners

Range 3D Vision Scanners manufactured in Russia. The user is offered two models: Spectrum and Pro. The flexible equipment is accurate and detailed and allows you to scan both miniature (less than 3 cm) and large (from 1 m) objects.

Terem3D booth demonstrated the capabilities of THOR 3D scanners ( fig. 6 ). According to the company, this is the first handheld 3D scanner that can digitize almost everything from a coin to a tractor. All you need to do is choose the right lens - one of the three. Patented hardware and software ensure the best results even when scanning complex objects with sharp edges or shiny, thin walls. Mini model accuracy up to 40 µm, Midi up to 70 µm, Maxi up to 150 µm.

Fig. 6 .

In the art gallery area, Texel presented a new version of the 3D scanner, thanks to which you can make a three-dimensional model of a person in 30 seconds. Two models were shown: the compact Texel Portal MX and the full-size Texel Portal BX.

Materials

At the booth of the manufacturing company REC, attention was paid to promising flexible materials for 3D printing: elastic Flex, similar in properties to the flexible rubber Rubber, as well as the most elastic and wear-resistant in the Sealant line, which also features high chemical resistance to oils, gasolines, alkalis and some acids.

The representative of the Print Product company first of all singled out Flex hard (resistant to ultraviolet, solvents and at the same time machined), ADS V-0 - flame retardant ABS, PC polycarbonate for printing durable products.

The company Filamentarno demonstrated a new material for printing wax models (wax). Products made from it without changing the technology can be used for any casting process, providing maximum cost reduction in the manufacture of small-scale and single products.

Other interesting materials were also shown here.

TOTAL CF‑5 carbon-filled polyurethane is a material with very low shrinkage, high temperature resistance and high wear resistance, designed for printing final products: gears, parts of mechanism cases. PROFLEX material is specially made for printing art products (such as life-size puppets presented at the exhibition). It is available in two colors and, unlike most FLEX materials, undergoes chemical post-processing. For printing lightweight structures, AEROTEX‑2 carbon-filled composite is suitable, which foams during the printing process. The density of the material after printing is about 0.8 g/cm3. In the process, it is possible to adjust the density and hardness of the structure.

Interesting applications

The company's clients were invited to work at the booth of the Russian manufacturer of materials Print Product, who illustrated various areas of 3D printing. Thus, the My3DSHoes company demonstrated the work of a factory for the production of individual shoes. In addition to printing individual insoles and other parts of shoes, the company has developed original technologies for gluing various materials to printed parts to ensure comfort.

In addition to printing individual insoles and other parts of shoes, the company has developed original technologies for gluing various materials to printed parts to ensure comfort.

Fig. 7.

Representatives of the construction industry - the companies 3DSHOP and "DUST NO" at first used additive technologies for their own needs, producing products that were difficult to purchase on the market: a casing for angle grinders for connecting to a vacuum cleaner, separators for grinders, etc. - prefabricated and collapsible products of various form and functionality. Later, a separate direction grew out of this, including an online store and the production of its own large-sized printers. An interesting development of the company was a new composite (printed mesh, covered with a thermally insulating layer such as foamed polyethylene). A sheet of this composite when heated by boiling water or dry exposure to 90 degrees can be molded. Due to the thermally insulated layer, the heated material does not burn (the temperature of the outer layer is 30–35 degrees), heat is stored inside. Moreover, the material remains plastic not for 10–15 seconds, but for a minute and a half. This is sufficient time to, for example, mold it for use in traumatology instead of the usual gypsum or expensive foreign materials.

Moreover, the material remains plastic not for 10–15 seconds, but for a minute and a half. This is sufficient time to, for example, mold it for use in traumatology instead of the usual gypsum or expensive foreign materials.

The highlight of the exhibition, of course, were the unusual exhibits of the art gallery: the Onyx dolls, the Reptiloid doll, a dinosaur with a movable jaw, a four-meter statue of a Girl with an oar.

Winners

As part of the exhibition, the list of winners of the 3D Print Expo Awards, the most influential companies of the year in the field of additive technologies, was traditionally announced. The organizers of this event are Smile Expo and SIU System.

This year the following companies were awarded nominations:

3DSYSTEMS. PRO - brand of the year;

MZTO - the best domestic manufacturer of 3D printers;

VORTEX - the best innovative company of the year;

CYBERON - the best development of the year;

TEREM 3D is the most demanded manufacturer of consumables;

RANGEVISION - Best 3D Scanning Company;

TOP3DSHOP is the best integrator of 3D equipment for additive technologies and digital manufacturing;

MAESTRO Rookie of the Year.

As part of the business program

, the exposition of the exhibition was traditionally supplemented by a rich business program, where one could not only get information, but also acquire new skills. In the lecture area, which was held with the support of RENA SOLUTIONS, they discussed novelties, changes, innovations in the field of additive technologies (Fig. 7). Among the topics of speeches are: intellectual property rights in 3D, integration of additive technologies in production, the use of 3D printing of sand

molds and models for investment casting, modeling of 3D printing processes, 3D printing with composites, etc. Round tables were held on the following topics: “Training for the industry of additive technologies”; "Best practices for the introduction of additive technologies in 2018". During the pitch session, the exhibiting companies made short presentations of their products, presented their brands and talked about the latest developments in the industry.

This range of models should satisfy the "thirst" of 3D printing fans of all skill levels, from hobbyists and beginners to professionals in the field of 3D production.

This range of models should satisfy the "thirst" of 3D printing fans of all skill levels, from hobbyists and beginners to professionals in the field of 3D production.  Its development took place taking into account the basic needs of the consumer in the most simple operation and compact size. The Replicator Mini is initially optimally tuned for speed and does not require any additional adjustments. This printer is a "one-touch printing" technology solution straight out of the box without any time-consuming setup. The Replicator Mini is priced at $1,375 and will go on sale this spring.

Its development took place taking into account the basic needs of the consumer in the most simple operation and compact size. The Replicator Mini is initially optimally tuned for speed and does not require any additional adjustments. This printer is a "one-touch printing" technology solution straight out of the box without any time-consuming setup. The Replicator Mini is priced at $1,375 and will go on sale this spring.  The work area of the new generation MakerBot Replicator has also changed, which is 11% larger than its predecessor. The device is now capable of producing 20.32cm x 25.4cm x 15.24cm 3D models. The 3D printer is now available for pre-order for $2899, and you can get it in February 2014.

The work area of the new generation MakerBot Replicator has also changed, which is 11% larger than its predecessor. The device is now capable of producing 20.32cm x 25.4cm x 15.24cm 3D models. The 3D printer is now available for pre-order for $2899, and you can get it in February 2014.

All you need is to buy the model you like and send it to print. Toys can be purchased individually, starting at $1, or as a set starting at $10.

All you need is to buy the model you like and send it to print. Toys can be purchased individually, starting at $1, or as a set starting at $10.