Botobjects 3d printer

Huge Surprise: Controversial botObjects is Acquired by 3D Systems: Technology to be integrated with new CubePro® C Printer - 3DPrint.com

In what could be seen as quite a shocker within the 3D printing space, but could also go a long way in solidifying 3D Systems’ consumer/prosumer 3D printing portion of their business, the company announced today that they have acquired botObjects. For those familiar with the 3D printing space, this announcement has to come as a bit of a surprise.

botObjects is a company that has provided a lot of hope within the consumer level 3D printing space. While this hope remained in the hearts of some, over the course of the past year to year and a half, that hope had begun to fade as many people who had pre-ordered the company’s printers began claiming that the botObjects was a scam. While botObjects claimed to be shipping printers out to those clients who had pre-ordered their machines, very few were actually getting them, and some believed that the entire company was actually some sort of hoax.

botObjects claimed that their FFF-based 3D printer could print in multiple colors, and even mix colors together during a print job, using a technology called PlasticJet Printing (PJP). While I personally confirmed this, by witnessing the printer in action at the Inside 3D Printing Conference in NY back in April, many individuals were not convinced. Some began thinking that botObjects was merely taking pre-orders, in order to run off with the money, while not actually working on manufacturing a product at all. Today comes news that will surprise even supporters of botObjects, and will certainly prove the company’s naysayers wrong.

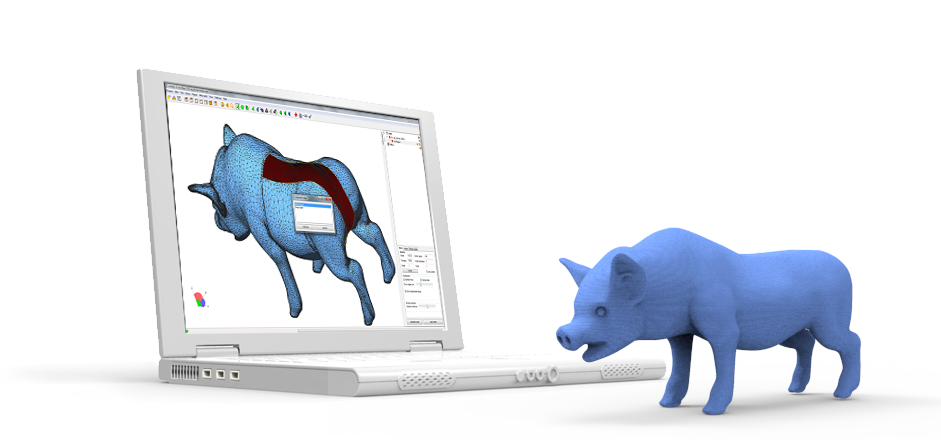

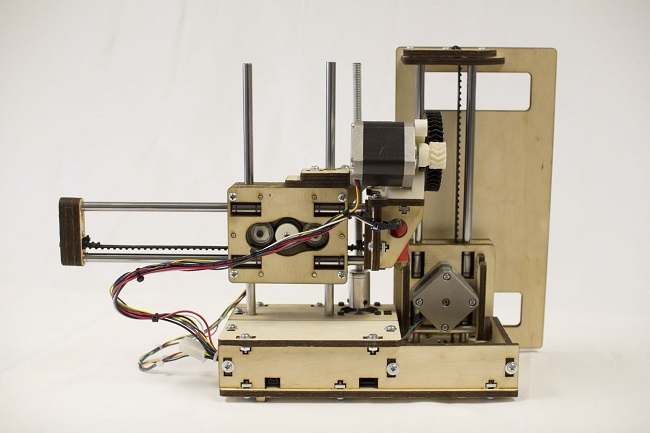

Original botObject ProDesk3D

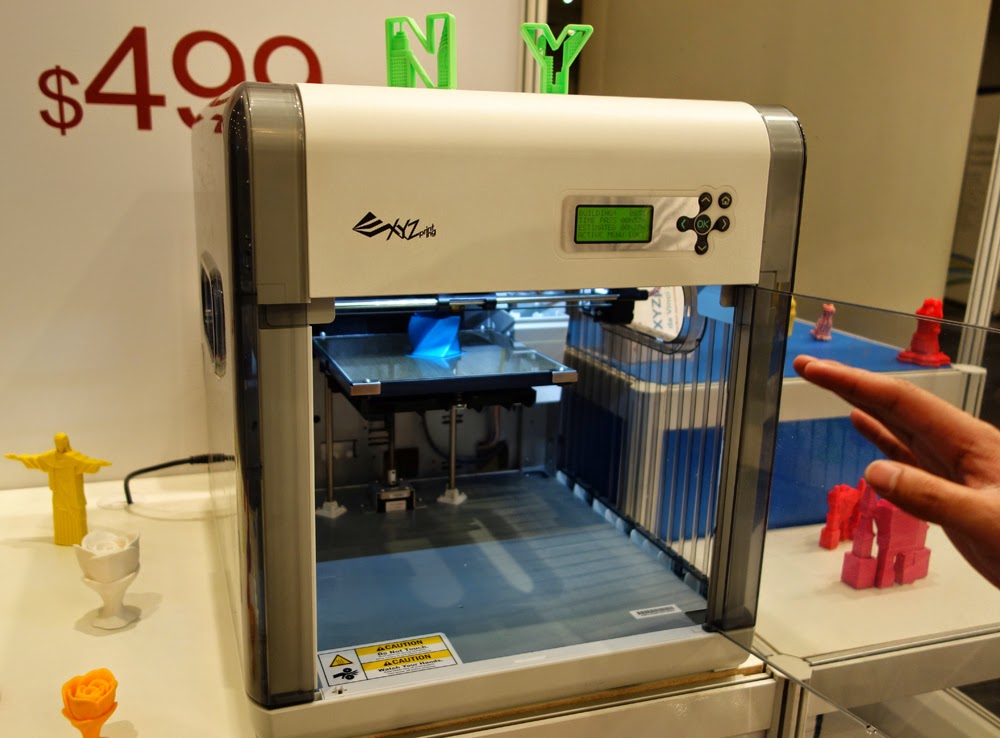

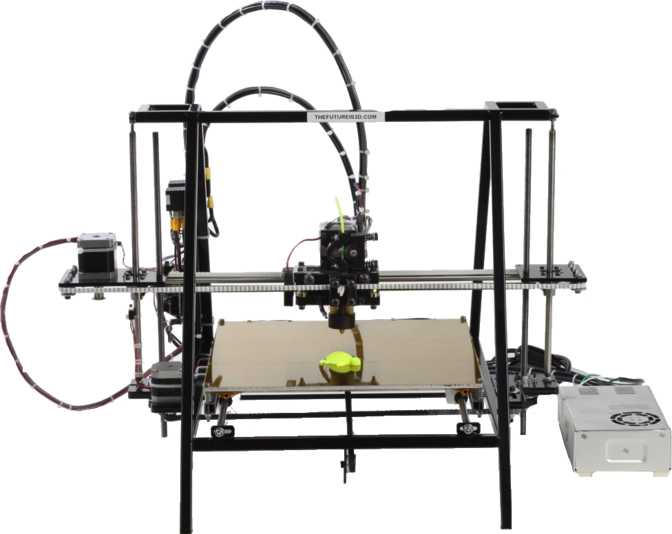

3D Systems (NYSE:DDD) today has announced that they have acquired botObjects and are using the technology behind the company’s printers in order to manufacture their own new CubePro® C Full-Color 3D Printer. While terms of the agreement were not released, those still suspicius about this technology can see it in action with their own eyes at CES 2015, where the CubePro® C Full-Color 3D Printer will be on display at the 3D Systems booth located at the Sands Expo, booth 72225.

“Joining the winning team at 3DS couldn’t have come at a better time as orders for our revolutionary full-color desktop printer continue to outstrip our resources,” explained Martin Warner, co-founder and CEO, botObjects. “Together we can bring this powerful technology to more users faster.”

The original botObjects ProDesk3D printer will be folded and the CubePro C by 3D Systems will emerge, offering a true full-color printing experience at a price tag of just $4,990. The CubePro C is capable of printing down to just 25-micron layers with speeds of up to 175mm per second, using both PLA and ABS material, as well as PVA support material.

“We are thrilled to add groundbreaking full-color with ultra thin-layer and high-speed technology from botObjects to our expanding consumer and prosumer 3D printing portfolio,” said Avi Reichental, President and CEO, 3DS. “We are even more excited to team up with botObjects founders, Martin Warner and Mike Duma, and together democratize the availability of this powerful 3D printer and accelerate its adoption globally.

”

As for those who are still awaiting pre-orders of the original ProDesk3D, the company plans to fulfill all of these orders. The CubePro C will only be available in limited supplies until they expand production later this year.

What do you think about this incredible turn of events for botObjects? Apparently this deal was in the works for some time, and perhaps was what was causing all of the significant delays and lack of communication on behalf of the company. Are you looking forward to the new CubePro C from 3D Systems? Discuss in the botObjects/3D Systems Acquisition forum thread on 3DPB.com. Check out the video of the original ProDesk 3D below.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d systems • acquisitions • botobjects • CES • ces 2015 • cubepro c • prodesk 3d

Please enable JavaScript to view the comments powered by Disqus.

BotObjects 3D printer promises huge leap forward, draws skeptics

According to BotObjects' product copy, this previously unknown hardware and software company has a revolutionary product on its hands in its new ProDesk3D 3D printer. Among other highlights, which my colleague Michelle Starr wrote about earlier this week for CNET Australia, the ability to print objects in a full range of colors from common PLA plastic would instantly put the ProDesk3D at the top of the consumer-grade printer market.

Follow along the reader comments on the various posts covering BotObjects announcement though, and you'll find a common refrain of skepticism.

"So we have computer-generated images of the printer. No images of prints. No images of the device proper. No cost. No details on the 'cartridge system'. No details on the internal mechanics (Either say 'based on the reprap pro' or say 'entirely new guide/position system'). Claiming capabilities and qualities far beyond what the most advanced/expensive devices on the market can claim," said an anonymous SlashDot poster.

Wired's Joseph Flaherty tweeted, "Lack of a proof of concept printed part is especially damning."

The most expansive doubt comes from Joris Peels, a former community manager at 3D printing bureau Shapeways, and cofounder of now-tabled 3D printing maker Origo. In a post on his blog VoxelFab entitled "My doubts about BotObjects," Peels goes through a point-by-point breakdown of BotObjects' announcement, leading off with the following:

I really want this thing to be true and real. It would be wonderful. And I will be the first to admit I was wrong and apologize profusely if this incredible idea is real. If this were a concept I would go easy on it but they say they have this device and it will be on the market in weeks. I am highly skeptical. Technically I don't think it's possible, they also don't seem to have the required knowledge of people who would have done this.

I took a cue from Peels's last point when I spoke earlier this week with BotObjects founders, Mike Duma and Martin Warner.

CNET: I've looked you both up online via Google, LinkedIn, and elsewhere. You have both been involved in Web and software development ventures, but I don't see any hardware engineering experience.

BotObjects ProDesk3D 3D printer. BotObjectsWarner: (Laughter). That's a great one. What a way to start. You're right, although I've worked with hardware vendors, this is our first foray in terms of creating a hardware venture.

CNET: Can I assume you've brought in engineers for product development?

Warner: Oh, absolutely. The composition of the team is very different from a traditional software venture, although BotObjects is also a software development company. But all of our hardware engineering has a whole different team composition to what we've done before, naturally so.

CNET: So where do those engineers come from? Are they affiliated with a university?

Warner: We're not disclosing anything about the team, because it's just not appropriate. But I can tell you they're of U.S. origin. They're out on the West Coast at the moment. And there's two engineers in the U.K. If you're asking whether they've done research for universities, the answer is 'yes.' Do they come from a university in terms of intellectual property, is this a spin-out? Absolutely not.

But I can tell you they're of U.S. origin. They're out on the West Coast at the moment. And there's two engineers in the U.K. If you're asking whether they've done research for universities, the answer is 'yes.' Do they come from a university in terms of intellectual property, is this a spin-out? Absolutely not.

CNET: Do they have 3D printing research experience?

Warner: Some have. A bunch of them are engineers from this space. You really can't step into it unless you're deep at the heart of it. It would be almost impossible.

CNET: Your spokesperson told me earlier that you're not going to discuss any product-specific details beyond those on the Web site and in the press release. Can you talk about anything that might calm some of the controversy surrounding your announcement?

Warner: I'm certainly not going to give away our press strategy or concede that we're going to preferred journalists. Keep in mind that we're just telling future customers that it's coming. If you check my background out, you'll know that we're not wasting anyone's time. The only people that have anything at risk are us, because our reputations mean a lot to us. So you'd better believe it's coming. At the outside we're talking two-and-a-half weeks before more information will become available.

If you check my background out, you'll know that we're not wasting anyone's time. The only people that have anything at risk are us, because our reputations mean a lot to us. So you'd better believe it's coming. At the outside we're talking two-and-a-half weeks before more information will become available.

Warner, who did most of the talking during the interview, went on to describe the ProDesk3D as a product that will combine both open and proprietary technologies, but he got no more specific than that. He also extended an invitation to an upcoming demonstration BotObjects will be hosting for the media here in New York. The date for that event has not yet been confirmed, but the company has said that it will being accepting pre-orders for the ProDesk 3D by June 1, and that it will release more information about the printer before it begins taking customer money.

Warner also pointed out that, alongside the comments questioning the feasibility of BotObjects' claims for the ProDesk 3D printer, the company has received an enthusiastic response from thousands of commenters worldwide, and inquiries about distribution from more than a hundred different countries.

Given the features BotObjects says the ProDesk 3D will offer: full-color PLA printing, self-calibrating build platform, 25 micron printing accuracy (four times the accuracy of the category leading MakerBot Replicator 2 and Replicator 2X), and for what the company has said will be competitive pricing, it's not surprising that 3D printing enthusiasts would be excited.

So far we have only the assurances of BotObjects founders that the ProDesk3D is a real product. Their entrepreneurial track record -- a business networking site, a film company, a recruiting service -- doesn't indicate a history of hardware product development or technology product marketing or manufacturing, but searching their prior dealings also doesn't turn up any malfeasance.

If BotObjects is a scam, this wouldn't be the first time 3D printing has seen a bad actor. A company called Massive Dynamics claimed to have a 3D printer in development, but it has since been exposed as, in all likelihood, a penny stock scam. But where equity fraud constitutes direct public harm, false claims on a Web site and in a press release are relatively harmless, at least until the pre-order button goes live.

A company called Massive Dynamics claimed to have a 3D printer in development, but it has since been exposed as, in all likelihood, a penny stock scam. But where equity fraud constitutes direct public harm, false claims on a Web site and in a press release are relatively harmless, at least until the pre-order button goes live.

At minimum, BotObjects has invited criticism by announcing the ProDesk3D and its industry-shaking features without evidence. Based on my experience reviewing a handful of printers and researching and writing about the industry, I don't find the criticism aimed at BotObjects unreasonable. It's also not impossible for major technology breakthroughs to come seemingly out of nowhere.

If the ProDesk3D is real, it could be a fantastic leap forward for 3D printing. Full-color prints in an attractive, easy-to-use product is the holy grail for this stage of the technology. I would like it to exist, and I'm choosing to remain cautiously hopeful. That position will quickly sour if BotObjects starts accepting pre-order money without substantiating its claims. We should learn more in a couple of weeks.

I would like it to exist, and I'm choosing to remain cautiously hopeful. That position will quickly sour if BotObjects starts accepting pre-order money without substantiating its claims. We should learn more in a couple of weeks.

Consumables for 3D printers. What and how to print.

Consumables for 3D printers: What and how to print? Here you will find answers to this question, as well as information about the latest materials available and in development.

xolodny

Loading

11/17/2022

621

Consumables

four

Follow author

Follow

Don't want to

As a preface:

- You ate everything again!

- I'm very sorry, I'm very hungry ...

Somehow they sent me some spools of various SolidFilament plastics for tests and reviews.

Here, here, ABS immediately went into "production", but my hands reached TPU only now, after almost 3 years.

Stosh.

I have never printed with pure TPU before, and all experience with "flex" is limited so far...

Read more

Consumables

17

Subscribe author

Subscribe

Don't want

I remember all your cracks, ePA-CF!

Until some time my acquaintance with composites of different grades was easy and cloudless. Materials always have their own specifics, but I found my own niche for each of them without any problems. There were also unsuccessful materials, but the one that will be discussed today is different. He's not bad, really. It simply should not be a composite - all this filling only harms it. However, first things first.

When in one...

Read more

Consumables

twenty

Subscribe to the author

Subscribe

Don't want

Hairy glass and children's pool

As you could see from the previous article, I am often asked to print something, if possible, designed for a direct hit by a nuclear warhead. For children, as a rule - they have comparable destructive power. So the acquaintance with the Filamentarno Total Pro GF-30 composite began with the same request.

For children, as a rule - they have comparable destructive power. So the acquaintance with the Filamentarno Total Pro GF-30 composite began with the same request.

They asked me to print the corners for the nets of an old children's pool table to replace the dead celluloid ones. At the same time setting...

Read more

Consumables

four

Subscribe to the author

Subscribe

Don't want

About two weeks ago I received new items - three-color PLA plastic from Eryone.

The manufacturer continues to increase the number of colors in the bar, and although we recently considered a two-color filament, a three-color filament is now available for sale. It gives a smoother gradient on the finished product. The basis of plastic is PLA, silk shades.

Four varieties:

• Red blue green

• Golden silver copper. ..

..

Read more

Consumables

26

Subscribe to author

Subscribe

Don't want to

Buttermilk for a catapult, or fluffy carbon fiber

My next foray into researching printing with composites began with a simple request from a little boy to fix his toy catapult. Purchased original was injection molded from ABS. It was dropped from the second floor, then ridden over with a scooter and apparently hit a couple of times with a hammer or something else hard in an attempt to repair the crack that had formed. In general, the catapult was destroyed, and in the formulation of the task, the emperor sounded ...

Read more

Consumables

40

Subscribe to the author

Subscribe

Don't want to

Trying out a pen: not a child's toy

My acquaintance with composites began with the fact that the existing Qidi I-mate S printer ceased to satisfy me. Mainly in the head and extruder parts. There is Mk10 on a Teflon tube, and printing at temperatures above 260 is impossible. In practice, this temperature is limited to rather 250 - I changed the clogged tube several times when I printed at higher temperatures. In other words, I learned to print with composites in order to print with composites - well ...

Mainly in the head and extruder parts. There is Mk10 on a Teflon tube, and printing at temperatures above 260 is impossible. In practice, this temperature is limited to rather 250 - I changed the clogged tube several times when I printed at higher temperatures. In other words, I learned to print with composites in order to print with composites - well ...

Read more

Consumables

3

Subscribe to the author

Subscribe

Don't want

In this article we will tell you about new photopolymer resins from our catalog!

Today we will move away from reviews of 3D printers and talk about consumables, namely photopolymer resins.

LIDER-3D is with you and this is a review of new photopolymer resins in our catalogue!

Contents:About brandsCreality Standard Rigid LCD UV ResinCreality Water Washable LCD UV ResineSUN Hard Tough ResinElegoo ABS-Like ResinVideo reviewSummaryWhere to buy?LIDER-3D business card. ..

..

Read more

Consumables

6

Subscribe to the author

Subscribe

Don't want

Hello everyone!

The other day I received a new series of rainbow colored PLA plastic from Eryone.

There are four colors in the new series. All colors are silk.

This series is also distinguished by coils. Eryone has completely redesigned the reels and made them out of cardboard for the purpose of working in Europe. You probably immediately remembered the products from Hi-Tech Plast and Sintec with their Deshman cartons in the form of coils.

But do not rush to swear....

Read more

Consumables

5

Follow the author

Subscribe

Don't want

Good afternoon!

Today I decided to publish a review of the prints of conventional plastics from Eryone. I mainly took unusual plastics from this manufacturer, but since there is a need for simple PETG and PLA, I decided to replenish the stocks of plastic with Erion coils from the sale of leftovers.

I mainly took unusual plastics from this manufacturer, but since there is a need for simple PETG and PLA, I decided to replenish the stocks of plastic with Erion coils from the sale of leftovers.

Today we will look at several colors of PETG.

Eryone's PETG plastic range is divided into three categories:

Monocolor

Transparent...

Read more

Consumables

eleven

Subscribe to the author

Subscribe

Don't want to

There was a need to print a wax ring to demonstrate to jewelers that it is generally possible to do it qualitatively on an FDM printer.

The only Russian-made Wax3D wax known to us from Filamentarno was chosen for printing!

Read more

- 1

- 2

- .

..

.. - 102

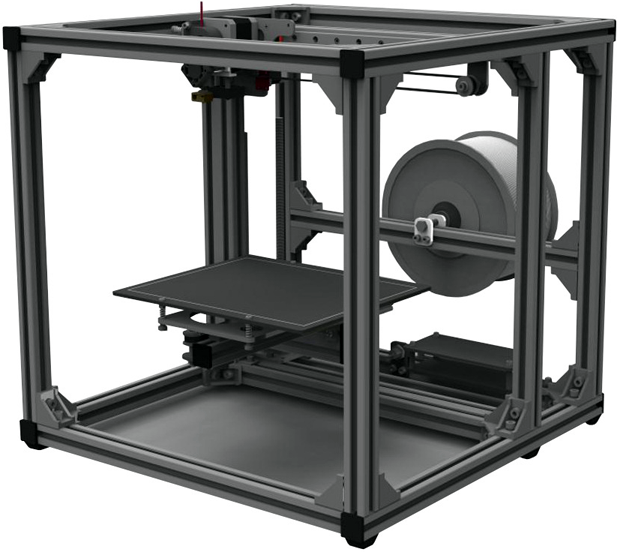

What is a 3D printer?

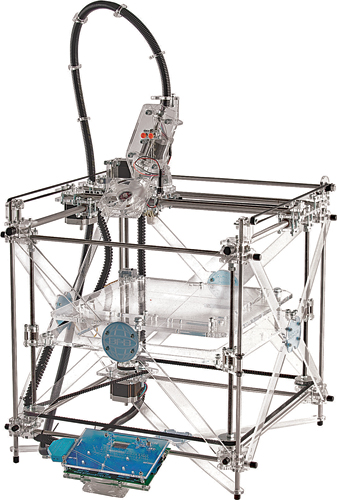

Sinterit plans to install a 3D laser sintering printer on your desktop

No desktop 3D selective laser sintering (SLS) machines have been launched on the market to date. Kits have been created, there are others in development. Add Sinterite Laser 3D Printer to the list. A startup from Krakow, Poland, presented a desktop device at Euromold 2015 with examples of printouts from the machine and the sales pitch leaving one dizzying… and a little skeptical. Why?

Kits have been created, there are others in development. Add Sinterite Laser 3D Printer to the list. A startup from Krakow, Poland, presented a desktop device at Euromold 2015 with examples of printouts from the machine and the sales pitch leaving one dizzying… and a little skeptical. Why?

Oh, things you can do

With the exception of a paper book (?), a small mechanism with moving gears and a small illegible design, we have yet to see any evidence that the machine actually makes prints, but we had the opportunity talk to Konrad Glowacki, former Software Engineer at Google, with whom we are well aware that the printer is real, is a desktop computer, and is scheduled to ship in January 2016 (March, according to the website). We wanted to know a little more about how this happened and how they can apparently do things that no one else has done.

Technical characteristics

Gabarit dimensions: 65 x 55 x 40 cm (25.6 x 21.6 x 15.7 inch)

weight: 30kg (66LBS)

LAZER 2KVT IR Type

Layer Thickness: 0. 06-0.15mm (2.4-5.9 mils)

06-0.15mm (2.4-5.9 mils)

Platen Size: 15x20x15cm (5.9x7.9x5.9in)

Maximum Print Size: 13x15cm 6.7 x 5.1 inches)

Speed (depending on model and material): 15 mm / h (0.6 in / h)

Efficiency: 30 cm³ / h (1.83 in³ / h)

Communication: Wi-Fi

Software: Sinterit Studio 2016 - print pre-processing

Cost: 6,990 euros (7,990 USD)

Detailed specifications here (pdf)

SolidSmack: How did the Sinterit SLS printer concept come about?

Konrad Glowacki: I bought the laser diode from the USA first, and some used PA12 powder. We set up a laser on a RepRap printer and 3D printed a small PLA bed to see if it would even work. It was a real pain, but during these tests we confirmed that our idea was feasible, so we started working on our first prototype.

SS: How many prototypes did you go through? What was the problem?

KG: Today we have the fifth iteration of our machine. In the process, we got stuck several times and thought about stopping this project. But each time, our friends, family, and even some acquaintances encouraged us to keep trying. We had problems with the hardware, the software (first we tried the open source slicer and control software), and finally we decided to write our own software, getting rid of all the problems with external software that kept limiting us.

In the process, we got stuck several times and thought about stopping this project. But each time, our friends, family, and even some acquaintances encouraged us to keep trying. We had problems with the hardware, the software (first we tried the open source slicer and control software), and finally we decided to write our own software, getting rid of all the problems with external software that kept limiting us.

SS: What was the turning point?

KG: It has been difficult (almost 2 years), but we are finally able to take orders, complete certification and ship the first printers in January 2016.

SS: How is it different from a do-it-yourself kit like Sinteratec?

KG: We ship a fully assembled unit with a guarantee, so it does not compare to a DIY kit from Sinteratec. We wish them all the best as we see that this market has a lot of potential and competition is always good for customers, encouraging both machines and software to release better ones over time.

Learn more