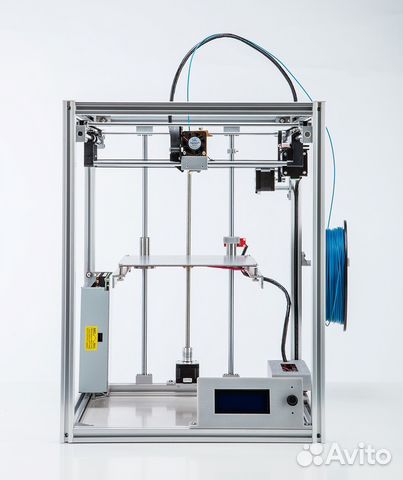

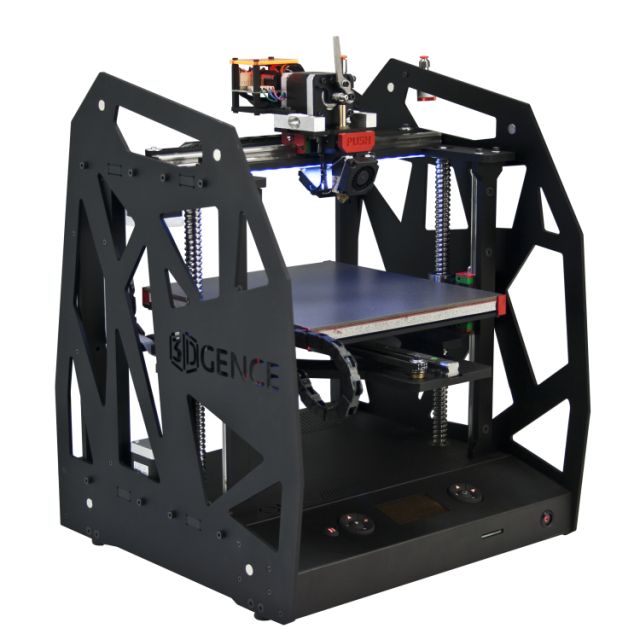

Consumer metal 3d printer

Desktop Metal Studio 3D Printer

DESKTOP METAL

STUDIO SYSTEM 2™An End-to-End Solution to 3D Print Complex Metal Parts In-HouseIntroducing the new Desktop Metal Studio 2 for metal 3D printing. The first end-to-end affordable solution for 3D printing complex metal parts in-house in a variety of metal alloys including stainless steel, copper and tool steels.

View Video Brochure Request Demo Request A Quote

- Overview

- Key Features

- Advantages

- How it Works

- Materials

- Applications

- Request a Quote

Accessible Metal 3D Printing

The Studio System 2 from Desktop Metal was created to enable engineers and design teams to produce complex metal parts faster, more accurately, and in a safe operating environment without the need for special facilities or dedicated operators. Just print and sinter; A two-step process that doesn’t require solvent debinder or tooling as in the case of MIM (metal injection molding).

Explore the Desktop Metal Studio by watching the video

Sophisticated Software

Powerful software creates build and sinter plans for every project and material. Automative supports and control parameters ensure a seamless 3D printing experience.

Maximize Productivity

3D print up to 24 cubic inches per day in a wide variety of metal materials. Maximum resolution for the printer is 50 μm

Built to Perform

The motion control system was built with encoded balls screws instead of belts, and combined with auto leveling and a heated build area you get excellent geometric fidelity and build success rates.

Affordable

Safe & Simple

Separable Supports

Precise, High-Quality Parts

Make Metal Work Faster

No more waiting for machined or cast parts. Iterate faster by printing highly complex metal parts–without leaving the office.

Iterate faster by printing highly complex metal parts–without leaving the office.

REQUEST INFO

How It WorksA metal 3D printing process in 3 easy-to-manage steps

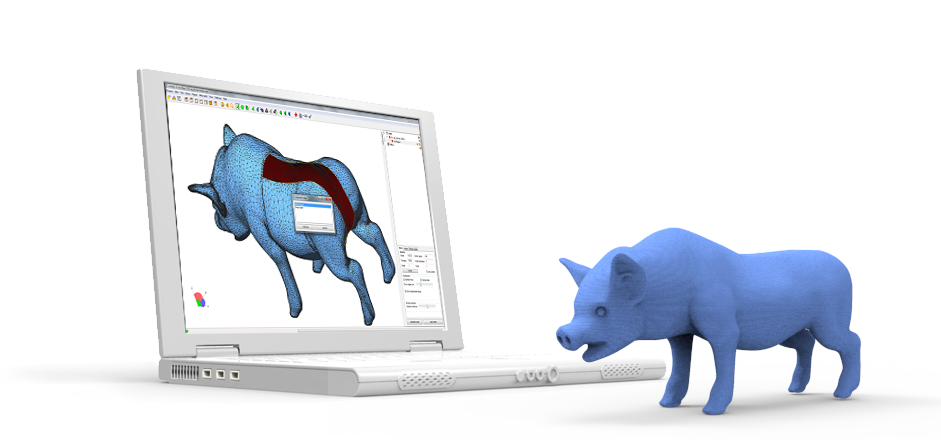

Step 1 – Prepare your files

Secure, web-based software fabricates from STL or CAD files, automatically generating supports and control parameters based on part geometry and material.

Step 2 – 3D Print

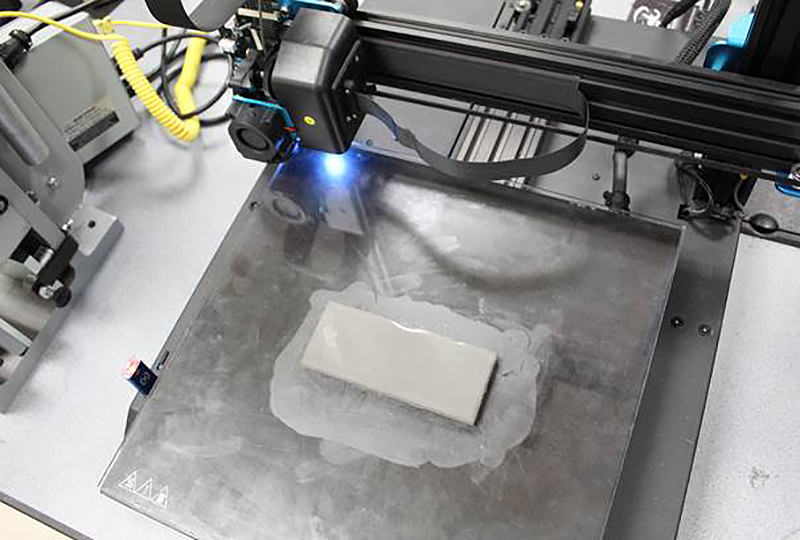

Layer by layer, a green part is shaped by extruding bound metal rods—metal powder held together by polymer binders—in a process called Bound Metal Deposition™.

Step 3 – Sinter

Once printed, parts are placed in the furnace. As the part is heated to temperatures near melting, the binder is removed and metal particles fuse together causing the part to densify up to 98%.

Introducing the new, swappable 250μm printhead that includes supporting software profiles. This enables new geometries and applications, resulting in achieving smaller parts and fine features with an improved surface.

There are camera’s everywhere, so why not put one in the in-chamber build plate? This camera captures live footage of the part as it prints, and is accessible in your web browser. Users now have complete insight of their part, and have the ability to monitor print success.

Stackable shelving is a new feature that increases part capacity of the debinder and furnace, giving greater throughput. Increased workload volume addresses bottlenecks typical at the debind sinter stages.

To achieve high quality parts, a new retort box design has been added to support thermal uniformity.

Eliminate some cost of consumables and achieve lower cost-per-part with external gas connections.

Studio Fleet is a custom and configurable metal 3D printing hardware solution for producing complex metal parts in low-mid volume.

MaterialsThe metallurgy behind the Studio System™ is built upon the material science and established powder supply chain of the metal injection molding (MIM) industry. When combined with Desktop Metal’s expansive in-house expertise in material processing, binder compounds, and metal 3D printing, the result is high-quality metal parts with affordable material costs.

When combined with Desktop Metal’s expansive in-house expertise in material processing, binder compounds, and metal 3D printing, the result is high-quality metal parts with affordable material costs.

17-4 Stainless Steel

(Studio System)

Material: 17-4 PH Stainless Steel

17-4 Stainless Steel is a precipitation hardening steel used in a wide range of industrial applications including those with mildly corrosive environments and high-strength requirements.

Specs- XY axis

- As sintered:

- Yield Strength: 695 MPa

- Ultimate Tensile Strength: 925 MPa

- Elongation at Break: 5.3%

- Hardness (HRC): 26

- Density (g/cc): 7.56

- As sintered:

- Manufacturing machinery

- Chemical processing

- Food processing

- Pump components

- Valving

- Fasteners

- Jigs and fixtures

- Bound Metal Deposition™

Learn more

316L Stainless Steel

(Studio System 2)

Material: 316L Stainless Steel

Characterized by its corrosion resistance and performance at both high and low temperatures, 316L stainless steel is a fully austenitic steel ideal for harsh environments.

- Sintered:

- Ultimate Tensile Strength: 533 MPa

- Yield Strength: 169 MPa

- Elongation: 66%

- Hardness (HRB): 66

- Density (relative): 97%

- Chemical and petrochemical processing

- Food processing

- Laboratory equipment

- Medical devices

- Marine

- Jewelry

- Power generation

- Petroleum refining

- Water treatment

- Pulp and paper manufacturing

- Bound Metal Deposition™

Learn more

h23 (Studio System 2)

Material: h23 Tool Steel

h23 tool steel is hot work steel with great hot hardness, resistance to thermal fatigue cracking, and stability in heat treatment. This makes it an ideal metal for both hot and cold work tooling applications.

Specs- Yield Strength:

- Sintered: 650 MPa

- Heat-treated: 1250 MPa

- Wrought, heat-treated: 1525

- Ultimate Tensile Strength:

- Sintered: 1325 MPa

- Heat-treated: 1720 MPa

- Wrought, heat-treated: 1950 MPa

- Elongation at Break:

- Sintered: 2.

3%

3% - Heat-treated: 5.8%

- Wrought, heat-treated: 9%

- Sintered: 2.

- Hardness:

- Sintered: 35

- Heat-treated: 45

- Wrought, heat-treated: 54

- Density:

- Sintered: ≥93.5%

- Wrought, heat-treated: 100%

- Extrusion dies

- Injection molds

- Hot forging dies

- Die casting cores, inserts and cavities

- Bound Metal Deposition™

Learn more

4140 Chromoly Steel

Studio System 2

Material: 4140 Chromoly Steel

One of the most versatile steels, 4140 steel is characterized by its toughness, high fatigue strength, and abrasion and impact resistance.

Specs- Yield Strength:

- Heat Treated: 1060 MPa

- Wrought (heat-treated): 1500 MPa

- Ultimate Tensile Strength:

- Heat Treated: 1450 MPa

- Wrought (heat-treated): 1990 MPa

- Elongation at Break:

- HeatTreated: 5.

5%

5% - Wrought (heat-treated): 10%

- HeatTreated: 5.

- Hardness (HRC):

- Heat Treated: 40

- Wrought (heat-treated): 52

- Density:

- Heat Treated: 95%

- Wrought (heat-treated): 100%

All-purpose steel industrial applications such as:

- Jigs and fixtures

- Automotive

- Bolts/Nuts

- Gears

- Steel couplings

- Bound Metal Deposition™

Learn more

Copper (Studio System 2)

Material: Copper

Copper is characterized by its electrical and thermal conductivity and ductility, and it is ideal for electrical equipment, plumbing, and heat transfer applications.

Specs- Sintered:

- Ultimate Tensile Strength: 195 MPa

- Yield Strength: 45 MPa

- Elongation: 37%

- Density (g/cc): 8.75

- Consumer and industrial electronics

- Heat exchangers

- Antennas

- Inductors

- Bound Metal Deposition™

Learn more

Ti64 (Studio System 2)

Material: Titanium Alloy

Ti64 is an alloy of titanium, aluminum, and vanadium with a high strength-to-weight ratio and corrosion resistance.

- Ultimate Tensile Strength:

- Sintered: 845 MPa

- Yield Strength:

- Sintered: 730 MPa

- Elongation:

- Sintered: 17%

- Density (Relative): 97.5%

A wide variety of high-performance applications such as:

- Specialty automotive components, including connecting rods and gearboxes for racing

- Prototyping of medical devices, including tweezers, forceps, clamps, suture instruments and more

- Consumer goods, including sporting goods and jewelry

- Bound Metal Deposition™

Learn more

IN625 Nickel Alloy (DM Studio System)

Material: Nickel Alloy Inconel 625

Inconel 625 is a high nickel super alloy ideal for harsh environments in or out of water, characterized by its excellent strength, heat & corrosion resistance.

SpecsMechanical Properties [as sintered]:

- Ultimate tensile strength (Xy): 725 MPa

- Yield strength (Xy): 303 MPa

- Elongation at Break: 34%

- Hardness (HRB): 83.

5

5 - Young’s Modulus: 199 GPa

- Density: 8.2 g/cc

- Defense

- Aerospace

- Chemical

- Nuclear

- Bound Metal Deposition

Learn More

D2 Tool Steel (DM Studio System)

Material: Corrosion Resistance Tool Steel

D2 tool steel is a versatile material that provides tooling grade strength while also offering corrosion resistance, a key benefit for conformally cooled applications.

SpecsMechanical Properties (After Quench & Temper):

- Transverse Rupture Strength (GPa): 3.1, ASTM B528

- Hardness (HRC): 56.5, ASTM E18

- Density: 7.5 g/cm³

Application

- Cutting components

- Conformally cooled injection molding inserts and cavities

- Cold forming tooling components

Learn More

Superior Properties

Similar to metal injection molding (MIM), the Desktop Metal Studio System leverages bulk sintering to achieve densities greater than 98%. Part performance is similar to wrought alloys and it is possible to tune part density with closed-cell infill.

Part performance is similar to wrought alloys and it is possible to tune part density with closed-cell infill.

Materials Available

17-4 PH Stainless

316L Stainless

h23 Tool Steel

4140 Chrome Moly

Copper

Inconel 625 Superalloy

Kovar F-15

Additional Materials: By enabling the use of metal powders from the MIM industry, our systems have access to a wide range of existing materials—from steels and aluminum to superalloys and titanium.

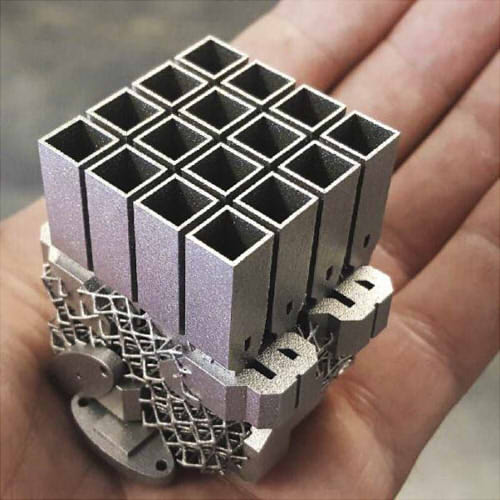

Near-Net-Shape Parts

The Desktop Metal Studio system produces near-net-shape metal parts with the accuracy and layer resolution needed for functional prototyping and a variety of other applications. A seamless 3D printing experience, from printing through to sintering, is created with powerful software and automatic support generation.

Tight Tolerances

± .002 in/in (geometry dependent)

Remove Supports by Hand

The Desktop Metal Studio system does not require any wire EDM or machining to remove support structures. Proprietary separable supports make it possible to remove support by hand because it is no bonded to the part. As a result, highly complex parts and print-in-place assemblies can be easily printed and put to use.

Proprietary separable supports make it possible to remove support by hand because it is no bonded to the part. As a result, highly complex parts and print-in-place assemblies can be easily printed and put to use.

Bring Affordable Metal 3D Printing In-House

SEE COMPATIBLE ALLOYS

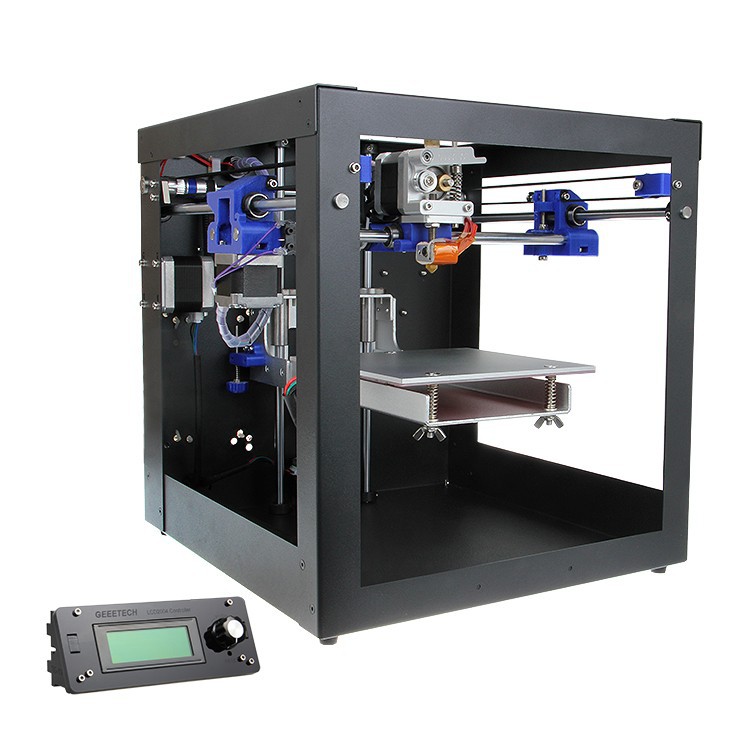

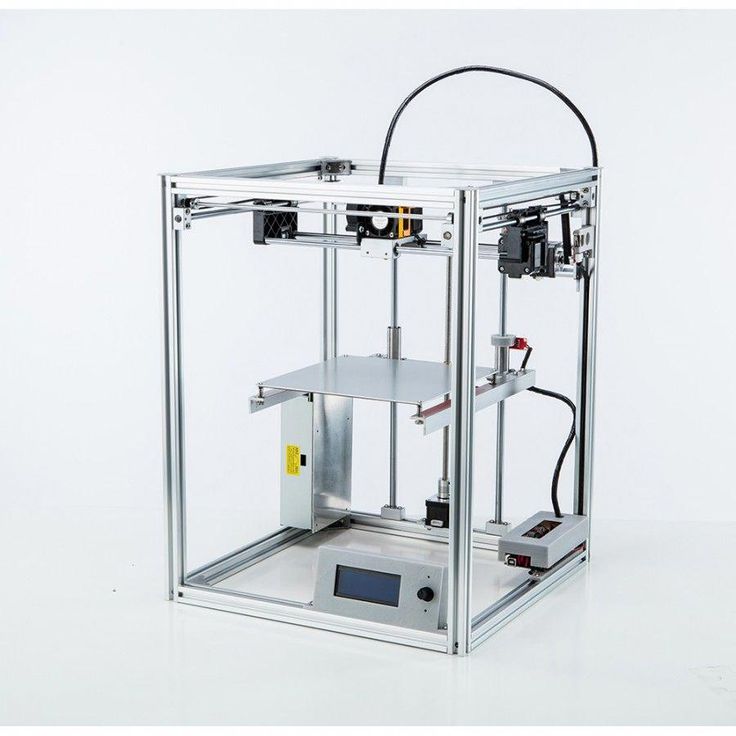

The HardwareThe Desktop Metal team designed the Studio 3D Printer to be the most accessible metal 3D printing solution to date.

With powerful web-based software, hand-removable support material, and fast material changes the

Studio System was designed from the ground up for seamless integration into your product development workflow.

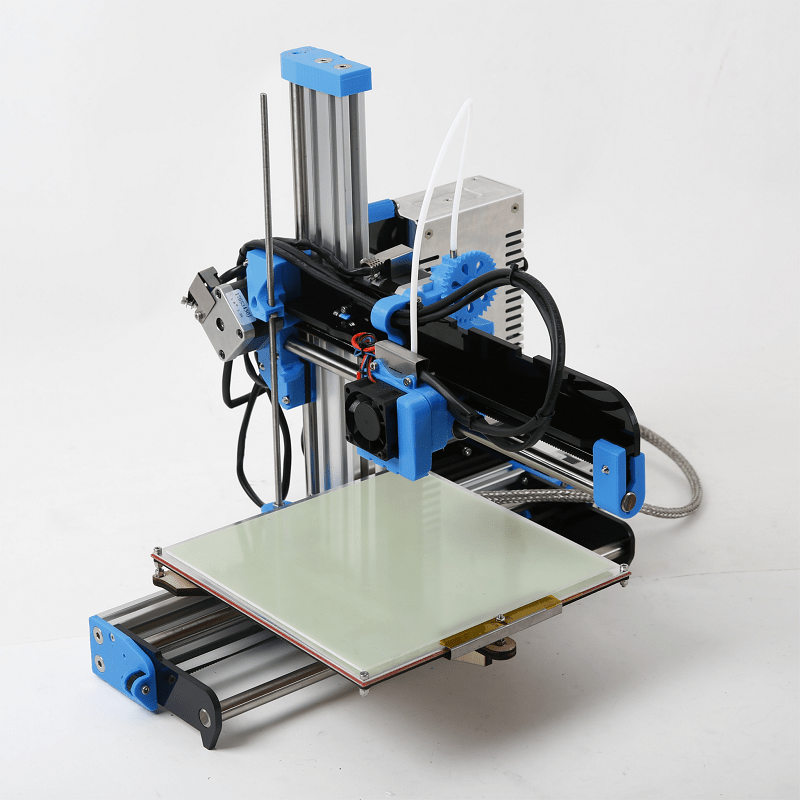

The Studio Desktop Metal 3D printer extrudes bound metal rods similar to a plastic FDM system. Unlike laser-based DMLS 3D printers that selectively bond metal powders the Studio system does not require any special safety or facility requirements and creates the opportunity to produce closed-cell infill for lightweight structures as well as work with a wider range of metal alloys.

| Build Volume | 300 x 200 x 200 mm (12 x 8 x 8 in) |

| Build Chamber | Heated |

| Extruder Assembly | Dual quick-release print heads |

| Layer height (in green state) |

|

| Nozzle diameter (Build media) |

|

Download Spec Sheet

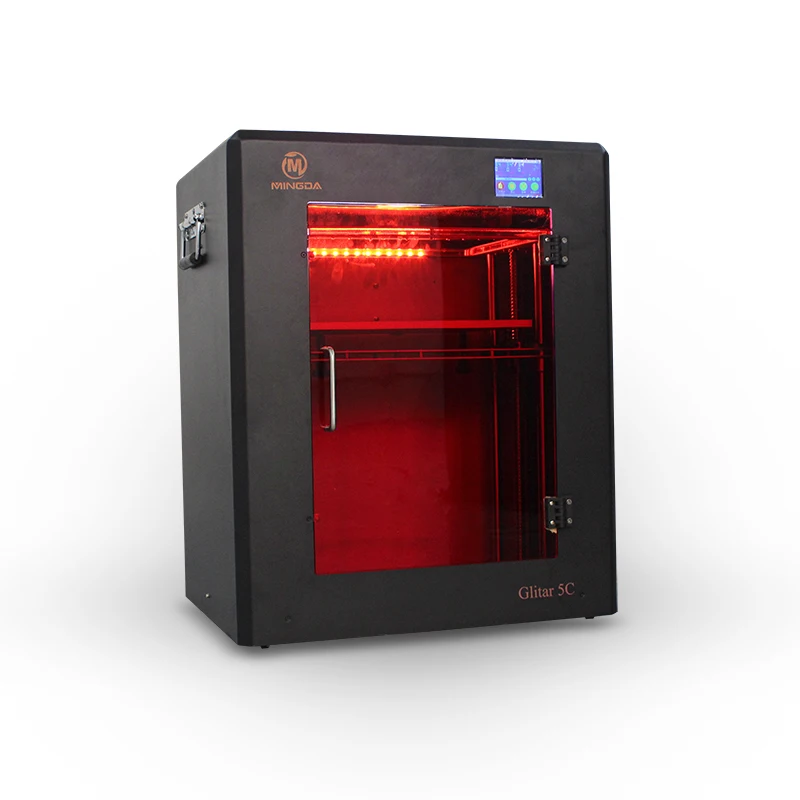

The Furnace

The Studio System 2 furnace is designed to be the easiest to use furnace ever made. It first heats parts to remove all binders, then increases the temperature to near-melting point to deliver industrial-strength sintering in an office-friendly package. Built-in temperature profiles tuned to every build and material ensure uniform heating and cooling without the residual stresses introduced in laser-based systems.

| Atmosphere | Partial-pressure sintering (vacuum-enabled) |

| Heating | SiC heating elements (4 sides) |

| Max Temperature | 1400 °C (2552 °F) |

| Workload surface area | 3,000 cm2 (465 in |

| Workload envelope | 300 x 200 x 170 mm (11.8 x 7.9 x 6.9 in) |

Download Spec Sheet

Software-Controlled Workflow

The Desktop Metal Studio system was designed as a complete workflow, with no third party equipment required. Every stage of the 3D printing process is fully automated and managed by software, making it simple to go from CAD to metal part.

Quick Material Changes

Compared to laser based systems, where material changes can pose safety risks and can take a week or more, the Studio 3D printer was designed to have swappable, safe-to-handle material catridges and quick release print heads.

Office-Friendly Sintering

A first of its kind, the sintering furnace has swappable aluminum gas canisters and optional hook ups for simple to manage gas. Built-in effluent filters, binder cold traps, safety fail safes, and detection systems make this system safe to use on the shop floor.

Expert Metallurgy Built-In

The Desktop Metal sintering oven combines unique materials profiles with part data to construct sintering plans for every part. With closed loop thermal control, real-time heating regulation throughout the sintering cycle is enabled ensuring every part is uniformly heated and cooled.

Low Volume Production with

Studio Fleet

LEARN MORE

Stainless steel, copper, and tool steels are some of the many critical allows the Studio System brings to 3D printing. Every alloy goes through meticulous qualification by world-leading materials scientists, and our core materials consistently meet or exceed industry standards.

17-4 PH Material datasheet

| 17-4 PH Stainless steel for strength and corrosion resistance | AISI 4140 low alloy, mid-carbon steel for high strength and toughness | h23 tool steel for hardness and abrasion resistance at elevated temperatures |

| 316L Stainless steel for corrosion resistance at high temps | Copper for thermal and electrical conductivity | Inconel 625 superalloy for strength and corrosion resistance at high temperatures |

Easy two-step process

Printed parts are placed directly in the furnace. No need for a solvent debind, just print and sinter.

Safety First

Odor-free and environmentally safe due to no solvent debind phase. No need for additional ventilators or respirators. Studio System 2 allows users to get the system up and running in no time.

High Quality Parts

Difficult geometry (which requires tall, thin, complex supports) is now possible thanks to new material formulations and print/sinter profiles.

Software Controlled Workflow

No metallurgist or machinist experience is required with an automated print to sinter workflow powered by Fabricate software

ApplicationsMachine Bracket

Jigs & Fixtures Titanium 64 (Ti64) Alloy

This machine bracket has been designed by using a gyroid lattice infill and titanium in place of 17-4PH stainless steel in order to reduce weight and material while maintaining the required functional strength and stiffness.

Full DescriptionIt would be impossible to produce this part’s geometry using conventional manufacturing processes due to its complexity. Moreover, 3D printing this new design on the Studio System 2 in Ti64 leads to reducing the part’s weight by 59 percent.

Ti64 for Studio System 2 produces lightweight 3D printed parts due to its high strength-to-weight ratio, thus becoming ideal for countless applications from key industries such as aerospace and defence, automotive, oil and gas, and medical.

- Estimated saving in part weight: 55-60%

- Bound Metal Deposition (BMD)™

Flower Nozzle

Industrial Equipment 316L Stainless Steel

This flower nozzle was 3D printed with Desktop Metal Studio System 2™ and it is used to atomize fluid in industrial equipment.

Full DescriptionDue to the complex geometry, this type of part would typically be cast followed by extensive secondary machining. With the Studio System 2™, the nozzle can be 3D printed without the lead times and setup costs of casting, enabling one-off and small-batch orders.

Specs- Size (mm): 123 x 123 x 45

- Cost to print ($): 184.00

Bound Metal Deposition™

Lathe Gear

Industrial Equipment 17-4 PH Stainless Steel

This part is a replacement gear for a vintage lathe. Metal 3D printing allows for the fabrication of legacy parts at a much lower cost.

In some cases, replacement parts are no longer available, either off the shelf or from the OEM (Original Equipment Manufacturer). Fabricating custom gears via hobbing and broaching is often expensive. With metal 3D printing, the manufacturing of such parts is possible at lower costs and reduced lead times.

Specs- Size (mm): 82 x 82 x 27

- Cost to print ($): 58.00

- Cost to machine ($): 260.67

- Savings vs. machining: 77.70%

Bound Metal Deposition™

APG Thread Checker Fixture

17-4 PH Stainless Steel (Studio System)

This fixture pushes a thread checker into a part on a manufacturing line. It stands for repeated use and must be easily produced to keep the manufacturing line up.

Full DescriptionThe fixture must be regularly replaced as it wears out. Printing the part with the Studio System eliminates CNC lead time and frees up the machine shop for more critical work.

- Size (mm): 47 x 28 x 15

- Cost to print: $14.00

- Bound Metal Deposition™

Tri Manifold

Manufacturing Alloy 625

This part converges three flow paths into one via internal channels. These channels would be impossible to machine and instead would need to be drilled as straight holes and plugged.

Full DescriptionPrinting on the Studio System allows these channels to be designed for their function rather than their manufacturing method. This part can be produced in just a few days with very little hands-on work.

Specs- Size (mm): 108 x 101 x 98

- Cost to print: ($) 906.00

- Cost to DMLS ($): 4069.28

- Savings vs. machining: 77.74%

Bound Metal Deposition™

Generative Piston Head

Generative Design, Prototyping 4140

Prototype piston head for a reciprocating engine, optimized with generative design. Typically CNC machined from aluminum alloy, pistons can be time-consuming and difficult to rapidly prototype and test.

Typically CNC machined from aluminum alloy, pistons can be time-consuming and difficult to rapidly prototype and test.

It often takes months or even years to move from design to production. With the Studio System, various piston designs can be easily prototyped and tested—speeding up product development timelines, reducing time to market, and introducing new opportunities for optimization, including generative design—all while avoiding CNC backlog and lead times.

Specs- Size (mm): 105 x 105 x 54

- Cost to print ($): 271.00

- Cost to machine ($): 568.13

- Savings vs. machining: 52.30%

Bound Metal Deposition™

YE6 Burner Tip

Tooling and Machinery 316L Stainless Steel

This burner tip was originally cast in the 1950s. With the Studio System, the company was able to recreate the part with properties similar to the original cast part, with no tooling cost or long lead times.

The quote for new tooling is usually in the tens of thousands of dollars. Thus, Studio System 2, a printer that was designed from the ground up for simple installation and use, allows for significant cost savings, especially when it comes to manufacturing obsolete parts at low costs and without compromising part quality.

Specs- Size (mm): 139 x 139 x 86

- Cost to print ($): 193.46

- Cost to machine: ($) 694.00

- Cost reduction: 72.00%

Bound Metal Deposition™

Helical Heat Exchanger

Manufacturing Copper

This heat exchanger enables a much higher heat transfer rate than a traditionally manufactured part. Used in chemical processing to cool a hot gas as it flows through a pipe.

Full DescriptionThe Studio System allows for the complex geometry of the heat exchanger to easily be printed as a single component. It would not be manufacturable as one component via CNC machining due to its thin external fins and a complex, internal helical cooling channel.

- Size (mm): 78 x 64 x 58

- Cost to print ($): 443.00

- Cost to machine ($): 2138.00

- Cost reduction: 79.28%

Bound Metal Deposition™

Zipper Mold

Material: h23 Tool Steel

This part is an injection mold insert for manufacturing zinc zippers.

Full DescriptionThe 3D printing of the mold inserts shortens production run lead time and allows rapid iteration and refinement of zipper designs. Using a high-resolution printhead allows for smaller parts with finer features, requiring less post-processing.

SpecsSize (mm): 46 x 27 x 18

Cost to print ($): 16.00

Bound Metal Deposition (BMD)™

Studio System™ | Desktop Metal

_Studio System™ applications

Studio System™ applications span a variety of industries including manufacturing, tooling, automotive, consumer, electronics, and oil & gas.

-

Extrusion Die

h23This die is used in the manufacture of extruded plastic framing.

Extrusion Die

-

Size (mm) 74 x 74 x 56

Cost to print ($) 156.00

Cost to machine ($) 329.67

Cost reduction 52.68%

-

Metal 3D printing reduces lead times and costs - allowing for rapid iteration and refinement of the die design. Furthermore, lower tooling costs and lead times makes low volume custom extrusion dies economically feasible.

-

Rook Chess Piece

316LOne of six types of movable objects used in the game of chess.

Rook Chess Piece

-

Size (mm) 46 x 46 x 72

Cost to print ($) 46.00

Cost to machine ($) 329.67

Cost reduction 52.68%

-

Unique chess piece designs can easily be 3D printed without the long lead times and costs associated with tooling. The Studio System’s high resolution print head produces small parts with fine features and surface finish.

-

YE6 Burner Tip

316LThis burner tip is used to shape the flame in industrial burners.

YE6 Burner Tip

-

Size (mm) 139 x 139 x 86

Cost to print ($) 193.46

Cost to machine ($) 694.00

Cost reduction 72.00%

-

This burner tip was originally cast in the 1950s, and the tooling has since been lost for it. When a customer needed a replacement, the quote for new tooling was in the tens of thousands of dollars.

With the Studio System, the company was able to recreate the part with properties similar to the original cast part, with no tooling cost or long lead times for the customer.

-

Putter

17-4 PHCustom designed golf putter is an example of the customization that is possible with 3D printing.

Putter

-

Size (mm) 135 x 92 x 38

Cost to print ($) 128.00

Cost to machine ($) 2203.00

Cost reduction 94.00%

-

Golf clubs, especially putters, are typically cast or machined.

With the Studio System, manufacturers can achieve excellent material properties without tooling or expensive CNC machining.

With the Studio System, manufacturers can achieve excellent material properties without tooling or expensive CNC machining. The Studio System allows for customization of parts like putters, so each player can have a design that is best suited to them. And when those designs go into mass production, they can be manufactured via binder jetting.

-

Flower Nozzle

316LThis flower nozzle is used to atomize fluid in industrial equipment.

Flower Nozzle

-

Size (mm) 123 x 123 x 45

Cost to print ($) 184.

00

00 -

Due to its complex geometry, these parts would typically be cast followed by extensive secondary machining. With the Studio System, the nozzle can be 3D printed without the lead times and setup costs of casting, enabling one-off and small batch orders.

-

Impeller

316LThis impeller is used to control the pressure and flow of fluids in equipment like pumps and compressors.

Impeller

-

Size (mm) 82 x 82 x 28

Cost to print ($) 63.

00

00Cost to machine ($) 2138.00

Cost reduction 97.05%

-

Their complex vanes make impellers expensive and difficult to manufacture. When a custom impeller is needed metal 3D printing accelerates design optimization and product development by dramatically reducing lead time and cost.

-

Sheet Metal Embosser

4140This custom embosser is used in sheet metal fabrication.

Sheet Metal Embosser

-

Size (mm) 47 x 28 x 15

Cost to print ($) 14.

00

00 -

Sheet metal tools are used for a broad range of fabrication operations, including stamping, bending, countersinking and embossing.

3D printing with the Studio System reduces tool fabrication costs, shortens production run lead time, and enables rapid iteration and refinement of the sheet metal designs and associated tooling.

-

Zipper Mold

h23This part is an Injection mold insert for manufacturing zinc zippers.

Zipper Mold

-

Size (mm) 46 x 27 x 18

Cost to print ($) 16.

00

00 -

3D printing the mold inserts shortens production run lead time and allows rapid iteration and refinement of zipper designs. Using a high resolution printhead allows for smaller parts with finer features, requiring less post processing.

-

Skateboard Truck

17-4 PHThis part attaches wheels to a skateboard deck, and was optimized using generative design tools

Skateboard Truck

-

Size (mm) 201 x 76 x 52

Cost to print ($) 161.

00

00Cost to DMLS ($) 1163.00

Cost reduction 86.00%

-

Generative design and 3D printing allows for the fabrication of innovative designs impossible with casting (the traditional production method for skateboard trucks).

The Studio System can print that previously impossible geometry, resulting in trucks that are more aesthetically pleasing, stronger, and lighter.

-

Master Drilling Sun Gear

17-4 PHThis part is a sun gear used in a planetary gearbox for an earth-drilling machine.

Master Drilling Sun Gear

-

Size (mm) 118 x 118 x 118

Cost to print ($) 658.

00

00Cost to machine ($) 916.00

Cost reduction 28.17%

-

After exploring a number of alternative manufacturing methods to produce the parts needed to keep crucial machinery up and running, Master Drilling chose 3D printing. The switch to 3D printing cut their lead time for replacement parts from about three months for off-shore castings, to just three weeks printing on-site, thereby reducing downtime for the earth drilling equipment.

-

Mouthpiece Mold

h23Mold insert is used to injection mold medical inhaler mouthpieces.

Mouthpiece Mold

-

Size (mm) 104 x 93 x 48

Cost to print ($) 345.00

Cost to machine ($) 716.77

Cost reduction 51.87%

-

3D printing the hard steel insert to near-net shape eliminates 95% of the required CNC machining and associated tool wear.

Because cooling accounts for 95% of the mold cycle time, the ability to incorporate conformal cooling channels into the mold can reduce mold cycle time and increase throughput.

-

UMC End Effectors

17-4 PHThese grippers are used to fixture and move aerospace forgings on a manufacturing line.

UMC End Effectors

-

Size (mm) 55 x 32 x 16

Cost to print ($) 23.00

Cost to machine ($) 194.00

Cost reduction 88.14%

-

The complex geometry of end effectors requires extensive CNC machining, resulting in long lead times that occupy valuable CNC capacity.

Using metal 3D printing allows for on-demand manufacturing of custom end effectors while lowering part cost and lead time.

Using metal 3D printing allows for on-demand manufacturing of custom end effectors while lowering part cost and lead time.

-

APG Thread Checker Fixture

17-4 PHThis fixture pushes a thread checker into a part on a manufacturing line.

APG Thread Checker Fixture

-

Size (mm) 47 x 28 x 15

Cost to print ($) 14.00

-

This fixture pushes a thread checker into a part on a manufacturing line.

As a wear item, it needs to stand up to repeated use, and must be easily produced to keep the manufacturing line up.

As a wear item, it needs to stand up to repeated use, and must be easily produced to keep the manufacturing line up.The fixture must be regularly replaced as it wears out. Printing the part with the Studio System eliminates CNC lead time and frees up the machine shop for more critical work.

-

BattleBots Bot Support

17-4 PHThis part is a structural member for use in the bot's robotic arm.

BattleBots Bot Support

-

Size (mm) 130 x 117 x 64

Cost to print ($) 106.

00

00Cost to machine ($) 551.90

Cost reduction 81.00%

-

This support is designed to carry a heavy load and withstand punishment. Engineers working on a bot used on a Discovery Channel program BattleBots had less than a month to produce a custom structural element on robotic arm. Using the Studio system, they were able to print a bracket capable of resisting bending and lateral motion while providing the stiffness, strength, weldability and fire resistance required.

-

APG Chuck Jaws

h23This part is used to hold a workpiece in place during machining lathe operations.

APG Chuck Jaws

-

Size (mm) 84 x 78 x 42

Cost to print ($) 117.00

Cost to machine ($) 426.36

Cost reduction 72.56%

-

These chuck jaws closely match the geometry of the part being machined - making them complex to machine. Printing them using the Studio System eliminates CNC lead time and frees up the machine shop for more critical work.

-

O-Ring End Effector

17-4 PHThis end effector is used to stretch and install O-rings on a hydraulic fitting.

O-Ring End Effector

-

Size (mm) 42 x 13 x 17

Cost to print ($) 7.00

Cost to machine ($) 152.17

Cost reduction 95.40%

-

Small, detailed parts like these end effectors typically require expensive CNC machining and have long lead times. Using the Studio System’s high resolution (250μm) printhead allows manufacturers to print small parts with fine features which would be difficult to machine

-

APG Coining Fixture

h23This fixture is used to achieve critical tolerances on metal injection molded (MIM) parts.

APG Coining Fixture

-

Size (mm) 110 x 57 x 31

Cost to print ($) 92.00

Cost to machine ($) 392.00

Cost reduction 75.63%

-

Fixture like this require custom geometry for each application, as well as superior wear resistance. The faster these parts are manufactured, the quicker a company can get get manufacturing lines running.

Printing these parts with the Studio System eliminates CNC lead time and frees up the machine shop for more critical work.

-

Helical Heat Exchanger

CopperUsed in chemical processing to cool a hot gas as it flows through a pipe.

Helical Heat Exchanger

-

Size (mm) 78 x 64 x 58

Cost to print ($) 443.00

Cost to machine ($) 2138.00

Cost reduction 79.28%

-

This heat exchanger enables a much higher heat transfer rate than a traditionally manufactured part.

Featuring thin external fins and a complex, internal helical cooling channel, this exchanger would not be manufacturable as one component via CNC machining.

Featuring thin external fins and a complex, internal helical cooling channel, this exchanger would not be manufacturable as one component via CNC machining. The Studio System allows for the complex geometry of the heat exchanger to easily be printed as a single component.

-

UHT Atomizer

316LThis part is a fuel atomizer for a steam boiler on a liquid natural gas (LNG) tanker.

UHT Atomizer

-

Size (mm) 74 x 74 x 71

Cost to print ($) 129.

00

00Cost to DMLS ($) 1089.00

Cost reduction 88.00%

-

This 3D printed atomizer features complex internal channels and oblong shaped holes, which could not be manufactured with traditional methods. With the Studio System, the engineers were able to radically redesign their conventional atomizers for significantly better performance.

-

Octopus Ring

316LExample of the unique jewelry that can be customized and scaled for a tailored fit.

Octopus Ring

-

Size (mm) 38 x 38 x 30

Cost to print ($) 14.

00

00 -

Unique jewelry pieces can be 3D printed without the design lock-in, long lead times and costs associated with tooling. The Studio System’s high resolution print head produces small parts with fine features and surface finish.

-

Lathe Gear

17-4 PHThis part is a replacement gear for vintage (circa 1940) lathe.

Lathe Gear

-

Size (mm) 82 x 82 x 27

Cost to print ($) 58.

00

Cost to machine ($) 260.67

Savings vs. machining 77.70%

-

In some cases, replacement parts are no longer available, either off the shelf or from the OEM. Fabricating custom gears via hobbing and broaching is often prohibitively expensive, but metal 3D printing allows for the fabrication of legacy parts at much lower cost.

-

Tri Manifold

Alloy 625This manifold is used to combine three flows into one common flow.

Tri Manifold

-

Size (mm) 108 x 101 x 98

Cost to print ($) 906.

00

Cost to DMLS ($) 4069.28

Savings vs. machining 77.74%

-

This part converges three flow paths into one via internal channels. These channels would be impossible to machine, and instead would need to be drilled as straight holes and plugged.

Printing on the Studio System allows these channels to be designed for their function rather than their manufacturing method. This part can be produced in just a few days with very little hands on work.

-

Generative Piston Head

4140Prototype piston head for a reciprocating engine, optimized with generative design.

Generative Piston Head

-

Size (mm) 105 x 105 x 54

Cost to print ($) 271.00

Cost to machine ($) 568.13

Savings vs. machining 52.30%

-

Typically CNC machined from aluminum alloy, pistons can be time consuming and difficult to rapidly prototype and test - often taking months or even years to move from design to production.

With the Studio System, various piston designs can be easily prototyped and tested—speeding up product development timelines, reducing time to market, and introducing new opportunities for optimization, including generative design—all while avoiding CNC backlog and lead times.

-

Pump Housing

17-4 PHThis is part of the housing for a hydraulic pump.

Pump Housing

-

Size (mm) 136 x 131 x 47

Cost to print ($) 243.00

Cost to machine ($) 708.68

Savings vs. machining 65.68%

-

This part would typically be cast, followed by secondary machining operations - resulting in long lead times and high costs.

By printing on the Studio System, the long lead time associated with casting can be avoided, and the cost to machine from scratch is greatly reduced - allowing the manufacturer to produce the part in-house and enabling cost-effective rapid design iteration and pilot runs.

-

Guitar tailpiece

17-4 PHThe guitar tailpiece anchors one end of the guitar strings.

Guitar tailpiece

-

Size (mm) 127 x 28 x 20

Cost to print ($) 36.00

Cost to machine ($) 343.

28

28Savings vs. machining 89.51%

-

The guitar tailpiece is typically cast from aluminum, and can be fairly expensive to customize for short manufacturing runs.

Printing in steel allows design freedom and part customization while eliminating tooling costs. Steel tailpieces also exhibit more pleasing resonance and sustain characteristics for some genres and playing styles.

-

Cuff Ring

316LExample of the unique jewelry that can be customized and scaled for a tailored fit.

Cuff Ring

-

Size (mm) 59 x 54 x 80

Cost to print ($) 43.

00

00 -

Unique jewelry pieces can be 3D printed without the design lock-in, long lead times and costs associated with tooling. The Studio System’s high resolution print head produces small parts with fine features and surface finish.

technologies, equipment, materials and new opportunities

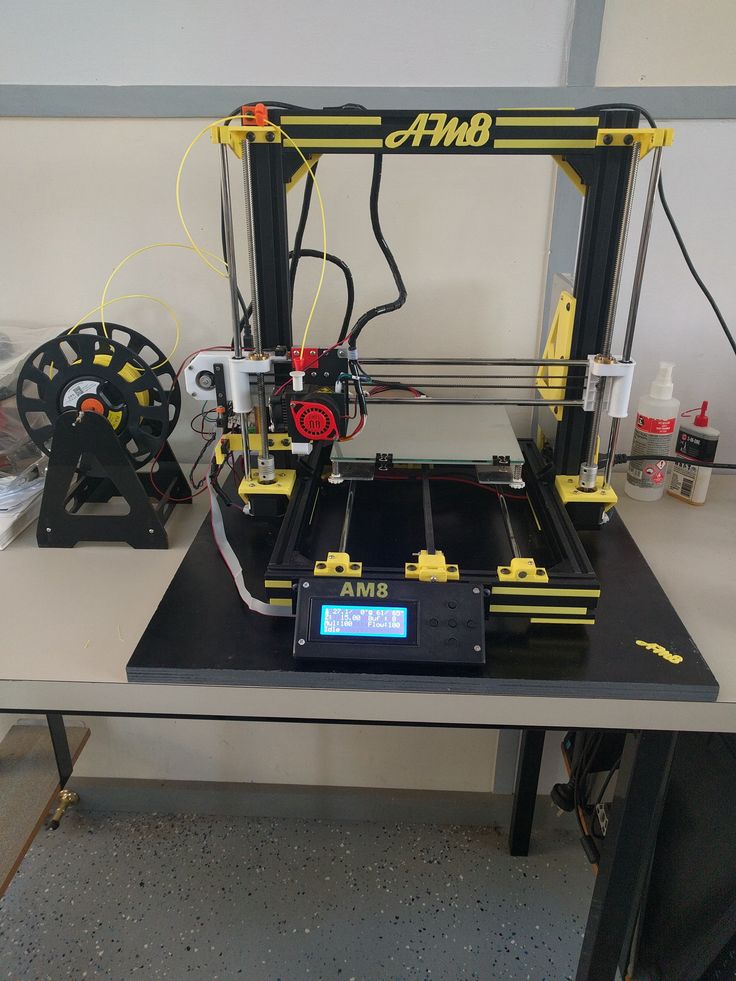

There is no hotter trend in 3D printing today than metal. We will talk about metal printing at home, how it is done on an industrial scale, about technologies, applications, printers, processes, prices and materials. Over the past few years, 3D metal printing has been actively gaining popularity. And this is quite natural: each material offers a unique combination of practical and aesthetic qualities, can be suitable for a wide range of products, prototypes, miniatures, decorations, functional details and even kitchen utensils. The reason metal 3D printing has become so popular is because the printed objects can be mass-produced.

The reason metal 3D printing has become so popular is because the printed objects can be mass-produced.

In fact, some of the printed parts are just as good (if not better) than those made by traditional methods. In traditional production, working with plastic and metal can be quite wasteful - there is a lot of waste, a lot of excess material is used. When an aircraft manufacturer makes metal parts, up to 90% of the material is simply cut off. 3D printed metal parts require less energy and waste is reduced to a minimum. It is also important that the final 3D printed product is up to 60% lighter than a traditional part. Billions of dollars could be saved in the aviation industry alone—mainly through weight savings and fuel savings. So, what do we need to know about metal 3D printing?

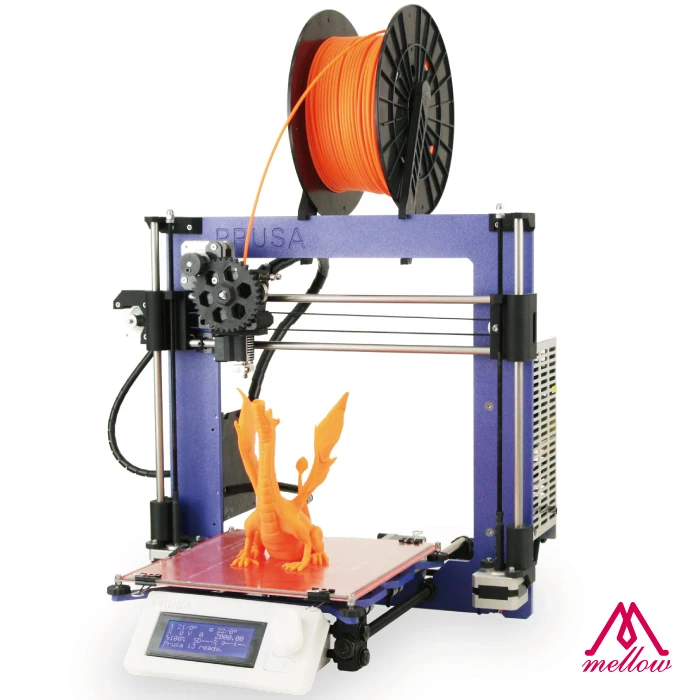

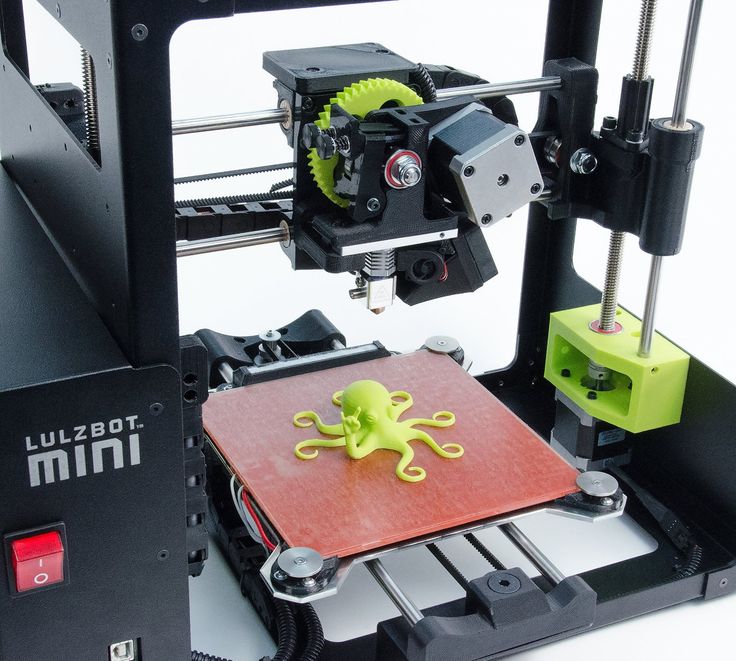

3D printing with metal at home

If you want to make objects at home that will look like metal, your best bet is to look at metalized PLA filaments (Photo: colorFabb)

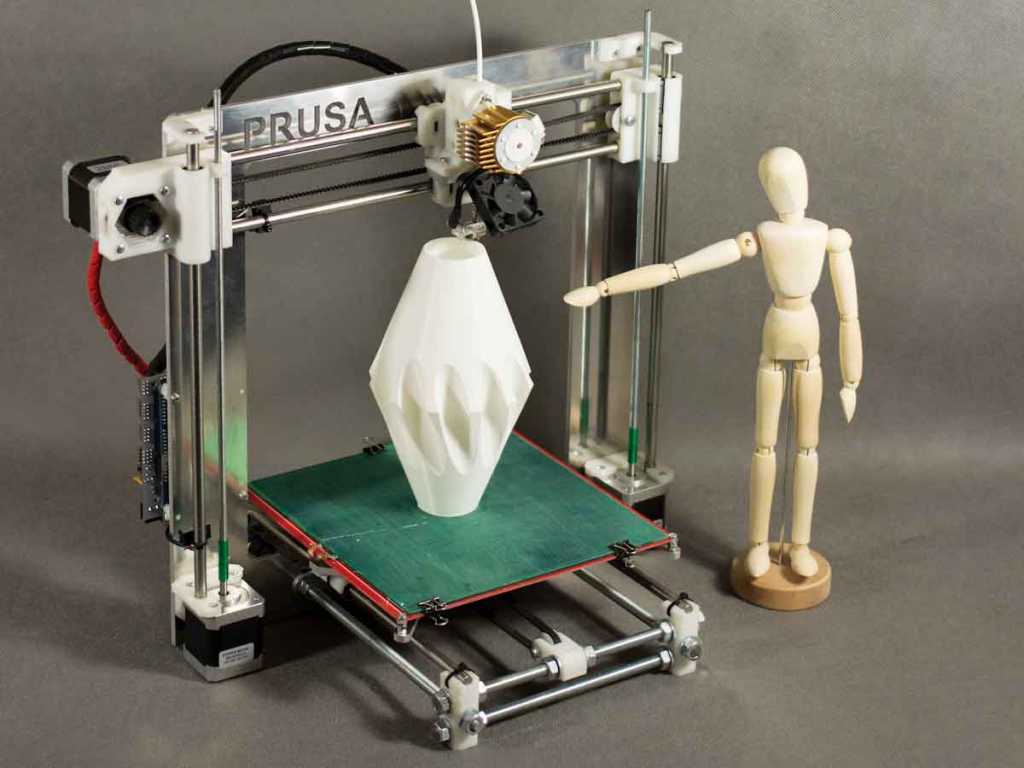

Where to start if you want to print metal objects at home? Given the extreme heat required for true metal 3D printing, a conventional FDM 3D printer will not be able to do this.

It is unlikely that in this decade it will be possible to print with liquid metal at home. Until 2020, you probably will not have a printer specialized for this purpose at home. But in a few years, as nanotechnology advances, we may see significant developments in new applications. This can be 3D printed with conductive silver, which will emit in much the same way as it does in 2D home printers. It will even be possible to mix different materials like plastic and metal in one object.

Materials for Metal 3D Printing at Home

Even though you can't print actual metal objects at home, you can turn to plastic filament that has metal powders added to it. Bestfilament, ColorFabb, ProtoPasta and TreeD Filaments offer interesting metal-PLA composite filaments. These filaments, containing a significant percentage of metal powders, remain pliable enough to be printed at low temperatures (200 to 300 Celsius) on virtually any 3D printer. At the same time, they contain enough metal to make the final object look, feel, and even weigh like metal. Iron-based filaments even rust under certain conditions.

Iron-based filaments even rust under certain conditions.

But you can go further. Typically, up to 50 percent metal powder is added to 3D printing filament. Dutch company Formfutura says they have achieved 85 percent metal powder with 15 percent PLA. These filaments are called MetalFil Ancient Bronze and Metalfil Classic Copper. They can be printed even at "moderate" temperatures from 190 to 200 degrees Celsius.

Metal 3D Printing Filament Spools, in this case by SteelFill and CopperFill colorFabb (Steel and Bronze), Ancient Bronze by Formfutura

Here are the key points about metal printing at home

- Get a unique metal surface and look

- Ideal for jewelry, figurines, household utensils, replicas

- Durability

- Objects are not flexible (structural dependent)

- Objects do not dissolve

- Not considered food safe

- Typical print temperature: 195 - 220°C

- Extremely low shrinkage on cooling

- Table heating not required

- Printing complexity is high, requires fine tuning of nozzle temperature, feed rate, post-processing

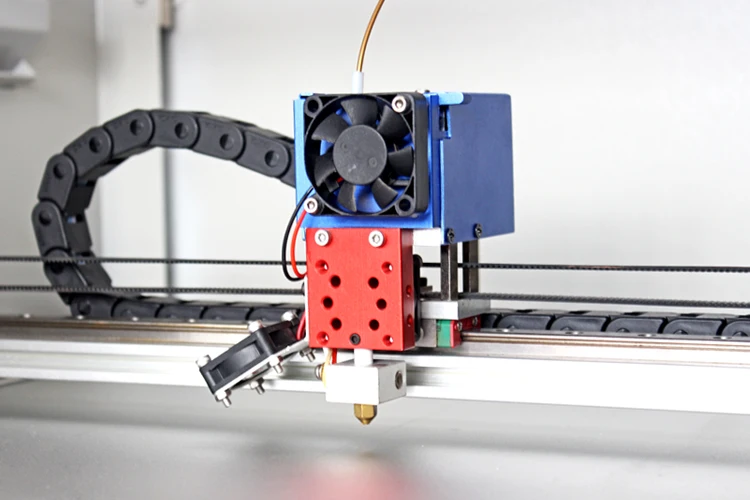

Preparing Your Home Printer for Metal 3D Printing

Since getting metal 3D prints is more difficult than usual, you may need to upgrade your 3D printer nozzle, especially if you are an entry-level printer. The metal filament wears it out quickly. There are hard-wearing hot-ends (like the E3D V6) that are themselves made of metal. They can withstand high temperatures and fit most printers. Be prepared for the fact that the nozzles will have to be changed frequently, because the metal filament is very abrasive.

The metal filament wears it out quickly. There are hard-wearing hot-ends (like the E3D V6) that are themselves made of metal. They can withstand high temperatures and fit most printers. Be prepared for the fact that the nozzles will have to be changed frequently, because the metal filament is very abrasive.

You will also need to take care of the final finishing of the surface (cleaning, grinding, oiling, waxing or priming) so that the printed metal object shines as it should.

How much is metal filament for 3D printing?

And what about metal filament for 3D printing? - you ask. Here are some examples:

- A 500-gram BFSteel and BFBronse coil from Bestfilament costs 1600–1800 ₽

- ColorFabb's 750 gram Bronzefill spool is $56.36

- ColorFabb's 750 gram Copperfill spool is $56.36

- Protopasta's Polishable Stainless Steel PLA Composite is $56 for 56 grams

- Protopasta's Rustable Magnetic Iron PLA Composite is $34.99 for 500 grams

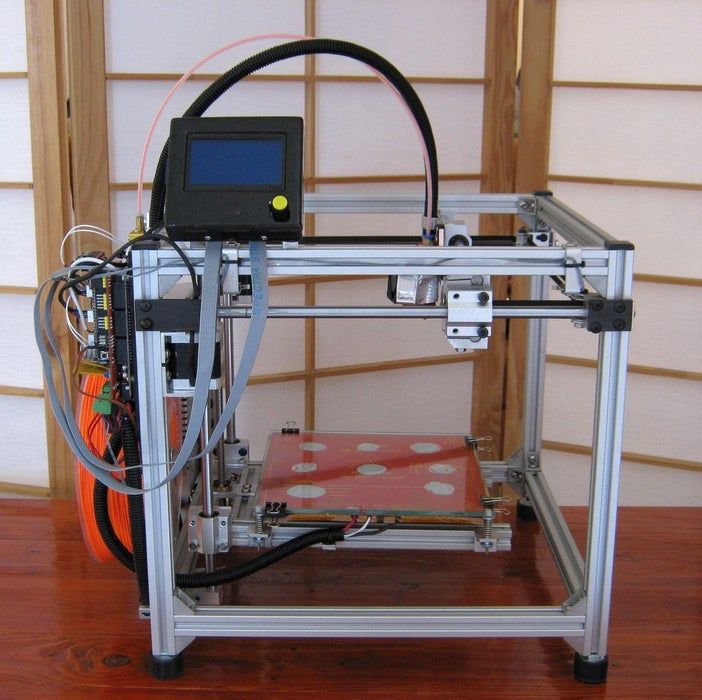

Industrial Metal 3D Printing

But what if you want better results or even full metal 3D printing? Should a real "metal" 3D printer be purchased for business needs? We wouldn't recommend it - unless you're going to be doing it every day. A professional metal 3D printer is expensive: EOS or Stratasys devices will cost you 100-500 thousand dollars. In addition, the costs will be even greater, since you will have to hire an operator, a worker to maintain the machine, as well as to finalize the printouts (polishing, for example). Just a note: In 2016, an affordable metal 3D printer didn't exist.

A professional metal 3D printer is expensive: EOS or Stratasys devices will cost you 100-500 thousand dollars. In addition, the costs will be even greater, since you will have to hire an operator, a worker to maintain the machine, as well as to finalize the printouts (polishing, for example). Just a note: In 2016, an affordable metal 3D printer didn't exist.

Reducing Metal 3D Printing Costs

If you are not going to open a metal 3D printing business, but still need a professionally 3D printed metal part, it is better to contact the appropriate company that provides such services. 3D printing services like Shapeways, Sculpteo and iMaterialise offer direct metal printing. They currently work with the following metal materials in 3D printing:

- aluminum

- steel

- brass

- copper

- bronze

- sterling silver

- gold

- platinum

- titanium

If you are a jeweler, you can also order wax models for casting in precious metals. If we talk about wax models, then in most cases it is they (with subsequent melting) that are used when printing with metals (including gold and silver). Not all orders are carried out directly by these firms. They usually turn to other metal 3D printing companies to complete the order. However, the number of such services around the world is growing rapidly. In addition, metal 3D printing techniques are becoming more and more common in companies that offer such services.

If we talk about wax models, then in most cases it is they (with subsequent melting) that are used when printing with metals (including gold and silver). Not all orders are carried out directly by these firms. They usually turn to other metal 3D printing companies to complete the order. However, the number of such services around the world is growing rapidly. In addition, metal 3D printing techniques are becoming more and more common in companies that offer such services.

The reason big companies love 3D printing so much is that it can be used to build fully automated lines that produce "topologically optimized" parts. This means that it is possible to fine-tune the raw materials and make the components thicker only if they must withstand heavy loads. In general, the mass of parts is significantly reduced, while their structural integrity is preserved. And this is not the only advantage of this technology. In some cases, the product turns out to be significantly cheaper and affordable for almost everyone.

Please note that metal 3D printing requires special CAD programs for modeling. It is worth paying attention to the recommendations of Shapeways - 3D printing metal guidelines. To delve further into the topic, check out Statasys’ information on related 3D printers and the nuances of metal 3D printing.

Here are some examples of Benchy test model prices for metal 3D printing:

- Metal plastic: $22.44 (former alumide, PLA with aluminum)

- Stainless steel: $83.75 (plated, polished)

- Bronze: $299.91 (solid, polished)

- Silver: $713.47 (solid, mirror polished)

- Gold: $87.75 (gold plated, polished)

- Gold: $12,540 (solid, 18K gold)

- Platinum: $27,314 (solid, polished)

As you might expect, solid metal 3D printing prices are quite high.

Metal 3D printing. Applications

GE LEAP aircraft engine parts 3D printed at Avio Aero (Photo: GE)

There are several industries that already use 3D printers to make everyday objects - you may not even know that these objects are printed.

- The most common case is surgical and dental implants, which in this design are now considered the best option for patients. Reason: they can be tailored to individual needs.

- Another industry is jewelry. Here, most manufacturers have abandoned resin 3D printing and wax casting, switching directly to metal 3D printing.

- In addition, the aerospace industry is becoming more and more dependent on 3D printed metal objects. The Italian company Ge-AvioAero was the first to do all-metal 3D printing. It manufactures components for LEAP aircraft engines.

- Another industry targeting metal 3D printing is the automotive industry. BMW, Audi, FCA are seriously considering this technology, not only for prototyping (3D printing has been used for this for quite some time), but also for making real parts.

Before metal 3D printing really takes off, however, there are some hurdles to overcome. And first of all, this is a high price, which cannot be made lower than during molding. Another problem is the low production speed.

3D metal printing.

Technologies

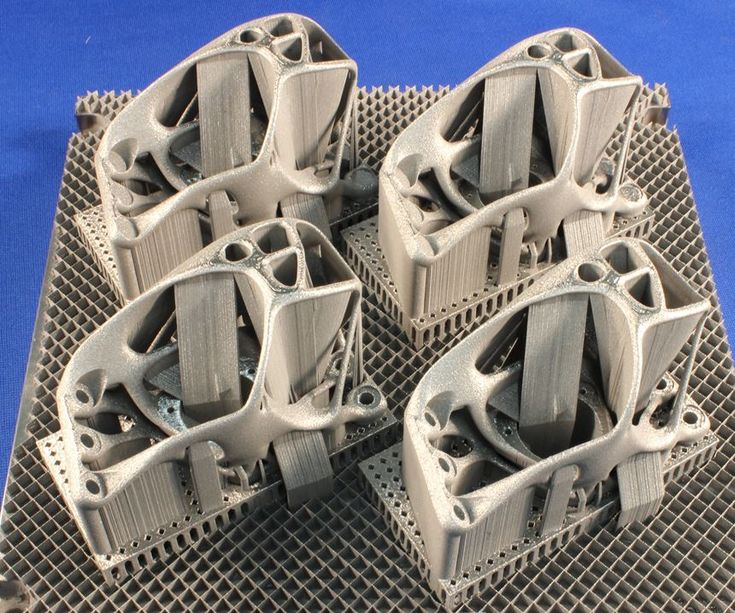

Most metal 3D printing processes start with an “atomized” powder

You can talk a lot about “metal” 3D printers, but their main problems remain the same as any other 3D – printers: software and hardware limitations, material optimization and multimateriality. We won't talk too much about the software, we'll just say that most of the major specialized software companies, such as Autodesk, SolidWorks and solidThinking, try to emphasize as much as possible the fact that as a result of the 3D metal printing process, you can get any shape you want.

In general, printed metal parts can be as strong as parts made by traditional processes. Parts made using DMLS technology have mechanical properties equivalent to casting. In addition, the porosity of objects made on a good "metal" 3D printer can reach 99.5%. In fact, manufacturer Stratasys claims that 3D printed metal parts perform above industry standards when tested for density.

In addition, the porosity of objects made on a good "metal" 3D printer can reach 99.5%. In fact, manufacturer Stratasys claims that 3D printed metal parts perform above industry standards when tested for density.

3D printed metal can have different resolutions. At the highest resolution, layer thickness is 0.0008 - 0.0012" and X/Y resolution is 0.012 - 0.016". The minimum hole diameter is 0.035 - 0.045″. Let's, however, consider what metal 3D printing technologies are.

Metal 3D Printing Process #1:

Powder Bed Fusion

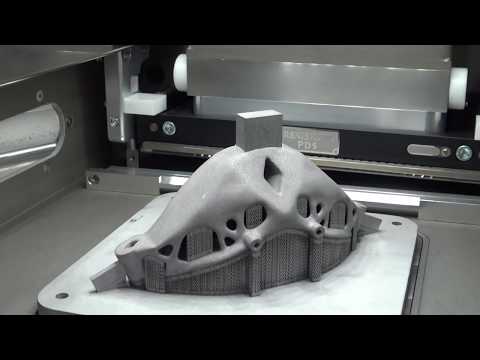

The metal 3D printing process that most relevant large companies use today is called Powder Bed Fusion. This name indicates that some source of energy (a laser or other energy beam) melts an "atomized" powder (i.e., a metal powder that is carefully ground into spherical particles), resulting in layers of a printed object.

There are eight major manufacturers of metal 3D printers in the world that already use this technology; while we are talking here, there are more and more such companies. Most of them are in Germany. Their technologies are called SLM (Selective Laser Melting - selective laser fusion) or DMLS (Direct Metal Laser Sintering - direct metal laser sintering).

Most of them are in Germany. Their technologies are called SLM (Selective Laser Melting - selective laser fusion) or DMLS (Direct Metal Laser Sintering - direct metal laser sintering).

Metal 3D printing process #2:

Binder Jetting

ExOne 3DP prints metal objects by binding the powder before firing it in a forge (photo: ExOne)

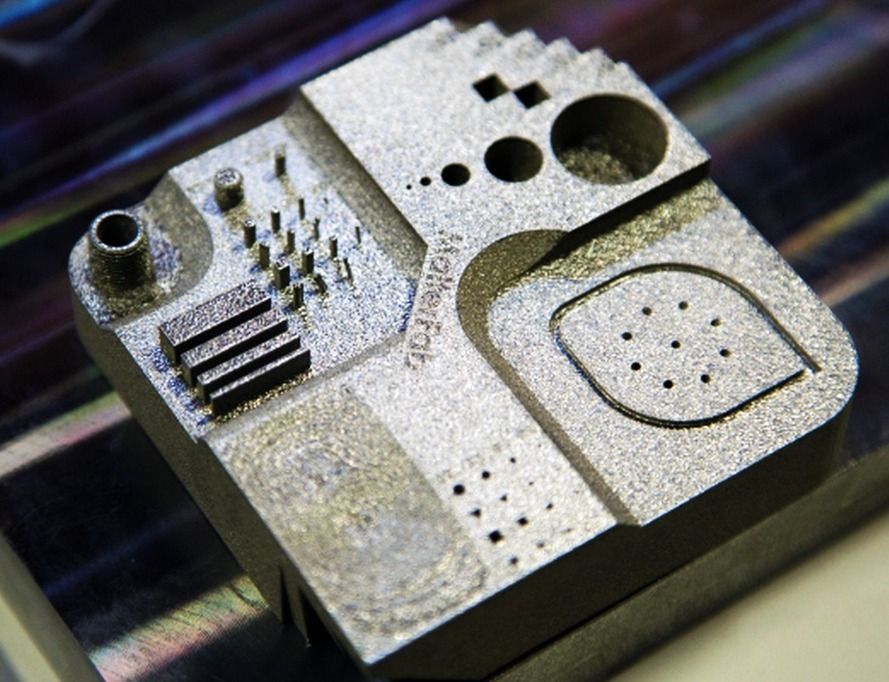

Another professional approach that also uses a powder base is called Binder Jetting. In this case, the layers are formed by gluing metal particles together and then sintering (or fusing) them in a high-temperature furnace, just like it is done with ceramics.

Another option, which is also similar to working with ceramics, is mixing metal powder into metal paste. A pneumatically extruded 3D printer (similar to a syringe bioprinter or an inexpensive food printer) forms 3D objects. When the required shape is reached, the object is sent to the furnace, i.e. in the mountains This approach is used in the Mini Metal Maker, apparently the only inexpensive "metal" 3D printer.

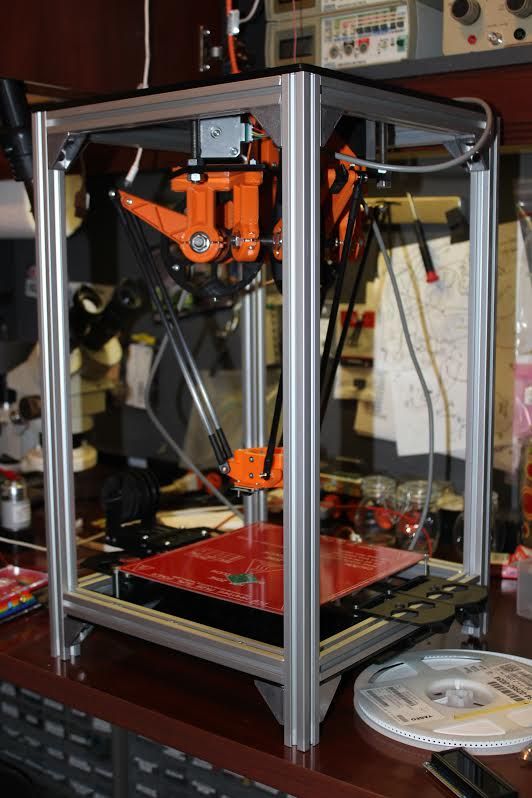

Metal 3D printing process #3:

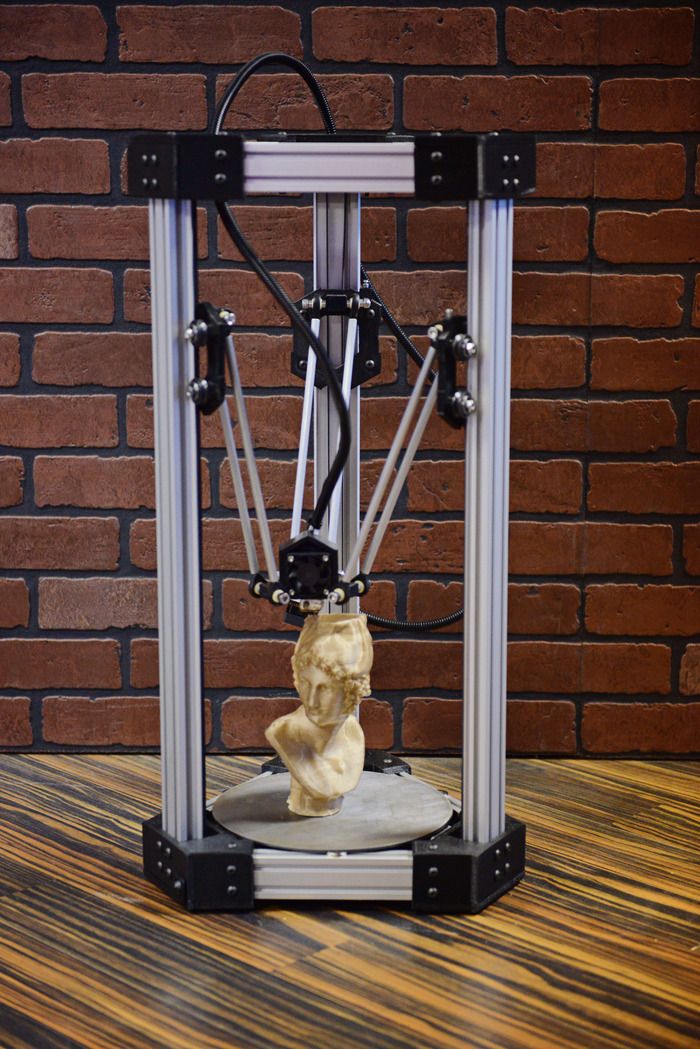

Metal Deposition

It may seem that the only 3D printing process that is left out of working with metals is layer-by-layer deposition. This is not entirely true. Of course, on some desktop device, simply fusing metal threads onto the base will not work. However, very large steel companies can do it. And they do. There are two options for working with "metal surfacing".

One is called DED (Directed Energy Deposition) or Laser Cladding. Here, a laser beam is used to melt the metal powder, which is slowly released and solidifies as a layer, and the powder is fed using a robotic arm.

Usually the whole process takes place in a closed chamber, but in the MX3D project, conventional 3D printing techniques were used to build a full-sized bridge. Another option for metal fusion is called EBAM (Electron Beam Additive Manufacturing - additive electron beam technology), which is essentially soldering, in which a very powerful electron beam is used to melt 3 mm titanium wire, and the molten metal forms very large finished structures. As for this technology, its details are known so far only to the military.

As for this technology, its details are known so far only to the military.

Metal 3D printing. Metals

3D Printing Metal #1: Titanium

Pure titanium (Ti64 or TiAl4V) is one of the most commonly used metals for 3D printing and is definitely one of the most versatile, strong and lightweight. Titanium is used both in the melting process in a preformed layer and in the process of spraying a binder and is used mainly in the medical industry (for the manufacture of personal prostheses), as well as in the aerospace industry, automotive and machine tools (for the manufacture of parts and prototypes). But there is one problem. Titanium is very reactive and explodes easily in powder form. Therefore, it is necessary that titanium 3D printing takes place in a vacuum or in an argon environment.

3D Printing Metal #2: Stainless Steel

Stainless steel is one of the cheapest 3D printing metals. At the same time, it is very durable and can be used in a wide range of manufacturing and even artistic and design applications. The type of steel alloy used also contains cobalt and nickel, is very difficult to break, and has a very high elasticity. Stainless steel is used almost exclusively in industry.

The type of steel alloy used also contains cobalt and nickel, is very difficult to break, and has a very high elasticity. Stainless steel is used almost exclusively in industry.

3D Printing Metal #3: Inconel

Inconel is a superalloy manufactured by Special Metals Corporation, its registered trademark. The alloy consists mainly of nickel and chromium and is very heat resistant. Therefore, it is used in the oil, chemical and aerospace (for black boxes) industries.

3D Printing Metal #4: Aluminum

Due to its lightness and versatility, aluminum is very popular in 3D printing. Aluminum alloys are commonly used.

3D Printing Metal #5: Cobalt-Chromium

This alloy has a very high specific strength (i.e. strength divided by density, which generally indicates the force required per unit area to break). It is most commonly used in the manufacture of turbines, dental and orthopedic implants, where 3D printing has become the dominant technology.

Metal for 3D printing №5. Copper and Bronze

With few exceptions, copper and bronze are used in wax melting processes, rarely in layer melting. The fact is that these metals are not very suitable for industry, they are more often used in the manufacture of works of art and crafts. ColorFabb offers both metals as the basis for a special metal filament.

Metal for 3D printing №6. Iron

Iron, incl. magnetic, also mainly used as an additive to PLA-based filaments, which are produced, for example, by ProtoPasta and TreeD.

Metal for 3D printing №7. Gold, silver, and other precious metals

Most preformed-layer companies can 3D print precious metals such as gold, silver, and platinum. Here, along with the preservation of the aesthetic properties of materials, it is important to achieve optimization of work with expensive starting powder. Precious metal 3D printing is required for jewelry, medical applications and electronics.

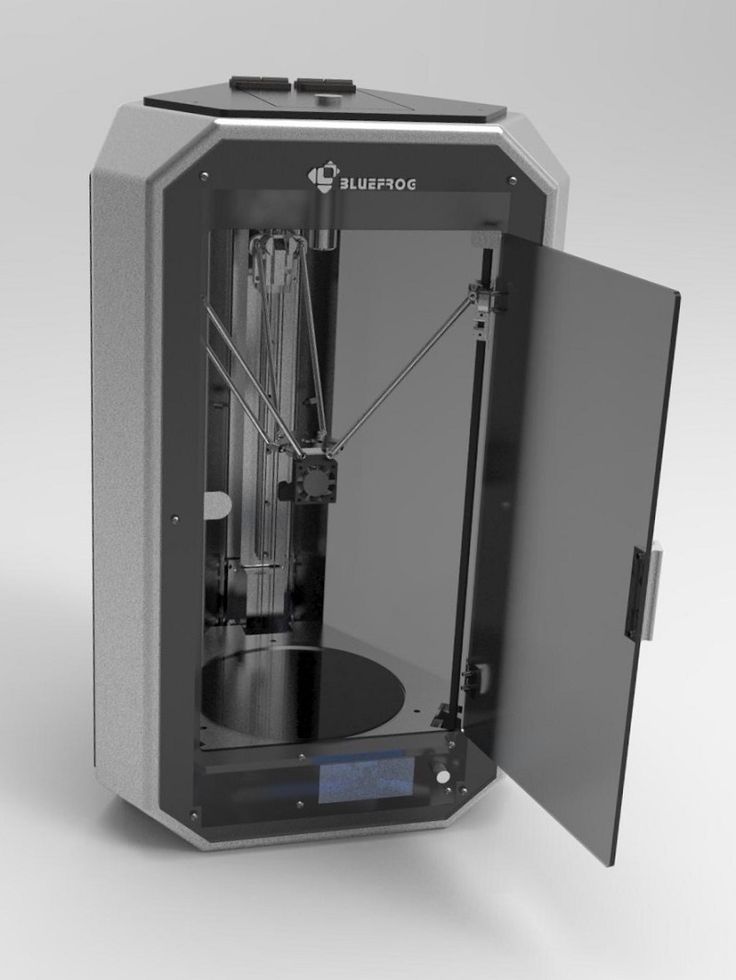

Metal 3D printing. Printers

Do not hesitate - the purchase of a metal 3D printer will not go unnoticed for your budget. It will cost at least 100-250 thousand dollars. Here is a list of a variety of "metal" printers, some of which can be found in firms providing 3D printing services.

Metal 3D Printer #1:

Sciaky EBAM 300 Metal Filament Printing

If you need to print really large metal structures, Sciaky's EBAM technology is your best bet. By order, the device can be built in almost any size. This technique is used mainly in the aerospace industry and the military. The largest of Sciaky's serial printers is the EBAM 300. It prints objects in a volume of 5791 × 1219 × 1219 mm.

The company claims the EBAM 300 is also one of the fastest industrial 3D printers on the market. A three-meter-sized titanium part for an aircraft is printed on it in 48 hours, while the material consumption is about 7 kg per hour. In general, forged parts that usually take 6-12 months to complete can be made in 2 days with this 3D printer.

In general, forged parts that usually take 6-12 months to complete can be made in 2 days with this 3D printer.

Sciaky's unique technology uses a high energy electron beam that melts a 3mm titanium rod at a typical melting rate of 3 to 9 kg per hour.

Metal 3D Printer #2:

Fabrisonic UAM - Ultrasonic 3D Printing

Another way to print large metal parts is UAM (Ultrasound Additive Manufacturing Technology) from Fabrisonic. The devices of this company are three-axis CNC cutters, to which welding heads are added for the additivity of the process. The metal layers are first cut and then ultrasonically welded. The largest Fabrisonic 7200 printer operates in a volume of 2 x 2 x 1.5 m.

#3 Metal 3D Printer:

Concept Laser XLine 1000 Metal Powder 3D Printing

modeling - 630 × 400 × 500 mm, and itself the size of a house.

Its German company, one of the main suppliers of 3D printers for aerospace giants like Airbus, recently introduced a new device, the Xline 2000.

This equipment uses two lasers and the working volume is 800 × 400 × 500 mm. Uses LaserCUSING laser technology (a variant of selective laser fusion) from Concept Laser, which allows you to print alloys of steel, aluminum, nickel, titanium, precious metals and even some pure substances (titanium and stainless steel).

Metal 3D printing. Services

There are more than 100 companies worldwide offering metal 3D printing services. We list the most popular services for consumer needs.

#1 Metal 3D Printing Service: Shapeways

The world's most popular 3D printing service, Shapeways offers two types of services. As a consumer, you can choose from a wide range of professionally designed objects, customize them, and then have them printed to your specifications. Like other 3D printing services, Shapeways offers a platform for designers to sell and print their work. Shapeways is also a good place for rapid prototyping: customers benefit from industrial-grade printers (EOS, 3D Systems) and personal technical support.

3D printing metals: aluminium, brass, bronze, gold, platinum, precious metal plating, silver, steel. There are also wax molds for jewelry purposes.

Metal 3D Printing Service #2: Sculpteo

Like Shapeways and i.materialise, Sculpteo is an online 3D printing service that allows anyone to upload 3D models and send them for fabrication in a wide range of materials. Like its competitors, Sculpteo provides a platform for hobbyists and professionals to showcase and sell their designs. The stable of Sculpteo printers includes highly professional machines from 3D Systems, EOS, Stratasys and ZCorp. Extensive technical documentation will help identify design flaws and select the right material for the project.

3D printing metals: alumide (plastic with aluminum particles), brass, silver.

Metal 3D Printing Service #3: iMaterialise

Materialise is a company that works with industrial clients to prototype 3D printed products. For casual users and designers, Materialize offers an online 3D printing service called i.materialise. As with Shapeways, this service allows anyone to upload their 3D designs and print them out. Once an object has been uploaded and successfully printed, a designer can list it for sale either in the gallery of the i.materalise online store or by embedding some code into their website.

For casual users and designers, Materialize offers an online 3D printing service called i.materialise. As with Shapeways, this service allows anyone to upload their 3D designs and print them out. Once an object has been uploaded and successfully printed, a designer can list it for sale either in the gallery of the i.materalise online store or by embedding some code into their website.

3D printing metals: alumide (plastic with aluminum powder), brass, bronze, copper, gold, silver, steel, titanium.

Metal 3D Printing Service #4: 3D Hubs

Through 3D Hubs, you can search for individuals and businesses that offer 3D printing services in your area, upload STL files (which are immediately assessed for defects), and contact directly with service providers to get the job done. The online 3D printing service also allows you to sort offers by materials, customer rating, distance and many other parameters. Whatever object you wish to print, there is likely to be someone nearby who can print it. A significant number of materials can be printed in industrial quality, such materials have an HD mark in the search field.

A significant number of materials can be printed in industrial quality, such materials have an HD mark in the search field.

3D printing metals: aluminium, bronze, cobalt-chromium, stainless steel, titanium.

Source

Tags:

Metal 3D Printing, Metal 3D Printing Process, Metal 3D Printing Industry, Metal 3D Printing Materials, Metal 3D Printer, Fasonic EBAM 300 , Concept Laser XLine 1000

Metal 3D printing | DMLS Printer | Equipment for additive manufacturing

Equipment Additive Manufacturing Equipment

What is additive metal manufacturing?

Eplus 3D Additive Metal Manufacturing

Metal 3D printing equipment and supplies

Eplus3D metal printers, from entry-level models to multi-laser machines, can be used for industrial grade additive manufacturing.