Borrow 3d printer

How to Make 3D Printed Stuff Without Owning a 3D Printer

By

Eric Ravenscraft

Comments (38)3D printing is really friggin’ cool, but promises that we’d all have one in our homes by now have turned out to be less than true. Fortunately, you don’t need one of your own to bring your imaginary creations to life.

You may still be wondering why you should care about 3D printing to begin with. It’s a fair question! While 3D printer prices haven’t plummeted like some expected, the community around them has grown considerably. Sites like Thingiverse have huge libraries of ready-to-print models that you can download everything from cool stuff like a miniature Millennium Falcon (hey, neat gift idea!), to useful things like phone stands or cord protectors. There are tons of things that you can print that are absolutely worth what they cost to make. They just might not be worth $500-2000 for the printer, as well. If your holdup is the hardware, here are some places that will let you print out objects without buying a mini factory.

Before you pick a place that’s going to make your 3D object, you need a 3D model to actually print. There are a few things you need to consider when you’re looking for something to make. Contrary to early adopter opinion, 3D printing isn’t the best solution for everything. When you’re getting started, ask yourself a few questions:

- Does what I want already exist somewhere else? When I was browsing 3D printed objects, I found a potentially useful bag carrier that would make bringing in groceries easier. Then I found this thing on Amazon for $6. 3D printing is cool, but it’s not always necessary. Before you order something, see if a regular mass-produced version exists.

- Does the model have any flaws? In case you’ve never worked with 3D models before, let me give you a tip: they’re hard to get right. Before you spend money on an object, read reviews where available, or look for pictures of an item after it’s been printed, rather than just the renders of what an object “should” look like.

- Do I need to alter or tweak this model? While you can technically change any 3D model using modeling software, some objects are easier to tweak than others. Thingiverse has an entire collection of customizable items with specific aspects you can tweak to fit your needs, like a Christmas tree stand with an adjustable diameter, so you can make it fit your tree. Before you download and print a model, make sure you check out all the possible ways to customize it that are available.

- What materials will this be made of? Wait, aren’t all 3D printed objects just colored plastic? Nope. You can get 3D printed objects in wax, sandstone, porcelain, and even precious metals like gold and silver. That’s super awesome, but it’s also another thing that can affect your object. If you’re going to make something other than plastic, check out material sample kits so you can see how durable your object might be, or how intricately it can be printed.

Even if you do your due diligence, keep in mind that printing isn’t always perfect. You may get an object that you need to sand down to make it look just right, or you may have an intricate object that doesn’t quite line up. Be prepared for the possibility that something might not come out exactly the way you envisioned it.

Option One: Order Through Online ServicesSeveral 3D printing services have popped up in the last few years that allow you to upload your own models and get them printed in whatever material you want. One of our (and your) favorites is Shapeways. This site lets you upload your own designs and get an immediate quote on how much a particular object will cost in a variety of materials. You can explore the object in a 3D model viewer.

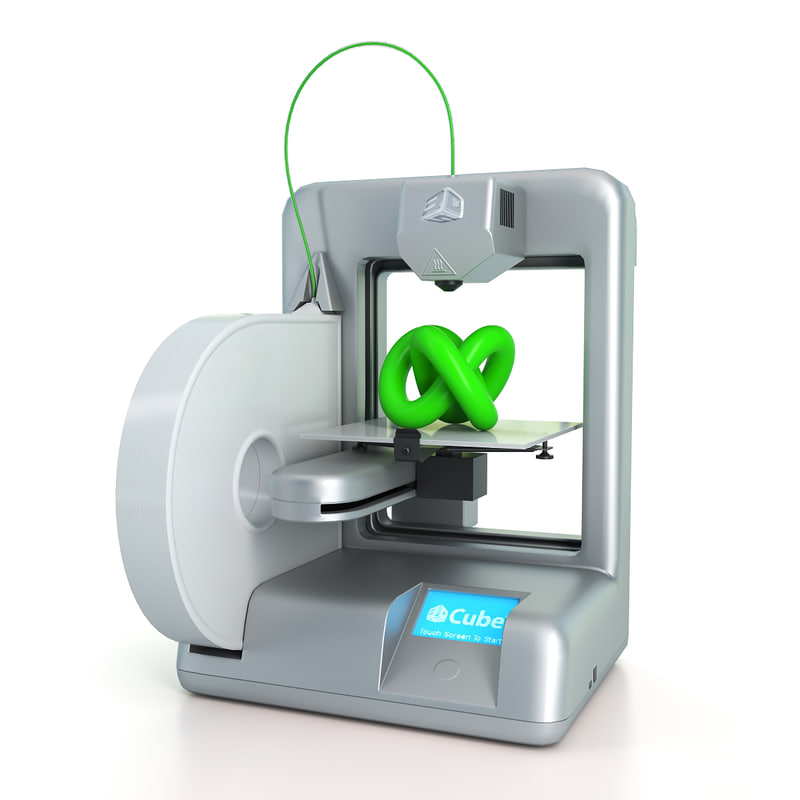

If you don’t have a ready-made 3D model to work with, services like You3Dit will pair you with designers who can help you create what you want, then print it for you. This can be a little more expensive than just uploading a model and ordering a print, but it also reduces the likelihood that you’re going to get a botched product. Not to mention, most 3D printing services will use industrial-grade equipment that can get a lot more detail than the typical consumer models that you’re used to seeing in stores.

Not to mention, most 3D printing services will use industrial-grade equipment that can get a lot more detail than the typical consumer models that you’re used to seeing in stores.

I have a confession: I don’t own a printer. And not the 3D kind: I don’t own a regular, 2D paper printer either. I just have so few instances where I need to print something, and unused printers break so much, that it just makes more sense to go down to a FedEx Office nearby and print something when I need it. Unsurprisingly, some stores have decided that this concept works just as well for 3D printing and now offer in-store printing of your own models.

UPS is one of the leaders in this area, with a few dozen locations nationwide that are equipped with 3D printers. They may not be nearby for everyone, but if you do happen to live near one, it’s probably easier to drive to a store for a bit, instead of buying a hulking machine just to make a cool figurine.

We’ve mentioned it before, but it bears repeating: go to your local library. When you get there, among the many other cool things they have, you may find a 3D printer. That’s right, libraries are cool. You heard it here first. If your library has a 3D printer, you may be able to use it for free (though you may have to buy or bring your own materials).

If you want to really get your hands dirty learning how to 3D print objects, this is one of your two best bets. Most libraries won’t have a clerk behind a desk who takes a USB stick and gives you a printed object. They’ll let you get hands-on with the software and learn how it works. Not every library will have staff that are experts in 3D modeling, but you can experiment on your own and learn how to do it yourself. Learning in a library. Imagine that.

Option Four: Join a Makerspace CommunitySo far this year, I’ve visited three different Makerspace communities in Atlanta, and every single one has had at least one 3D printer. If you can find a Maker Faire in your town, or a local maker community, and you’re even slightly interested in 3D printing, take a day and visit. If you’re actually looking to learn how 3D printing works, this will be the most educational and likely the most rewarding.

If you can find a Maker Faire in your town, or a local maker community, and you’re even slightly interested in 3D printing, take a day and visit. If you’re actually looking to learn how 3D printing works, this will be the most educational and likely the most rewarding.

Not only will most makerspaces have shared resources (like 3D printers!), they also have people who are experienced in using them on site. You probably won’t be able to walk in the front door, ask for a print job, and walk out. Instead, you can join classes, or work directly with someone who knows what they’re doing.

In my experience, this was the best way to get started with 3D printing, as you learn some of the intricacies of what you’re doing, not to mention the problems that can arise. Despite cool demo videos, prints can become improperly aligned, nozzles can get clogged, or material can come out unevenly. All of these can quickly ruin a project, especially if you don’t know how to fix your printer.

Owning a 3D Printer Probably Isn’t a Good Idea to Begin WithWith all of these options on the table, you might reasonably start to wonder, “Is it ever going to be worth owning a 3D printer?” And the truth is. ..probably not? It’s easy to imagine a wonderful world where anything you can imagine, you can build. The reality is that 3D printers are still printers. They get clogged, jammed, and misaligned, and they can ruin your day when they don’t work right.

..probably not? It’s easy to imagine a wonderful world where anything you can imagine, you can build. The reality is that 3D printers are still printers. They get clogged, jammed, and misaligned, and they can ruin your day when they don’t work right.

3D printing services, on the other hand, are much more consumer friendly. You can use models you find online (or make yourself) and get someone else who knows what they’re doing to make the product itself. If you really want to get one to learn how to make your own stuff, libraries and makerspaces are going to be way better for you than just buying a 3D printer for your house and fiddling with it until something good comes out. For enthusiasts and regular makers, owning a 3D printer might be a great idea, but for the rest of us, contracting that work is likely going to be the best bet for a long time to come.

Photos by Creative Tools and Karen Blakeman.

3D Printing in 3 Steps (Yes, Only 3!)

3D Printing in 3 Steps (Yes, Only 3!) | Staples.comby Kevin Ackerman, Staples® Contributing Writer

Since it gives computer users the ability to produce tangible objects in a variety of materials and colors right from their desktop, 3D printing seems as if it would be technically complicated (or just magical). But in reality, it’s not all that different from printing in two dimensions on paper.

To produce a printed page, all computer users need is a document, a computer and access to a printer — and, of course, ink and paper. Likewise, printing in 3D only requires three similar things. Sure, the technologies differ, but that’s the basic gist, as these three steps explain.

Step 1: Develop a Concept

If you were to open a document file on your computer, hit some random keys on your keyboard and press Print, you’d have a paper printout — though it wouldn’t make much sense. With 3D printing, you can’t make a shape that easily, not even a poor one, so it’s worth beginning the process by putting some thought into your object.

With 3D printing, you can’t make a shape that easily, not even a poor one, so it’s worth beginning the process by putting some thought into your object.

Start by knowing what you’d like to print in three dimensions. If you don’t have an idea or concept, there are plenty of free suggestions online to get you started. Web sites like Thingiverse.com offer a library of pre-designed objects that you can print with any 3D printer to gain experience. Or you can be inspired by people who are already using 3D printing technology.

Phoenix-based sculptor Kevin Caron uses 3D printing to refine his artwork before making full-sized versions. "Mostly what I'm doing is proof of concept designs. You know, will it stand up, does it look right and are the proportions correct on it?” he says.

And Chris Considine, CEO and founder of Los Angeles–based CXC Simulations, uses 3D printing to prototype custom-designed parts for racing simulators that are so realistic, they are used by professional race car drivers. "We need 3D orienting to see if the part feels exactly how we want it to feel,” he says.” We went through about 30 versions before we found the one that was perfect for us. Other than 3D printing, there’s truly no way you could have done that without building it over and over again."

"We need 3D orienting to see if the part feels exactly how we want it to feel,” he says.” We went through about 30 versions before we found the one that was perfect for us. Other than 3D printing, there’s truly no way you could have done that without building it over and over again."

Step 2: Hop on a Computer

Once you know what you want to produce, it’s time to sit down at a computer and make it happen. 3D prints are most commonly generated from an STL or .stl file. Standing for “stereolithography” (what 3D printing was named when it was first invented), this file format is to 3D printing what the .doc file is to document output.

To open and manipulate an STL file, you’ll need computer-aided design (CAD) software. For decades, these programs have been used by everyone from architects to product designers, so there are many kinds of CAD software available.

SketchUp is a free modeling program designed to be straightforward and allow anyone to create three-dimensional renderings, whether simple or complicated. Likewise, Tinkercad keeps the design process easy by providing just three simple tools. It also runs in a Web browser and offers step-by-step design lessons to demonstrate how easy 3D printing can be.

Likewise, Tinkercad keeps the design process easy by providing just three simple tools. It also runs in a Web browser and offers step-by-step design lessons to demonstrate how easy 3D printing can be.

Meanwhile, programs like AutoCAD are favored by many experienced professionals, having been used in the design and prototyping of millions of products throughout the years.

To run these programs, you don’t need a particularly powerful computer. Caron uses an HP desktop machine to create his digital sculptures. "It's not a big screaming gaming computer by any means,” he says. "It's just a small office computer and it handles the CAD program just fine.”

Step 3: Get Access to a 3D Printer

Most people assume they need to own a 3D printer to produce digitally rendered objects, but that isn’t true. Sure, owning a desktop 3D printer can put your designs within arm’s reach. But driving across town to pick up your objects at a Staples 3D printing service location or having them delivered by mail can be just as convenient for some businesses.

For example, Caron owns a CubeX™ commercial 3D printer. With the ability to print objects up to the size of a basketball, this device produces designs in plastic and in more than 4,000 different colors. He’s also used print-on-demand services to produce sculptures that he couldn’t make on his office’s machine.

"They’re breathtaking when you see them,” he says of the two acrylic sculptures. "The detail that I could view on the computer came out in the print — it just blew me away.” Caron is planning to scale his designs down and turn them into jewelry to sell. "I've gotten one back in a polished glass and it's stunning. You can’t tell it from gold other than by the weight."

If you are interested in using 3D printing but need help with these steps, visit one of our stores that offers 3D printing services (currently in Los Angeles and New York City). There, we can help you with all the steps, from getting in touch with designers to actual 3D printing. You can even get in our 3D printing photo booth and have your face put on a figurine.

You can even get in our 3D printing photo booth and have your face put on a figurine.

Go from Concept to Reality

Some businesses would argue that 3D printing, whether it’s done in the office or at an outside service, is worth its weight in gold. "I can go from concept in my head to holding the part in sometimes as quickly as an hour,” says Considine. "It’s a very powerful thing for an engineer to have. It's liberating."

Related Articles

7 Things You Didn't Know About 3D Printing

In the ever-expanding universe of 3D printing, no one knows it all. Though the technology has been around since the 1980s, it’s only recently... Read more

8 Tips from MakerBot for Making Better 3D-Printed Objects for Your Small Business

Both an art and a science, 3D printing is actually easy to do, but difficult to master. The experts at MakerBot have seen... Read more

The experts at MakerBot have seen... Read more

Carrie Mae Rose

Does mankind’s destiny lie in the stars? Artist Carrie Mae Rose thinks so. Her show... Read more

Bestreview. Summing up the results of the past days and awarding the winner

Good day, dear friends!

Sometimes, looking through the photos you sent me, I catch myself thinking that my place of work can be compared with NIICHAVO (Scientific Research Institute of Witchcraft and Wizardry, the setting for the fantastic stories of the Strugatsky brothers). Sometimes I can’t keep up with all your achievements in 3D printing, and as the hero of the story of science fiction brothers, I think that I got into magic and sorcery.

Don't believe me?! Then see for yourself!

Literally 10 years ago, preparations for Halloween began 2-3 months in advance. After all, it was necessary to choose a character for the holiday, stock up on all the necessary paraphernalia for the image, buy/sew/borrow a costume. Now the preparation process takes much less time. It is enough to think over and choose a hero, and all the necessary details can be printed on a printer.

After all, it was necessary to choose a character for the holiday, stock up on all the necessary paraphernalia for the image, buy/sew/borrow a costume. Now the preparation process takes much less time. It is enough to think over and choose a hero, and all the necessary details can be printed on a printer.

For example, friends from Chita "MetvKube" helped in creating a bright image for a beautiful girl:

Jason Norton didn't go unnoticed at the Halloween party. Of course, the masked man will get most of the attention. I think that everyone will ask themselves the question: who hides his face, and for what purpose does he do it, will the intrigue be revealed, will the mask be removed?

Colleagues from Krasnoyarsk continue the theme of the man in the mask. This time, the necessary details were printed to create the image of the famous superhero “Daredevil”.

I think with the advent of 3D printing, Game of Thrones fans can transform into their favorite characters at least every day. After all, the necessary attributes of the image, which are very difficult to find on sale, can be printed! For example, colleagues from Nizhny Novgorod helped in the embodiment of the image of Sansa Stark.

After all, the necessary attributes of the image, which are very difficult to find on sale, can be printed! For example, colleagues from Nizhny Novgorod helped in the embodiment of the image of Sansa Stark.

“Winter is coming!”. But 3D printing works in all weather conditions!

But fans of films about a fantastic future have a chance to imagine themselves as space rangers saving their planet from the invasion of foreign invaders.

The main weapon of space defenders performed by Alexander Sudarkin and Dmitry Karpukhin.

And, of course, what is Halloween without a pumpkin. By the way, as the survey showed, this orange vegetable is most often associated with the most mystical holiday.

I present to your attention the “ominous pumpkins” printed by friends from Abakan.

But even in Halloween there are characters that make it hard not to smile when you look at them.

The “king of emerald” dragons and the inimitable Omniam, printed by Dmitry Govorukhin, can also be classified as a cohort of evil spirits, but evil spirits are very nice and kind (look into their eyes! There is so much friendliness and curiosity in them).

And, of course, the winner of the “character with an overwhelming dose of mercy” nomination is baby Groot.

Another important attribute of Halloween is sweets. To create a special holiday atmosphere for cookies, you can choose some original shape.

Ideas for baking from colleagues from Miass, Tomsk and Pskov.

Of course, Halloween has not gained enough fame yet and not everyone celebrates it. Therefore, I present to your attention a selection of November works, the use of which you will find in everyday life.

The use of 3D printing to create interior items is becoming more and more popular. Agree that very often it is quite difficult to find a thing that is ideal in color and design, it is at such moments that printing comes to the rescue.

Interior elements performed by Andrey Babeshko, Oleg Zolotorev, colleagues from Pskov and friends from NIOZ.3D

The work of colleagues from Pskov and Andrei Babeshko continues the theme of outstanding interior solutions.

Friends from Chita "MetvKube" offered such an interesting interior solution for the outer facade of the building.

Lots of light, air and space! Colleagues from St. Petersburg embodied the most daring ideas and solutions in the layout of the mansion for Johnny Depp.

Watch, enjoy, dream!

Another example of using 3D printing to create layouts. Modeling and reconstruction of the building of the 19th century by Ildar Tazeev.

Did you know that 3D printers are also actively used in medicine? For example, in the creation of anatomical models.

If you are not ready to admire the smile of poor Yorick, but your soul needs a plastic friend, then pay attention to the work of colleagues from Stary Oskol.

I'm sure you won't be allergic to such a cat!

Each epoch has its own characteristic things peculiar only to this time. The iconic features of the 21st century can be called vape and, again gaining popularity, hookah. We do not undertake to judge whether this is good or bad. We only note that 3D printing is actively used in this area as well.

We do not undertake to judge whether this is good or bad. We only note that 3D printing is actively used in this area as well.

For example, colleagues from Chita printed details for a decorative hookah:

An analogue of the coilbuilder v3 pro kit (vape) printed by friends from Gomel:

It seems to me that in the near future the interiors of cars will be completely made of plastic. Alexey Grigoryan and colleagues from Izhevsk confirm my theory.

And already traditional. New parts printed to replace the old ones. Examples of work from colleagues from Irkutsk, Abakan, Izhevsk and Krasnoyarsk.

And, of course, through the efforts of 3D printing and a colleague from Miass, Tomsk, Khabarovsk and OOO OBYOM, not a single household appliance was saved from a lonely death in an electrical engineering dump. Still, it's great that now a broken part is so easy to replace! It is enough to print a new one, and a second “life” will begin for your beloved au pair.

More useful work from Sergey Romanovsky, colleagues from Miass, Tomsk, Stary Oskol, Moscow.

A celebration of white and geometric shapes. Even ordinary card holders and springs can be not only functional, but also beautiful.

On the front of 3D printing, you can highlight your own drummers of labor.

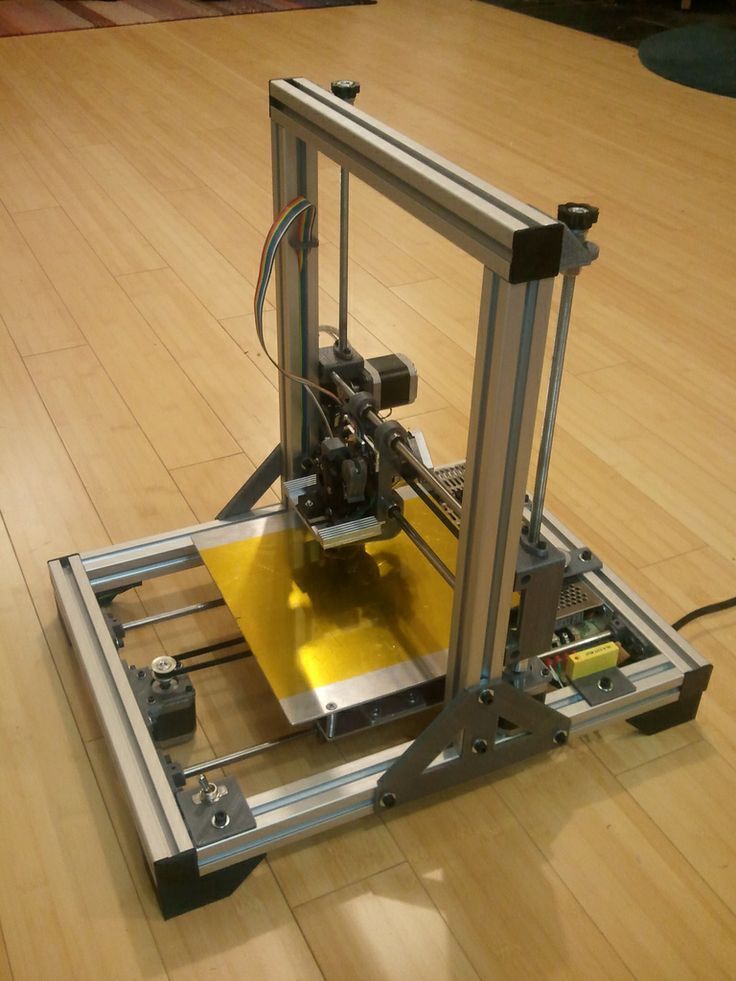

Colleagues from Sevastopol 3D-SEVAS have recently printed a Z-axis drive:

Coils for power transformers:

At Alexey Cherenkov, the beginning of November passed under the motto “First of all, first of all, a 3D printer, and then everything else”.

During this time, a powerful laser pointer was printed:

The motorization of the EQ3 telescope continues:

The parts necessary for production are printed:

Made by 3D printer:

Laser engraver:

3D printer repaired:

A large number of necessary parts printed:

And now it's time to talk about the work that this time impressed us the most.

A two-meter luminous pillar from colleagues from Tomsk.

By the way, you can charge your phone from it.

Fans of non-standard interior solutions suggest paying attention to this work. I think that by purchasing such a lamp / charger, the title of the owner of the original house will definitely be yours.

Colleagues, the plastic coil of your choice will come to you with the next order!

Running out of plastic? Order it here.

Send us your works and we will be happy to tell you about them!

And we also award the author of the best work!

You can see the winners of past weeks here »»»

write to our mail [email protected],

call 8-800-234-47-78,

and, of course, remember that there is Vkontakte and Telegram!

Interview with Rusal's Technical Director Viktor Mann

Additive technologies are gaining more and more popularity among manufacturers. Victor Mann, technical director of Rusal, spoke about what is hidden behind the term "additive technology", how it changes the production process and whether it can revolutionize the aluminum industry in the near future in an interview with Gazeta. Ru.

Ru.

- Let's start with the main question. What is additive technologies?

— The most striking example of additive technologies is 3D printing, which is becoming more and more mainstream. For a long time, when processing a part or product, excess metal was removed by machine tools, that is, it was about the “removal” of material. Additive technologies work on the opposite principle - they allow the part to "build up". This requires only a 3D printer, a 3D model of the product and metal powder. Thanks to this technology, parts and assemblies with complex geometry can be created as a whole, within the framework of one technological operation. In addition, the production time of the final product is significantly reduced.

— How could this “build-up” change the steel industry? How do additive technologies affect accuracy, manufacturing time, production cost?

- Now the technology is only gaining market, so the costs for manufacturers are quite high: this applies to both equipment and raw materials.

Nevertheless, the market is growing, along with this, prices for equipment are falling, powders are becoming more affordable, and now it is very important for any company to take its share in this market just at the stage of its formation, in order not only to become a leading manufacturer, but also determine the segment development vector.

As for aluminum, additive technologies will not revolutionize production in the near future: primary metal, alloys, and semi-finished products will not go anywhere. But the share of products made using additive technologies will certainly continue to grow.

close

100%

— In what areas can aluminum parts created using these technologies be useful?

- Aluminum products created using additive technologies will be used in the automotive and mechanical engineering, in the aerospace industry, growth is expected in the consumer electronics segment. For example, if we talk about the aviation industry, we, together with Russian Helicopters, have successfully manufactured aircraft parts using our own AlSi10Mg alloy powder.

By and large, these are the areas where aluminum is already in demand, and all areas of aluminum application, including potential ones, are open to new technology. And to expand the possibilities of using additive technologies around the world, and Rusal is no exception, work is underway to create new powder alloys with improved properties.

With the reduction in the cost of production technology, with the discovery of new alloys, compositions, the demand for additive parts will only grow. The advantage of additive technologies lies primarily in the absence of restrictions inherent in traditional production methods.

A significant advantage is the possibility of an individual approach, when changes to the product do not require reconfiguration of equipment and replacement of expensive technological equipment.

- What parts can be created with current capabilities? In your opinion, is metal printing now more about developments and prototypes, or is it about ready-made things?

— The possibilities of creating aluminum parts using additive technologies are limited only by the capabilities of the equipment, more precisely by the size of the working space of a 3D printer, but this barrier is gradually becoming a thing of the past. Almost anything can be made. Indeed, the greatest advantages of 3D printing are in prototyping, because even with the high cost of the technology, the opportunities for creating "piece" samples are wider in terms of development time and resources involved.

Almost anything can be made. Indeed, the greatest advantages of 3D printing are in prototyping, because even with the high cost of the technology, the opportunities for creating "piece" samples are wider in terms of development time and resources involved.

But it would be wrong to attribute the use of additive technologies exclusively to the development stage: in single and small-scale production, the growing opportunities of the 3D printing market are already actively used. In addition, the use of additive technologies is practically waste-free, and in terms of the growing importance of the environmental component of production, 3D printing will become even more in demand by companies.

— By the way, what is more important in metal 3D printing — the printer itself or the material?

— The printer is a tool, the quality of the final product depends on its characteristics. If the equipment does not have sufficient accuracy, then no quality of aluminum powder will correct the situation. But this also applies to the material from which we manufacture products, so talking about the priority of the printer or metal is not entirely true. The final product depends equally on the quality of the equipment and the material.

But this also applies to the material from which we manufacture products, so talking about the priority of the printer or metal is not entirely true. The final product depends equally on the quality of the equipment and the material.

— Are the printers produced in Russia or do we import them from abroad?

- If we talk about 3D printers, then, unfortunately, they are mostly imported. It was not us who stood at the origins of the technology, and samples of printers were not created in Russia, so now we need to catch up with the leaders.

Nevertheless, positive developments in this direction should also be noted - some Russian companies, for example, the Regional Engineering Center of UrFU and TsNIITMASH, are actively developing their own 3D printers, which will be manufactured using domestic components.

— What is the situation with powders?

— Here Russia has much more opportunities now. For example, Rusal has the strongest research and production base for the production of aluminum powders - we produce powders at specialized sites of enterprises in the Irkutsk region and Volgograd, and the company's ETC activity allows us to be optimistic about the development of this area.

At the moment, the world market for aluminum powders for 3D printing is not so large and is about 170 tons per year, about 500-700 tons of powders are produced from other metal alloys.

But in the medium term, we intend to take up to 25% of the world market for aluminum powders for 3D printers.

— How is the situation with additive technologies in Russia in general? Does the state provide any support, financial or bureaucratic? Is there a "government order" for the relevant specialists?

- One of the main problems for Russia in the development of additive technologies is the lack of qualified specialists in this field, as well as the lack of national standards for additive manufacturing. However, these issues are being addressed.

Now we are taking measures to widely introduce additive technologies. First of all, work is underway in the field of regulatory documentation. For example, in the United States, standards in the field of additive technologies have been in place for more than five years, which facilitates their application in high-tech industries.