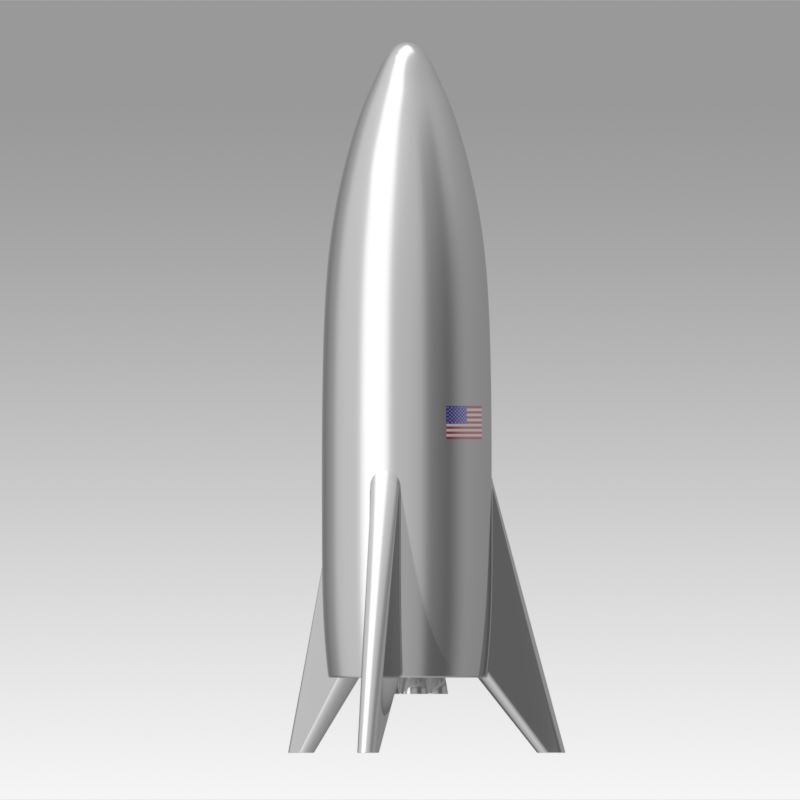

Spacex starship 3d print

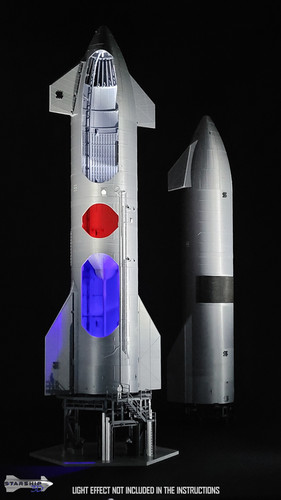

Starship S20 & Superheavy BN4 3d Model digital STL Model

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Click to zoom

119 sales |

5 out of 5 stars €24. 99

Loading

VAT Included

Explore related categories

Listed on Sep 25, 2022

149 favorites

Report this item to Etsy

Choose a reason…There’s a problem with my orderIt uses my intellectual property without permissionI don’t think it meets Etsy’s policiesChoose a reason…

The first thing you should do is contact the seller directly.

If you’ve already done that, your item hasn’t arrived, or it’s not as described, you can report that to Etsy by opening a case.

Report a problem with an order

We take intellectual property concerns very seriously, but many of these problems can be resolved directly by the parties involved. We suggest contacting the seller directly to respectfully share your concerns.

If you’d like to file an allegation of infringement, you’ll need to follow the process described in our Copyright and Intellectual Property Policy.

Review how we define handmade, vintage and supplies

See a list of prohibited items and materials

Read our mature content policy

The item for sale is…not handmade

not vintage (20+ years)

not craft supplies

prohibited or that use prohibited materials

not properly labeled as mature content

Please choose a reason

Tell us more about how this item violates our policies.Tell us more about how this item violates our policies.

▷ spacex starship 3d models 【 STLFinder 】

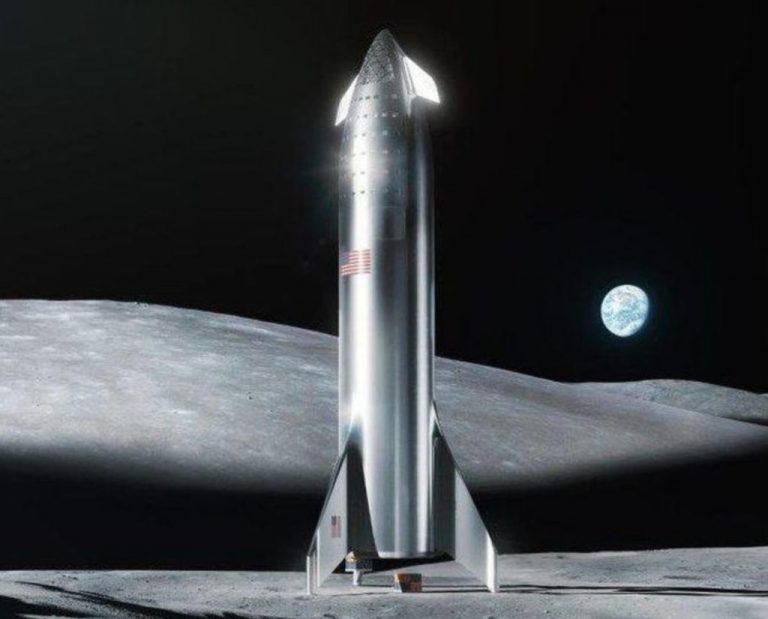

SpaceX Starship

thingiverse

Here is the STL for the SpaceX starship I made. ...It includes the new and old engine layout.

...It includes the new and old engine layout.

SpaceX Starship

sketchfab

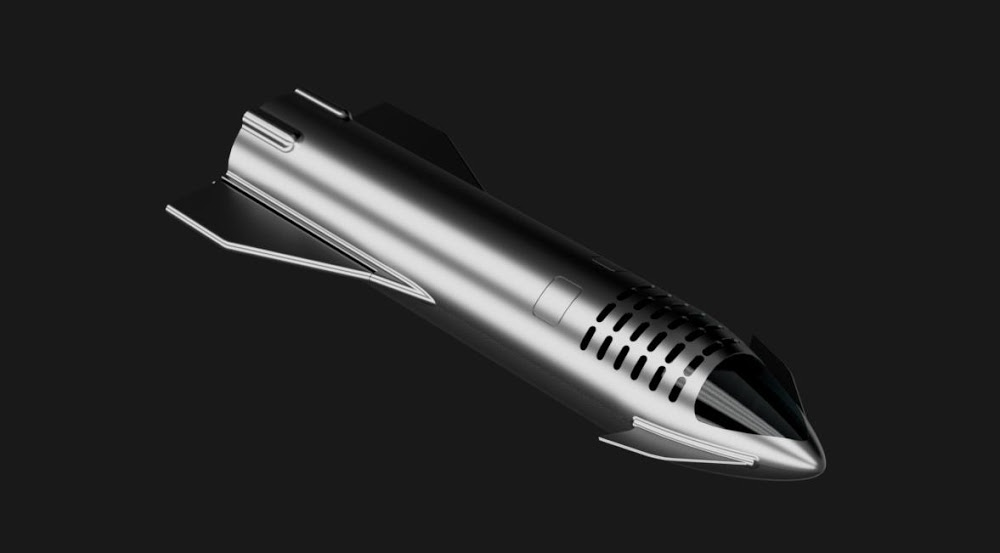

My usual minimalistic take on the SpaceX Starship. My first shot in a very long time at creating a vehicle. I think I’m fairly happy with it. ...Now let’s get our collective butts to Mars!

SpaceX-StarShip

thingiverse

SpaceX-StarShip made with solid works and render by fusion 360, enjoy!! ... - If you want to supportme :) <a href="https://www.buymeacoffee.com/TheoROCHARD" target="_blank"><img src="https://cdn.buymeacoffee.com/buttons/v2/default-orange.png" alt="Buy...

SpaceX Starship

thingiverse

Here is a model of the SpaceX StarShip. This rocket will be the largest and most powerful vehicle ever made. Starship will be responsible for missions to Mars, the Moon, and possibly even missions on earth. StarShip has the capability to carry up...

This rocket will be the largest and most powerful vehicle ever made. Starship will be responsible for missions to Mars, the Moon, and possibly even missions on earth. StarShip has the capability to carry up...

SpaceX Starship

grabcad

This is a work in progress Starship Model

SpaceX Starship

thingiverse

I couldn't find an easy-to-print model of the latest design of Elon Musk's Starship, so I designed one that isn't difficult to print and doesn't take too long. ...If you have any questions post them in the comments below.

SpaceX Starship 3D model

cgtrader

SpaceX Starship model

SpaceX Starship Model

grabcad

SpaceX Starship model and Assembly

Rocket, SpaceX starship

cults3d

A 3D model of SpaceX starship

SPACEX Starship SN10

grabcad

This is an accurate Model of SpaceX Starship from SpaceX Drawings which is 3D printable

SpaceX Starship fincan

thingiverse

SpaceX Starship fincans for 3in and 4in tubes. Intended to be 3D printed and then epoxied to the body tube. ...I will be posting the nosecone shortly.

Intended to be 3D printed and then epoxied to the body tube. ...I will be posting the nosecone shortly.

SpaceX Starship Superheavy 2020

myminifactory

SpaceX Starship & Superheavy scale: 1/100. ...Check out the SpaceshipMania YouTube for assembly and more: https://www.youtube.com/watch?v=uh5AMnK6FD4

SpaceX Starship SN8

myminifactory

SpaceX Starship SN8 kit scale: 1/100. ...Check out the SpaceshipMania YouTube for assembly and more: https://www.youtube.com/watch?v=89CaSA5p2fc

SpaceX Starship HLS

myminifactory

SpaceX Starship HLS scale: 1/100. ...Check out the SpaceshipMania YouTube channel for assembly and more: https://www.youtube.com/channel/UCQXI2_3fN9TameVbDKW-ODg

...Check out the SpaceshipMania YouTube channel for assembly and more: https://www.youtube.com/channel/UCQXI2_3fN9TameVbDKW-ODg

SpaceX Starship Cookie Cutter

thingiverse

For your Enjoyment and inspiration, to celebrate the first SpaceX Starship belly flop. ... PETG is not dishwasher safe in my experience!

SpaceX STARSHIP SN10

thingiverse

This is the most upto date Version of SpaceX SN10 Starship from Accurate Drawings

Rocket SpaceX Starship

sketchfab

Starship is a new generation manned spacecraft being developed by the private American company SpaceX. ...Starship is designed to launch more than 100 tons of payload into low orbit.

...Starship is designed to launch more than 100 tons of payload into low orbit.

[OLD] SpaceX Starship SN8

thingiverse

SpaceX Starship prototype SN8! Not much to say about this one, other than it's got flaps! FLAPS! If you print this, post a make! ...I'd love to see it :D

SpaceX Starship SN10

cults3d

Easy to print model of spaceX Starships with movable print-in-place flaps! Close the flaps to lock the screw even more securely. You can use it for show or as storage for pens, brushes, rulers or anything else which fits in there. ...It's pretty...

SpaceX Starship LEGO

sketchfab

. .. model. ...LEGO model of SpaceX Starship on Mars. Feel free to support on LEGO IDEAs if you like ;) https://ideas.lego.com/projects/f1cda019-d668-4d6e-bcd5-7b2057e07369 https://www.instagram.com/awesomeclublego/ www.awesomeclub.io Cheers. ...Steve.

.. model. ...LEGO model of SpaceX Starship on Mars. Feel free to support on LEGO IDEAs if you like ;) https://ideas.lego.com/projects/f1cda019-d668-4d6e-bcd5-7b2057e07369 https://www.instagram.com/awesomeclublego/ www.awesomeclub.io Cheers. ...Steve.

SpaceX Starship Lit Ornament

thingiverse

An ornament of the SpaceX Starship that fits around a standard Christmas mini light. Inspired by the design by AndysTechGarage (https://www.thingiverse.com/andystechgarage) and suggested by u/Tqm2012 on Reddit. The hook is designed to be able to hang...

SpaceX Starship (Outdated)

thingiverse

--THIS DESIGN IS NOW OUTDATED-- This is a model of the SpaceX Starship design as of June 2019, and will more than likey be outdated by the time you're reading this :P. I haven't printed this yet, but I'm pretty sure it's printable. I made the...

I haven't printed this yet, but I'm pretty sure it's printable. I made the...

SpaceX Starship Mk1

thingiverse

This is a 1:250 model of the SpaceX Starship in the configuration from the Elon Musk presentation on 9/28/2019. It has now been taken apart to finish construction and the design will probably change slightly before it flies, but I wanted to make this...

SpaceX Starship "Dear Moon"

thingiverse

Its key component is a private spaceflight involving Maezawa, several artists and one or two crew members on board SpaceX Starship flying on a circumlunar trajectory around the Moon. The project was unveiled in September 2018 and the flight is. ..

..

SpaceX Starship S20/B4

thingiverse

This is a custom made model of the SpaceX starship prototypes Ship 20 and Booster 4 (also known as S20/B4 or SN20/BN4) this pair of vehicles is now retired THIS MODEL IS 1:100 SCALE TO THE REAL VEHICLE, SO IT IS QUITE LARGE i am working on the next...

[OLD] SpaceX Starship SN5

thingiverse

... just slice and print! Print with supports, just to be safe. Go SpaceX, go Starship! UPDATE 10/27/2020: Updated the post to include "E-Z" versions of the tank sections without reinforcing bars inside the rings. ...Makes the print a lot easier.

SpaceX Starship Mk1

thingiverse

This is a 1:275 model of the SpaceX Starship Mk1. Over the past few months, SpaceX has been constructing a prototype starship vehicle at their facility in Boca Chica Texas. Last night (9/28/19) Elon Musk delivered a presentation giving the public...

Over the past few months, SpaceX has been constructing a prototype starship vehicle at their facility in Boca Chica Texas. Last night (9/28/19) Elon Musk delivered a presentation giving the public...

SpaceX Starship Lit Ornament

prusaprinters

An ornament of the SpaceX Starship that fits around a standard Christmas mini light. Inspired by the design by AndysTechGarage (<a href="/andystechgarage">https://www.thingiverse.com/andystechgarage</a>) and suggested by u/Tqm2012 on Reddit. The hook...

SpaceX Starship Hopper

thingiverse

This is a model of SpaceX's Starship Hopper. It was designed from scratch using the renders and pictures available so far.

There are two versions:

- all in one (aio), hence you can print the whole body in one piece.

- a split up body into three...

It was designed from scratch using the renders and pictures available so far.

There are two versions:

- all in one (aio), hence you can print the whole body in one piece.

- a split up body into three...

SpaceX Starship SN8

thingiverse

(See updates at bottom of section.) SpaceX's Starship SN8 high-altitude prototype: My first real model! I started this back in December originally intended for a smaller scale, but I went too far into detail and had to scale it up to it's current...

3D printing and space: the most important

1. The use of additive technologies in the manufacture of spacecraft parts.

3D printing is actively used in the aerospace industry for the manufacture of prototypes, engine parts and tooling. Its use allows the manufacturer to reduce the cost of products, improve their performance, and significantly reduce the time of manufacture of individual products. All major companies involved in aerospace production are turning to additive technologies in one way or another.

All major companies involved in aerospace production are turning to additive technologies in one way or another.

Mostly 3D printed engine parts. Thus, the American company Aerojet Rocketdyne has signed a contract for 1.6 billion dollars for the production of the RS-25 rocket engine, some of the parts for which will be made on a 3D printer. Production of a single part by traditional methods could take half a year - 3D printing allowed Aerojet Rocketdyne to reduce time and costs, significantly speed up the prototype production process. In addition, the company successfully uses additive technologies in other projects.

Another US company, Rocket Lab, is building New Zealand's first orbital launch station. It is from there that it is planned to launch the world's first rocket, the oxygen-hydrocarbon engine of which is completely printed on a 3D printer.

The list would be incomplete without businessman and designer Elon Musk. His company SpaceX has successfully tested 3D-printed SuperDraco engines to be used in the Dragon spacecraft and is also working on the Raptor Rocket propulsion system.

Other industrial giants didn't stop at engines. Blue Origin used over 400 3D printed parts on New Sheppard's first flight in June 2015.

And Boeing has contracted Oxford Performance Materials, a leading additive manufacturing specialist, to produce 600 3D printed parts for the new Starliner space taxis.

Additive technologies are also used in promising projects of the near future. NASA is using advanced techniques in preparing for a Mars mission: 3D printing is already being used to create prototypes, manufacture parts in space, and even make engine parts for a future ship that will go to Mars.

The Russian aerospace industry is also beginning to introduce 3D printing. For these purposes, the Roscosmos Corporation has received a unique domestic 3D printer Router 3131 with a large print field. He will create elements of spacecraft.

2. The use of 3D printing in the production of satellites and devices.

Another direction in the aerospace industry, which we decided to consider separately, is additive technologies in the production of satellites. Unlike a rocket, the cost of a satellite is significantly lower, but it can also be reduced by paying attention to innovative technologies.

Unlike a rocket, the cost of a satellite is significantly lower, but it can also be reduced by paying attention to innovative technologies.

Aerospace giant Boeing has done just that by using 3D printing to produce modular satellites. Now one device costs, on average, 150 million dollars - this price is due not only to the high-tech component, but also to the significant cost of the labor force involved in production. When using 3D printers, the cost and production time of satellites are significantly reduced.

Small start-ups and research projects have more modest goals, but 3D printing helps them too. A team of researchers at Northwestern Nazarene University in Idaho awaits the launch of their 3D-printed MakerSat satellite, the first in the state, into space. The dimensions of the device are only 10x10x11.35 cm, and it is created from available polymers for 3D printing (ABS, ULTEM and nylon).

High performance satellite developer Millennium Space Systems recently announced the completion of a pre-production model of the ALTAIR series, which is now being prepared for launch into space. The new technologies used in the design of the satellite will make new space missions possible. For example, 3D printing will save on the cost of sending parts into space and reduce the time it takes to prepare and conduct missions.

The new technologies used in the design of the satellite will make new space missions possible. For example, 3D printing will save on the cost of sending parts into space and reduce the time it takes to prepare and conduct missions.

Russian scientists also excelled. In 2016, the Tomsk-TPU-120 small satellite was developed at the Tomsk Polytechnic University. When creating the device, scientists and students of Tomsk Polytechnic University used additive technologies - the frame and most of the components are printed on a 3D printer. On March 31, 2016, the 3D satellite left the Earth and settled in orbit.

Juno flew even further. The NASA space station with that name entered Jupiter's orbit in the summer of 2016. This event is also important for 3D printing, as Juno became the first spacecraft with 3D printed parts - titanium waveguide elements manufactured by Lockheed Martin.

3. Space 3D printers.

Astronauts in orbit often cannot provide themselves with everything they need and have to wait for cargo that arrives at the International Space Station (ISS) during scheduled flights. Unfortunately, during this time the crew is not insured against accidents or breakdowns of important systems. 3D printing experiments in space offer the potential to print needed parts if any parts fail in space. This is very important for future flights to Mars and other planets: for a long time, the colonists will not be able to receive help from Earth. Therefore, in the forthcoming expeditions, it is extremely important to use all available opportunities for the manufacture of products on board ships and space stations.

Unfortunately, during this time the crew is not insured against accidents or breakdowns of important systems. 3D printing experiments in space offer the potential to print needed parts if any parts fail in space. This is very important for future flights to Mars and other planets: for a long time, the colonists will not be able to receive help from Earth. Therefore, in the forthcoming expeditions, it is extremely important to use all available opportunities for the manufacture of products on board ships and space stations.

Such experiments have been carried out on the ISS since 2014. It was then that the Zero G 3D printer manufactured by Made in Space was delivered to the American segment of the station. The first print took place on November 24, 2014 and marked a new era in the development of 3D technologies. The printed object was a part of the printer itself, the faceplate of the printhead, symbolizing the ability to one day print a 3D printer in space on a 3D printer. In 2016, another Made in Space printer called the Additive Manufacturing Facility (AMF) was delivered to the ISS.

Since then, print trials on the ISS have taken place regularly. One of the latest ideas was an innovative plan by the Canadian company 3D4MD, which involved printing medical devices, such as splints or surgical instruments, on the ISS. To create devices such as custom splints for broken fingers, 3D4MD's developers could use, for example, measurements taken during the preparation of spacesuits and create a model on Earth. The 3D model can then be sent to the ISS, where the tire will be 3D printed.

Roskosmos is also developing a similar project. An experiment called "3D printing" should confirm the possibility of using a 3D printer in the absence of gravity. This device was created within the walls of the Tomsk Polytechnic Institute and agreed with the engineers of RSC Energia. The printer will go to the ISS in 2018.

Not being able to conduct experiments in space, other powers organize experiments on the ground. A development team from China recently successfully tested the first 3D printer designed for weightless conditions. Many difficult tests were carried out in the French city of Bordeaux.

Many difficult tests were carried out in the French city of Bordeaux.

4. 3D bioprinting in space.

It is known that in outer space there is electromagnetic and radiation radiation that has a detrimental effect on biological tissues. In order for the astronaut to be able to endure all the hardships of the flight, the protection of the ship alone is not enough - it is necessary to think about high-quality medical care. And if it does not help, then it’s about replacing any organs.

That is why the Russian United Rocket and Space Corporation (ORSC) agreed on an experiment to use a 3D bioprinter on the International Space Station (ISS). Its developer was the Russian laboratory 3D Bioprinting Solutionsspecializing in bioprinting technologies. Scientists hope that the magnetic bioprinter will make it possible to create tissues and organs in space. It is expected that the device will be delivered to the ISS by 2018.

There are no analogues of the Russian project abroad yet.

5. Construction of structures using building 3D printing.

One of the most basic problems in the construction of buildings on extraterrestrial objects is the limited amount or lack of building material. The only available raw materials that do not need to be transported from our planet are local geological rocks. It is not surprising that scientists are solving the problem of using them in the construction of buildings.

For example, engineers at Northwestern University in the US have found a way to use quality materials in situations where resources are limited. We are talking about the process of additive manufacturing from special materials that mimic the lunar and Martian regolith. These are strong and elastic materials that are produced using powdered substances that resemble rocks from the surface of the Moon and Mars.

It is likely that this technology will be used in the colonization of Mars. Due to extreme temperatures and high radiation on the surface of the "red planet", the first colonizers will need reliable shelters. NASA experts propose using 3D printing to create a "dome" of ice from the surface of Mars, covered with a transparent membrane of fluoroplast-40. One of the main advantages of a water-based dwelling is that such walls protect from cosmic radiation, but do not prevent the penetration of light - this creates some comfort. In addition, when choosing materials, other criteria were taken into account - their strength and reliability, the ability to withstand the difficult conditions of Mars.

NASA experts propose using 3D printing to create a "dome" of ice from the surface of Mars, covered with a transparent membrane of fluoroplast-40. One of the main advantages of a water-based dwelling is that such walls protect from cosmic radiation, but do not prevent the penetration of light - this creates some comfort. In addition, when choosing materials, other criteria were taken into account - their strength and reliability, the ability to withstand the difficult conditions of Mars.

The European Space Agency (ESA) is working in the same direction and has already achieved some results. Scientists from the Austrian University of Applied Sciences in Wiener Neustadt managed to 3D print a small needle and a corner wall from JSC-Mars-1A material, which mimics Martian soil.

In addition to serious research, there are quite unexpected projects. So, experts from the ESA we mentioned thought about saving the souls of the first lunar colonists and planned to build a temple on the moon using 3D printing. This building, poetically named Temple of Eternal Light, will be located in the center of a residential complex for the first lunar settlers and will combine a prayer place and an observatory. The designers believe that the temples on the moon will revive the lost connection between mankind and the cosmos.

However, according to Vyacheslav Bobin, head of the Center for the Study of Natural Substances at the Institute for the Integrated Exploration of the Subsoil of the Russian Academy of Sciences, the construction of settlements on the Moon is not such a fantastic prospect as you might think. A new Russian lunar exploration program could provide the conditions for building a base using 3D printing. If Russian researchers manage to identify a suitable location for the colony, Bobin believes a 3D printer could be used to construct buildings later on.

That's not all the exciting news about space 3D printing. What can you say, for example, about 3D-printed rocket fuel or the use of 3D technologies in the development of a unique space suit for the first participants in a Martian mission?

Read even more up-to-date information in our special section "Space" and don't forget to congratulate your family and friends on Cosmonautics Day!

How technology is used in orbit

Stories

Stories

Anna Polyakova

Editor (RB)

Anna Polyakova

3D printing is conquering another industry - aerospace. Not only is this technology changing the way spacecraft are built, but it could also play an important role in the future colonization of other planets.

Not only is this technology changing the way spacecraft are built, but it could also play an important role in the future colonization of other planets.

However, space is a difficult environment to work in, and 3D printing faces a number of challenges in it. In this article, we will look at six main ones.

Anna Polyakova

Article content:

- Imperfect surfaces not suitable for space

- 3D printing in zero gravity becomes more difficult

- Popular FDM printing almost impossible without gravity

- Parts sometimes sticky

- Not all tools can be 3D printed

- Building "houses" can be a logistical nightmare

Imperfect surfaces are not suitable for space

Printing parts and entire spaceships in a 3D printer is a truly exciting prospect. It will reduce waste from production, as well as help create lighter and more fuel-efficient rockets. However, this technology has a serious problem.

It will reduce waste from production, as well as help create lighter and more fuel-efficient rockets. However, this technology has a serious problem.

3D printing produces imperfect surfaces. This becomes apparent when looking at a 3D printed part through a microscope. It may work on Earth, but space requires a different level of accuracy, as errors are almost unacceptable there. A flawed surface can develop cracks and be damaged by countless objects flying through space.

3D printing in zero gravity becomes more difficult

Now we are not saying that 3D printing in space, without gravity at all, is impossible. However, organizing this process is not easy.

The basic design of a 3D printer remains the same, but printing in zero gravity requires special additions. In space, gravity no longer holds the layers of an object together before they cool, so the material itself must be sticky and prevent them from separating from each other.

Popular FDM printing is almost impossible without gravity

FDM printing is a well-known standard that can be stumbled upon by google "3D printing". If you have a 3D printer, chances are it is an FDM printer. FDM printing is good, but some believe that there are more functional and accurate technologies that use powder or photopolymer.

However, weightlessness makes these processes practically impossible. The lack of gravity makes it difficult to combine parts during printing. However, there are companies that are currently working with NASA to find potential alternatives to FDM printing.

Parts are sometimes sticky

As mentioned above, due to the lack of gravity, 3D printers must hold parts in place and hold layers together during FDM printing. There have been several cases of objects getting stuck on the build plates so hard that both the build plates and the printer were damaged.

Although 3D printers have been successfully printed many times in space, there are occasional issues that indicate that the process is not yet perfect.

Not all tools can be 3D printed

One of the biggest benefits of having a 3D printer on a ship is the ability to travel light into space. All necessary tools and spare parts can be simply printed. But how to figure out what to take with you, and what can a 3D printer handle?

Although researchers do their best to ensure the safety of space flight, people and ships are always exposed to unforeseen factors that are difficult to predict. What to take with you and what to leave behind 3D printing is not an easy choice.

Building "houses" can be a logistical nightmare

When people finally get to planet X, they probably won't want to work in harsh conditions. Perhaps living quarters and laboratories will be created using 3D printers.