3D printer strategy

The 3-D Printing Revolution

Idea in Brief

The Breakthrough

Additive manufacturing, or 3-D printing, is poised to transform the industrial economy. Its extreme flexibility not only allows for easy customization of goods but also eliminates assembly and inventories and enables products to be redesigned for higher performance.

The Challenge

Management teams should be reconsidering their strategies along three dimensions: (1) How might our offerings be enhanced, either by us or by competitors? (2) How should we reconfigure our operations, given the myriad new options for fabricating products and parts? (3) How will our commercial ecosystem evolve?

The Big Play

Inevitably, powerful platforms will arise to establish standards and facilitate exchanges among the designers, makers, and movers of 3-D-printed goods. The most successful of these will prosper mightily.

Leer en español

Ler em português

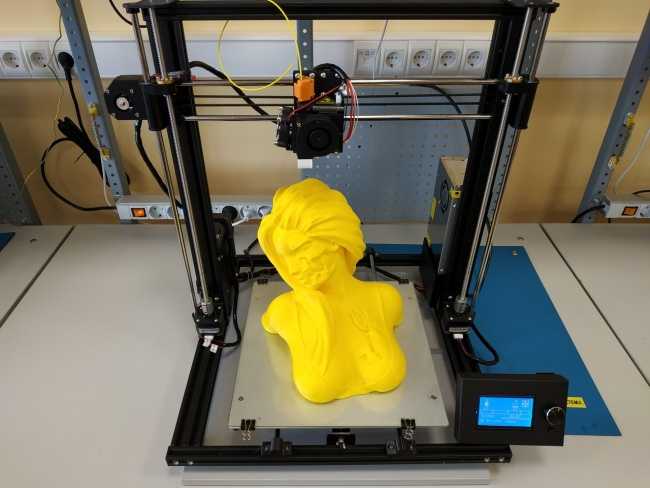

Industrial 3-D printing is at a tipping point, about to go mainstream in a big way. Most executives and many engineers don’t realize it, but this technology has moved well beyond prototyping, rapid tooling, trinkets, and toys. “Additive manufacturing” is creating durable and safe products for sale to real customers in moderate to large quantities.

The beginnings of the revolution show up in a 2014 PwC survey of more than 100 manufacturing companies. At the time of the survey, 11% had already switched to volume production of 3-D-printed parts or products. According to Gartner analysts, a technology is “mainstream” when it reaches an adoption level of 20%.

Among the numerous companies using 3-D printing to ramp up production are GE (jet engines, medical devices, and home appliance parts), Lockheed Martin and Boeing (aerospace and defense), Aurora Flight Sciences (unmanned aerial vehicles), Invisalign (dental devices), Google (consumer electronics), and the Dutch company LUXeXcel (lenses for light-emitting diodes, or LEDs). Watching these developments, McKinsey recently reported that 3-D printing is “ready to emerge from its niche status and become a viable alternative to conventional manufacturing processes in an increasing number of applications. ” In 2014 sales of industrial-grade 3-D printers in the United States were already one-third the volume of industrial automation and robotic sales. Some projections have that figure rising to 42% by 2020.

” In 2014 sales of industrial-grade 3-D printers in the United States were already one-third the volume of industrial automation and robotic sales. Some projections have that figure rising to 42% by 2020.

Further Reading

More companies will follow as the range of printable materials continues to expand. In addition to basic plastics and photosensitive resins, these already include ceramics, cement, glass, numerous metals and metal alloys, and new thermoplastic composites infused with carbon nanotubes and fibers. Superior economics will eventually convince the laggards. Although the direct costs of producing goods with these new methods and materials are often higher, the greater flexibility afforded by additive manufacturing means that total costs can be substantially lower.

With this revolutionary shift already under way, managers should now be engaging with strategic questions on three levels:

First, sellers of tangible products should ask how their offerings could be improved, whether by themselves or by competitors. Fabricating an object layer by layer, according to a digital “blueprint” downloaded to a printer, allows not only for limitless customization but also for designs of greater intricacy.

Fabricating an object layer by layer, according to a digital “blueprint” downloaded to a printer, allows not only for limitless customization but also for designs of greater intricacy.

Second, industrial enterprises must revisit their operations. As additive manufacturing creates myriad new options for how, when, and where products and parts are fabricated, what network of supply chain assets and what mix of old and new processes will be optimal?

Third, leaders must consider the strategic implications as whole commercial ecosystems begin to form around the new realities of 3-D printing. Much has been made of the potential for large swaths of the manufacturing sector to atomize into an untold number of small “makers.” But that vision tends to obscure a surer and more important development: To permit the integration of activities across designers, makers, and movers of goods, digital platforms will have to be established. At first these platforms will enable design-to-print activities and design sharing and fast downloading. Soon they will orchestrate printer operations, quality control, real-time optimization of printer networks, and capacity exchanges, among other needed functions. The most successful platform providers will prosper mightily by establishing standards and providing the settings in which a complex ecosystem can coordinate responses to market demands. But every company will be affected by the rise of these platforms. There will be much jockeying among incumbents and upstarts to capture shares of the enormous value this new technology will create.

Soon they will orchestrate printer operations, quality control, real-time optimization of printer networks, and capacity exchanges, among other needed functions. The most successful platform providers will prosper mightily by establishing standards and providing the settings in which a complex ecosystem can coordinate responses to market demands. But every company will be affected by the rise of these platforms. There will be much jockeying among incumbents and upstarts to capture shares of the enormous value this new technology will create.

These questions add up to a substantial amount of strategic thinking, and still another remains: How fast will all this happen? For a given business, here’s how fast it can happen: The U.S. hearing aid industry converted to 100% additive manufacturing in less than 500 days, according to one industry CEO, and not one company that stuck to traditional manufacturing methods survived. Managers will need to determine whether it’s wise to wait for this fast-evolving technology to mature before making certain investments or whether the risk of waiting is too great. Their answers will differ, but for all of them it seems safe to say that the time for strategic thinking is now.

Their answers will differ, but for all of them it seems safe to say that the time for strategic thinking is now.

Additive’s Advantages

It may be hard to imagine that this technology will displace today’s standard ways of making things in large quantities. Traditional injection-molding presses, for example, can spit out thousands of widgets an hour. By contrast, people who have watched 3-D printers in action in the hobbyist market often find the layer-by-layer accretion of objects comically slow. But recent advances in the technology are changing that dramatically in industrial settings.

Some may forget why standard manufacturing occurs with such impressive speed. Those widgets pour out quickly because heavy investments have been made up front to establish the complex array of machine tools and equipment required to produce them. The first unit is extremely expensive to make, but as identical units follow, their marginal cost plummets.

Additive manufacturing doesn’t offer anything like that economy of scale. However, it avoids the downside of standard manufacturing—a lack of flexibility. Because each unit is built independently, it can easily be modified to suit unique needs or, more broadly, to accommodate improvements or changing fashion. And setting up the production system in the first place is much simpler, because it involves far fewer stages. That’s why 3-D printing has been so valuable for producing one-offs such as prototypes and rare replacement parts. But additive manufacturing increasingly makes sense even at higher scale. Buyers can choose from endless combinations of shapes, sizes, and colors, and this customization adds little to a manufacturer’s cost even as orders reach mass-production levels.

However, it avoids the downside of standard manufacturing—a lack of flexibility. Because each unit is built independently, it can easily be modified to suit unique needs or, more broadly, to accommodate improvements or changing fashion. And setting up the production system in the first place is much simpler, because it involves far fewer stages. That’s why 3-D printing has been so valuable for producing one-offs such as prototypes and rare replacement parts. But additive manufacturing increasingly makes sense even at higher scale. Buyers can choose from endless combinations of shapes, sizes, and colors, and this customization adds little to a manufacturer’s cost even as orders reach mass-production levels.

A big part of the additive advantage is that pieces that used to be molded separately and then assembled can now be produced as one piece in a single run. A simple example is sunglasses: The 3-D process allows the porosity and mixture of plastics to vary in different areas of the frame. The earpieces come out soft and flexible, while the rims holding the lenses are hard. No assembly required.

The earpieces come out soft and flexible, while the rims holding the lenses are hard. No assembly required.

Printing parts and products also allows them to be designed with more-complex architectures, such as honeycombing within steel panels or geometries previously too fine to mill. Complex mechanical parts—an encased set of gears, for example—can be made without assembly. Additive methods can be used to combine parts and generate far more interior detailing. That’s why GE Aviation has switched to printing the fuel nozzles of certain jet engines. It expects to churn out more than 45,000 of the same design a year, so one might assume that conventional manufacturing methods would be more suitable. But printing technology allows a nozzle that used to be assembled from 20 separately cast parts to be fabricated in one piece. GE says this will cut the cost of manufacturing by 75%.

U.S. hearing aid companies converted to 100% 3-D printing in less than 500 days.

Additive manufacturing can also use multiple printer jets to lay down different materials simultaneously. Thus Optomec and other companies are developing conductive materials and methods of printing microbatteries and electronic circuits directly into or onto the surfaces of consumer electronic devices. Additional applications include medical equipment, transportation assets, aerospace components, measurement devices, telecom infrastructure, and many other “smart” things.

Thus Optomec and other companies are developing conductive materials and methods of printing microbatteries and electronic circuits directly into or onto the surfaces of consumer electronic devices. Additional applications include medical equipment, transportation assets, aerospace components, measurement devices, telecom infrastructure, and many other “smart” things.

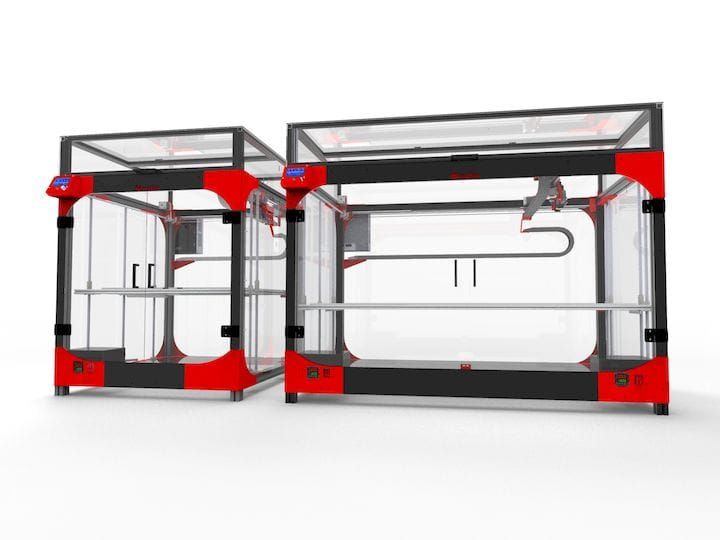

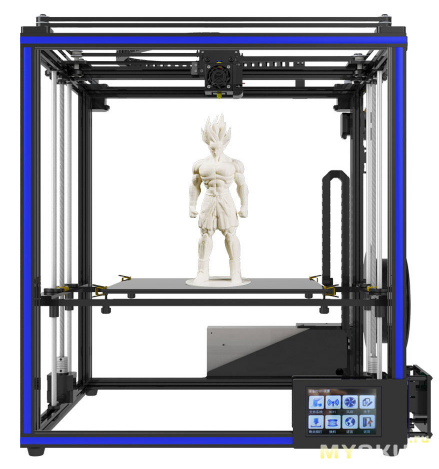

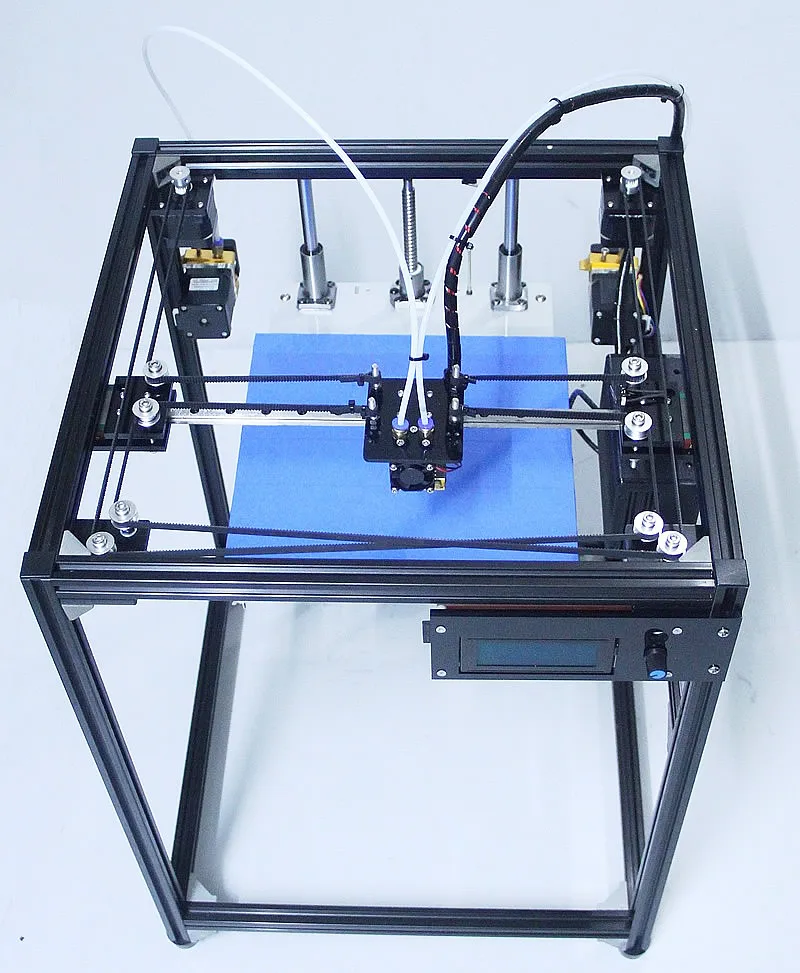

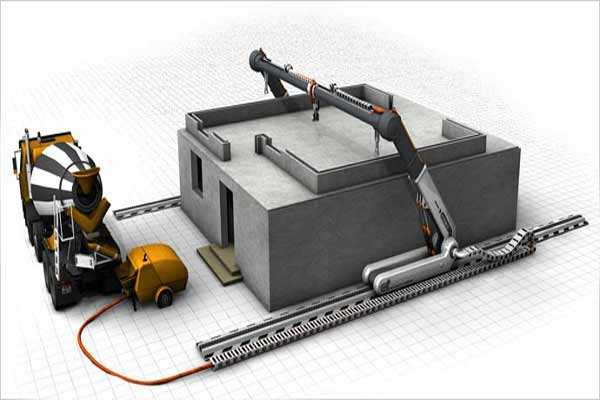

The enormous appeal of limiting assembly work is pushing additive manufacturing equipment to grow ever larger. At the current extreme, the U.S. Department of Defense, Lockheed Martin, Cincinnati Tool Steel, and Oak Ridge National Laboratory are partnering to develop a capability for printing most of the endo- and exoskeletons of jet fighters, including the body, wings, internal structural panels, embedded wiring and antennas, and soon the central load-bearing structure. So-called big area additive manufacturing makes such large-object fabrication possible by using a huge gantry with computerized controls to move the printers into position. When this process has been certified for use, the only assembly required will be the installation of plug-and-play electronics modules for navigation, communications, weaponry, and electronic countermeasure systems in bays created during the printing process. In Iraq and Afghanistan the U.S. military has been using drones from Aurora Flight Sciences, which prints the entire body of these unmanned aerial vehicles—some with wingspans of 132 feet—in one build.

When this process has been certified for use, the only assembly required will be the installation of plug-and-play electronics modules for navigation, communications, weaponry, and electronic countermeasure systems in bays created during the printing process. In Iraq and Afghanistan the U.S. military has been using drones from Aurora Flight Sciences, which prints the entire body of these unmanned aerial vehicles—some with wingspans of 132 feet—in one build.

Three-Dimensional Strategy

This brief discussion of additive manufacturing’s advantages suggests how readily companies will embrace the technology—and additional savings in inventory, shipping, and facility costs will make the case even stronger. The clear implication is that managers in companies of all kinds should be working to anticipate how their businesses will adapt on the three strategic levels mentioned above.

Offerings, redesigned.

Product strategy is the answer to that most basic question in business, What will we sell? Companies will need to imagine how their customers could be better served in an era of additive manufacturing. What designs and features will now be possible that were not before? What aspects can be improved because restrictions or delivery delays have been eliminated?

What designs and features will now be possible that were not before? What aspects can be improved because restrictions or delivery delays have been eliminated?

For example, in the aerospace and automotive industries, 3-D printing will most often be used in the pursuit of performance gains. Previously, the fuel efficiency of jet fighters and vehicles could be enhanced by reducing their weight, but this frequently made them less structurally sound. The new technology allows manufacturers to hollow out a part to make it lighter and more fuel-efficient and incorporate internal structures that provide greater tensile strength, durability, and resistance to impact. And new materials that have greater heat and chemical resistance can be used in various spots in a product, as needed.

Want to know how fast the 3-D future is coming? Don’t look only at adoption rates among manufacturers. Look at the innovation rates of inventors. In 2005 only 80 patents relating to additive manufacturing materials, software, and equipment were granted worldwide, not counting duplicates filed in multiple countries. By 2013 that number had gone into orbit, with approximately 600 new nonduplicative patents issued around the globe.

By 2013 that number had gone into orbit, with approximately 600 new nonduplicative patents issued around the globe.

What are some of the companies behind these patents? Not surprisingly, the two leaders are Stratasys and 3D Systems, rivals that have staked out positions in additive manufacturing. They hold 57 and 49 nonduplicative patents respectively. As befits its printing heritage, Xerox, too, has invested heavily in additive technologies for making electronics and has developed a strong alliance with 3D Systems. Panasonic, Hewlett-Packard, 3M, and Siemens likewise hold numerous patents.

But surprisingly, the largest users of 3-D printing have also been active innovators. Fourth on the list, with 35 patents, is Therics, a manufacturer of medical devices. These commercial companies understand additive manufacturing’s potential to give them important advantages over competitors.

Also noteworthy among patent holders are companies that straddle both worlds. GE and IBM are important manufacturers but are increasingly invested in platforms that optimize value chains run by other companies. GE (11 patents) is developing the industrial internet, and IBM (19) has worked out what it is calling the “software-defined supply chain” and optimization software for smart manufacturing systems. Both are well positioned to take on similar roles with regard to additive manufacturing—and both bear watching as models for how incumbents can capture disproportionate value from a highly disruptive technology.

GE (11 patents) is developing the industrial internet, and IBM (19) has worked out what it is calling the “software-defined supply chain” and optimization software for smart manufacturing systems. Both are well positioned to take on similar roles with regard to additive manufacturing—and both bear watching as models for how incumbents can capture disproportionate value from a highly disruptive technology.

In other industries, the use of additive manufacturing for more-tailored and fast-evolving products will have ramifications for how offerings are marketed. What happens to the concept of product generations—let alone the hoopla around a launch—when things can be upgraded continually during successive printings rather than in the quantum leaps required by the higher tooling costs and setup times of conventional manufacturing? Imagine a near future in which cloud-based artificial intelligence augments additive manufacturing’s ability to change or add products instantly without retooling. Real-time changes in product strategy, such as product mix and design decisions, would become possible. With such rapid adaptation, what new advantages should be core to brand promises? And how could marketing departments prevent brand drift without losing sales?

Real-time changes in product strategy, such as product mix and design decisions, would become possible. With such rapid adaptation, what new advantages should be core to brand promises? And how could marketing departments prevent brand drift without losing sales?

Operations, reoptimized.

Operations strategy encompasses all the questions of how a company will buy, make, move, and sell goods. The answers will be very different with additive manufacturing. Greater operational efficiency is always a goal, but it can be achieved in many ways. Today most companies contemplating the use of the technology do piecemeal financial analysis of targeted opportunities to swap in 3-D equipment and designs where those can reduce direct costs. Much bigger gains will come when they broaden their analyses to consider the total cost of manufacturing and overhead.

How much could be saved by cutting out assembly steps? Or by slashing inventories through production only in response to actual demand? Or by selling in different ways—for example, direct to consumers via interfaces that allow them to specify any configuration? In a hybrid world of old and new manufacturing methods, producers will have many more options; they will have to decide which components or products to transition over to additive manufacturing, and in what order.

Additional questions will arise around facilities locations. How proximate should they be to which customers? How can highly customized orders be delivered as efficiently as they are produced? Should printing be centralized in plants or dispersed in a network of printers at distributors, at retailers, on trucks, or even in customers’ facilities? Perhaps all of the above. The answers will change in real time, adjusting to shifts in foreign exchange, labor costs, printer efficiency and capabilities, material costs, energy costs, and shipping costs.

This article also appears in:

A shorter traveling distance for products or parts not only saves money; it saves time. If you’ve ever been forced to leave your vehicle at a repair shop while the mechanic waits for a part, you’ll appreciate that. BMW and Honda, among other automakers, are moving toward the additive manufacturing of many industrial tools and end-use car parts in their factories and dealerships—especially as new metal, composite plastic, and carbon-fiber materials become available for use in 3-D printers. Distributors in many industries are taking note, eager to help their business customers capitalize on the new efficiencies. UPS, for example, is building on its existing third-party logistics business to turn its airport hub warehouses into mini-factories. The idea is to produce and deliver customized parts to customers as needed, instead of devoting acres of shelving to vast inventories. If we already live in a world of just-in-time inventory management, we now see how JIT things can get. Welcome to instantaneous inventory management.

Distributors in many industries are taking note, eager to help their business customers capitalize on the new efficiencies. UPS, for example, is building on its existing third-party logistics business to turn its airport hub warehouses into mini-factories. The idea is to produce and deliver customized parts to customers as needed, instead of devoting acres of shelving to vast inventories. If we already live in a world of just-in-time inventory management, we now see how JIT things can get. Welcome to instantaneous inventory management.

Indeed, given all the potential efficiencies of highly integrated additive manufacturing, business process management may become the most important capability around. Some companies that excel in this area will build out proprietary coordination systems to secure competitive advantage. Others will adopt and help to shape standard packages created by big software companies.

Ecosystems, reconfigured.

Finally comes the question of where and how the enterprise fits into its broader business environment. Here managers address the puzzles of Who are we? and What do we need to own to be who we are? As additive manufacturing allows companies to acquire printers that can make many products, and as idle capacity is traded with others in the business of offering different products, the answers to those questions will become far less clear. Suppose you have rows of printers in your facility that build auto parts one day, military equipment the next day, and toys the next. What industry are you part of? Traditional boundaries will blur. Yet managers need a strong sense of the company’s role in the world to make decisions about which assets they will invest in—or divest themselves of.

Here managers address the puzzles of Who are we? and What do we need to own to be who we are? As additive manufacturing allows companies to acquire printers that can make many products, and as idle capacity is traded with others in the business of offering different products, the answers to those questions will become far less clear. Suppose you have rows of printers in your facility that build auto parts one day, military equipment the next day, and toys the next. What industry are you part of? Traditional boundaries will blur. Yet managers need a strong sense of the company’s role in the world to make decisions about which assets they will invest in—or divest themselves of.

Aurora Flight Sciences can print the entire body of a drone in one build.

They may find their organizations evolving into something very different from what they have been. As companies are freed from many of the logistical requirements of standard manufacturing, they will have to look anew at the value of their capabilities and other assets and how those complement or compete with the capabilities of others.

The Platform Opportunity

One position in the ecosystem will prove to be the most central and powerful—and this fact is not lost on the management teams of the biggest players already in the business of additive manufacturing, such as eBay, IBM, Autodesk, PTC, Materialise, Stratasys, and 3D Systems. Many are vying to develop the platforms on which other companies will build and connect. They know that the role of platform provider is the biggest strategic objective they could pursue and that it’s still very much up for grabs.

Platforms are a prominent feature in highly digitized 21st-century markets, and additive manufacturing will be no exception. Here platform owners will be powerful because production itself is likely to matter less over time. Already some companies are setting up contract “printer farms” that will effectively commoditize the making of products on demand. Even the valuable designs for printable products, being purely digital and easily shared, will be hard to hold tight. (For that matter, 3-D scanning devices will make it possible to reverse-engineer products by capturing their geometric design information.)

(For that matter, 3-D scanning devices will make it possible to reverse-engineer products by capturing their geometric design information.)

Everyone in the system will have a stake in sustaining the platforms on which production is dynamically orchestrated, blueprints are stored and continually enhanced, raw materials supplies are monitored and purchased, and customer orders are received. Those that control the digital ecosystem will sit in the middle of a tremendous volume of industrial transactions, collecting and selling valuable information. They will engage in arbitrage and divide the work up among trusted parties or assign it in-house when appropriate. They will trade printer capacity and designs all around the world, influencing prices by controlling or redirecting the “deal flow” for both. Like commodities arbitrageurs, they will finance trades or buy low and sell high with the asymmetric information they gain from overseeing millions of transactions.

Any manufacturer whose strategy for the future includes additive techniques has to lay out a road map for getting there. Companies already on the journey are taking things step-by-step, but in three different ways.

Companies already on the journey are taking things step-by-step, but in three different ways.

Trickle Down

Some start with their high-end products, knowing that their most sophisticated (and price-insensitive) customers will appreciate the innovation and flexibility. The luxury will trickle down in the time-honored way as the technology matures and becomes more affordable. Automotive manufacturers, for example, tend to engineer one-off parts specially for Formula One racing cars and then find ways to introduce versions of those innovations to high-end sports and luxury cars. As engineers’ familiarity with the technology grows, they spot opportunities to bring it to parts for mass-market car segments.

Swap Out

Other pioneers proceed in a less splashy way, focusing first on the components of a given product that are easiest to migrate to additive manufacturing. The objective is to develop the organization’s know-how by advancing to more-challenging components of the same product. This is common in aerospace, where companies have selected a specific product, such as an F-35 fighter jet, and started with mundane brackets and braces before moving to, say, internal panels and partitions. As the manufacturers learn more, they begin printing the fighter’s exterior skin. Experiments with printing its load-bearing structures are now under way.

This is common in aerospace, where companies have selected a specific product, such as an F-35 fighter jet, and started with mundane brackets and braces before moving to, say, internal panels and partitions. As the manufacturers learn more, they begin printing the fighter’s exterior skin. Experiments with printing its load-bearing structures are now under way.

Cut Across

A third approach is to find components that show up in multiple products and use them to establish a 3-D foothold. For example, a design improvement for a fighter jet could be transferred to drones, missiles, or satellites. Such cross-product improvement builds knowledge and awareness throughout the company of how additive manufacturing can enhance performance on key dimensions such as weight, energy use, and flexibility.

The common theme here is small, incremental steps. In all three approaches, engineers are being given fascinating new puzzles to solve without having their world upended by still-evolving methods and materials, thus minimizing risk and resistance to change. It is up to more-senior managers to maintain the appropriate level of pressure for taking each successive step. As they push for further adoption, they should allow naysayers to explain why 3-D printing isn’t right for a given part or process, but then challenge them to overcome that roadblock. Traditionalists will always be quick to tell you what 3-D printing can’t do. Don’t let them blind you to what it can.

It is up to more-senior managers to maintain the appropriate level of pressure for taking each successive step. As they push for further adoption, they should allow naysayers to explain why 3-D printing isn’t right for a given part or process, but then challenge them to overcome that roadblock. Traditionalists will always be quick to tell you what 3-D printing can’t do. Don’t let them blind you to what it can.

Responsibility for aligning dispersed capacity with growing market demand will fall to a small number of companies—and if the whole system is to work efficiently, some will have to step up to it. Look for analogs to Google, eBay, Match.com, and Amazon to emerge as search engines, exchange platforms, branded marketplaces, and matchmakers among additive manufacturing printers, designers, and design repositories. Perhaps even automated trading will come into existence, along with markets for trading derivatives or futures on printer capacity and designs.

In essence, then, the owners of printer-based manufacturing assets will compete with the owners of information for the profits generated by the ecosystem. And in fairly short order, power will migrate from producers to large systems integrators, which will set up branded platforms with common standards to coordinate and support the system. They’ll foster innovation through open sourcing and acquiring or partnering with smaller companies that meet high standards of quality. Small companies may indeed continue to try out interesting new approaches on the margins—but we’ll need big organizations to oversee the experiments and then push them to be practical and scalable.

And in fairly short order, power will migrate from producers to large systems integrators, which will set up branded platforms with common standards to coordinate and support the system. They’ll foster innovation through open sourcing and acquiring or partnering with smaller companies that meet high standards of quality. Small companies may indeed continue to try out interesting new approaches on the margins—but we’ll need big organizations to oversee the experiments and then push them to be practical and scalable.

Digital History Replicated

Thinking about the unfolding revolution in additive manufacturing, it’s hard not to reflect on that great transformative technology, the internet. In terms of the latter’s history, it might be fair to say that additive manufacturing is only in 1995. Hype levels were high that year, yet no one imagined how commerce and life would change in the coming decade, with the arrival of Wi-Fi, smartphones, and cloud computing. Few foresaw the day that internet-based artificial intelligence and software systems could run factories—and even city infrastructures—better than people could.

The future of additive manufacturing will bring similar surprises that might look strictly logical in hindsight but are hard to picture today. Imagine how new, highly capable printers might replace highly skilled workers, shifting entire companies and even manufacturing-based countries into people-less production. In “machine organizations,” humans might work only to service the printers.

And that future will arrive quickly. Once companies put a toe in the water and experience the advantages of greater manufacturing flexibility, they tend to dive in deep. As materials science creates more printable substances, more manufacturers and products will follow. Local Motors recently demonstrated that it can print a good-looking roadster, including wheels, chassis, body, roof, interior seats, and dashboard but not yet drivetrain, from bottom to top in 48 hours. When it goes into production, the roadster, including drivetrain, will be priced at approximately $20,000. As the cost of 3-D equipment and materials falls, traditional methods’ remaining advantages in economies of scale are becoming a minor factor.

Local Motors can print a good-looking roadster from bottom to top in 48 hours.

Here’s what we can confidently expect: Within the next five years we will have fully automated, high-speed, large-quantity additive manufacturing systems that are economical even for standardized parts. Owing to the flexibility of those systems, customization or fragmentation in many product categories will then take off, further reducing conventional mass production’s market share.

Smart business leaders aren’t waiting for all the details and eventualities to reveal themselves. They can see clearly enough that additive manufacturing developments will change the way products are designed, made, bought, and delivered. They are taking the first steps in the redesign of manufacturing systems. They are envisioning the claims they will stake in the emerging ecosystem. They are making the many layers of decisions that will add up to advantage in a new world of 3-D printing.

A version of this article appeared in the May 2015 issue (pp. 40–48) of Harvard Business Review.

40–48) of Harvard Business Review.

The Free Beginner's Guide - 3D Printing Industry

Welcome to 3DPI”s Beginner’s Guide to 3D Printing. Whether you are new to 3D printing technology or just looking to close a few knowledge gaps, we’re glad you stopped by. By now, most of us have heard, at some level, about the potential of 3D printing. But with this guide we are offering insights into the history and the reality of 3D printing — the processes, materials and applications — as well as measured thoughts on where it might be heading. We hope you’ll find this to be one of the most comprehensive 3D printing resources available, and that no matter what your skill level is, there will be plenty in here to meet your needs.

Are you ready? Let’s get started !

01 - Basics

3D Printing — also known as additive manufacturing — has been quoted in the Financial Times and by other sources as potentially being larger than the Internet. Some believe this is true. Many others urge that this is part of the extraordinary hype that exists around this very exciting technology area. So what really is 3D printing, who generally uses 3D printers and what for ?

Some believe this is true. Many others urge that this is part of the extraordinary hype that exists around this very exciting technology area. So what really is 3D printing, who generally uses 3D printers and what for ?

Overview

The term 3D printing covers a host of processes and technologies that offer a full spectrum of capabilities for the production of parts and products in different materials. Essentially, what all of the processes and technologies have in common is the manner in which production is carried out layer by layer in an additive process which is in contrast to traditional methods of production involving subtractive methods or moulding/casting processes. Applications of 3D printing are emerging almost by the day, and, as this technology continues to penetrate more widely and deeply across industrial, maker and consumer sectors, this is only set to increase. Most reputable commentators on this technology sector agree that, as of today, we are only just beginning to see the true potential of 3D printing. 3DPI, a reliable media source for 3D printing, brings you all of the latest news, views, process developments and applications as they emerge in this exciting field. This overview article aims to provide the 3DPI audience with a reliable backgrounder on 3D printing in terms of what it is (technologies, processes and materials), its history, application areas and benefits

3DPI, a reliable media source for 3D printing, brings you all of the latest news, views, process developments and applications as they emerge in this exciting field. This overview article aims to provide the 3DPI audience with a reliable backgrounder on 3D printing in terms of what it is (technologies, processes and materials), its history, application areas and benefits

Introduction – What is 3D printing ?

3D Printing is a process for making a physical object from a three-dimensional digital model, typically by laying down many successive thin layers of a material. It brings a digital object (its CAD representation) into its physical form by adding layer by layer of materials.

There are several different techniques to 3D Print an object. We will go in further details later in the Guide. 3D Printing brings two fundamental innovations: the manipulation of objects in their digital format and the manufacturing of new shapes by addition of material.

Digital

+

Additive Manufacturing

Technology has affected recent human history probably more than any other field. Think of a light bulb, steam engine or, more latterly, cars and aeroplanes, not to mention the rise and rise of the world wide web. These technologies have made our lives better in many ways, opened up new avenues and possibilities, but usually it takes time, sometimes even decades, before the truly disruptive nature of the technology becomes apparent.

It is widely believed that 3D printing or additive manufacturing (AM) has the vast potential to become one of these technologies. 3D printing has now been covered across many television channels, in mainstream newspapers and across online resources. What really is this 3D printing that some have claimed will put an end to traditional manufacturing as we know it, revolutionize design and impose geopolitical, economic, social, demographic, environmental and security implications to our every day lives?

The most basic, differentiating principle behind 3D printing is that it is an additive manufacturing process. And this is indeed the key because 3D printing is a radically different manufacturing method based on advanced technology that builds up parts, additively, in layers at the sub mm scale. This is fundamentally different from any other existing traditional manufacturing techniques.

And this is indeed the key because 3D printing is a radically different manufacturing method based on advanced technology that builds up parts, additively, in layers at the sub mm scale. This is fundamentally different from any other existing traditional manufacturing techniques.

There are a number of limitations to traditional manufacturing, which has widely been based on human labour and made by hand ideology rooting back to the etymological origins of the French word for manufacturing itself. However, the world of manufacturing has changed, and automated processes such as machining, casting, forming and moulding are all (relatively) new, complex processes that require machines, computers and robot technology.

However, these technologies all demand subtracting material from a larger block whether to achieve the end product itself or to produce a tool for casting or moulding processes and this is a serious limitation within the overall manufacturing process.

For many applications traditional design and production processes impose a number of unacceptable constraints, including the expensive tooling as mentioned above, fixtures, and the need for assembly for complex parts. In addition, the subtractive manufacturing processes, such as machining, can result in up to 90% of the original block of material being wasted. In contrast, 3D printing is a process for creating objects directly, by adding material layer by layer in a variety of ways, depending on the technology used. Simplifying the ideology behind 3D printing, for anyone that is still trying to understand the concept (and there are many), it could be likened to the process of building something with Lego blocks automatically.

In addition, the subtractive manufacturing processes, such as machining, can result in up to 90% of the original block of material being wasted. In contrast, 3D printing is a process for creating objects directly, by adding material layer by layer in a variety of ways, depending on the technology used. Simplifying the ideology behind 3D printing, for anyone that is still trying to understand the concept (and there are many), it could be likened to the process of building something with Lego blocks automatically.

3D printing is an enabling technology that encourages and drives innovation with unprecedented design freedom while being a tool-less process that reduces prohibitive costs and lead times. Components can be designed specifically to avoid assembly requirements with intricate geometry and complex features created at no extra cost. 3D printing is also emerging as an energy-efficient technology that can provide environmental efficiencies in terms of both the manufacturing process itself, utilising up to 90% of standard materials, and throughout the products operating life, through lighter and stronger design.

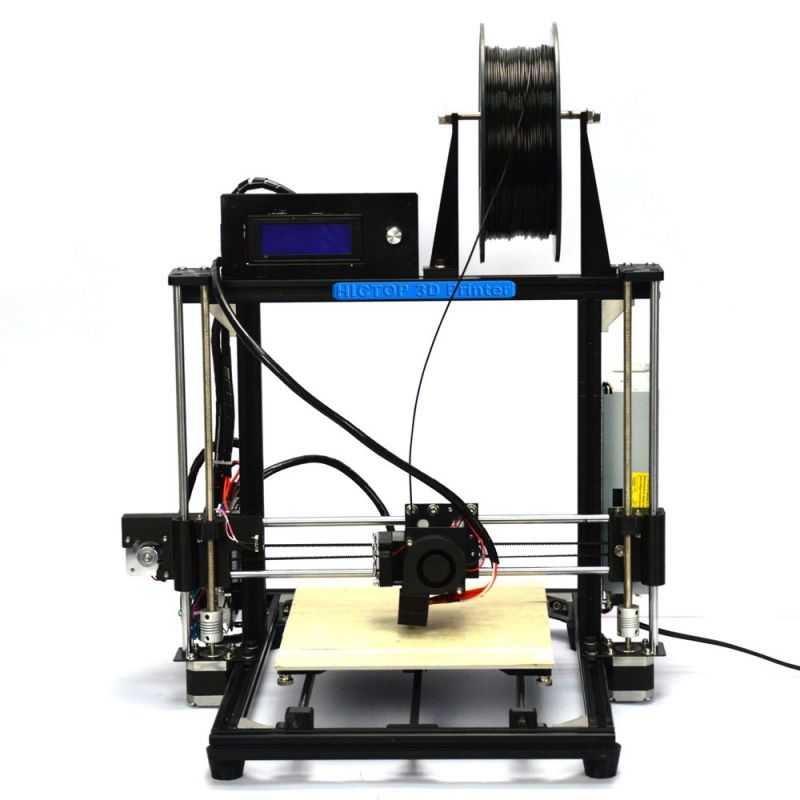

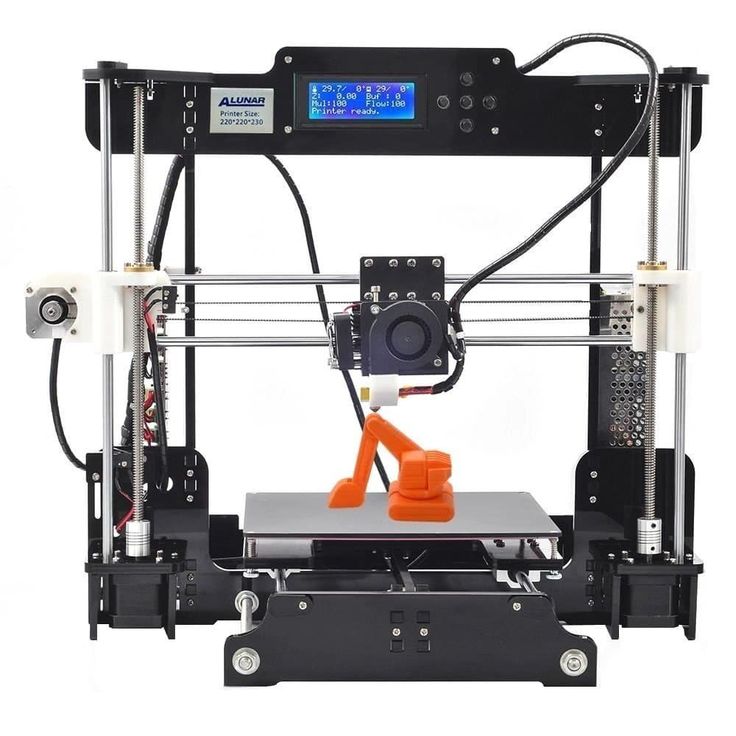

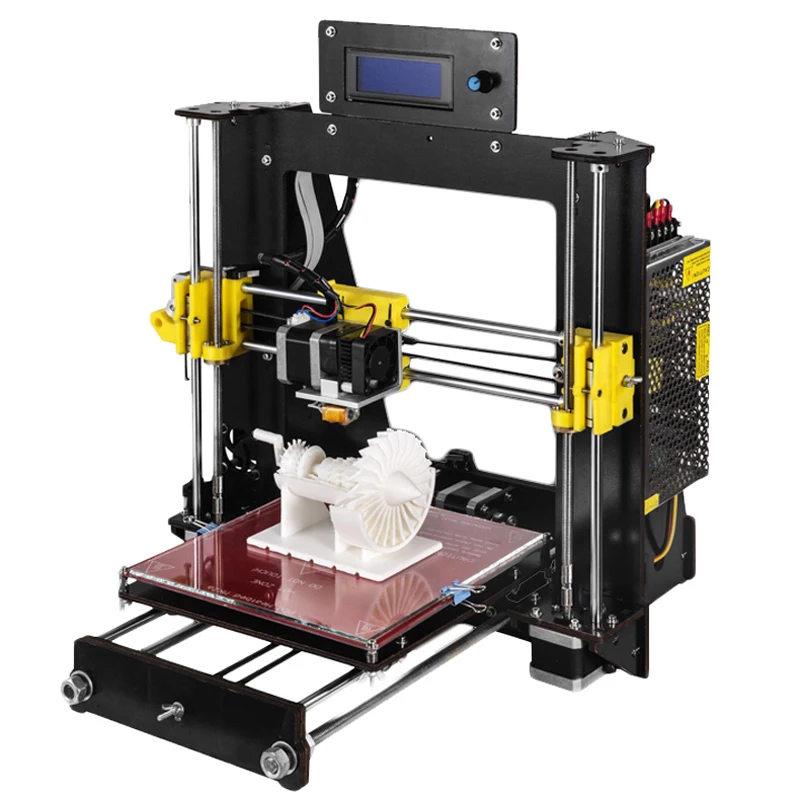

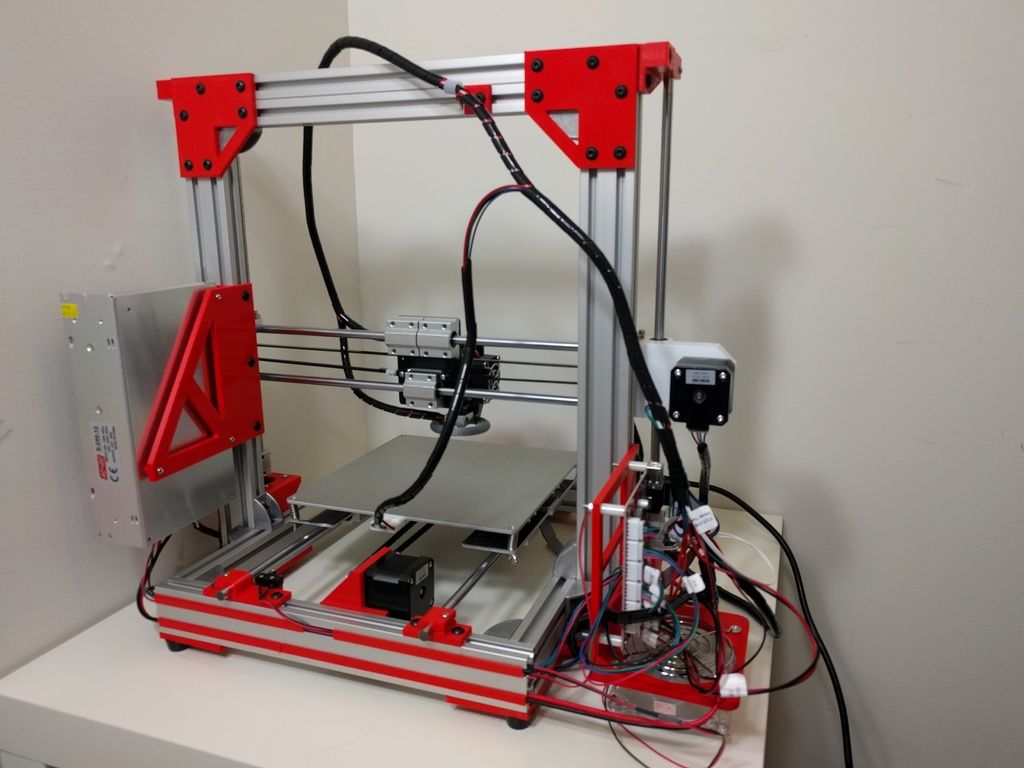

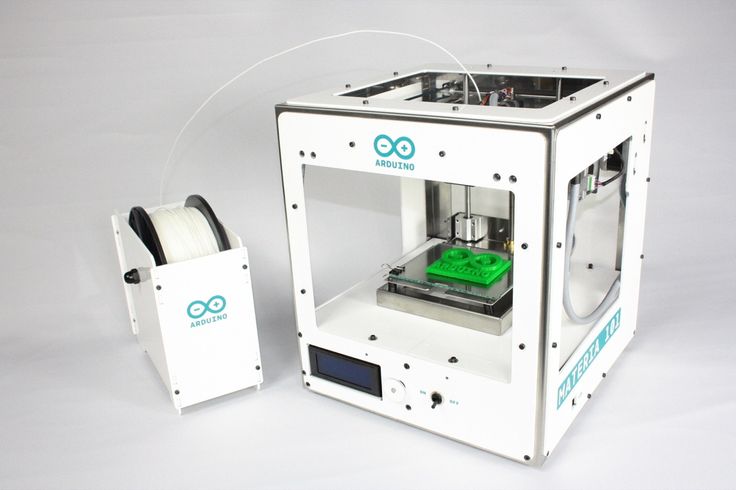

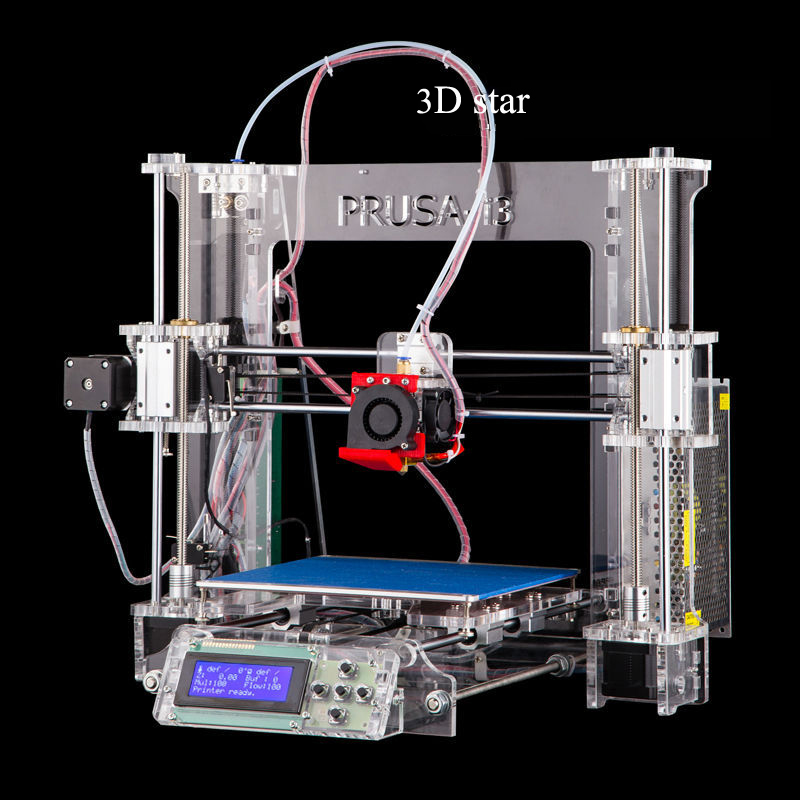

In recent years, 3D printing has gone beyond being an industrial prototyping and manufacturing process as the technology has become more accessible to small companies and even individuals. Once the domain of huge, multi-national corporations due to the scale and economics of owning a 3D printer, smaller (less capable) 3D printers can now be acquired for under $1000.

This has opened up the technology to a much wider audience, and as the exponential adoption rate continues apace on all fronts, more and more systems, materials, applications, services and ancillaries are emerging.

02 - History

The earliest 3D printing technologies first became visible in the late 1980’s, at which time they were called Rapid Prototyping (RP) technologies. This is because the processes were originally conceived as a fast and more cost-effective method for creating prototypes for product development within industry. As an interesting aside, the very first patent application for RP technology was filed by a Dr Kodama, in Japan, in May 1980. Unfortunately for Dr Kodama, the full patent specification was subsequently not filed before the one year deadline after the application, which is particularly disastrous considering that he was a patent lawyer! In real terms, however, the origins of 3D printing can be traced back to 1986, when the first patent was issued for stereolithography apparatus (SLA). This patent belonged to one Charles (Chuck) Hull, who first invented his SLA machine in 1983. Hull went on to co-found 3D Systems Corporation — one of the largest and most prolific organizations operating in the 3D printing sector today.

Unfortunately for Dr Kodama, the full patent specification was subsequently not filed before the one year deadline after the application, which is particularly disastrous considering that he was a patent lawyer! In real terms, however, the origins of 3D printing can be traced back to 1986, when the first patent was issued for stereolithography apparatus (SLA). This patent belonged to one Charles (Chuck) Hull, who first invented his SLA machine in 1983. Hull went on to co-found 3D Systems Corporation — one of the largest and most prolific organizations operating in the 3D printing sector today.

3D Systems’ first commercial RP system, the SLA-1, was introduced in 1987 and following rigorous testing the first of these system was sold in 1988. As is fairly typical with new technology, while SLA can claim to be the first past the starting post, it was not the only RP technology in development at this time, for, in 1987, Carl Deckard, who was working at the University of Texas, filed a patent in the US for the Selective Laser Sintering (SLS) RP process. This patent was issued in 1989 and SLS was later licensed to DTM Inc, which was later acquired by 3D Systems. 1989 was also the year that Scott Crump, a co-founder of Stratasys Inc. filed a patent for Fused Deposition Modelling (FDM) — the proprietary technology that is still held by the company today, but is also the process used by many of the entry-level machines, based on the open source RepRap model, that are prolific today. The FDM patent was issued to Stratasys in 1992. In Europe, 1989 also saw the formation of EOS GmbH in Germany, founded by Hans Langer. After a dalliance with SL processes, EOS’ R&D focus was placed heavily on the laser sintering (LS) process, which has continued to go from strength to strength. Today, the EOS systems are recognized around the world for their quality output for industrial prototyping and production applications of 3D printing. EOS sold its first ‘Stereos’ system in 1990. The company’s direct metal laser sintering (DMLS) process resulted from an initial project with a division of Electrolux Finland, which was later acquired by EOS.

This patent was issued in 1989 and SLS was later licensed to DTM Inc, which was later acquired by 3D Systems. 1989 was also the year that Scott Crump, a co-founder of Stratasys Inc. filed a patent for Fused Deposition Modelling (FDM) — the proprietary technology that is still held by the company today, but is also the process used by many of the entry-level machines, based on the open source RepRap model, that are prolific today. The FDM patent was issued to Stratasys in 1992. In Europe, 1989 also saw the formation of EOS GmbH in Germany, founded by Hans Langer. After a dalliance with SL processes, EOS’ R&D focus was placed heavily on the laser sintering (LS) process, which has continued to go from strength to strength. Today, the EOS systems are recognized around the world for their quality output for industrial prototyping and production applications of 3D printing. EOS sold its first ‘Stereos’ system in 1990. The company’s direct metal laser sintering (DMLS) process resulted from an initial project with a division of Electrolux Finland, which was later acquired by EOS.

Other 3D printing technologies and processes were also emerging during these years, namely Ballistic Particle Manufacturing (BPM) originally patented by William Masters, Laminated Object Manufacturing (LOM) originally patented by Michael Feygin, Solid Ground Curing (SGC) originally patented by Itzchak Pomerantz et al and ‘three dimensional printing’ (3DP) originally patented by Emanuel Sachs et al. And so the early nineties witnessed a growing number of competing companies in the RP market but only three of the originals remain today — 3D Systems, EOS and Stratasys.

Throughout the 1990’s and early 2000’s a host of new technologies continued to be introduced, still focused wholly on industrial applications and while they were still largely processes for prototyping applications, R&D was also being conducted by the more advanced technology providers for specific tooling, casting and direct manufacturing applications. This saw the emergence of new terminology, namely Rapid Tooling (RT), Rapid Casting and Rapid Manufacturing (RM) respectively.

In terms of commercial operations, Sanders Prototype (later Solidscape) and ZCorporation were set up in 1996, Arcam was established in 1997, Objet Geometries launched in 1998, MCP Technologies (an established vacuum casting OEM) introduced the SLM technology in 2000, EnvisionTec was founded in 2002, ExOne was established in 2005 as a spin-off from the Extrude Hone Corporation and Sciaky Inc was pioneering its own additive process based on its proprietary electron beam welding technology. These companies all served to swell the ranks of Western companies operating across a global market. The terminology had also evolved with a proliferation of manufacturing applications and the accepted umbrella term for all of the processes was Additive Manufacturing (AM). Notably, there were many parallel developments taking place in the Eastern hemisphere. However, these technologies, while significant in themselves and enjoying some local success, did not really impact the global market at that time.

During the mid noughties, the sector started to show signs of distinct diversification with two specific areas of emphasis that are much more clearly defined today. First, there was the high end of 3D printing, still very expensive systems, which were geared towards part production for high value, highly engineered, complex parts. This is still ongoing — and growing — but the results are only now really starting to become visible in production applications across the aerospace, automotive, medical and fine jewellery sectors, as years of R&D and qualification are now paying off. A great deal still remains behind closed doors and/or under non-disclosure agreements (NDA). At the other end of the spectrum, some of the 3D printing system manufacturers were developing and advancing ‘concept modellers’, as they were called at the time. Specifically, these were 3D printers that kept the focus on improving concept development and functional prototyping, that were being developed specifically as office- and user-friendly, cost-effective systems. The prelude to today’s desktop machines. However, these systems were all still very much for industrial applications.

The prelude to today’s desktop machines. However, these systems were all still very much for industrial applications.

Looking back, this was really the calm before the storm.

At the lower end of the market — the 3D printers that today are seen as being in the mid range — a price war emerged together with incremental improvements in printing accuracy, speed and materials.

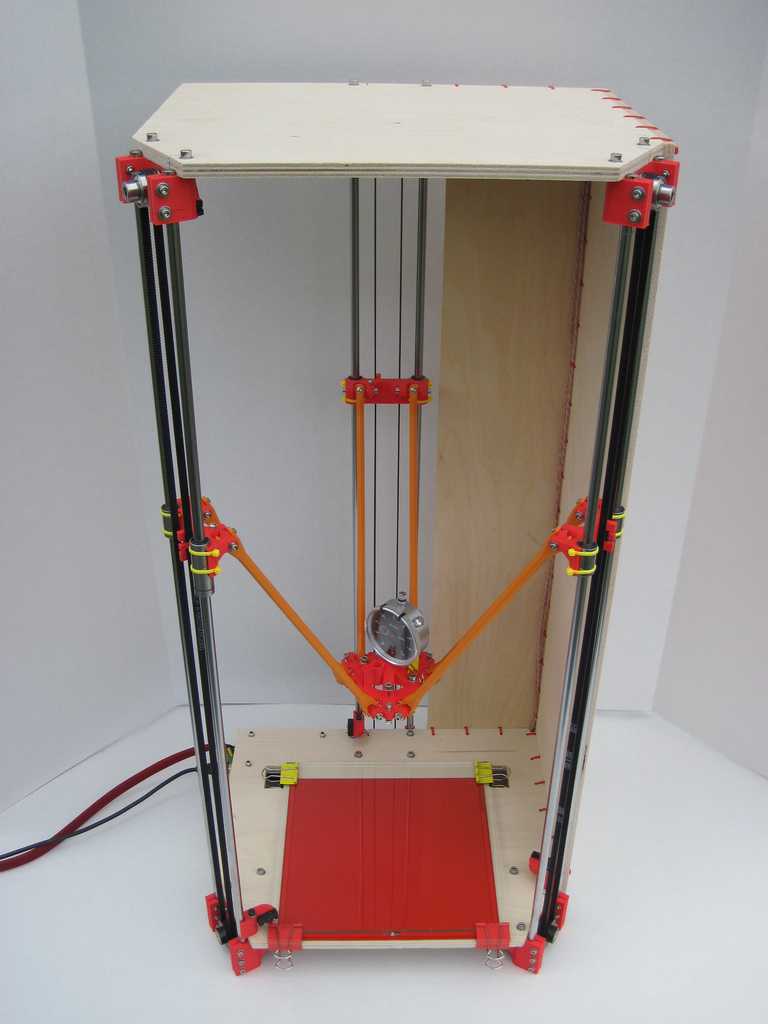

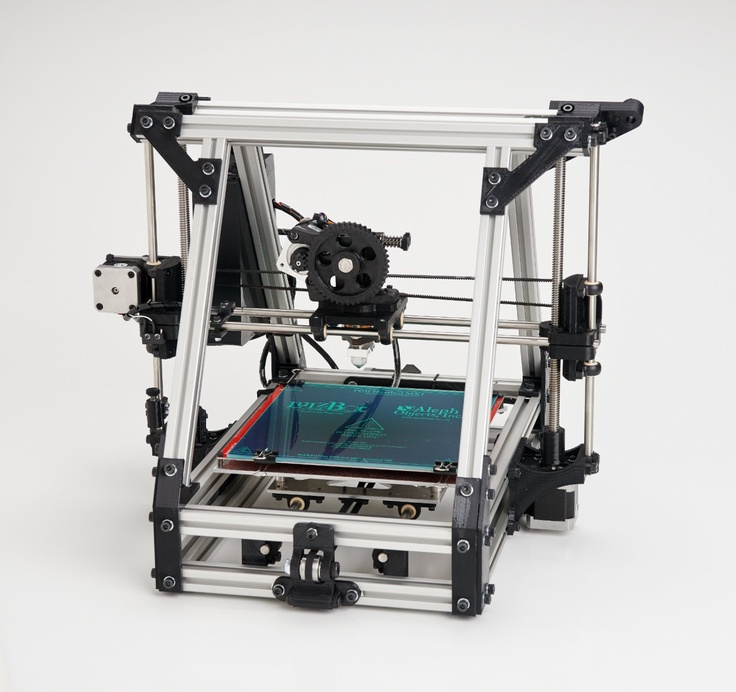

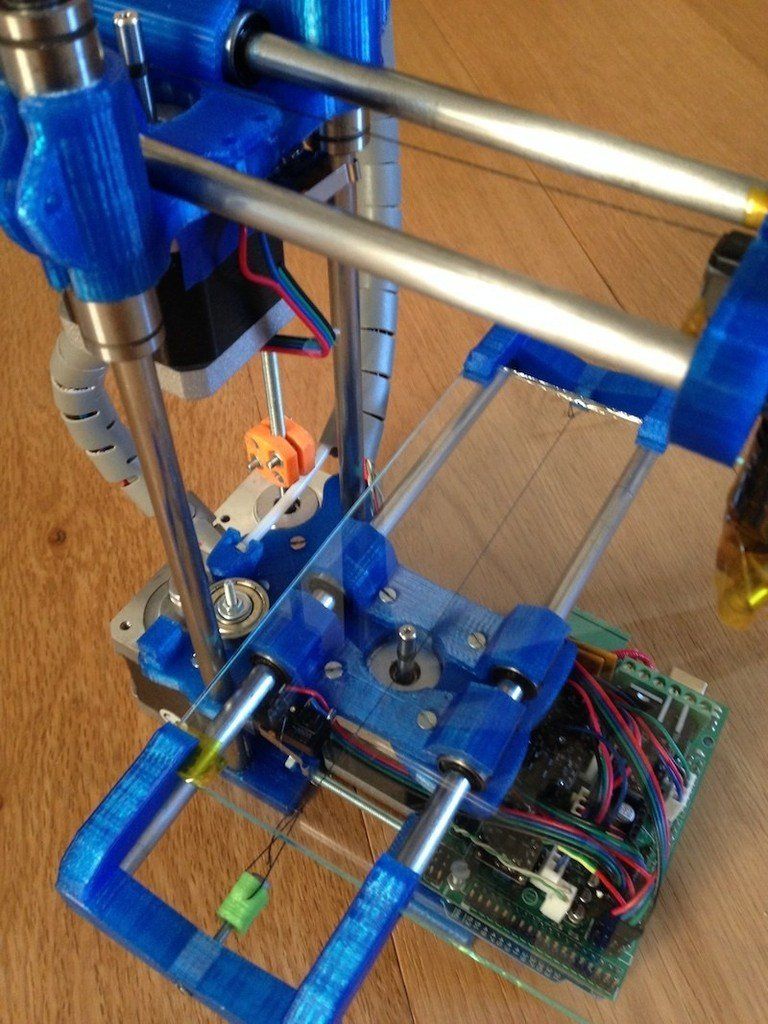

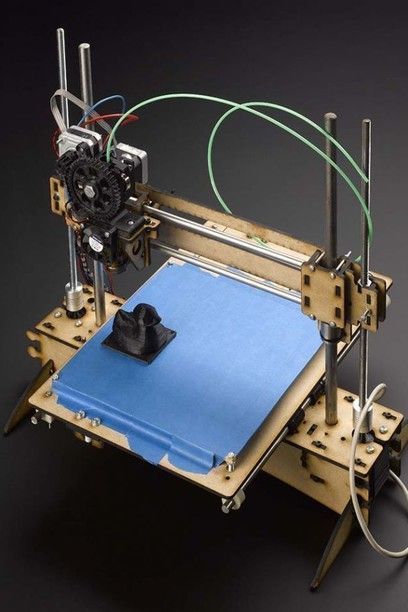

In 2007, the market saw the first system under $10,000 from 3D Systems, but this never quite hit the mark that it was supposed to. This was partly due to the system itself, but also other market influences. The holy grail at that time was to get a 3D printer under $5000 — this was seen by many industry insiders, users and commentators as the key to opening up 3D printing technology to a much wider audience. For much of that year, the arrival of the highly-anticipated Desktop Factory — which many predicted would be the fulfillment of that holy grail — was heralded as the one to watch. It came to nothing as the organization faltered in the run up to production. Desktop Factory and its leader, Cathy Lewis, were acquired, along with the IP, by 3D Systems in 2008 and all but vanished. As it turned out though, 2007 was actually the year that did mark the turning point for accessible 3D printing technology — even though few realized it at the time — as the RepRap phenomenon took root. Dr Bowyer conceived the RepRap concept of an open source, self-replicating 3D printer as early as 2004, and the seed was germinated in the following years with some heavy slog from his team at Bath, most notably Vik Oliver and Rhys Jones, who developed the concept through to working prototypes of a 3D printer using the deposition process. 2007 was the year the shoots started to show through and this embryonic, open source 3D printing movement started to gain visibility.

Desktop Factory and its leader, Cathy Lewis, were acquired, along with the IP, by 3D Systems in 2008 and all but vanished. As it turned out though, 2007 was actually the year that did mark the turning point for accessible 3D printing technology — even though few realized it at the time — as the RepRap phenomenon took root. Dr Bowyer conceived the RepRap concept of an open source, self-replicating 3D printer as early as 2004, and the seed was germinated in the following years with some heavy slog from his team at Bath, most notably Vik Oliver and Rhys Jones, who developed the concept through to working prototypes of a 3D printer using the deposition process. 2007 was the year the shoots started to show through and this embryonic, open source 3D printing movement started to gain visibility.

But it wasn’t until January 2009 that the first commercially available 3D printer – in kit form and based on the RepRap concept – was offered for sale. This was the BfB RapMan 3D printer. Closely followed by Makerbot Industries in April the same year, the founders of which were heavily involved in the development of RepRap until they departed from the Open Source philosophy following extensive investment. Since 2009, a host of similar deposition printers have emerged with marginal unique selling points (USPs) and they continue to do so. The interesting dichotomy here is that, while the RepRap phenomenon has given rise to a whole new sector of commercial, entry-level 3D printers, the ethos of the RepRap community is all about Open Source developments for 3D printing and keeping commercialization at bay.

Since 2009, a host of similar deposition printers have emerged with marginal unique selling points (USPs) and they continue to do so. The interesting dichotomy here is that, while the RepRap phenomenon has given rise to a whole new sector of commercial, entry-level 3D printers, the ethos of the RepRap community is all about Open Source developments for 3D printing and keeping commercialization at bay.

2012 was the year that alternative 3D printing processes were introduced at the entry level of the market. The B9Creator (utilising DLP technology) came first in June, followed by the Form 1 (utilising stereolithography) in December. Both were launched via the funding site Kickstarter — and both enjoyed huge success.

As a result of the market divergence, significant advances at the industrial level with capabilities and applications, dramatic increase in awareness and uptake across a growing maker movement, 2012 was also the year that many different mainstream media channels picked up on the technology. 2013 was a year of significant growth and consolidation. One of the most notable moves was the acquisition of Makerbot by Stratasys.

2013 was a year of significant growth and consolidation. One of the most notable moves was the acquisition of Makerbot by Stratasys.

Heralded as the 2nd, 3rd and, sometimes even, 4th Industrial Revolution by some, what cannot be denied is the impact that 3D printing is having on the industrial sector and the huge potential that 3D printing is demonstrating for the future of consumers. What shape that potential will take is still unfolding before us.

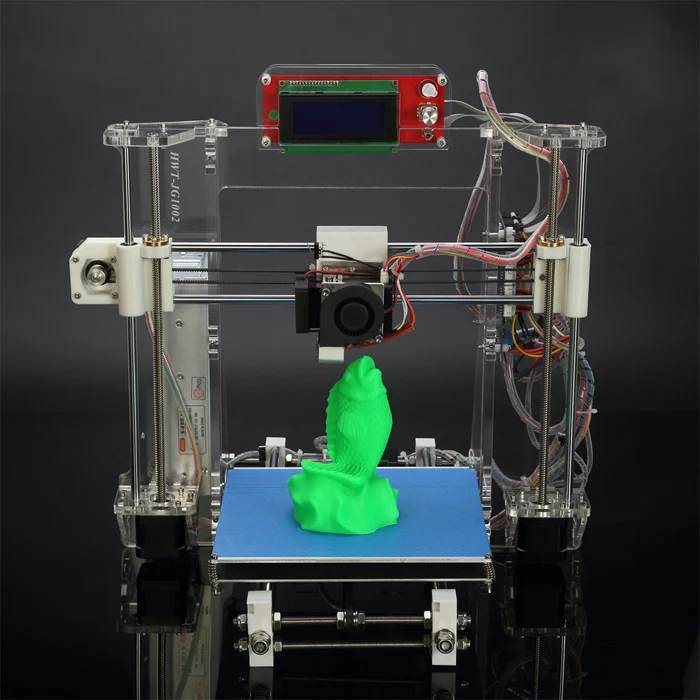

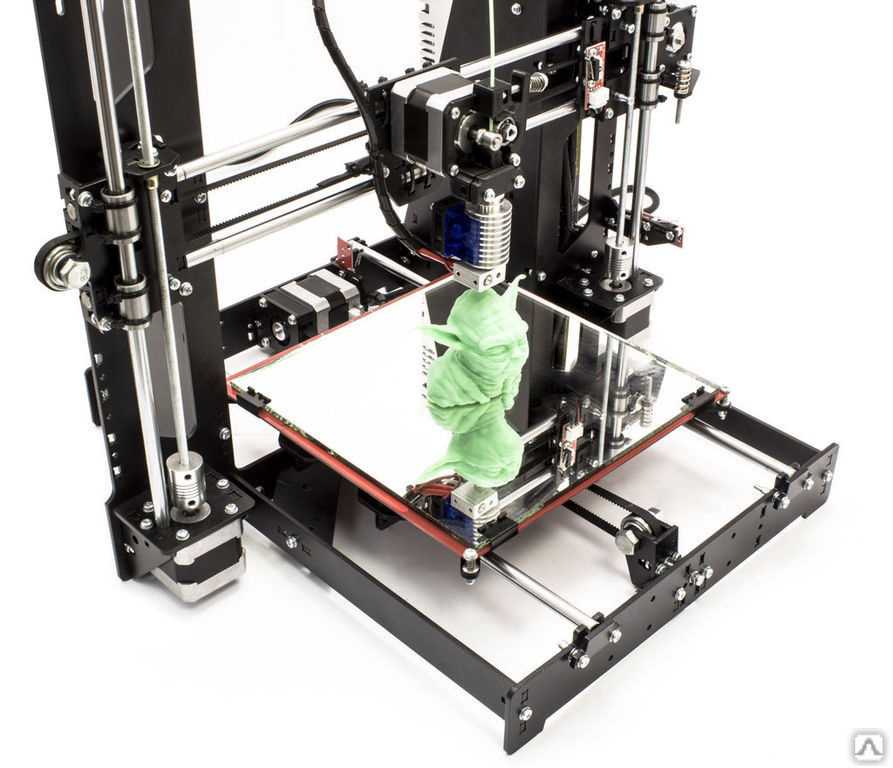

03 - Technology

The starting point for any 3D printing process is a 3D digital model, which can be created using a variety of 3D software programmes — in industry this is 3D CAD, for Makers and Consumers there are simpler, more accessible programmes available — or scanned with a 3D scanner. The model is then ‘sliced’ into layers, thereby converting the design into a file readable by the 3D printer. The material processed by the 3D printer is then layered according to the design and the process. As stated, there are a number of different types of 3D printing technologies, which process different materials in different ways to create the final object. Functional plastics, metals, ceramics and sand are, now, all routinely used for industrial prototyping and production applications. Research is also being conducted for 3D printing bio materials and different types of food. Generally speaking though, at the entry level of the market, materials are much more limited. Plastic is currently the only widely used material — usually ABS or PLA, but there are a growing number of alternatives, including Nylon. There is also a growing number of entry level machines that have been adapted for foodstuffs, such as sugar and chocolate.

Functional plastics, metals, ceramics and sand are, now, all routinely used for industrial prototyping and production applications. Research is also being conducted for 3D printing bio materials and different types of food. Generally speaking though, at the entry level of the market, materials are much more limited. Plastic is currently the only widely used material — usually ABS or PLA, but there are a growing number of alternatives, including Nylon. There is also a growing number of entry level machines that have been adapted for foodstuffs, such as sugar and chocolate.

How it Works

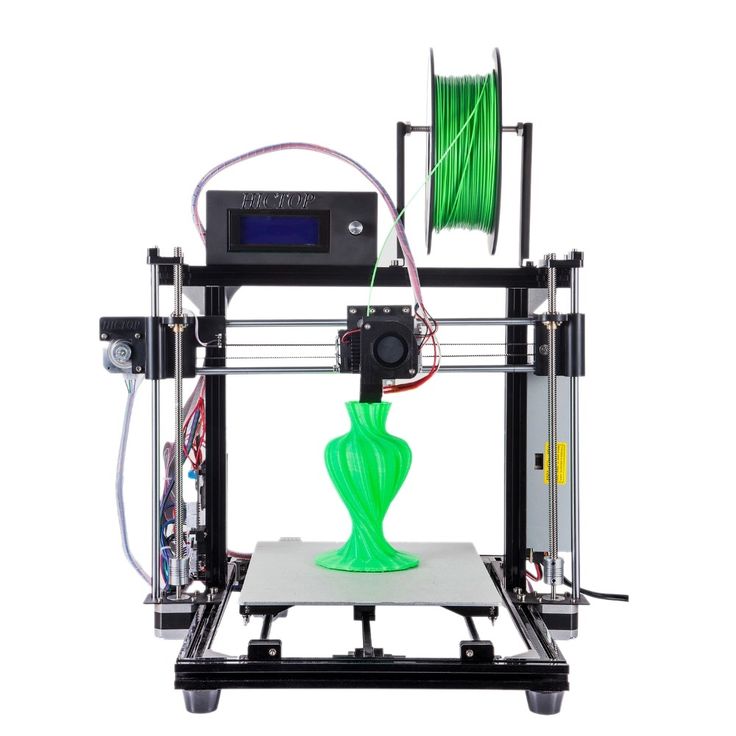

The different types of 3D printers each employ a different technology that processes different materials in different ways. It is important to understand that one of the most basic limitations of 3D printing — in terms of materials and applications — is that there is no ‘one solution fits all’. For example some 3D printers process powdered materials (nylon, plastic, ceramic, metal), which utilize a light/heat source to sinter/melt/fuse layers of the powder together in the defined shape. Others process polymer resin materials and again utilize a light/laser to solidify the resin in ultra thin layers. Jetting of fine droplets is another 3D printing process, reminiscent of 2D inkjet printing, but with superior materials to ink and a binder to fix the layers. Perhaps the most common and easily recognized process is deposition, and this is the process employed by the majority of entry-level 3D printers. This process extrudes plastics, commonly PLA or ABS, in filament form through a heated extruder to form layers and create the predetermined shape.

Others process polymer resin materials and again utilize a light/laser to solidify the resin in ultra thin layers. Jetting of fine droplets is another 3D printing process, reminiscent of 2D inkjet printing, but with superior materials to ink and a binder to fix the layers. Perhaps the most common and easily recognized process is deposition, and this is the process employed by the majority of entry-level 3D printers. This process extrudes plastics, commonly PLA or ABS, in filament form through a heated extruder to form layers and create the predetermined shape.

Because parts can be printed directly, it is possible to produce very detailed and intricate objects, often with functionality built in and negating the need for assembly.

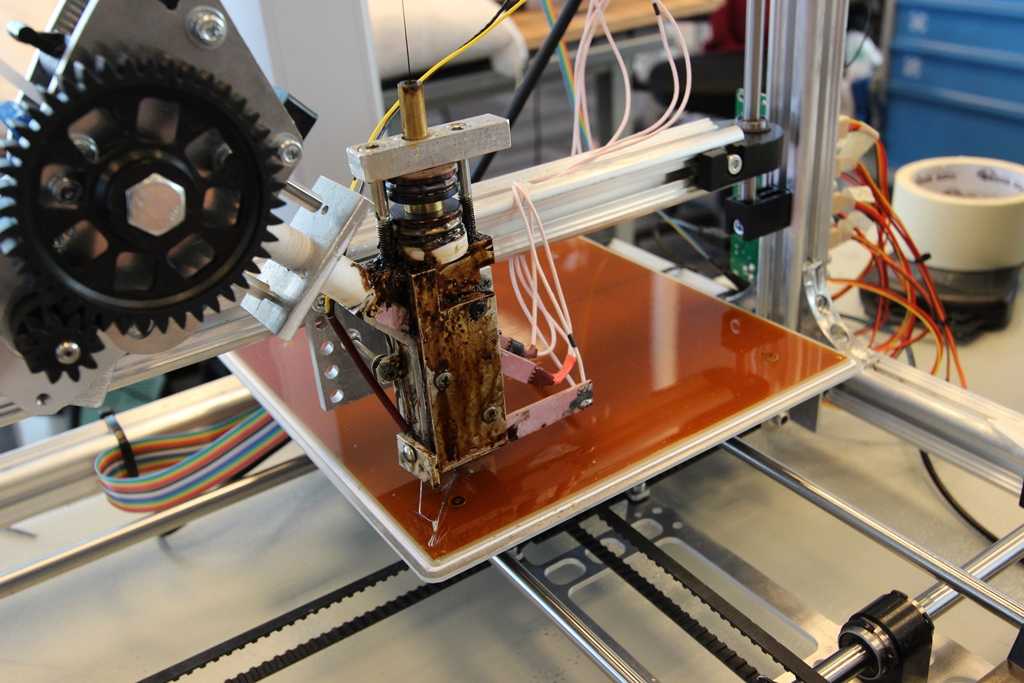

However, another important point to stress is that none of the 3D printing processes come as plug and play options as of today. There are many steps prior to pressing print and more once the part comes off the printer — these are often overlooked. Apart from the realities of designing for 3D printing, which can be demanding, file preparation and conversion can also prove time-consuming and complicated, particularly for parts that demand intricate supports during the build process. However there are continual updates and upgrades of software for these functions and the situation is improving. Furthermore, once off the printer, many parts will need to undergo finishing operations. Support removal is an obvious one for processes that demand support, but others include sanding, lacquer, paint or other types of traditional finishing touches, which all typically need to be done by hand and require skill and/or time and patience.

However there are continual updates and upgrades of software for these functions and the situation is improving. Furthermore, once off the printer, many parts will need to undergo finishing operations. Support removal is an obvious one for processes that demand support, but others include sanding, lacquer, paint or other types of traditional finishing touches, which all typically need to be done by hand and require skill and/or time and patience.

04 - Processes

Stereolithography

Stereolithography (SL) is widely recognized as the first 3D printing process; it was certainly the first to be commercialised. SL is a laser-based process that works with photopolymer resins, that react with the laser and cure to form a solid in a very precise way to produce very accurate parts. It is a complex process, but simply put, the photopolymer resin is held in a vat with a movable platform inside. A laser beam is directed in the X-Y axes across the surface of the resin according to the 3D data supplied to the machine (the . stl file), whereby the resin hardens precisely where the laser hits the surface. Once the layer is completed, the platform within the vat drops down by a fraction (in the Z axis) and the subsequent layer is traced out by the laser. This continues until the entire object is completed and the platform can be raised out of the vat for removal.

stl file), whereby the resin hardens precisely where the laser hits the surface. Once the layer is completed, the platform within the vat drops down by a fraction (in the Z axis) and the subsequent layer is traced out by the laser. This continues until the entire object is completed and the platform can be raised out of the vat for removal.

Because of the nature of the SL process, it requires support structures for some parts, specifically those with overhangs or undercuts. These structures need to be manually removed.

In terms of other post processing steps, many objects 3D printed using SL need to be cleaned and cured. Curing involves subjecting the part to intense light in an oven-like machine to fully harden the resin.

Stereolithography is generally accepted as being one of the most accurate 3D printing processes with excellent surface finish. However limiting factors include the post-processing steps required and the stability of the materials over time, which can become more brittle.

DLP — or digital light processing — is a similar process to stereolithography in that it is a 3D printing process that works with photopolymers. The major difference is the light source. DLP uses a more conventional light source, such as an arc lamp, with a liquid crystal display panel or a deformable mirror device (DMD), which is applied to the entire surface of the vat of photopolymer resin in a single pass, generally making it faster than SL.

Also like SL, DLP produces highly accurate parts with excellent resolution, but its similarities also include the same requirements for support structures and post-curing. However, one advantage of DLP over SL is that only a shallow vat of resin is required to facilitate the process, which generally results in less waste and lower running costs.

Laser Sintering / Laser Melting

Laser sintering and laser melting are interchangeable terms that refer to a laser based 3D printing process that works with powdered materials. The laser is traced across a powder bed of tightly compacted powdered material, according to the 3D data fed to the machine, in the X-Y axes. As the laser interacts with the surface of the powdered material it sinters, or fuses, the particles to each other forming a solid. As each layer is completed the powder bed drops incrementally and a roller smoothes the powder over the surface of the bed prior to the next pass of the laser for the subsequent layer to be formed and fused with the previous layer.

As the laser interacts with the surface of the powdered material it sinters, or fuses, the particles to each other forming a solid. As each layer is completed the powder bed drops incrementally and a roller smoothes the powder over the surface of the bed prior to the next pass of the laser for the subsequent layer to be formed and fused with the previous layer.

The build chamber is completely sealed as it is necessary to maintain a precise temperature during the process specific to the melting point of the powdered material of choice. Once finished, the entire powder bed is removed from the machine and the excess powder can be removed to leave the ‘printed’ parts. One of the key advantages of this process is that the powder bed serves as an in-process support structure for overhangs and undercuts, and therefore complex shapes that could not be manufactured in any other way are possible with this process.

However, on the downside, because of the high temperatures required for laser sintering, cooling times can be considerable. Furthermore, porosity has been an historical issue with this process, and while there have been significant improvements towards fully dense parts, some applications still necessitate infiltration with another material to improve mechanical characteristics.

Furthermore, porosity has been an historical issue with this process, and while there have been significant improvements towards fully dense parts, some applications still necessitate infiltration with another material to improve mechanical characteristics.

Laser sintering can process plastic and metal materials, although metal sintering does require a much higher powered laser and higher in-process temperatures. Parts produced with this process are much stronger than with SL or DLP, although generally the surface finish and accuracy is not as good.

Extrusion / FDM / FFF

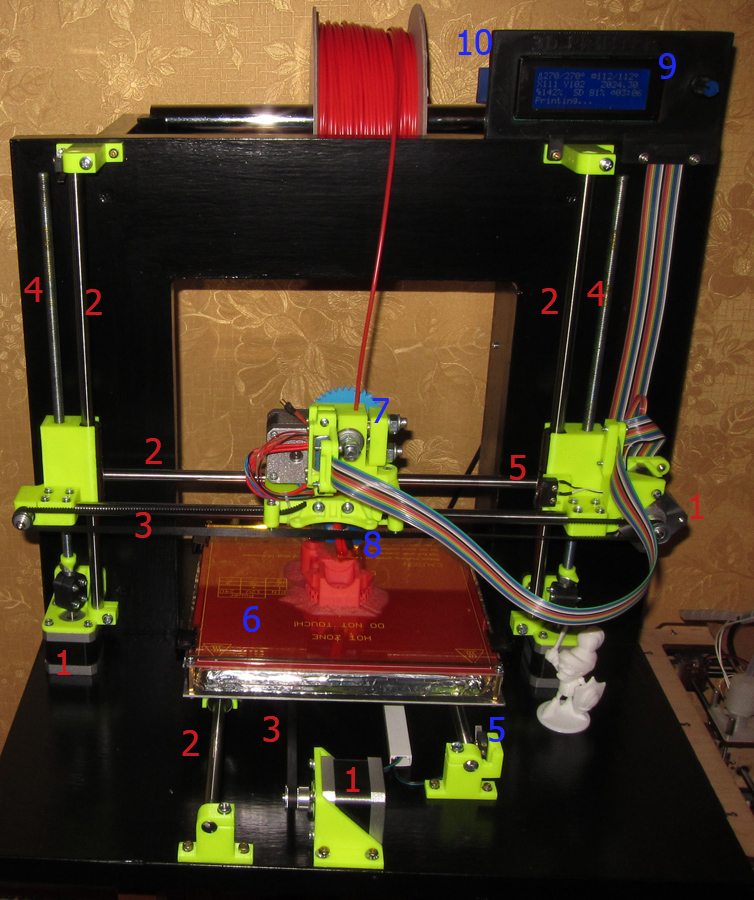

3D printing utilizing the extrusion of thermoplastic material is easily the most common — and recognizable — 3DP process. The most popular name for the process is Fused Deposition Modelling (FDM), due to its longevity, however this is a trade name, registered by Stratasys, the company that originally developed it. Stratasys’ FDM technology has been around since the early 1990’s and today is an industrial grade 3D printing process. However, the proliferation of entry-level 3D printers that have emerged since 2009 largely utilize a similar process, generally referred to as Freeform Fabrication (FFF), but in a more basic form due to patents still held by Stratasys. The earliest RepRap machines and all subsequent evolutions — open source and commercial — employ extrusion methodology. However, following Stratasys’ patent infringement filing against Afiniathere is a question mark over how the entry-level end of the market will develop now, with all of the machines potentially in Stratasys’ firing line for patent infringements.

However, the proliferation of entry-level 3D printers that have emerged since 2009 largely utilize a similar process, generally referred to as Freeform Fabrication (FFF), but in a more basic form due to patents still held by Stratasys. The earliest RepRap machines and all subsequent evolutions — open source and commercial — employ extrusion methodology. However, following Stratasys’ patent infringement filing against Afiniathere is a question mark over how the entry-level end of the market will develop now, with all of the machines potentially in Stratasys’ firing line for patent infringements.

The process works by melting plastic filament that is deposited, via a heated extruder, a layer at a time, onto a build platform according to the 3D data supplied to the printer. Each layer hardens as it is deposited and bonds to the previous layer.

Stratasys has developed a range of proprietary industrial grade materials for its FDM process that are suitable for some production applications. At the entry-level end of the market, materials are more limited, but the range is growing. The most common materials for entry-level FFF 3D printers are ABS and PLA.

At the entry-level end of the market, materials are more limited, but the range is growing. The most common materials for entry-level FFF 3D printers are ABS and PLA.

The FDM/FFF processes require support structures for any applications with overhanging geometries. For FDM, this entails a second, water-soluble material, which allows support structures to be relatively easily washed away, once the print is complete. Alternatively, breakaway support materials are also possible, which can be removed by manually snapping them off the part. Support structures, or lack thereof, have generally been a limitation of the entry level FFF 3D printers. However, as the systems have evolved and improved to incorporate dual extrusion heads, it has become less of an issue.

In terms of models produced, the FDM process from Stratasys is an accurate and reliable process that is relatively office/studio-friendly, although extensive post-processing can be required. At the entry-level, as would be expected, the FFF process produces much less accurate models, but things are constantly improving.

The process can be slow for some part geometries and layer-to-layer adhesion can be a problem, resulting in parts that are not watertight. Again, post-processing using Acetone can resolve these issues.

Inkjet

There are two 3D printing process that utilize a jetting technique.

Binder jetting: where the material being jetted is a binder, and is selectively sprayed into a powder bed of the part material to fuse it a layer at a time to create/print the required part. As is the case with other powder bed systems, once a layer is completed, the powder bed drops incrementally and a roller or blade smoothes the powder over the surface of the bed, prior to the next pass of the jet heads, with the binder for the subsequent layer to be formed and fused with the previous layer.

Advantages of this process, like with SLS, include the fact that the need for supports is negated because the powder bed itself provides this functionality. Furthermore, a range of different materials can be used, including ceramics and food. A further distinctive advantage of the process is the ability to easily add a full colour palette which can be added to the binder.

A further distinctive advantage of the process is the ability to easily add a full colour palette which can be added to the binder.

The parts resulting directly from the machine, however, are not as strong as with the sintering process and require post-processing to ensure durability.

Material jetting: a 3D printing process whereby the actual build materials (in liquid or molten state) are selectively jetted through multiple jet heads (with others simultaneously jetting support materials). However, the materials tend to be liquid photopolymers, which are cured with a pass of UV light as each layer is deposited.

The nature of this product allows for the simultaneous deposition of a range of materials, which means that a single part can be produced from multiple materials with different characteristics and properties. Material jetting is a very precise 3D printing method, producing accurate parts with a very smooth finish.

Selective Deposition Lamination (SDL)

SDL is a proprietary 3D printing process developed and manufactured by Mcor Technologies. There is a temptation to compare this process with the Laminated Object Manufacturing (LOM) process developed by Helisys in the 1990’s due to similarities in layering and shaping paper to form the final part. However, that is where any similarity ends.

There is a temptation to compare this process with the Laminated Object Manufacturing (LOM) process developed by Helisys in the 1990’s due to similarities in layering and shaping paper to form the final part. However, that is where any similarity ends.

The SDL 3D printing process builds parts layer by layer using standard copier paper. Each new layer is fixed to the previous layer using an adhesive, which is applied selectively according to the 3D data supplied to the machine. This means that a much higher density of adhesive is deposited in the area that will become the part, and a much lower density of adhesive is applied in the surrounding area that will serve as the support, ensuring relatively easy “weeding,” or support removal.

After a new sheet of paper is fed into the 3D printer from the paper feed mechanism and placed on top of the selectively applied adhesive on the previous layer, the build plate is moved up to a heat plate and pressure is applied. This pressure ensures a positive bond between the two sheets of paper. The build plate then returns to the build height where an adjustable Tungsten carbide blade cuts one sheet of paper at a time, tracing the object outline to create the edges of the part. When this cutting sequence is complete, the 3D printer deposits the next layer of adhesive and so on until the part is complete.

The build plate then returns to the build height where an adjustable Tungsten carbide blade cuts one sheet of paper at a time, tracing the object outline to create the edges of the part. When this cutting sequence is complete, the 3D printer deposits the next layer of adhesive and so on until the part is complete.

SDL is one of the very few 3D printing processes that can produce full colour 3D printed parts, using a CYMK colour palette. And because the parts are standard paper, which require no post-processing, they are wholly safe and eco-friendly. Where the process is not able to compete favourably with other 3D printing processes is in the production of complex geometries and the build size is limited to the size of the feedstock.

EBM

The Electron Beam Melting 3D printing technique is a proprietary process developed by Swedish company Arcam. This metal printing method is very similar to the Direct Metal Laser Sintering (DMLS) process in terms of the formation of parts from metal powder. The key difference is the heat source, which, as the name suggests is an electron beam, rather than a laser, which necessitates that the procedure is carried out under vacuum conditions.

The key difference is the heat source, which, as the name suggests is an electron beam, rather than a laser, which necessitates that the procedure is carried out under vacuum conditions.

EBM has the capability of creating fully-dense parts in a variety of metal alloys, even to medical grade, and as a result the technique has been particularly successful for a range of production applications in the medical industry, particularly for implants. However, other hi-tech sectors such as aerospace and automotive have also looked to EBM technology for manufacturing fulfillment.

05 - Materials

The materials available for 3D printing have come a long way since the early days of the technology. There is now a wide variety of different material types, that are supplied in different states (powder, filament, pellets, granules, resin etc).

Specific materials are now generally developed for specific platforms performing dedicated applications (an example would be the dental sector) with material properties that more precisely suit the application.

However, there are now way too many proprietary materials from the many different 3D printer vendors to cover them all here. Instead, this article will look at the most popular types of material in a more generic way. And also a couple of materials that stand out.

Plastics

Nylon, or Polyamide, is commonly used in powder form with the sintering process or in filament form with the FDM process. It is a strong, flexible and durable plastic material that has proved reliable for 3D printing. It is naturally white in colour but it can be coloured — pre- or post printing. This material can also be combined (in powder format) with powdered aluminium to produce another common 3D printing material for sintering — Alumide.

ABS is another common plastic used for 3D printing, and is widely used on the entry-level FDM 3D printers in filament form. It is a particularly strong plastic and comes in a wide range of colours. ABS can be bought in filament form from a number of non-propreitary sources, which is another reason why it is so popular.

PLA is a bio-degradable plastic material that has gained traction with 3D printing for this very reason. It can be utilized in resin format for DLP/SL processes as well as in filament form for the FDM process. It is offered in a variety of colours, including transparent, which has proven to be a useful option for some applications of 3D printing. However it is not as durable or as flexible as ABS.

LayWood is a specially developed 3D printing material for entry-level extrusion 3D printers. It comes in filament form and is a wood/polymer composite (also referred to as WPC).

Metals

A growing number of metals and metal composites are used for industrial grade 3D printing. Two of the most common are aluminium and cobalt derivatives.

One of the strongest and therefore most commonly used metals for 3D printing is Stainless Steel in powder form for the sintering/melting/EBM processes. It is naturally silver, but can be plated with other materials to give a gold or bronze effect.

In the last couple of years Gold and Silver have been added to the range of metal materials that can be 3D printed directly, with obvious applications across the jewellery sector. These are both very strong materials and are processed in powder form.

Titanium is one of the strongest possible metal materials and has been used for 3D printing industrial applications for some time. Supplied in powder form, it can be used for the sintering/melting/EBM processes.

Ceramics

Ceramics are a relatively new group of materials that can be used for 3D printing with various levels of success. The particular thing to note with these materials is that, post printing, the ceramic parts need to undergo the same processes as any ceramic part made using traditional methods of production — namely firing and glazing.

Paper

Standard A4 copier paper is a 3D printing material employed by the proprietary SDL process supplied by Mcor Technologies. The company operates a notably different business model to other 3D printing vendors, whereby the capital outlay for the machine is in the mid-range, but the emphasis is very much on an easily obtainable, cost-effective material supply, that can be bought locally. 3D printed models made with paper are safe, environmentally friendly, easily recyclable and require no post-processing.

The company operates a notably different business model to other 3D printing vendors, whereby the capital outlay for the machine is in the mid-range, but the emphasis is very much on an easily obtainable, cost-effective material supply, that can be bought locally. 3D printed models made with paper are safe, environmentally friendly, easily recyclable and require no post-processing.

Bio Materials

There is a huge amount of research being conducted into the potential of 3D printing bio materials for a host of medical (and other) applications. Living tissue is being investigated at a number of leading institutions with a view to developing applications that include printing human organs for transplant, as well as external tissues for replacement body parts. Other research in this area is focused on developing food stuffs — meat being the prime example.

Food

Experiments with extruders for 3D printing food substances has increased dramatically over the last couple of years. Chocolate is the most common (and desirable). There are also printers that work with sugar and some experiments with pasta and meat. Looking to the future, research is being undertaken, to utilize 3D printing technology to produce finely balanced whole meals.

Chocolate is the most common (and desirable). There are also printers that work with sugar and some experiments with pasta and meat. Looking to the future, research is being undertaken, to utilize 3D printing technology to produce finely balanced whole meals.