Best color for 3d printing

Which Filament Colors Should You Buy?

3D Insider is ad supported and earns money from clicks, commissions from sales, and other ways.

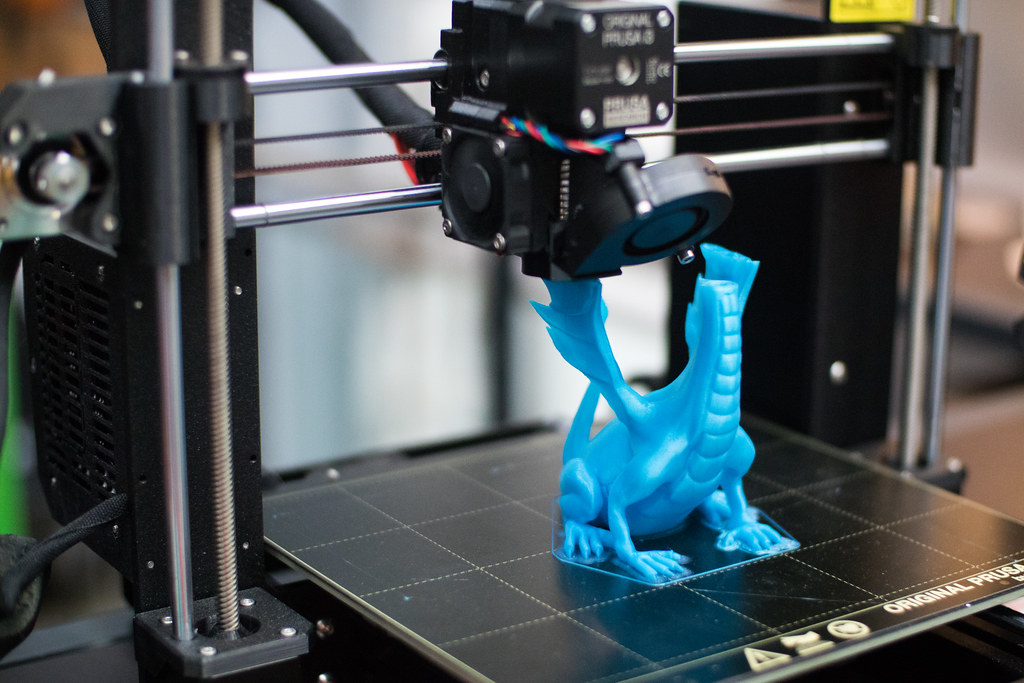

One of the best things about FDM printing is the fact that there are probably several hundred different types and brands of filament materials out there. From standard PLA to high-temperature filaments and fancy gold-colored ones, it seems that there’s a brand-new and innovative market to hit the market every single year.

However, this embarrassment of riches can also be intimidating for beginners to the hobby. Which filament should you have if you’re still new? Which filament should you always keep in stock? Is there a particular filament that can help you level up your 3D printing skills? We’ll answer all those questions in this article.

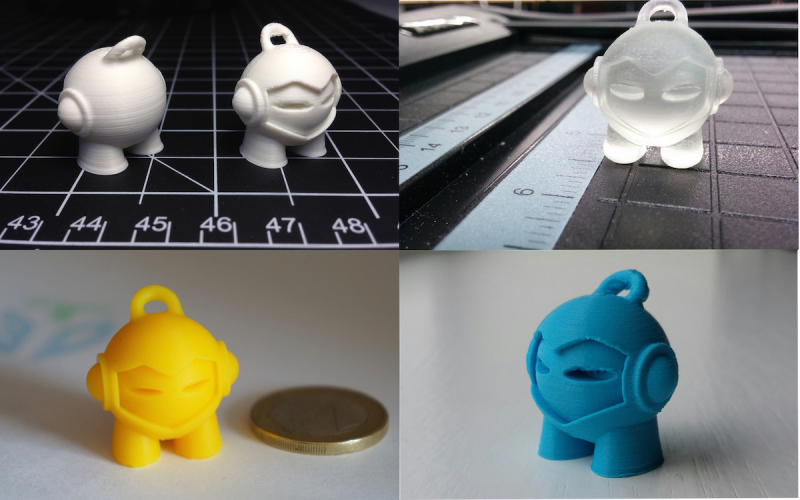

As a beginner, it’s tough to figure out what works for you. The best way to ease yourself into this hobby is to realize how much fun it can be, despite the frustrating moments. This sampler pack of four different colors (blue, green, orange, and red) from Gizmo Dorks is a great way to get you to start experimenting with your new 3D printer without spending too much.

Each of the four spools that come with this sampler pack only weighs 200 grams, so it’s not a huge commitment. And while the colors aren’t exceptionally good, you should be able to come up with a few interesting and fun projects.

The great thing about PLA is that it’s a very beginner-friendly material. If your printer doesn’t come with a heated bed, or if you don’t have a glass bed, then you can still work with PLA perfectly fine. It’s also not prone to warping, which is one of the biggest challenges in 3D printing.

You can also take this chance to try your hand at finishing your PLA prints. Colored PLA prints are best for this. All it takes is some sandpaper and a polishing compound and you should be golden. The techniques for finishing PLA are nothing complex and you’ll get the hang of it after a while.

When you suddenly get an idea of something to 3D print, you will want to have a filament on hand that’s easy to work with, versatile, and inexpensive. PLA in either White or Natural colors is perfect for this. As we’ve mentioned, PLA is one of the easiest materials to work with.

Since it prints at relatively lower temperatures and does not warp, you can print with PLA at high speeds. This means turning your idea into reality as quickly as possible. The reason we’re going with either White or Natural is that it’s very easy to paint PLA with any color that strikes your fancy. This is much better than being stuck printing with blue or hot pink filament because that’s all you have.

The other reason we’re going with PLA as our ‘go-to’ filament is the fact that it’s sustainable and 100% biodegradable. When experimenting, you will invariably go through failed prints that you need to scrap. This does not help our planet’s problem with solid waste, so we prefer going with PLA for our more ‘disposable’ projects. Keep in mind that PLA filament can come with non-biodegradable additives, like paint, so double-check with the manufacturer if their products are 100% biodegradable.

Keep in mind that PLA filament can come with non-biodegradable additives, like paint, so double-check with the manufacturer if their products are 100% biodegradable.

To experiment with – PVA

Polyvinyl Alcohol (PVA) is certainly one of the more unusual filament materials because, when used correctly, it should not show up on the final print. Instead, PVA is used as a material for support structures in case your design has a lot of overhanging features. You will need a printer with multi-extruder features to fully realize the potential of PVA, so perhaps this is something you’ll have to save for later.

What makes PVA such an excellent support material? For one, this isn’t true for all filament types. PVA is particularly suitable for PLA because they print at similar temperatures, which means that one filament will not compromise the quality of the other. If you’ve got a lot of PLA on hand, then printing with PVA as support is an excellent way to expand your 3D design horizon.

The other peculiar characteristic of PVA is that it readily dissolves in water. PVA is the same material used for those laundry detergent pods that you can just throw in the wash. This means that finished prints with PVA supports can be simply submerged in water to completely dissolve those support structures away. Best of all, the vinyl alcohol that gets dissolved in the water is completely safe for disposal down your sink.

To learn advanced techniques – Clear TPE

TPE, or Thermoplastic Elastomer, is also one of the more unusual filaments you can try. The best way to describe it is rubber-like – flexible, with excellent impact resistance, and a non-slip characteristic. It could be useful as a phone case, non-slip pad, gaskets for your pipes, or a door stopper.

All this talk about TPE’s physical characteristics may not seem like a big deal, but one thing you need to know is that printing with flexible filaments is a whole different monster. You’ll have to anticipate a lot of deformation and buckling inside the extruder assembly, as well as issue with bed adhesion and stringing. However, these are nothing that a bit of tweaking of the printer settings and application of adhesives to the print bed won’t solve.

However, these are nothing that a bit of tweaking of the printer settings and application of adhesives to the print bed won’t solve.

The usefulness of TPE more than makes up for its slightly more complicated printing process. It’s not the toughest material to work with, but it’s a great way for you to learn about the more nuanced aspects of 3D printing.

To learn advanced techniques, Part 2 – White ABS

It’s peculiar to see that one of the top two most popular filaments used in 3D printing is also one of the toughest to work with. This is probably a testament to the usefulness of ABS mostly because of its toughness, thermal stability, and chemical stability. It has a lot of commercial and industrial uses, despite the setback innate to the material.

For beginners, ABS can prove to be one of the most frustrating filaments. It prints at very high temperatures, and you’re going to need an appropriately hot print bed. It’s also notoriously prone to warping, so you’re certainly going to need some adhesives. Even those measures may not be enough, and there’s a whole range of tools and methods that you can try to get the perfect ABS print.

Even those measures may not be enough, and there’s a whole range of tools and methods that you can try to get the perfect ABS print.

From brims and rafts to enclosures for your build platform, there’s no shortage of all the creative ways that 3D printing professionals have come up with to overcome the challenges of ABS. If you haven’t printed with ABS before, the best way to learn how to do it is to go ahead and give it a try.

One more thing we should mention is that ABS emits noxious and possibly carcinogenic gaseous compounds during printing. Don’t print with ABS in a room without ventilation and try to stay away from the printer as much as you can. If necessary, only tinker with your 3D printer with the appropriate breathing protection that can filter out chemical compounds.

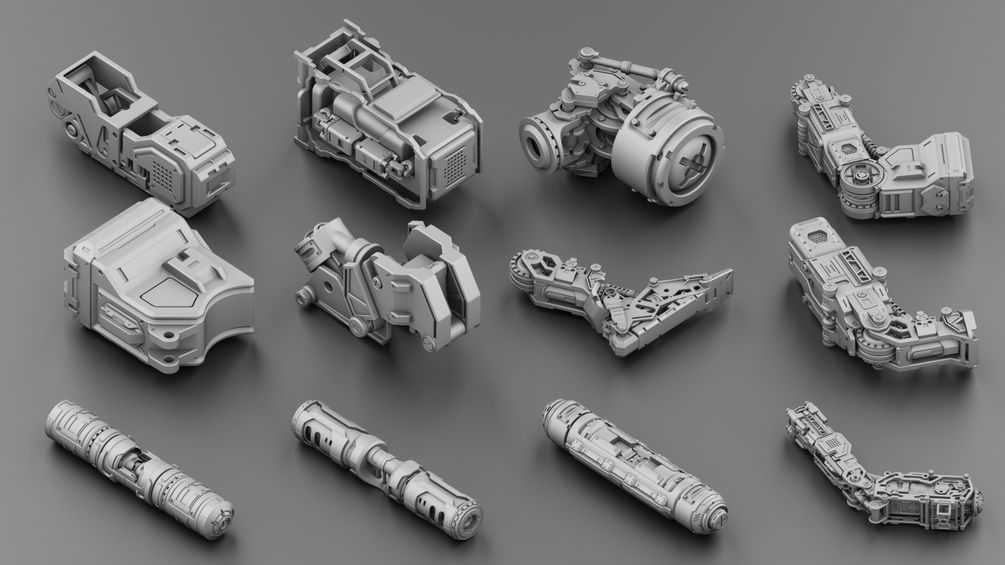

Going back to the fun side of things, there are now filaments that you can use to 3D print objects that simulate the look of wood and certain metals. Called composite filaments, these filaments are typically made of fine solid particles suspended in a PLA matrix in varying ratios. The use of PLA means that printing with these filaments is pretty easy while delivering a unique visual appeal.

The use of PLA means that printing with these filaments is pretty easy while delivering a unique visual appeal.

This sample pack of composite filaments from AMOLED includes Wood, Bronze, Marble, and Shining Gold. The names should be enough to tell you what material each of the filaments is mimicking. This is a great way to spruce up your old designs or come up with 3D prints that are nice enough to be given as gifts.

While these filaments come up with prints that already look very good, you can make them even better with some finishing. Depending on the filament, there are various finishing options available to you. Wood can be finished with some polishing and wood lacquer, while bronze can be can rusted to get that unique patina color.

Composite filaments are a great way to stretch your creative muscles without giving you too much of a hard time. Just make sure to read the printing instructions of the filament you’re getting – you may have to swap out your printer’s stock nozzle with something a little more wear-resistant.

Final thoughts

If you’re just starting with 3D printing, our advice is to take it slow. It’s easy to get excited about all the different filaments available out there only to find yourself in over your head with how problematic they can be. The skills will take some time to develop, but you’ll get there eventually by reading up on new stuff and trying them out.

No matter which filament you use, don’t forget that 3D printing should be fun. It’s an exercise in creativity and in how you can turn your imagination into reality. It’s not always simple, but it does not have to be complicated.

Warning; 3D printers should never be left unattended. They can pose a firesafety hazard.

Best 3D Printing Filament Colors

So you’re just getting into 3D printing but want to make sure you have everything you need to get started. What are the best 3D printing filament colors?

The best filament colors for 3D printing that you should have in your arsenal include white, grey, blue, red, green, purple, rainbow, heat-changing, and even glow-in-the-dark. Conversely, some of the worst filament colors for 3D printing that you should avoid are neon colors, black, and yellow.

Conversely, some of the worst filament colors for 3D printing that you should avoid are neon colors, black, and yellow.

If you’re in the market for some new 3D printing filaments, then you’ve likely seen the wide breadth of choices available to you. It seems like filament makers have figured out how to make just about any color under the sun. In this article, we’ll go over some of the best filament colors out there for making the perfect 3D prints every time. You’ll also learn about three of the worst 3D printing filament colors that you should consider avoiding.

Since you’re here reading this article, we know that you really just want to know what the best 3D printing filament colors are. And to ensure we’re giving the most accurate information that we can, we’ve combined our own experience and knowledge with the opinions of others in the field and research through discussion forums. We’re confident that the filament colors seen below are truly the best ones you should get your hands on to start printing!

What Are The Best 3D Printing Filament Colors?

While listing the best 3D printing filament colors might be a bit subjective, since everyone has their own color preferences, we’re going to do our best! Based on the input from a number of 3D printing enthusiasts, we’ve come up with the following list of the six best filament colors on the market. So without further ado, let’s just straight into it.

So without further ado, let’s just straight into it.

Normal 3D Printing Filament Colors

White

Picture of a White Printer FilamentWhite is a fan favorite among just about everyone who’s serious about 3D printing. Its simple manufacturing process that doesn't require any additional pigmentation makes it compositionally strong compared to many other colors — especially those at the very bottom of this list.

To make it even better, white is also the easiest color to paint. Since it’s white, you don’t have to worry about needing to cover up another color underneath whatever you’re trying to paint. And since many enthusiasts like to paint their prints to make them perfect, white is the best base color to go with.

Grey

Picture of a Grey Printer FilamentGrey is a great filament color for 3D printing for many of the same reasons as white. It’s easy to manufacture, doesn’t have any of the brittleness or fading issues that the colors at the end of this article have, and it’s also incredibly easy to cover and paint.

Many people that regularly 3D print will default to either grey or white as their normal color to 3D print with. Grey has a bit of a range of colors as well, but for most people, a lighter grey is typically used more commonly. The lighter it is, the easier it is to paint over. But if you want something a bit darker, an average grey-colored filament will provide a great looking print!

Standard Colors (Blue, red, green, purple, orange)

Picture of Standard Color Printer FilamentsFor those of you who don’t really want to use grey or white and then paint the print whatever color you like or anyone who just wants to add some color to their 3D model collection, then many “standard” colors are some of the best to use. When we say standard colors we’re referring largely to the primary and tertiary colors that make up everything else.

Of those colors, the best ones to use for 3D printing are blue, red, green, orange, and purple. You might have noticed one exclusion, and a primary color at that — yellow. As you’ll read about later, yellow fades more than any of these other colors. But feel free to use these five colors to make some eye-popping prints!

As you’ll read about later, yellow fades more than any of these other colors. But feel free to use these five colors to make some eye-popping prints!

Unique 3D Printing Filament Colors

Silk Rainbow Multicolor

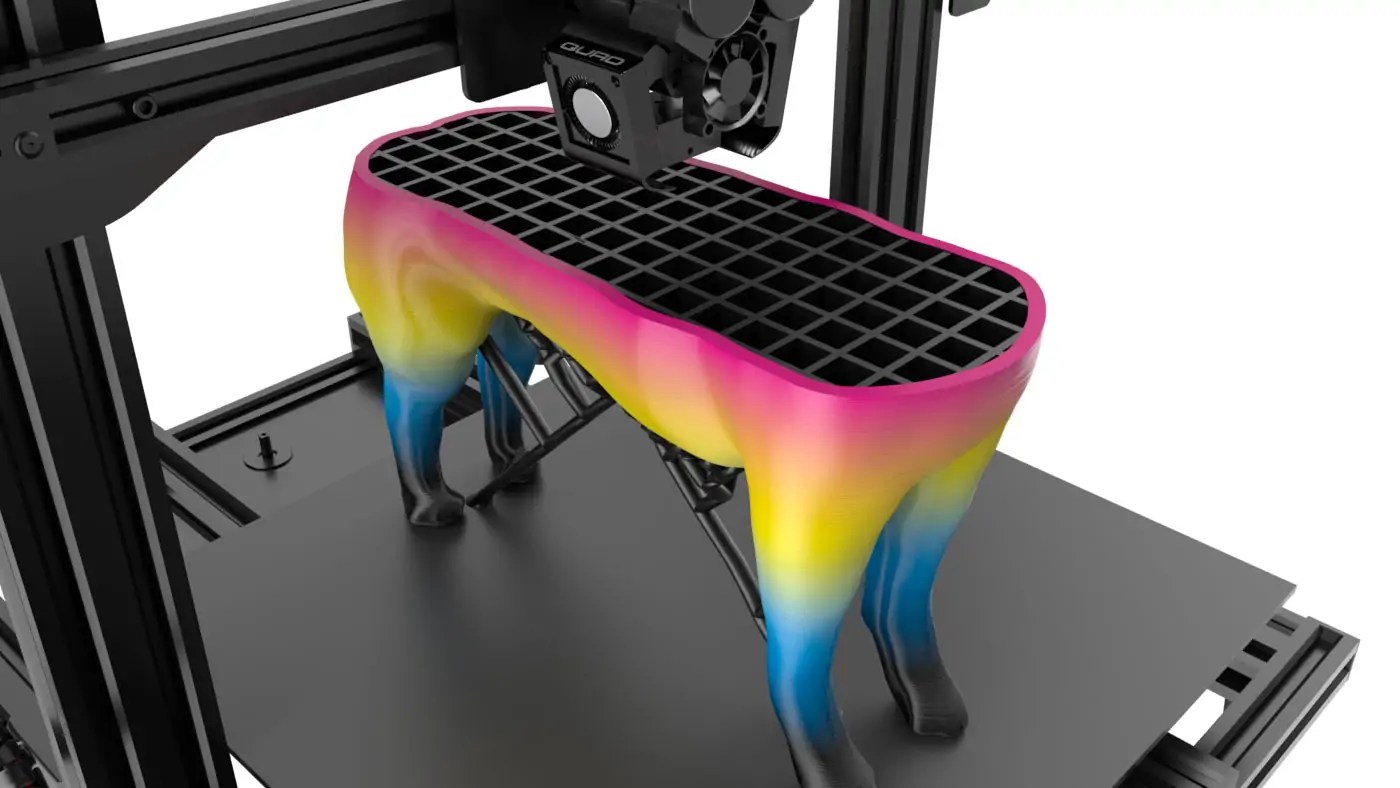

Picture of a Silk Rainbow Multicolor Printer FilamentWhile the above colors are great for the vast majority of 3D prints and enthusiasts, sometimes you want to change things up a bit. And one of the best ways to do that is with a rainbow multicolor filament. Our personal recommendation is to go with one of the “silk” ones that give the final print a shiny, smooth finish.

While you can get rainbow filament that looks like a normal rainbow, there are so many variations out there to choose from that you can have hundreds of rainbow prints and still not have tried them all! Keep in mind, with rainbow filaments it’s better to use them on bigger prints so that there’s enough room for multiple colors to show up.

Thermochromic (Heat-Changing) Filament

Picture of a Thermochromic (Heat-Changing) FilamentAs 3D printing becomes more advanced, one of the most intriguing new technologies in filament coloration is using thermochromic filaments. That sounds like a fancy word, but it’s just the more technical way of saying that the color of the filament changes based on heat.

That sounds like a fancy word, but it’s just the more technical way of saying that the color of the filament changes based on heat.

While the colors involved in thermochromic 3D printing filament can be all sorts of various combinations, our favorite is the Zi-Rui Thermochromic PLA Filament. Depending on the temperature, the print will change from yellow, to orange, to black. So if you move it around the room, you could get different color variations. How cool is that?

Glow In The Dark Filament

Picture of a Glow In The Dark FilamentLast but not least, we have another fan-favorite: glow in the dark 3D printing filaments. While this one might be a bit controversial since some of the cheap brands don’t offer a very high-quality filament, it’s so popular that we just couldn’t leave it off our list.

After all, think back to being a kid. Weren’t things that glowed in the dark just the coolest things ever? We all still have a bit of a kid inside us, and glow in the dark is still pretty cool! With this type of filament, you can print yourself an entire glow in the dark cache of little models and figurines. Just make sure you get a high-quality filament, such as HATCHBOX, for example!

Just make sure you get a high-quality filament, such as HATCHBOX, for example!

Which 3D Printing Filament Colors Should You Avoid?

Now that you know about some of the best filament colors for 3D printing, you should probably get an idea of what some of the worst ones are. For one reason or another — which we’ll explain for each one — the next few colors you see listed here are ones that you might want to avoid using in your 3D printing.

Neon Colors

While this isn’t exactly a specific color or anything, it is widely discussed in the 3D printing world that neon colors in general are one of the main filament types or colors to steer clear of. While they can certainly create some of the most eye-popping prints that you’ll ever see, they come with a slew of potential issues.

Depending on the brand, quality, color, and more, neon colored 3D printing filaments can be a headache to use. Some of them don’t bond well and begin to fall apart. Others come out looking almost transparent, revealing the support structures inside and not looking the way you’d want it to. Overall, you’ll likely be happier with the colors mentioned above!

Overall, you’ll likely be happier with the colors mentioned above!

Black

We know, we know. Black is one of the best looking colors on quite a few things that you might be 3D printing. And the truth is, with a high-quality brand you might actually have no issues whatsoever using black filament. But for many brands and many users, black filament tends to lead to excessive brittleness and easier cracking. Why is this?

The issue of a black coloration leading to brittleness actually isn’t something that only comes up with 3D printing. It’s an issue in the entire textile industry. This is because oftentimes, black goods are the result of an over-dye, i.e. something that was meant to be a different color didn't match what it was supposed to look like. It then goes to a pile of black to be re-dyed.

It is this multifaceted dying process that leads to the black filament (and other materials) being more brittle than its other-colored counterparts.

Yellow

Unlike the black filament above, yellow isn’t something to be avoided because of it being too brittle. No, instead you might want to consider avoiding using yellow filament just because of its coloration over time. Yellow pigment can be made from a lot of different sources, and its brilliance makes it a popular choice for 3D printing enthusiasts.

No, instead you might want to consider avoiding using yellow filament just because of its coloration over time. Yellow pigment can be made from a lot of different sources, and its brilliance makes it a popular choice for 3D printing enthusiasts.

But the issue with yellow pigment is that it tends to react to UV light (think sunlight) more than other colors, and not in a good way. Yellow begins to break down and decay faster under UV light than other colors, which leads to the color fading much more quickly.

3D printing in color - rich color in full color 3D printing!

May202015

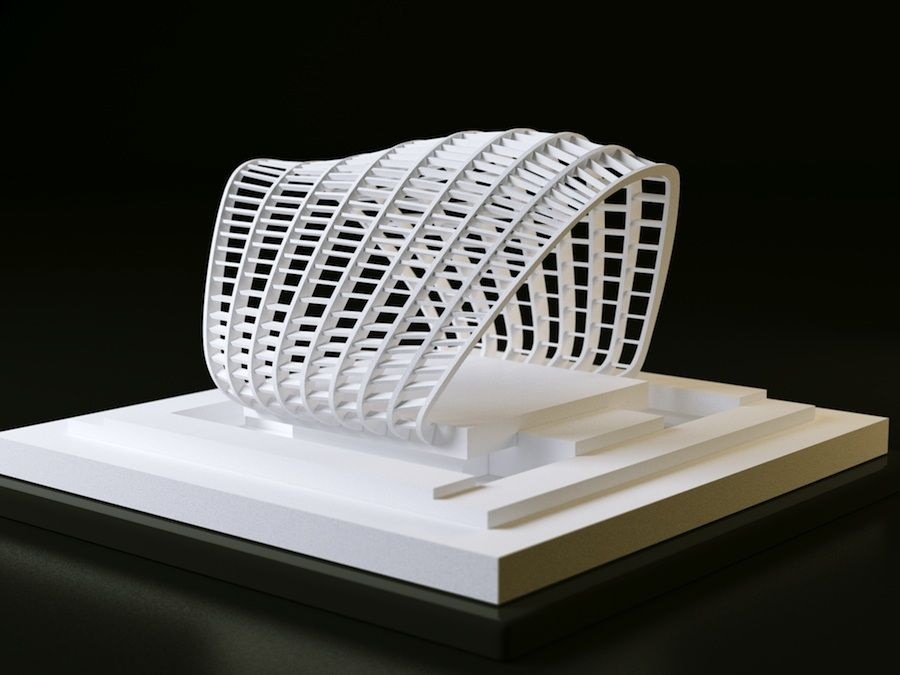

Color 3D printing: what it is

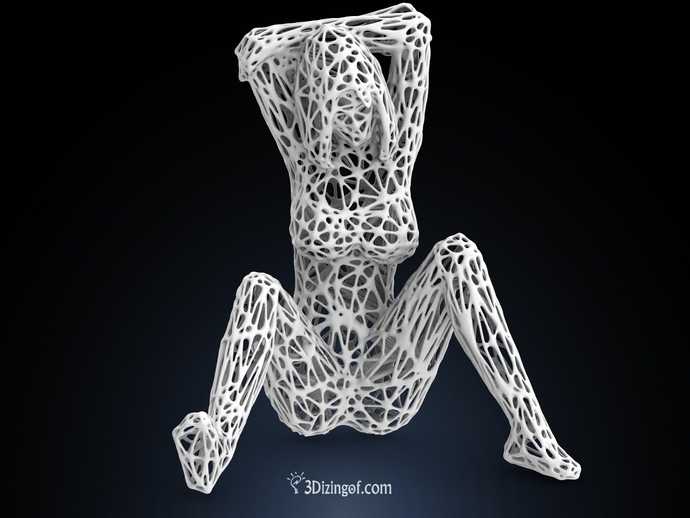

Full Color Sandstone (FCS) is currently the only material that opens up the possibility of full color 3D printing. This material is a great choice for creating human figurines, miniatures, memes, and other fun and realistic color models. Color 3D printing is a universal working tool for various purposes. Full-color professional 3D printers work according to the following scheme: they apply thin layers of powder and, using an adhesive component mixed with paint, bind this powder together, repeating the section of the future model in order to reproduce the whole product. Just like with 2D color printing, the colors on the printout may differ from those displayed on the screen. nine0007

Just like with 2D color printing, the colors on the printout may differ from those displayed on the screen. nine0007

Each pixel on the screen is made up of RGB red, green, and blue, while full-color printing sandstone uses cyan, magenta, yellow, and black (CMYK printing palette). When modeling for this material, there are several tricks that will help you significantly improve color reproduction, and we will talk about them below.

Color 3D Printing Tips

- First, it's important to know that CMYK color 3D printing is better at rendering light, bright, contrasting colors. To get a good result, avoid blurry borders, gradient transitions and shadows. The complex colors you see in photographs of photorealistic models are actually quite difficult to reproduce. nine0015

- Please note that some colors are simply difficult to print. For example, brown tones are difficult to reproduce because these colors require mixing all 4 inks (CMYK). And as a result, we can get an unpredictable result (a large amount of paint and a porous powder surface with uneven absorption).

- Be sure to take into account the wall thickness when 3D modeling, it is very important in painting.

Color 3D Printing Features

When you prepare a color 3D model for printing, you only specify the color of the surface - the texture determines the color outside, not inside the object. Actually, this is correct, since printers can only paint the outer layer of the model. After printing is complete, dip each model in Cyanoacrylate. This coating increases the strength of the model, and gives the color brightness and depth. If your model has a significantly varying wall thickness, then different sections of the model will absorb different volumes of this coating. As a result, you will see slight color changes, this effect is especially pronounced in massive models. nine0003

Also pay attention to the following points:

- If you make the model hollow and maintain a wall thickness of approximately 3 mm, then the color will be more uniform, and the cost of 3D printing, by the way, will be greatly reduced;

- If your model requires variable wall thicknesses, it is better to have a smooth transition between thicknesses, this will avoid sudden changes in color saturation;

- Technical approval versus actual approval; nine0014 Another issue to keep in mind is that you are working with a powder that absorbs the ink.

Even though the inkjet printhead resolution is 300DPI, the effective texture map resolution is probably closer to 50DPI. Keep this in mind when designing small details, especially on small models.

Even though the inkjet printhead resolution is 300DPI, the effective texture map resolution is probably closer to 50DPI. Keep this in mind when designing small details, especially on small models. We hope these tips have helped you improve the color and quality of your prints. If you landed on this page by accident and are interested in the presented method, we recommend that you familiarize yourself with the possibilities of color 3D printing in more detail and, if necessary, place an order. nine0003

Back to main page

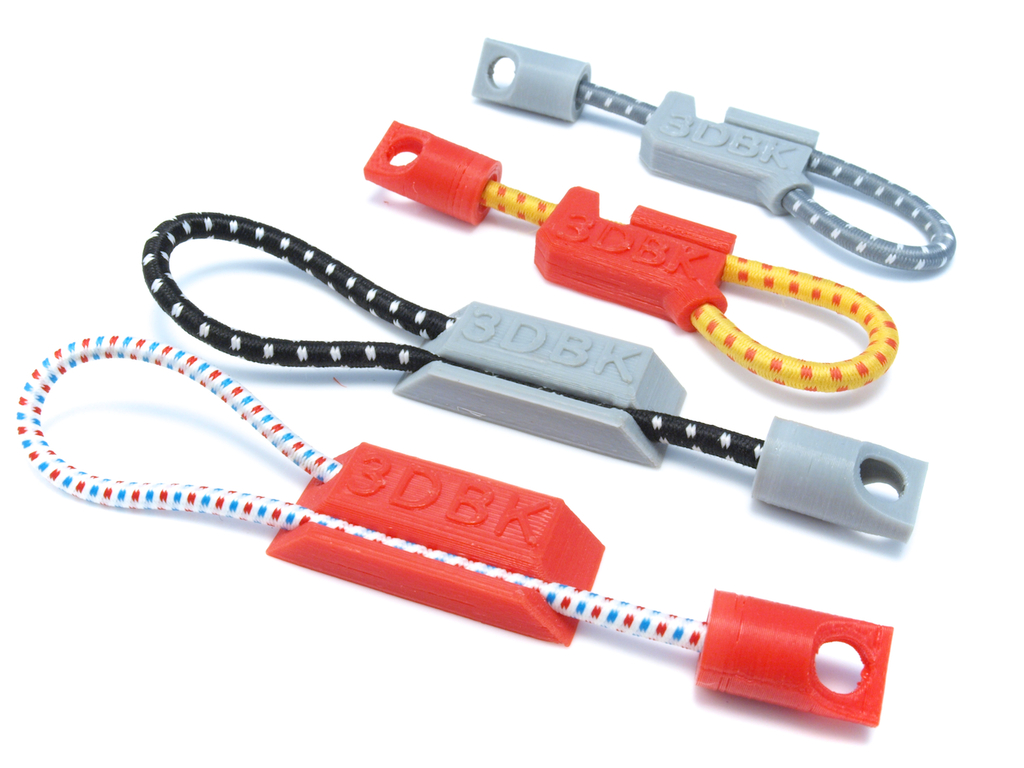

Plastic colors for 3D printing | 3D printing Voronezh

FDM 3D printing uses plastic filament (ABS, PLA, etc.), which can be of different colors and shades. For technical printing (bushings, gears, fasteners, etc.) and printing of products for painting, the color of the plastic does not really matter, so we recommend using the colors listed below for these purposes. In the manufacture of products in which color matters (souvenirs, layout details, body parts without further processing, etc. ), we suggest choosing the desired color from those suggested below. nine0003

), we suggest choosing the desired color from those suggested below. nine0003

To order printing in the selected color, specify its type, color or number in the comment to the order in the 3D printing calculation form.

Plastic color does NOT affect the cost of 3D printing. But if custom-made plastic is required, then in some cases (unclaimed color) the cost of printing may be higher (we hope for understanding).

Please note! Not all available colors may be available at the moment. If the desired color is not in stock, then it is available on order 3-12 days. Specify the possibility of supplying colors on request. nine0003

The color of the plastic on your monitor may differ from the actual color of the plastic due to color rendering and display settings.

ABS Plastic

PLA plastic

HIPS plastic

SBS Plastic

PET-G PLC

Colors ABS Plastic Plastic

ABS in the presence with butadiene and styrene. The most popular material for 3D printing. Easy to post-process. nine0075

The most popular material for 3D printing. Easy to post-process. nine0075

For 3D printing of bushings, gears, fittings, fasteners, latches and other technical elements, the recommended plastic color is natural ABS. This milky white plastic contains no dyes and is easy to work with. When grinding natural ABS plastic, there are no streaks on the surface of products that are inherent in colored plastics due to color disturbance due to mechanical action. Therefore, after grinding, the products are usually ready for use without additional processing. nine0003

Also, ABS plastic in black, gray and white is often used for technical printing.

ABS colors for color printing

available

ABS colors

on request

PLA colors

available

It is used for precise printing or when printing of dimensional models is required. It has extremely low shrinkage.

PLA plastic is Food Access Certified, so its most common use is in cookie and gingerbread molds. The second most important use of PLA plastic in 3D printing is for large-sized products. Due to low shrinkage and the ability to print without a thermal camera, PLA plastic is used to print products with sizes from 10 cm or more on each side. Both for the first and for the second application of PLA plastic, the color that performs a decorative function is important. We offer you to choose the desired color for your future product from those suggested below. nine0003

The second most important use of PLA plastic in 3D printing is for large-sized products. Due to low shrinkage and the ability to print without a thermal camera, PLA plastic is used to print products with sizes from 10 cm or more on each side. Both for the first and for the second application of PLA plastic, the color that performs a decorative function is important. We offer you to choose the desired color for your future product from those suggested below. nine0003

PLA plastic colors

on request

HIPS plastic colors

available

HIPS plastic is an impact-resistant, widespread plastic based on polystyrene, modified by the introduction of rubber particles. Has low shrinkage. It is used in the production of household appliance parts, car interior parts, electronic equipment housings, etc.

HIPS plastic is often used for technical purposes to create soluble supports or for printing parts. In this regard, white (natural) and gray colors are most often in demand. Since HIPS has a lower density than ABS and PLA and is not afraid of water, it is often used in ship and aircraft modeling, where the color has an aesthetic value. Available HIPS colors can be selected below. nine0003

In this regard, white (natural) and gray colors are most often in demand. Since HIPS has a lower density than ABS and PLA and is not afraid of water, it is often used in ship and aircraft modeling, where the color has an aesthetic value. Available HIPS colors can be selected below. nine0003

Colors of HIPS plastic

on request

Colors of SBS (Watson) plastic

available

SBS plastic is a high quality polymer based on a copolymer of styrene and butadiene. Differs in the increased flexibility, durability and low hygroscopicity. Has access to food. Can be stored and used underwater. There are transparent and translucent colored modifications to simulate glass.

SBS plastic is approved for food products, but unlike PLA plastic, it is not afraid of prolonged contact with water and has good elasticity. SBS plastic is available in a transparent modification, which allows you to create models with translucent walls, similar to glass. To give full transparency, SBS plastic is post-treated with a solvent. An example of the use of SBS plastic is the 3D printing of a glass with translucent walls, which can be crushed and restores its shape. SBS is well suited for printing large items. nine0003

To give full transparency, SBS plastic is post-treated with a solvent. An example of the use of SBS plastic is the 3D printing of a glass with translucent walls, which can be crushed and restores its shape. SBS is well suited for printing large items. nine0003

Colors of SBS (Watson) plastic

on request

Colors of PET-G plastic

available

PET-G is an impact-resistant plastic made of polyethylene terephthalate with the addition of glycol. It is characterized by high strength and low hygroscopicity. Has access to food.

PET-G is stronger than ABS but has low shrinkage comparable to PLA. It is intended for the press of especially strong, and also large-sized products. Unlike PLA, it can be used for printing technical products with a long service life. It tolerates prolonged contact with water. Resistant to most oils and technical fluids. It is processed, glued, dissolved with dichloromethane - methylene chloride.