3D print bike frame

Canyon unveils sustainable concept 3D printed mountain bike prototype

0Shares

Bicycle manufacturer Canyon has debuted a concept 3D printed mountain bike prototype which aims to demonstrate a more sustainable method of bicycle production.

Working with software and 3D printing service provider Materialise, Canyon 3D printed the bike’s frame and fork as part of Bike Magazine Germany’s ‘Ride Green’ campaign. The finished bike was showcased at the recent Cycle Show in London.

The Ride Green bike

The aim of the Ride Green project was to design a bike that is as sustainable as possible, with all its components being fully recyclable. The materials used also needed to be reusable without compromising the quality of the parts produced, while reducing waste was another key goal of the project.

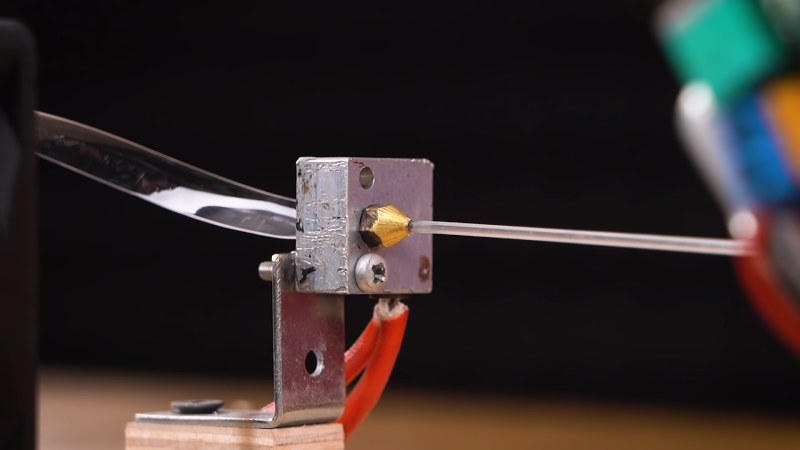

Canyon was tasked with building the bike’s cradle-to-cradle frame and fork, and settled on 3D printing as the most suitable, and sustainable, method of production. The firm enlisted Materialise’s selective laser melting (SLM) 3D printing technology to fabricate the components in order to achieve the frame’s desired unique shape.

Materialise is no stranger to the bicycle sector, having deployed its technology to print 2,000 parts for fellow bicycle manufacturer Pinarello’s Dogma F racing bike last year. In addition to achieving substantial weight reductions for a crucial seat clamp component for the bike, the company also created a full-service, customized production workflow for the project.

Canyon’s 3D printed bike frame. Photo via Bike Magazine.In order to meet the sustainability requirements of the project, the frame and fork were 3D printed from recycled aluminum powder. Canyon also wished to reduce the overall amount of raw material used in the fabrication of the frame, not only to improve the bike’s environmental impact but also to lower the frame weight and provide performance benefits.

Canyon also wished to reduce the overall amount of raw material used in the fabrication of the frame, not only to improve the bike’s environmental impact but also to lower the frame weight and provide performance benefits.

The frame is comprised of a skeleton that forms its structure, which is enclosed within an outer shell to provide additional protection and more desirable surface properties.

The frame was 3D printed in three pieces, each taking around six hours to produce. Once printed, the frame and fork weighed just 2 kilograms. While Canyon says there are currently no plans for the bike to enter production, the project could potentially influence how the company’s future models are designed and manufactured.

The bicycle frame was 3D printed in three parts and glued together. Photo via Bike Magazine.Boosting cycling performance with AM

Given 3D printing’s ability to consolidate multiple parts into single lightweight components and produce components with previously unachievable geometries, the technology’s benefits have been increasingly realized by bicycle manufacturers in recent years.

For instance, custom bicycle producer Sturdy Cycles has switched the production of its titanium bicycle parts to Headmade Materials’ Cold Metal Fusion (CMF) technology, and has previously worked with RAM3D to print parts for its road bikes. British Cycling even enlisted Renishaw’s help to 3D print aluminum and titanium parts for its new track bike on show at the Tokyo 2022 Olympic Games.

Meanwhile, some 3D printing firms have taken to kickstarter to launch their 3D printed bicycle components, such as Headmade Materials and Element22 who launched their jointly-developed novel Titanum 3D printed bike pedal design on the platform last year.

Elsewhere, the likes of Fizik and Specialized have used Carbon’s DLS 3D printing technology to improve the weight and comfort of their saddles, while Stratasys’ h450 machine has been used by DQBD to produce fully personalized 3D printed saddles that offer increased performance efficiency.

The Argo Adaptive short-nosed saddle’s 3D printed lattice. Photo via Fizik.

Photo via Fizik.Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews, and webinar replays.

Featured image shows Canyon’s 3D printed bike frame. Photo via Bike Magazine.

Tags British Cycling Canyon Carbon Cycle show 2022 Element22 fizik Headmade Materials Materialise Pinarello RAM3D Renishaw Ride Green campaign Specialized Stratasys Sturdy Cycles

Hayley Everett

Hayley is a Technology Journalist for 3DPI and has a background in B2B publications spanning manufacturing, tools and cycling. Writing news and features, she holds a keen interest in emerging technologies which are impacting the world we live in.

Have 3D Printed Bicycle Frames Finally Become a Viable Reality?

Search

-

1042

Have we finally reached a tipping point where 3D frames will be both practical and commercially viable?In global engineering and manufacturing, 3D printing has been big news for quite a while. In the case of bicycle frames, this means rather than joining pre-made tubes together with some form of welding or gluing, the entire frame is built from scratch in one process, by adding many fine layers in quick succession of whatever the frame material might be, such as titanium or carbon fibre.

It would have to be a decade already since we first started seeing reports of 3D printed bicycle frames. There has even been a failed Australian attempt, through Melbourne based Titomic with input from frame building and design veteran Peter Teschner.

There has even been a failed Australian attempt, through Melbourne based Titomic with input from frame building and design veteran Peter Teschner.

But despite huge promises of efficiencies that would allow commercially viable custom production of bicycles even in high wage countries like Australia, we’ve yet to see anything beyond predictions and prototypes.

One of the challenges has been that the equipment and software engineering required to 3D print something as large and complex as a bicycle frame is very expensive.

But with the bike industry booming and more venture capital than ever flooding in, that hurdle has been overcome, at least by Silicon Valley (USA) based Arevo.

In early September Arevo announced not only, ‘the completion of the world’s largest 3D printing facility for carbon fibre composite additive manufacturing’, but also the first shipment of bicycles and e-bikes with frames made by their 3D printer.

During Eurobike 2019, Arevo presented a prototype 3D-printed carbon fibre composite bicycle frame. Since August 2020, they’ve been offering on-demand production of customised frames.

Since August 2020, they’ve been offering on-demand production of customised frames.

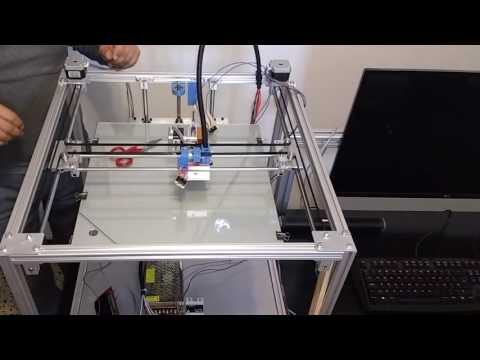

Now with the introduction of the next generation high speed additive manufacturing system for large continuous carbon fibre composite structures, Aqua 2, the production process has become four times faster than its predecessor.

The Arevo Aqua 2 3D printer can make an entire carbon fibre bicycle frame from scratch. Is this how bicycle frame manufacture is going to look in future?Arevo is operating a full range of production systems – including 70 Aqua 2 3D printers. According to one source the Arevo Aqua 2 3D printers cost US $500,000 (A$685,000) each.

In true Silicon Valley style, Areva has raised US$85 million (A$116 million) in funding so far, from some of the biggest names in venture capital.

According to Arevo, additive processes such as 3D printing enables, ‘fast, on-demand and comparatively cost-effective production’ compared to conventional methods. As a result, the company is using these systems to print not only bicycle frames and other sports equipment, but much more, such as automotive parts, aerospace components and even complex architectural structures.

Arevo CEO Sonny Vu said, “After introducing the Aqua2 3D printing system last year, which is four times faster than the Aqua 1, we have now focused on the production and operation of these systems. Currently, a total of 76 systems are in live production worldwide. They are all connected to the cloud and in use at our various sites. This puts Arevo in an excellent position to serve the growing global demand for both our own consumer brands and the needs of our B2B customers.”

Arevo’s own brands include Superstrata, a bicycle and e-bike brand, and Scotsman, an e-scooter brand. Coinciding with the completion of the new facility, Arevo has also shipped the first Superstrata bicycles and e-bikes with carbon fibre composite frames out of the 3D printer. In addition, the developers are just completing engineering for the Scotsman e-scooter.

Join the Conversation:

What do you think about the prospects of 3D printing for the bicycle industry?

JOIN THE CONVERSATION:

🚲 Best Bicycle 3D Printable STL Files・Cults

🚲 Best Bicycle 3D Printable STL Files

Free Download Bicycle Accessories 3D Files

A selection of valve covers, mounts, holders and racks for your bike that you can make with 3D printer. There are so many bike accessories out there and they can be very expensive, 3D printing is a great way to cut costs! 3D printing is also a great solution for inventing ideas that will make everyday life on your bike easier. nine0007

There are so many bike accessories out there and they can be very expensive, 3D printing is a great way to cut costs! 3D printing is also a great solution for inventing ideas that will make everyday life on your bike easier. nine0007

Customizable Bike Mount for Modular Mounting System

Free

3D Printed Bike

Free

Wall Rack

Free

mountain bike wall mount

Free

GoPro bike mount

Free

Bicycle Water Bottle Cage

Free

Stand Phone For Bike

Free

Water Bottle Holder

Free

Pizza Valve Cap

Free

Stormtrooper Valve Cap

Free

Coffee Cup Holder

Free

Brompton logo tap

Free

Presta valve cap with thread _ Presta Cap valve with thread

Free

Smartphone Support Magnetic Bike

0,50 €

nine0008 GoPro Handlebar Mount (customizable)Free

bike flashlight mount

Free

MOUSQUETON

Free

SR Suntour fork top cap socket (FAA122 replacement)

Free

Handelbar mount for Samsung S5 with wireless Qi charging - weather proof

Free

bike support go pro diameter 32 mm

Free

Bike Light

Free

Triathlon extension

Free

Smartphone bike holder

Free

Bar-End bike Plugs

Free

Saddle mount for "Smart LED / Planet Bike" lights

Free

Bike FlashLight Quick Release Mount

Free

iPhone 6 Holder

Free

Draisienne bike (IKEA hack collection) by Andreas Bhend and Samuel N.

Bernier

Bernier Free

The Bicycle Bubble Machine

Free

iPhone XS/6s Holder for GARMIN Mount (eTrex/Oregon/Colorado Series)

Free

bike holder

Free

Pinces pantalon pour le velo - Cycling Trouser Clips

Free

nine0008 Mud BikeFree

TUTUGO | Coffee Cup Valve Caps

Free

Fizik ICS Integrated Clip System Saddle adapter for Planet Bike / SMART Led Lights

Free

Clamping Knob For M8 Nut

Free

Bead buddy for bicycle tire installation

Free

Deer Bike Rack

Free

iPhone 6 Plus Holder

Free

Bicycle Stand - 2 Part for use on the Road

Free

bike cleaning wheel

Free

Lightweight press-fit MTB handlebar plugs

Free

Graziella Back Light Mount

Free

Yet Another Bicycle Flashlight Holder

Free

Beach umbrella holder for your bike

Free

Bike Attachment for iPhone 5, 4 and 4S

Free

nine0008 ISCG bash guardFree

derSchraederFlatter - Tire deflator for Schraeder valves

Free

Here is our selection of best stl files for bike, all these accessories are taken from 3D Cults library files and 3D printed beautifully .

This collection includes free 3D files of bicycle accessories. Numerous 3D models of are perfect for all types of bikes: mountain, city or racing bike . There are no restrictions on the type of bike, so you can even resize or reshape the 3D files to match the shape of your bike or frame.

In this way, 3D designers offering their creations on the Cults 3D file upload platform compete in ingenuity to make your everyday life on a bike easier . For example, you can easily attach your phone to the handlebar, carry water bottles, or attach your GoPro to the bike. Once you get home, there are 3D printable solutions that will allow you to store your bike. You can even stand out by 3D printing custom decorations for your bike, like 3D printed valve caps in the shape of a pizza or a Lego man head!

3D printed handlebars for Tour de France 9 winning bikes0001 3D printed handlebars for Tour de France winning bikes

- Industry

- Automotive

- Task

-

Manufacture of a bicycle frame and handlebars for Colnago, a manufacturer of racing bicycles for the Tour de France.

Learn more