Zortrax m200 3d printer review

Zortrax M200 Review 2022 [Everything You Need To Know]

So how good is the Zortrax M200 3D printer actually? Read our definitive Zortrax M200 review and discover everything there is to know about this 3D printer!

By Justin Evans

3.9

See Price

It can be troublesome to choose a high-end 3D printer. After all, when you increase your budget, you also increase the number of choices available. Some of these printers will be intended for commercial use, but some are just for enthusiasts looking to take their hobby to the next level.

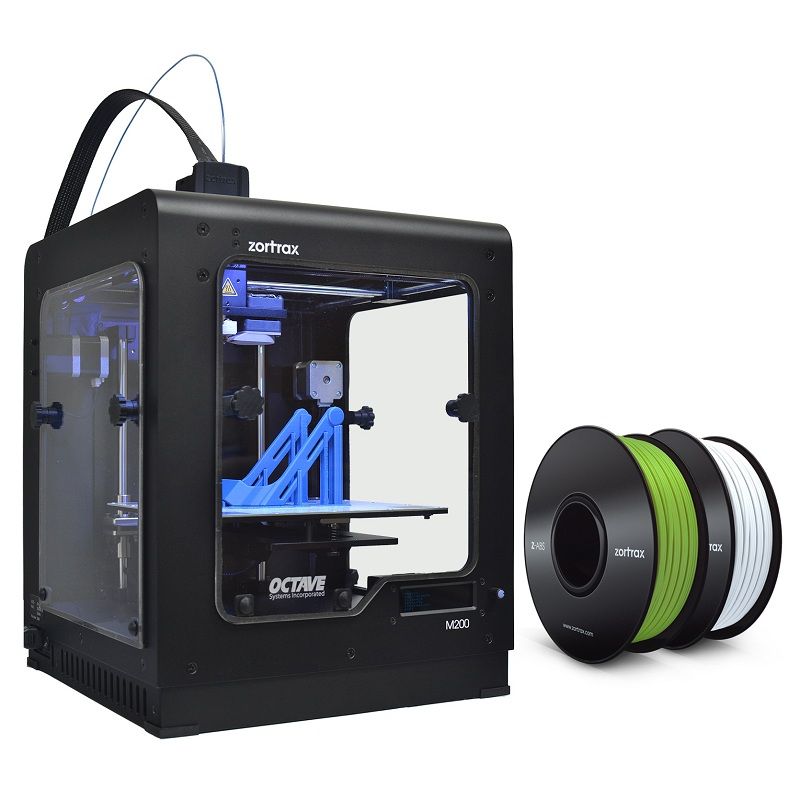

That’s why we’re demystifying 3D printers. Today, we’re looking at the Zortrax M200. This is a high-end printer that’s seen a spike in popularity thanks to its decision to allow third-party materials last year. With that out of the way, let’s jump right into our review.

| Filament Diameter | 1. |

| Extruders | 1 |

| Supported Materials | PLA, ABS, HIPS, Exotics |

| Connectivity | USB, SD card |

| Printing Speed | 100mm/s |

| Build Volume | 7.9 x 7.9 x 7.1” |

Table of ContentsShow

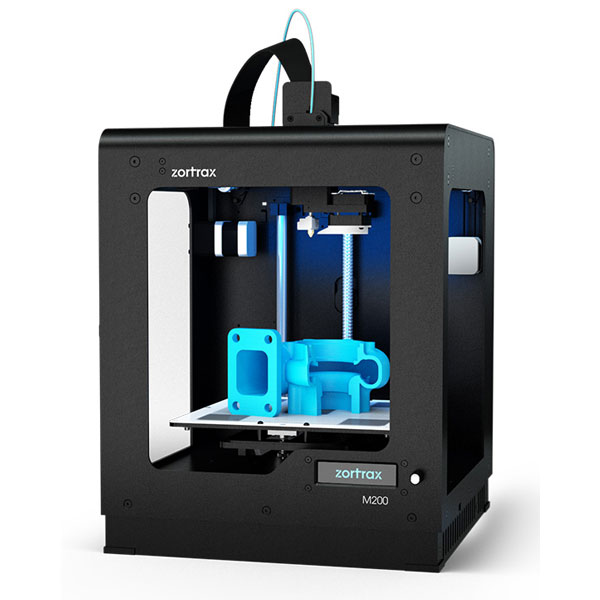

Design

The M200 certainly looks like an expensive printer. It has a sleek black design with rounded edges and an integrated LCD controller, after all. More importantly, its build area is enclosed, allowing it to keep a constant temperature easier. This is a blessing if you want to print with materials like ABS.

The build plate is heated and made of glass. The extruder can go as high as 290°, so you have a lot of scope here for different materials. Unfortunately, there’s just one extruder, so you can expect printing to move forward at a fairly slow rate. This printer’s specs claim a maximum speed of 100mm/s, which seems to back this up.

You should note that this is a fairly large printer, although it’s still capable of fitting on a desktop. At more than a foot long in every direction, it’s really intended for those with a little extra space.

Printing

Prints come across pretty nicely with the M200. You’ll see nice, rounded surfaces, and sharp edges with little material waste. Even fairly complex structures can be printed, which is where many printers, even some high-end ones, fail. Best of all, this printer is very quiet unless you crank up the speed.

We’ve seen several expensive 3D printers that can only handle the most basic filaments. In contrast, the M200 can print with all the most common materials, as well as some more exotic ones like glass-filled filaments. Plus, as we mentioned earlier, you’re not limited to just Zortrax’s own brand anymore.

This 3D printer is excellent for those that want a little extra quality. If it were slightly faster, it’d be the ideal model for small businesses, but it could still be a strong choice if you’re looking for quality over quantity.

Features

This is one of the only printers we’ve encountered that has a screen that’s not a pain to use. Its menus are well-organized, its functionality extensive. You can, of course, choose to control it straight from the computer if you’d like. There’s also an SD card slot for importing models.

Let’s not neglect to mention the large build area. Often, you’ll find that premium printers have vertical build areas, but this one is cubic, allowing you to create more expansive models without having to connect them afterward.

WiFi compatibility is fairly rare in 3D printers, but we can’t help but wish for it anyway. The ability to trigger and observe prints while away from your computer would help the M200 stand even further above its peers, and make it an absolute must-have.

Cost

The Zortrax M200 costs around $2000 on its own. However, if you’d like to add a heat cover, that’ll cost you an additional $200. As such, it’s clear that this is a printer with a high initial investment. But what about the day-to-day running costs?

But what about the day-to-day running costs?

Well, the cost of filament depends on how much you print. For instance, small spools of PLA can be bought for around $10, but if you’re using glass filament instead, you’ll see that price rise dramatically. Still, this can be said of any printer and the ability to use all these materials helps it stand out from the crowd.

Support

There’s a huge amount of support material available for the M200 on Zortrax’s website. Seriously – everything you’ll need to fix any problems short of a hardware failure is included here. You can also submit a help request, although you’ll need to provide proof of purchase to get any kind of a response.

The warranty is pretty generous too. It lasts one year for businesses, but two years for individuals. Compare that to several other models that offer just six months coverage, and it’s clear why the M200 has become a hobbyist’s favorite since its release.

This help doesn’t just extend to the printer itself. There’s also extensive documentation and help for using the proprietary Z-Suite application. The other good news is that this is compatible with both Windows and Mac, although if you’re a Linux user, you’ll have to use a different program instead.

There’s also extensive documentation and help for using the proprietary Z-Suite application. The other good news is that this is compatible with both Windows and Mac, although if you’re a Linux user, you’ll have to use a different program instead.

Solidoodle Press Review

Zortrax M200 Review | Tested by GearLab

Price: $1,600 List

Pros: Great support, excellent bed adhesion

Cons: Awful initial assembly, pricey

Manufacturer: Zortrax

By David Wise and Austin Palmer ⋅ Jun 14, 2017

Our Editors independently research, test, and rate the best products. We only make money if you purchase a product through our links, and we never accept free products from manufacturers. Learn more

The Zortrax is a futuristic, sleek printer that creates excellent prints, most of the time. It's very easy to use, with a software program, printer, and filament all made by the manufacturer. However, this limits the capabilities of the printer substantially.

It's very easy to use, with a software program, printer, and filament all made by the manufacturer. However, this limits the capabilities of the printer substantially.

The Zortrax M200, a great printer but not an award winner.

Credit: Jenna Ammerman

Performance Comparison

To rank these products, we set up an exhaustive testing process with over 45 different tests, split among four metrics — Ease of Use, Print Capabilities, Support, and Print Quality — assigning a score to each printer in each model. We ranked each product form 0-100, with more detail on the performance of each model in the following sections.

The Zortrax was a step behind the Ultimaker and was awful at bridging.

Credit: Jenna Ammerman

Print Quality

First and foremost in our test, the Print Quality metric made up 40% of the overall score. We printed a large selection of test model and had a rating panel judge them. Our test consisted of printing PLA and ABS for most printers but with the Zortrax's proprietary filament restrictions, we had no proxy for PLA. Every test print was printed in Z-ABS, using the recommended settings. The Zortrax did score very well, earning a 7 out of 10 in this critical metric.

Our test consisted of printing PLA and ABS for most printers but with the Zortrax's proprietary filament restrictions, we had no proxy for PLA. Every test print was printed in Z-ABS, using the recommended settings. The Zortrax did score very well, earning a 7 out of 10 in this critical metric.

The set of prints from the Zortrax made in Z-ABS, a proprietary filament.

Credit: Jenna Ammerman

The first test print we evaluated was 3D Benchy — a torture test that is frequently used to evaluate these products. The Benchy produced by the Zortrax was very smooth and the only level ABS print, though the bridging was subpar.

Everything but the bridging was excellent on this little tugboat.

Credit: Jenna Ammerman

Next, we evaluated the bridging test and the Eiffel Tower produced by the M200. This printer is quite terrible at bridging, with the outer layers and infill drooping drastically.

The Eiffel Tower broke when removing from the build plate, the structure just too fragile overall to remove with the ridiculously strong bed adhesion of the Zortrax.

The Eiffel Tower broke when removing from the build plate, the structure just too fragile overall to remove with the ridiculously strong bed adhesion of the Zortrax.Once again, the bridging was terrible on this printer.

Credit: Jenna Ammerman

Moving on to the next group prints, the Zortrax did reasonably well. The articulated elephant was average, with freely moving legs and a smooth body but having a mediocre neck and ears. The nickel test was slightly subpar, with the hole being too large and leaving wiggle room. The overhang test was superb, only dropping in quality on the steepest overhangs — similar to the Lulzbot.

The overhangs printed by the M200 were excellent.

Credit: Jenna Ammerman

The next two prints turned out poorly, as they both required substantial bridging — a weakness of the Zortrax. The platform jack had awful bridges and some wobble but still opened and closed without too much difficulty. The hollow cube had abysmal bridging but the rest was smooth and could have been cleaned up to look alright.

The hollow cube had abysmal bridging but the rest was smooth and could have been cleaned up to look alright.

Once again, the bridging needs some work.

Credit: Jenna Ammerman

The M200 printed our pair of low-poly figurines with aplomb, doing an excellent job on one and an average on the other. The average one had a few mishaps with the smallest tips, dropping its score.

The low-poly figures were exemplary.

Credit: Jenna Ammerman

The Zortrax did well at printing the spiral vase and tall tower but fared poorly in our support test. The vase was great, though the wall thickness was a little high. The tall tower was smooth all the way to the top, with only a little wobble towards the very top. The M200 did poorly at the support test, requiring us to resort to pliers to remove the sacrificial components.

The support test was subpar but the tower and vase came out quite nice.

Credit: Jenna Ammerman

Finally, the Zortrax did quite well in our final two prints: a threaded lid and jar.

The threaded lid and jar turned out excellent.

Credit: Jenna Ammerman

The threads had a few small bumps on them but still threaded together smoothly and the details on the lid were well done.

Assembling the Zortrax, especially the side panels, was quite frustrating.

Credit: Jenna Ammerman

Ease of Use

Starting a trend, the Zortrax scored well in this metric — which made up 30% of the final score — earning a 7 out of 10 once again. We evaluated the ease of the initial setup and assembly, the connectivity, and display of the printer, as well as how much frustration swapping filaments and leveling the bed caused.

The initial setup on this printer was quite vexing. You need to install the build plate, attach some cable routing clips, connect some cables, add a filament spool holder and guide tube, then add the side panels and the door.

Needless to say, this was a complicated process, needlessly hindered by the unclear directions. The side panels and door were by far the most difficult part, making this printer the most difficult to assemble. However, this model was very easy to use after the initial assembly. The bed levels semi-automatically, with the printer probing and then telling you how to adjust the knobs.

The side panels and door were by far the most difficult part, making this printer the most difficult to assemble. However, this model was very easy to use after the initial assembly. The bed levels semi-automatically, with the printer probing and then telling you how to adjust the knobs.

This model includes an SD card to USB adapter, as this model lacks a USB connector. Prints can be loaded from a computer via this adapter, or this printer is capable of standalone printing directly from an SD card. The M200 has a small display that shows estimated time left and amount completed. It is also quite easy to swap filaments on this model, navigating to the necessary section of the menu on the machine, which will then heat the nozzle and run the extruder motor to expel the filament, similar to the FlashForge or QIDI, with the added benefit of stopping automatically — something the other two printers will not do.

The capabilities of this printer are limited, as it is restricted to proprietary filament and software.

Credit: Jenna Ammerman

Print Capabilities

This next metric accounted for 20% of the final score for these products, based on the build volume and build plate, the filament capabilities, maximum extruder temperature, and software compatibility of each model. The Zortrax M200 scored alright, earning a 5 out of 10.

This model had a somewhat average build envelope, measuring in at 200 x 200 x 180mm. The build plate was exceptional, with its gridded pattern of holes ensuring that we almost no issues with bed adhesion. In fact, we had the opposite problem with this printer, struggling to remove prints and inadvertently breaking some of the more fragile ones in the process.

The perforated metal bed on the Zortrax practically eliminated the print peeling off the bed, actually making the prints difficult to remove.

Credit: Jenna Ammerman

The Zortrax is only compatible with the Z-Suite software program, severely limiting the settings you can adjust to fine tune your print quality.

This printer is also limited to a proprietary filament, mainly due to the fact that you can not finely adjust the temperature it prints at, limited only to the preset temperature profiles.

This printer is also limited to a proprietary filament, mainly due to the fact that you can not finely adjust the temperature it prints at, limited only to the preset temperature profiles. The Z-Suite proprietary slicing software.

Credit: Jenna Ammerman

This model only has one layer cooling fan but the extruder has a listed maximum temperature of 380°C. However, you are still restricted to the six varieties of Zortrax filament: Z-ULTRAT, Z-HIPS, Z-GLASS, Z-PETG, Z-PCABS, Z-ESD.

Support

The final metric in our review, Support, accounts for the remaining portion of the score, 10%. We compared the ease at contacting and helpfulness of the customer support team, as well as the quality of documentation — mainly looking for instructional videos — and the included warranty with each printer. The Zortrax scored quite well, earning an 8 out of 10 for this metric.

There were a huge number of instructional videos on the manufacturer's website, covering most common issues or questions. You can contact the customer support service by support form or instant messenger. Unfortunately, there was not a phone number to contact. However, we found the response to our questions to be both prompt and helpful. Finally, there is a 24-month warranty included for the individual customer or a 12-month warranty included for the corporate purchaser.

You can contact the customer support service by support form or instant messenger. Unfortunately, there was not a phone number to contact. However, we found the response to our questions to be both prompt and helpful. Finally, there is a 24-month warranty included for the individual customer or a 12-month warranty included for the corporate purchaser.

Value

While this printer did score well in our tests, it was also on the more expensive side — not really a value option.

Conclusion

The Zortrax M200 is a great all-around printer. Our main issues with this model were the somewhat horrendous assembly process and the lack of compatibility with generic filaments or other software programs. However, if you are willing to commit to Zortrax for all of your future filament purchases and can make it through the initial setup, then this might be an option to consider. You also have the added benefit of never really having to worry about bed adhesion issues again!

Review of the 3D printer Zortrax M200

Content

-

- Appeal

- Complex

- Cinematics

- Preparation for

- 9000

- Results

In 2011, the development of the M200 3D printer started, and in 2013, the Polish company Zortrax became known throughout the 3D world thanks to its Kickstarter campaign. The aim of the campaign was the launch of the M200, which promised ease of use and professional quality. The campaign raised $180,000. In 2014, the first Zortrax store was opened, and at the moment the brand is already represented in 50 countries with 160 partners. nine0003

The aim of the campaign was the launch of the M200, which promised ease of use and professional quality. The campaign raised $180,000. In 2014, the first Zortrax store was opened, and at the moment the brand is already represented in 50 countries with 160 partners. nine0003

The printer consistently holds the top lines in the 3D Hubs community, taking first place in the ratings. Users note the high print quality, reliability and ease of use.

Initially, Zortrax was optimized for printing only with its own production of plastics. Despite the great variety (currently there are 9 types of filament), many were repelled by the impossibility of printing with third-party plastics. In new versions of the software, manufacturers have solved this problem - the ability to print with third-party materials has been added. nine0003

Appearance

The printer is made of durable aluminum and looks very solid and reliable. No distortion or backlash was noticed anywhere. Build quality is top notch.

Strict black color, smoothed corners - the design of the printer can be called minimalistic and concise.

Equipment

Includes:

- Spool holder.

- Material guide tube and fasteners. nine0008

- Coil of Zortax proprietary material.

- Power cable.

- SD card and card reader.

- Protective gloves.

- Knife.

- Scalpel.

- Hexagon set.

- Nozzle wrench.

- Nozzle cleaning strings 0.4 and 0.35.

- Wire cutters.

- Spatula.

- Tweezers.

- Grease for printer moving parts. nine0008

- Safety goggles.

The set is very decent. The manufacturer decided to make sure that the user does not have to buy or order from simple to the most specific tools. Even the nozzle cleaning needle is available in 2 versions - for a nozzle with a diameter of 0.4 and 0.35 (by default, a 0.4 mm nozzle is installed on the printer).

Kinematics

The kinematics of the printer is a copy of the famous Ultimaker. It turned out to be a win-win solution. nine0003

A powerful ball screw is installed along the Z axis instead of the already familiar trapezoidal screw.

The extruder turned out to be all-metal. The maximum heating temperature is 280 degrees. The “cube” of the heater into which the nozzle is screwed is fixed. A trifle, but thanks to this, the nozzle is very easy to unscrew and you don’t have to look for ways to fix the heater.

The feed motor is located on the print head. This is the so-called direct-feed plastic. Of course, this solution makes the print head heavier, but it allows you to print all types of plastics, including soft Flex and rubber. nine0003

The print platform is a bit unusual - perforated, like on UP printers.

The advantage of this solution is very good adhesion (sticking models to the table during printing). There is no need to use glue or stickers so that the models do not peel off during printing.

The only inconvenience is that you will always have to print on a substrate (raft).

The board is made and designed specifically for the printer. All wires are shielded. nine0003

Preparing for work

After unpacking, the printer needs to be prepared for printing: connect the extruder cable, install and connect the printing platform, calibrate the printer.

The cable is connected very easily - you need to open the top of the extruder and plug the cable into the connector. It's nice that the cable is additionally securely fixed with latches.

We connect the connectors on the platform and install it on magnetic fasteners. nine0003

When turned on, the printer asks to download a file from the manufacturer's website and save it to a USB flash drive. Without this, the printer will not start. The M200 does not support Wi-Fi connection, files can only be transferred via a USB flash drive.

Download, restart the printer. Everything works.

Everything works.

The printer menu is simple and convenient. There are points for loading, unloading plastic and calibration. Choose a calibration.

The printer is calibrated "hot". We are waiting for the printer to heat up the nozzle and the table. After that, following the instructions on the screen, we calibrate. The printer will alternately poke the nozzle into the metal squares on the platform and ask you to unscrew or tighten a certain screw at the bottom of the platform. nine0003

Calibration is complete, you can start printing.

SW

Zortrax Z-Suite proprietary slicer is used as printer software. The printer will not work with other slicers.

To download and run the program, you will have to enter the serial number of the printer.

Z-Suite has a very nice and intuitive interface. We launch the program and select our Zortrax model.

We load the model and place it on the table. nine0003

Preparation for printing takes place in several stages:

- Model analysis.

The slicer will show the weak and problem areas of the model.

The slicer will show the weak and problem areas of the model.

- Show support. Here you can select the overhang angle of the model, at which the support will be set, and slightly edit the support. Support is edited by "blocks". You cannot add or remove support pointwise.

- Print settings. Here you can choose either a ready-made profile for native Zortrax plastic or set your own settings for any material. The range of settings is very decent. nine0128

- Preview. In preview mode, you can add pauses at different heights. This will come in handy if you want to print a multi-colored model.

The file is saved not in the usual GCode format, but in the native ZCode format.

Results

Despite the fact that we have not yet had time to conduct printed tests, the printer already pleases with its thoughtfulness. Zortrax showed incredible attention to detail, and it is not at all surprising that the M200 printer has repeatedly become the best according to Make magazine and the specialized Internet platform 3D Hubs. nine0003

nine0003

The printer conquers with its reliability and competent design, the Z-Suite software also pleased with its friendly interface and the presence of the necessary functions. The lack of a Wi-Fi connection was a little disappointing, but this was compensated by a very rich package bundle.

M200 is almost omnivorous, making it a good helper for large and small productions. Of course, with the condition that you will have enough print area of 200x200x180 mm. Otherwise, we recommend taking a closer look at its older brother - M300 with a construction area of 300×300×300 mm. nine0003

Oops.. there seems to be no such page

Apparently, you've landed on a page that either doesn't exist or was deleted long ago. Start your search first!

Request a call back

Telephone

By clicking on the button, you agree to the privacy policy of

Item added to cart

Go to cart

Product added to compare

Compare products

Cannot compare more than 4 products

Invoice or quotation request

Organization name:

Your e-mail

Your phone

Name of contact person:

Legal address:

Comment:

By clicking on the button, you agree to the privacy policy of

Goods on the way, find out when delivery

Your name:

Your e-mail

Your phone

By clicking on the button, you agree to the privacy policy of

Contact us

How to call

By phone +7(495)155-45-19. Your call will be answered by an answering machine. We won't call back if you don't speak up. Each request is processed, we contact clients in accordance with requests. Prepare the information you want to report, send it to the answering machine and we will call you back. We kindly request: do not be silent and do not hang up, this is just an answering machine. 🙂 Other most effective ways to get in touch: nine0003

Your call will be answered by an answering machine. We won't call back if you don't speak up. Each request is processed, we contact clients in accordance with requests. Prepare the information you want to report, send it to the answering machine and we will call you back. We kindly request: do not be silent and do not hang up, this is just an answering machine. 🙂 Other most effective ways to get in touch: nine0003

- Write to Telegam @techno3dru

- Whatsapp +74951554519

- Write Email [email protected]

Is the product in stock

On the product page, under the product name, there are 3 statuses:

- In stock - We have this item in stock. Make a purchase with the Buy button.

- Pre-order - goods on the way, delivery soon. Find out about delivery times by clicking on 'Delivery times' or make a purchase using the Buy button.

Learn more