3D printing process ppt

PPT – 3D Printing: A Beginner's Ultimate Guide PowerPoint presentation | free to download

About This Presentation

Transcript and Presenter's Notes

Title: 3D Printing: A Beginner's Ultimate Guide

1

3D Printing

- A Beginner's Ultimate Guide

2

What 3D Printing is?

- 3D printing doesnt mean three duplications of a

print. - Its mean three-dimensional printing.

- The printing is done via the automated process to

build a three-dimensional object. - The process is known as additive manufacturing.

3

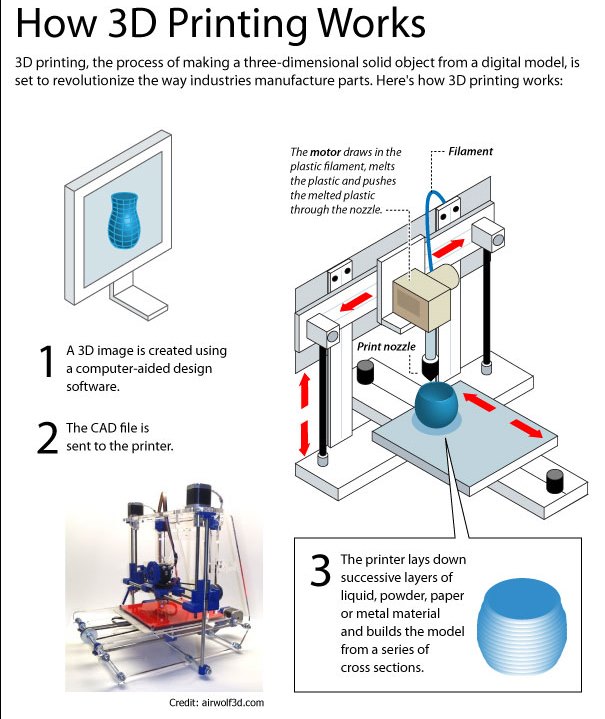

How does 3D Printer Works?

- Printing is done by adding material rather than

taking it away - The additive process continues to add successive

layers until the object is created.

4

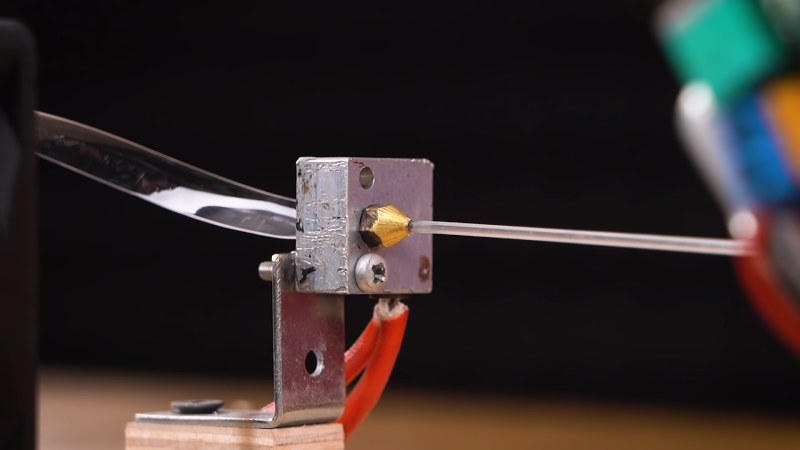

What are Major Components of 3D Printer?

- Filament A material (often plastic) used for

printing - Extruder The part of printing machine used for

melting filament - Nozzle A small hole from which melted filament

is extruded - Bed The surface where the produced object is

kept - Heated Bed A print surface kept heated for

better adhesion - Stepper Motor A motor machine used to move the

printer components

5

What are the Benefits of 3D Printing?

- It helps to customize designs and materials

- It is applied in aerospace to assemble complex

parts - It enables the producers to get rapid prototyping

of complex systems - It helps to create durable models for

architecture construction Industry - It allows the maritime experts to generate spare

parts for their equipment - It helps in printing surgical models and custom

prosthetics for medical professionals

6

In what ways, 3D Printing has Limitations?

- Everything comes with opportunities and

limitations, so the 3D printing.

- Limitation of size, unable to create mega objects

- Restriction of Material, unable to print using

multiple materials at a time - Multi-material 3D printers do exist but not

common in use

7

What are major types of 3D Printing?

- Fused Deposition Modeling (FDM)

- Stereo-lithography (SLA)

- Selective laser sintering (SLS)

- Selective laser melting (SLM)

- Binder jetting

8

Contact Us

- XERATEK

- Phone 971 4 3997714

- Email enquiry_at_xeratekuae.com

- Website www.xeratekuae.com

About PowerShow.com

PPT – 3D Printing Materials PowerPoint presentation | free to download

About This Presentation

Transcript and Presenter's Notes

Title: 3D Printing Materials

1

3D Printing Materials

Alfa Chemistry

2

3D Printing Materials

Photosensitive resin

Ceramic materials

3D printing bioplastics

Polymer gel

Engineering plastics

High-strength carbon fiber reinforced composite

Rubber materials

3D printing metal

3

Engineering plastics

ABS

PC

Engineering plastics have excellent strength,

hardness, impact resistance, resistance and

anti-aging property

Nylon-like materials

PA

4

ABS

ABS materials are the preferred engineering

plastics for 3D printing by fused deposition due

to their good hot melt property and impact

strength.

5

PA

PA has high strength and flexibility, so it can

directly use 3D printing to manufacture equipment

parts. PA carbon fiber parts manufactured by 3D

printing have high strength and toughness and can

be used for mechanical tools instead of metal

tools.

Due to the adhesiveness and powder

characteristics of PA, it can be mixed with

ceramic powder, glass powder, metal powder, and

low-temperature 3D printing of ceramic powder,

glass powder, and metal powder can be achieved by

bonding.

6

PC

PC has excellent strength, its strength is about

60 higher than ABS material, so it is suitable

for the application of super-strong engineering

products.

Engine peripheral parts

Door handle sets

Brake pedals

7

Photosensitive resin

Polymer monomer Prepolymer

Due to its good liquid flow and instant

photocuring properties, liquid photosensitive

resin is the material of choice for 3D printing

consumables for high-precision product printing.

8

Rubber materials

Rubber materials possess a variety of levels of

elasticity. The hardness, elongation at break,

tear resistance and tensile strength of rubber

make them ideal for applications requiring

anti-skid or soft surfaces.

9

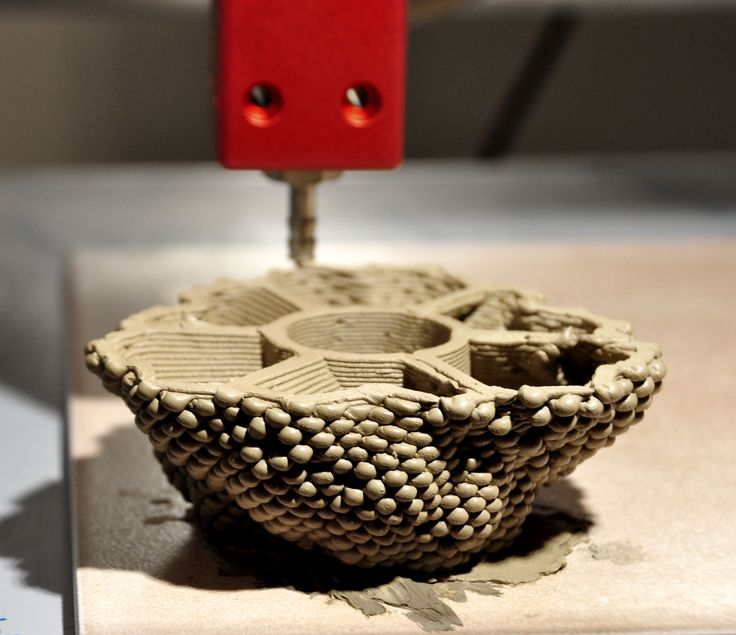

Ceramic materials

High strength

Low density

High hardness

Chemical stability

High temperature resistance

Corrosion resistance

10

3D printing metal

Titanium alloy

Aluminum alloy material

Cobalt-chromium alloy

Gold

Stainless steel

Silver

The metal powder used in 3D printing generally

requires high purity, good sphericity, narrow

particle size distribution and low oxygen content.

11

Polymer gel

12

High-strength carbon fiber reinforced composite

Compared to traditional extrusion or injection

molding methods, 3D printing can precisely set

its overall performance by precisely controlling

the orientation of carbon fibers and optimizing

specific mechanical, electrical and thermal

properties. Since 3D printed composite parts can

Since 3D printed composite parts can

only be fabricated one layer at a time, each

layer can achieve any desired fiber orientation.

Complex shape parts combined with reinforced

composite materials have excellent high

temperature and chemical resistance.

13

3D printing bioplastics

PLA

As an environmentally friendly plastic, PLA is

biodegradable into active compost. The

biodegradable polymer material can be molded by

3D technology to produce its PLA tissue

engineering scaffold with growth ability.

PETG

PHB

14

Suite 212, Waverly Plaza, 755 Waverly Avenue,

Holtsville, NY 11742, USA

info_at_alfa-chemistry.com

Fax 1-516-927-0118

15

Copyright 2012 - 2018 Alfa Chemistry. All

Rights Reserved.

About PowerShow.com

3D printing - online presentation

Similar presentations:

Master class on 3D printing. Picaso 3D

Picaso 3D

Possibilities of 3D technologies

Additive technologies: 3D printing

3D Printing Technologies and Trends

3D printing. Future and prospects. (Part 1)

RobotBuilder. 3D modeling programs. 3D printer

Additive technologies

3D Printing Technologies

Additive manufacturing technologies

3D printing

FABLUB BISHKEK

3D printing

Contents

01

What is 3D printing?

02

3D printing type

03

3D printing process

04

3D printer and slicer software

FABLAB BISHKEK

What is 3D printing?

An additive manufacturing process that

creates a physical object from a digital design

FABLAB BISHKEK

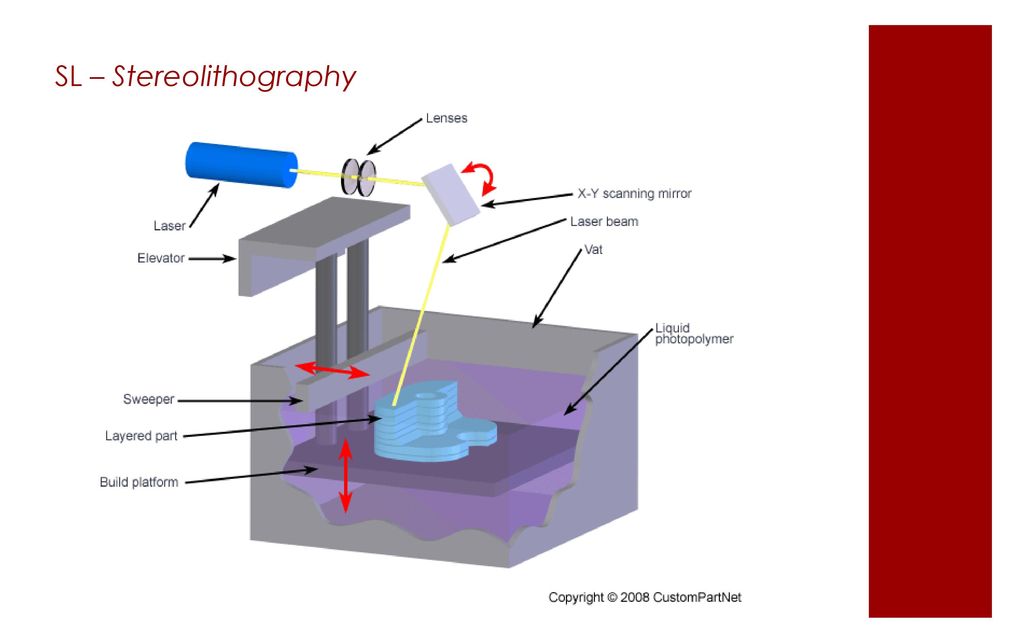

SLA

FDM

By charkes W. Hull

By S. Scott Crunmp

vs

Invented at 1986

Invented in 1989

Patent validity

2006

Patent validity

2012

Not a new technology!

FABLAB BISHKEK

Create complex designs

Customize each and every item

Pros

No tools or molds needed, over

low fixed costs

Speed and ease of prototyping, quick and less

risky way to market

Less waste

FABLAB BISHKEK

Higher cost for large production

Cycles

Cons

Less choice of material, color, finishing

Limited strength and endurance

Low accuracy

Fablab Bishkek

Car manufacturer

Doctor

Dentizing

Dipmate

Aerosmic companies

Aerosmes

additive manufacturing process that creates

a physical object from a digital design

FABLAB BISHKEK

Fused extrusion

FDM

/

FFF

(Fusion Fused Modeling) / (Fused Fiber Fabrication)

FDM Technology Diagram

FABLAB BISHKEK

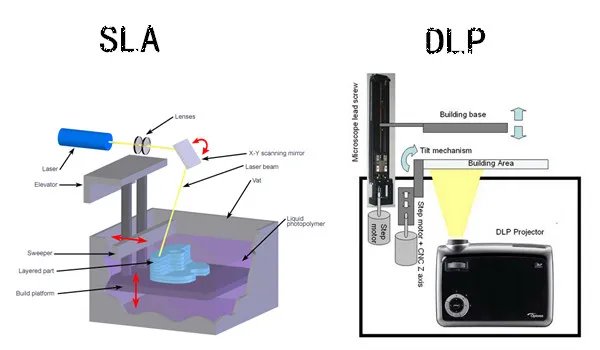

Photocurable

SLA / DLP

(Stereolithography Machine) / (Digital Light Processing) SLA5 FABL02 Technology Diagram BISHKEK

Sintering

SLS

(Selective Laser Sintering)

SLS Technology Diagram

FABLAB BISHKEK

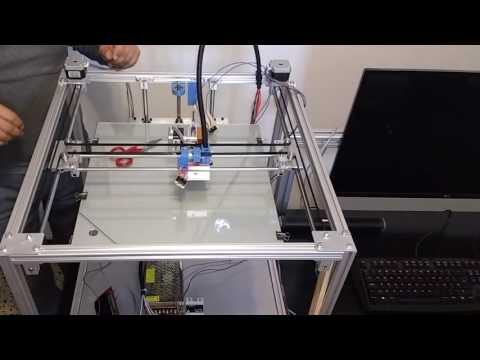

Structure of the FFF type 3D Printer

l Head

l Extruder

l Fiber

l Support

l Hot table

FABLAB BISHKEK

Fiber

Granule

FABLAB BISHKEK

ABS

PLA

(Acrylonitrile butadiene styrene)

(Poly lactic acid)

general purpose plastics

Matt surface

VS

60% cornstarch

Biodegradable plastic and glossy surface

FABLAB BISHKEK

ABS

PLA

ol)

(Poly lactic acid)

Relatively soft

Can be bent

Printed at high temperature

Nozzle : 230˚C ~ 260˚C

Bedding : 90˚C ~ 110˚C

Harmful gas

Hard

Can be broken

Printed at relatively low temperature

˚C ~ 220˚C

Bedding : 20˚C ~ 70˚C

Relatively less harmful gas

Easy to complete

Difficult to complete

High shrinkage

Low shrinkage

Acetone fumigation possible

Acetone fumigation impossible

FABLAB BISHKEK

Metallic

Fiber

(Wood Fibre)

(Flexible Fibre)

Others: need to set higher temperature than ABS / PLA

FABLAB BISHKEK

The

3D printing process is an additive manufacturing process that creates a

physical object from a digital design

FABLAB BISHKEK

Starting! - 3D printing process

Concept

Have an idea for a

structure that a

manufacturer wants to make.

3D modeling

Using the 3

D modeling tools, create a shape for the idea.

Also, we can download the

model online.

Slicing

Using the

slicer program, cut

horizontally of the

model file

According to the specification with

nter we can install

various us

triplets

3D printing

Slicer) will print out the

result.

FABLAB BISHKEK

Getting Started! - How can I get a design for 3D printing?

- Design your own

TINKERCAD: https://www.tinkercad.com/

Autodesk FUSION 360: http://www.autodesk.com/products/fusion-360/overview

FABLAB BISHKEK

See I bring to your attention

- MOOC (Massive Open Online Courses)

https://www.coursera.org/

https://iversity.org/en/

https://www.edx.org/

http://www.openuped .eu/courses

https://www.udacity.com/

https://www.futurelearn.com/

https://ocw.mit.edu/index.htm

https://www.pluralsight.com/

https://www. class-central.com/

class-central.com/

https://www.skillshare.com/

http://www.digitaltutors.com/11/index.php

https://www.lynda.com/

FABLAB BISHKEK

Getting started! - How can I get a design for 3D printing?

- Find design online

Thingiverse:

3D Map:

Image Converter:

Cults:

YM(YouMagine):

Instructable:

Wevolver:

http://www.thingiverse.com/

https://touch-mapper .org/en/

http://3dp.rocks/lithophane/

https://cults3d.com/

https://www.youmagine.com/

http://www.instructables.com/

https://www.wevolver .com/

FABLAB BISHKEK

3D Printer : Sindoh 3DWOX 1

Website: https://3dprinter.sindoh.com/

FABLAB BISHKEK

Printer Specifications

Print Technology

FFF

Print Head

Single Nozzle 40 9025 Nozzle Dia. 25

Maximum assembly size

210 x 200 x 195 mm

(WxDxH)

Fiber material

PLA, ABS, ASA, PETG, etc

Connectivity

USB, Ethernet (1G), Wi-Fi

Layer thickness

0. 05 ~ 0.40 mm

05 ~ 0.40 mm

Fiber diameter

1.75mm

Size Weight

421 × 433 × 435

15kg

User Interface 5-inch Full Color Touch Screen

Leveling

Auto + Manual

Cartridge Loading

Auto

FABLAB BISHKEK

Printer Specifications

Auto Cartridge Loading Automatic Loading

Security Camera

Check print status via

WiFi

Slicer

Slicer3DWOX Desktop Slicer

Sindoh Cloud Slicer

Simplify3D input file format Ver.4.1

Operating system stl, ply, obj, G-code(RepRap)

Window 7 or above

Mac OSX 1

FABLAB BISHKEK

Slicer program

Slicer is a program that creates G-code by

cutting a simulation file into multiple layers.

FABLAB BISHKEK

Temperature

*Datasheet for reference only

- Temperature of materials.

Materials

PLA

ABS

TPU *ref.

The extrusion temperature

190 ~ 220 ℃

220 ~ 260 ℃

230 ~ 260 ℃

Best temperature

200 ℃

230 ℃

230 ℃

Subold temperature

50 ~ 70 ℃

80 ~ 110 ℃

40 ~ 50 ℃ 50 ℃

The temperature of the 3D printer parts.

Materials

Extrusion

Bedding

Chamber

ABS

230℃

90℃

50℃

PLA

200℃

60℃

400℃ FASH2BLK5 Examples

4005 FASH2BLK50025 source code

FABLAB BISHKEK

Thank you!

English Russian Rules

3D printing - online presentation

Similar presentations:

3D Printing Technologies and Trends

Additive technologies: 3D printing

Additive manufacturing technologies

3D printing

3D printing technologies at the enterprise "3D Techno"

Methods and technologies for prototyping products. (Lecture 7)

Control of technological processes based on computer CAD systems in mechanical engineering. (Lecture 7)

Additive manufacturing

Additive technologies in mechanical engineering

Additive technologies

3D printing

3D printer

3D printer (fabber, Rapid Prototyper) is a peripheral device that uses the

method of layer-by-layer creation of a physical object from a digital 3D model.

Charles Hull - Founder of 3D Systems Corporation

3D printing - additive manufacturing

Application:

• Prototyping (rapid prototyping),

• Finished product manufacturing (rapid manufacturing).

Printer resolution - thickness

applied layers (Z-axis) 16-200 microns.

Accuracy

printer

-

accuracy

positioning of the print head in the

horizontal plane (along the X and Y axes)

10-100 microns.

Two types of materials:

support materials.

structural

and

Method

Extrusion

Technology

Fused Deposition Modeling

(FDM or FFF)

Wireframe

Free Form Manufacturing

Electron Beam Fusing (EBFȝ)

Direct Laser Metal Sintering (DMLS)

Powder Fusion

Electron Beam Fusion (EBF)

Selective laser melting (SLM)

Titanium alloys, cobalt-chromium

alloys, stainless steel, aluminum

Selective thermal sintering (SHS)

Powdered thermoplastics

Selective laser sintering (SLS)

Thermoplastics, metal powders,

ceramic powders

Gypsum, plastics, metal powders,

sand mixtures

Paper, metal foil,

plastic film

Photopolymers

Photopolymers

Inkjet(3DP)

Lamination

Object Fabrication

Lamination (LOM)

Stereolithography (SLA)

Digital LED Projection (DLP)

Polymerization

Materials used

Thermoplastics (such as Polylactide

(PLA), Acrylonitrile Butadiene Styrene (ABS)

, etc. )

)

Almost any metal

alloys

Almost any metal

alloys

Titanium alloys

Layer-by-layer printing (

Depositioned 905 resin molten filament) Modeling, FDM)

FDM

technology

additive manufacturing

models, prototypes and finished products by layering melted

extruder for FFF

Printrbot printer

Electron Beam Fusion (EBFȝ)

manufacturing

Development by Karen Taminger, NASA Langley Research Center (LaRC)

FDM variation

Prototype device testing

using EBFȝ technology

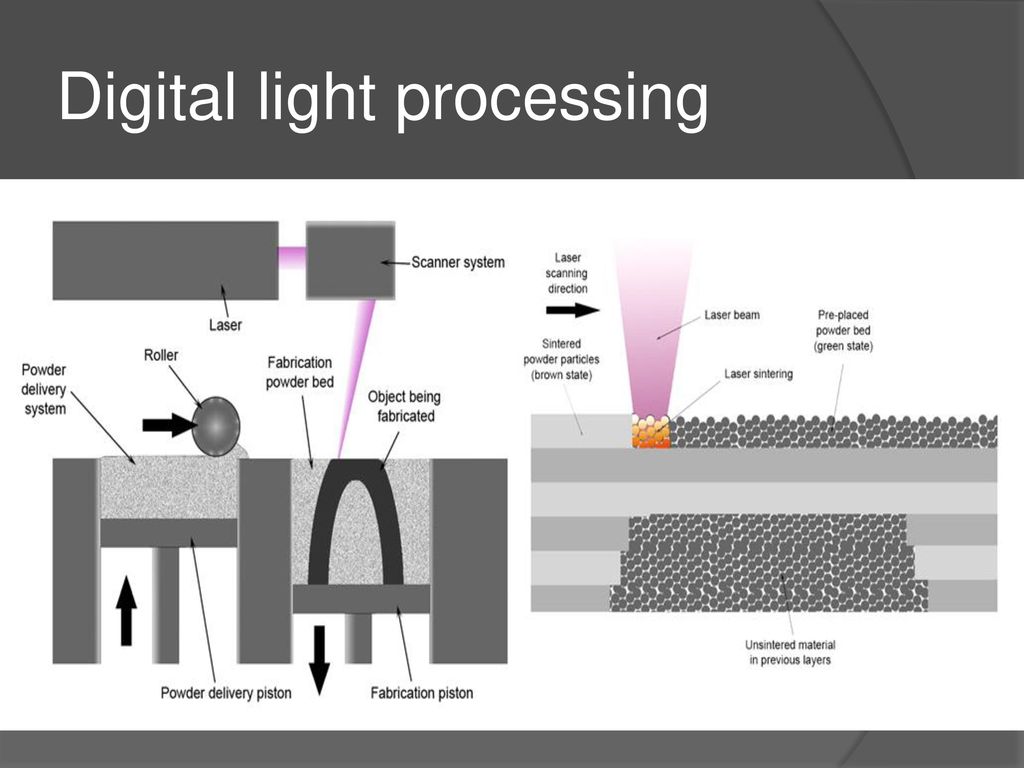

Laser sintering25 of powder materials (

Selective Laser Sintering, SLS)

SLS

technology

additive manufacturing

models, prototypes and finished products

fusible powder material

(plastic, metal) by melting it under

laser radiation.

Designed by Carl Deckard and Joseph Beeman,

University of Texas at Austin, mid-1980s.

Acquired in 2001 by competing

company 3D Systems.

The last of the SLS

technology patents was filed on January 28, 1997,

expired on January 28, 2014, and

technology is publicly available.

Rapid Prototyping

Solutions

Five Star Plastics

New Balance Company

uses

SLS technology to create

footwear

Selective Laser Melting (SLM)

Developed by the Institute for Laser Technology (ILT)

Fraunhofer Society in Aachen and F&S

Stereolithographietechnik GmbH in Paderborn.

Today the technology belongs to SLM

Solutions GmbH and ReaLizer GmbH

A variation of SLS

technology The process takes place in a working chamber filled with

inert gases (argon). Oxygen free

avoids consumable oxidation

(printing with metals is possible).

Part for the J2-X rocket motor, printed

by NAS

Direct Metal Laser Sintering (DMLS)

Developed by EOS, Munich

A variation of Selective Laser Sintering or SLS

and Selective Laser Melting Melting" or SLM).

DMLS allows the

to create solid

metal parts.

print resolution ~20 µm

DMLS installation

Rocket engine parts

Super Draco

Elon Musk, Space X Company

Material: Nickel-Chrome

Inconel Heat Resistant Alloy

Electron Beam Melting (EBM)

A variation of SLS and SLM

The main difference is the use of electronic emitters instead of lasers

Titanium implant obtained using EBM

Industrial EBM machine manufactured

by the Swedish company Arcam AB

Craniofacial

implant fabricated with

EBM technology

Selective heat sintering (SHS)

A variation of SLS technology

Used for fusible materials

Desktop SHS printer - Blueprinter

Models printed using the SHS method

Stereolithography (Stereo Lithography

Apparatus, SLA)

Charles Hull in 1984 patent

Stereolithography

(SLA

)

additive manufacturing technology models,

prototypes

and

finished

products

from

liquid

photopolymer

resins.

Curing

resin

occurs due to irradiation with an ultraviolet laser

Manufacturers:

• F&S Stereolithographietechnik GmbH,

• 3DSystem,

• Institute of Laser and

Information Technologies of the Russian Academy of Sciences.

Resolution

down to 15 microns

Desktop

Stereolithography

OWL Printer

Nano

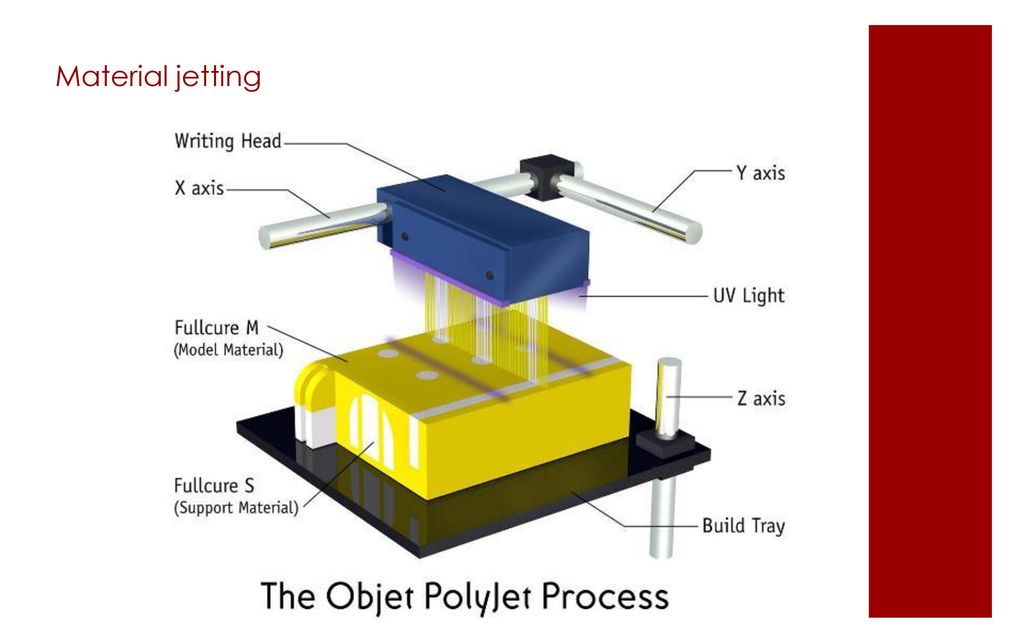

Digital LED Projection (DLP)

Variation of SLA technology

Difference - use of LED projector

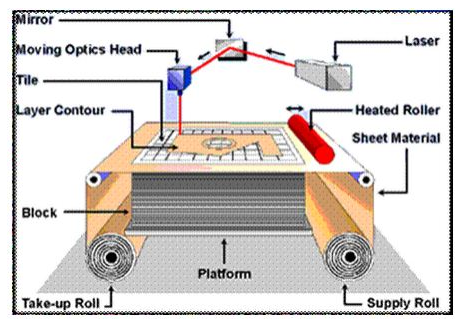

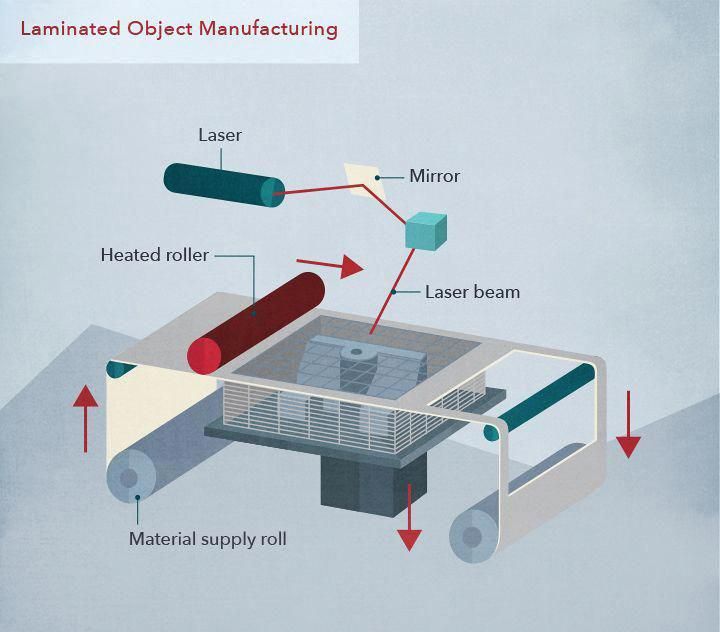

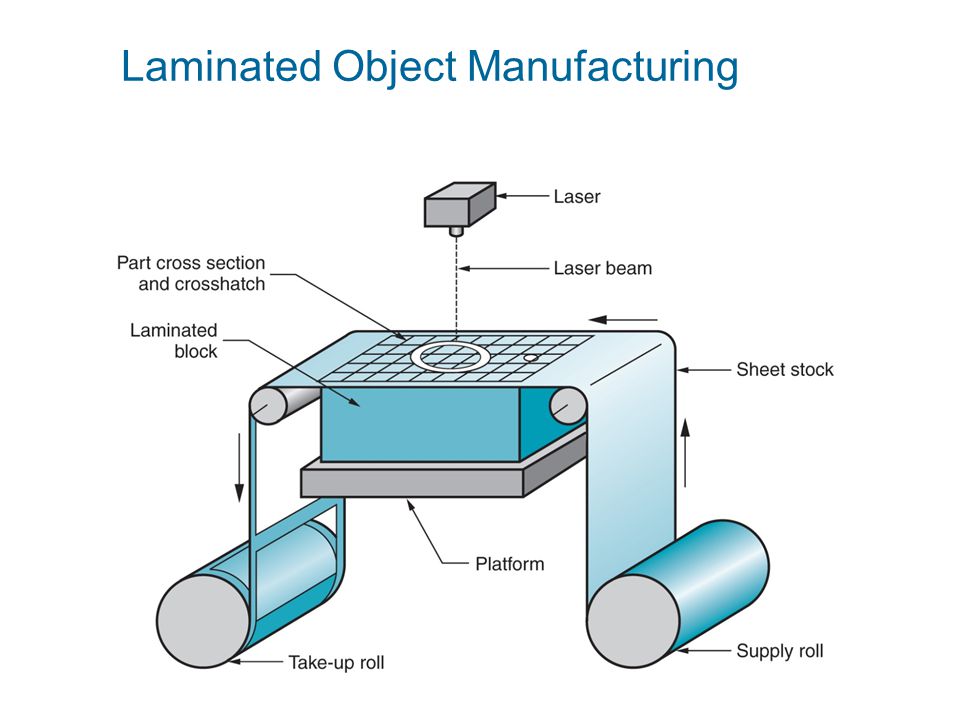

Sheet lamination

materials (Laminated Object Manufacturing,

LOM)

Manufacturer: Helisys Inc.

LOM

-

technology

forming

layer-by-layer bonding (heating, pressure)

thin films

working material

with

cutting (using a laser beam or

cutting

tool) 90.025 corresponding contours

Mcor 3D Printer

Matrix Plus

3D Inkjet Printing (3DP)

R&D MIT

Institute (MIT), 1993

Name Variations:

• Ink Jet Modeling

• Multi-Jet Modeling, MJM,

• PolyJet,

• Drop-On-Demand-Jet,DODJet.