Kickstarter 3d printer tiko

The Tiko Printer: What Happens When You Innovate Too Much

Sometime in the very distant future, the Universe will become the domain of black holes. Energy and entropy will be compressed into minuscule quantum fluctuations. Even in this domain of nothingness, there will still be one unassailable truth: you should not buy a 3D printer on Kickstarter.

We’re no strangers to failed 3D printer crowdfunding campaigns. Around this time last year, backers for the Peachy Printer, an inordinately innovative resin printer, found out they were getting a timeshare in Canada instead of a printer. This was unusual not because a crowdfunding campaign failed, but because we know what actually happened. It’s rare to get the inside story, and the Peachy Printer did not disappoint.

For the last few months, we’ve been watching another crowdfunding campaign on its long walk to the gallows. The Tiko 3D printer is another 3D printer that looks innovative, and at the time of the crowdfunding campaign, the price couldn’t be beat. For just $179 USD, the backers of the Tiko printer would receive a 3D printer. Keep in mind the Tiko launched nearly two years ago, when a bargain-basement printer still cost about $400. Fools and money, or something like that, and the Tiko 3D printer campaign garnered almost three million dollars in pledges.

Now, after almost two years of development, Tiko is closing up shop. In an update posted to the Tiko Kickstarter this week, Tiko announced they are laying off their team and winding down operations. It’s a sad but almost predictable end to a project that could have been cool. Unlike so many other failed crowdfunding campaigns, Tiko has given us a post-mortum on their campaign. This is how the Tiko became a standout success on Kickstarter, how it failed, and is an excellent example of the difference between building one of something and building ten thousand.

Why the Tiko Was a Hit

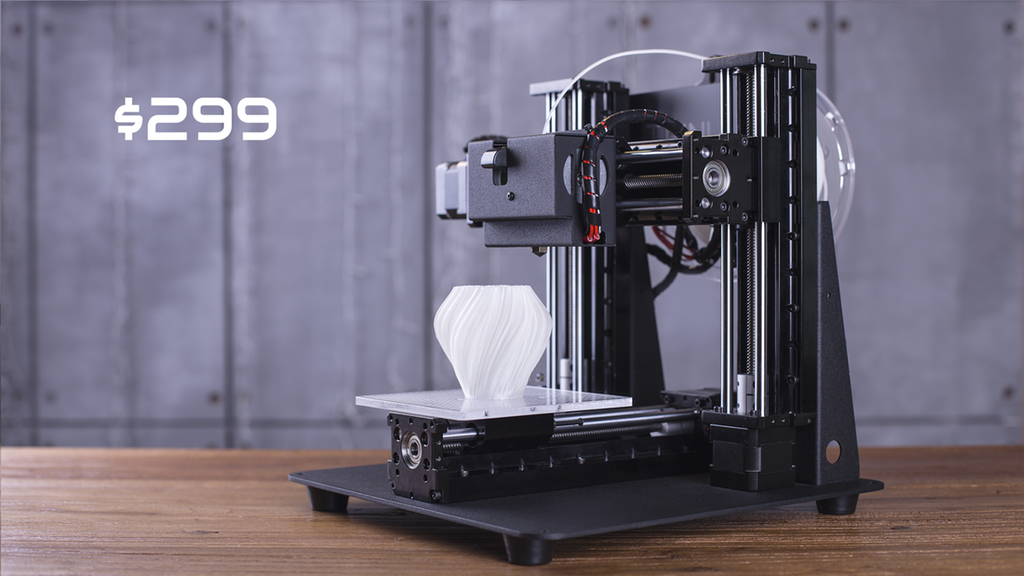

The Tiko printer was an easy sell. All you had to do was look at your favorite tech blog and see someone was selling a 3D printer for less than one hundred dollars. Yes, that was the super early bird price, but that’s cheap for a 3D printer. In 2015, unimaginably so. The regular price, and what non-early bird Kickstarter backers paid, was only $179 USD. Even today, with the machinations of dozens of factories in China, this is a very inexpensive price point. In fact, only with the upcoming release of Monoprice’s $150 delta printer will we see a printer that is as capable while still being this inexpensive.

Yes, that was the super early bird price, but that’s cheap for a 3D printer. In 2015, unimaginably so. The regular price, and what non-early bird Kickstarter backers paid, was only $179 USD. Even today, with the machinations of dozens of factories in China, this is a very inexpensive price point. In fact, only with the upcoming release of Monoprice’s $150 delta printer will we see a printer that is as capable while still being this inexpensive.

The astonishing economy of the Tiko leads to an obvious question. How did the Tiko team plan to build a 3D printer and send it out the door for less than $200? Even today, sourcing and building the most bare bones i3 clone will cost more than that. In 2015, the costs were even higher.

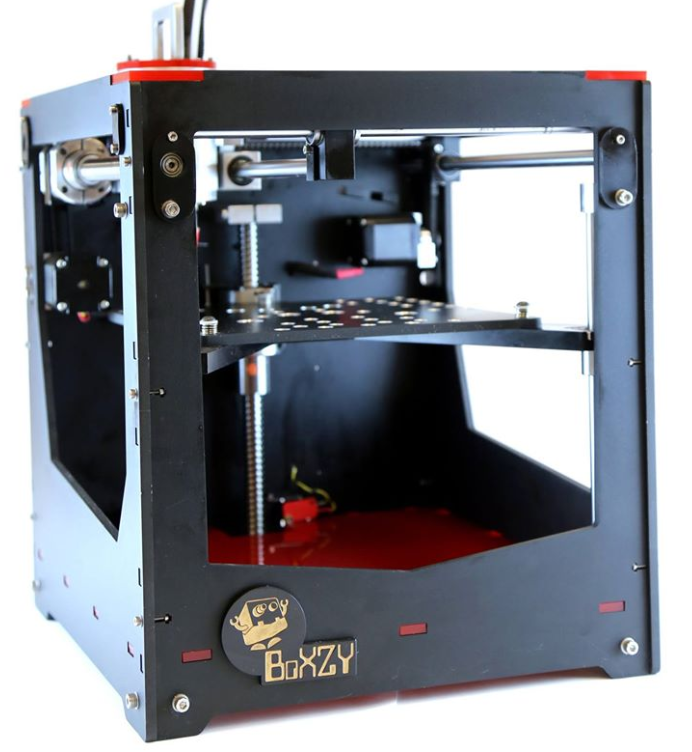

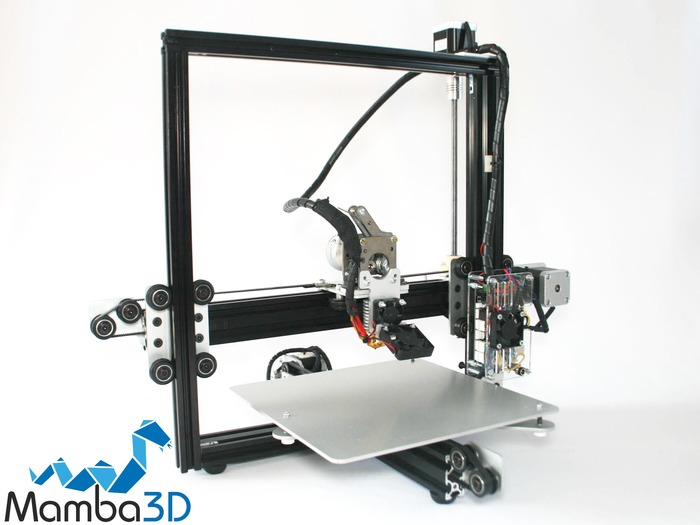

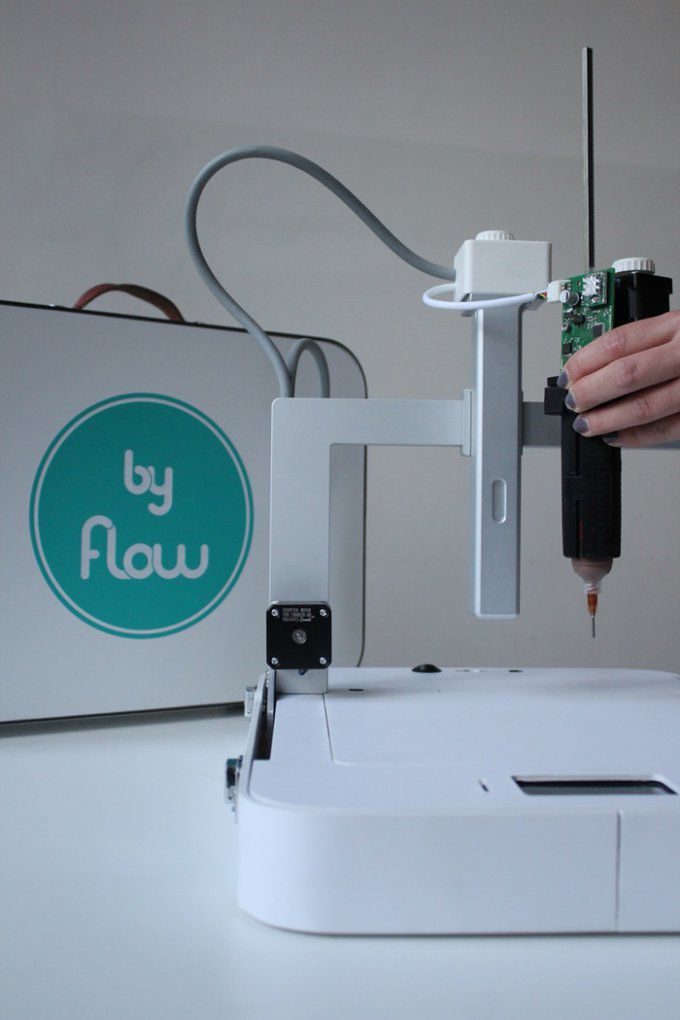

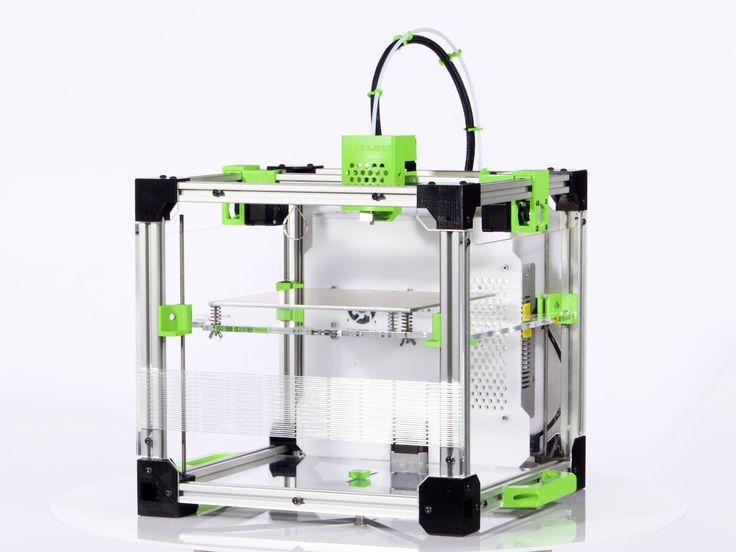

Tiko’s unibody construction. By building a linear motion system into the enclosure, Tiko significantly reduced the cost of their bill of materials.The answer comes from something that sounds like it’s glomming onto Apple ad copy: unibody construction. The body of the Tiko is a single part with an integrated c-channel used as the linear rails of this delta bot. This unibody construction is, quite simply, ingenious. If you’ve ever assembled a RepRap Mendel, or any of the other threaded rod printer monstrosities from back in the day, you know the frame of a 3D printer is what makes or breaks the build. By using an extrusion with integrated rails, the Tiko team brought the cost of a frame down while making their assembly easier. From a manufacturing standpoint, Tiko’s unibody construction is brilliant, and we won’t be surprised when we see another delta bot with the same sort of enclosure.

The body of the Tiko is a single part with an integrated c-channel used as the linear rails of this delta bot. This unibody construction is, quite simply, ingenious. If you’ve ever assembled a RepRap Mendel, or any of the other threaded rod printer monstrosities from back in the day, you know the frame of a 3D printer is what makes or breaks the build. By using an extrusion with integrated rails, the Tiko team brought the cost of a frame down while making their assembly easier. From a manufacturing standpoint, Tiko’s unibody construction is brilliant, and we won’t be surprised when we see another delta bot with the same sort of enclosure.

At its very core, Tiko was innovative. This is a 3D printer that was built around standardized manufacturing processes. Yes, building a ‘unibody’ 3D printer will require a significant capital investment to get the first printer off the assembly line. Once that’s done, though, the creators of the Tiko printer would have a viable product that could be manufactured for far less than their competitors.

Why the Tiko Failed

Tiko put a lot of innovation into their unibody frame. Unfortunately, they decided to extend that innovation to the rest of the printer. Even before the Tiko Kickstarter was a week old, the 3D printer forumheads had questions about the Tiko printer.

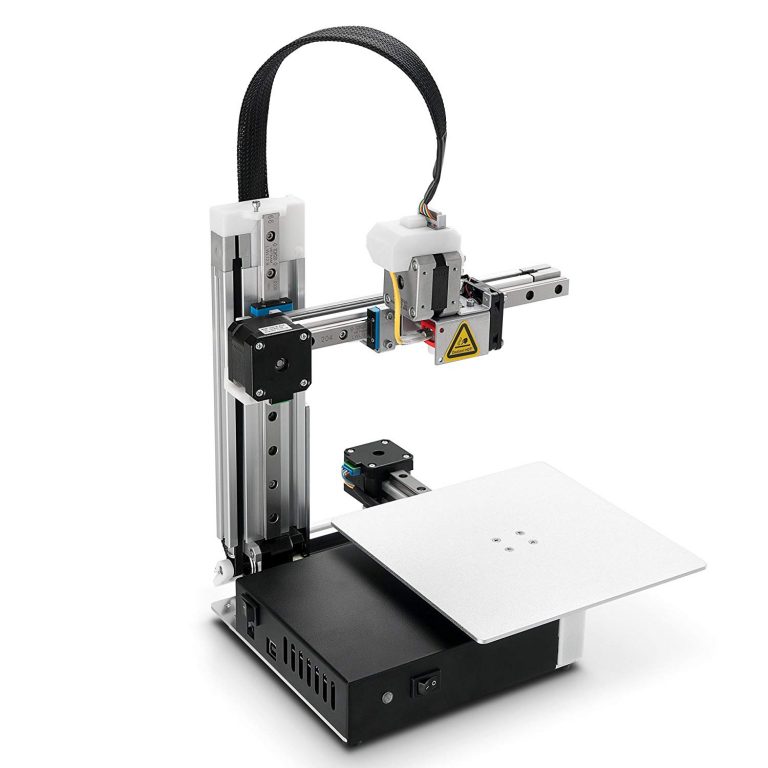

The usual method for linear motion in a 3D printer is a stepper motor. NEMA 17 stepper motors are par for the course. The historical pricing of NEMA 17 motors is itself interesting: back in 2008, before the RepRap project came to fruition, it wasn’t unrealistic to spend $40 on a single NEMA 17 motor with a driver. Now, you can pick up the same parts for less than half that cost.

Instead of relying on the ecosystem that has enabled very inexpensive printers, Tiko chose to go their own way. They used cheaper but much lower torque stepper motors on their printer. This would cause severe issues with the printer. Of the over four thousand units Tiko shipped, there were far too many reports of layer shifting and missed steps than you would expect. In the most severe cases, the Tiko printer could not print a simple cube.

In the most severe cases, the Tiko printer could not print a simple cube.

Even in the electronics, Tiko strove for innovation.

Right now, the state of electronics for 3D printers is heavily derived from the original RepRap projects. Derivatives of the Arduino Mega, using the ATmega2560 and ATmega32u2 microcontrollers, are the norm. The new LulzBot Brain Box uses a RAMBo board with this microcontroller. The electronics for the vast majority of 3D printers is derived from those initial 3D printer experiments, and that means a decade of technical debt.

Tiko advertised WiFi printing during their Kickstarter campaign. Right now, the easy way to do a WiFi printer would be a standard ATmega-based controller board with an ESP8266 WiFi module. This would be easy, but it wouldn’t be cheap. Instead of the easy solution, Tiko turned to a neat WiFi-enabled microcontroller released by Texas Instruments. The CC3200 gave the Tiko a powerful ARM Cortex-M4 microcontroller and WiFi. Given the smooth acceleration found in even the cheapest ARM controller boards, this is a win.

The CC3200 gave the Tiko a powerful ARM Cortex-M4 microcontroller and WiFi. Given the smooth acceleration found in even the cheapest ARM controller boards, this is a win.

But there’s a reason everyone keeps using older Arduino-based controller boards. Nearly all the firmware for 3D printers is built around the Arduino Mega. Building a printer controller board around a relatively new part means building everything from scratch. This is development time Tiko didn’t have, and engineering time Tiko couldn’t afford.

Despite this, Tiko actually managed to build and ship over four thousand printers. Given Tiko took in nearly three million dollars from 16,000 Kickstarter backers, this doesn’t sound like much. Consider the decisions Tiko made, and it’s remarkable. They had ordered their complete BOM before a prototype was finalized. The decision to use cheap stepper motors led directly to the very poor performance of the finalized design. The efforts to fix hardware problems in software were not effective. Eventually, Tiko had too much technical debt to pay off. It certainly didn’t help that this was a 3D printer selling for a bargain-basement price, either. There’s only so much margin on a $200 printer, and from the start there wasn’t much left over for the engineering needed to make a good, cheap 3D printer.

Eventually, Tiko had too much technical debt to pay off. It certainly didn’t help that this was a 3D printer selling for a bargain-basement price, either. There’s only so much margin on a $200 printer, and from the start there wasn’t much left over for the engineering needed to make a good, cheap 3D printer.

The Future of Tiko

By the end of 2016, Tiko was effectively dead. Last week, they gave up, shutting down production, and refusing to refund backers. Tiko has even refused refunds on shipping costs, a move that led to an online petition and — get this — a Kickstarter campaign to start a class action lawsuit against Tiko. Tiko is dead, although they are actively pursuing additional investors.

Far too often we look at Kickstarters from an engineering perspective. What’s missing in these discussions is a look at Kickstarters from a business perspective. What Tiko has done is out-innovated themselves. They came up with a rather remarkable system for the frame of a 3D printer, but one that isn’t quite right for a hardware startup. They developed brand new hardware for the 3D printer community but backed themselves into a corner when their engineering team couldn’t keep up. They spent all their money buying components before their design was finalized. These aren’t poor engineering decisions, they’re poor business decisions.

They developed brand new hardware for the 3D printer community but backed themselves into a corner when their engineering team couldn’t keep up. They spent all their money buying components before their design was finalized. These aren’t poor engineering decisions, they’re poor business decisions.

Twelve thousand people have spent $200 (plus about $60 in shipping) on a printer they won’t receive. Four thousand people have a printer that doesn’t live up to their expectations. The Tiko team has a three million dollar failure hanging over their heads. No one is happy with this situation. Yet it can all be traced back to a single problem. This is what you get when you innovate too much.

$179 Tiko 3D Printer Is The Latest High-Profile Kickstarter Casualty

“Tiko is the 3D printer you’ve been waiting for,” reads the tagline on Tiko’s 2015 Kickstarter campaign. “Simple, accessible, and dependable, all for a pledge of $179.”

Sadly it turns out that you’ll be waiting a lot longer for it, while that “dependable” description can also be discarded. And that $179 investment isn’t sounding such good value, either.

And that $179 investment isn’t sounding such good value, either.

That’s because Tiko, the “Unibody 3D printer” is the latest casualty in a spate of high-profile Kickstarter 3D printer projects. Despite having raised a whopping $2,950,874 against a $100,000 funding goal, the printer’s creators have taken to Kickstarter to reveal that the project is, for all intents and purposes, cancelled. Although the creators claim to have shipped 4,100 printers out (a total of 16,538 backers pledged money) it seems that’s where it might end.

“We had no idea how difficult it would be to go from a prototype to mass production,” Tiko’s creators wrote in an update. “We learned along the way, but most mistakes were costly and irreversible. Our greatest mistake was committing to inventory too soon. We didn’t realize it at first, but by ordering components in bulk, we had backed ourselves into a corner. Design flaws appeared, and we were trapped. By the time we understood our predicament, it was already too late. We were in too deep, and there was no turning back. Our cheerful mission to empower innovators had become a struggle to survive.”

We were in too deep, and there was no turning back. Our cheerful mission to empower innovators had become a struggle to survive.”

Now, the team says it is speaking with investors, but acknowledges that “these discussions cannot be rushed. It’s a lengthy process, and it could take months for us to reach something conclusive.” They promise an update at some point in the future.

It’s just the latest in a terrible run of crowdfunded 3D printers which, for reasons of both price and features, sounded almost too good to be true — and then turned out to be exactly that.

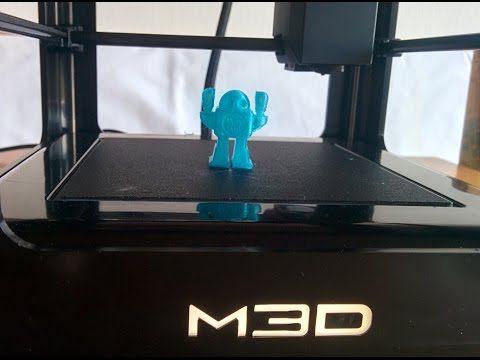

“If you go through the top 20 crowdfunded 3D printer campaigns and examine who succeeded versus who didn’t, there’s not a huge success rate for the top campaigns,” Michael Armani, CEO and cofounder of 3D printing company M3D, which raised $3.8 million on Kickstarter, told Digital Trends. “We’re observing the industry going to chaos. It’s one company after another that’s going down. A lot of people say we should be happy as one of the survivors, but the truth is that I’m sad. I’m really disappointed to see so many companies failing. Kickstarter has really become the wild west in a lot of ways.”

I’m really disappointed to see so many companies failing. Kickstarter has really become the wild west in a lot of ways.”

While companies like M3D have delivered on the promise of affordable 3D printers, Armani is correct in observing that crowdfunded 3D printers are looking like an increasingly toxic investment for backers. Any time you get into a tech “race to the bottom” things aren’t looking good — and, sadly, it seems that this is the paradigm we’re stuck in right now.

The mismanaged Tiko is just the latest example of that effect. And its out-of-pocket backers are the victims.

Editors' Recommendations

- Fighting football injuries with 3D-printed, hyper-personalized pads

- The best 3D printers under $500

- Wild new 3D printer makes parts by sending titanium particles supersonic

- Volkswagen joins list of automakers closing factories due to coronavirus

- 3D-printing technique produces tiny, highly detailed objects in seconds

TIKO 3D printer - controversial Kickstarter project

A small report on the purchase of a 3D printer (used) from the eBay site (America).

The Tiko 3D printer is a small and interesting device.

Details under the cut.

Greetings to all visitors of the site 3dtoday.ru !

A short story about how I bought and completed the 3D printer of the famous startup Tiko 3D.

This is quite an interesting 3D printer with delta kinematics. Not without childhood diseases of course. nine0003

Tiko official website.

I have long wanted to participate in large crowdfunding companies. I occasionally participate in small ones. Especially in the field of various technologies.

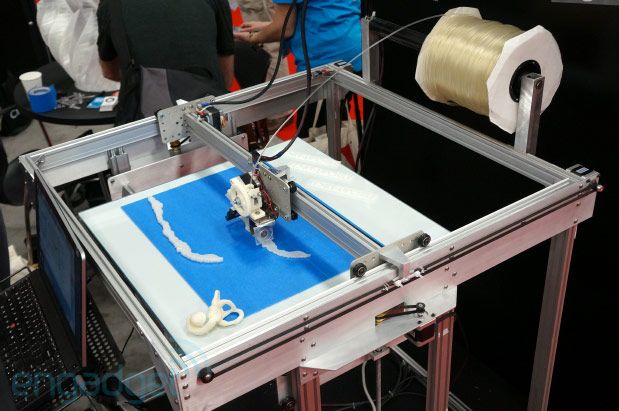

I constantly monitor new startups with 3D printers and 3D printing. Now we are raising funds for a small and inexpensive Geeetech E180A printer. As for the Tiko project specifically, The Unibody 3D Printer is one of the most successful projects at the start. Tiko raised over $2.9 million. There were over 16,000 backers. nine0003

Project page on kickstarter

I didn't manage to buy it as a backer. The last opportunity to deposit funds was closed at the beginning of this year. The guys collected much more than they had planned and, to celebrate, began to spend money. They launched mass production of printers ... not completely correcting children's sores. For example, the lack of airflow. Well, there were certain problems with accelerations and inertia at high speeds - the printer still "specializes" for printing up to 30 mm / s , although it is clear that it can be more.

The last opportunity to deposit funds was closed at the beginning of this year. The guys collected much more than they had planned and, to celebrate, began to spend money. They launched mass production of printers ... not completely correcting children's sores. For example, the lack of airflow. Well, there were certain problems with accelerations and inertia at high speeds - the printer still "specializes" for printing up to 30 mm / s , although it is clear that it can be more.

I had to look for one of the used printers. There are quite a lot of them (there were) - the backers refuse, they do not know how to get rid of the received device. There were several options on eBay, at very low prices. It was possible to take for a quarter or half the price of a printer in excellent condition.

Here is the lot I won.

The seller is one of the first backers, a firefighter from Cloverdale, California, who bought and was upset because he could not print on the printer. The printer had a minimal gap, a virtually untouched native spool of filament. nine0003

The printer had a minimal gap, a virtually untouched native spool of filament. nine0003

At the moment (at the time of the publication of the review) - it was not possible to buy a printer on eBay or on the official website (out of stock). In the title of the review, I indicate the lot, which I also bought.

But there are other interesting options , for example, M3D Micro - a similarly inexpensive device with children's "sores", around $100. Can be taken for a child or as a first printer. Similar to the Tiko 3D, the M3D Micro's pros are its small size and good looks (and it's easier to ship). nine0003

Characteristics:

Brand: TIKO

Model: Unibody 3D Printer

Type of kinematics: deltabot

Construction area: Diameter 125 mm. Height 125mm

Features: load-bearing housing, Wi-Fi hotspot, built-in slicer.

Adhesion: polymer backing.

Effector: steel+ceramic, 0.4mm

Materials: PLA/ABS.

Dimensions: 222 x 235.9 x 450mm

A small infographic from the official site: the main functions that startups relied on are indicated. nine0003

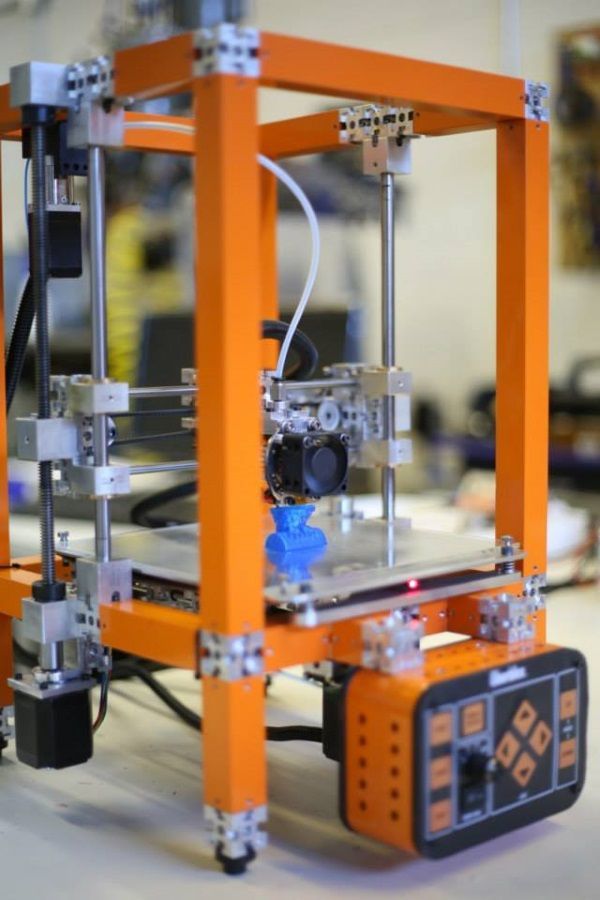

Externally, the TIKO 3D printer looks like a white plastic tower with a transparent insert. The coil is located at the top under the cover. The whole structure is fixed on the supporting white part of the body. Removable underlay. There is no heating or cooling.

Unibody dimensions and build area illustration

Done right, this is a good printer. Of course, not everything is smooth with him, but we will try to cope.

I was looking for a suitable lot for a long time (there were three options during the summer months). But there were no problems to win the lot - not the most popular product. nine0003

Purchased the printer through an intermediary forwarder (details at the end).

After about 20 days (painful waiting, especially for the results of customs clearance) I received a huge box.

Inside original packaging with printer, printer in foam shell.

“Shell” repeats the shape of the printer - very good packaging.

Separately, I will highlight the instructions - very detailed.

There was also a backer's card and a DVD.

There was a separate power source in the cell - an adapter for 12V (2.5A)

Spool with native blue PLA filament has been installed in the compartment at the top.

Spool is almost intact. True, plastic for six months in printed form has already begun to crack and break.

Cell for the coil

Unpack the printer, check the condition

Delivered whole))) The printer deservedly takes its place on the desktop. It looks like the rest of the office equipment - very good. At least the design is head and shoulders above that of Pryush.

It looks like the rest of the office equipment - very good. At least the design is head and shoulders above that of Pryush.

Manufacturer's label. The basic information is carefully indicated, up to the connection address. nine0003

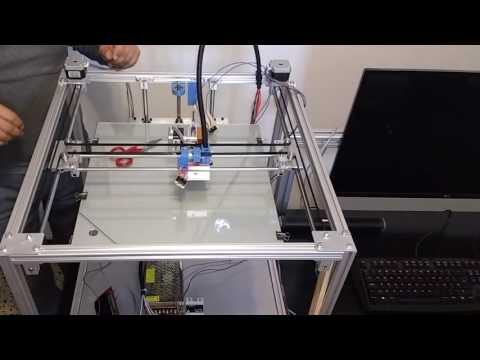

A photo of the printer on the desktop. Connects via Wi-Fi.

I will tell you in detail about the design.

The main focus of the developers is minimalism and lightness of design.

Minimal effector: composite+ceramic. It heats up quickly, does not require blowing the thermal barrier.

The extruder motor is centrally located on the main body.

Carriages are lightweight, made of flexible plastic such as high impact polystyrene (or similar). You can take it off and put it back on with almost no effort. nine0003

Guides (3 pcs) - plastic "rails".

Uses small 12 volt BYJ-48 motors.

The motors move on the rack. Lubrication is present.

Please note: the limit switch is mounted on the carriage itself.

Power connector

Rods and effector - everything is as light as possible.

The backlight is dynamic, strong enough. The LEDs are arranged in a ring on the board.

All harnesses are plugged in. A flexible cable goes to the hotend. nine0003

Bowden tubes with fittings. Can be disassembled, disconnect the tube for maintenance. Made very thoughtfully.

The print base has a special plastic pad for adhesion.

Print marks from previous owner visible.

The Tiko board is very specific. It has Wi-Fi and a slicer on board.

All parts of the printer - the design turned out to be very technological.

We connect the printer to the outlet, we are waiting for the software to download (after downloading, the backlight turns on). nine0003

To connect to the printer, you need to select the Tiko Wi-Fi network and then you need to type in the browser line:

print.tiko/editor or - 192.168.1.1 .

Connect from a smartphone in the same way.

When turned on, the printer thinks for a while, then starts blinking in greeting.

Loading the model (Add object)

You can also use the manual options (menu on the left). This is the heating of the nozzle, the loading and unloading of the filament. nine0003

Insert the filament into the tube and push it all the way into the extruder mechanism.

Press Load filament and wait for the end

You can extrude a little to check

The result of extrusion

Unloading is similar - Unload filament

Select a model, press print

The slicer is working. You can print. Don't forget about calibration. When printing, you can skip the calibration step (or run it automatically).

You can print. Don't forget about calibration. When printing, you can skip the calibration step (or run it automatically).

Print settings

Printing in progress

To stop printing, you can lift and tilt the printer

When accessed from a smartphone, the same pages open. And slicing does not "strain" the smartphone.

It is extremely convenient to perform calibration from a smartphone - it is easier to control and adjust the nozzle manually

Before printing, select the option for manual calibration (or automatic)

The meaning is to alternately set the height (touch) of the nozzle on the table surface. nine0003

Use the ▲ and ▼ keys to adjust the nozzle close (well, or under the paper) to the substrate.

Press Done for each step (3 dots).

The printer moves to the next point.

Finishing and parking

Calibration completed

You can send the first model to print.

When I turned on the printer, I had a series of beeps and an error "301" - auto-home failure. It was necessary to correct one of the engines on the rail. By the way, they install almost effortlessly. nine0003

Loading filament. Here I encountered the fact that the old filament was present (and two colors at once). The former owner printed with silver filament, which was pushed heavily through the nozzle. I had to clean it by hand.

It is necessary to push through the old filament, which remained in the area after the extruder - the former owner could not cope, he apparently had a clogged nozzle or tube.

Loading did not go through normally, apparently there were pieces of the old filament inside. nine0003

nine0003

Disconnect the tubes from the extruder (there is a simple clamp) and push through.

I pushed mine by hand with the nozzle warmed up.

Until I pushed out all the remnants of native plastic, and mine appeared (green).

Now standard loading

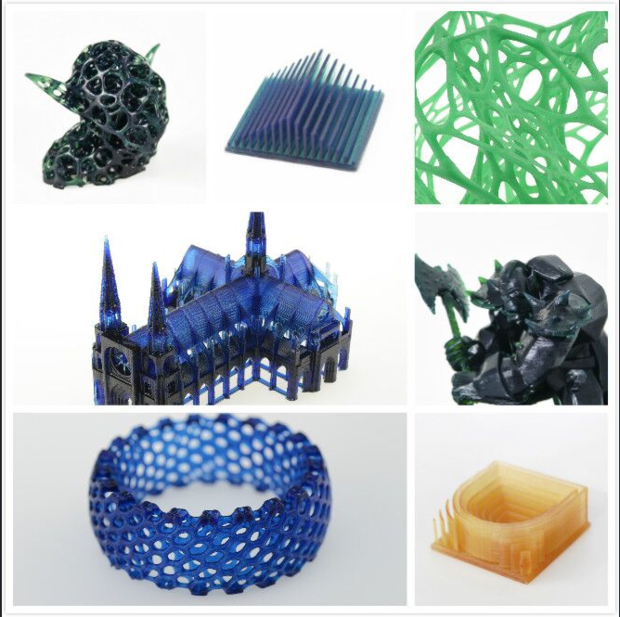

First print.

Raft does not turn off on models (Gcode editing only)

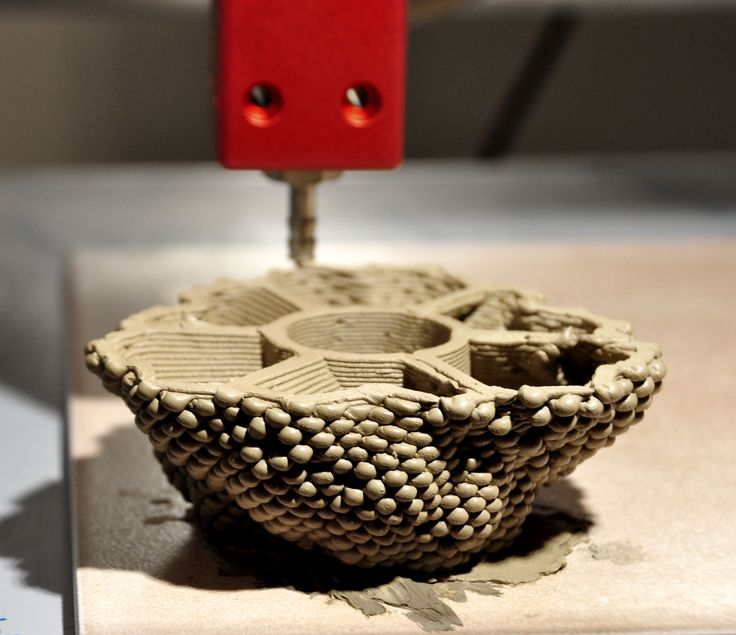

It can be seen that the printer does not have enough airflow. The plastic is starting to sag.

By the way, one of the pieces of the 'native' blue plastic got on the photo - it broke and such pieces got stuck in the tubes. Apparently forced to sweat the first owner. nine0003

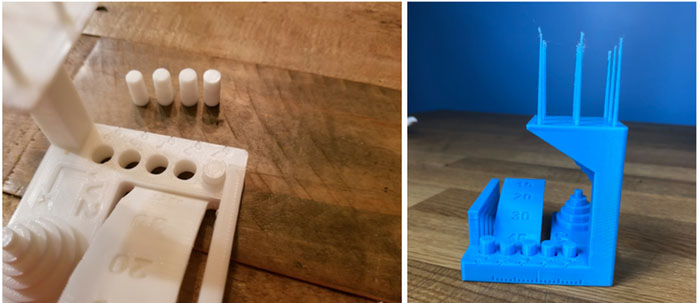

Printing a test cube

The cube turned out better.

Calibration steps.

By the way, the Z-hope option is enabled. The printer raises its head slightly when moved.

The printer raises its head slightly when moved.

Top slightly smeared from overheating.

Again it is clear that there is not enough airflow for PLA.

Pay attention to the printer modification models on thingiverse, in particular to this collection. The easiest way to implement this is with tubes and a small turbine or compressor. nine0003

You can print the tube holder for the effector.

This is what it looks like assembled. Tubes can be used silicone with an outer diameter of 6 mm (as from an aquarium).

Additionally, you can print a tee for pipes (one inlet, and three pieces are blown).

An aquarium compressor or turbine can be used for blowing.

I used a 12V impeller with a tube adapter.

It blows quite well, but I would like more

Pre-printed some splitters.

The tubes are threaded into the holders on the effector.

Alternatively separate nozzles can be used.

The hot end of the printer is best insulated with silicone tape or Kapton.

After installing the blower with a turbine, I started printing again.

That's what happened. For PLA, the print quality has increased to an acceptable level

For comparison, both models: on the green (without blowing), the edges are smoothed due to the lack of blowing of the model during printing

And similarly "native" Tiko test model. The print quality has grown)))

Here are a couple of printed models.

Hare Flat Figurine

The print quality is quite tolerable, especially for a $100 printer.

Frog

I will note some hairiness. Still, the turbines are not enough, I will put the compressor from the aquarium (larger and quieter).

Print animation))))

Quite an entertaining process.

Pins:

Fairly good budget 3D printer with excellent price/quality ratio. The guys from the startup Tiko got almost . Almost - because improvements are required.

Pros : Great balance between price and features. There is a built-in slicer (a huge plus when controlled from a smartphone / tablet), there is Wi-Fi, backlight, some functions such as turning off the printer by tilting and auto-calibration.

Cons : Due to the servo drives used in the design, the printer turned out to be very slow, the carriages and motors need to be heavier. And given that there is no more than complete airflow in the drain, it is difficult to print PLA with good quality. Improvements and treatment of "childhood diseases" of the printer are required. nine0003

Improvements and treatment of "childhood diseases" of the printer are required. nine0003

Regarding shipping: on the one hand, the price is decent, on the other hand, it is an opportunity to get a printer for half the price.

Details of the reseller I used and the shipping process

The printer, like most Kickstarter startups, was sold in America. To bring to the Russian Federation, you need to either negotiate with the seller (not everyone agrees), or use the services of an intermediary. I have been looking for a suitable one for a long time (the weight of the printer is about 5.5 kg, the dimensions are also decent - this directly affects the cost of delivery). I turned to intermediaries with a question about the possibility of sending exactly a 3D printer, in packaging, transport tariff, as well as with a question about the declaration and customs clearance. nine0003

The cheapest was Pochtoy . In agreement with the support of Pochtoy.com, the declaration indicated the name simply TIKO printer , without 3D (this is an extra clue for customs).

Pochtoy reseller site We register, we get the address, we indicate the address in our Ebay account.

We make a purchase (payment) in our name, but to the Pochtoy.com warehouse.

After receiving the goods, check in your account (photos of appearance).

Money:

Price calculator. Delivery of such a voluminous and heavy cargo as a 3D printer costs a little more than $50 (see there are different tariffs, it is better to take a cheaper one - it takes longer, but customs is easier). When ordering, I used the code: GADGETUSA ($5 per account), in my opinion, is still valid.

Useful links:

Tiko 3D official website Official website forum Project page on kickstarter Acquisition and setup experience from rubyfox Models for printer modifications on thingiverse Discount calendar nine0003

Tiko 3D Printer - A Kickstarter project that almost took off

Probably someone followed this odious project on the Kickstarter site. Someone heard about this printer from third-party sources, and even on this portal it was mentioned several times: tiko 3d. And in the comments, even someone wrote that he was a baker and was waiting for this printer ... But this is all a prelude, and then the real story begins. One day, I accumulated a few extra bucks in my PayPal account and, out of habit, I went to the e-bay site in search of something interesting. I soon found some interesting used 3D printers for very little money. And I thought, why not? I'll take a small printer and put it side by side with a computer on the loggia, there are just 30 centimeters on the side. And began to consider the available options. They offered cubes from M3D in large quantities, I heard about their problems and understood why they were sold so much, but this, in principle, did not frighten me. Almost anything can be brought to mind :) And then I came across an advertisement for the sale of a Tiko 3D printer. The seller wrote that he is the exclusive baker among the first who ordered this printer, its number is 6 or 9.

Someone heard about this printer from third-party sources, and even on this portal it was mentioned several times: tiko 3d. And in the comments, even someone wrote that he was a baker and was waiting for this printer ... But this is all a prelude, and then the real story begins. One day, I accumulated a few extra bucks in my PayPal account and, out of habit, I went to the e-bay site in search of something interesting. I soon found some interesting used 3D printers for very little money. And I thought, why not? I'll take a small printer and put it side by side with a computer on the loggia, there are just 30 centimeters on the side. And began to consider the available options. They offered cubes from M3D in large quantities, I heard about their problems and understood why they were sold so much, but this, in principle, did not frighten me. Almost anything can be brought to mind :) And then I came across an advertisement for the sale of a Tiko 3D printer. The seller wrote that he is the exclusive baker among the first who ordered this printer, its number is 6 or 9. .. He received it, but on the second print, the extruder stopped feeding plastic and he sells everything as is for half the price. For $100. I wrote to him that I was ready to buy for $ 80, he replied that he would give in for 95. They agreed on that. :)

.. He received it, but on the second print, the extruder stopped feeding plastic and he sells everything as is for half the price. For $100. I wrote to him that I was ready to buy for $ 80, he replied that he would give in for 95. They agreed on that. :)

By the time I paid for the purchase, I already knew what problems this device has and how to solve them. Thanks to Walter of Thingiverse who also bought it and posted a ton of info on how to get it up to par. The failure of the extruder did not scare me either, since most parts can be replaced. Although now I understand that if the problems were in the control board, then nothing could be done. And the fee here is very interesting ... In general, the package arrived by express delivery to the parcel post warehouse, since I have been using this service for a long time and everything has always been on top. But not this time)0003

Having ordered fast delivery and paid the approximate cost in a parcel in a day, they answered me that they could not send it by express, since this is a 3D printer and it does not fit the household appliances section. Although I did not specifically write that this is a 3D printer, but indicated that this is a used Tico printer. It's funny that a small printer with dimensions not exceeding 25cm in a triangular base is considered industrial equipment. Well, okay, I had to send it by plane to Germany and then by regular Russian Post. For an overabundance of funds introduced, I ordered improved packaging and increased insurance. And now the package has arrived...

Although I did not specifically write that this is a 3D printer, but indicated that this is a used Tico printer. It's funny that a small printer with dimensions not exceeding 25cm in a triangular base is considered industrial equipment. Well, okay, I had to send it by plane to Germany and then by regular Russian Post. For an overabundance of funds introduced, I ordered improved packaging and increased insurance. And now the package has arrived...

Enhanced packaging usually includes additional rigid cardboard and full tape with reinforced tape. Here, alas, I did not notice additional cardboard, but at least they wrapped it with adhesive tape ...

The box is most likely native and it is good that the original TIKO packaging has been preserved and it turned out to be very vandal-resistant. (The sweets were put in a parcel, as usual).

Inside lay the printer itself, the power supply, a magnet-gift from the package and an envelope as if under a disk. But in fact, there was a postcard from the manufacturer, where there were special words of gratitude for the premium bakers from the kickstarter. nine0003

But in fact, there was a postcard from the manufacturer, where there were special words of gratitude for the premium bakers from the kickstarter. nine0003

The same branded TIKO packaging. by the way, the caring seller also put all the printouts that he could do on this printer))

The TIKO printer looks chic, which bribed me) Fully aluminum case in the upper part and a transparent base. The bottom is removable, it is also a table for printing. A type of rubber mat with an interesting texture is glued on the table. The rug is soft and easy to squeeze through with your fingers. The table itself also bends, but not much. Most likely it is made of nylon or plastic of similar properties. nine0003

The printer was immediately with a branded PLA plastic spool. She's a little smaller than anyone I know. Possibly comparable in size to Taulman coils.

But a standard FD coil won't fit in there.

Starting the printer... The hardest part of this process at first was... Finding where to insert the power cord. The hole is small and inconspicuous located at the bottom end, next to the transparent base. I was looking for him for two minutes exactly.

After the power is connected, the printer starts blinking smoothly with the backlight, at this moment it has already created a WiFi host to which you need to connect by typing www.tiko.print in the browser or 192.168.1.1 In my case, the first option did not work in any way, but the second one immediately picked up.

When you first turn on the printer, it offers to connect to your WiFi network, this is necessary to download updates and it was also intended that it would work with a cloud print service, but alas, this will never be implemented. It's good that all the updates have arrived, judging by the firmware version, it was updated 3 times. If you read the Tiko printer forum, then there are many complaining about terrible printing and hoping that the next firmware update will fix this and the printer will start printing well. Alas, guys, the problem here is not in the software part. nine0003

Alas, guys, the problem here is not in the software part. nine0003

After all the simple settings, the print window opens.

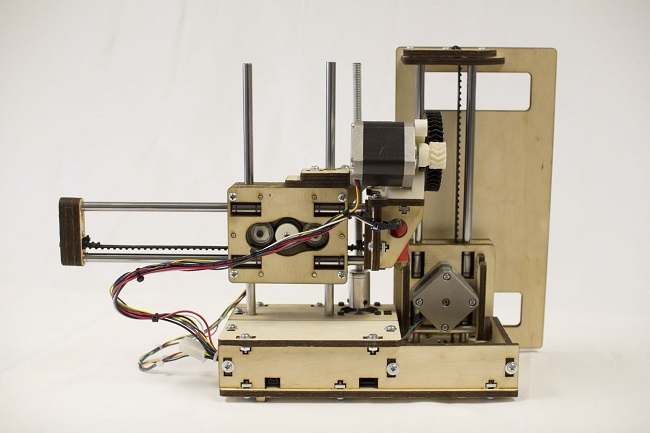

Yes, it's that simple. I took it out of the box, plugged it into a power outlet, connected via WiFi, and after 3 minutes you can already print. It is enough just to throw STL into the browser. This is the perfect printer for beginners. I took the STL, threw it into the printer and pressed the print, that's all. No more manipulation is needed. But alas, the chic idea was not 100% finalized. Despite the Unibody aluminum body with built-in rails. The carriages are made of the same plastic as the base. That is, something like nylon, and since it is based on 12 volt BYJ-48 motors, the carriages are as light as possible, which is why the nylon guides sliding along the rails are very flimsy and the whole structure has backlash. The head of the printer is made of metal, but again the guides are plastic. Also, there is no blowout. The video on kickstarter says that an innovative convection system is used here, when hot air itself rises and airflow is not required ... Yeah, of course, only the rise of this air is so insignificant that it is clearly not enough to remove heat from PLA plastic. Okay, let's try to print. nine0003

Also, there is no blowout. The video on kickstarter says that an innovative convection system is used here, when hot air itself rises and airflow is not required ... Yeah, of course, only the rise of this air is so insignificant that it is clearly not enough to remove heat from PLA plastic. Okay, let's try to print. nine0003

The demo model is already built into the printer, you just need to press the print button.

All settings are default to start with.

Temperature set to 210, layer 0.2, infill 25%.

We press the button and the printing starts... The interest runs... But no, the printer does not move.

Trying to load and unload the filament. It seems to be doing something. The brightness changes. But when you press print, it does not print. Ok, let's deal with the filament first. Why is there no submission?

Everything turned out to be banal. The bar crumbled and stood somewhere in the spacer.

The bar crumbled and stood somewhere in the spacer.

I unscrewed the tube clamp and inserted my bar from the back side and pushed out all the pieces of the crushed bar.

This is what TIKO looks like from the inside. The yellow cable is an interesting feature of this printer. An accelerometer is built into the head and the auto level is implemented on this sensor.

The head drives up from the surface of the table from the edge and rests on the table with a nozzle, while the head tilts, then the printer slowly raises the head up and at the moment when the head becomes parallel to the horizon, it fixes this value, lifts it up until the limit switches are activated and repeats the procedure on the next two corners. The process is funny. True, the table cover from this at three points deteriorates a little. nine0003

Video of the calibration process: TIKO auto calibrate And a piece of video of the start of printing a simple cube 20x20mm:

Link if the video is not inserted: Tiko printing And Timelapse video of printing the cube:

the print button, you can disconnect from the printer's network and it will continue to print completely offline. In general, this is a great idea: a printer with a built-in print server and a slicer, fully automatic. And spoils this idea only one, but a very significant omission. nine0003

Print quality.

It prints disgustingly out of the box. Moreover, it turns out even more or less with a native filament, as soon as you insert a non-native one, it already becomes critical how the temperature, retract, etc. are set. Yes, it needs to be configured on all printers. But all that I had before allowed me to fit into fairly wide ranges so as not to change the settings 10 times for each plastic manufacturer.

But all that I had before allowed me to fit into fairly wide ranges so as not to change the settings 10 times for each plastic manufacturer.

This is the test cube 20x20x10mm. A pair of sides are curved, one outward, the other inward. There are some gaps in the center of the layers, the filling does not reach the walls. Raft is required and is not disabled. The surface above the raft turns out to be nasty))) Not smooth, but nasty. nine0003

Lower corners turned up because the layer above the raft lay poorly. raft by the way does not turn off and is not configured.

This is the very first print, when there was some native plastic left in the bowden tube after the extruder.

Due to a poorly adjusted first layer gap and raft, the model was torn off the platform and it was not finished printing. but the next white figure was printed out and came out so-so.

there are displacements of layers and hairiness, in general, the whole thing is some kind of curve))) In general, there is room to grow and something to tweak. nine0003

Finally, a couple more photos of the cube and the miracle table.

This is how the printer turned out, and in principle it is clear why the project did not take off, the printer had too many problems out of the box, and there were not enough resources for improvements.

Although in general there are quite a lot of interesting solutions, just look at the nozzle. Titanium nozzle with a ceramic annular compact heater, this is a fairy tale. Heats up in a couple of seconds! A fully cast aluminum body with built-in rails, such a solution should have given amazing accuracy, but alas, the backlash due to the lighter weight of the bottom brackets ruined everything. By the way, one solution to this problem is just to add weights to each carriage.