Best 3d printer settings for pla

Tips and Settings for the Best 3D Prints – Clever Creations

Image: Polymaker

Our site is reader-supported. When you buy via the affiliate links on this site, we will receive a commission at no cost to you. All opinions remain our own. Learn more

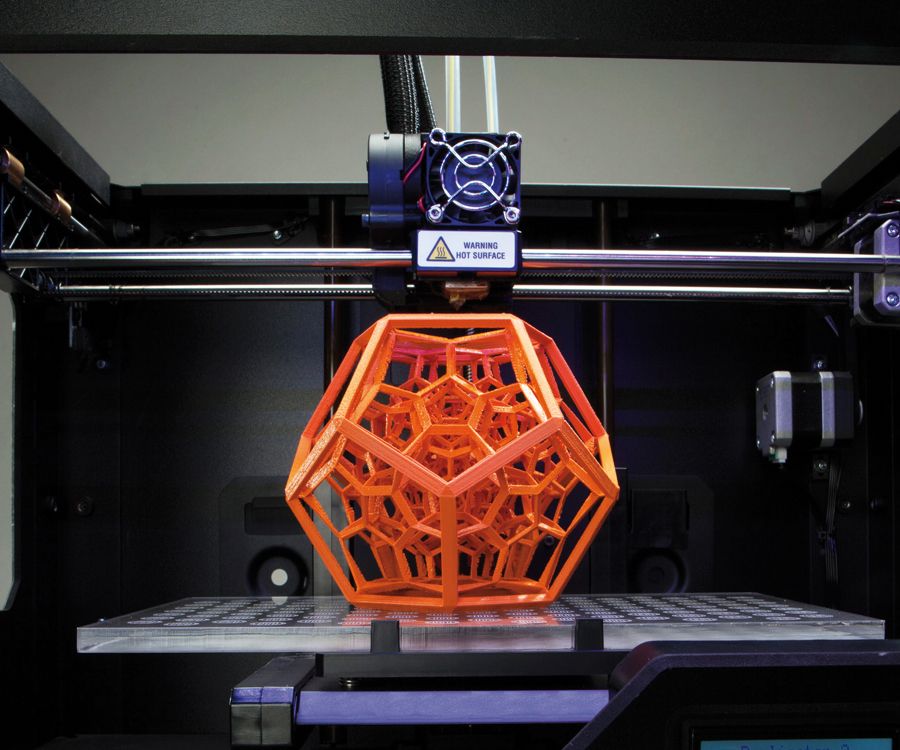

Are you thinking of trying to 3D print with PLA filament? PLA is one of the most popular materials for 3D printing and an excellent choice for beginners because it’s easy to use and more economical than other filament options. Even so, there are some things you need to know before buying your first spool.

We’ll tell you all about what PLA is, why it’s a great option for 3D printing, and what settings and temperatures you should use for the best results.

What is PLA?

PLA (Polylactic acid) is a thermoplastic made from organic materials instead of petroleum. Short for polylactic acid, PLA is a compostable bioplastic derived from corn starch, sugarcane, and other types of renewable resources.

PLA has a wide variety of applications and is used in plastic bottles, plastic wrap, and some medical devices. While it is an efficient green alternative for product packaging and biodegradable components, PLA has a low heat tolerance which makes it unsuitable for any uses requiring direct contact with warm environments.

Why 3D Print With PLA?

PLA filament is one of the most popular materials for 3D printing because its material properties like low printing temperature makes it easy to print with. It is economical to produce, which leads to lower costs on filament. It is also easy to work with, mostly odorless, and biodegradable.

PLA filament is ideal for beginners and makers with budget 3D printers who don’t have advanced printing features. Unlike other filaments, like ABS, PETG and Nylon, PLA can be 3D printed without a heated build plate or 3D printer enclosure.

Image: Ajrocket1 via Wikimedia, CC BY-SA 4.0

PLA filament spools are typically made of either plastic or cartonDownsides of PLA

While there are several benefits to using PLA filament for 3D printing, there are also some downsides.

The biggest drawback of polylactic acid is its low melting point and low glass transition temperature. These make it easy to print with but limit the durability of the finished products. 3D prints made with PLA filament are unable to withstand high temperatures and will start to soften and warp from being left in a hot car, or in direct sunlight on a hot day.

Using specialty PLA filament blends (also known as PLA+ / Pro PLA filament) can make your finished 3D prints more resistant to high temperatures without affecting the printing temperature. However, these do come at a higher cost.

Another issue with PLA is that it is not as easy to post-process as other filament options like ABS. While 3D prints made from ABS can be smoothed by placing them in a closed container with acetone, PLA is resistant to most chemical smoothers. Instead, smoothing PLA 3D prints is done by sanding and/or covering with an epoxy resin.

To learn more about the differences between PLA vs ABS, check out our guide on the two materials. We also have a great article comparing PETG vs PLA if you want an alternate option to PLA without the downsides and strong 3D printing fumes of ABS.

We also have a great article comparing PETG vs PLA if you want an alternate option to PLA without the downsides and strong 3D printing fumes of ABS.

What Do You Need to 3D Print With PLA?

As mentioned above, it is quite easy to print with PLA filament. That means even the most basic 3D printers can usually handle it with little difficulty.

Hot End

PLA filaments usually work well with nearly every hot end. If your hot end is capable of reaching a temperature of around 200 degrees Celsius, you can 3D print PLA with it. Most hotends for 3D printing are more than capable of reaching that nozzle temperature with little issue.

Similarly, to 3D print with PLA, your hot end does not need a fully constrained filament path. This is different from when working with flexible filament, for example.

You also don’t need an all-metal hot end for PLA either, since its low printing temperature means you won’t melt the non-metal components near your nozzle. When 3D printing high-temperature filaments, like Nylon or PEEK, you risk melting PTFE tubing and other non-metal components inside the hot end.

Image: syvwlch via Wikimedia, CC BY 2.0

Not all extruders are compatible with high-temperature filamentsHeated Bed

PLA also does not warp or deform that much as it cools, so it does not strictly require a heated bed to 3D print. This is different from when printing with ABS, where it is beneficial for the entire print to stay consistent and limit big differences in temperature.

The unnecessity of a heated bed makes PLA filament a great choice for 3D printing enthusiasts on a budget, as a heated bed adds additional costs (both in hardware and electricity usage) to the 3D printer.

That said, a heated bed is still an advantage when it comes to 3D printing PLA, as higher temperatures can increase bed adhesion of the first layer.

You can print PLA on most types of build plate surfaces, including metal, glass, and BuildTak. It does occasionally need an adhesive added to the surface of the bed if it is not sticking well on its own.

This can be as simple as a basic glue stick or as complex as a 3D print-specific adhesive. Painters’ tape on the bed is another popular way to make your PLA 3D prints stick.

Painters’ tape on the bed is another popular way to make your PLA 3D prints stick.

Tips for PLA 3D Printing

It’s easy to get great results with PLA filament. If you are new to 3D printing, it is your best chance for getting good prints right away without too much fuss. It is just as easy to work with on a 3D printer under $300 as it is on a $1000 3D printer.

Even so, there are a few things to be aware of when starting to 3D print with PLA material.

How to Get the First Layer Right

It’s important to get the first layers just right with any 3D print, and PLA prints are no exception. The first layers are the building blocks for the whole print, so if they are off, the rest of the print will be as well.

Bed Leveling

The easiest way to get great-looking PLA prints is to have a level print bed. If your bed is uneven, certain areas of your first layers will be very close to the build plate while others are too far away. Not only does this make it difficult for the first layer to adhere to the build plate, it causes poor layer adhesion overall and makes the rest of the print unstable.

If your 3D printer does not offer automatic bed leveling, you might want to consider upgrading it with a BLTouch sensor to remove the need for manual leveling.

Nozzle Height

Your nozzle height is important to keep your first PLA print layers clean and well-adhered to the print bed. If the nozzle is too close to the bed, the melted filament will have difficulty extruding from the nozzle. If the nozzle is too far away from the print bed, the filament extrudes out in loose layers and doesn’t adhere well to the print bed or the previous layers.

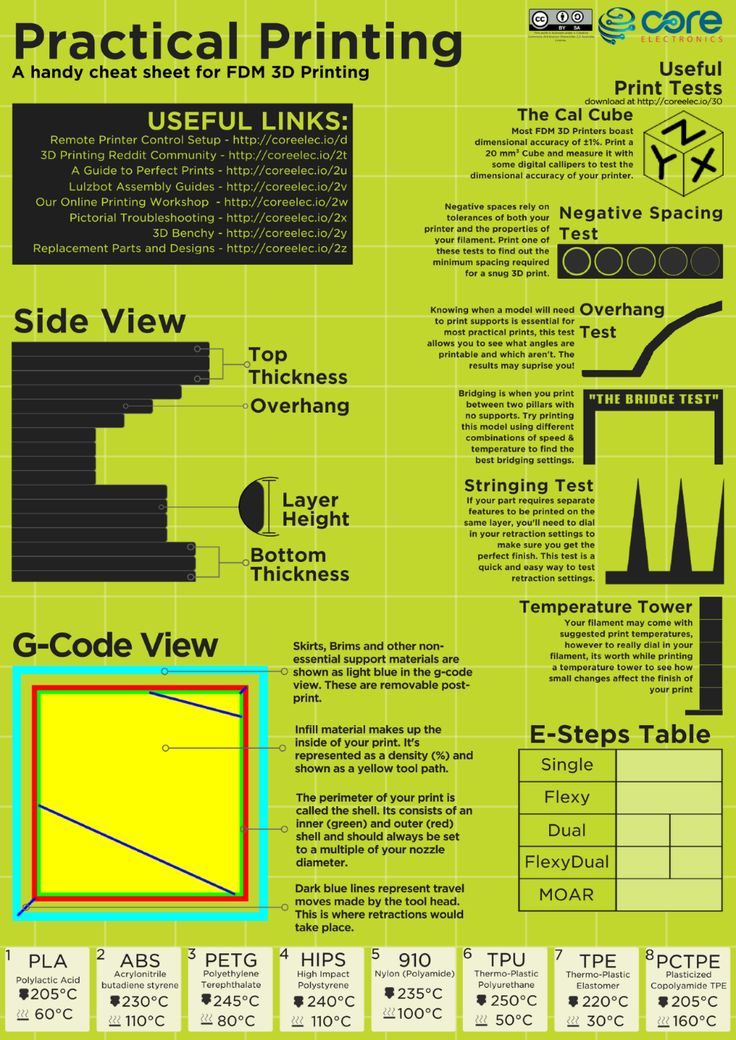

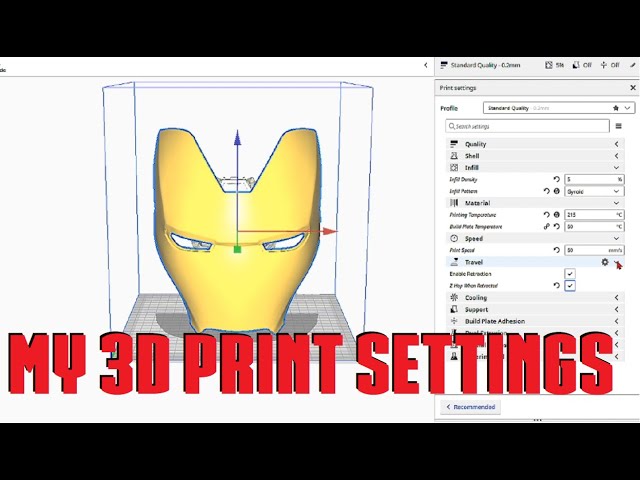

Recommended PLA Print Settings

PLA is one of the easier 3D printing materials to get good print quality with even with a basic 3D printer. That being said, you need to know which PLA print settings to use in your slicing software to get the best results.

- Nozzle Temperature: 195-220C

- Bed Temperature: 60-70C (optional for better adhesion to the printer bed)

- Layer Height: 0.

2mm for standard speed and quality

2mm for standard speed and quality - Print Speed: 30-90mm / second

- Bed Material: Glass, aluminum, BuildTak.

Other settings like infill percentage, wall thickness, retraction speed, etc. are dependent on the individual project. For example, more infill is better for strength while a lower percentage is better to save filament. The download pages of most 3D models will give you the optimal settings for these settings.

Other Tips

Get the Temperature Right

Most PLA filaments work within a set range of printing temperatures. What exact temperature you should use depends on your 3D printer and the brand of PLA filament. Sometimes temperature settings can even vary between different colors of the same brand of filament since the pigments used to color them can affect the way filament behaves.

When trying a new type of PLA filament, you’ll need to experiment to find the best settings for your 3D printer. Check the specifications of your filament to find the ideal printing temperature range and run test prints starting at the lowest temperature. Work your way up by increasing the extruder temperature 5-10 degrees on each additional test print until you find the temperature that works best with your machine.

Check the specifications of your filament to find the ideal printing temperature range and run test prints starting at the lowest temperature. Work your way up by increasing the extruder temperature 5-10 degrees on each additional test print until you find the temperature that works best with your machine.

You can also print a temperature tower to do this within one print. Just be sure to track the specific PLA filament, 3D printer and settings you used so you remember what you tested for later.

Use a Good Quality Filament

It can be tempting to cut corners by using the cheapest PLA spool possible, but you almost always trade quality for those cheap prices. Inconsistent filament diameters, breakage from moisture, inconsistent tension on the spool, and other quality issues will make printing harder and result in a lot of waste.

You are better off buying a decent-quality PLA filament for a slightly higher cost per spool for easy printing and good results. There are many things that can go wrong during a 3D print, so controlling the obvious ones with good materials and parts makes the whole process much easier.

If you aren’t sure what brand to choose, head over to our guide on the best PLA filament brands to see our top picks.

Troubleshooting

My PLA Keeps Breaking Mid-print

Breaking PLA during 3D printing is most often caused by old or improperly stored filament. PLA can absorb moisture from the air, which causes it to turn brittle. If you bend your filament and it easily snaps in half, it’s probably been exposed to too much moisture.

A good way to fix and prevent this is by using a filament dry box for your 3D printing material. These keep filament dry for when you need it. Some even have the ability to dry out filament that has absorbed too much moisture, offering you the opportunity to restore brittle PLA.

Recommended:

The 10 Best Filament Storage Containers and Dry Boxes

If your PLA bends like it’s supposed to, the problem could be due to improper tension. Either the filament wasn’t wound on the spool consistently during production (a common problem with cheap filaments) or it is getting too much resistance at your spool holder.

My PLA Keeps Jamming My Extruder

A jamming 3D printer extruder is common with cheaper PLA filaments. It is usually because the filament’s diameter is not consistent. It can also be caused by the filament not being perfectly round, which is yet another sign of poor filament quality.

The best way to ensure that your filament is the size and shape it is supposed to be is to buy a quality filament that has been manufactured with precise tolerances. This will prevent PLA filament getting stuck in the PTFE tube.

Extruder jamming can also occur when the extruder temperature is set too low. However, this is harder to do with PLA than other materials like ABS, since PLA plastic has a pretty wide range of tolerances for extrusion temperature.

Many PLA+ filaments are formulated to avoid extruder jams and clogs. You can learn more about the differences between standard PLA vs PLA+ in our dedicated article.

Conclusion

PLA 3D printing is a great option for getting good print quality without the hassle of complicated print settings you sometimes have with other materials. You can 3D print PLA with a low extruder temperature and no heated bed or enclosure. While PLA does have some downsides, it is still one of the best materials for 3D printing beginners.

You can 3D print PLA with a low extruder temperature and no heated bed or enclosure. While PLA does have some downsides, it is still one of the best materials for 3D printing beginners.

If you have any questions, for example if you are wondering if PLA is food safe, don’t hesitate to ask us in the comments!

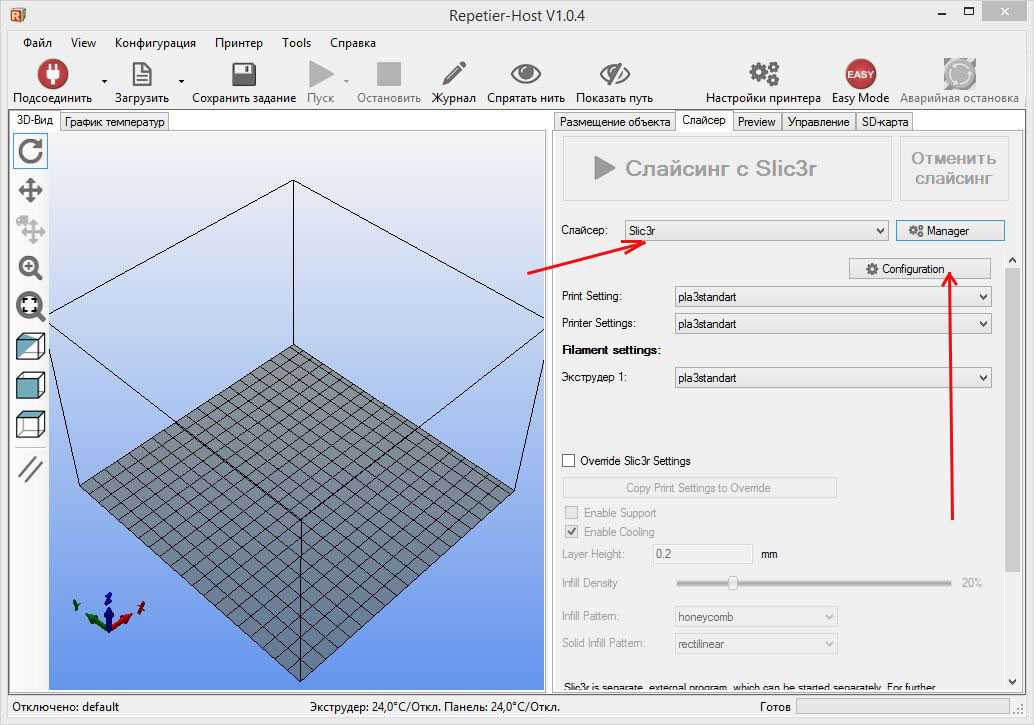

Choosing the Correct Slicer Settings

As any experienced 3D printing enthusiast will tell you, slicer settings make a big difference when working with different materials. ABS and PLA filaments share similar properties, but you still need to adjust your settings to get the best results with each material.

To give you an idea of the best slicer settings for PLA and ABS, this article will take you through all the most critical settings. You will have to hone these settings to match both your 3D printer and filament. This process is much easier when you have a head start.

What Is the Difference Between PLA and ABS 3D Printer Filament?

There are several key differences between PLA and ABS that you need to be aware of before you start printing with them. PLA is generally regarded as easier to print with, though it isn’t as strong or durable as ABS. But what else is different?

PLA is generally regarded as easier to print with, though it isn’t as strong or durable as ABS. But what else is different?

PLA (Polylactic Acid)

PLA is a popular thermoplastic that is derived from plant starches. While this material isn’t as strong as other 3D printer filaments, it is extremely easy to print with and suffers little from issues like warping. PLA is also great at adhering to almost any build surface.

ABS (Acrylonitrile Butadiene Styrene)

ABS is made from a blend of three different plastics/rubbers. It is stronger than PLA, but also harder to print with. ABS likes to warp, requires higher temperatures than PLA, and can also pose health risks when misused.

It's worth taking the time to learn about different 3D printer filament types so that you can also choose the best option for your projects.

Nozzle & Bed Temperature

FDM 3D printers use heat to soften filament materials so that they can be shaped and bonded together. ABS and PLA have very different nozzle and bed temperature requirements; ABS prefers it hotter, while PLA works well in cooler conditions.

ABS and PLA have very different nozzle and bed temperature requirements; ABS prefers it hotter, while PLA works well in cooler conditions.

PLA 3D Printer Nozzle & Build Surface Temperatures

You can print PLA without a heated build surface, as long as it has a texture that the plastic will adhere to. Despite this, PLA benefits from a bed temperature between 50°C and 60°C.

Your build surface also needs to be level to work properly. Learning how to level your 3D printer bed takes time and patience, but the results are well worth it.

The best nozzle temperature for PLA usually ranges between 200°C and 215°C. You can use temperature tower calibration 3D models to find the best printing temperature for your printer.

ABS 3D Printer Nozzle & Build Surface Temperatures

It is almost impossible to print ABS without a heated bed, as this material suffers from serious warping when exposed to different temperatures. Using a heated bed between 90°C and 110°C is a good place to start with ABS.

ABS has a higher melting point than PLA. It is best to aim between 210°C and 250°C before you start experimenting with ABS 3D printing temperatures.

Layer Height

As its name suggests, layer height is the height of each of the layers created by your 3D printer. Both PLA and ABS are extremely forgiving when it comes to layer height, and you should choose this setting based on the size of your nozzle and the quality you want. For example, a 0.4mm nozzle should be used for layer heights between 0.12mm and 0.28mm.

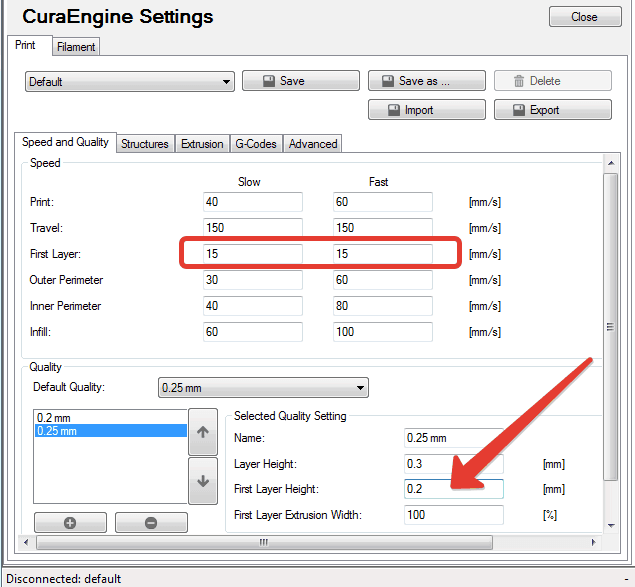

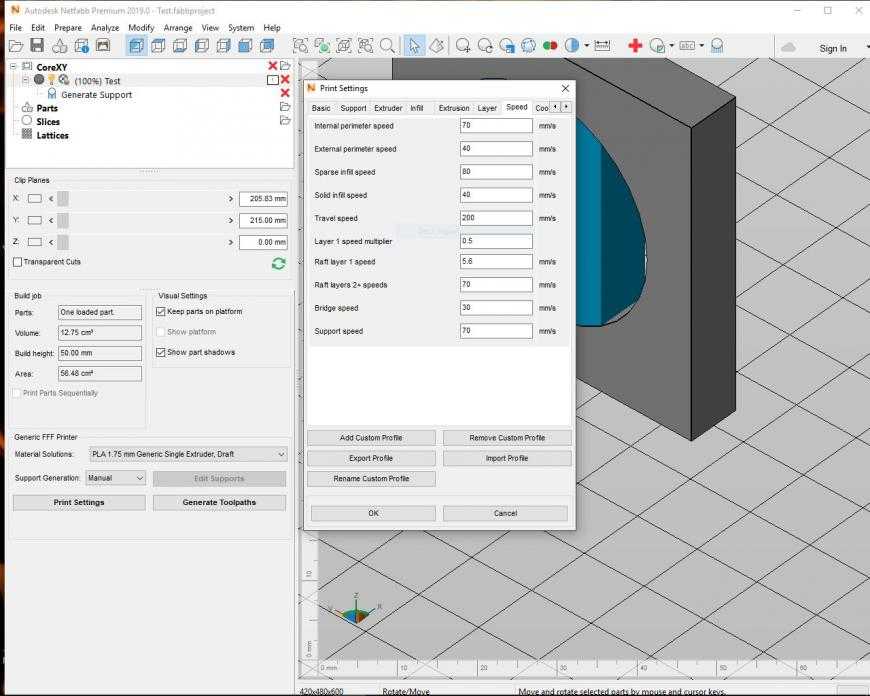

Movement Speed

Your 3D printer extruder and hotend move around to create your 3D prints, and the speed of these movements has to be precise. Both PLA and ABS print well with movement speeds between 40mm/s and 60mm/s. Going too slowly can cause over-extrusion, while going too fast can cause under-extrusion and poor-quality prints.

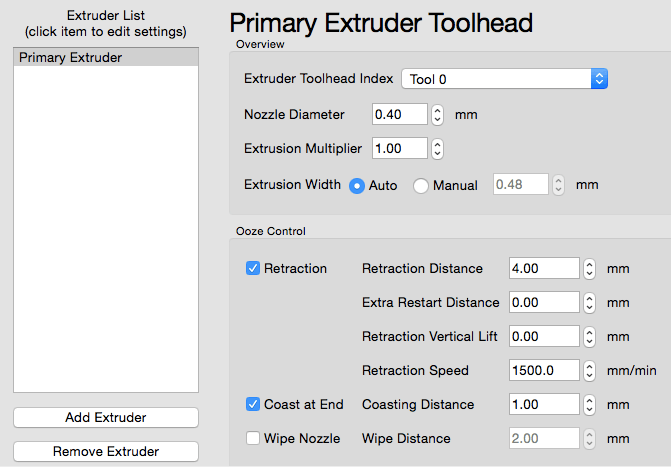

Retraction Speed & Distance

Many 3D printers are able to retract filaments to stop extrusion. This makes it possible for the hotend to move around without leaving strings of plastic behind it. Both PLA and ABS work well with a retraction speed between 40mm/s and 60mm/s and a restriction distance between 0.5mm and 1mm for direct-drive extruders, and between 30mm/s and 50mm/s with a 2mm distance for Bowden setups.

Infill Type & Density

It is unusual to print a solid object with an FDM printer. Instead, infill patterns fill the space inside the object, saving weight, filament, and time. Both ABS and PLA work best with at least 10% infill density, but you can push this up to 30% for a stronger object. Beyond 30% infill density you won’t get a significant strength increase in most cases.

Many slicer programs allow you to choose from a range of different infill patterns/types. The pattern you choose can impact the strength of your prints and the time it takes to 3D print them, but the difference is too small for many users to notice.

Support Type & Material

Supports are a vital part of 3D printing, making it possible to print objects with overhangs that would otherwise be in the open air. PLA and ABS work well with both tree-like supports and regular tower supports. The overhang angle you choose dictates how steep an overhang has to be before supports are generated. 0 degrees will support all overhangs, while 90 degrees will support no overhangs; 55 degrees is a good place to start. It's worth keeping in mind that different slicers handle supports in their own ways.

It is always worth thinking about the materials you use for your 3D-printed supports. Multi-material prints work with water-soluble filaments that disappear when they are soaked in water. This is great for strong materials like ABS and materials with good adhesion, like PLA.

3D Print Additions

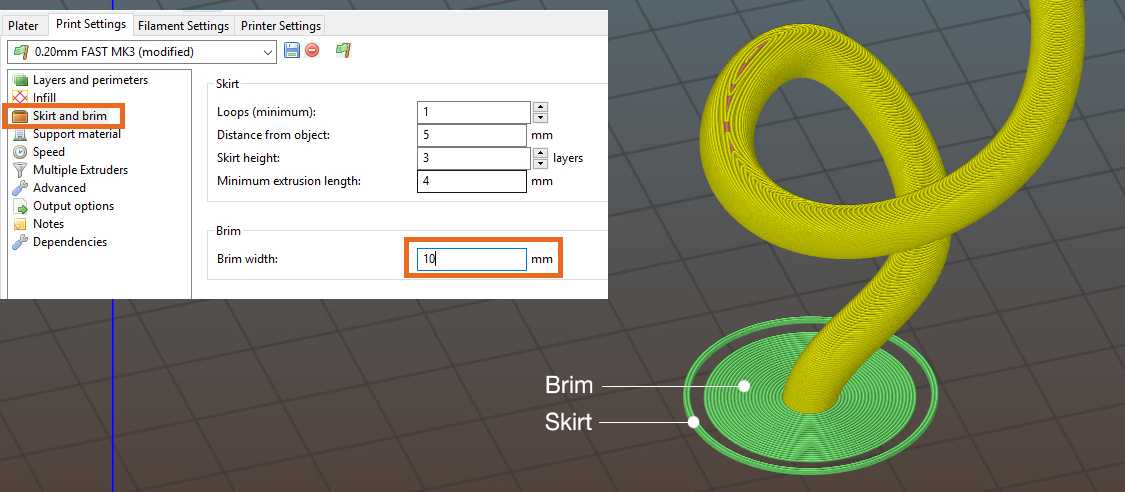

Most slicer tools are able to include a range of additions to your 3D prints. This includes rafts and brims to help with surface adhesion, along with other tools like wiping towers and walls. Rafts provide the perfect base for many PLA 3D prints, especially if your slicer software turns up the heat for the first few layers. This can give you control over the small amount of warping that can occur with PLA.

ABS warps far more readily than PLA, and a raft can serve to make this worse if your bed isn’t leveled correctly. Brims can prove much better for ABS than rafts, as they anchor each corner and round it off. This spreads the stress caused by warping and makes it easier for the object to remain on the print bed.

3D Printer & Part Cooling

PLA and ABS are similar, but their cooling needs are drastically different. PLA benefits from being cooled as soon as it comes out of the nozzle, but ABS prefers no part cooling at all. Using part cooling with ABS increases the chance of warping and poor layer adhesion, but enclosure cooling is still a good idea.

General 3D Printer Structure (Beds & Enclosures)

PLA is an incredible material that is suitable for almost any FDM 3D printer. Glass, metal, and taped build surfaces can all provide excellent results, and you don’t need any sort of enclosure to print with this material.

ABS, on the other hand, is a very different story. Enclosures are vital for ABS 3D printing. Not only do they protect the print as it is made, but they also trap heat and reduce the chance of warping as the part cools down. Thankfully, you can make your own 3D printer enclosure with relative ease if you follow a guide.

3D Print With ABS and PLA

As two of the most common 3D printable materials on the market, it makes sense that PLA and ABS are well-tested. Even so, you should always work to dial in your printer to make sure that you are choosing the best settings for your filament brand and the 3D object itself.

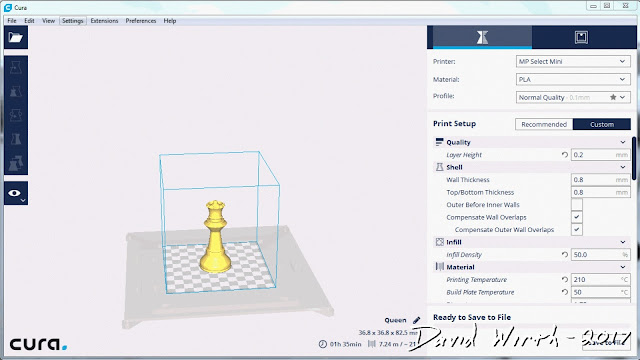

Optimal Cura settings for PLA 3D printing

3DPrintStory 3D printing process Optimal Cura settings for 3D printing with PLA plastic

Through trial and error, you can gradually fine-tune your Cura settings for 3D printing with PLA (as well as many other 3D printing materials). The article below provides recommendations from personal experience that may be helpful if you are using PLA plastic on your 3D printer and Cura to slice and prepare your 3D print modes.

In addition to explaining preferred temperature settings, advanced support and infill settings are detailed, along with many other factors that affect 3D printing without defects or issues.

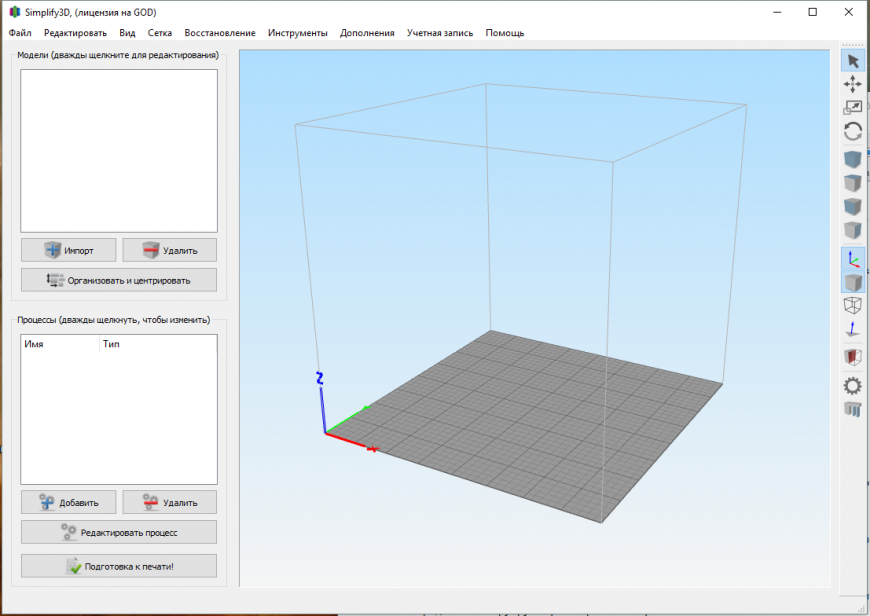

*** The following settings are for Cura and tested on Lulzbot TAZ 3D printers with an E3D host. We have successfully used these settings on our TAZ3 and TAZ5 printers as well as the HATCHBOX 3.0mm PLA. Simplify 3D uses very similar profiles. Environmental conditions and material manufacturer can also greatly affect these settings

3D print quality settings

The height of the 3D print layer is very dependent on the nozzle size of your 3D printer, as well as the quality you want to achieve. A 3D printer with a 0.6mm nozzle can achieve layer thicknesses of up to 0.4mm, and a part with a layer height of 0.1mm will take twice as long to produce as one with a 0.2mm nozzle, so these factors are important to consider.

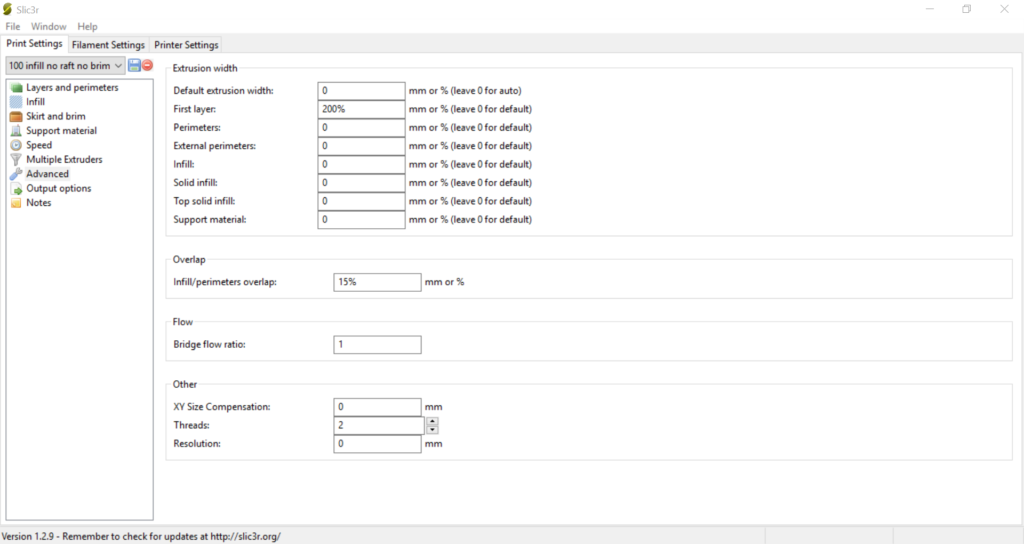

Our default 3D print quality setting is 0.25mm layer height. Then we fine-tune the retract settings for the PLA. The resulting profile for Cura will be:

- Minimum Travel: 1.5mm

- Enable Combing: All

- Minimal Extrusion Before Retracting: 0.005mm

- Z Hop When Retracting: .1mm

trying to eliminate gaps. This will help prevent "burrs" from appearing on the sides of the 3D model. "Z Hop" is set to 0.1mm when retracted, so thin sections of 3D models are less likely to be damaged.

When we click on the "Advanced Settings" tab in Cura, we look at the "Retraction" and "Quality" sections. We set the retraction speed to 10 mm/s and the distance to 1.5 mm. In the "Quality" menu in the "Advanced section" we do not increase the initial layer thickness, but increase the initial line width to 115%. We have found that this helps improve adhesion to the table without compromising the quality of the 3D print.

The pictures below show examples of 3D printing. From left to right, 100 micron layer height (high quality), 250 micron layer height (standard quality), and 380 micron layer height (draft quality).

Infill settings

To get a clean PLA print, we always try to include at least 4 bottom/top layers (i.e. you have to multiply the layer height by at least 4). It can increase depending on how flat the object is, how high the fill density is set, and how thick your layer is. A long rectangular piece with a layer height of 0.1mm will require more than 10% infill and at least 7 bottom/top layers to avoid pitting. The print below had just such a problem: too little infill and too few bottom/top layers, spoiling the 3D print result.

The preferred infill density percentage is unique to your particular 3D model, as are the quality settings. Infill overlap settings are something to focus on to improve the surface quality of a 3D model.

This 3D model had 10% infill and 3 bottom/top layers at a layer height of 0.25mm, which was not enough for a smooth top surface.

This 3D model had 20% infill and 5 bottom/top layers at a layer height of 0.25mm, which was enough for a beautiful outer surface.

Infill Overlap

Infill Overlap refers to the percentage of infill overlap on the shells. When the number of shells is low and the percentage of infill overlap is set above 12%, we notice "veining" on the surface of finished 3D models, especially on large translucent PLA parts. We prefer almost all of our PLA models to have an 8% overlap. The photo below shows an example of two shells with a 15% overlap of translucent blue PLA. While the effect looks pretty cool, we needed to reduce the fill overlap to get this veining defect to disappear.

Speed and temperature

As we warned above, these PLA settings work well with E3D enabled Lulzbot TAZ printers. These temperatures (and speeds) may vary depending on the 3D printer and how long it has been used.

Our nozzle operates at a comfortable (but slightly higher than average) temperature of 205-210°C for PLA. We usually preheat the table to 60°C, but since we added a thicker 1/4 inch glass, we increased it to 65°C. This thicker glass makes the table process easier and also prevents cracks and chips. We've used PLA on tables that don't have a heating option, but it's definitely better to have a heated table. The glass stage heated to 65° helps prevent warping and prevents parts from being torn off during the 3D printing process.

We run our printers a little slower to ensure the best surface quality. We usually set our average speed to 60mm/s, with slower settings for the outer and top/bottom layers. In advanced mode we have the following speed settings:

- Travel Speed: 150 mm/s

- Bottom Layer Speed: 25 mm/s

- Infill Speed: 60 mm/s

- Top/Bottom Speed: 40 mm/s

- Outer Shell Speed: 40 mm/s

- Inner Shell Speed: 60mm/s

Support Material Settings

We found the support settings to be one of the hardest things to change. Each material requires a different infill percentage and angle. Each one also requires a unique distance from the 3D model for easy removal.

Anyone who has been typing long enough probably doesn't like working with caliper settings. Our recommendations for support material settings are as follows:

- Structure Type: Lines

- Overhang Angle for Support: 50°

- Fill Amount: 15%

- Distance X/Y: 0.

8mm settings

- Distance Z: 0.16mm

support, you will also find a type of base to grip with the table. While "brim" settings are not usually needed for PLA parts, large 3D models can warp and narrow parts have a hard time sticking to the table without tipping over. In our PLA settings, this option is usually disabled by default, and we enable it manually for such special cases.

The problem with base coats, especially on PLA, is that they are difficult to remove. We've had parts where the edge is much harder to remove than the base backing material. This forced us to switch to the narrower "skirt" version instead of "brim".

With "None" selected as the first layer type, click "…" to see more options. Then we change the number of lines to 10-15, the initial distance to 0.01mm and the minimum length to 250mm. This allows the first layer to form only on the outside of the 3D model. Although the outer side will still require additional processing, this saves a lot of time removing margins from the inner thin parts of the 3D model.

Cooling

And finally, the last section on the advanced settings tab is the ability to activate the active cooling fan. The fan for PLA plastic should always be kept on. If you try to turn off the cooling fan, you may get unpleasant defects (for example, in the photo below).

The resulting cooling settings for Cura using PLA plastic are as follows:

- Fan Full on at Height: .5mm

- Speed Min: 35%

- Speed Max: 75%

- Minimum Speed: 10mm/s

- Cool Head Lift: off

Conclusions models require minor changes. Certain 3D printing angles may require your support settings to be slightly closer in the Z or X/Y axis. As with any 3D print media settings, these PLA settings need to be adjusted for each make/model of 3D printer.

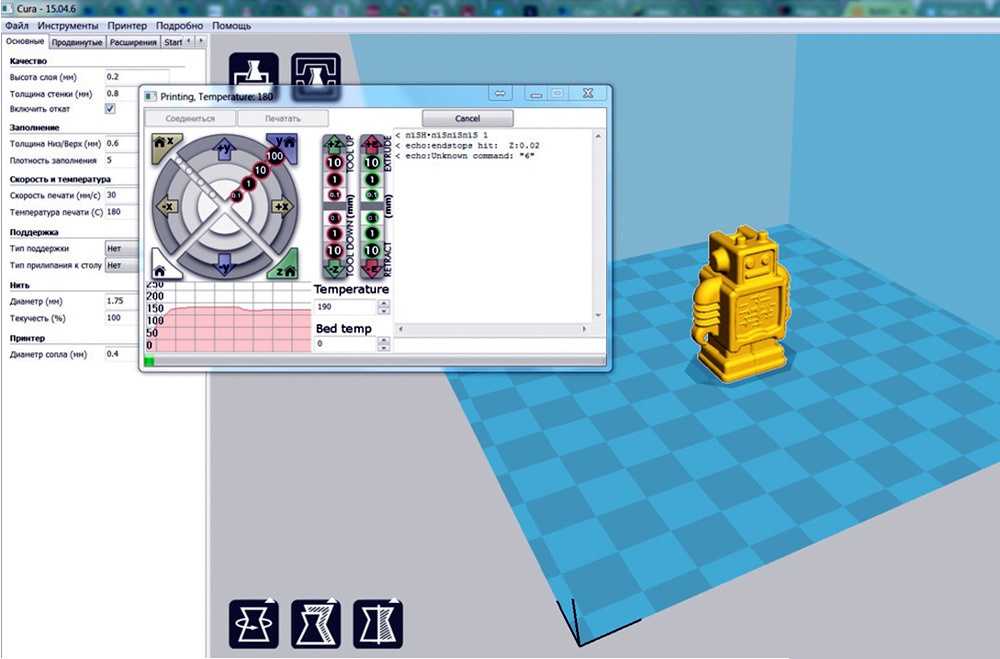

PrintScreen with our basic and advanced settings are shown below:

Cura settings profile for PLA you can download here.

PLA print settings | How to choose modes for PLA filament

PLA plastic filament is used in FDM 3D printers. This is a truly amazing material that is environmentally friendly and non-toxic. During printing, it does not “stink”, but emits a light aroma of popcorn. The thing is that it is made on the basis of natural plant materials - corn, potatoes, cane, etc.

This is a truly amazing material that is environmentally friendly and non-toxic. During printing, it does not “stink”, but emits a light aroma of popcorn. The thing is that it is made on the basis of natural plant materials - corn, potatoes, cane, etc.

If you compare PLA with ABS, it turns out that the former is harder, and therefore the process of applying the next layer will be slower. But this has a positive effect on the result of printing, because the products are smoother. However, this imposes its own characteristics on the print settings, the choice of which should be guided by the characteristics of the material.

PLA plastic specification

PLA plastic for 3D printer has a number of key characteristics. Depending on the brand, the properties may vary slightly. However, this material is characterized by:

- strength and stiffness;

- translucent and even transparent;

- wide range of colors;

- smooth, detailed finished models and shiny surface.

PLA turns out to be easier to work with, ideal for those new to 3D printing as it doesn't warp or shrink like ABS. But it is less heat-resistant and already at 70 degrees it can begin to deform.

The material has the following specifications:

PLA print settings

The most important layer in FDM 3D printing will always be the first layer. It must be fixed on the desktop to avoid further deformation. In this regard, PLA plastic is less demanding in comparison with ABS. But many use special substrates, blue tape or glue stick. You can print simply on glass, especially if the 3D printer is equipped with a heated table. The optimum temperature in this case will be 70 degrees, although in some cases, it has been experimentally established that the best results are achieved on a cold table.

The second point is that it is important to correctly set the height of the extruder. The nozzle should be at such a height that a standard sheet can easily pass between it and the work table.

Next, you need to decide on the standard set of settings:

- temperature;

- layer thickness;

- table temperature (if heated).

Another important point to get the best print result from PLA is to use the blower at full power. So the plastic will be cooled in time and not deformed.

As with ABS, print performance will be derived empirically. For example, the temperature will be set to 200 degrees and then raised or lowered by 5 degrees until the best option is found, in which the layers will perfectly hold together, have time to freeze and not swim.

And the average PLA printing settings are as follows:0169

+ + +

+ + + +

+ +

+

+ +

+ 9000 + 9000 + 9000 + 9000 + 9000 + 9000 + 9000 + 9000 + 9000 + 9000 + 9000 + 9000 + 9000 +

+ + + + +

+ +

+ + + +

+

+ + + + +

+ + + +

Durability at home

+ + +

+ + +

+ + + +

+ + + +

+ + + +

+

-10°C to +30°C

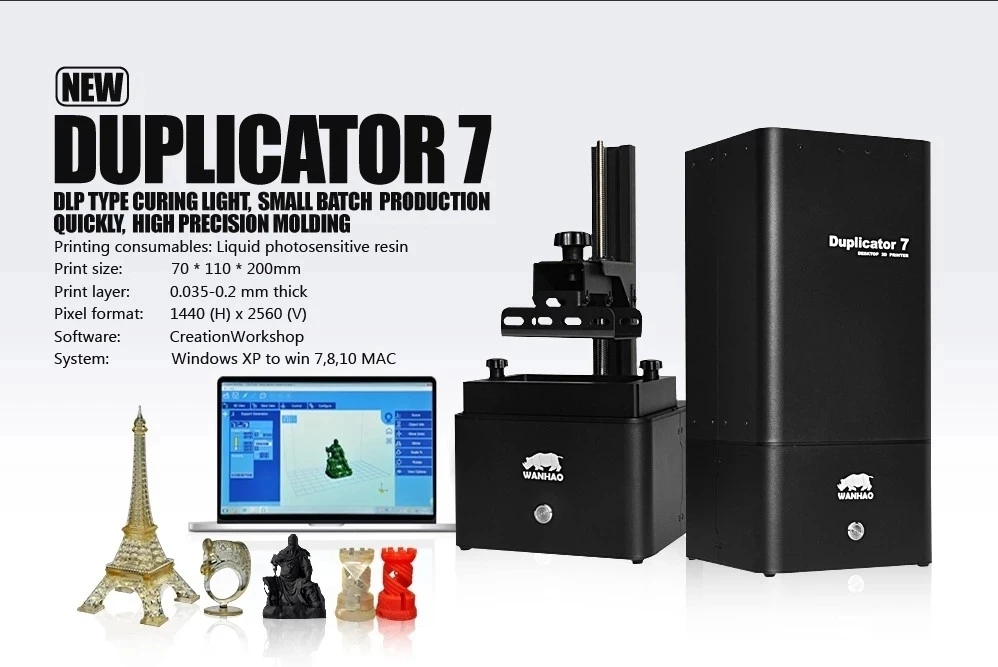

Simplify3D PLA print settings

Below are the recommended settings for PLA plastic printing and job preparation in the Simplify3D slicer.