Best 3d printer kit under 200

Best 3D Printers Under $200 in 2022 (Reliable & Good Quality)

With $200 in hand, it’s entirely possible to pick up a reliable starter 3D printer. To help steer you towards your best options and avoid the duds, we’ve pieced together this guide to the best 3D printers under $200.

Long gone are the days of prohibitive prices for finicky, DIY kits. Nowadays, even entry-level printers produce good quality prints and, more importantly, a painless printing experience. Better yet, resin printers now sell for under $200, making high-resolution printing just about affordable.

Read on for our top picks; each guaranteed to make the most of those $200.

Best 3D Printers Under $200 2022

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

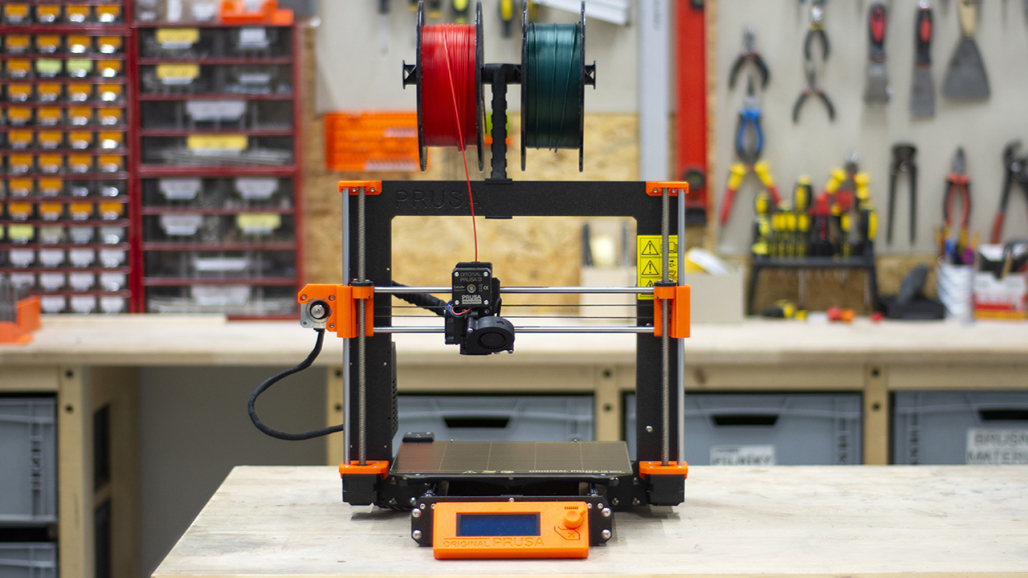

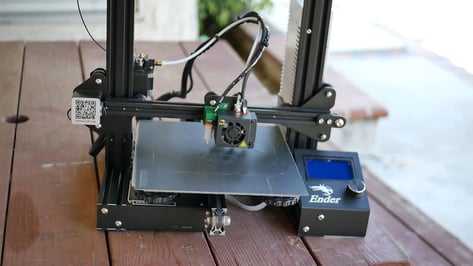

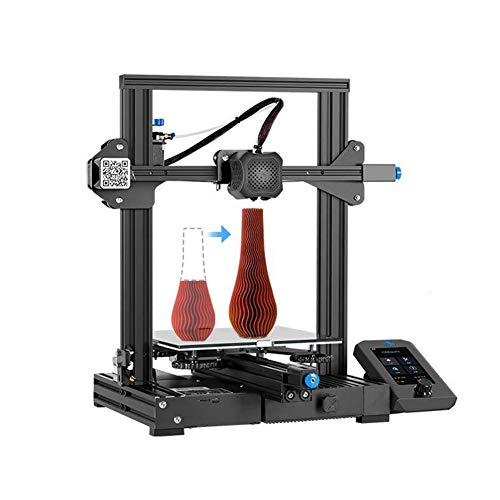

Creality Ender 3 – overall top 3D printer for $200

- Price: $189 — Available at Creality official store here / Amazon here

- Build volume: 220 x 220 x 250 mm

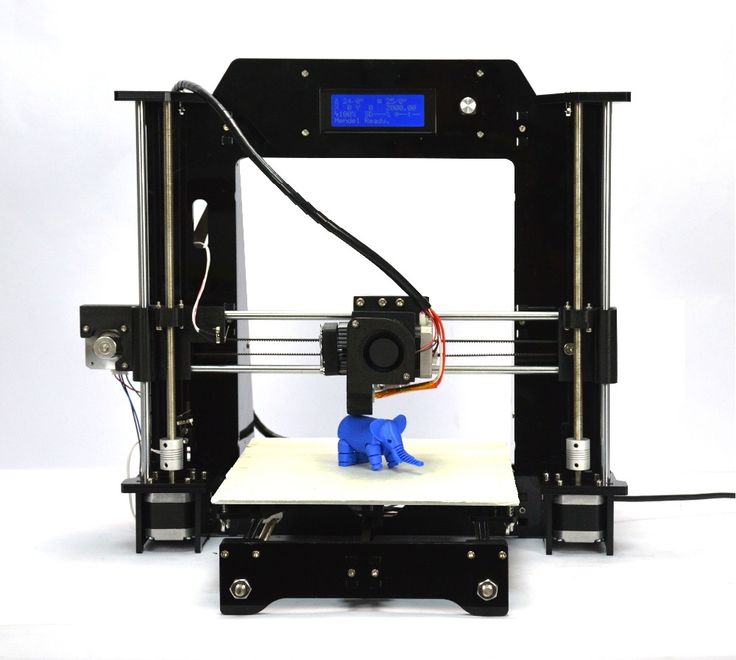

Few other printers have spawned quite as many clones as the classic Creality Ender 3, a testament to its ongoing appeal to thrifty makers and its position as a benchmark for inexpensive hobby printers. After all, imitation is the sincerest form of flattery.

While an open-source printer teaming with upgrade and tinkering options by design, the Creality Ender 3 veers sharply away from dime-a-dozen budget kit printers in favor of an uncomplicated, semi-assembled build. It nails the basics, handing you the keys to a reliable machine capable of decent print quality.

Turning to specifics, the Creality Ender 3 comes decked out with a 220 x 220 x 250 mm build volume, surprisingly decent for the price with enough space to craft relatively large parts and even multiple quantities of the same. The print-resume function is also worth bringing up, if only because it has no business being equipped on a sub $200 printer. Hats off to Creality for squeezing it in.

Alongside, Creality has thrown in a BuildTak-style heated bed, hitting a peak of 110°C. That’s theoretically enough for ABS if you’re game for tinkering your way to a successful print. The Creality Ender 3 has manual bed leveling, as expected for a printer under $200, and tricky control dial LCD; not ideal, but par for the course here.

If you’re looking for one of the ‘the best’ 3D printers under $200, we have no issues recommending the Creality Ender 3, even though the printer has hit veteran status now. It’s one for beginners eager to claw their way up that steep learning curve, as well as hobbyists limited by a tight budget.

Voxelab Aquila

- Price: Check price on Amazon here

- Build volume: 220 x 220 x 250 mm

While the Voxelab Aquila unabashedly channels the Creality Ender 3 in both design and price, there’s enough here to make it a viable alternative to the budget king for beginners. The main reason is that the Voxelab Aquila doesn’t float around the $200 mark but well under, often as low as $160-$170, a small price to pay for a confident little printer that’s a genuine pleasure to use.

It’s fairly remarkable what Voxelab offers for the price. A 220 x 220 x 250 mm build volume provides ample room to craft decently-sized prints, a heated carborundum glass bed shines with both PLA and ABS filament, and a color screen makes for easy navigation. Then there’s a 32-bit silent motherboard, filament auto-feeding, silent stepper motors, and open-source slicer support to cap things off.

Then there’s a 32-bit silent motherboard, filament auto-feeding, silent stepper motors, and open-source slicer support to cap things off.

Like all printers in this category, there are trade-offs, namely manual bed leveling, SD card connectivity, and hands-on assembly, though miles away from the complexity of piecing together a full-on kit printer. Beginners up for a challenge shouldn’t be put off, and that’s where we see Voxelab Aquila hitting its stride: it’s a superb novice printer that produces surprisingly good prints for the price.

There’s also the Voxelab Aquila X2, fundamentally the same printer, but with a filament sensor thrown in with a slight price jump to match.

Alternatively, for those looking to save a bit more cash, there’s the ultra-budget Voxelab Aquila C2. Voxelab has swapped out the color LCD for a mono display, shifted the supply from underneath to the side, and removed some of the metal plating on the base on the printer.

In our estimation, the savings aren’t worth the downgrade, and you’re better served spending a little more for the full-fat Voxelab Aquila.

Monoprice Mini Delta V2 – Best Fast 3D Printer Under $200

- Price: Check price on Amazon here

- Build volume: 110 x 110 x 120 mm

Small but mighty, the Monoprice Mini Delta V2 is a beginner-friendly speed demon, courtesy of Monoprice opting for a Delta design rather than the Cartesian design found on most $200 printers. It’s fast, really fast – 170mm/sec – and won’t break the bank.

Unlike most printers in this price range, the Monoprice Mini Delta V2 ships fully assembled and ready to print. Features like automatic bed leveling, a color touchscreen, Wi-Fi connectivity, and support for PLA and ABS help in that respect, too, removing many of those time-sapping initial stumbling blocks. It’s also anchored to an all-metal frame and prints at a reasonably low 30dBA.

Plug and play appeal aside, the Monoprice Mini Delta V1’s overall print quality is good for the price, aided by a 40‑200 microns resolution suited to delivering strong all-around details and finish. With a tight 110 x 110 x 120 mm build volume, the Monoprice Mini Delta V1 has its limits. Still, for a first printer, primarily used to experiment and learn, there’s enough print area for parts like small figurines, decorative pieces, and modest household items.

With a tight 110 x 110 x 120 mm build volume, the Monoprice Mini Delta V1 has its limits. Still, for a first printer, primarily used to experiment and learn, there’s enough print area for parts like small figurines, decorative pieces, and modest household items.

While Monoprice is trying to bring a pro-grade printer’s convenience and ease of use to the low-cost category, the Mini Delta V2 has experimentation potential thanks to full open-source slicer compatibility. It pairs beautifully with the likes of Cura, for example.

If you’re nervous about tackling a kit or semi-assembled printer and want easy printing above all else, we highly recommend the Monoprice Mini Delta V2. It’s versatile, and most of all, dirt cheap for what amounts to a robust set of features.

Voxelab Proxima 6.0 – Best Resin 3D Printer Under $200

- Price: Check price on Amazon here

- Build volume: 130 x 76 x 155 mm

Flashforge’s decision to pump out budget-friendly printers under the Voxelab name has produced some low-cost gems, not least the Voxelab Proxima 6. 0, one of the few resin printers available for less than $200.

0, one of the few resin printers available for less than $200.

The appeal is clear here: the Voxelab Proxima 6.0 undercuts competing resin printers like the Elegoo Mars 2 while still offering fundamentally the same features, and more importantly, on par overall print quality. For tabletop gamers, collectors, and amateur model makers, it delivers all the precision and fine detail we’ve come to expect from the big entry-level resin players.

You’ll find a boilerplate 6-inch 2K monochrome LCD pushing 50 microns XY resolution, a smack-bang average 130 x 76 x 155 mm build volume, and welcome niceties like a 3.5-inch touchscreen and compatibility with ChituBox, Lychee, and Voxelab’s in-house VoxelPrint slicer, a basic reskin of FlashPrint.

Read more: the best SLA slicers

The Voxelab Proxima 6.0 arrives fully assembled, standard stuff for resin printers. The only barrier to firing up that first print is an assisted bed leveling process that’s quick and over in seconds.

While we’d be the first to recommend low-cost resin printers like the Elegoo Mars 2 and the Anycubic Photon Mono range, there’s no question that the Voxelab Proxima 6.0 offers an almost identical printing experience for less than $200. Beat that, and we’ll reassess, but for the time being, the Voxelab Proxima 6.0 is the best resin 3D printer under $200.

Anycubic Mega Zero 2.0

- Price: Available on Anycubic official store here / Check price on Amazon here

- Build volume: 220 x 220 x 250 mm

The new kid on the ultra-budget printer block is another printer born from the Creality Ender 3’s enduring legacy, the Anycubic Mega Zero 2.0. New in the sense that Anycubic has slapped on a 2.0, but a known quantity as it borrows heavily from the shelved original Mega Zero.

The upgrades are there, not least a new heated bed that sees the AnyCubic Mega Zero 2.0 fit for PLA and trickier ABS. It boasts an average 220 x 220 x 250 mm build volume equal to the other printers on our list.

Anycubic has also woven in an easy manual bed leveling system and painless, modular assembly, so even though there’s some hands-on setup, it won’t baffle beginners. The magnetic bed helps the removal of prints, another solid, user-friendly feature worth mentioning.

Overall, it’s a simple, unassuming printer that stretches those $200 to great effect. It’s a gateway printer for those curious about 3D printing but conscious of keeping the wallet-hit to a minimum while making sure a passing interest has the makings of long-term hobby. If you’re looking for something a little different from the Ender 3, not to say something more modern, the Anycubic Mega Zero 2.0 is well worth considering.

Buyer’s Guide- Things To Consider

3D Printer Technology

By virtue of sitting on the lower end of the 3D printer pricing scale, the best 3D printers use one of two printing technologies.

FDM

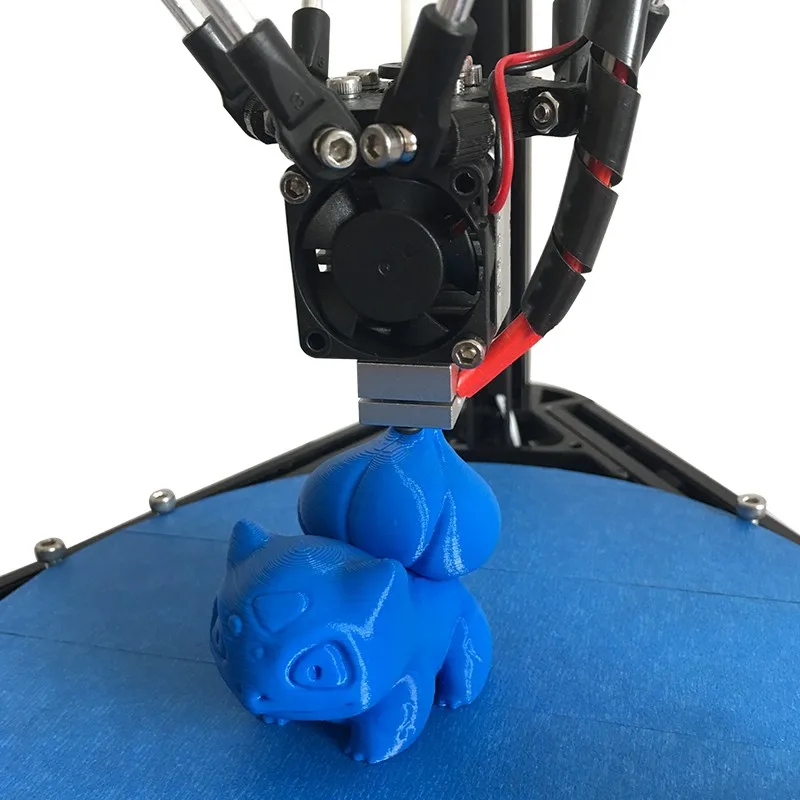

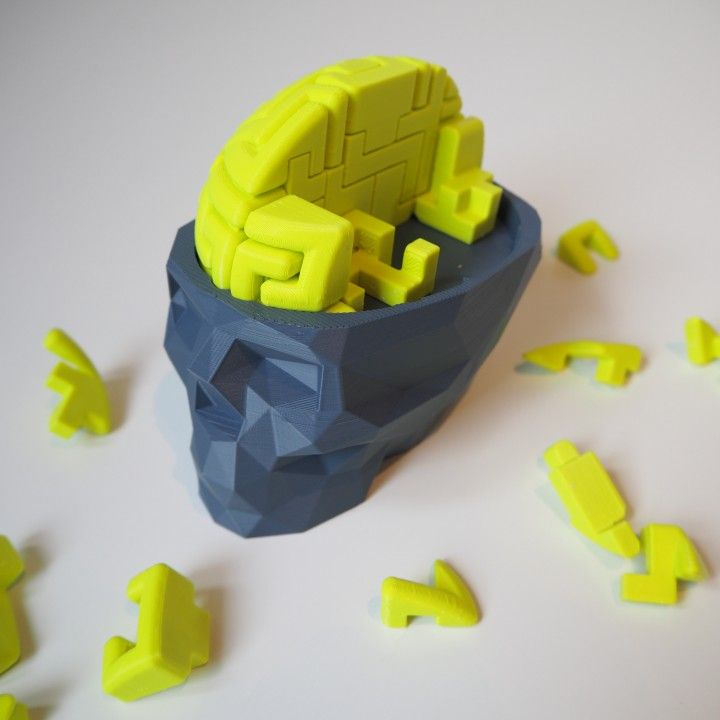

Fused deposition modeling is an additive technology whereby an extruder heats filament and deposits it layer by layer to create a print. Most, if not all, sub $200 printers employ FDM technology. Generally, FDM printers offer layer resolutions of around 100 microns.

Most, if not all, sub $200 printers employ FDM technology. Generally, FDM printers offer layer resolutions of around 100 microns.

Resin

Resin printers use a targeted UV light source applied to photo-sensitive liquid resin to cure or form a print layer by layer. The best resin 3D printers under $300 offer layer resolutions below 50 microns for parts with higher precision, finer details, and smoother finish than FDM printers.

Resin printers priced under $200 are generally less common than FDM due to the complexity and higher cost of the underlying technology.

Material Types

At $200, it’s worth keeping in mind that material compatibility is limited. Most FDM printers can handle PLA and possibly ABS, but the options are slim beyond that.

PLA, or polylactic acid, is a thermoplastic with a low melting point and is arguably the easiest material to print for hobbyists and amateurs. It’s suited to decorative parts, low-stress household items, and rapid prototyping. It’s flexible, odorless, biodegradable, and affordable.

It’s flexible, odorless, biodegradable, and affordable.

ABS, or Acetonitrile Butadiene Styrene, is a tough, durable thermoplastic with a relatively high melting point. Makers favor ABS for parts subject to stress, weathering, and repeated use. ABS is inexpensive but trickier to print and produces smelly fumes that can be harmful when inhaled.

Resolution and Layer Height

Although there are many factors at play when it comes to the resolution of a print, layer height offers a quick-glance estimate of a printer’s precision. For FDM printers under $200, 100 microns is standard and sufficient for a good overall print quality. 50 microns and below are typical for resin printers, enough for feature-rich parts.

Build Volume

When shopping around for a 3D printer, be sure to consider the build volume on offer. Build volume indicates the maximum size print a machine can produce.

In the $200 range, you’ll find average-sized build volumes roughly around 220 x 220 x 250 mm, matching the specifications of the Ender 3. This grants enough room for a good range of 3D parts, including household items, multiple of the same small part, models, toys, and more.

This grants enough room for a good range of 3D parts, including household items, multiple of the same small part, models, toys, and more.

Resin printers have a much smaller build volume, offset by printing higher quality parts with more detail and accuracy.

Open and Enclosed Frame/Chamber

Other than enclosed resin printers, all $200 3D printers feature an open frame design due to the lower manufacturing costs. In practice, this means the parts are readily accessible, helpful for tinkering, modifications, and upgrades.

There are downsides, most pronounced when printing with ABS, which ideally require an enclosed chamber to maintain stable ambient temperatures. When ABS cools too quickly, the material is prone to warping and curling. An enclosed chamber helps mitigate these errors by slowing the cooling process.

Bed Leveling

Most 3D printers under $200 have manual or assisted bed leveling, requiring some hands-on time with the printer for proper calibration. There are outliers such as the Monoprice Mini Delta, but this is down to the Delta design rather than a concerted decision on the manufacturer’s part to implement the technology.

There are outliers such as the Monoprice Mini Delta, but this is down to the Delta design rather than a concerted decision on the manufacturer’s part to implement the technology.

FAQs

What Is The Best 3D Printer Under $200?

Nothing beats the classic Creality Ender 3. It’s a known quality with a massive community of devoted makers to back it up and help with any issues, upgrades, or modifications. The Voxelab Aquila comes in a close second for a solid balance between affordability and performance for something with a modern twist.

What Is The Best FDM 3D Printer/Kit Under $200?

The printers listed above are all strong picks, and they all come highly recommended. But, gun to our head, we’d once again suggest the Creality Ender 3 for most. Otherwise, for those that favor convenience, the Monoprice Mini Delta simplifies the printing process for first-timers and has you printing in minutes.

What Is The Best SLA/Resin 3D Printer Under $200?

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

You may also be interested in other price range 3D printers:

- Best 3D printers under $300

- Best 3D printers under $500

- Best 3D printers under $1000

- Best 3D printers under $2000

The Best 3D Printers under US$200

Welcome to the Thomas guide to the best 3D printers under US$200 2022. Thomas has been connecting North American industrial buyers and suppliers for more than 120 years. When you purchase products through our independent recommendations, we may earn an affiliate commission.

If you're interested in trying your hand at a little 3D printing at home, or perhaps you're on the hunt for early Christmas presents, we've compiled this list of the best 3D printers under US$200 on Amazon. We recently wrote about the best 3D printers under US$300, and, after scouring the market, were pleasantly surprised to note that there are a lot of great starter 3D printers that are even more budget-friendly.

We recently wrote about the best 3D printers under US$300, and, after scouring the market, were pleasantly surprised to note that there are a lot of great starter 3D printers that are even more budget-friendly.

Image credit: Shutterstock/Kyrylo Glivin

3D printing is known as "additive manufacturing" or "rapid prototyping" in industry settings and is the production—or "printing"—of prototypes, layer by layer, via a computer-aided design (CAD) file. 3D printers for home use are becoming more and more prevalent, with many people getting on board and enjoying printing their own items from the comfort of their own home. There's something quite satisfying about being able to print up anything you need—from spare parts for repairing broken items, to cup holders or bottle openers—in just a few moments. What used to be science fiction, is now a daily part of life, and for as little as a couple of hundred bucks.

What's the Best 3D Printer Under US$200?

While top 3D printers can go up into the thousands of dollars, for simple home use there are plenty of models under US$200 that can serve their purpose. We've found the best 3D printer for kids, the best budget 3D printer, the best desktop 3D printer—and many more—all under US$200. Scroll down to see our top picks for the best 3D printer under US$200 according to happy shoppers.

We've found the best 3D printer for kids, the best budget 3D printer, the best desktop 3D printer—and many more—all under US$200. Scroll down to see our top picks for the best 3D printer under US$200 according to happy shoppers.

Thomas’ Top Picks for the Best 3D Printer under US$200 2022

Best 3D Printer Under US$200 in 2022: Anycubic 3D Printer | Buy Now

Best-Rated 3D Printer Under US$200: Elegoo 3D Printer | Buy Now

Best Most Affordable 3D Printer: Kingroon 3D Printer| Buy Now

Best 3D Printer on Sale: Creality 3D Printer | Buy Now

Best Large 3D Printer under US$200: Longer 3D Printer| Buy Now

Best Mini 3D Printer: Phrozen 3D printer| Buy Now

Best Desktop 3D Printer: Entina Mini 3D Printer| Buy Now

Best 3D Printer for Children and Beginners: Tecqeq 3D Printer| Buy Now

Best 3D Printer Pen: 3Doodler| Buy Now

Scroll down to read more about these top picks for the best 3D Printer under US$200, according to many happy buyers.

*Prices listed in this article were as shown in US$ on Amazon.com (USA) as of October 2022

1. Best 3D Printer Under US$200—Anycubic 3D Printer

For a quick start, easy setup, assembly, and leveling, and software that is extremely user-friendly, the Anycubic Photon UV LCD 3D Printer is the way to go. Allowing you to print products with intricate detailing, this 3D printer tops the list for the best 3D printer under US$200 in 2022, and it's currently on sale with US$100 chopped off the original price. One of the 1,400-plus reviewers wrote, "The prints are incredible. They look store-bought. If you need small detailed parts or wish to do minis, create and print your own chess pieces, the sky's the limit."

Specifications

Material: Metal

Color: Yellow/Black

Weight: N/A

BUY NOW: US$279. 99, Amazon

99, Amazon 2. Best-Rated 3D Printer Under US$200—Elegoo 3D Printer

The Elegoo Mars UV photocuring 3D printer is an impressive printing machine that comes semi-assembled, saving you the hassle of spending extensive time researching setup. Its 3.5-inch color touch screen, advanced photocuring technology, quick print time, mere five-minute warmup time, and an option to hollow out prints before slicing to effectively save resin, are just some of the reasons over 1,700 Amazon reviewers are raving about it. A common theme in reviews is the intricate detailing in its prints, and the extremely low price.

Specifications

Material: Aluminum, resin

Color: Mars 2

Weight: 16.46 Pounds

BUY NOW: US199.99 (Was US$259.99), Amazon3. Most Affordable 3D Printer—Kingroon 3D Printer

It's understandable that you may not want to spend much on a 3D printer if you're just starting out, so the Kingroon DIY Aluminum Resume Printer is a great choice. At just under US$180, this economical 3D printer should not be judged by its price. It comes with a preloaded assisted level MicroSD card with printable 3D models that are the perfect entry into the 3D printing world, and the user-friendly touch screen makes operation a piece of cake. As regards assembly and leveling, one user explained that it was "super easy. I did it with my six-year-old daughter helping me in about 20 minutes [by] reading the instructions. The leveling process was incredibly easy, thanks to the guided leveling that was built into the printer."

At just under US$180, this economical 3D printer should not be judged by its price. It comes with a preloaded assisted level MicroSD card with printable 3D models that are the perfect entry into the 3D printing world, and the user-friendly touch screen makes operation a piece of cake. As regards assembly and leveling, one user explained that it was "super easy. I did it with my six-year-old daughter helping me in about 20 minutes [by] reading the instructions. The leveling process was incredibly easy, thanks to the guided leveling that was built into the printer."

Specifications

Material: Aluminum

Color: Black/KP3S

Weight: 16.2 Pounds

BUY NOW: US$179.99, Amazon4. Best 3D Printer on Sale—Creality 3D Printer

At almost half price, this Amazon's Choice 3D printer is a steal. On sale for under US$200, the Creality LD002R LCD Resin 3D printer, with air filtering system, 3. 5-inch "Smart Touch" full-color screen, fast slicing software, high precision and resolution, and quick leveling, is—according to one happy customer—a "Solid printer for a beginner." The review continues, "Bought this with zero clues on what to do with resin printing — now I have made about a grand on my Etsy shop... Ended up buying a second one about four days [after purchase] because it had already paid for itself. It hasn't failed me yet."

5-inch "Smart Touch" full-color screen, fast slicing software, high precision and resolution, and quick leveling, is—according to one happy customer—a "Solid printer for a beginner." The review continues, "Bought this with zero clues on what to do with resin printing — now I have made about a grand on my Etsy shop... Ended up buying a second one about four days [after purchase] because it had already paid for itself. It hasn't failed me yet."

Specifications

Material: Resin

Color: Black/Orange

Weight: 15.43 Pounds

BUY NOW: US$199, Amazon5. Best Large 3D Printer under US$200—Longer 3D Printer

Another Amazon's Choice product, the Longer LK4 3D Printer, with 2.8-inch touch screen, resume-printing function (for if the power goes out mid-print), fast heating hot-bed, and a built-in safety power supply, is quite a remarkable machine for the price. It comes almost fully pre-assembled so you can get printing ASAP, and has the space (220x220x250mm) and capacity to print large objects, allowing you to let your imagination run wild.

It comes almost fully pre-assembled so you can get printing ASAP, and has the space (220x220x250mm) and capacity to print large objects, allowing you to let your imagination run wild.

Specifications

Material: Metal

Color: Black

Weight: 119.3 Pounds

BUY NOW: US$214.82 (Was US$247.43), Amazon6. Best Mini 3D Printer—Phrozen 3D Printer

If you're not a fan of the big and bulky, the fast-printing Phrozen Sonic Mini will take up all of 13x10 inches of space on your desk or workshop countertop—and it's easy on the eye, too! This resin 3D printer has a user-friendly operating system, offline printing function, and uses parallel UV LED technology for premium accuracy and quality. It can get to work in just five minutes, and doesn't need much maintenance. One user explains, "Phrozen has reduced costs by using plastic for the chassis and other elements instead of metal. .. This printer is fast, it's lightweight, and the cost is very attractive."

.. This printer is fast, it's lightweight, and the cost is very attractive."

Specifications

Material: Resin

Color: Red/Black

Weight: 12.47 Pounds

BUY NOW: US$129.99 (Was US$269.99), Amazon7. Best Desktop 3D Printer Under US$200—Entina 3D Printer

At just 8.3''x8.3''x11.4'' inches in size, and weighing in at a petite 6.61 lbs, a good choice for the best mini 3D printer, the lightweight and portable Entina Mini Tina 2, is the perfect desktop addition. Made with 3D-printing beginners, and children in mind, it comes practically fully pre-assembled, equipped with 2.4" LCD screen and Wiibulider slicer software that makes it easy to conduct offline printing using the MicroSD Card., a removable magnetic build plate, a resume-printing function, and a one-year warranty.

One customer wrote "If you want to get your feet wet with 3D printing this is perfect. Also amazing for kids who will love it. Highly recommend.", it even can be as a family project "Works great and helps kids and parents learn how to set up 3D printing and how these printers work. It's pretty cool to print something out of plastic filament!"

Also amazing for kids who will love it. Highly recommend.", it even can be as a family project "Works great and helps kids and parents learn how to set up 3D printing and how these printers work. It's pretty cool to print something out of plastic filament!"

Specifications

Material: Plastic

Color: Grey

Weight: 6.61 Pounds

BUY NOW: US$149, Amazon8. Best 3D Printer for Children and Beginners—Tecqeq 3D Printer

A 3D printer is invaluable for children's educational purposes, i.e. science projects. This Tecqeq mini desktop 3D printer which costs under US$120 is perfect for kids to start their STEM journey. Assembly is quick, it's extremely user-friendly, and also very quiet. "My son and I have pushed this into some pretty complex models with terrific results. Fun fun fun, and a low price point to buy into. " reads one review. "Setup was easy and only took a few min. My son is super excited to have his owe printer."

" reads one review. "Setup was easy and only took a few min. My son is super excited to have his owe printer."

Specifications

Material: Pla

Color: Black/Orange

Weight: 3.09 Pounds

BUY NOW: US$89.99 (Was US$119.99), Amazon9. Best 3D Printer Pen—3Doodler

Not quite ready for a whole 3D printing machine just yet? Not to worry; the 3Doodler Create+ 3D printing pen is the ideal way to get into 3D printing, and, at just $80, is quite a bargain considering you can 3D "doodle" anything you like. Extremely easy to use, the kit comes with everything you need to get started, including three plastic refill packs, stencils, and maintenance tools. One of the almost 1,000 reviews reads, "This takes creativity to a whole new and different level. You lift your pen off the paper and go into the 3rd dimension. .. up!... I am a very happy customer, and very impressed with the quality of the product, how it flows, and looks."

.. up!... I am a very happy customer, and very impressed with the quality of the product, how it flows, and looks."

Specifications

Material: Plastic

Color: Black

Weight: 1 Pound

BUY NOW: US$59.99 (Was US$79.99), AmazonBest 3D Printers under US$200—Summary

The Anycubic Photon UV LCD 3D Printer tops our list for the best 3D printer under US$200 in 2022, and, with over 2,500 Amazon reviews, the Elegoo Mars UV photocuring 3D printer comes in at a close second. We hope our review of 3D printers has been helpful. For more 3D printers and other 3D printing suppliers, including 3D printer filaments suppliers, additive manufacturing suppliers, 3D photographic printing services, and 3D sand printing additive manufacturing, consult our additional guides or visit the Thomas Supplier Discovery Platform.

Other 3D Printing Articles

- Top 3D Printing Services Companies in the USA

- Origins of 3D Printing and Additive Manufacturing

- Overview of 3D Printing Technologies

- Top 3D Printing Manufacturers and Suppliers (Publicly Traded and Privately-Owned)

- Top Suppliers of Additive Manufacturing Consulting Services

- All About Material Jetting

- All About Multi Jet Modeling (MJM) 3D Printing

- All About Fused Deposition Modeling

- All About Stereolithography 3D Printing

- All About Photopolymerization

- All About Sheet Lamination/Laminated Object Manufacturing

- All About Electron Beam Additive Manufacturing

- All About Direct Energy Deposition 3D Printing

- All About Binder Jetting 3D Printing

- All About Powder Bed Fusion 3D Printing

- All About Direct Metal Laser Sintering 3D Printing

- All About Selective Laser Sintering 3D Printing

- All About Selective Laser Melting 3D Printing

- All About Selective Heat Sintering 3D Printing

- All About Digital Light Processing 3D Printing

- All About Continuous Liquid Interface Production

Other Best Product Articles

- The Best 3D Printers under $300

- The Best 3D Printing Software

- The Best 3D Printer Under $1000

- The Best 3D Printer Under $500

More from Custom Manufacturing & Fabricating

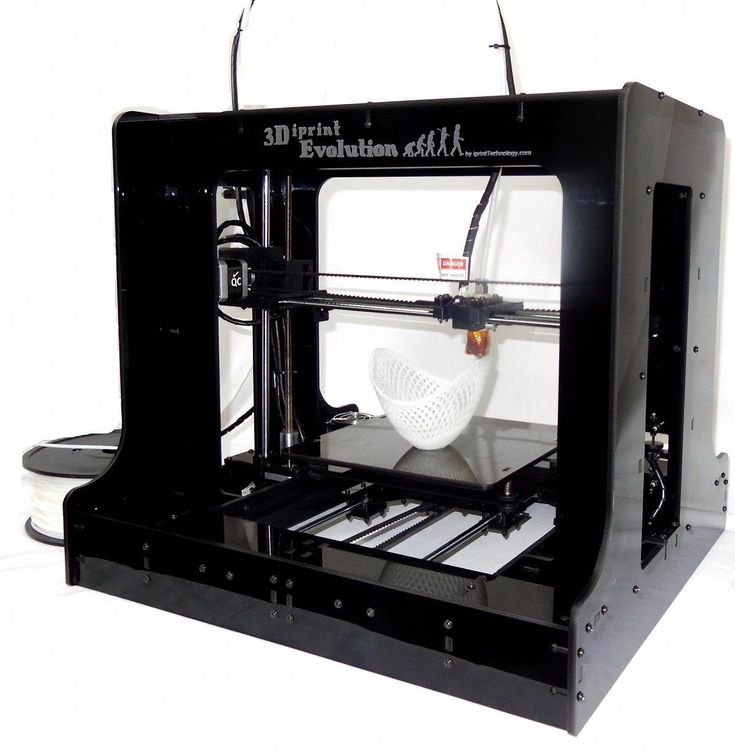

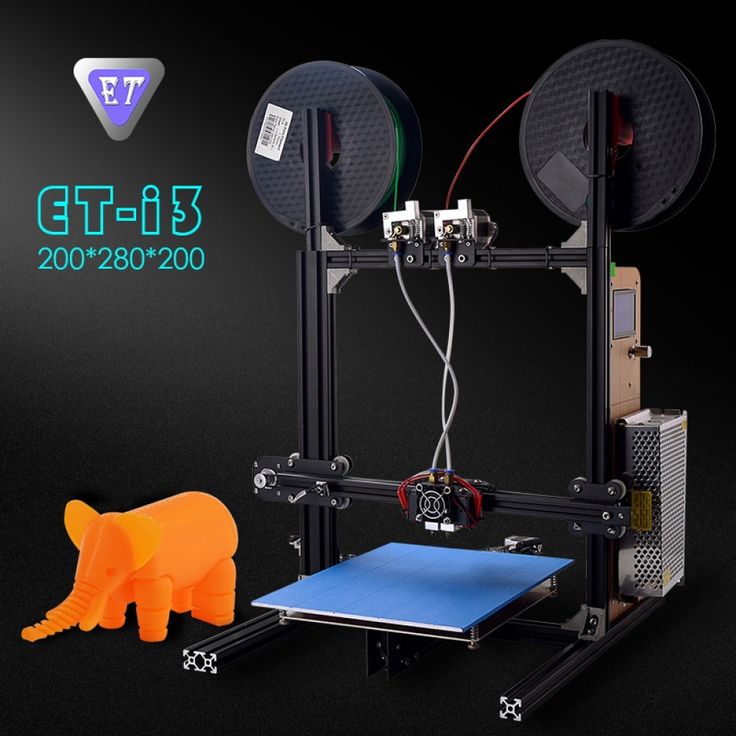

3D printer assembly kit vs self-assembly, which is cheaper? / 3D printers, machines and accessories / iXBT Live

3D printing and 3D printers have long been in use, from year to year the price of the printers themselves, components and consumables is falling lower and lower. Reading numerous forums where owners of eminent branded printers costing from 50,000 to 250,000 rubles complain about the same problems as with cheap self-assembly ones, I thought. If there is no difference, why pay more? I have already tested 2 ready-made sets of 3D printers from China in practice and I was very pleased with the quality. One interesting point remains, what comes out cheaper? Assemble yourself from components or buy one of the sets?

Reading numerous forums where owners of eminent branded printers costing from 50,000 to 250,000 rubles complain about the same problems as with cheap self-assembly ones, I thought. If there is no difference, why pay more? I have already tested 2 ready-made sets of 3D printers from China in practice and I was very pleased with the quality. One interesting point remains, what comes out cheaper? Assemble yourself from components or buy one of the sets?

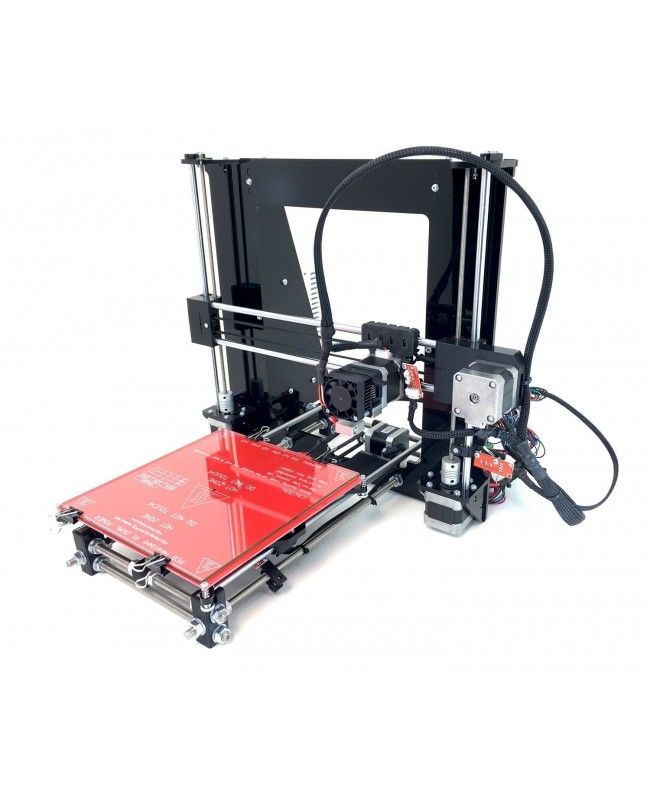

The photo shows my printer from the previous review - JG Aurora, dressed in a steel frame. In principle, I just replaced the frame and that's it, but the printer began to look much better. He didn’t get much better at typing, before that everything was in order, but it prompted me to certain thoughts. Why is it necessary to take sets with a brand, as if Chinese or European, and overpay them, albeit a little in the case of China, but still. And if you take components without a frame, and buy the frame already here in Russia? Wouldn't it come out cheaper?

I started looking for the cheapest 3D printer kit on a well-known site and found a suitable one for 8,700 rubles. about. The price already includes delivery.

about. The price already includes delivery.

Let's take a closer look at this set.

The basis of any 3D printer is the brain. The brains here are standard - Arduina Mega 2560 and the shield for it - Ramps 1.4.

In principle, this is a standard and most printers are assembled on this scheme. More expensive boards, such as MKS Gen or Base, are also based on the same Arduin.

The main thing here is to look at the Ramps for the presence of unsoldered places or, on the contrary, extra influxes, because of this, most often people have problems.

Next. I see in this set there is a four-line LCD2004 screen with a card reader. This is a very convenient addition, I have not used a 3D printer + computer for a year now. I throw a G-code for printing on a memory card and the printer prints offline.

The red scarf is an adapter for Ramps with leads for this screen, it is included in the kit, as well as wires for the screen.

Drivers, wires, limit switches. It's all there. Drivers are ordinary - DRV8825, limit switches on boards, wires without braid. Cheap and cheerful, but effective. Radiators were also put to the drivers. The motors here are also standard for most 3D printers, these are NEMA17 stepper motors.

It's all there. Drivers are ordinary - DRV8825, limit switches on boards, wires without braid. Cheap and cheerful, but effective. Radiators were also put to the drivers. The motors here are also standard for most 3D printers, these are NEMA17 stepper motors.

Also in the set there is a heating element for the table - MK2A board on a textolite basis. For me, this is a more successful heater than the MK3 version, which is integrated on an aluminum plate. The fact is that I print on glass and I don’t need an additional layer between the glass and the heater. MK2 will heat up faster.

And the crown of this set is the E3D version 5 clone print head. The head comes assembled with a heating element and a thermistor. The only thing missing is a pushing mechanism for plastic - an extruder. And since there are 5 motors here, it means that only a small part of the extruder is needed. Under this element, a Bowden-type extruder is required, which means the plastic will be fed through a PTFE tube to a heated nozzle. I don’t see a PTFE tube in the picture, although the seller writes that it is included, perhaps he means a small Teflon tube inside the thermal barrier.

I don’t see a PTFE tube in the picture, although the seller writes that it is included, perhaps he means a small Teflon tube inside the thermal barrier.

Now what is missing in the set.

Well, the main missing piece is the frame. I bought 2 types of steel frames from Nioz and Soberistanok. The Nioz is easier to assemble and doesn't require any printed parts, but there are no bolts included. The assembler puts bolts in the kit, but the frame itself uses a few printed elements, without a printer, which are not so easy to get. Both frames are cut in Chelyabinsk and at a price of about 3000-3500 rubles. without painting and weight 3-5 kg. delivered by a transport company. For delivery from Chelyabinsk to Moscow, I paid a little less than 600 rubles for the frame.

The cost of the frame 3800 + delivery is 4400 rubles.

In addition to the frame, shafts, bearings, trapezoidal or conventional screws and belt spools must be added.

Shafts, like the frame, are better to take from us in Russia, they come out cheaper than on Aliexpress. For example, a set of shafts for a given frame from the same Nioz will be 1380r.

For example, a set of shafts for a given frame from the same Nioz will be 1380r.

Trapezoidal screws with a nut on Ali are almost 2 times cheaper and come out at about 800r per pair.

Only a Bowden extruder and a pair of belted spools need to be added.

The extruder is also better to take on Ali: Bowden Extruder - 600 rubles.

There is already a motor mount to the frame and a good hardened steel gear with fine teeth is used.

GT-2 belt can be taken from the same seller: GT-2 belt — 200 rubles, especially since it already has 2 spools.

Bearings - 400 rubles for 12 pieces, which is quite enough.

And you also need to add a power supply, this is about 1400r.

Total comes out to about 17900r.

All that remains is to upload the Marlin firmware to the board via the Arduino IDE and adjust the parameters for your printer. It is convenient to substitute the necessary parameters into the firmware using a calculator, for example this one: http://prusaprinters. org/calculator/

org/calculator/

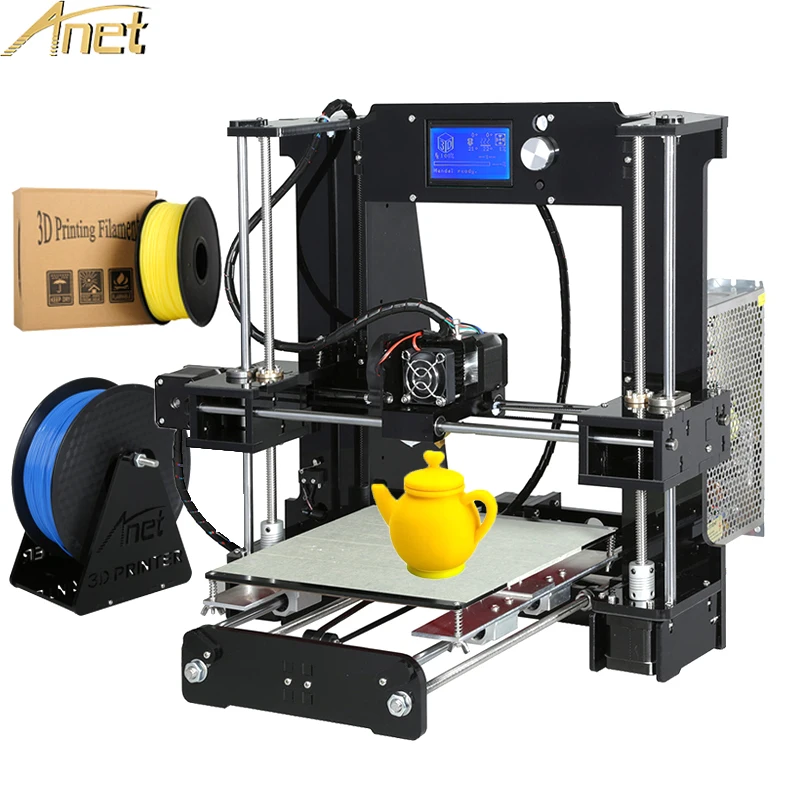

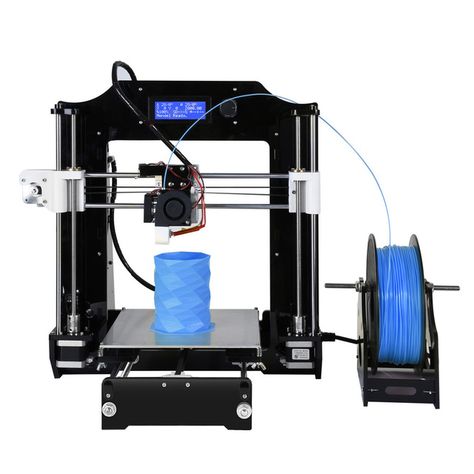

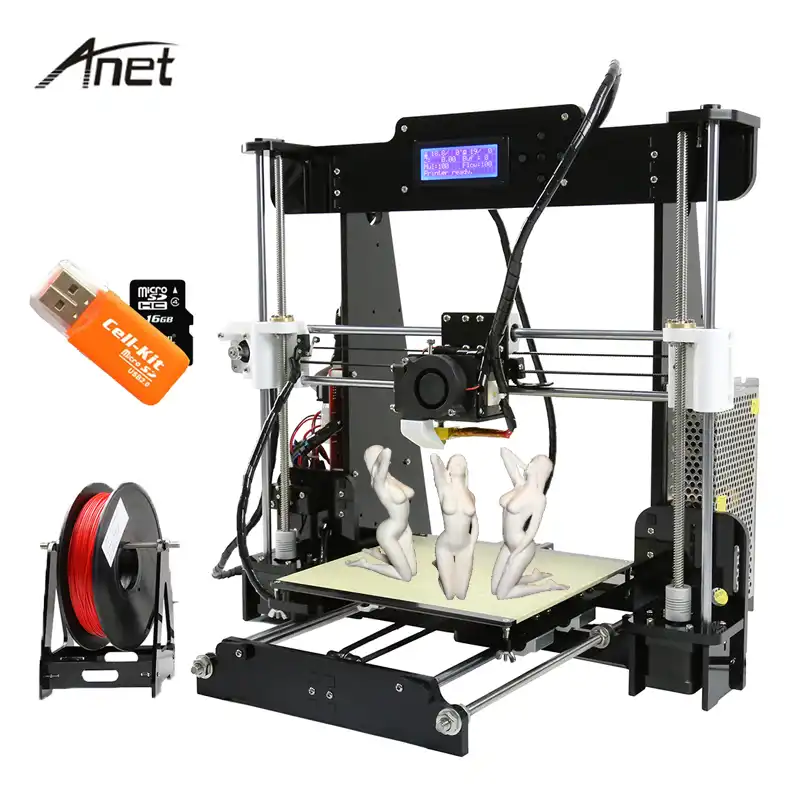

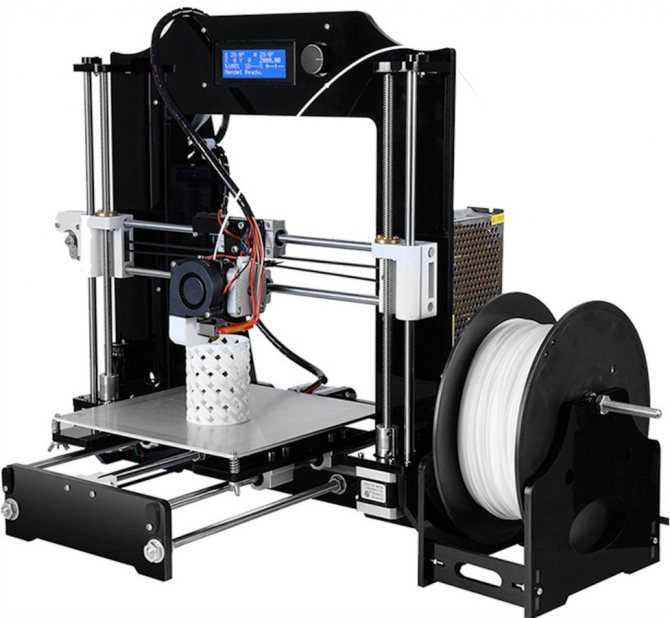

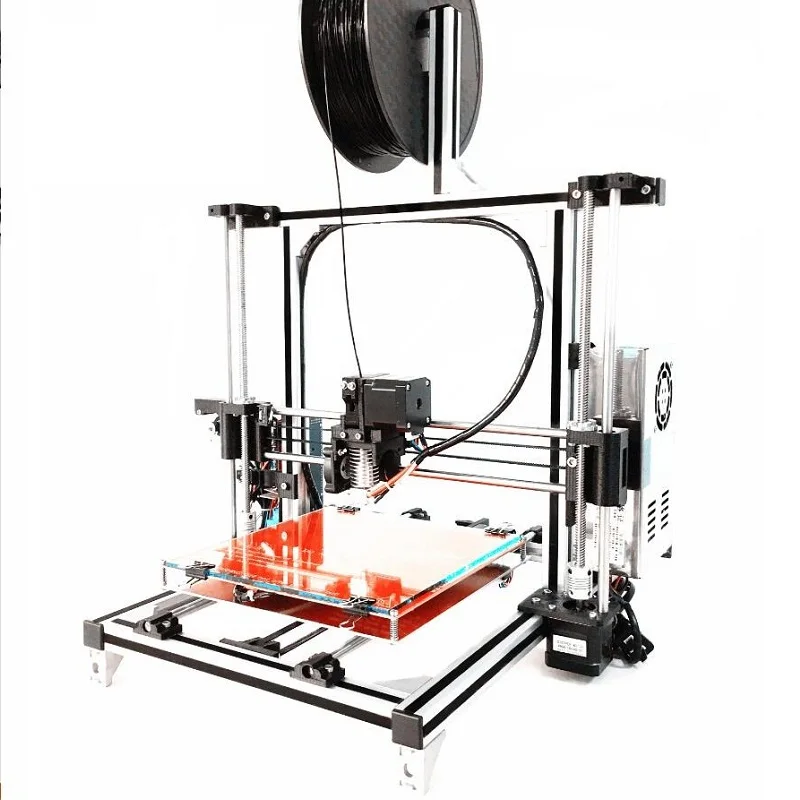

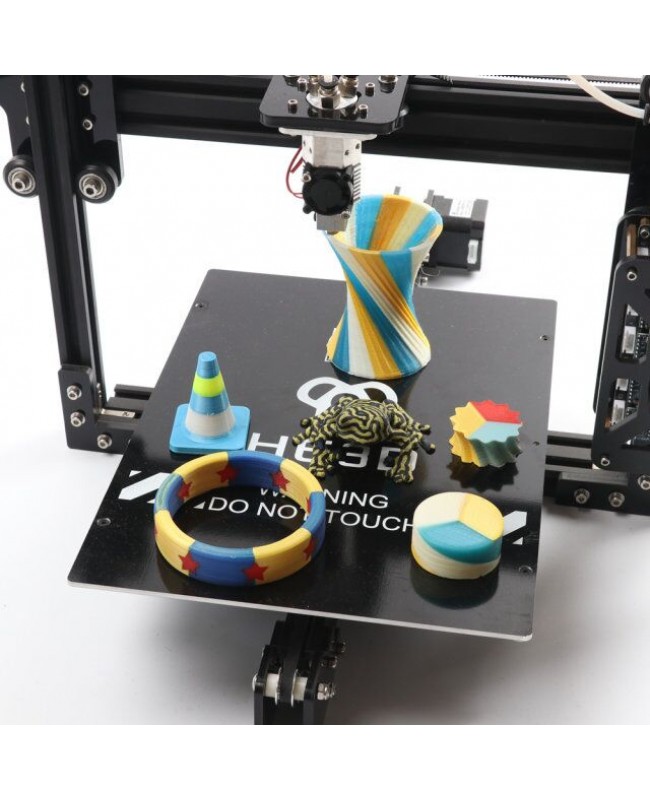

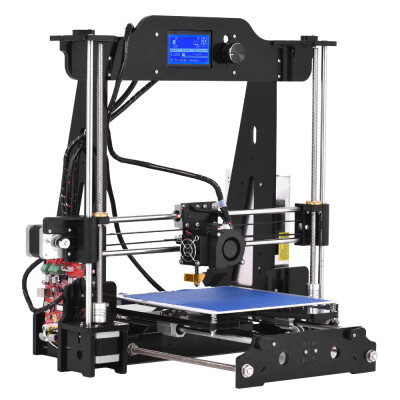

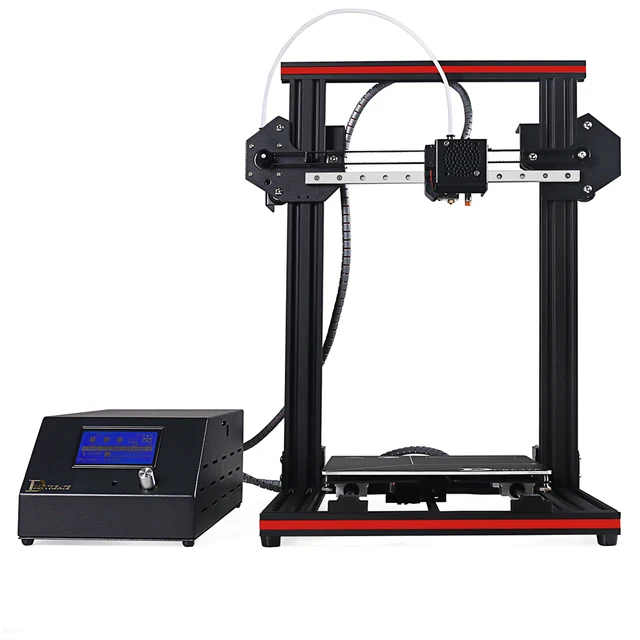

Now consider the assembly kit, for example the cheapest one - Annet A6.

According to the link, the manufacturer is listed as Infitary, but this is definitely a clone of the rather popular Annet A6, possibly with some modifications.

Let's compare it with the set above. There are already trapezoidal screws and even with aluminum dampers. A more expensive Direct-type extruder is installed and already with blowing, which has a positive effect when printing with PLA or HIPS plastics.

Heating table is more expensive - MK3, although MK2 is more attractive for me. The control board is not a sandwich from Mega + Ramps, but something more impressive, there is no board name in the description, but everything looks in order, it resembles something from the MKS line.

There is also a screen 2004 with a card reader and additionally there is a stand for a reel with plastic.

The price for such a set of 3D printer is about 14200r.

That is, it turns out a difference of about 4000 rubles. Which just matches the steel frame. And printers with a steel frame are already being sold for 25,000 rubles, for example, in the same Chelyabinsk.

In principle, I suspected that taking a 3D printer kit from the Chinese is about the same as assembling it yourself in parts, only in the kit everything is already set up and fits together, and in a self-assembly printer you will also have to figure out what to connect and tinker with firmware.

Another option to get an inexpensive 3D printer remains - buying on Avito, etc. through ads, but here you need to monitor message boards more often in search of good offers, and even then, you can end up with a problem copy.

News

Publications

As usual, winter came unexpectedly. Snow closed the road and the road services did not start the fight against it in time. While driving, the resulting snow slush in the wheel arches became. ..

..

This Ugreen stand is designed primarily for large gaming laptops. The stand is equipped with a 20 cm fan, RGB lighting and four levels of adjustment...

Nowadays, more and more An elementary marketing campaign is gaining popularity among banks - to encourage customers to receive new cards with a simple and banal distribution of money. Actually, because...

Floodlights should be used to illuminate the working area and work objects. In this case, the spotlight PHOTON FL-30W6K65-PIR has an adjustable motion sensor that allows... ...

Repair is easy to start and almost impossible finish. So this time we will talk about another tool that I happened to use it when repairing an apartment, namely, about a drill-driver Bort...

A small guide for choosing a 3D printer for beginners / Sudo Null IT News

The reason for writing this article was the article “ I wanted to buy an inexpensive 3D printer, but I looked at YouTube and got sick of ”, at the end of which the author asks to answer a few questions. I will try to answer from the point of view of my seven years of experience as a 3D modeler and 3D printer. First, a few caveats.

I will try to answer from the point of view of my seven years of experience as a 3D modeler and 3D printer. First, a few caveats.

This article will not contain advice: “Buy a printer from manufacturer X - it is good, but do not take manufacturer Y in any case”, only general recommendations.

Informal classification of printers, adopted in the domestic segment of printers.

Everything written is based on the personal experience of the author and is his personal opinion.

If these warnings do not scare you - welcome under cat.

First, let me introduce myself: my name is Maxim and I bought the first printer back in 2013. It was a Chinese clone of Makerbot 2 with the hilarious name "Migce Cuble".

Photo from the personal archive There was almost no information on 3D printing on RuNet, only one topic on the “Roboforum” and several scattered articles about what a cool thing it is - 3D printing, so to master it I had to google a lot in English, come up with their crutches and delve deeply into the physics and technology of the printer. We must pay tribute, in the English-speaking segment, then there was an active development of this technology and interesting articles such as “Selection of the type of notches of the extruder feed gear for a specific type of plastic” or “Determination of the optimal printing temperature using a strain gauge installed on the extruder” came across. Since then, 7 years have passed. I managed to master modeling, assemble a printer from scratch, be a moderator of “3D Today” for a while, work as a freelancer in the field of modeling and printing, organize a prototyping circle for children and bring it to the Russian level. Recent achievements: volunteered as a coordinator for the supply of plastic in the project “ Anti covid makers ”. A lot has changed during this time, including printers in my home zoo. One thing has remained unchanged - the question: "What should I buy as my first printer?".

We must pay tribute, in the English-speaking segment, then there was an active development of this technology and interesting articles such as “Selection of the type of notches of the extruder feed gear for a specific type of plastic” or “Determination of the optimal printing temperature using a strain gauge installed on the extruder” came across. Since then, 7 years have passed. I managed to master modeling, assemble a printer from scratch, be a moderator of “3D Today” for a while, work as a freelancer in the field of modeling and printing, organize a prototyping circle for children and bring it to the Russian level. Recent achievements: volunteered as a coordinator for the supply of plastic in the project “ Anti covid makers ”. A lot has changed during this time, including printers in my home zoo. One thing has remained unchanged - the question: "What should I buy as my first printer?".

Currently, two types of printers are mainly used at home: printing using FDM (FFF) technology - layer-by-layer plastic fusion, fed in the form of a rod and SLA (LCD) - printing with a photocuring polymer. FDM technology is more common, due to the lower cost of equipment and consumables, but in recent years, the prices of LCD printers and printing resins have decreased significantly and photopolymer printing has almost caught up with FDM printing in terms of cost and entry level.

FDM technology is more common, due to the lower cost of equipment and consumables, but in recent years, the prices of LCD printers and printing resins have decreased significantly and photopolymer printing has almost caught up with FDM printing in terms of cost and entry level.

To be honest, I almost never did SLA printing and I still don't have an LCD printer in my home zoo (but it may appear soon), so I'll talk mainly about FDM printers. They can be divided into 3 main categories according to the type of mechanics:

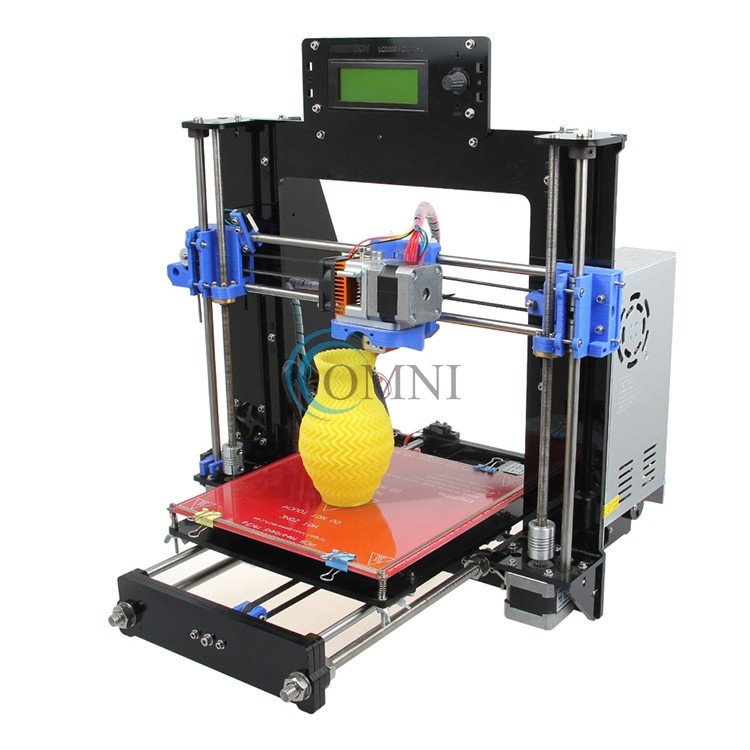

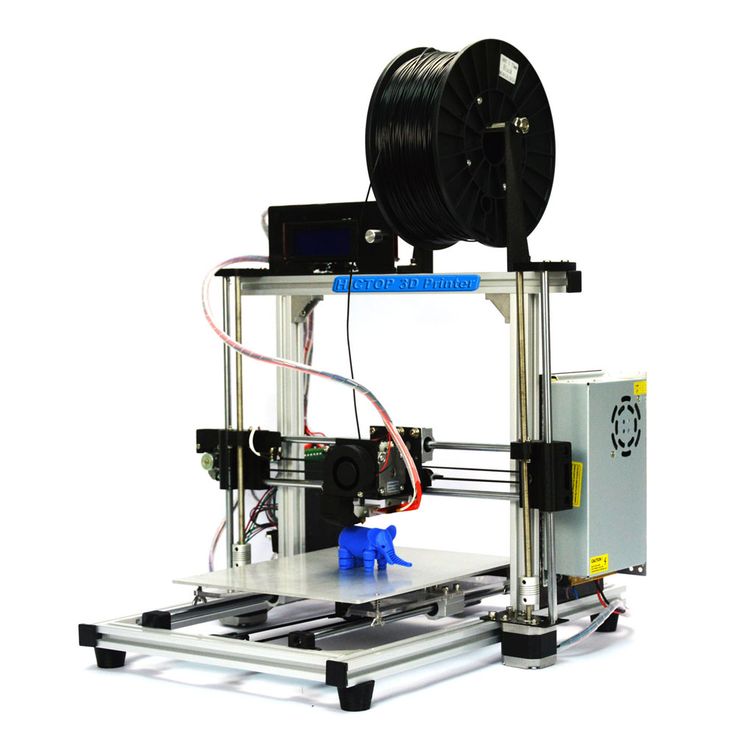

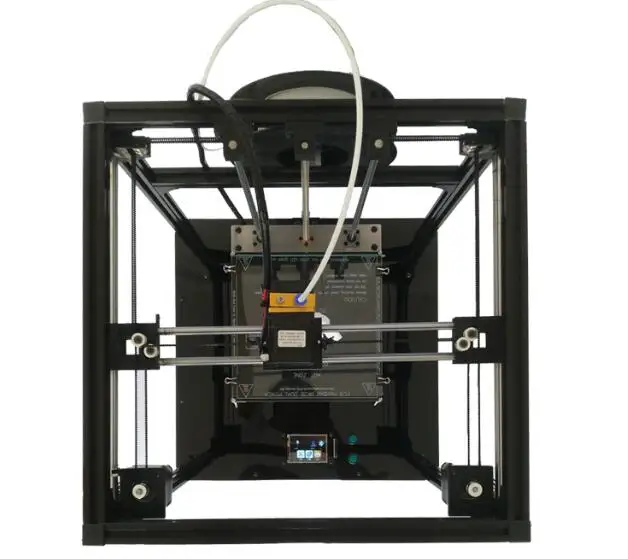

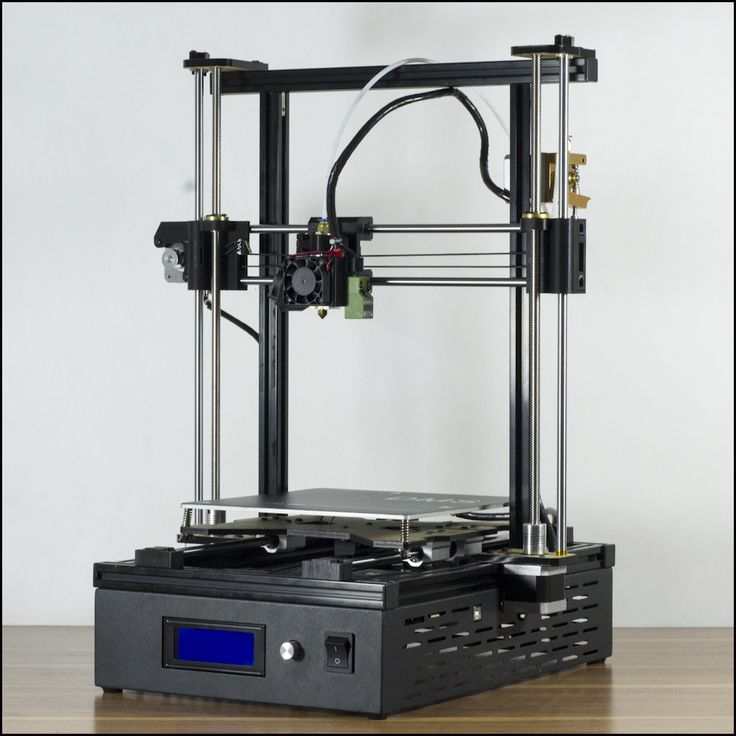

Drygostables - printers with a table movable horizontally. Perhaps the most common printer model. It is distinguished by low cost of components, ease of assembly and adjustment, for which it is loved by the Chinese and printers. The disadvantages include the difficulty of creating a closed body and printing thin, tall parts that begin to wobble as the height increases, especially if the part is printed from flexible plastic such as TPU.

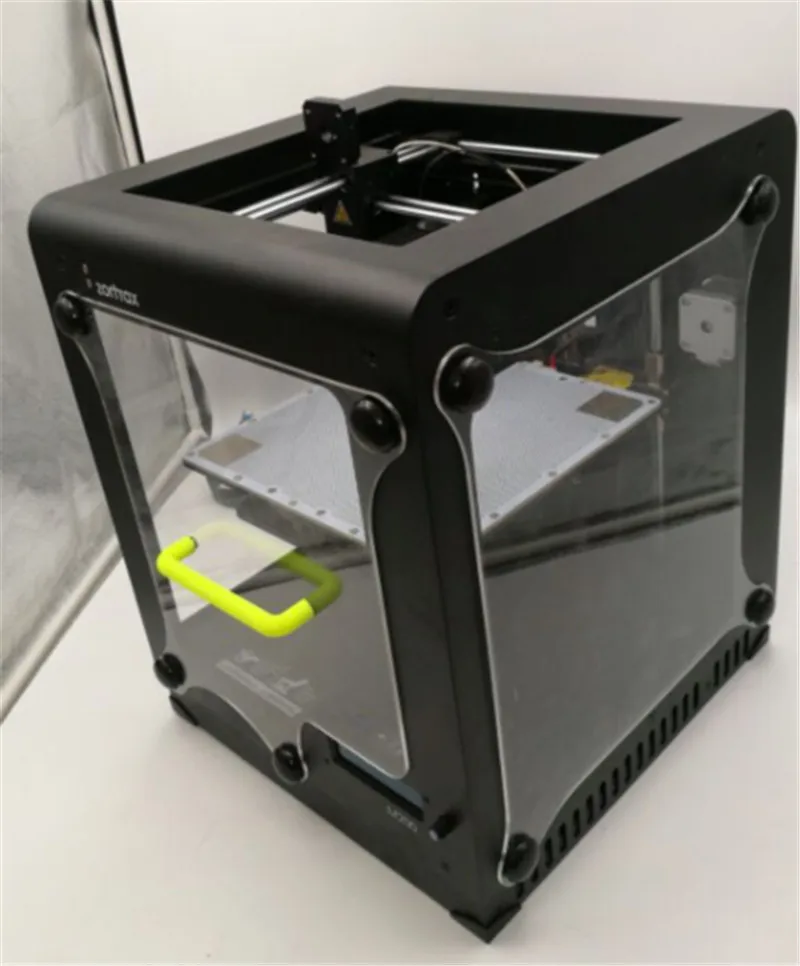

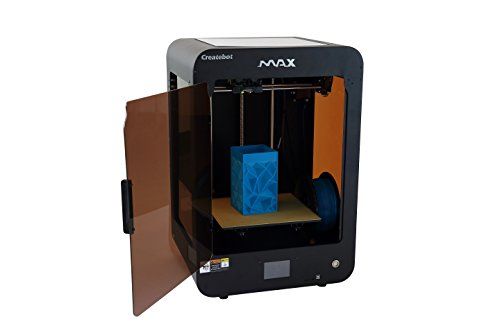

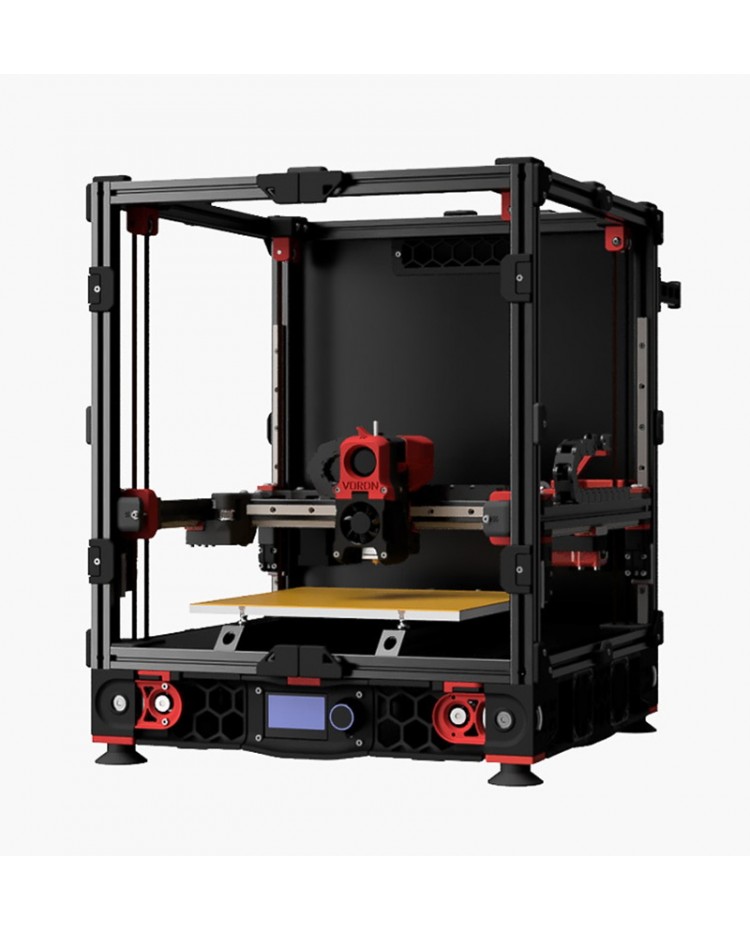

Cubes - printers in which the table travels vertically. The cost of such printers is higher, as are the requirements for straightness of hands during assembly and setup. But a properly designed die delivers faster print speeds while maintaining print quality. At the same time, the design of the printer is very easy to make closed, which allows printing with engineering plastics such as ABS and Nylon. This type of design is often used in semi-industrial and industrial grade printers. Some manufacturers manage to shove the drygost into the body of the cube, but this does not bring any special advantages for printers.

Typical cubes Delta - printers with the so-called delta kinematics, when the print head is attached to carriages moving along vertical guides using a system of rods. The cost of the mechanics of such printers is comparable to the cost of dry-tables. Can print at very high speeds. But they are very demanding on the correctness of keeping the dimensions, the straightness of the hands during assembly and adjustment, and the speed of the “brains” due to the complex mathematical calculations of the trajectory of the head movement.

Strongly not recommended as a first printer, although the widespread use of the table level sensor somewhat reduces the requirements for straight hands during setup and operation.

Typical deltasBy availability on the market, 3 main categories can also be distinguished:

Chinese (cheap Chinese printers) are almost always designers, even if they come assembled.

-

The advantages include low cost, wide distribution and uniformity, which allows you to buy failed parts in the nearest radio shop or on well-known Chinese sites. Popular models gather around a relatively large number of users who actively share their experience in the field of self-repair and improvement of this type of printer. The most popular models will most likely be printed right out of the box, but will require improvements during more or less long-term operation.

-

The downsides include the quality of the components/assembly and the need to refine these printers to obtain acceptable print quality/speed.

It is recommended to take models that have already formed a large community around them. This means that most of the shortcomings have already been identified and there are standard inexpensive methods to solve them.

It is recommended to take models that have already formed a large community around them. This means that most of the shortcomings have already been identified and there are standard inexpensive methods to solve them.

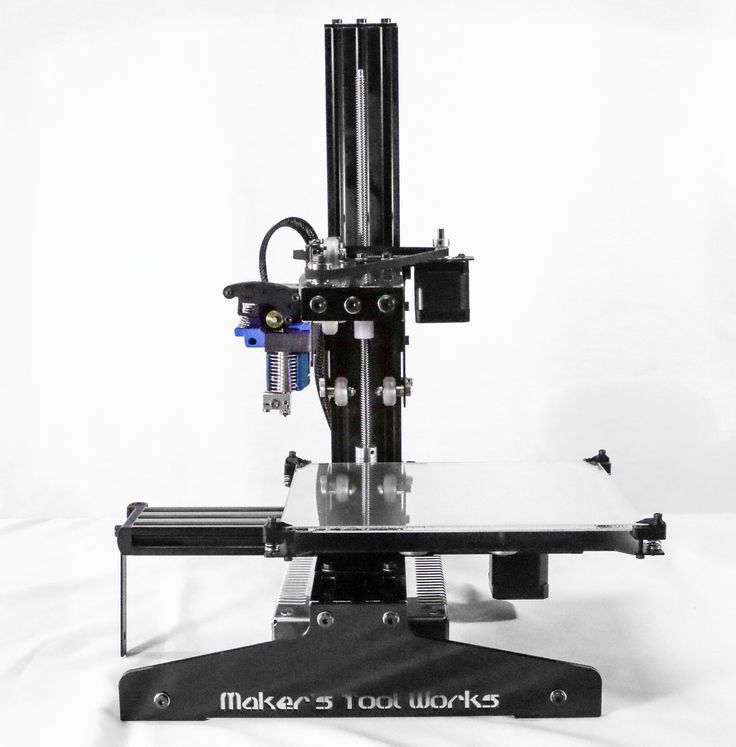

Kits (assembly kits, mainly domestic production) - google for the words “ ZAV ”, “ UlTi ”, “ UlTi ”, etc. Usually they are a set for assembling a plywood cube. Recently, options with metal cases have appeared. Supplied in different versions - from a kit for building a case with printed parts, ending with completely finished assembled products.

-

The pluses include a fairly good engineering study, the ability to choose the components for the mechanical and electronic parts and make the printer completely to your requirements. With good components, they provide fast, stable and high-quality printing. The price is somewhat more expensive than Chinese printers, but cheaper than semi-professional printers of domestic or European / American manufacturers.

-

The disadvantages include a decent amount of time spent on assembly and waiting for components if you decide to save money and order these components yourself from different sellers and assemble a printer from them. When assembling, direct hands are required.

Factory Printers (domestic or American/European semi-professional printers). There are a lot of models, the designs are very different.

-

The advantage of this class of printers is printing with acceptable quality out of the box. In addition, you get operational reliability and warranty support from the manufacturer.

-

The main disadvantage is the price. It is often not clear what factors it depends on. You can buy a high-quality printer relatively inexpensively, or you can take something incomprehensible for a high price. The second disadvantage is the presence of specific solutions that are incompatible with popular solutions on the market: these can be nozzles with their own thread pitch, special fans, electronics, belts, and even slicers.

Some are demanding on the quality of plastic, there are models that work only on chipped coils.

Some are demanding on the quality of plastic, there are models that work only on chipped coils.

Now that we have decided on the classification of printers, we can proceed to the procedure for choosing a printer for yourself, your loved one. If you are on fire with the purchase of a 3D printer, first decide what you are going to take it for, the type and configuration of the printer depends on it. Let's analyze several typical situations:

I want to do something for myself and my family - if you don't plan to print products from engineering plastics that can withstand decent loads and temperatures, a Chinese drygostol or a cube will suffice. If you have a budget and want to figure out how the printer works before starting, and not during printing, you can look in the direction of domestic assembly kits - with them you can get the best quality and painlessly switch to engineering plastics.

I can't do anything with my hands, but I have to. Therefore, I want a printer that will do everything for me - in this case it is better to look at semi-professional printers. If the budget is not enough, you can look at used ones or order an assembly of a domestic set - usually manufacturers offer this service through intermediaries. When ordering an assembly - look for experience and positive reviews, there are nuances.

Therefore, I want a printer that will do everything for me - in this case it is better to look at semi-professional printers. If the budget is not enough, you can look at used ones or order an assembly of a domestic set - usually manufacturers offer this service through intermediaries. When ordering an assembly - look for experience and positive reviews, there are nuances.

I want to print for sale - a farm of the same type of printers, depending on the budget. If there is no budget, but there are resources for regular tuning / repair - you can even from Chinese drygosts. Additionally - a printer with a large print area, a printer with a closed case and a heated table for printing engineering plastics, an SLA / LCD printer for printing products with a high degree of detail.

Whether at work or at home, the need arises to design and print enclosures and parts. If only small prototypes are planned - an LCD printer, if functional products - a closed cube with the ability to print with engineering plastics.

Kids are growing up and this is the technology of the future, I want you to master - see what printers are used in prototyping competitions in your area. Take the same one. May be used.

I want to make figurines for desktops, beautiful little things for home - LCD printer.

I want to figure out what kind of technology and how it works in general - a kit for assembling a domestic manufacturer. By the time you collect it, you will understand.

There is no money at all, but I want to print, I will collect it myself from scratch - it will turn out better and cheaper than the Chinese. Strange as it may seem, no. The cost of components with Ali will be more expensive than a printer with Ali. Of course, if there is a machine park, the ability to use it, a set of iron, shafts and electronics lying around in the corner of the workshop, it can burn out. There are options for building printers from boards and furniture rails, but their print quality is, to put it mildly, lame. For example, the construction of the printer shown below cost its author 80-9, according to him.0 dollars.

For example, the construction of the printer shown below cost its author 80-9, according to him.0 dollars.

If you want to completely build your printer from scratch, then it's better to treat this as a separate hobby and accept that it will not turn out very cheap. Well, or look in the direction of used printers.

I don’t know why I need a printer, but I want to try - a Chinese or a domestic assembly kit. Can be used. If it doesn't work, you can always resell.

Decided on the type of printer - what to look for first of all when buying ?

-

Firstly, on the rigidity of the structure - the accuracy and speed of printing depend on it. It is in the direction of strengthening the rigidity that your first modifications of the Chinese printer will be directed, since the material “steel plasticine 3 (c)” is considered an unaffordable luxury for the Chinese. In the case of the purchase of domestic kits, the situation is slightly better.

-

Secondly - if the printer will be in the apartment - "silent" drivers for stepper motors. 3D printing is not a fast process, and having a constant loud enough buzzer under your ear is annoying.

-

Third - the presence of a heated table and ease of modification to a closed case. Over time, the desire (need) to print ABS will come, and it is problematic to do this on an open drygost.

-

Fourthly, the presence of a good plastic blowing system is also important.

-

Fifthly, when choosing printers with CoreXY, H-Bot or Delta mechanics, it is highly desirable to have a 32-bit control board, or you will encounter fading (freezes) at high print speeds.

-

In the sixth, seventh, etc. - there are many nuances in the design of printers. If something is unclear, feel free to ask the community.

In any case, if you are going to buy or have already bought a 3D printer, start learning some 3D editor.