Mid range 3d printer

The Best Cheap 3D Printers for 2022

While we'd hesitate to call 3D printing a mature technology, you might say it has reached its teenage years. Through their first decade-and-change, 3D printers have come down in price, grown easier to set up and operate, and become more reliable. And you may pay less than you expect: Many once-high-end features have migrated down to inexpensive models.

PC Labs has been reviewing 3D printers since 2013. Today, the state of 3D printing is strong, but that wasn’t always the case. For the first several years, it was often an adventure getting one of these printers up and running, let alone successfully through our testing regimen. Issues with filament-based—aka fused filament fabrication (FFF) or fused deposition modeling (FDM)—printers were abundant.

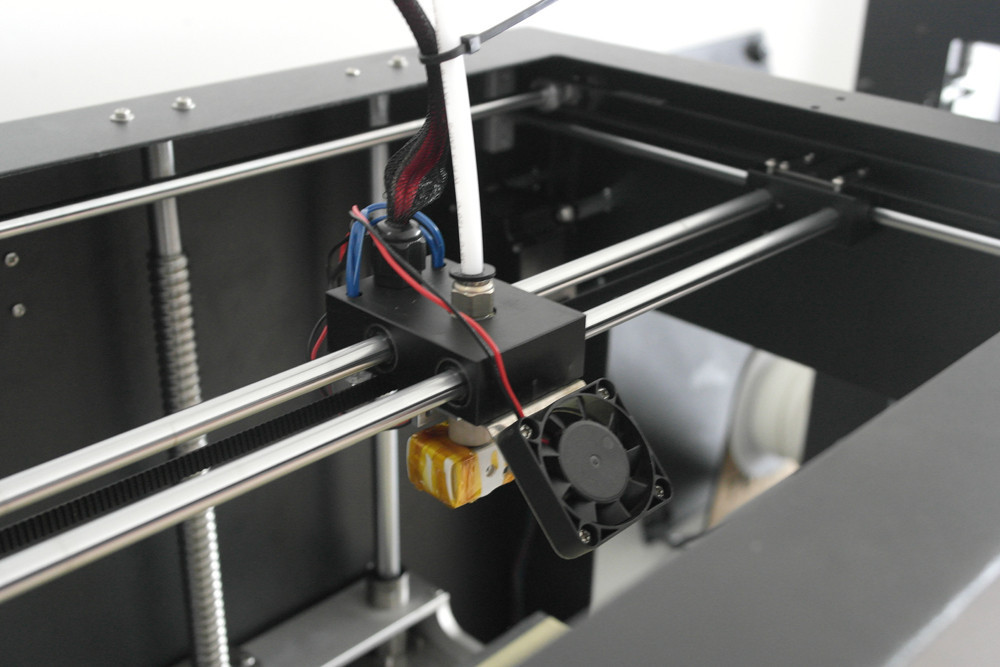

Filament feeders had to be coaxed into delivering filament from the spool to the extruder. Print beds had to be manually aligned. The extruder or hot end had to be positioned just right to minimize the gap between the nozzle and the build plate (the flat surface on which the object is printed). Objects frequently stuck to the build plate, and required careful, sometimes unsuccessful, efforts to pry them off. These and other issues required painstaking effort to resolve, often combined with calls to tech support.

Not so much anymore. While they can still be rebellious at times, 3D printers have grown up a lot, and achieving the 3D printer basics has gotten a lot less likely to end in a shouting match over small things. And they've gotten a lot more affordable, too, for curious DIY-ers and hobbyists to try.

If you're in the market for a beginner or low-cost 3D printer, it's important to know how lower-end models differ. Read on for mini-reviews of the top budget 3D printers we've tested. After that, we go into more detail on understanding the 3D printer specs and tech relevant to beginning buyers. Ready to take the plunge? Read on.

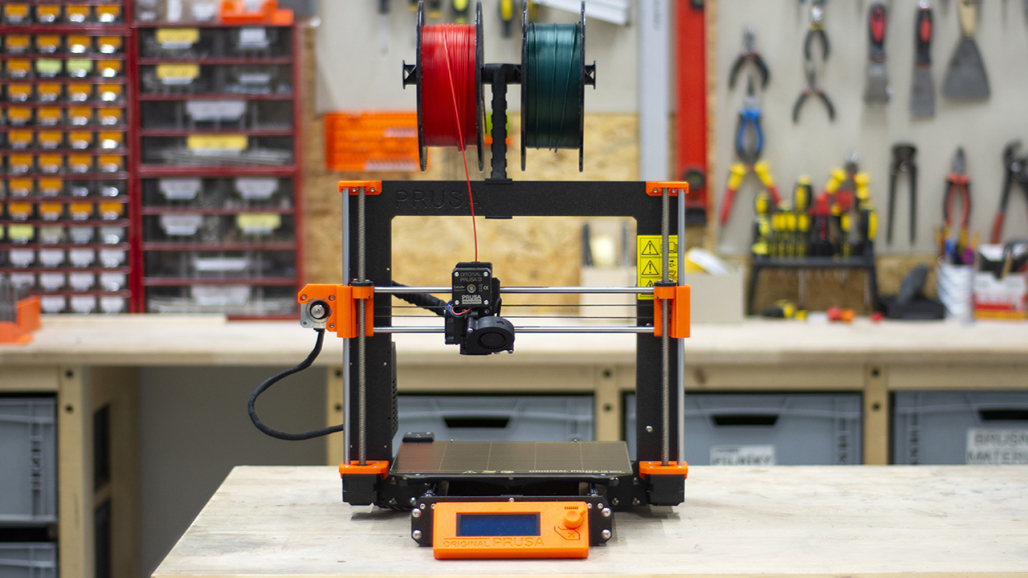

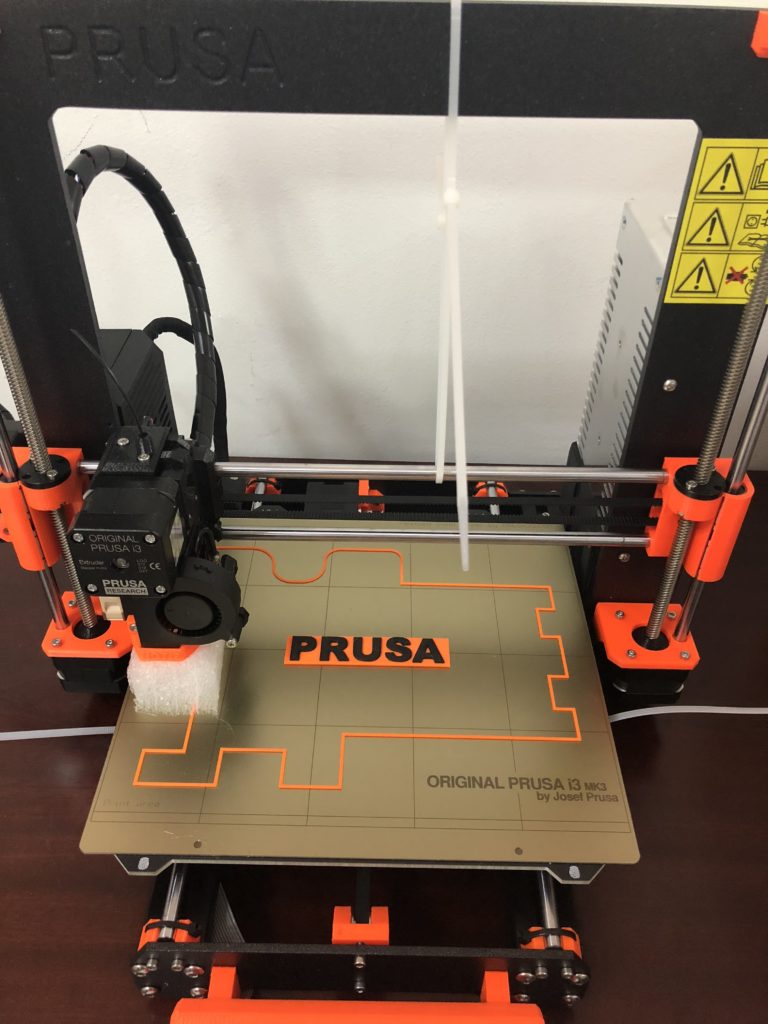

Original Prusa Mini

Best Overall Budget 3D Printer

4.5 Outstanding

Bottom Line:

It requires assembly and calibration care (plus shipping from the Czech Republic), but the Original Prusa Mini is a compact, open-frame 3D printer that consistently produces superb-quality output for a great price.

PROS

- Top-notch object quality

- Supports a variety of filament types

- Useful, professionally printed user guide

- Great support resources

- Versatile, user-friendly software

CONS

- First-layer calibration can be tricky

- Only includes starter packets of filament

- Requires monitoring if young children or pets are around

| Sold By | List Price | Price | |

|---|---|---|---|

| Prusa Research | $399.00 | $399.00 | See It (Opens in a new window) |

Read Our Original Prusa Mini Review

XYZprinting da Vinci Mini

Best Budget 3D Printer for Schools, Community Centers

4.0 Excellent

Bottom Line:

The XYZprinting da Vinci Mini is a consumer-oriented 3D printer that provides a winning combination of low price, ease of setup and use, solid print quality, and smooth, misprint-free operation.

PROS

- Very low price.

- Reasonably priced filament.

- Good print quality.

- No misprints in testing.

- Easy setup and operation.

- Quiet.

- Prints over a USB or Wi-Fi connection.

CONS

- Occasional problems in trying to launch prints.

- Removing printed objects from the print bed is sometimes tricky.

| Sold By | List Price | Price | |

|---|---|---|---|

| Walmart | $199.95 | $199.95 | See It (Opens in a new window) |

| Amazon | $199.95 | $199.95 | See It (Opens in a new window) |

Read Our XYZprinting da Vinci Mini Review

Toybox 3D Printer

Best Budget 3D Printer for Children

4.0 Excellent

Bottom Line:

The Toybox 3D Printer works well as a model designed for children, offering reliable printing from a browser or mobile device and a few thousand toys to print, plus creative options to output drawings or photos. Just bear in mind the tiny build area.

Just bear in mind the tiny build area.

PROS

- Reliable, misprint-free printing

- Easy setup

- One-touch operation

- Well-composed help resources

- Access to more than 2,000 printable toys and projects

- Lets you create your own printable designs

CONS

- Tiny build area

- Not ideal for importing 3D files created elsewhere

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $299.00 | $299.00 | See It (Opens in a new window) |

| Toybox Labs | $379.00 | $299.00 | See It (Opens in a new window) |

Read Our Toybox 3D Printer Review

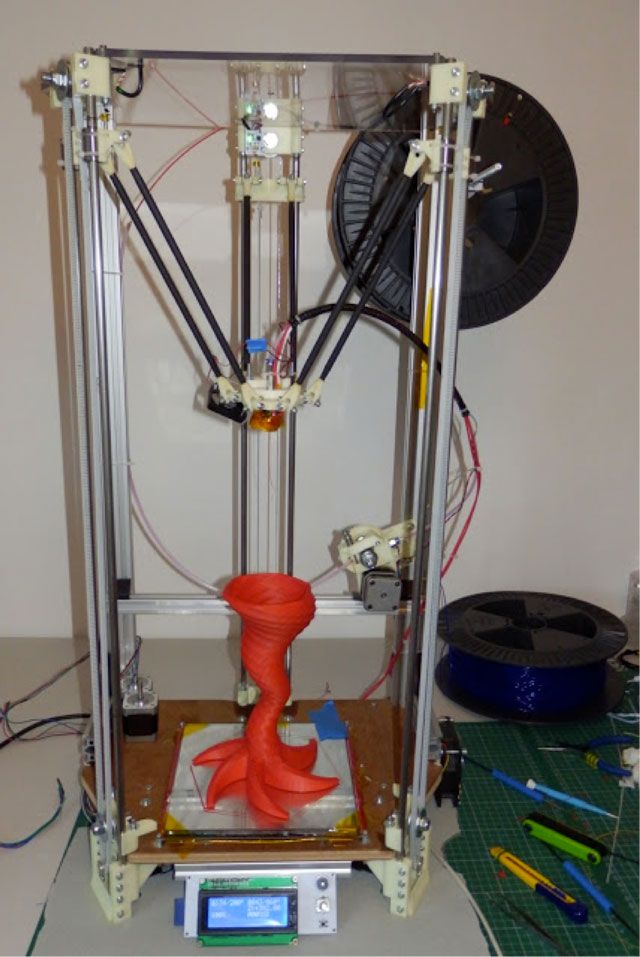

Monoprice Mini Delta V2 3D Printer

Best Budget 3D Printer for Beginners, Non-Techies

4.0 Excellent

Bottom Line:

3D printing gurus will be intrigued by the Monoprice Mini Delta V2's use of the delta rather than Cartesian coordinate system, but beginners will just enjoy its low price, ease of use, and speedy printing.

PROS

- Sub-$200 price

- Quick, nearly misprint-free printing

- Easy setup and operation

- Sturdy steel-and-aluminum frame

- Supports multiple filament types

CONS

- Tiny build area

- So-so print quality

- Mere one-year warranty

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $179.99 | $179.99 | See It (Opens in a new window) |

Read Our Monoprice Mini Delta V2 3D Printer Review

Anycubic i3 Mega S

Best Budget 3D Printer With an Open Design, Big Build Area

3.5 Good

Bottom Line:

The Anycubic i3 Mega S, an inexpensive open-frame 3D printer, produced decent-quality prints in our testing. To get the most out of it, though, may require precise calibration.

PROS

- Modestly priced

- Large build area for an inexpensive printer

- Supports a variety of filament types

- Generally solid print quality

- Uses well-known Cura software

CONS

- Finicky print-platform alignment

- Supported coils of filament are small

- Poorly placed spool holder

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $229./91f3dfd02cdc286.s.siteapi.org/img/353ea9928d2283b0b7f1f3b4b8f8864c90a6b903.jpg) 98 98 | $229.98 | Check Stock (Opens in a new window) |

Read Our Anycubic i3 Mega S Review

Anycubic Vyper

Best Budget 3D Printer for the Biggest Build Area Possible

3.5 Good

Bottom Line:

Anycubic's modestly priced Vyper whips up large 3D prints on its open-frame design, and provides automatic print-bed leveling. Just know that some minor assembly is required—and printed objects may require a bit of cleanup.

PROS

- Relatively large build area

- Automatic bed leveling

- Simple assembly

CONS

- Short (one-year) warranty

- Includes only a small starter filament coil

- Using Cura software with the Vyper requires tweaking a couple of settings

- Test prints showed some "hairy" filament residue

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $429. 99 99 | $429.99 | See It (Opens in a new window) |

| AnyCubic | $369.00 | $319.00 | See It (Opens in a new window) |

Read Our Anycubic Vyper Review

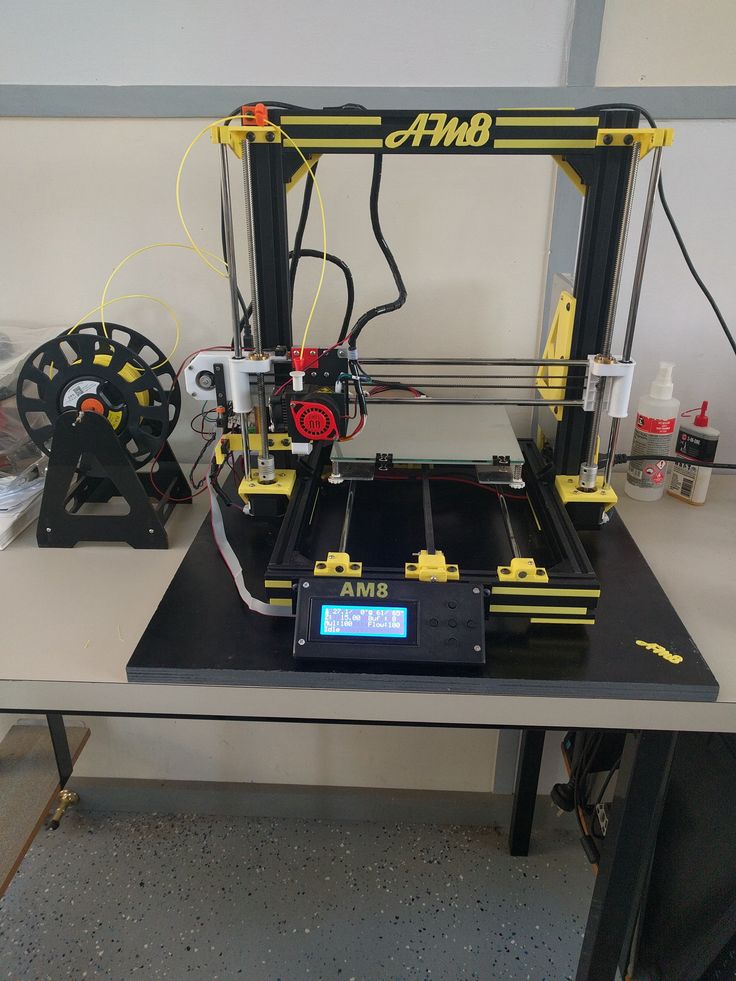

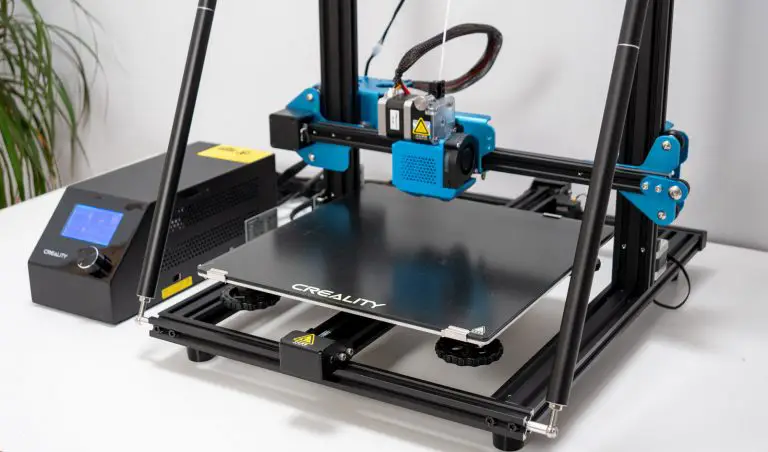

Creality Ender-3 V2

Best Budget 3D Printer for Tinkerers and DIY Types

3.5 Good

Bottom Line:

Hands-on tweaking defines Creality's budget-price Ender-3 V2, an open-frame 3D printer that you build from a kit. It produces generally above-par prints, but its print bed can be tricky to keep leveled.

PROS

- Inexpensive

- Slightly above-average print quality

- Good-size build area for its price

- Supports several filament types

CONS

- Manual print-bed leveling can be tricky

- Setup instructions could be deeper, more legible

- Questionable quality control on some parts

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $299. 00 00 | $246.00 | See It (Opens in a new window) |

Read Our Creality Ender-3 V2 Review

Flashforge Finder 3D Printer

Best 3D Printer for the Very Tightest Budgets

3.5 Good

Bottom Line:

The Flashforge Finder 3D Printer is moderately priced and offers good print quality, but it proved tricky to get up and running in our tests.

PROS

- Quiet.

- Good print quality.

- Connects via USB 2.0 cable, USB thumb drive, or Wi-Fi.

- Reasonably priced.

CONS

- Some objects pulled off the platform during testing.

- Poor documentation.

- Modest build volume.

- Limited to printing with polylactic acid filament (PLA).

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $729.00 | $729.00 | Check Stock (Opens in a new window) |

Read Our Flashforge Finder 3D Printer Review

Polaroid PlaySmart 3D Printer

Best Budget 3D Printer for Dabbling in Small Objects

3. 5 Good

5 Good

Bottom Line:

The Polaroid PlaySmart 3D Printer is a compact, stylish 3D printer with above-par overall print quality, but, alas, a tiny build area for the money.

PROS

- Small, lightweight for a desktop 3D printer.

- Easy to set up and use.

- Supports PLA, PETG, and wood composite filaments.

- Multiple-color support.

- Wi-Fi camera monitors print jobs.

- Prints from USB drives, SD cards, or mobile devices.

CONS

- High price for its capabilities.

- Small build area.

- Too-brief warranty.

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $699.00 | $699.00 | See It (Opens in a new window) |

Read Our Polaroid PlaySmart 3D Printer Review

XYZprinting da Vinci Jr. 1.0 A Pro

Best Budget 3D Printer With Closed Design, Roomy Build Area

3. 5 Good

5 Good

Bottom Line:

The XYZprinting da Vinci Jr. 1.0 A Pro is a moderately priced closed-frame 3D printer with a large build volume and overall good performance, but a potentially balky filament-feeding system.

PROS

- Spacious build area

- Works with third-party filaments

- Self-leveling print bed

CONS

- Build plate is not heated

- Limited to PLA- and PETG-based filaments

- Guide tube is prone to detaching

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $299.95 | $199.95 | See It (Opens in a new window) |

| Best Buy | $449.95 | $449.95 | Check Stock (Opens in a new window) |

Read Our XYZprinting da Vinci Jr. 1.0 A Pro Review

Monoprice Voxel 3D Printer

Best Budget 3D Printer for Cheap Filament

3. 0 Average

0 Average

Bottom Line:

The Monoprice Voxel is an under-$400 3D printer that's easy to set up and use. It exhibits generally good print quality, but it was unable to print two of our test objects.

PROS

- Easy to set up and use.

- Budget price for printer and filament spools.

- Supports PLA, ABS, and several composite filament types.

- Versatile software.

- Prints over Ethernet or Wi-Fi, or from a USB thumb drive.

CONS

- Frequent misprints on certain test objects.

- Slightly balky touch screen.

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $449.99 | $369.26 | See It (Opens in a new window) |

| Walmart | $429.99 | $369.26 | See It (Opens in a new window) |

Read Our Monoprice Voxel 3D Printer Review

Buying Guide: The Best Cheap 3D Printers for 2022

How to Buy a Cheap 3D Printer

The biggest changes to 3D printers over the last few years have come to the cheaper models. Nowadays, many of those classic, ornery 3D-printing issues have been resolved (most of the time, anyway), even for consumer and bargain-priced 3D printers. Automatic print-bed leveling is the norm, and you can usually remove 3D-printed objects from heated and/or flexible build plates with a minimum of coaxing. And most 3D printer manufacturers have either developed and refined their own software, or have adapted an open-source printing platform such as Cura(Opens in a new window).

Nowadays, many of those classic, ornery 3D-printing issues have been resolved (most of the time, anyway), even for consumer and bargain-priced 3D printers. Automatic print-bed leveling is the norm, and you can usually remove 3D-printed objects from heated and/or flexible build plates with a minimum of coaxing. And most 3D printer manufacturers have either developed and refined their own software, or have adapted an open-source printing platform such as Cura(Opens in a new window).

(Credit: Zlata Ivleva)

What separates more expensive 3D printers from cheap ones ("cheap" defined as $500 or less, for the purposes of this article) is often a select group of features. These include the build volume, the type of frame, the varieties of supported filament, the software, and the connectivity mix. Let's run through those in turn.

What's the Right Build Volume for a 3D Printer?

A 3D printer’s build volume is the maximum dimensions (HWD) of a part that it can print. (We say “a part” because a 3D-printed object can consist of multiple parts that are printed, then glued or otherwise pieced together.) While the smallest build volume of any 3D printer we have tested is 3.9 by 3.9 by 4.9 inches, we consider any build volume smaller than 6 by 6 by 6 inches to be small, any between that and 10 by 10 by 10 inches as medium, and any printer with at least one build dimension of more than 10 inches as having a large build volume.

(We say “a part” because a 3D-printed object can consist of multiple parts that are printed, then glued or otherwise pieced together.) While the smallest build volume of any 3D printer we have tested is 3.9 by 3.9 by 4.9 inches, we consider any build volume smaller than 6 by 6 by 6 inches to be small, any between that and 10 by 10 by 10 inches as medium, and any printer with at least one build dimension of more than 10 inches as having a large build volume.

(Credit: Molly Flores)

As a general rule, inexpensive 3D printers have small build volumes, while more expensive ones have larger build volumes. This depends in part on the type of printer. Closed-frame 3D printers—and most semi-open models, which have a rigid top, base, and sides but are open in front and, often, back—tend to have small build volumes, while open-frame printers, lacking as rigid a physical structure, often have relatively large build volumes for the price. You'll want to weigh the build volume against the kinds of objects you will print.

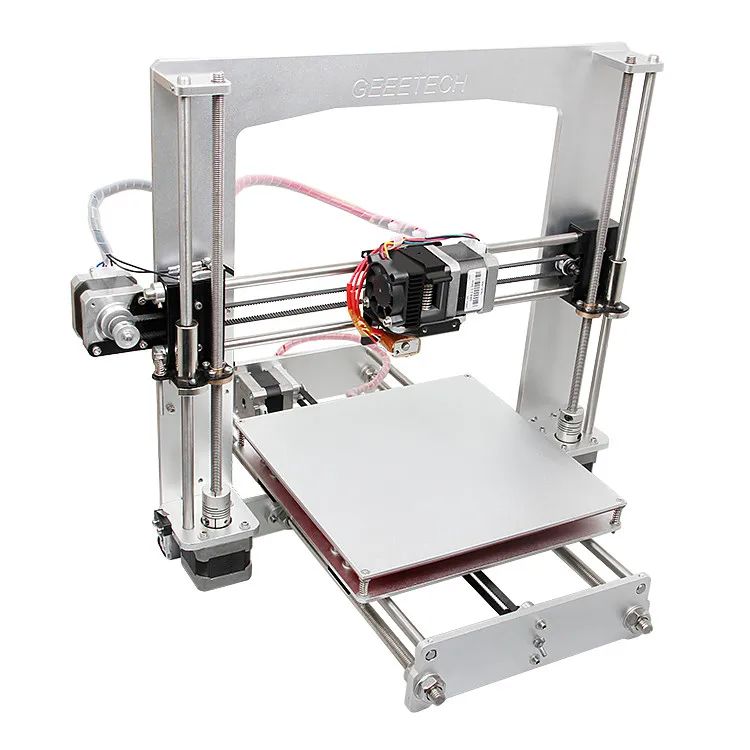

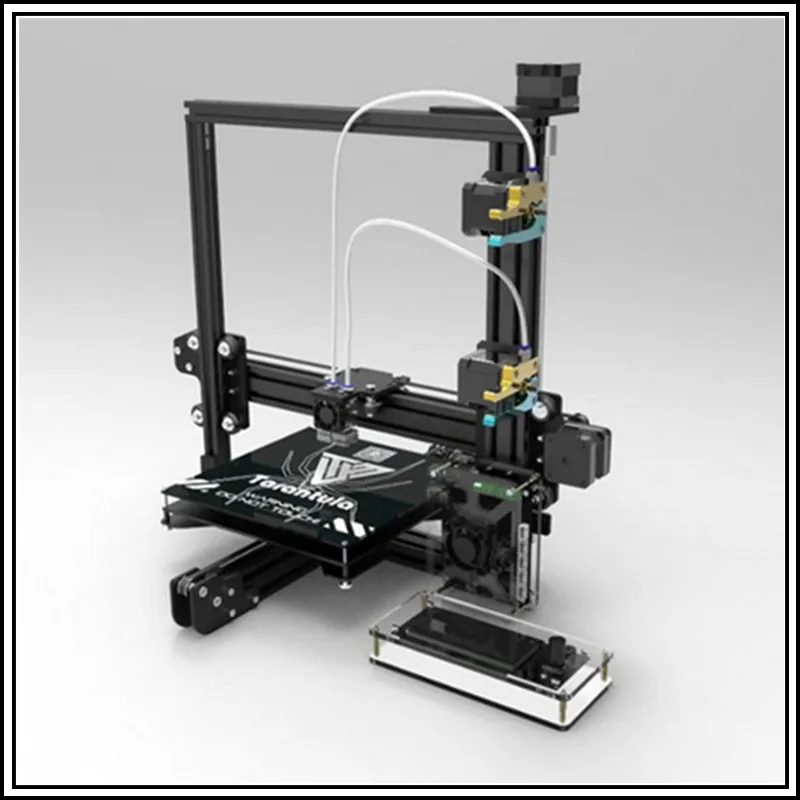

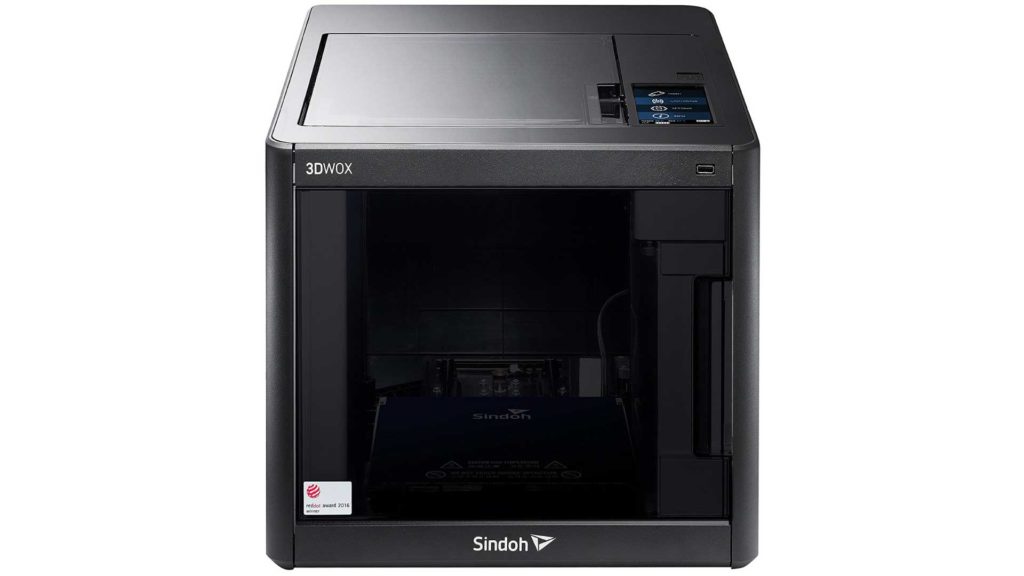

Should I Get an Open-Frame or Closed-Frame 3D Printer?

Which brings us to the frame "form factor" question: open-frame versus closed-frame. Closed-frame 3D printers are boxlike devices, with a rigid base, walls (with a see-through door in front), and top. Among their advantages? They muffle the operating noise, as well as reduce the odor from melted filament (which is potentially an issue with ABS plastic), and they provide some protection for people or pets who might inadvertently touch the hot extruder. A downside: They tend to have smaller build volumes than open-frame 3D printers, which have fewer (often, no) walls to constrict them.

(Credit: Zlata Ivleva)

Low-cost 3D printers include both open-frame and closed-frame models, as well as a few stereolithography printers. If a relatively large build volume is a priority, you’re likely to get more bang for the buck with an open-frame model. Open-frames do have some clear downsides by definition: They tend to be noisy, emit odors when certain plastics are melted, and provide little protection for someone who might touch the hot extruder.

(Credit: Molly Flores)

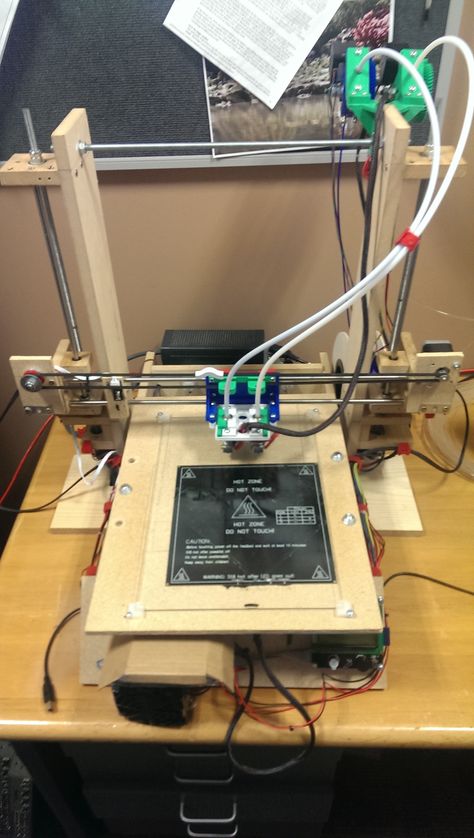

Also, recognize some potential negatives of open frames, depending on the model. Some require assembly, being essentially kits, and most require more setup care than a closed-frame printer, plus more maintenance to keep them running smoothly. Still, these very traits should not deter—and may even appeal to—hobbyists and DIY folks.

What Should I Look for in 3D Printer Software and Connectivity?

Gone are the days when tinkerers had to cobble together several different programs to get a 3D printer to run. Manufacturers either include their own 3D printing program or modify an existing platform such as the open-source Cura.

3D printing software performs three main functions: processing an object file (resizing, moving, rotating, and in some cases duplicating it), slicing it (into virtual layers, based on your chosen resolution), and printing it. These are almost universally combined into a seamless process. Some high-end printers have software that supports a wider range of settings you can tweak, but even the basic suites work at least reasonably well.

More likely to vary among the cheaper set is the array of connection options from model to model. Nearly all have a USB Type-A port to fit a thumb drive for printing from document files. Most also have a USB Type-B port for connecting directly to a computer, and some offer Wi-Fi, too (or as an alternative), while a handful let you connect via Ethernet to share the printer across a local network.

Some printers support storing 3D files on an SD or microSD card (which may also contain the printer’s system files). Most 3D printer manufacturers (even the discount ones) have a mobile app to launch and monitor print jobs, and a few provide access to cloud services from which you can print.

While high-end 3D printers tend to have an abundance of connection choices, discount models vary widely in their choices. Some are generous and some are basic, so it pays to assess what a given model offers.

What Should I Look for in Filament Support?

Filament support tends to be a key area that separates the cheaper models from the higher-end ones. (See our guide to understanding 3D printing filaments for more particulars.) Inexpensive 3D printers tend to support a limited number of plastic filament types, some of them only PLA and/or ABS.

(See our guide to understanding 3D printing filaments for more particulars.) Inexpensive 3D printers tend to support a limited number of plastic filament types, some of them only PLA and/or ABS.

Recommended by Our Editors

3D Printing: What You Need to Know

3D Printer Filaments Explained

(Credit: Molly Flores)

PLA (polylactic acid) is a biodegradable, plant-based polymer, while ABS (acrylonitrile butadiene styrene) is the same tough plastic that Legos are made from. Objects printed from ABS are durable and nontoxic, though the material can be tricky to work with. ABS can emit an acrid, unpleasant odor during printing, and the bottom corners of objects being printed with it have a tendency to curl upward a bit, especially if you are using a non-heated print bed. This can lead to unsightly prints, and/or prints prematurely pulling off the build plate, ruining them.

Many entry-level and low-price 3D printers stick exclusively to PLA. If you want to experiment with a larger variety of filaments—which include water-soluble filament, wood- and metal-laced composites, and both tough and flexible varieties—you may have to pay more, although a few discount models support a wide range of materials.

If you want to experiment with a larger variety of filaments—which include water-soluble filament, wood- and metal-laced composites, and both tough and flexible varieties—you may have to pay more, although a few discount models support a wide range of materials.

Should I Consider a 3D Printing Pen Instead?

Although they aren’t printers per se, inexpensive 3D pens are close kin to 3D printers—using the same filament types and a similar extrusion system—and we include them in the 3D printing category. Rather than tracing out a programmed pattern, you use the 3D pen much like a normal pen, except that you draw with molten plastic. You can trace a pattern or draw freehand, and even draw in three dimensions as the plastic quickly solidifies and hardens once extruded.

(Credit: 3Doodler)

Most 3D pens cost less than $100, and some cost $50 or less. At a glance, 3D pens may appear to be toys, but some artists and craftspeople have taken to them, as it is possible to make quite complicated and beautiful objects with them. If your aim in 3D printing is something closer to freehand design and free expression than computer-centric, structured, and repeatable output, you might give one a try.

If your aim in 3D printing is something closer to freehand design and free expression than computer-centric, structured, and repeatable output, you might give one a try.

So, What Is the Best Cheap 3D Printer to Buy?

Buying a budget 3D printer needn’t mean a world of sacrifice. Plenty of capable and reliable models sell at less than $500, and while they may not be as feature-rich as their more expensive cousins, there's no sense in paying for things you don’t need.

Many casual 3D-printing experimenters will be fine with printing over a USB cable or from a thumb drive, and sticking to PLA may be the best choice for a starter 3D printer. If you focus just on the features you want, you may be pleasantly surprised at what you find. Below, check out a spec breakdown of the best under-$500 3D printers we have reviewed, paralleling our picks above. Also, for a look at the broader market, see our guide to our favorite 3D printers overall.

The Best Mid-Range 3D Printers in 2022

Home Mobile The Best Mid-Range 3D Printers in 2022

TechJunkie is supported by our readers. When you make a purchase through our links, we may earn a commission. Read More.

When you make a purchase through our links, we may earn a commission. Read More.

You can find many 3D printers on the market that fit different budgets. It can be hard to pick the one that is right for you, so we’ve done some research without you even having to step foot in a store. You will need to determine if a printer has good print quality, speed, price-performance ratio, build volume, etc. You should also take note of what type of materials the printer you’re looking at supports. The most common materials are ABS and PLA, but others can also use NYLON, TPE, HIPS, TPU, Wood Fill, Metal Fill, etc. You should also think carefully about the type of prints you want to do; you need to decide if you need a big printer or if you’ll be okay with a smaller option. The most affordable printers you can get sell for under $300, while the more upscale models cost more than $3,000. Thankfully, many mid-range options have been taking the market by storm over the years, and you can expect to print some high-quality 3D models. Let’s look at some of the best mid-range 3D printers in 2022.

Let’s look at some of the best mid-range 3D printers in 2022.

01 Monoprice Voxel

The Monoprice Voxel is an attractive choice to many because, along with having a reasonable price tag, it also allows you to achieve quality prints in the comfort of your home. A unique feature it has is the quick change nozzle that makes switching out the nozzles easy and fast without using extra tools. It also has a removable and flexible heated build plate that you can quickly change out to start a new print. The plate can be heated up to 60°C. Loading your filaments into the printer is easy thanks to the auto-feeding feature that works with the filament sensor. The sensor will automatically notify you when you are low on filament and pause the printer until you reload it. You won’t need to worry about the initial setup because the Voxel is shipped fully calibrated and ready to use. It’s also easy to adjust the distance of the bed and the nozzle using the touchscreen display on the printer. The printer works with Mac OS X, Windows XP/Vista/7/8/10, and Linux. If Voxel could improve certain areas, it would be its Wi-Fi connectivity and software.

The printer works with Mac OS X, Windows XP/Vista/7/8/10, and Linux. If Voxel could improve certain areas, it would be its Wi-Fi connectivity and software.

Specification

Monoprice Voxel

Amazon

02 ANYCUBIC Photon Mono X

If you’re looking for the best 3D printer that guarantees low-cost, SLA printing, the ANYCUBIC Photon Mono X is the ideal choice for you. This printer is a fast resin 3D Printer with a maximum print speed of 60 mm/h. Its printing volume is about 7.55″ x 4.72″ x 9.84″, so it’s large enough for you to print multiple models of the same size simultaneously. Users can also set the printer to stop printing immediately after opening its cover. This printer is four times faster than the Photon because its layer printing time is decreased to only 1-2 seconds. Its increased speed is all thanks to its 8.9-inch 4K Monochrome LCD. The printer promises ultra-precision printing thanks to its matrix parallel UV light source. It’s even more stable because of its clearance nut combination, stepper motor, and dual linear rails utilized by its Z-axis. Users should download the ANYCUBIC app when printing because it allows you to monitor the UV Photocuring printing progress instantly. You also won’t have to worry about the printer overheating since it has a new UV cooling system. The other valuable features are a safe power supply with UL certification, a new responsive and intuitive UI menu, and a support Chitu box slicer. You will get a machine security guarantee for a year and a lifetime of technical support upon purchase.

Users should download the ANYCUBIC app when printing because it allows you to monitor the UV Photocuring printing progress instantly. You also won’t have to worry about the printer overheating since it has a new UV cooling system. The other valuable features are a safe power supply with UL certification, a new responsive and intuitive UI menu, and a support Chitu box slicer. You will get a machine security guarantee for a year and a lifetime of technical support upon purchase.

Specification

ANYCUBIC Photon Mono X

Amazon

03 ANYCUBIC Vyper

Another 3D printer from ANYCUBIC that’s worth the purchase is the ANYCUBIC Vyper. The printer might be small, but its printing volume can reach 9.6 x 9.6 x 10.2 inches. It features an intelligent, automatic leveling system that can detect 16-points and instantly adjust its nozzle’s height. It takes one click to auto-level it, and your printer will be good to go without any extra input. The Vyper packs a punch with its Cortex -M3 architecture main control chip and 32-bit motherboard, so you can expect it to run smoothly and quickly. It also won’t be loud since it has a TMC2209 silent driver and voltage output control. The Vyper has a PEI spring steel magnetic platform that works well, even at high temperatures. You can use filaments like ABS, PLA, TPU, and PETG. The printer can handle a heavy workload because it has a double fan two-way heat dissipation system that can cool the printer down quickly. Your prints will be precise and without any print layer marks since the printer has a patented Z-axis gap elimination module. Users can easily control the printer using its 4.3-inch touch screen. The Vyper also has a double-gear extrusion system, material breakage detection, resume print function, and it’s easy to assemble. Like other ANYCUBIC products, you will get lifetime technical support and a year’s worth of machine security.

It also won’t be loud since it has a TMC2209 silent driver and voltage output control. The Vyper has a PEI spring steel magnetic platform that works well, even at high temperatures. You can use filaments like ABS, PLA, TPU, and PETG. The printer can handle a heavy workload because it has a double fan two-way heat dissipation system that can cool the printer down quickly. Your prints will be precise and without any print layer marks since the printer has a patented Z-axis gap elimination module. Users can easily control the printer using its 4.3-inch touch screen. The Vyper also has a double-gear extrusion system, material breakage detection, resume print function, and it’s easy to assemble. Like other ANYCUBIC products, you will get lifetime technical support and a year’s worth of machine security.

Specification

ANYCUBIC Vyper

Amazon

04 FlashForge Adventurer 4

When you no longer consider yourself a beginner in 3D printing, you can go for intermediate printers like the FlashForge Adventurer 4. This printer features a removable snap-in nozzle that will only take about three seconds to replace, and the best part is you won’t need any extra tools to do it. The nozzle can heat up to 265℃, and it supports filaments like PETG, PETG-CF, PC, ABS, PLA-CF, PLA, and PC. The Adventurer 4 has real auto-leveling and superb first-layer printing. Your platform will run steady thanks to its dual Y-axis guide rail, and it will ensure flatness using a software-controlled 9-point compensation. You can conveniently head to another room and cook or watch TV while printing because the printer has a built-in HD camera that can send photos of whatever’s printing to your phone or computer via Wi-Fi. This printer also has a removable magnetic build plate with a 200 x 200 x 250 mm maximum print volume. The plate can be bent using two handles, so removing models is easy and quick. You won’t have to worry about your prints getting dusty or having foul smells since the printer has a HEPA13 air filter. An external bracket is unnecessary because the printer already has a built-in 1 KG filament spool holder.

This printer features a removable snap-in nozzle that will only take about three seconds to replace, and the best part is you won’t need any extra tools to do it. The nozzle can heat up to 265℃, and it supports filaments like PETG, PETG-CF, PC, ABS, PLA-CF, PLA, and PC. The Adventurer 4 has real auto-leveling and superb first-layer printing. Your platform will run steady thanks to its dual Y-axis guide rail, and it will ensure flatness using a software-controlled 9-point compensation. You can conveniently head to another room and cook or watch TV while printing because the printer has a built-in HD camera that can send photos of whatever’s printing to your phone or computer via Wi-Fi. This printer also has a removable magnetic build plate with a 200 x 200 x 250 mm maximum print volume. The plate can be bent using two handles, so removing models is easy and quick. You won’t have to worry about your prints getting dusty or having foul smells since the printer has a HEPA13 air filter. An external bracket is unnecessary because the printer already has a built-in 1 KG filament spool holder.

Specification

FlashForge Adventurer 4

Amazon

05 Phrozen Sonic Mini 8K 3D Printer

The Phrozen Sonic Mini 8K 3D Printer is a stand-out for mid-range SLA printers on the market. Its selling point is its 8K resolution, with its LCD module reaching around 7500 X 3240 pixels. You get a maximum build volume of 6.5 x 2.8 x 7 inches, and the printer makes use of a Linear Projection LED Module. You can immediately start printing once you unbox the printer because it already comes with a plastic scraper, metal scraper, an Allen key, disposable gloves, funnel, 80 grit Sandpaper, and two pre-sliced test prints. You even get an 8 GB USB thumb drive containing ChituBox Basic 1.9.0 slicer software and a Quick Start guide. Users can get smoother and more detailed prints when using the printer with Phrozen’s Aqua Gray 8K resin. The Sonic Mini 8K features a sturdy design made from metal, and the FEP won’t touch your work surface thanks to its all-metal vat with feet. You will also love its fantastic adhesion from its laser-etched build plate. This 3D printer is ideal for those who plan to print jewelry and miniatures. Some reported that the build plate isn’t the simplest to clean, but it’s doable. It’s also not the most affordable compared to its competitors, but the quality of prints you get makes the price worth it.

You will also love its fantastic adhesion from its laser-etched build plate. This 3D printer is ideal for those who plan to print jewelry and miniatures. Some reported that the build plate isn’t the simplest to clean, but it’s doable. It’s also not the most affordable compared to its competitors, but the quality of prints you get makes the price worth it.

Specification

Phrozen Sonic Mini 8K 3D Printer

Phrozen Store

Table of Contents

Our Process & Method

We're not just tech junkies, but we're also tech experts. Each and every "Best of.." list on TechJunkie is curated by our content-area subject matter experts to provide a well-rounded, unbiased perspective to help and inform you, our reader. Our lists are constantly reviewed and updated, so you can be sure you're reading relevant and up to date information.

The Cheapest GSync Monitors

Read More

How to choose a 3D printer? Main parameters and characteristics of devices

The 3D technology market is growing and expanding, every year dozens of new devices appear on it. Among them are 3D printers using FDM, SLA, SLS technology, and many other modifications with a different set of functions. How to choose a 3D printer in 2019?

Among them are 3D printers using FDM, SLA, SLS technology, and many other modifications with a different set of functions. How to choose a 3D printer in 2019?

Popular printing technologies

3D printing is a modern technology that is increasingly being used in the construction, medicine, jewelry, footwear, decor and home industries. In this regard, there are several hundred 3D printers on the market with different configurations, purposes, types of materials used, quality and convenience. If we evaluate the cost of 3D printers, then in general the devices can be divided into three groups:

- budget models;

- medium price category;

- business class.

Also, 3D printers differ in printing technology, which ultimately affects the final result, as well as the cost of the device. Consider the most popular of the methods of volumetric printing.

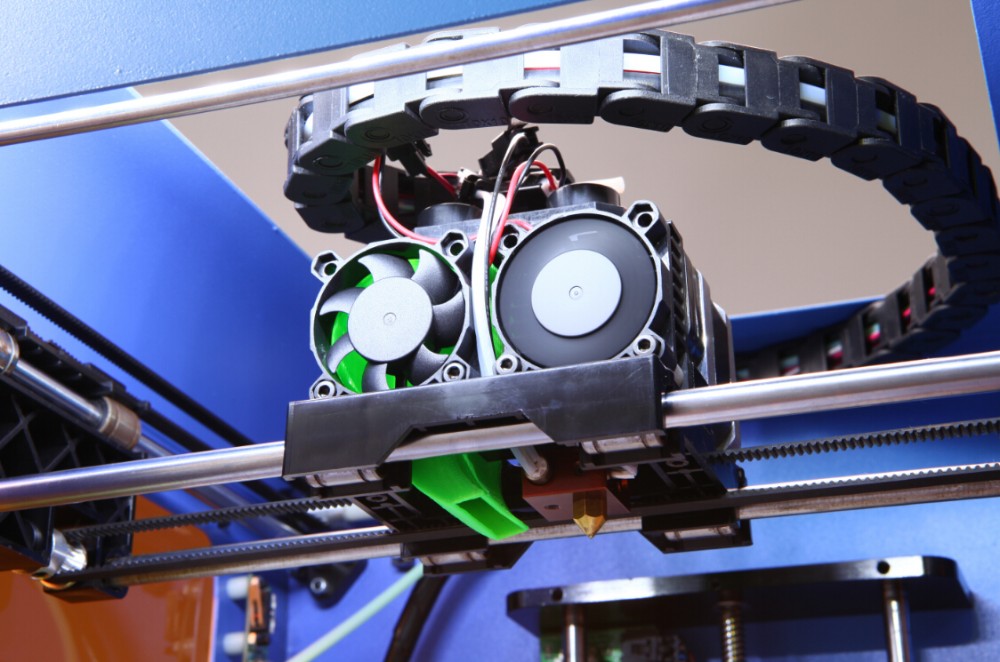

FDM. The most common printing technology that is often used by 3D printer manufacturers: such devices are affordable and produce quite decent quality products. 3D printing is done using a plastic filament that the printer melts in the process and then deposits the melted material in predetermined areas.

3D printing is done using a plastic filament that the printer melts in the process and then deposits the melted material in predetermined areas.

SLA. This is a more expensive but more precise technology and is well suited for printing small items such as jewelry. These 3D printers work with photopolymer. The printer acts on it with a special beam that turns the material into hard plastic.

SLS. This is a high-precision and expensive printing technology based on layer-by-layer sintering of powder materials (polyamides, plastics) using a laser beam. Such printers are designed for industrial use and are distinguished not only by their high cost, but also by their large size.

What to decide before ordering a 3D printer

A 3D printer is a large-scale purchase and quite expensive, even if you are going to purchase a device for volumetric printing of a budget price segment. It is necessary to approach the choice of a 3D printer responsibly and carefully, evaluating all the nuances of its use - it should serve for quite a long time. Before you start looking closely at various models and evaluating their technical characteristics, you need to decide on your goals and capabilities.

Before you start looking closely at various models and evaluating their technical characteristics, you need to decide on your goals and capabilities.

Targets. The project for which the 3D printer will be used and determines its main parameters. Here it is important to know whether the device will be used every day or from time to time, for entertainment or for making money. If we are talking about making souvenirs and small things for yourself, then you can get by with a budget and compact option. If a 3D printer is needed for the streaming production of items (jewelry, handmade), then a more expensive device will be needed.

Budget. The cost of 3D printers ranges from 150 to several tens of thousands of dollars, depending on the print material, quality, durability and purpose of the device. In addition, before buying a 3D printer, you need to calculate how many consumables you will need to achieve your goals and how much they will cost. It is not worth saving on a 3D printing device if it will need to be used constantly and it will be needed at work. To implement complex and large-scale projects, the functions and capabilities of just a budget printer may not be enough.

It is not worth saving on a 3D printing device if it will need to be used constantly and it will be needed at work. To implement complex and large-scale projects, the functions and capabilities of just a budget printer may not be enough.

3D printing material. When choosing materials, you need to consider what exactly you are going to print. This is especially true for projects with a commercial component, where quality comes first. The selected 3D printer should use the material that is most suitable for the end use. The most affordable materials for 3D printing are ABS and PLA plastics.

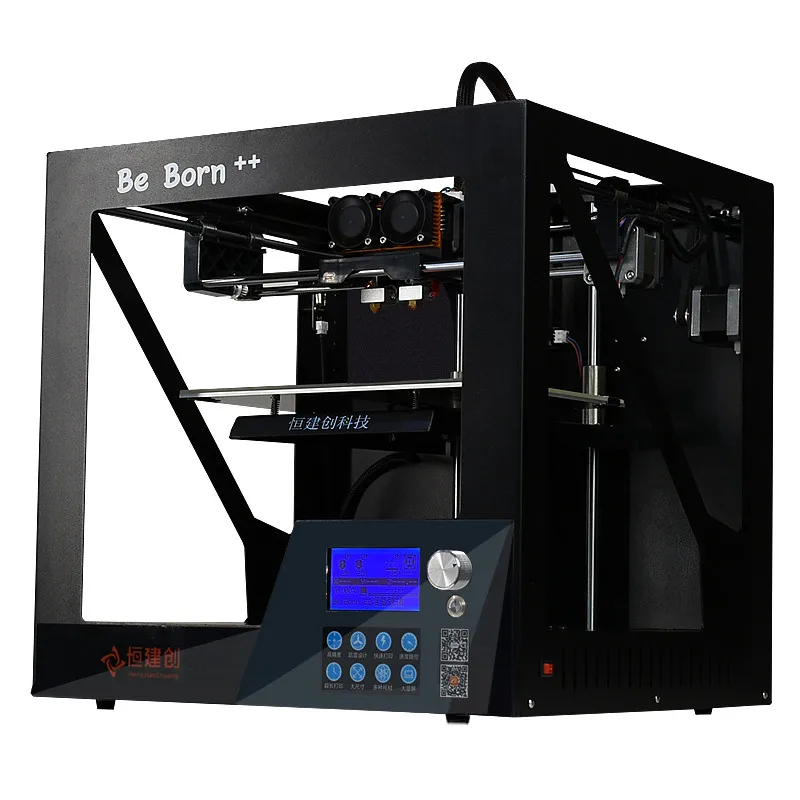

Colours. In order to create products of different colors, you need to purchase a printer with several extruders, and this feature increases the cost of the device.

How to choose a 3D printer

Having decided what you need a 3D printer for, how often it will be used and how much it should cost, you can start looking for the right model. Each of them has characteristics that are worth paying attention to.

Each of them has characteristics that are worth paying attention to.

Manufacturer

The top companies producing 3D printing devices are mainly concentrated in a few countries of the world.

- USA. This is the leading country in terms of the quantity and quality of manufactured devices, the most well-known manufacturers of 3D printers are located here. Many firms have been operating in the market since the advent of additive technologies themselves. Usually American-made products are of high quality.

- Europe. The second region after the USA in the ranking of 3D printer production. European companies offer decent quality for a very reasonable price.

- China. China's 3D printing printers are quite diverse, the market in this region offers a wide range, and many production facilities are located here. You should be careful when choosing Chinese-made products - high quality is not always found, but among the variety of these 3D printers you can find a reliable model that will last for several years.

- Russia. The first Russian companies that produce 3D printers opened in 2010, now this market is well developed in the country. The most famous manufacturers of 3D printers in Russia are PICASO 3D, Magnum, Imprinta, 3Dquality.

Printing speed and accuracy

This is one of the most important characteristics that you should pay attention to in the first place. The quality of the result, the detailing of printed products depends on how high the accuracy is. The speed at which the extruder moves affects how quickly the product will be finished. When it comes to commercial 3D printing, you should focus on maximum speed. The type of material that will be printed also affects how fast the printer will work.

Construction area size

On a large construction area, you can print large objects, and the larger the print area, the more product you can produce. This parameter is important to consider if you plan to print objects of different sizes or especially large products. For small parts and souvenirs, a large build area is not needed, but if the project requires printing on an industrial scale, then a 3D printer with a large build area is needed. It is also worth considering that printing of large objects can be broken down into smaller forms, which will later be glued together.

For small parts and souvenirs, a large build area is not needed, but if the project requires printing on an industrial scale, then a 3D printer with a large build area is needed. It is also worth considering that printing of large objects can be broken down into smaller forms, which will later be glued together.

Plastics

If we are talking about the most popular type of 3D printer (FDM), then you need to carefully study the list of materials available for printing. The description of each device should indicate the types of plastic with which it works and which it can melt.

Filament thickness

Most home use FDM 3D printers use plastic filament, which is sold in spools of about 1 kg. Such a thread comes in different thicknesses - 1.75 mm and 2.85 mm, the first option is most often used. The thickness of the layers is not affected by the characteristics of the thread, it depends on the extruder. You can buy reels for printers from any brand, with the exception of rare exceptions when the printer uses only materials from its own manufacturer.

Mechanics of a 3D printer

It is important to evaluate all the nuances of assembling a 3D printer as a whole: this is the design itself, which can be closed and open; type of guides, on which work with flexible plastics depends; type of extruder responsible for the thickness of the layers. For example, when working with materials with a high thermal shrinkage rate (ABS, HIPS, PC), a closed case is needed to maintain a constant temperature during manufacture (otherwise the product may deform during the creation of layers). The printed object in such printers heats up and cools down evenly, does not delaminate and does not change shape.

Heating of the printing platform

A separate point is the possibility of heating the printing table in a 3D printer. This characteristic is important if you are going to use plastics with a high level of thermal shrinkage - this is an indicator of how much the material shrinks after cooling. Since 3D printing is done in layers, without additional heating of the printing platform, the first layer will change shape even before the second layer is applied. This is fraught with deformation of the object and delamination.

This is fraught with deformation of the object and delamination.

Vertical and horizontal resolution

The horizontal resolution (XY) determines how detailed the printed object will be. This characteristic represents the minimum movement that the print head is capable of during operation. The lower the index, the more accurate the products are. Vertical resolution (Z) is responsible for the thickness of the layer - the higher the value, the thicker and more visible the layers of the 3D printed object will be.

What to be prepared for after buying a 3D printer

- After choosing the right model, decide where it will be located - especially for large devices that will be constantly in operation. When heating plastic, it is often necessary to ventilate the room, so it is better to choose the appropriate place for the printer.

- If you are going to use the printer with someone (relatives, colleagues), then make sure that other people have mastered the safety rules and basic skills of working with a 3D printer.

For use with children, it is better to choose a simple device more reliable.

For use with children, it is better to choose a simple device more reliable. - Finished products often still have to be processed: with a file, knife, scissors. This is necessary to get rid of protruding threads, possible sagging, roughness.

Conclusions

The more precisely you can determine for what purposes a 3D printer is needed, what materials it should work with and how high-precision it should be, the faster you will be able to choose the optimal device for 3D printing. It is also important to calculate how much money will have to be spent on materials and - in the case of print for commerce - whether the final price of the printed product is adequately calculated. With the right approach to choosing a 3D printer, you will get a device that will justify the investment in it and last for years.

All about 3d printing. how does a 3d printer work? which 3d printer to choose?

What industries use 3D printers

These printers are used in the following areas:

- consumer electronics design;

- in the development of packaging material;

- in the jewelry direction;

- in toy production;

- in the aerospace industry;

- automobile manufacturing, etc.

Separately, it is worth noting the use of these devices in the medical field. For several years now, they have been using prosthetics for teeth. Unlike previous technologies, this method is cheaper and more reliable, as it has high accuracy. Another area in medicine where the technique is used is 3D prototyping of bones and joints to create implants.

What is 3D printing

3D printing is a process of additive (layered) creation of objects, using a solid material, based on a CAD model. Such a three-dimensional model in STL format is sent to a special printer, which creates a real object layer by layer from different materials.

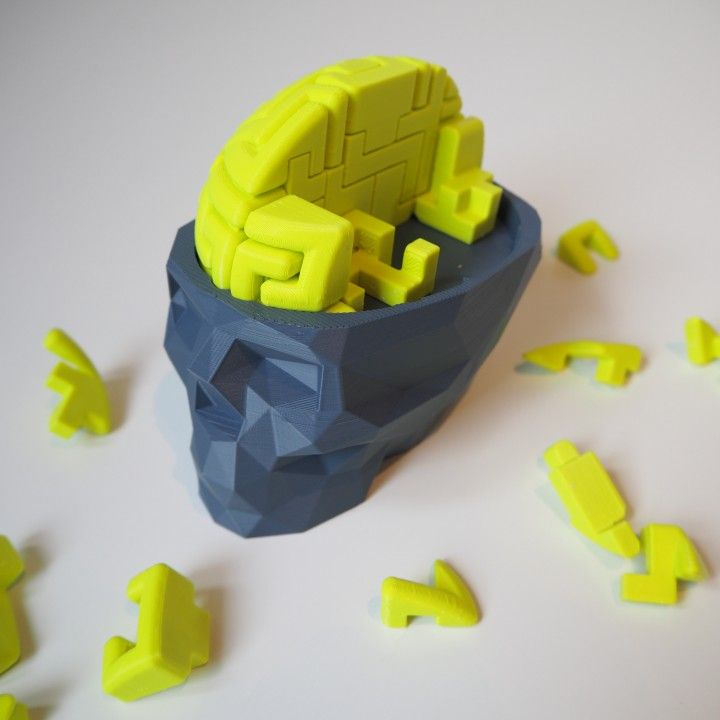

The 3d printer can print many items, such as pen cap, clothespins, furniture fittings, plastic Christmas tree toys, toys for children, etc. They can easily make a plastic phone case and even original chess pieces.

Industrial models are the largest, professional devices are slightly smaller, and home 3D printers are considered the smallest.

3D printing technology

Considering the types and characteristics of 3D printers, you need to understand what 3D printing technology is. The main essence of the printer's work is the creation of three-dimensional models, the processing of a digital layout and its implementation in plastic or other suitable material. As a result, you can get a physical object that can be used for its intended purpose. Technology requires:

- 3D printer - a device for creating a layer-by-layer layout, using a specially created 3D model in a computer program;

- suitable material for production;

- medium power computer for processing preset parameters.

Printing technology is such that to start the device requires its connection to a computer, also in some printer models you can load layouts on a storage medium (memory cards, etc.)

Connection socket and card reader.

With the help of the slicer program, an object will be created that will be “printed” on the printer. Modern technologies allow printing from sand, paper, metal, wax. Even chocolate is actively used. The printing process is completely robotic - a person only needs to set a program and press start.

Modern technologies allow printing from sand, paper, metal, wax. Even chocolate is actively used. The printing process is completely robotic - a person only needs to set a program and press start.

FDM entry-level 3D printers

This category contains the most budget options. The basis of the printing process is layer-by-layer directions FDM (Fused deposition modeling). Under the influence of high temperatures, the plastic thread melts and is applied in thin layers creating a three-dimensional model. In inexpensive models, there is one nozzle for extruding threads.

The most famous among budget photopolymer LCD 3D printers is the Anycubic Photon Zero model.

Among the advantages of entry-level printers:

- Low price.

- Good for beginners who want to get familiar with how these devices work.

- Easy to install and set up

Disadvantages:

- This printer does not have a closed chamber.

- The design is unreliable compared to professional devices, often such equipment consists of a steel frame

- There is no closed case, so not all types of plastic are used to work on the device.

These are mainly PLA, SBS, PETG.

These are mainly PLA, SBS, PETG.

What else can 3D printers do?

The use of 3D printing

is relevant in all modern industries. Electronic components, jewelry, homes, living tissue, and even food can all be created or shaped on dedicated printers using the right consumables. Applications for 3D printing:

- Design;

- Industry;

- Manufacturing;

- Development;

- Experimental and scientific activities;

- Service industry;

- Medicine;

- Architecture, construction;

- Robotics;

- Mechanical engineering;

- Instrumentation;

- Conceptual developments.

See samples

0254 is calculated individually. If you have any questions CONTACT US.

We will calculate the cost and term of 3D printing of your products.

Powder bonding technology

Powder bonding technology, also known as Binding powder by adhesives, allows not only creating three-dimensional models, but also coloring them.

Printers with binding powder by adhesives technology use two types of materials: starch-cellulose powder from which the model is formed, and a water-based liquid adhesive that glues the layers of powder. Glue comes from the print head of the 3D printer, binding the powder particles together and forming the outline of the model. After printing is completed, excess powder is removed. To give the model additional strength, its voids are filled with liquid wax.

Powder bonding technology

Legend:

1-2 – the roller applies a thin layer of powder to the working surface; 3 - inkjet printhead prints with drops of a binding liquid on a layer of powder, locally strengthening a part of a solid section; 4 - process 1-3 is repeated for each layer until the model is ready, the remaining powder is removed

Currently, 3D printers with powder bonding technology are manufactured by Z Corporation.

Polar 3D printers

A rather new but interesting kinematic polar scheme is introduced to the market by the Polar company of the same name. As the name implies, printing uses a polar coordinate system - instead of the usual XYZ, the positioning of the extruder is set by radius and angle.

As the name implies, printing uses a polar coordinate system - instead of the usual XYZ, the positioning of the extruder is set by radius and angle.

The platform of these 3D printers is round, rotates in a circle and moves entirely along one horizontal axis, while the extruder moves only up and down. Imagine a turntable - the printer's printhead works like a pickup stylus moving across a record. The only difference is that here the “plate” not only rotates, but the “needle”, on the contrary, is limited in movement.

SCARA

SCARA (Selective Compliance Articulated Robot Arm) - kinematics based on the movement of the working unit in a horizontal plane due to rotation in the joints of the lever mechanism.

The devices built on this scheme are distinguished by very high accuracy and repeatability, much higher than that of traditional robotic manipulators, low noise and vibration levels, and compactness. If we talk about Cartesian and SCARA robots of comparable size and mass, then scara is usually not only more accurate, but also faster.

At the same time, these devices are expensive, have limited XY rigidity, a smaller area of work and freedom of movement.

Work example:

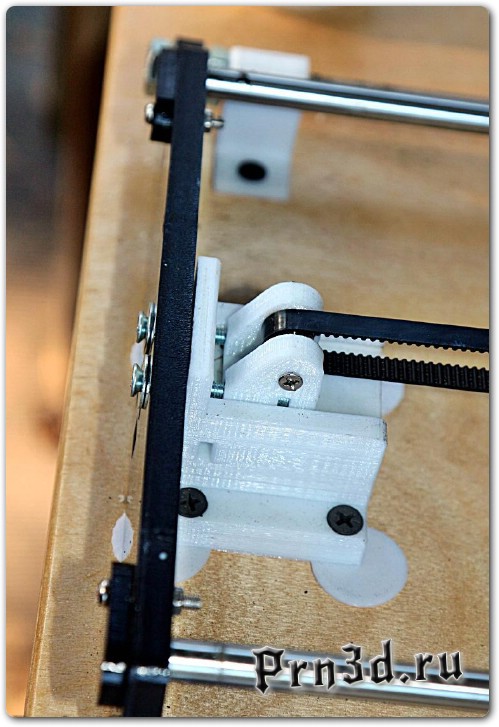

CoreXY and H-Bot Cartesian kinematic variations

These kinematic schemes are often found in commercial applications. Differ in original methods of positioning of an extruder. In both kinematics, the platform moves up and down.

TheCoreXY has two frame-mounted motors that drive two belts to move the extruder carriage along the XY axes.

H-Bot kinematics for 3D printer based on similar mechanics but with a different belt drive. In this case, there is only one belt and it is stretched in a shape resembling the letter H (ash) circled around the contour, for which the scheme was called ash-bot.

When both motors are running in the same direction, the carriage moves along the X axis, in different directions - along the Y axis. When one of the motors remains stationary, the carriage moves diagonally.

Printing example:

3D printing technology

Considering the types and characteristics of 3D printers, you need to understand what 3D printing technology is. The main essence of the printer's work is the creation of three-dimensional models, the processing of a digital layout and its implementation in plastic or other suitable material. As a result, you can get a physical object that can be used for its intended purpose. The technology requires:

- 3D printer - a device for creating a layer-by-layer layout, using a specially created 3D model in a computer program;

- suitable material for production;

- medium power computer for processing preset parameters.

Printing technology is such that the device needs to be connected to a computer to start working, also in some printer models it is possible to load layouts on a storage medium (memory cards, etc.)

Connection connector and card reader.

With the help of the slicer program, an object will be created that will be “printed” on the printer. Modern technologies allow printing from sand, paper, metal, wax. Even chocolate is actively used. The printing process is completely robotic - a person only needs to set a program and press start.

Modern technologies allow printing from sand, paper, metal, wax. Even chocolate is actively used. The printing process is completely robotic - a person only needs to set a program and press start.

Models of professional 3D printers

Professional devices may differ in their purpose, technology and other characteristics.

Here are just a few models that are in demand among consumers:

- The Stratasys Objet 24 is a professional printer for highly detailed printing. The production was based on PolyJet 3D printing technology. It is used to print models for functional testing. The device is preferred by designers and engineers.

- 3D systems Projet 3600 Dental - with it you can build extremely clear and smooth details. The device is purchased by dentists and jewelry establishments.

- MAKERBOT REPLICATOR Z18, LeapFrog Xeed and StarLight 3D - used in jewelry. They are professional FDM printers.

Advantages and disadvantages of delta bots

Delta kinematics, compared to Cartesian models, has a higher print speed, but less accuracy at the edges of the model. The reason is that all three attachment points are involved in the movement of the extruder, their motors work simultaneously, which leads to the accumulation of errors in the positioning of the coordinates.

The reason is that all three attachment points are involved in the movement of the extruder, their motors work simultaneously, which leads to the accumulation of errors in the positioning of the coordinates.

Other benefits:

-

Small size. The design is high, but in length and width does not take up much space.

-

No protruding parts. You can independently increase the rigidity of the frame and close the case.

-

Possibility to build high vertical models.

Drawbacks:

-

High price category.

-

Difficult to self-assemble. It will be difficult for beginners to assemble the structure accurately enough, so it is recommended to use ready-made solutions that come assembled.

-

The specifics of working with polar coordinates: less common software and more expensive electronics, because higher requirements for the processing power of the filling.

Printing example:

Benefits of the Cartesian circuit

Of all the types of FDM 3D printer kinematics, Cartesian ones show almost perfect results stability. FDM consumables are low cost and come in the widest range of colors and materials. Often, Cartesian 3D printers are used for commercial purposes - for printing on order and for the sale of household objects, souvenirs and jewelry.

Cartesian 3D printers have long and firmly established themselves in the lives of amateurs and professionals of 3D printing. Therefore, there are many thematic communities on the network with comprehensive information about the design of printers, working with them and creating models, from simple to complex.

Cartesian models can be decomposed for printing, allowing you to create 3D printed objects of any size, not limited by the volume of the printer. Many 3D printers come as a build kit. For beginners and those who do not want to understand the printer device, manufacturers supply ready-made devices. With them, you can print models almost after unpacking.

With them, you can print models almost after unpacking.

https://youtube.com/watch?v=ej7tDcrgOmc

Pros and cons of polar mechanics

Polar 3D printers allow you to create large objects, while saving money due to high energy efficiency. They still have low accuracy, but in the long run, perhaps the manufacturer will be able to solve this problem.

These 3D printers include the Polar 3D model. In this 3D printer, there is no heating of the print platform, which makes it difficult to use ABS. It has modest dimensions, good performance, but low accuracy compared to delta printers and models with a Cartesian coordinate system. The manufacturer recommends purchasing a model for educational purposes.

In this 3D printer, there is no heating of the print platform, which makes it difficult to use ABS. It has modest dimensions, good performance, but low accuracy compared to delta printers and models with a Cartesian coordinate system. The manufacturer recommends purchasing a model for educational purposes.

Printing example:

SECOND GROUP: extruder X and Y, working platform Z

- just up and down.

Second group of classification

The three most popular 3D printers of the second group are Ultimaker, RapMen and MakerBot Cupcake.

Ultimaker 9 3D printer0005

The Ultimaker 3D printer, developed by German engineers, quickly gained popularity around the world. The printer is "ode" in a wooden case, it is difficult to assemble, but it has good speed and print quality. Analogues of this model are the Chinese devices LX Maker Acrilic R1, LX Maker Special Plastic and LX Maker Double Nozzles.

RapMen 3D Printer

RapMen 3D Printer belongs to the Rep-Rap category. The device can be identified by its lightweight square design and cruciform designs on the side panels.

The device can be identified by its lightweight square design and cruciform designs on the side panels.

The most popular representative of the second group, without a doubt, is the MakerBot 3D printer. Its ancestor, the Cupcake model, was made from a wooden profile, had two extruders and was able to print two-color models. Cupcake was replaced by the Thing-o-matic 3D printer, and only then did the well-known Replicator and Replicator 2 devices appear.

MakerBot Replicator 3D printer

including Come3D C120N, Wanhao Duplicator 4 Black DH, etc.

Aircraft industry

Wait, many in our Telegram chat will say, what other 3D printed engines? Is it possible? Quite, and additive manufacturing is successfully used in many areas of mechanical engineering, including the aviation and space industries, where 3D-printed engine parts are quickly becoming commonplace. It's all about 3D printing methods such as selective laser sintering (SLS) and deposition welding (SLM). These methods allow you to create high-precision parts, consisting entirely of metals and alloys.

These methods allow you to create high-precision parts, consisting entirely of metals and alloys.

Will there be 3D pilots soon?

Fine powders are used as raw materials, which are heated almost to the melting point and then sintered or alloyed along predetermined contours using ultra-precise lasers. Although there were initially some doubts about the strength of such products, numerous experiments dispelled fears: the density of the parts obtained is almost the same as cast counterparts, and the ability to manufacture the most complex components as a whole makes it possible to avoid the formation of weak zones that usually appear at the site of welds.

3D printed engine parts, up to injectors, are already being used on SpaceX devices, Airbus is actively and successfully testing 3D printed parts of engines and supporting structures of airliners, and 3D printed swirlers created by the All-Russian Research Institute of Aviation can be considered a domestic example. materials (VIAM) for promising PD-14 engines currently undergoing flight tests.

materials (VIAM) for promising PD-14 engines currently undergoing flight tests.

Professional printer features

Professional 3d printer performs the same functions as cameras and video equipment for professionals. That is, they facilitate the work of photographers and those involved in video filming.

This equipment clearly shows its purpose. Devices can be divided into industrial, jewelry, culinary, dental, medical, etc. So, for example, dental printers are intended only for dental activities - for printing crowns, prostheses, etc.

These devices have their main distinguishing qualities:

- High precision and detail.

- High performance.

- High speed printing.

- Availability of additional features.

- Relatively high cost.

So, the FDM printer often has additional printheads. An industrial 3D printer can even produce small batches of finished products, as well as produce high-quality samples for testing and presentations.