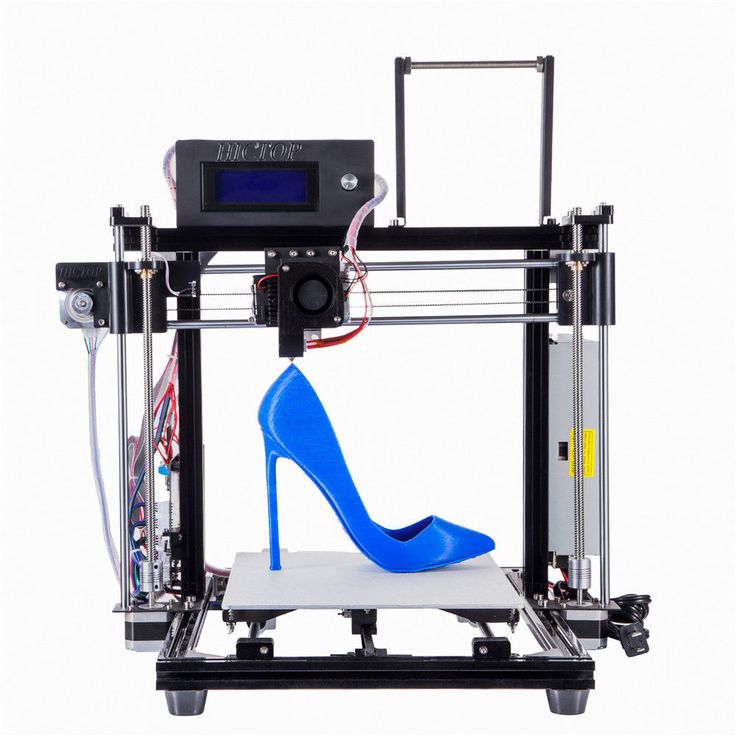

Abs 3d printer

Everything you need to know about ABS 3D printing

Before you get started with ABS 3D Printing, we’ve compiled some of the basic information you’ll need to know. Read on to learn the advantages, disadvantages, history and applications of ABS 3D printing

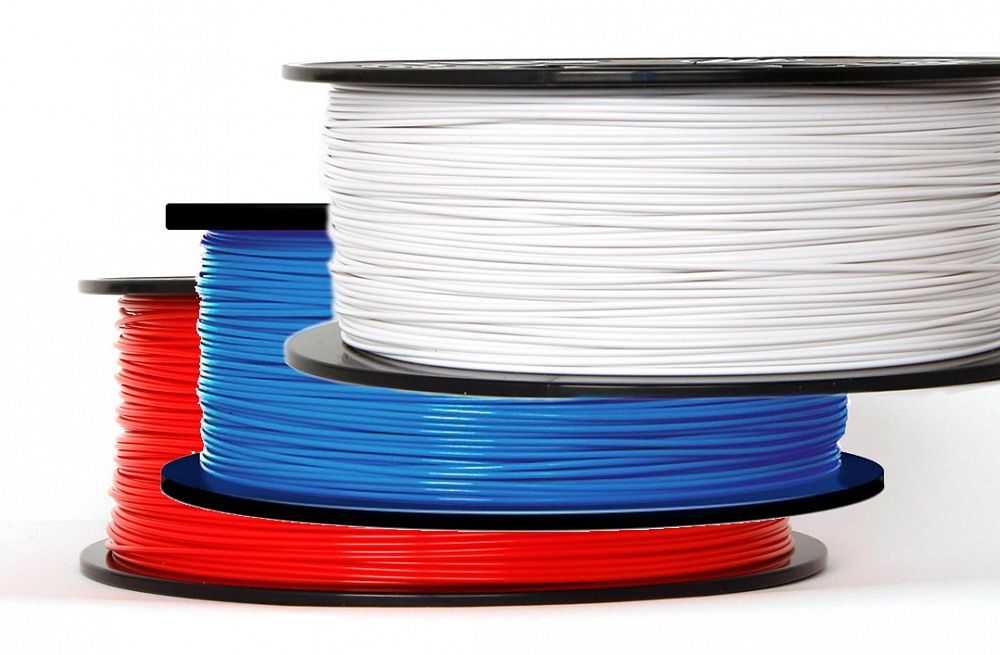

ABS Filament and 3D printed OXO Thermometer Housing

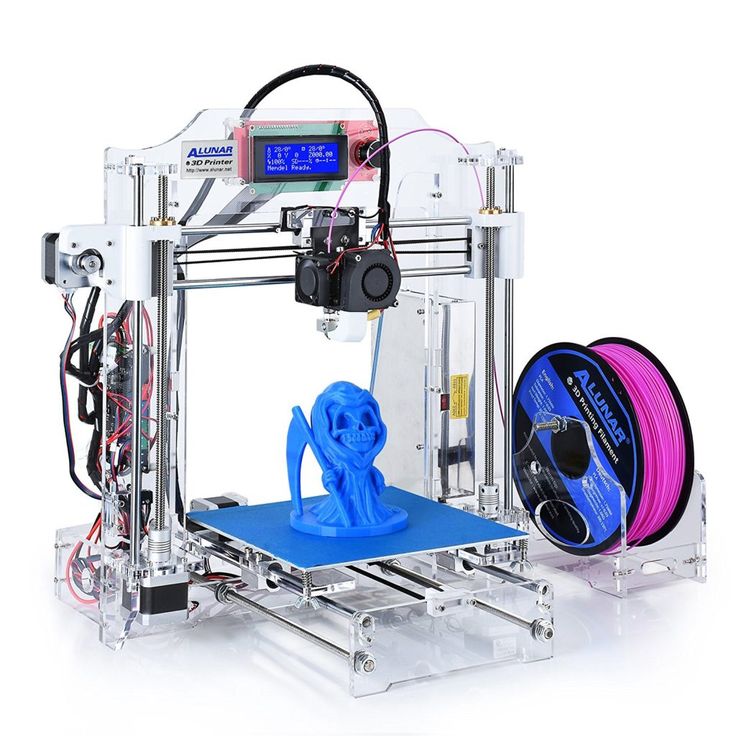

Fused Deposition Modeling (FDM) 3D printing has been around since the early 1990s. It was the third major 3D printing technology to be developed, and is currently one of the most widely used. As the technology developed, materials also started to develop and ABS was one of the first materials to be introduced to 3D printing. It was a known material and already in use in traditional manufacturing processes, making it a natural fit to 3D printing.

Today, ABS is the most popular FDM 3D printing material for professional applications. ABS is a difficult material to 3D print and through this article we intend to share everything you need to know about ABS 3D Printing.

UNDERSTANDING ABS AS A MATERIAL

ABS or Acrylonitrile Butadiene Styrene is a thermoplastic copolymer – it can be melted to form liquid and cooled to form solid, and this process can be repeated many times without any significant degradation in its properties.

Chemical Composition

ABS is a polymer of acrylonitrile and styrene in the presence of polybutadiene. The general composition is 20% acrylonitrile, 25% butadiene and 55% styrene. By altering the composition of these compounds, the properties of ABS can be modified to improve its toughness, heat and impact resistance. The butadiene, which is a rubbery substance, imparts resilience even at low temperatures while the styrene gives the plastic a shiny, water-tight surface.

LEGO bricks are injection molded out of ABS plastic

Professional Applications

ABS is widely known for its impact, chemical and heat resistance. It also exhibits high structural strength, stiffness, and excellent high and low temperature performance, which make it suitable for automotive components and kitchen appliances. ABS also displays great electrical insulation properties, making it a common choice for applications in housing and casing of electrical components.

ABS also displays great electrical insulation properties, making it a common choice for applications in housing and casing of electrical components.

ABS has a low production cost and is relatively easy to machine,, making it an ideal material for mass production of everyday products. ABS is also fairly easy to post-process as it can be glued and painted.

Examples of products that are manufactured in ABS include kitchen appliance housings, automobile dashboard and bumper, protective equipment like headgear, electrical casings and covers, Lego bricks and other toys, and even musical instruments.

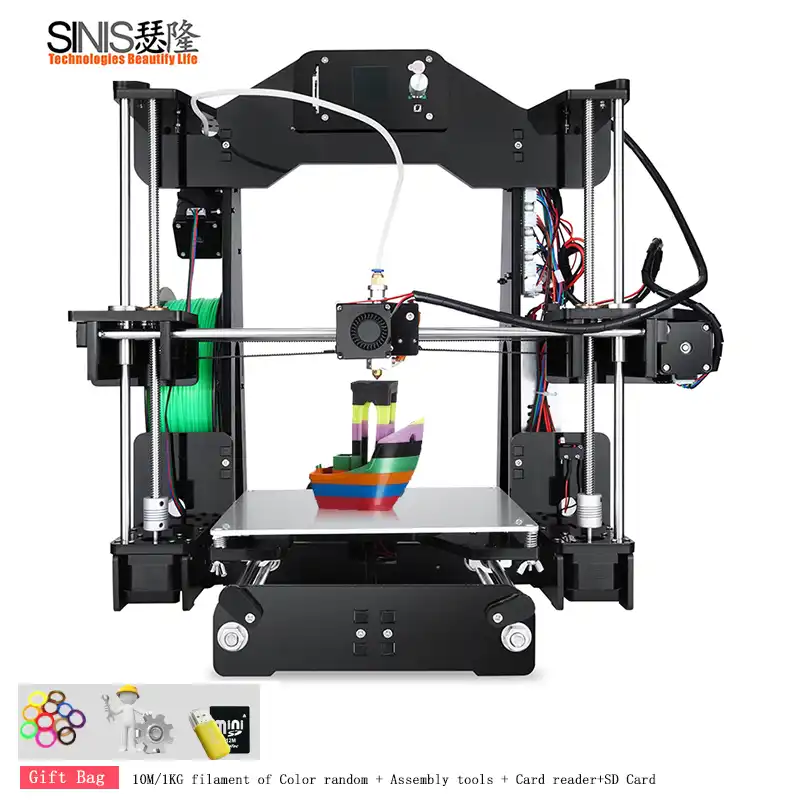

FUSED DEPOSITION MODELLING (FDM) ABS 3D PRINTING

ABS offers many benefits to users but it is also important to note that it can be difficult to successfully print with this material.

Common Challenges with ABS 3D Printing

Users have to face a variety of challenges while 3D printing with ABS. ABS 3D printing is synonymous with critical issues like warping, curling and cracking that affect the print shape, dimension and performance. These issues are directly caused by ABS’s propensity to shrink up to 2% as it cools. When this cooling occurs unevenly at each layer, the result can be poor-layer adhesion and cracking. First-layer adhesion is also a problem for ABS and users have to resolve the same through a tedious trial and error methodology.

These issues are directly caused by ABS’s propensity to shrink up to 2% as it cools. When this cooling occurs unevenly at each layer, the result can be poor-layer adhesion and cracking. First-layer adhesion is also a problem for ABS and users have to resolve the same through a tedious trial and error methodology.

ABS shrinks significantly leading to warped parts

Solutions to ABS 3D Printing

Even though ABS faces multiple challenges, solving them is definitely possible. With careful consideration and proactive measures, the challenges can be easily overcome. We help you with a list of problems and factors to consider while printing with ABS material.

First we need to understand ABS material properties.

FDM ABS MATERIAL PROPERTIES

| TECH SPECS | Imperial | Metric |

|---|---|---|

| Heat Deflection (ASTM 648, 66 psi) | 210°F | 99°C |

| Flexural Modulus (ASTM D790, 15 mm/min) | 377,000 psi | 2,600 MPa |

| Tensile Strength at yield (ASTM D638, 50 mm/min) | 0. 806 psi 806 psi | 43 MPa |

| Tensile Modulus (ASTM D638, 50 mm/min) | >348,000 psi | >2,400 MPa |

| Strain at Yield - Elongation (%) | >5.6% | >5.6% |

| Notched Impact Strength (ASTM D256) | >3.6 ft-lb/in | >192 J/m |

(Specifications for MakerBot ABS)

GUIDELINES TO ABS 3D PRINTING

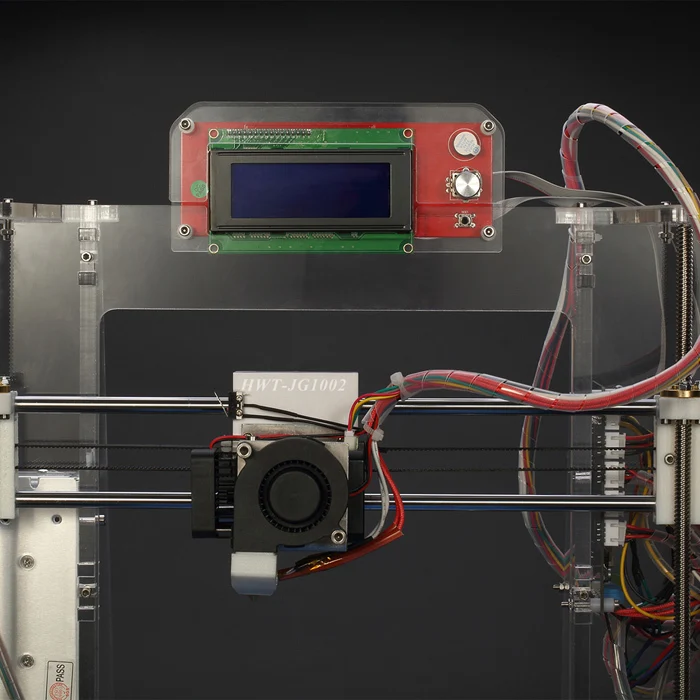

Ideal Extrusion Temperature Range

It is important for users to always print ABS within the ideal or recommended temperature range. The temperature range is provided by the filament manufacturer and the entire range should be explored for the ideal temperature for your 3D printer and the environment you are working in. For METHOD the extruder temperature for ABS is 245°C.

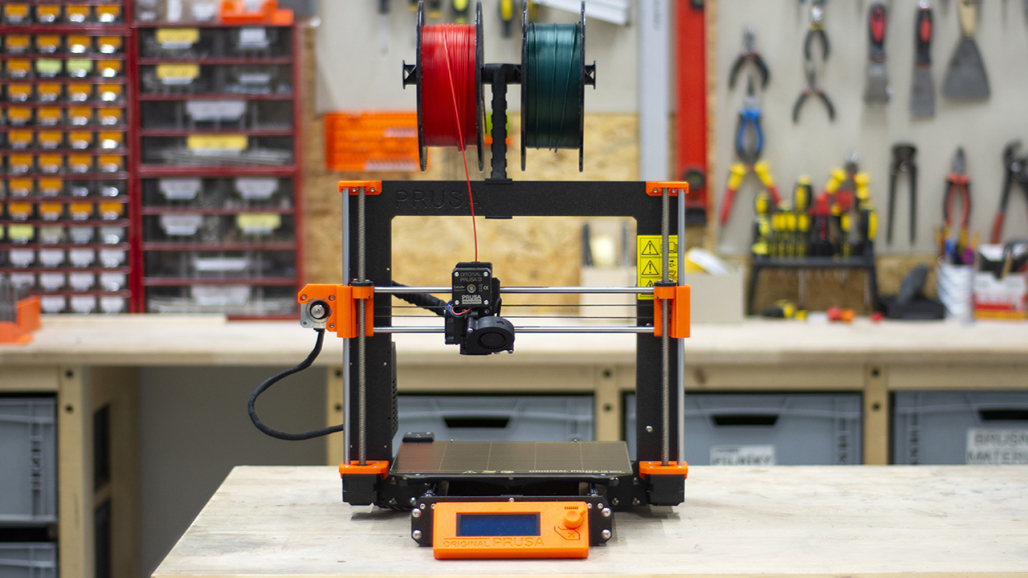

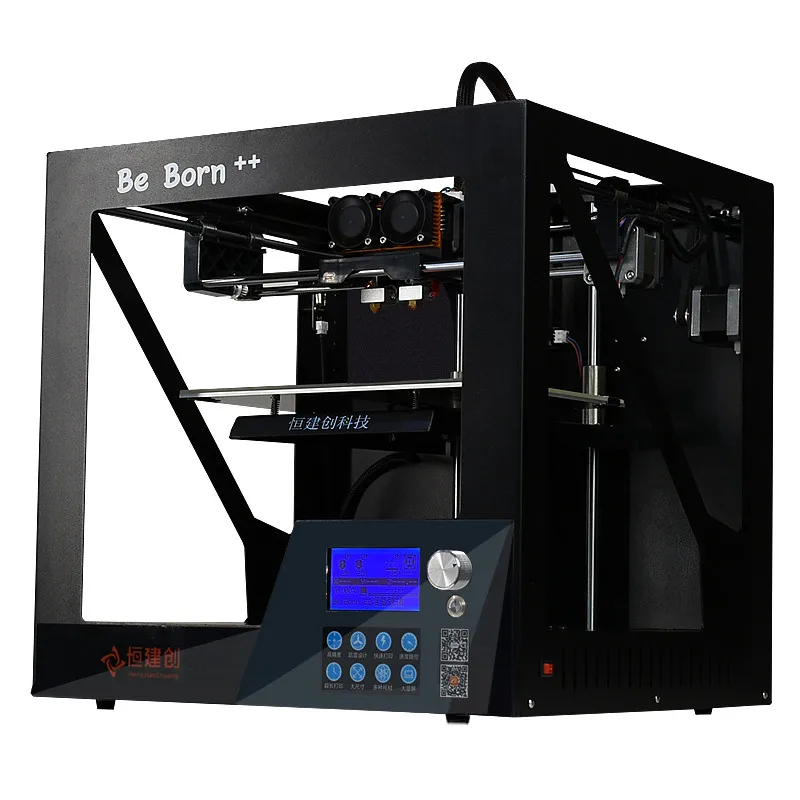

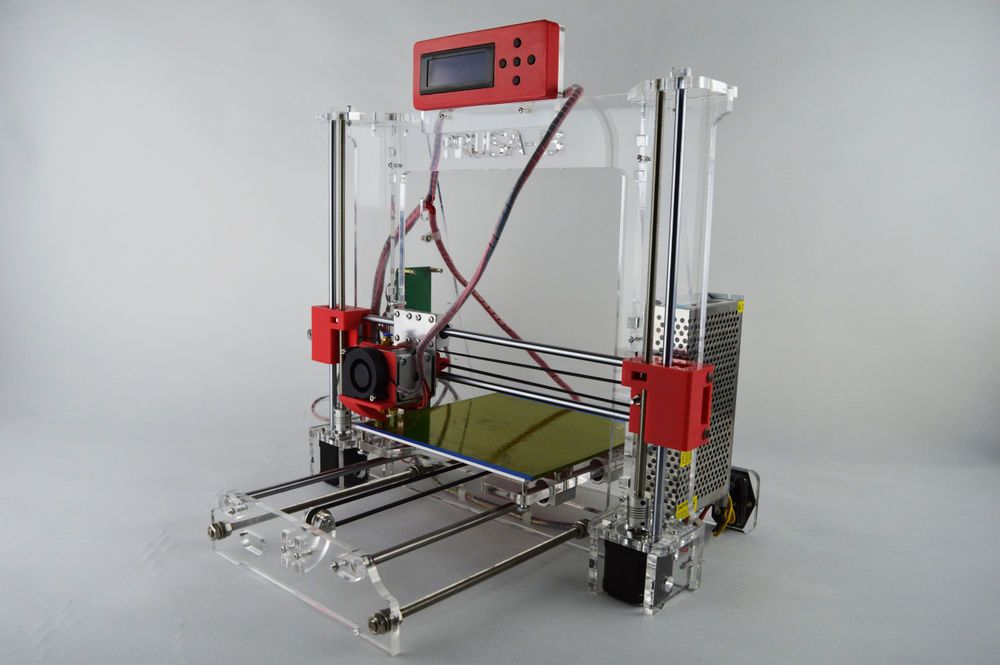

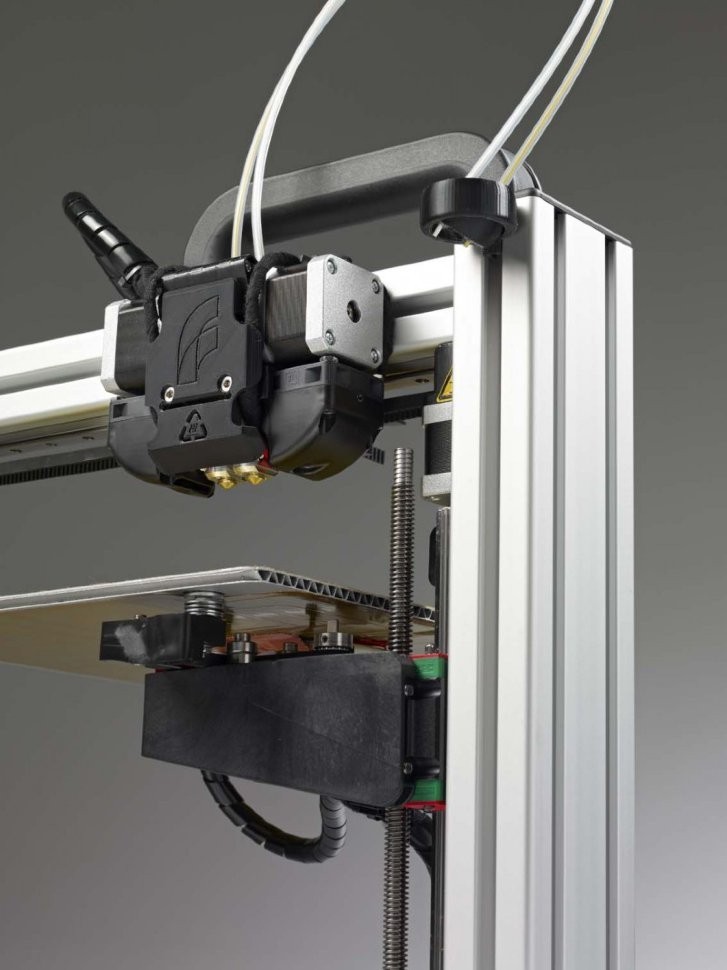

Heated Build Plate vs Heated Build Chamber

Due to ABS’s rate of shrinkage while cooling, it is strongly recommended that a heated build chamber is used when printing. This will allow the print to maintain an elevated temperature until the job is complete, at which point the entire print is able to cool at a constant rate ensuring dimensional accuracy and structural integrity are maintained. If a heated chamber is not an option, another less ideal option is to use a heated build plate with an enclosure. The heat on the build plate will increase adhesion while the enclosure will attempt to mimic a heated chamber. Note that for the second configuration, the part’s accuracy and strength will decrease as the part’s size increases.

This will allow the print to maintain an elevated temperature until the job is complete, at which point the entire print is able to cool at a constant rate ensuring dimensional accuracy and structural integrity are maintained. If a heated chamber is not an option, another less ideal option is to use a heated build plate with an enclosure. The heat on the build plate will increase adhesion while the enclosure will attempt to mimic a heated chamber. Note that for the second configuration, the part’s accuracy and strength will decrease as the part’s size increases.

Real ABS vs Modified ABS

There are many formulations of ABS and depending on what type of 3D printer you have access to, you may elect to choose a variety that has been modified to favor less curling. These modifications tend to have a negative impact on material properties so ensure you know what you are getting before you purchase. If your goal is to closely mimic ABS used in injection molding, you’ll want to stick with the least modified version of ABS you can find. Remember, real ABS will require a heated build chamber to print well.

Remember, real ABS will require a heated build chamber to print well.

Ventilation

ABS 3D printing should always be carried out in a well ventilated room. Typically an open office environment with industrial HVAC should do the trick.

Warping, Curling & Cracking

Warping, curling & cracking can be big problems in ABS 3D printing. If not controlled, the print can warp, curl, or even crack after a few layers. These problems are visible only after some printing is done and so the print has to be constantly monitored to make sure the print is running perfectly. To reduce the chances of Warping, Curling & Cracking users have to take certain precautions as mentioned below.

First Layer Adhesion

Users should ensure that the first layer of the print has sufficient adhesion. The first layer adhesion can be controlled through multiple means like using a heated bed or a heated chamber. Both these features are important for ABS printing and help in keeping the printed part well heated. The heat prevents the layers from completely solidifying, thus avoiding warping or cracking.

The heat prevents the layers from completely solidifying, thus avoiding warping or cracking.

Using Gluing agent

To increase the first layer adhesion, users can apply glue to the print bed. They can either use a regular glue stick, or specially formulated Magigoo adhesive or use ABS slurry.

ABS Slurry: It is a mixture of ABS filament pieces mixed with acetone. The mixture forms a thick gooey substance that is spread over the print bed to act as a glue. Take adequate care while creating this mixture.

Using Bed Adhesion Tools

Users can also try to control the warping and cracking issues through slicer settings. Slicer softwares have bed adhesion tools like raft and brim. These can significantly improve the first layer adhesion of the print.

Raft: Raft is a horizontal structure over which the entire part is 3D printed. Its sole purpose is to increase the surface area in touch with the bed.

Brim: The brim is similar to a raft but a brim only extends from the outer surface of the print. It has no contact with the print’s underside.

It has no contact with the print’s underside.

Tweak Slicer Settings

Other slicer settings that can help in increasing the bed adhesion are fan settings. Fans can be either run at low speeds for the entire duration of the print or else simply switched off while printing with ABS. This will help in keeping the print warm and in a heated state to improve bed adhesion.

advantages

➜ Manufacturing-Grade Material: ABS filament offers great mechanical properties like strength, ductility, impact, and wear resistance. This makes it an important manufacturing-grade material

➜ Easy to Post-Process: ABS can be machined, polished, sanded, filed, drilled, painted, glued, etc. with extreme ease, and the finish is still good.

➜ Wide-Ranging Applications: It has wide ranging applications in prototyping, especially for aesthetic prototypes and end-use parts as well.

DISADVANTAGES

➜ Warping, Curling & Cracking: ABS is highly prone to warping, curling & cracking. Without necessary precautions, the print will fail.

Without necessary precautions, the print will fail.

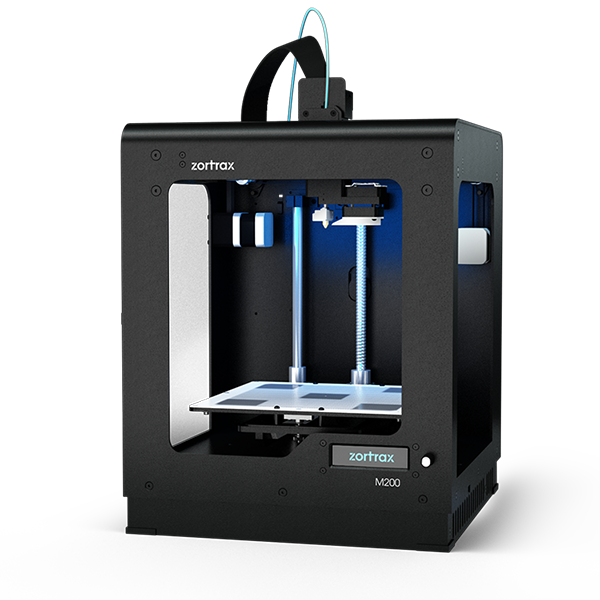

➜ Advanced Feature Requirements: ABS is a demanding material and it requires multiple features to ensure it is successfully printed. For most hobbyist and even professional level 3D printers, ABS will produce inconsistent results, while traditional industrial 3D printers can be out of reach due to high costs. Next generation desktop 3D printers such as the MakerBot METHOD are changing this with industrial features designed to control the 3D printing environment and produce consistent results while still being affordable.

WHERE TO BUY?

ABS material can either be bought from filament manufacturers or 3D printer manufacturers. For the MakerBot METHOD, we recommend use of MakerBot ABS as it is optimized to deliver great results.

Looking for a professional 3D printing platform that works with a variety of manufacturing-grade materials? Learn more at makerbot.com/method.

A Note to MakerBot METHOD Users Printing ABS:

The above guide is intended to discuss the challenges and techniques for printing ABS with a variety of desktop 3D printers. METHOD is designed to print real ABS without modification or special settings thanks to its unique environmental regulation features such as the heated build chamber. It is recommended to use optimized ABS settings within MakerBot Print for best results.

METHOD is designed to print real ABS without modification or special settings thanks to its unique environmental regulation features such as the heated build chamber. It is recommended to use optimized ABS settings within MakerBot Print for best results.

Related Posts

Ultimate Materials Guide - Tips for 3D Printing with ABS

Overview

ABS (Acrylonitrile Butadiene Styrene) has a long history in the 3D printing world. This material was one of the first plastics to be used with industrial 3D printers. Many years later, ABS is still a very popular material thanks to its low cost and good mechanical properties. ABS is known for its toughness and impact resistance, allowing you to print durable parts that will hold up to extra usage and wear. LEGO building blocks are made from this material for that same reason! ABS also has a higher glass transition temperature, which means the material can withstand much higher temperatures before it begins to deform. This makes ABS a great choice for outdoor or high temperature applications. When printing with ABS, be sure to use an open space with good ventilation, as the material tends to have a slight odor. ABS also tends to contract quite a bit as it cools, so controlling the temperature of your build volume and the part inside can have major benefits.

This makes ABS a great choice for outdoor or high temperature applications. When printing with ABS, be sure to use an open space with good ventilation, as the material tends to have a slight odor. ABS also tends to contract quite a bit as it cools, so controlling the temperature of your build volume and the part inside can have major benefits.

- Low Cost

- Good impact and wear resistance

- Less oozing and stringing gives models smoother finish

- Good heat resistance

- Heavy warping

- Needs heated bed or heated chamber

- Produces a pungent odor while printing

- Parts tend to shrink leading to dimensional inaccuracy

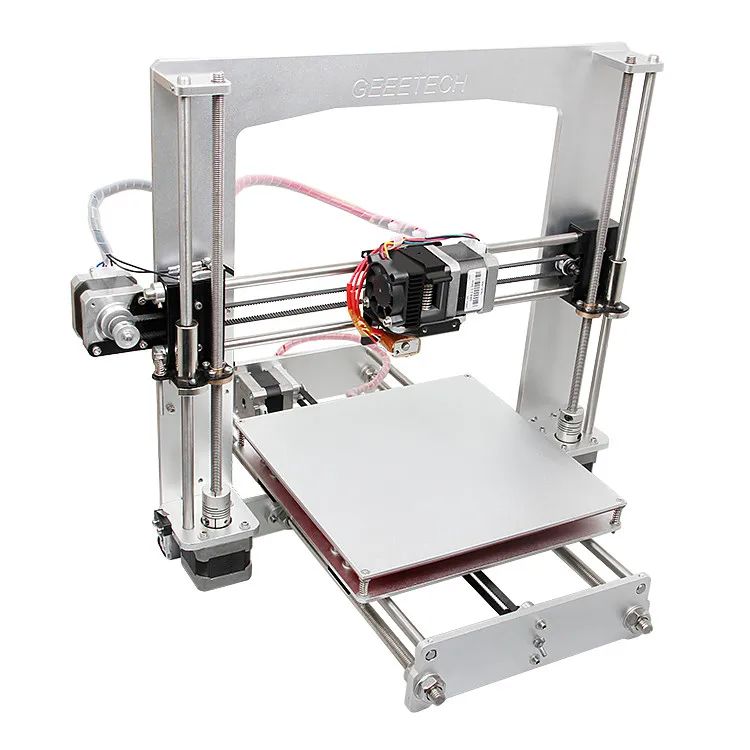

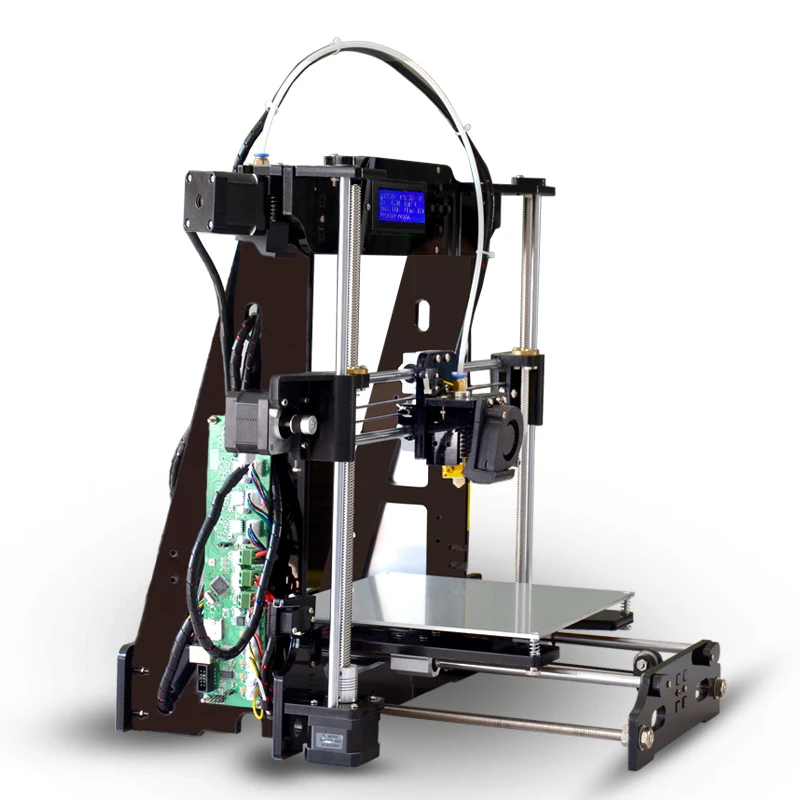

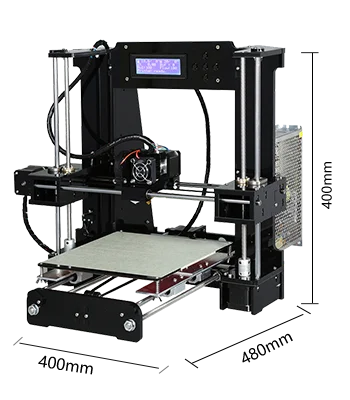

Hardware Requirements

Before 3D printing with ABS make sure your 3D Printer meets the hardware requirements listed below to ensure the best print quality.

Bed

Temperature: 95-110 °C

Heated Bed Required

Enclosure Recommended

Build Surface

Kapton tape

ABS Slurry

Extruder

Temperature: 220-250 °C

No special hot-end required

Cooling

Part Cooling Fan Not Required

Best Practices

These tips will help you reduce the chances of common 3D printing issues associated with ABS such as warping and fumes.

Control Warping

One of the most common print quality issues with ABS is warping. As the plastic cools from its extrusion temperature down to the room temperature, this change in temperature causes the plastic to shrink and contract. This can be particularly troublesome for the first layer, as this change in size can frequently cause the part to separate from the bed, ruining the print. You can minimize this effect using a proper build surface heated to 110º C. The build platform will transfer some of its heat to the first few layers of your part, which will prevent them from shrinking and separating from the bed. It is also common to set the extruder temperature about 10 to 20 degrees higher for the first few layers of your print, which can also help reduce the risk of separation. Simplify3D gives you complete control over your bed and extruder temperatures, so you easily set the desired values on a per-layer basis using the Temperature tab of your process settings. While these changes can help with the bottom layers of your print, taller parts may have issues as the layers get further away from the bed. When printing larger parts, consider adding an enclosure around your printer to maintain a higher temperature around your print. The enclosure can also prevent wind drafts that could rapidly cool the part during printing. If you’ve followed these steps, but you’re still having trouble with warping and separation, our Print Quality Guide has an entire section dedicated to warping which can give you even more information on the topic: How to Prevent Warping.

While these changes can help with the bottom layers of your print, taller parts may have issues as the layers get further away from the bed. When printing larger parts, consider adding an enclosure around your printer to maintain a higher temperature around your print. The enclosure can also prevent wind drafts that could rapidly cool the part during printing. If you’ve followed these steps, but you’re still having trouble with warping and separation, our Print Quality Guide has an entire section dedicated to warping which can give you even more information on the topic: How to Prevent Warping.

Using Brims and Rafts

When printing large parts, or thin delicate parts, you may find that you still have trouble getting these parts to properly adhere to the bed. In these cases, adding a brim or a raft to your print can be a great way to anchor these part to the build platform and prevent warping. A brim will add several rings of plastic around your model on the first few layers, creating extra surface area to hold down the edges of your part. Using a raft will actually print an entirely new plastic structure underneath your print, which can be removed after the print is completed. The rafts in Simplify3D were heavily optimized for Version 4.0 allowing them to print faster and use more material, but you may still find that a brim is faster for larger parts. If you want to learn more about these options, we have an in-depth article that explains all of the differences between rafts, skirts, and brims to help you get started.

Using a raft will actually print an entirely new plastic structure underneath your print, which can be removed after the print is completed. The rafts in Simplify3D were heavily optimized for Version 4.0 allowing them to print faster and use more material, but you may still find that a brim is faster for larger parts. If you want to learn more about these options, we have an in-depth article that explains all of the differences between rafts, skirts, and brims to help you get started.

Print In a Well Ventilated Area

Printing with ABS is known to produce a strong odor with fumes that could potentially be harmful if inhaled in large quantities. Avoid confined spaces and place your printer in a well-ventilated area to avoid these issues. Newer 3D printers may include a separate air-filtration system or HEPA filter that can deal with these fumes right from the source. If you printer doesn’t include these features or you’re limited in where you can place it, consider opening a window or using a flexible air duct from your local hardware store to help route the fumes outside.

Pro-Tips

- Bed adhesion can be improved by using an ABS slurry. You can make this slurry on your own by mixing small pieces of ABS filament with acetone and applying the mixture on the bed. There are also several pre-packaged versions of the product that can be purchased.

- When doing a dual extrusion print, PLA can be a good break-away support material as it does not adhere strongly to ABS.

Get Started with ABS

Here are a few tips to help you get started with ABS. You can view some common applications below, select from a typical sample project, or even view popular filament brands if you’re looking to stock up on this low cost material.

Common Applications

- Cases or Project Enclosures

- Toys or Action Figures

- Automotive hardware

Sample Projects

- Lego Bricks

- Door Catch

- Fidget Spinner

Popular Brands

- Hatchbox ABS

- FormFutura ABS pro, EasyFil ABS, TitanX

- eSun ABS, ABS+

- HobbyKing ABS

ABS for 3D printing

The high strength of ABS makes it suitable for structural applications

ABS (Acrylonitrile Butadiene Styrene, ABS) is a high-impact thermoplastic that has become very popular in industry and additive manufacturing.

The excellent mechanical and physical properties of ABS plastic make it possible to use this material to create all kinds of objects of practical value. ABS plastic is widely used in the automotive, medical and souvenir industries, in the production of sports equipment, plumbing, bank cards, furniture, toys, etc.

The relatively low cost of ABS plastic and the relative ease of use as a consumable have led to ABS's high popularity among 3D printing enthusiasts. ABS is one of the most popular materials for FDM/FFF printing.

Safety ABS

ABS is relatively safe and does not pose a threat under normal conditions. However, heating ABS releases toxic acrylonitrile fumes, which means you need to take some precautions when 3D printing. Evaporation is generally low due to the relatively slow material consumption of FDM printing. To ensure a completely safe environment, only good ventilation of the room or an extractor is required. It is also worth bearing in mind that ABS plastic reacts with ethanol, which leads to the release of styrene.

It is also worth bearing in mind that ABS plastic reacts with ethanol, which leads to the release of styrene.

Do not use finished ABS products to store hot food and drinks or alcohol at any temperature.

ABS Specification

| Glass Transition Temperature | About 105°C |

| Flexural strength | 41 MPa |

| Tensile strength | 22 MPa |

| Tensile modulus | 1627 MPa |

| Elongation | 6% |

| Shrinkage on cooling | Up to 0.8% |

| Material density | Approx. 1.05 g/cm³ |

Please note that the actual dimensions of the 3D printed ABS will depend on the manufacturer's specifications. In many cases, ABS is blended with other thermoplastics (such as polystyrene), resulting in changes in extrusion temperature, resistance to certain solvents, etc.

In many cases, ABS is blended with other thermoplastics (such as polystyrene), resulting in changes in extrusion temperature, resistance to certain solvents, etc.

Advantages and disadvantages of ABS

The main disadvantage of ABS is its relatively low resistance to direct sunlight. In addition, the potential toxicity of the material somewhat limits its use in the manufacture of toys, food packaging and medical instruments.

A wide range of colors is demonstrated with Lego bricks made from ABS plastic

At the same time, ABS plastic has a number of positive qualities:

- Almost unlimited colors

- Moisture resistant

- Acid resistance

- Oil resistance

- Relatively high heat resistance, reaching up to 115°C in some material grades

- Non-toxic at relatively low temperatures and in the absence of alcohol exposure

- Increased impact resistance

- High elasticity

- High durability in the absence of direct sunlight

- Easy to machine

- Good affordability

- High solubility in acetone

Use in 3D printing

The result of processing a model from ABS plastic with acetone vapor

Printing with ABS plastic is associated with certain technological difficulties due to a rather high tendency to shrink, that is, to loss of volume during cooling. As a result, the formation of deformations and delamination of models is possible. This point is taken into account by manufacturers optimizing 3D printers for ABS printing by installing heated work platforms and providing varying degrees of climate control in the working chamber. Some methods for dealing with deformations are described in the section "How to avoid deformation of models when 3D printing".

As a result, the formation of deformations and delamination of models is possible. This point is taken into account by manufacturers optimizing 3D printers for ABS printing by installing heated work platforms and providing varying degrees of climate control in the working chamber. Some methods for dealing with deformations are described in the section "How to avoid deformation of models when 3D printing".

In addition to being machinable, ABS is easily soluble in acetone and some other solvents, which makes it possible to produce fairly large models from component parts by gluing. In addition, the processing of finished models with acetone vapor allows you to smooth the outer surfaces and achieve complete tightness. For more information on processing with acetone, see the "Processing 3D Printed Models" section.

Go to the main page of the 3D Printing Encyclopedia

PLA and ABS for 3D printing: what's the difference?

3DPrintStory 3D printing process PLA and ABS for 3D printing: what's the difference?

PLA or ABS: Which one to use and when? The article reveals the difference between these plastics and shows the areas of their use.

Some of the most popular plastics for 3D printing using Fused Deposition Modeling (FDM) technology are ABS and PLA. Both are thermoplastics. This means that they become malleable when heated - so you can shape them and when cooled they will retain their shape. Both materials are made into bars that you can feed into your 3D printer's extruder. The printing process when using ABS and PLA is very similar.

Despite their apparent similarity, ABS and PLA are different. Some 3D printers can only print with PLA plastic at all.

ABS and PLA - brief definitions

PLA (PolyLactic Acid) is a biopolymer, i.e. a biodegradable plastic. It is made from renewable materials such as cornstarch or sugar cane. In addition to 3D printing, PLA is used for packaging, plastic bottles and cups. It is considered to be more environmentally friendly compared to ABS.

ABS (Acrylonitrile-Butadiene Styrene) oil-based plastic. This is a tough material that is used to create household appliances, electrical equipment and even Lego bricks.

Comparison of the main characteristics of the PLA and ABS

The table below shows the main characteristics of PLA and ABS plastic:

| Parameter | PLA | ABS | MELT FLOT FLAT FLAT FLAT FLAT FLAT FLAT FLAT FLOW / 10 min. | 9.7 cm3 / 10 min.0002 | 70-82 190-220 ° C | 230-250 ° C |

| Recommended print temperature | 50-70 ° C (not to gnaw) | 80-120 ° C (be sure to warn) |

What does each of the above characteristics mean?

- Melt flow index characterizes the ease of flow of the molten polymer. It is measured in the amount of material that passes through a capillary of a certain diameter and length in 10 minutes.

- The glass transition temperature is the point at which a hard and brittle material becomes molten or elastic with increasing temperature. This is an important characteristic if you are printing a model that will interact with hot water or drinks: for example, a PLA coffee mug is not a good idea.

ABS plastic in this case is also a bad option: see the "Recommended Applications" section below.

ABS plastic in this case is also a bad option: see the "Recommended Applications" section below. - The pour point characterizes the limit of resistance to heat: at temperatures above this, the object will bend. If your 3D printer is equipped with a heated table, the temperature of this table must be below this temperature; otherwise, the object is deformed during 3D printing.

- Melting point (or melting point) - everything is obvious here - the temperature at which the material begins to melt.

- 3D printing temperatures are typically higher than melting temperatures, as the plastic must be melted (not just started melting) as it is fed through the extruder nozzle.

Mechanical and physical properties

PLA is more brittle and has a higher surface hardness. More prone to breakage during bending. Acetone treatment (to improve surface smoothness) is not possible.

The illustration below shows a key printed in ABS.

When printed at the manufacturer's recommended temperatures, ABS parts will be much harder and more resistant to impact and stress than PLA. That is, ABS is better suited for printing mechanical components and parts and objects with high resistance to aggressive environments. In addition, ABS parts are more flexible and bend rather than break under external pressure. ABS is better malleable, post-processing is easier. Printed models can be sanded, painted. They can be treated with acetone to get a smooth, shiny surface.

That is, ABS is better suited for printing mechanical components and parts and objects with high resistance to aggressive environments. In addition, ABS parts are more flexible and bend rather than break under external pressure. ABS is better malleable, post-processing is easier. Printed models can be sanded, painted. They can be treated with acetone to get a smooth, shiny surface.

Easy to 3D print

In general, PLA is best for beginners to get into 3D printing. ABS plastic is more prone to the standard 3D printing problem of shrinkage (i.e. when the first layers cool too quickly and begin to curl around the edges, causing the model to come off the table at the corners). Printing ABS plastic will require experimentation to find the optimal settings.

PLA has another drawback - it tends to clog the nozzle of the extruder, as it is more sticky and expands more when melted. To avoid clogging the nozzle, it is recommended to follow the manufacturer's instructions. The layers lay down well and are unlikely to be bent around the edges. The printed product is easier to separate from the table than similar ones made of ABS plastic. Heated bed is optional (but can improve print quality if used correctly). The 3D printer doesn't have to be kept in a closed case (but again, using a case can result in better results). To increase the adhesion of the table, it is recommended to use special tape (also known as 3D printing tape).

The layers lay down well and are unlikely to be bent around the edges. The printed product is easier to separate from the table than similar ones made of ABS plastic. Heated bed is optional (but can improve print quality if used correctly). The 3D printer doesn't have to be kept in a closed case (but again, using a case can result in better results). To increase the adhesion of the table, it is recommended to use special tape (also known as 3D printing tape).

ABS tends to shrink more than PLA.

ABS is printed at higher temperatures than PLA, which greatly reduces the chance of nozzle clogging. In addition, less force is required to feed the material into the nozzle. Since ABS shrinks as it cools, the part can come off the table (especially when 3D printing tall models). To avoid this, it is necessary to use a heated table. It is desirable that the printer has a case. Since the grip on the table is worse than that of PLA, various problems can arise. To improve adhesion to the table, it is recommended to use Kapton tape (withstands temperatures up to 400ºC). True, tape is expensive, so there is an alternative option - spray hairspray on the table before printing.

True, tape is expensive, so there is an alternative option - spray hairspray on the table before printing.

Storage conditions

Both plastics (PLA/ABS) absorb moisture from the air. To avoid this, the air is pumped out during packaging. Manufacturers of materials for 3D printing recommend using spools as quickly as possible, as quality begins to suffer over time. Unpacked material should be stored in a dry place.

If PLA is stored for a long time, you may notice bubbles during 3D printing. Doing so may clog the nozzle and degrade the surface quality of the printed product. While wet PLA can be dried under warm air, heat can degrade the material's structure and change thermal properties, which will affect print temperatures.

When printing with damp ABS, bubbles may also occur. If you dry it with warm (but not too much) air, for example, using a food dehydrator, the thermal properties of the plastic will not change.

Vapors and odor

When you 3D print with resins (PLA/ABS), you will smell. The smell depends on the media used and the printing temperature.

The smell depends on the media used and the printing temperature.

PLA smells almost pleasant, some people liken this smell to warmed waffles or sweets.

ABS smells bad when heated. Some complain of headaches and even nausea due to 3D printing. If you are printing indoors, good ventilation is recommended.

Degradability and durability

PLA is biodegradable - it is made from plant materials. Since it needs a little heat to decompose, you can safely throw it into the trash containers.

ABS does not biodegrade but can be recycled.

Both materials (PLA/ABS) degrade when exposed to sunlight and moisture. ABS is more stable and more chemical resistant than PLA.

What to choose?

Both materials are available in different colors; there are even translucent materials. Some specialty materials are only available as a mixture based on PLA. This is wood, metal, etc.

The photo below shows ColorFabb's "Bamboofill". The material contains 80% PLA and 20% bamboo sawdust.

Prices for PLA and ABS

Prices are in the same range, but as a rule, PLA plastic is a bit more expensive. Naturally, PLA plastics with impurities of wood or other materials are more expensive.

Recommended Applications

PLA is widely used in 3D printing, such as household items, gadgets and toys. It's great if flexibility isn't your primary requirement. In this it is inferior to ABS. On the other hand, it is biocompatible and can be safely used in accessories that interact with the skin.

Due to its relatively low melting point, PLA is not suitable for objects that are exposed to heat. When heated above 60ºC, PLA plastic products begin to lose their shape. Do not use PLA in objects that are exposed to sunlight for a long time or are in cars.

ABS is best suited for objects that are exposed to high temperatures, can be dropped or can take bending loads. ABS can be used for models subject to mechanical shock.

ABS is not food safe: especially when the material comes into contact with hot liquids or warm food.