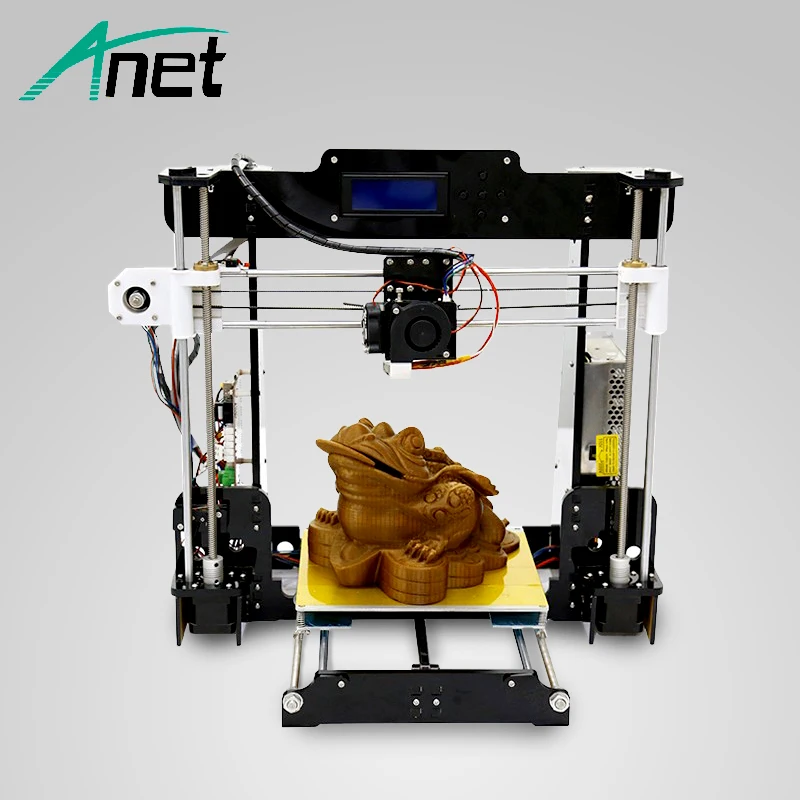

Prusa i3 3d printer specs

Original Prusa i3 MK3S+ 3D printer

The Original Prusa i3 MK3S+ is the latest version of our award-winning 3D printers. We have upgraded the MK3S with a brand new SuperPINDA probe for improved first layer calibration, added high-quality bearings and various useful design tweaks to make the printer easier to assemble and maintain. The MK3S+ includes all the proven features of the previous models, including the heatbed with removable PEI spring steel print sheets, automatic Mesh Bed Leveling, filament sensor, power loss recovery (power panic) and safety features. And it is still as silent as ever!

The functionality of the MK3S+ can be further enhanced by our unique Multi-Material Upgrade 2S for printing with up to 5 filaments simultaneously.

Main Features

SuperPinda Probe

SuperPINDA probe features a hiqh-quality sensor for a fully-automatic Mesh Bed Leveling process. Before every print, the printer probes the bed in several places and creates a virtual heightmap of the print area. This process ensures that the first layer will always be spot on!

Quality Bearings & more

The MK3S+ features a new set of metal clips for the high-quality bearings on the Y-axis. The belt tensioning mechanism on the X-axis was reworked and the X-end plastic parts reinforced. The filament path in the extruder was altered for better support of flexible filaments.

Removable Print Sheets

Spring steel sheets are easy to maintain and make removing the printed object from the print surface a breeze. We offer three types of print surface: smooth, textured and satin to cover all your needs when printing from a wide range of different materials - most of which do not require any special separation layers or surface preparation.

High-Quality Parts

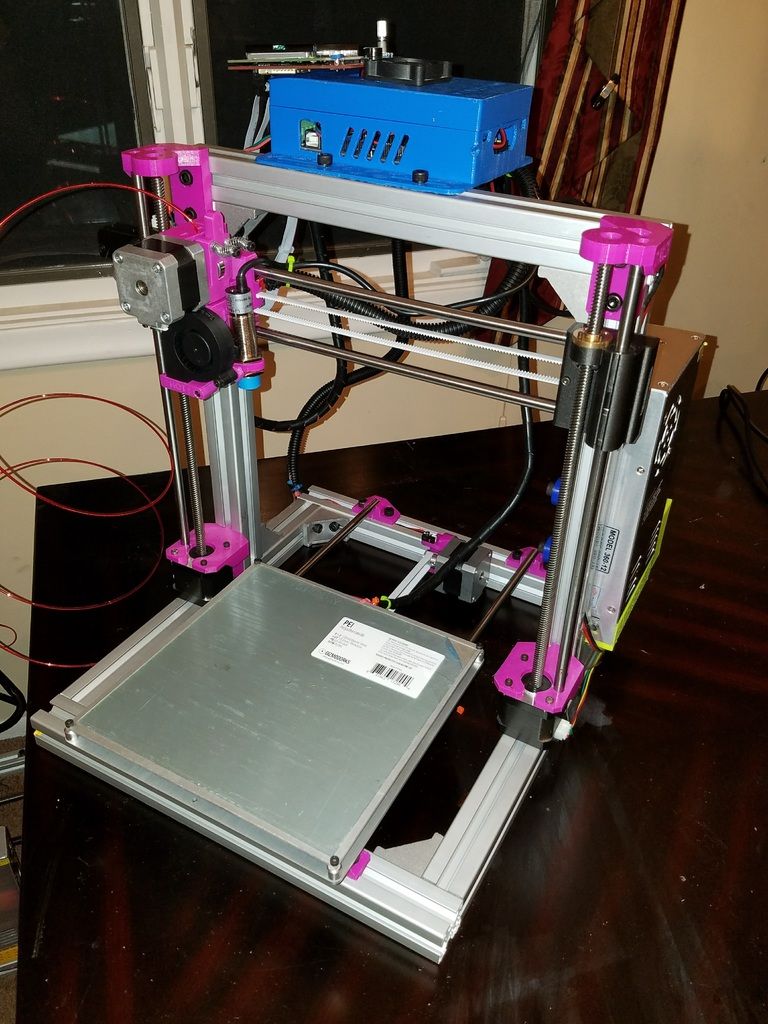

The MK3S+ features an aluminum extrusion Y-axis assembly. Thanks to the milled dural frame, the MK3S+ is stable, rigid, and easy to assemble. Combined with our internally developed extruder featuring Bondtech gears and the E3D V6 hotend, the MK3S+ can print high-quality objects up to 210 mm in height.

Thanks to the milled dural frame, the MK3S+ is stable, rigid, and easy to assemble. Combined with our internally developed extruder featuring Bondtech gears and the E3D V6 hotend, the MK3S+ can print high-quality objects up to 210 mm in height.

Power Loss Recovery

Are you afraid of a blackout ruining your 48-hour print? Worry no more - the MK3S+ can deal with that! The printer can fully recover from the loss of power and continue printing exactly where it left off. It detects power interruptions and shuts down the heatbed and extruder heating, and saves the last known location.

Filament Sensor

The MK3S+ further enhances the reworked extruder from the MK3S. The built-in filament sensor uses a reliable trigger system, which detects whether a strand of filament is inserted into the extruder. It can detect any type and color of filament and is not susceptible to mechanical wear.

Mesh Bed Leveling

Thanks to the SuperPINDA probe, the MK3S+ can use the Mesh Bed Leveling process to compensate for microscopic imperfections of the print sheet, and inconsistencies caused by the assembly and stacking of the manufacturing tolerances of various parts. Achieving a great-looking first layer is quick and easy.

Achieving a great-looking first layer is quick and easy.

Slice with PrusaSlicer

Our internally developed multiplatform slicer comes with in-house made and fully tested profiles for all of our 3D printers and a wide range of filaments. With built-in tools, such as advanced support generation, cutting, automated object distribution, ironing and many others, you will turn your 3D models into print files in no time!

Support for a wide range of Materials

The MK3S+ is fully compatible with a wide range of various types of materials. No matter whether you want to print something for fun from PLA and flexible materials, or you need to produce durable prototypes from PETG, ASA, Polycarbonate and Polypropylene - the MK3S+ can handle them with ease.

Open-source Hardware & Firmware

We develop firmware for all of our 3D printers and test every new version thoroughly before release. Ongoing development and regular updates ensure that our machines are packed with useful features, such as print sheet profiles, automated calibration, Mesh bed leveling, advanced diagnostics, remaining print time estimation, Octoprint support and more!

Ongoing development and regular updates ensure that our machines are packed with useful features, such as print sheet profiles, automated calibration, Mesh bed leveling, advanced diagnostics, remaining print time estimation, Octoprint support and more!

Technical Parameters

| Build Volume | 25×21×21 cm (9.84"×8.3"×8.3") |

| Layer height | 0.05 - 0.35 mm |

| Nozzle | 0.4mm default, wide range of other diameters/nozzles supported |

| Filament diameter | 1.75 mm |

| Supported materials | Wide range of thermoplastics, including PLA, PETG, ASA, ABS, PC (Polycarbonate), CPE, PVA/BVOH, PVB, HIPS, PP (Polypropylene), Flex, nGen, Nylon, Carbon filled, Woodfill and other filled materials. |

| Max travel speed | 200+ mm/s |

| Max nozzle temperature | 300 °C / 572 °F |

| Max heatbed temperature | 120 °C / 248 °F |

| Extruder | Direct Drive, Bondtech gears, E3D V6 hotend |

| Print surface | Removable magnetic steel sheets(*) with different surface finishes, heatbed with cold corners compensation |

| Printer dimensions (without spool) | 7 kg, 500×550×400 mm; 19. 6×21.6×15.7 in (X×Y×Z) 6×21.6×15.7 in (X×Y×Z) |

| Power consumption | PLA settings: 80W / ABS settings: 120W |

* Consumable parts, such as PEI sheets (smooth, textured, etc.) are not covered by warranty as the coatings are designed to diminish over time unless failure has occurred due to a defect in materials or workmanship. Cosmetic damage, including but not limited to scratches, dents, cracks, or other cosmetic damage is also not covered by the warranty. Only defective sheets on arrival are covered by warranty.

Sample Prints

Full Features List (July 2022 Edition)

- Controller: EINSY RAMBo 8-bit board with Trinamic 2130 drivers (256 microstepping), co-developed with Ultimachine, sensorless homing for X and Y axes

- Mesh Bed Leveling: Advanced high-quality SuperPINDA sensor (Super Prusa INDuction Autoleveling sensor)

- Print sheet profiles: Firmware supports print sheet profiles to store Live Z calibration data to enable quick switching between different print sheets.

- Filament sensor: IR sensor built-in, supports filament auto-loading. Print pauses when filament runs out.

- Power Panic: Hardware-based, single G-code line accuracy

- Ethernet connection: via Raspberry Pi (optional)

- Wi-Fi connection: via Raspberry Pi (optional)

- Advanced sensors: 3 thermistors, fans RPM monitoring, SuperPINDA

- Calibration: Automatic, Mesh Bed Leveling, SelfTest

- Print medium: SD card (16 GB card included)

- Firmware update: via PC (USB cable)

- PSU: Custom-made Delta PSU with hardware-based power panic

- Advanced features: Automatic filament loading, steel sheet profiles, Octoprint compatibility and more

- New features introduced through firmware upgrades

Awards & Press Reviews

Thanks to all of these (and many other) features, the MK3S became the “Best 3D Printer” according to ALL3DP. The MK3S is also the highest-rated 3D printer, and the “Editor’s Choice”, in the prestigious MAKE:MAGAZINE’s Digital Fabrication Guide 2019. The MK3S is also featured in TechRadar's Best 3D printers of 2021 as The best all-around 3D printer. NY Times wrote that "...of the 11 printers we’ve tested over the past five years, the Prusa i3 MK3S printer has produced the largest and best-looking prints." According to ZDNet, the MK3S is "The best pro-sumer 3D printer under 1000 USD."

The MK3S is also the highest-rated 3D printer, and the “Editor’s Choice”, in the prestigious MAKE:MAGAZINE’s Digital Fabrication Guide 2019. The MK3S is also featured in TechRadar's Best 3D printers of 2021 as The best all-around 3D printer. NY Times wrote that "...of the 11 printers we’ve tested over the past five years, the Prusa i3 MK3S printer has produced the largest and best-looking prints." According to ZDNet, the MK3S is "The best pro-sumer 3D printer under 1000 USD."

6 reasons to buy the MK3S+

1

Great User Support

We offer 24/7 tech support via live chat and email in seven languages. Our printers come with detailed instructions and guides for easy assembly and maintenance. You can also visit our knowledge base, community forum, Facebook groups and official Blog, where we publish useful 3D printing tips and tricks, contests and more!

2

Advantages of an Assembled 3d Printer

Compared to the assembly kit, the assembled printer differs only in the form in which you receive it. The printer comes pre-assembled and tested right out of the box. To start your first print, simply plug it in, run the initial calibration, and you are good to go. It is an ideal choice for businesses where there is a need to start printing as soon as possible.

The printer comes pre-assembled and tested right out of the box. To start your first print, simply plug it in, run the initial calibration, and you are good to go. It is an ideal choice for businesses where there is a need to start printing as soon as possible.

3

Built-in Safety Features

Original Prusa 3D printers are well-known for their reliability and safe operation. Every part of our printers is thoroughly tested in-house. The MK3S+ is equipped with three thermistors and comes with a custom-built high-quality Delta power supply. The printer can recognize issues with heating and stop operation to prevent damage.

4

Open-source and Community Friendly

All parts of our printer are open-source, which means we publish all source codes and blueprints online. The community around our products is huge and the feedback is overwhelmingly positive - don't believe us? Check out Facebook groups and YouTube videos! There's so much to do with your 3D printer - buying it is just the beginning!

5

Ready for the Multi-Material Upgrade 2S

Multi Material Upgrade 2S is our unique add-on option for printing with up to 5 different filaments simultaneously. Multi-material could be your next step in the 3D printing world and the MK3S and MK3S+ are completely ready for the upgrade! MMU2S also allows you to print a soluble support interface - check out the video!

Multi-material could be your next step in the 3D printing world and the MK3S and MK3S+ are completely ready for the upgrade! MMU2S also allows you to print a soluble support interface - check out the video!

6

Upgradability

One of the most popular features of the Original Prusa i3 concept is upgradability. When you buy our 3D printer, you can upgrade it later to a newer version, so you don't need to buy a whole new model every two years like, for example, your phone or laptop. We also keep supporting our 3D printers with regular firmware updates that bring new features!

Ready to print settings

We provide high print settings with the printer, so you don't have to dive into complex new programs the second you finish the build. You can start printing right away, and this gives you a great head start!

These settings are great for all kinds of objects, not just for a couple of prepared showpieces. After a while, when you're familiar with the printer, you can, of course, dive into tinkering ;-)

After a while, when you're familiar with the printer, you can, of course, dive into tinkering ;-)

We are developing our own slicing software. PrusaSlicer is a feature-rich, frequently updated tool that contains everything you need to export the perfect print files for your Original Prusa 3D printer. But of course, we also have the settings for the third party slicers like Simplify3D, Cura, etc.

Discount program for Original Prusa i3 assembled printer owners

Our discount program for the Original Prusa i3 assembled printer owners gives you a 10% discount on subsequent orders of the Original Prusa i3 assembled printers and selected filaments.

How does it work?

To enter the discount program, you only need to purchase your first Original Prusa i3 assembled printer for the full price. After the assembled printer is delivered to you, your Prusa account automatically applies the 10% discount on the assembled i3 printers. So your next assembled i3 printer will be discounted by 10% :-). Make sure to be always logged into your Prusa account, to have the discount applied.

So your next assembled i3 printer will be discounted by 10% :-). Make sure to be always logged into your Prusa account, to have the discount applied.

Along, with the discount on the assembled i3 printers, the discount does apply to selected filaments too. Most importantly including our high-precision filament, the Prusament!

MK3S+ vs MINI+ Comparison

| Original Prusa i3 MK3S+ | Original Prusa MINI+ | |

Build volume |

250 x 210 x 210 mm | 9.84 x 8.3 x 8.3 in | 180 x 180 x 180 mm | 7 x 7 x 7 in |

Layer height |

0.05 – 0.35 mm | 0.05 – 0.25 mm with 0.4 mm nozzle |

Max travel speed |

200+ mm/s | 200+ mm/s |

Max hotend/heatbed temp. |

300 °C / 120 °C (572 °F / 248 °F) |

280 °C / 100 °C (536 °F / 212 °F) |

Mainboard |

Einsy RAMBo 8-bit board with Trinamic 2130 drivers co-developed with Ultimachine |

Custom 32-bit Buddy electronics with STM32 and latest Trinamic 2209 silent stepper drivers |

MMU2S support |

Yes |

No |

Extruder |

Direct drive |

Bowden system with 3:1 gearing |

LCD screen |

Monochromatic LCD |

2. |

Print surface |

magnetic heatbed with removable PEI spring steel sheets |

magnetic heatbed with removable PEI spring steel sheets |

Filament diameter |

1.75mm |

1.75mm |

Number of materials (simultaneously) |

1 | 1 |

Nozzle diameter |

0.4mm (default) / other nozzle diameters supported |

0.4mm (default) / other nozzle diameters supported |

Supported materials |

Any thermoplastic including Nylon and Polycarbonate |

Most thermoplastics except Carbon filled |

Filament sensor |

Yes (IR) |

Optional upgrade |

Power panic |

Hardware-based, single G-code line accuracy |

Future software upgrade, single layer accuracy |

Ethernet connection |

Via Raspberry Pi |

Yes |

Wi-Fi connection |

Via Raspberry Pi |

Separate future upgrade (ESP Wi-Fi module) |

Advanced sensors |

3 thermistors + SuperPINDA, fan RPM sensors |

3 thermistors + SuperPINDA, fan RPM sensors |

Farm mode |

No |

Yes (upcoming feature) |

Calibration |

Automatic, Mesh Bed Leveling |

Automatic, Mesh Bed Leveling |

Print medium |

SD card |

USB drive / LAN |

Firmware update interface |

USB port |

USB drive / LAN |

Power supply |

240W, custom made by Delta with Power Panic HW |

160W, external adapter by Mean Well or Delta depending on the region |

Kit price |

799 USD / 849 EUR (VAT incl. ) ) |

429 USD / 459 EUR (VAT incl.) |

Assembled printer price |

1099 USD / 1159 EUR (VAT incl.) |

459 USD / 489 EUR (VAT incl.) |

FAQ - Frequently Asked Questions

Relevant for

:

MINIMINI+MK2.5MK2.5SMK3MK3SMMU1MMU2SPlus 1.75 mm

Last updated

a year ago

This article is also available in following languages:

How do I get the kit or assembled printer owner discount?

As stated on our website: Prusa3D, if you purchase an assembled i3 printer, we offer a 10% discount on your subsequent purchases of assembled i3 printers and on selected filaments. If you choose to purchase your printer as a kit, we offer a 5% discount on selected filaments. In both cases, the discount is automatically activated in your account as soon as your first kit or printer is shipped.

If you choose to purchase your printer as a kit, we offer a 5% discount on selected filaments. In both cases, the discount is automatically activated in your account as soon as your first kit or printer is shipped.

Can I have my printers frame signed by Jo?

Josef can sign the frame, but please know it can delay the expedition for over a month. He is very busy these days. If it's OK with you, you can ask for the signature in an email or via Live Chat.

What are the printer dimensions?

The dimensions are (W×L×H or X×Y×Z):

- An assembled Mini printer has 12.6 × 13 × 15 inch / 320 × 330 × 380 mm and 5 kg

- Mini print area: 7×7×7 inch / 180 × 180 × 180 mm

- An assembled SL1 printer has 8.7 × 9.45 × 16.3 inch / 220 × 240 × 415 mm and 11 kg

- SL1 print area: 4.7 × 2.6 × 5.9 inch / 120 × 68 × 150 mm

- An assembled i3 (MK2/3) printer itself has 16.

5 × 16.5 × 15 inches / 420 × 420 × 380 mm and 7 kg

5 × 16.5 × 15 inches / 420 × 420 × 380 mm and 7 kg - MK3/S print area: 9.8 × 8.2 × 8.2 inches / 250 × 210 × 210 mm

Keep in mind that the mini and all i3 printers need some more space when in use. Especially in front of and behind them, as the heatbed is moving outside their footprint. Count with 19.7 × 21.5 × 21.5 inches / 500 × 550 × 450 mm (400 × 450 × 450 mm for the Mini), without the spool or MMU.

If you are building an enclosure, you can add even more space in every direction, for better access and manipulation. For the MMU, add 150 mm / 6 in, in height, and think about where to put the 5 spools (behind the printer or above).

What is the printing precision/tolerance of the Original Prusa?

According to our testing, the precision tolerance of a well-assembled Original Prusa printer is 0,1 mm on the Z-axis and 0,3 mm on X and Y. It can be as little as 0,05 mm on all axes, after making additional calibrations such as the Extrusion multiplier calibration and Extruder linearity correction.

However, please note that the material is also relevant: it can shrink while cooling down, and low-quality filaments with uneven diameter will cause uneven extrusion. The optimization of the model for 3D printing (overhangs, etc.) is also important. Our printers are tested even for the 0.25 mm nozzle, which is more precise compared to the standard/stock nozzle with a 0.4 mm diameter.

This article studies the accuracy of FDM printing in more detail.

What tools do I need when working with my Original Prusa?

All necessary tools (pliers, screwdriver, hex keys, wrenches…) are included in the package. If you are wondering what else you could need, here is a list of some nice-to-have things:

- 3.5'' side-cutter/flush-cutter pliers

- White permanent marker

- Compressed air

- Big bottle of IPA 91% to clean the sheet

- Acetone (only with the smooth sheet)

What is the life expectancy of the printer?

According to our testing, the average maintenance-interval of our printers is around 800 print-hours. When it needs to be serviced, most frequently, it’s the nozzle that needs to be changed, and then it can continue printing for many hundreds of hours more.

When it needs to be serviced, most frequently, it’s the nozzle that needs to be changed, and then it can continue printing for many hundreds of hours more.

The ideal air temperature is from 20 - 30 °C (68 - 86 °F) and the ideal air humidity is 25 %.

What is the power consumption of a PRUSA printer?

The average power-consumption that we have measured, at 26 °C (room temperature), is 80 W when printing generic PLA and 120 W when printing generic ABS.

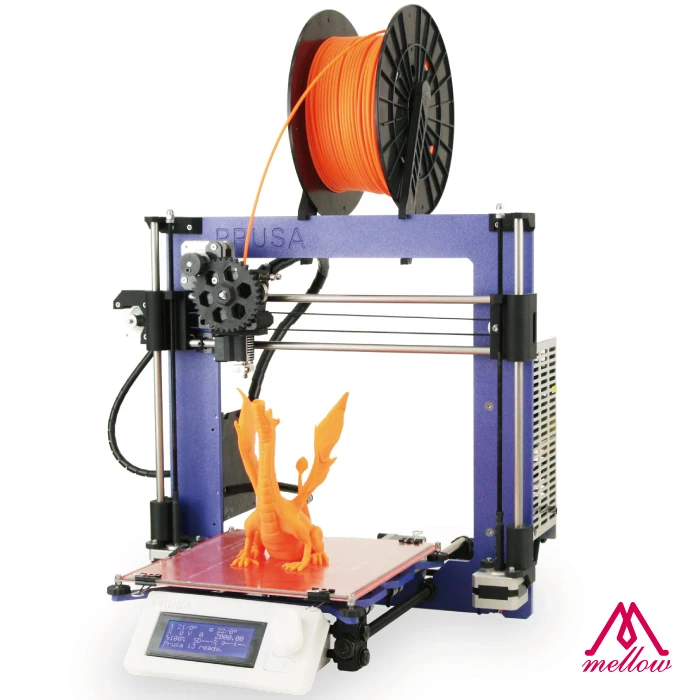

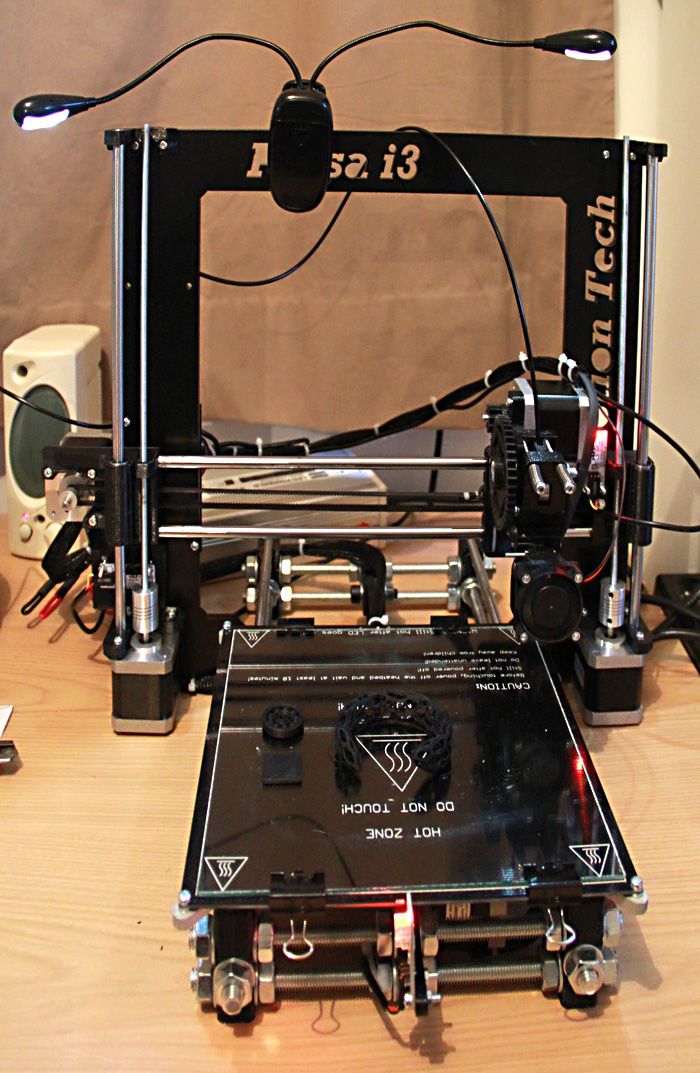

Original Prusa i3 MK2

3D printer reviewSpecifications and features

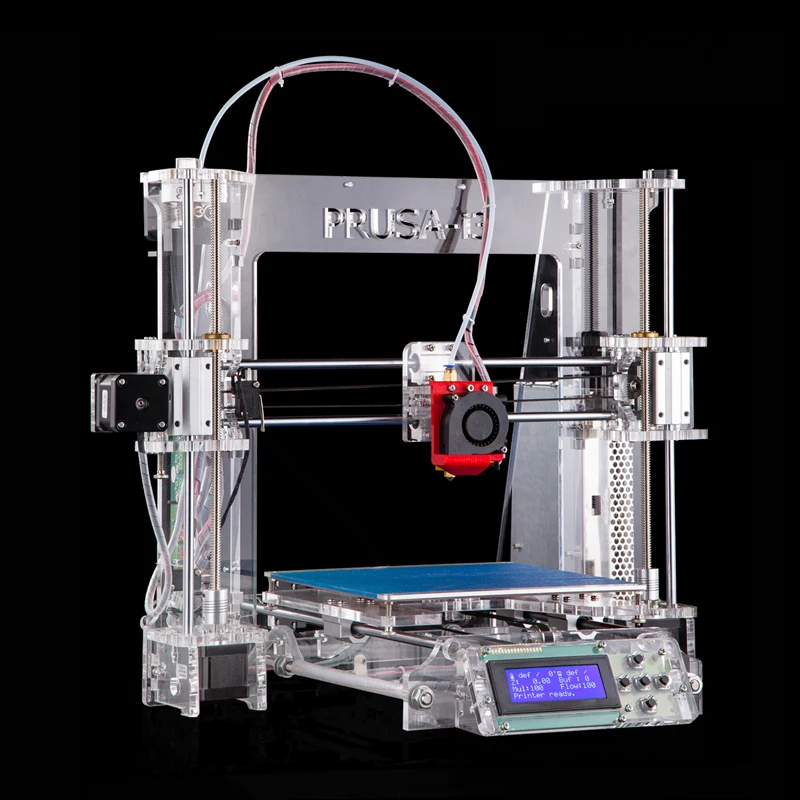

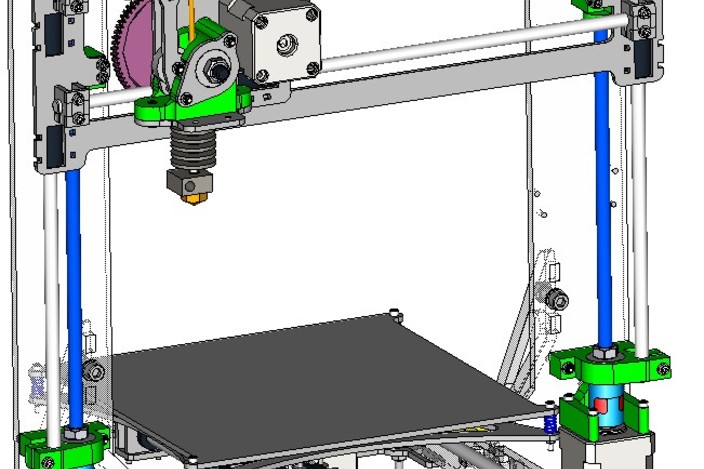

Prusa i3 is an open source software and mechanical project. And the MK2 model gives us new interesting features.

The MK2 design is a tried and tested solution with a vertical center plate that is the base for the Z and X axes and M12 guide screws. This design allows for a working space of 250 mm wide, 210 mm deep and 200 mm high.

The model is printed on the heated table MK42. This solves most adhesion problems. This table has good rigidity, so you don’t have to invent a bicycle and install some kind of heat-resistant glass surface on top. In addition, the top of the printing table is covered with a thin PEI film. Thanks to this, fingerprints will not remain on it. The table heats up and cools down very quickly. If you're printing with PLA, the platen heats up at about the same speed as the extruder.

This solves most adhesion problems. This table has good rigidity, so you don’t have to invent a bicycle and install some kind of heat-resistant glass surface on top. In addition, the top of the printing table is covered with a thin PEI film. Thanks to this, fingerprints will not remain on it. The table heats up and cools down very quickly. If you're printing with PLA, the platen heats up at about the same speed as the extruder.

In addition, the MK42 table has zones with different heating characteristics. Due to this, such an unpleasant moment as more intense cooling at the corners of the table is compensated (the fact that the table has different temperatures from the edges to the center has a bad effect on printing 3D models from high-temperature plastics with a large contact surface).

The Original Prusa i3 MK2 has an E3D v6.1 all-metal extruder. This means that you can use almost any material for 3D printing: PLA, ABS, PET, nylon, wood-based materials or brass particles. If you want to experiment with carbon, you can put a hardened nozzle. If you need precision, you can install a nozzle with a diameter of 0.25 mm. In fact, the print quality with the original nozzle is excellent, but you can't help but notice how much flexibility the E3D v6.1 gives you.

If you want to experiment with carbon, you can put a hardened nozzle. If you need precision, you can install a nozzle with a diameter of 0.25 mm. In fact, the print quality with the original nozzle is excellent, but you can't help but notice how much flexibility the E3D v6.1 gives you.

An inductive sensor is located next to the extruder. In my opinion, such a solution should be implemented in all modern 3D printers. This inductive sensor is easy to set up, operates directly from 5V, takes up very little space.

The sensor performs several tasks. First, the virtual mesh of the 3D printing table is corrected. Due to this, even if there are small deformations, they are included in the extruder movement program. Secondly, if you have built the original Prusa i3 MK2, it has special calibration spots on the print table. Thanks to these calibration sections, the X and Y axes are automatically calibrated and small deviations, which are bound to occur during assembly, will also be compensated.

By the way, in many reviews of this 3D printer model, for some reason the last moment is missed. Well, it calibrates itself, and it's great ... But! Automatic calibration technology using calibration squares was not just developed by the Prusa Research team. Since it's open-source, this technique has become part of the Marlin firmware and now anyone can use it!

In most cases, you will interact with the Original Prusa i3 MK2 via an inconspicuous LCD control panel. In our opinion, the handle with the wheel looks amazing! In addition, the handle is very comfortable to use. Yes, this seems to be a trifle, but in fact, it is precisely such trifles in total that make a 3D printer as a whole better and more convenient. And it is the little things that distinguish a quality product from a quality fake.

Using the LCD screen, you can start calibration, feed media. And it won't be running simple scripts. If something goes wrong, such as the heating elements don't respond with the correct signal or the sensor doesn't send a signal at the expected distance, the Original Prusa i3 MK2 will not continue in "self-destruct mode"

During operation, the heating systems are protected by the Ultimachine Mini Rambo . On the opposite side of the frame is a power supply without a cooler. During operation, it is hot to the touch.

On the opposite side of the frame is a power supply without a cooler. During operation, it is hot to the touch.

It is very convenient that the power supply has a special cover on the side of the connectors. You do not have to worry about connecting individual wires, just connect the power cord to the IEC fuse connector, and the other side of the cable to the Mini Rambo motherboard. This is amazing! The frame is also grounded using the power supply.

Another interesting innovation concerns wires. Among the wires that go to the extruder and the heated table, 3 mm nylon thread is mixed in, which prevents them from tangling and bending. In our opinion, a very interesting and elegant solution to the problem with wires.

Assembly and print quality

If you decide to assemble the Original Prusa i3 MK2 yourself, you need to set aside five hours. There is a high-quality video of the complete assembly and launch of this model, which was recorded by Thomas Sanladerer (the author of the original English review, by the way). On the video, the assembly took more than 5 hours, but you also had to spend time on entertaining the audience ;).

On the video, the assembly took more than 5 hours, but you also had to spend time on entertaining the audience ;).

The manual covers each assembly step, the automatic calibration process. Although the quality of the photographs in the printed version is not the best, you can find the same instructions online. There, the images are stored in excellent quality.

Two 3D printers were ordered for the review. One fully assembled and the second as separate parts for self-assembly. Unfortunately, the assembled printer arrived with minor damage. Apparently, the table latch broke and as a result the LCD case was damaged. I printed the new case myself, but in fact, if such a situation arises, Prusa Reseach will send you a new part under warranty without any problems.

After assembling the Prusa Kit, it turned out that they work exactly the same. In fact, if it weren't for damage in transit and slight differences in frame color, they could only be distinguished by the serial number.

Each printer comes with a test program. And the quality is really amazing!

The dragon pictured below is the first piece printed on the assembled Original Prusa i3 MK2. Printed through a cloud service, without installing software on a PC. There is simply nothing to complain about!

But what's the point of a quality test print? After all, we are counting on excellent printing of our own, not test 3D models. Well, Prusa Research provides all the necessary programs for installation on different operating systems: Windows, Mac OS. If you are using GNU/Linux, there are separate instructions for installing the required packages. The software contains all the necessary drivers, pre-configured slicer, printer host, Netfabb installer, tools for color printing.

I would like to consider drivers separately. When you connect Original Prusa i3 MK2 via USB, it connects via serial port. So you can use it from PC, Raspberry PI, Octoprint or other cloud based 3D printing solution. There is full support for Windows 10 (most likely Windows 8.1 as well), so you can use the integrated Builder app to print directly from professional CAD programs like Solidworks.

This is really cool, and apart from 3D Systems and Stratasys, no other 3D printer provides such a wide range of possibilities. In general, if you become the proud owner of an Original Prusa i3 MK2, you can use any Windows application that supports direct 3D printing. Very, very comfortable.

Naturally, you can use the traditional methods of exporting your model to an STL file and processing it in a slicing software. Slicing software Slic3r with ready-made settings is included. This version has some features and modifications compared to those available for official download.

It has a full profile with settings for a 3D printer, for different layer heights, nozzle sizes and a whole range of 3D printing materials - from standard ones like PLA, ABS, PET to Taulman T-Glase or Bridge Nylon. All the materials we tried to work with gave excellent 3D printing results (if, of course, you choose the right settings).

All the materials we tried to work with gave excellent 3D printing results (if, of course, you choose the right settings).

If you prefer to work with other slicing programs such as Cura or Simplify3D, you can download ready-made profiles with printer settings from the official Prusa website.

In our opinion, the availability of ready-made settings for different slicing programs is a huge plus. After spending half a day or more building a 3D printer, having fun with settings and messing up the first 5-10 models is not the most inspiring thing to do. And thanks to ready-made configurations, you can set up your usual software in one click and get excellent quality 3D printing on the Original Prusa i3 MK2.

You will only have to play with the settings if you are using a really unusual material for 3D printing.

Let's now move on to the software part. The software for the Original Prusa i3 MK2 is constantly being improved and if you use Slic3r you will see notifications about the possibility of updating the firmware. After tuning, we were offered some updates that should improve performance, but to be honest, the difference is not noticeable.

After tuning, we were offered some updates that should improve performance, but to be honest, the difference is not noticeable.

One of the coolest features is color printing. Even though the Original Prusa i3 MK2 prints in one color, the development team has included some features to implement color 3D printing (by changing the material in the extruder). You can set up color printing using the LCD controller or by adding G-code coordinates, after reaching which the 3D printer will prompt you to change the material in the extruder.

Original Prusa i3 MK2 - the perfect 3D printer?

Yes, we can say that the testing of the Original Prusa i3 MK2 showed that it is indeed a very good 3D printer. But do not forget that although this is a very successful, but still an ordinary FDM printer, which has certain limitations inherent in the technology of layer-by-layer deposition modeling.

There was an example of bad 3D printing. But in defense, we can say that the model is already complicated and at the same time was reduced relative to the base dimensions. As a result, the transitions were too sharp and you can see the result in the photo below.

As a result, the transitions were too sharp and you can see the result in the photo below.

While the Original Prusa i3 MK2 is running, you can choose between "power" or "silent" mode. The failed model was printed in quiet mode (this mode is really quiet. The loudest part is the working cooler to cool the model). Perhaps printing in powerful mode would be better. But if you use the powerful mode, being in the same room with a 3D printer is not comfortable. 9The 0005

Original Joseph Prusa i3 MK2 is $845.79 (self-assembled) or $1,087.79 (assembled). Although not the most "advanced" mainstream model, it is in many ways superior to its counterparts and even the most innovative models. At the same time, some fundamentally new and really useful features have been implemented.

Original Prusa i3 MK2 prints great right from the start, without the need for tedious manual adjustments. Probably, this is really one of the highest quality open-source 3D printers today.

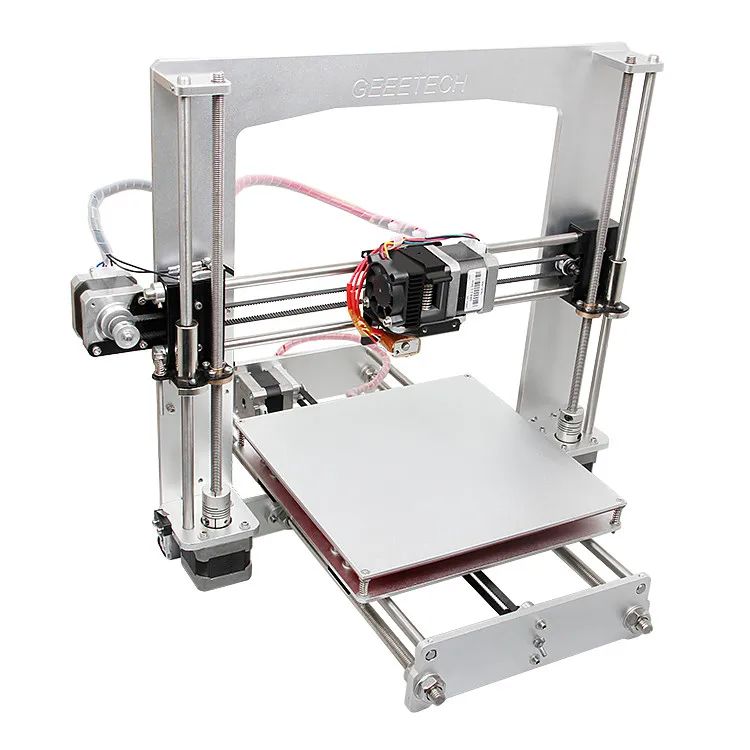

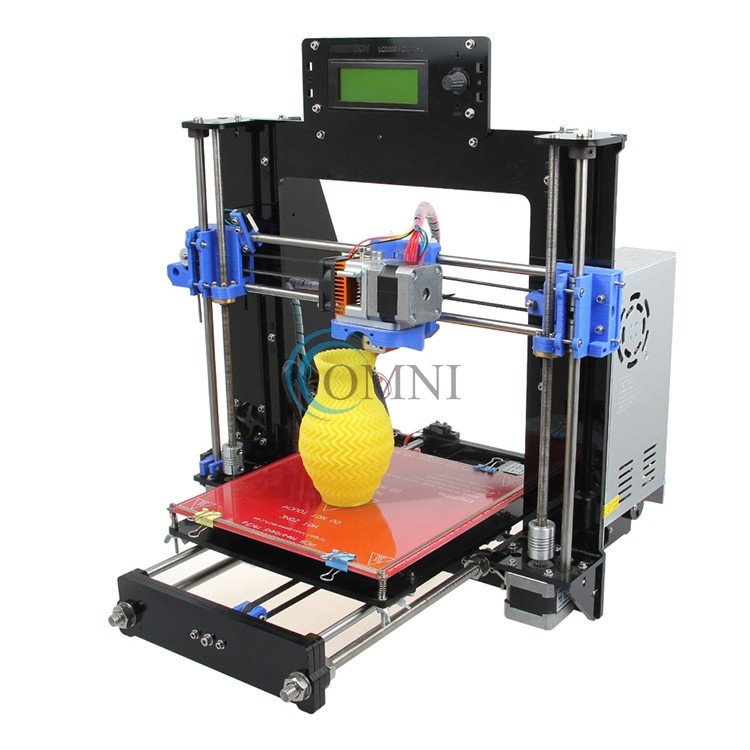

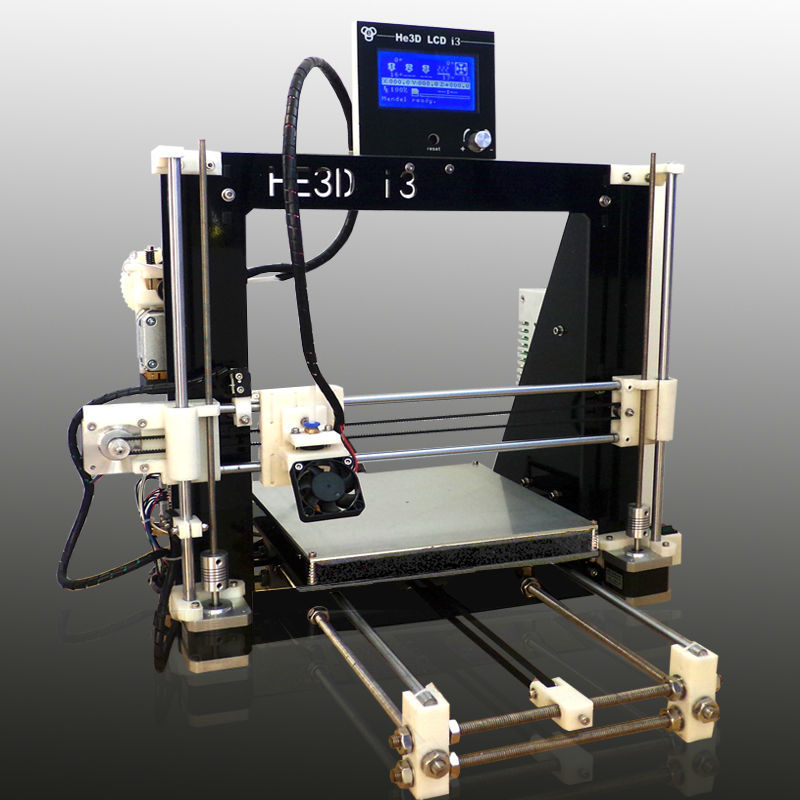

3D printer RepRap Prusa i3 ver.

R3D with delivery to any city

R3D with delivery to any city home » 3D printers » Collected RepRap » Buy 3D printer Prusa i3 ver. R3D

Description Reviews (0) Similar items (1)

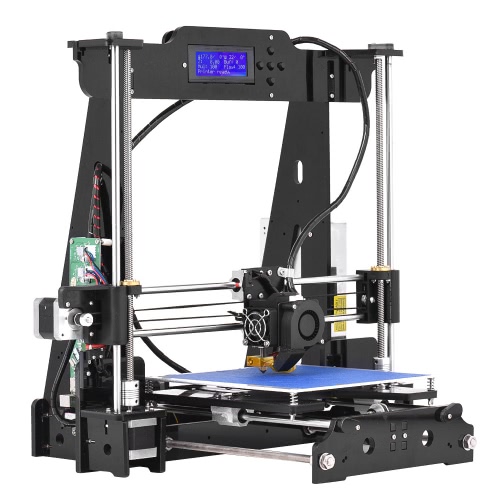

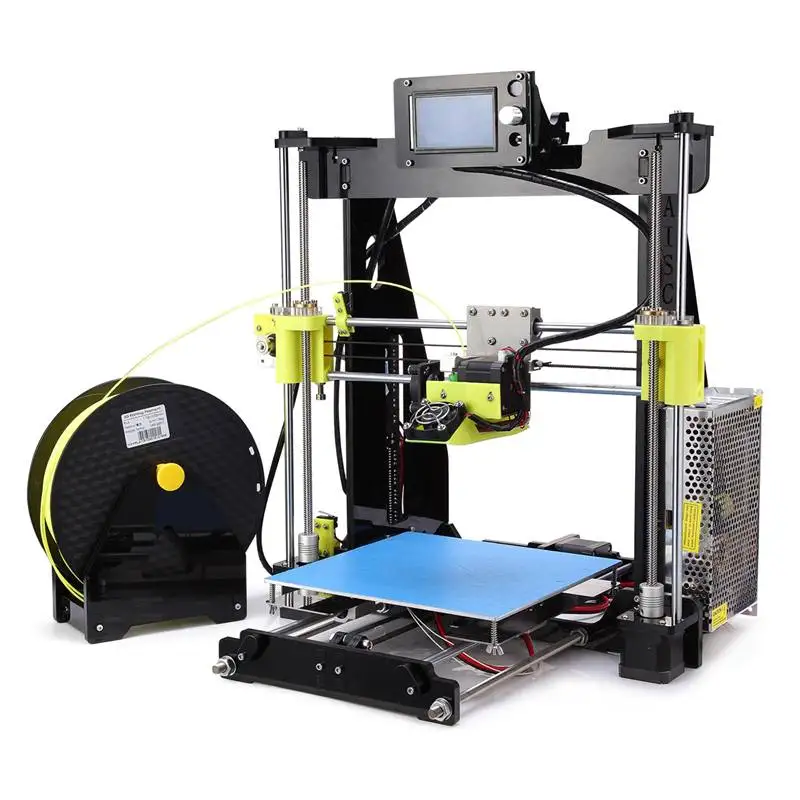

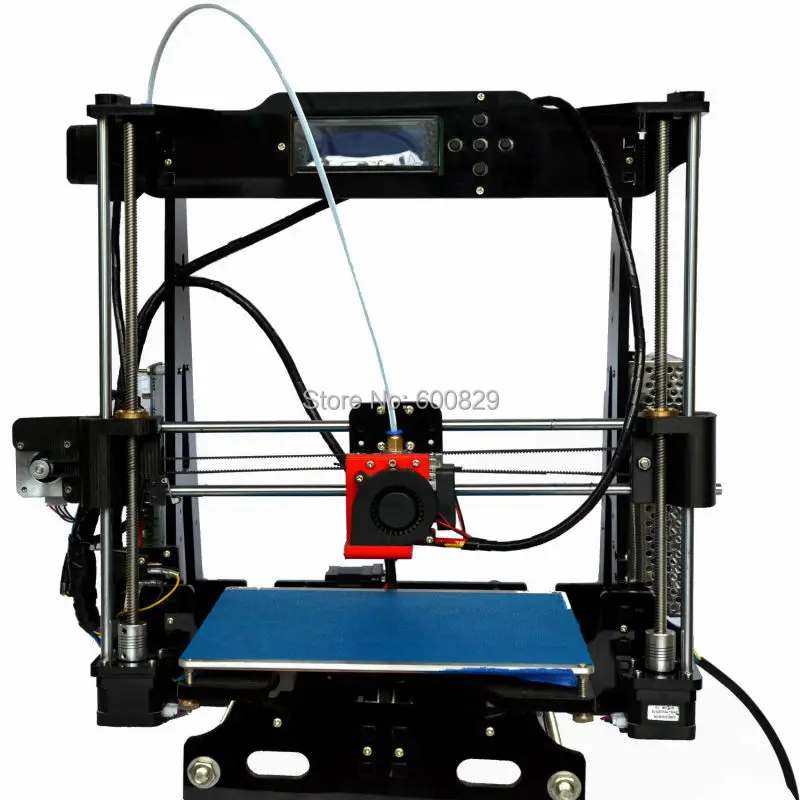

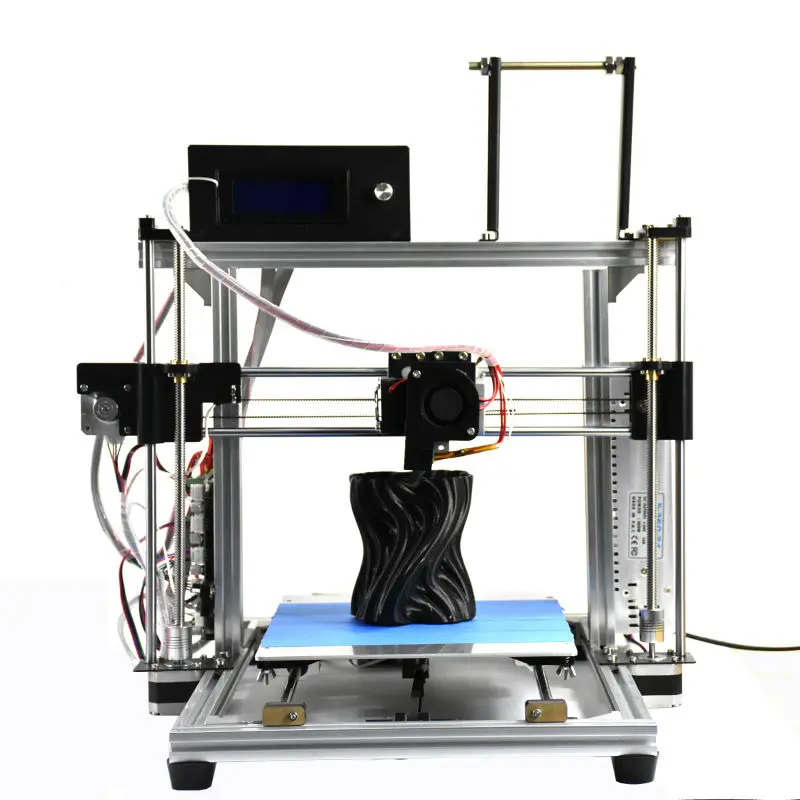

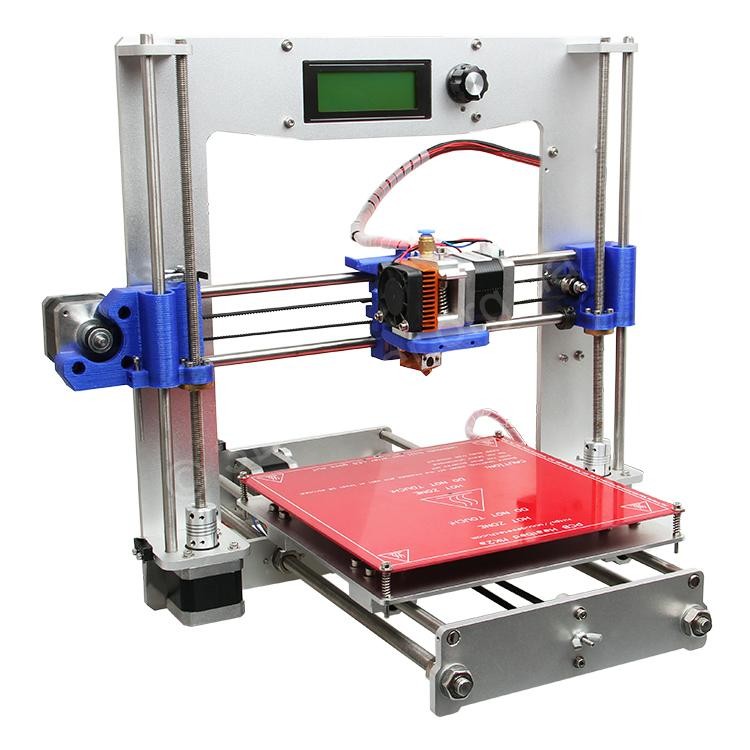

Prusa i3 ver. R3D - An improved version of the RepRap project Prusa i3 3D printer, which has a circular airflow, which allows for better printing. The heated platform is insulated with cork, which ensures fast and uniform heating of the entire platform, as well as maintaining the desired, stable temperature throughout the entire printing time. One of the most successful and popular models for home use. This 3D printer differs from its predecessors from the Prusa family by a RIGID ACRYLIC BODY, an increased print area, the ability to print with various materials - ABS, PLA, HIPS, FLEX, PVA. The inexpensive Prusa i3 3D printer has a small size, but at the same time a sufficient build area (200 x 200 x 170 mm), which makes it the best option for personal use. This model provides reliability, quality and high speed of the press.

Complete set

- Electronics

- 1 PC. - Arduino Mega 2560 rev3 controller board

- 1 PC. - Shield RAMPS 1.4

- 4 things. - Stepper motor drivers A4899

- 3 pcs. - Mechanical EndStop v1.2

- 1 PC. - HotEnd MK8

- 1 PC. - Heating table MK2a PCB

- 1 PC. - Thermistor EPCOS NTC 3950 100K (for heated table)

- 5 pieces. - NEMA17 stepper motors

- 1 PC. - Power supply 12V 30A 360W

Specifications

Basic:

- Printer dimensions: 430 x 490 x 460 mm

- Weight: 10 kg

Print Options:

- Print technology: FDM (Fused Deposition Modeling)

- Print area: 200x200x170 mm

- Layer height: 50 µm

- Material used: ABS, PLA, HIPS, FLEX, PVA (filament diameter 1.75 mm)

- Heated platform: maximum temperature 120 0С

Software:

- Firmware: Repetier Firmware

- Software: Repetier-Host

- OS Compatibility: Windows, Mac OS, Linux

Extruder parameters:

- Nozzle diameter: 0.

4mm ( 0.2-0.5mm )

4mm ( 0.2-0.5mm ) - Thread diameter: 1.75 mm

- Number of heads: 1

One of the most successful and popular models for home use. This 3D printer differs from its predecessors from the Prusa family by a RIGID ACRYLIC BODY, an increased print area, the ability to print with various materials - ABS, PLA, HIPS, FLEX, PVA. The inexpensive Prusa i3 3D printer has a small size, but at the same time a sufficient build area (200 x 200 x 170 mm), which makes it the best option for personal use. This model provides reliability, quality and high speed of the press.

Complete set

- Electronics

- 1 PC. - Arduino Mega 2560 rev3 controller board

- 1 PC. - Shield RAMPS 1.4

- 4 things. - Stepper motor drivers A4899

- 3 pcs. - Mechanical EndStop v1.2

- 1 PC. - HotEnd MK8

- 1 PC. - Heating table MK2a PCB

- 1 PC. - Thermistor EPCOS NTC 3950 100K (for heated table)

- 5 pieces.

- NEMA17 stepper motors

- NEMA17 stepper motors - 1 PC. - Power supply 12V 30A 360W

Specifications

Basic:

- Printer dimensions: 430 x 490 x 460 mm

- Weight: 10 kg

Print Options:

- Print technology: FDM (Fused Deposition Modeling)

- Print area: 200x200x170 mm

- Layer height: 50 µm

- Material used: ABS, PLA, HIPS, FLEX, PVA (filament diameter 1.75 mm)

- Heated platform: maximum temperature 120 0С

Software:

- Firmware: Repetier Firmware

- Software: Repetier-Host

- OS Compatibility: Windows, Mac OS, Linux

Extruder parameters:

- Nozzle diameter: 0.4mm ( 0.2-0.5mm )

- Thread diameter: 1.75 mm

- Number of heads: 1

| Weights and dimensions | |

| Weight | 9. |

8″ graphic 65k color screen

8″ graphic 65k color screen