Best 3d printer for mass production

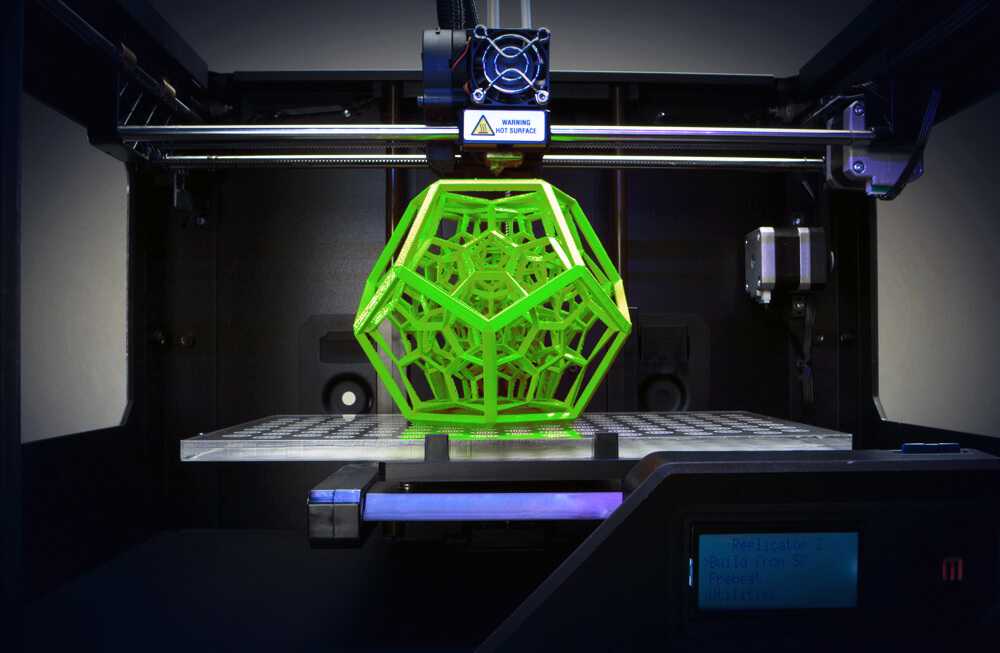

Large Scale 3D Printing For Mass Production

There are several ways 3D printing can speed up the process of getting products to market. Whether it be with the seamless creation of prototypes, or the full-scale manufacturing of end-user products, 3D printing alleviates key pain points in the supply chain.

Contact a Carbon Expert

3D Printing In Mass Production Explained

Different Types of Additive Manufacturing

With so many types of additive manufacturing, a.k.a. 3D printing, on the market today, businesses have a plethora of options for streamlining mass production.

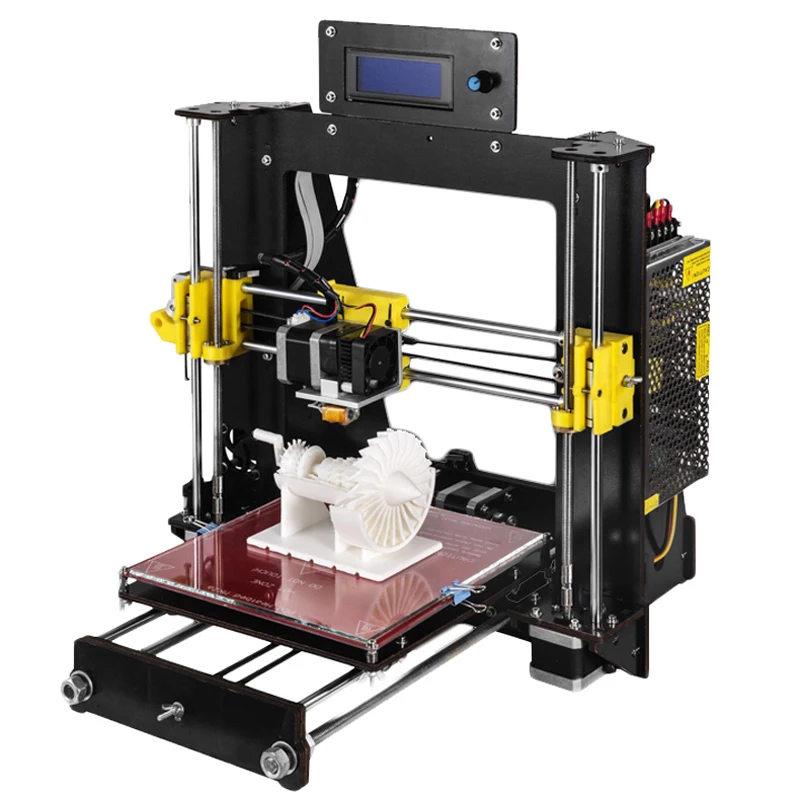

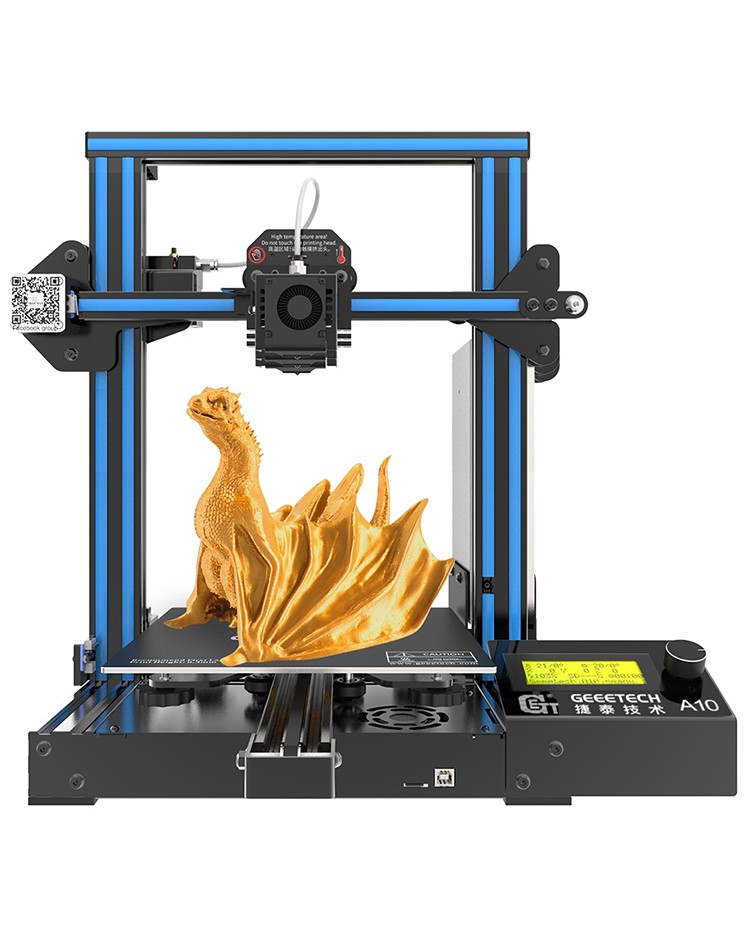

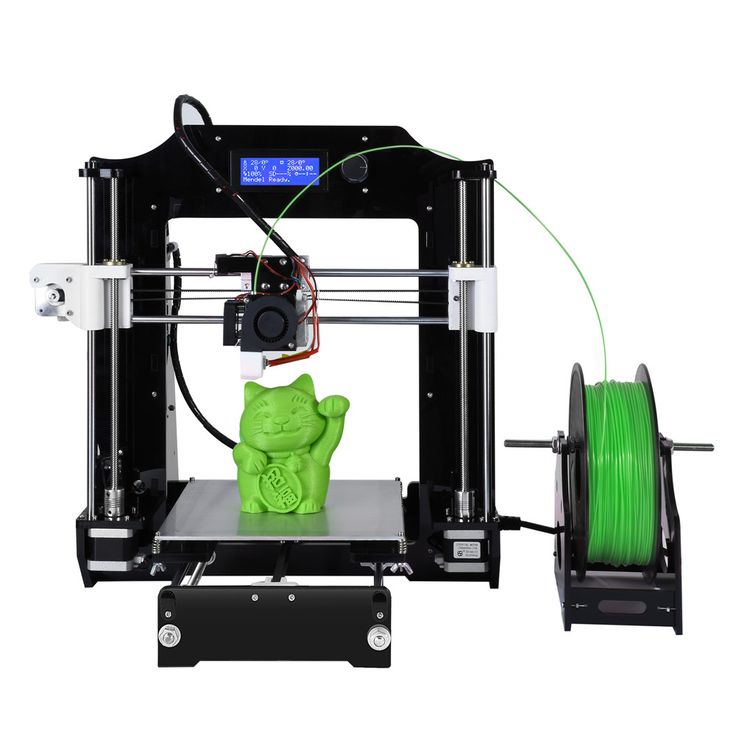

More often than not, the type of component you need to make will dictate your choice of 3D printing technology. For example, Fused Filament Fabrication (FFF) is a great choice for low-volume prototypes, while Stereolithography (SLA) is a better option for end-use parts.

Rapid Prototyping to Accelerate Production Processes

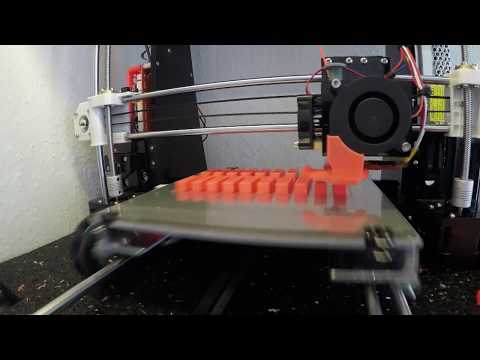

Rapid prototyping greatly accelerates mass manufacturing, making it an extremely popular use for 3D printers.

While functional prototypes are critical during the early design phases of new parts, it can take a very long time to outsource prototype manufacturing. With in-house rapid prototyping, engineers can quickly produce physical models to inspect for functionality and design flaws.

Allows for High Volume of Products

Because additive manufacturing technologies like Digital Light Synthesis (DLS) have progressed so much in the last few years, they can now be used to mass-produce high-quality, end-user products. In fact, the Carbon Digital Light Synthesis process was used to print soles for over 100,000 pairs of Adidas shoes in a single year.

Where 3D Printing is Winning in High-Volume Production

Faster Production Processes

Once you have established a working prototype, there are several ways that additive manufacturing can increase your manufacturing volume:

- Flexibility in production

- High customization

- Increased affordability

- Rapid tooling

Whether it be printing forms to be used for injection molding or printing custom soles for sneakers, additive manufacturing gets your products to market quicker.

Adaptive to New Technologies

Because 3D printing is extremely customizable, it is also extremely adaptive to new technologies. From manufacturing novel components to integrating software with artificial intelligence (AI), the sky is the limit for 3D printing processes.

High Volume with High Quality

Until recently, 3D printing hasn’t been applicable for mass production.

Traditionally, additive manufacturing processes like FFF printing haven’t been able to produce parts of high enough quality for end-user products. This is where more sophisticated processes, like DLS, come in to reshape mass production as a whole.

As the 3D printing landscape continues to evolve, novel technologies create new opportunities for high-volume production.

The Benefits of 3D Printing For Mass Production with Carbon

From first-rate manufacturing techniques to top-quality composites, Carbon is the top 3D printing company in the industry.

High-speed Manufacturing Process

Carbon has developed a full suite of technologies, materials, and processes to streamline the manufacturing process:

- Carbon Digital Light Synthesis 3D printers

- Carbon Engine Design software

- Carbon Production Network

- Carbon 3D printing materials

By working within the carbon network, you have all the tools needed to incorporate additive manufacturing into your business model.

Superior 3D Printing Technology

Carbon DLS technology utilizes photopolymer resins and UV light to print extremely complex geometries and shapes. With Carbon DLS, UV images are cast into a photopolymer, where they then harden into printed parts.

Carbon has a variety of DLS 3D printers available that produce components with unmatched performance, high resolution, and exceptional surface quality.

High-Quality End Products on Any Budget

Because Carbon hardware, software, and services are built with scalability in mind, we are able to offer cutting-edge 3D printing at affordable prices.

Carbon has developed different product offerings to ensure that no matter what your budget, you have access to the world’s top 3D printing technology:

- Carbon 3D printer leasing program

- Carbon Production Network

If you aren’t exactly sure about your 3D printing needs, start by outsourcing parts from a Carbon Production Partner.

Rapid Prototype Functional Parts

Carbon 3D printers are capable of producing both rapid prototypes and functional parts. No matter what your additive manufacturing needs, Carbon will ensure you produce a greater number of parts in a shorter time.

No matter what your additive manufacturing needs, Carbon will ensure you produce a greater number of parts in a shorter time.

On-demand Support Whenever You Need It

As part of the Carbon subscription model, we take care of routine maintenance, software upgrades, and system troubleshooting. Even better, if you have questions about operating a Carbon 3D printer, we provide real-time customer support.

Industry Leaders Trust Carbon With Their Mass Production

Whether it be rapid prototyping or mass production, 3D printing reduces the time it takes to get products to market. With the Carbon platform, we’ve taken the best elements of additive manufacturing and built them into an ecosystem that simplifies the production line.

With cutting-edge hardware, software, processes, and composites, industry leaders from across the globe trust Carbon with their 3D printing needs.

Handle Your 3D Printing For Mass Production With Carbon

With Carbon, you can rapidly design, develop, and scale production for better products in less time. Contact Us to discuss streamlining your business with 3D printing for mass production.

Contact Us to discuss streamlining your business with 3D printing for mass production.

3D as It’s Meant to Be

Interested in utilizing Carbon to accelerate product development? Reach out to us at [email protected] to learn more!

The Best Industrial 3D Printer Reviews of 2022

business.com receives compensation from some of the companies listed on this page. Advertising Disclosure

Home

> Technology

> Computers

By

Brian Nadel

,business.com Contributing Writer

| UpdatedAug 26, 2022

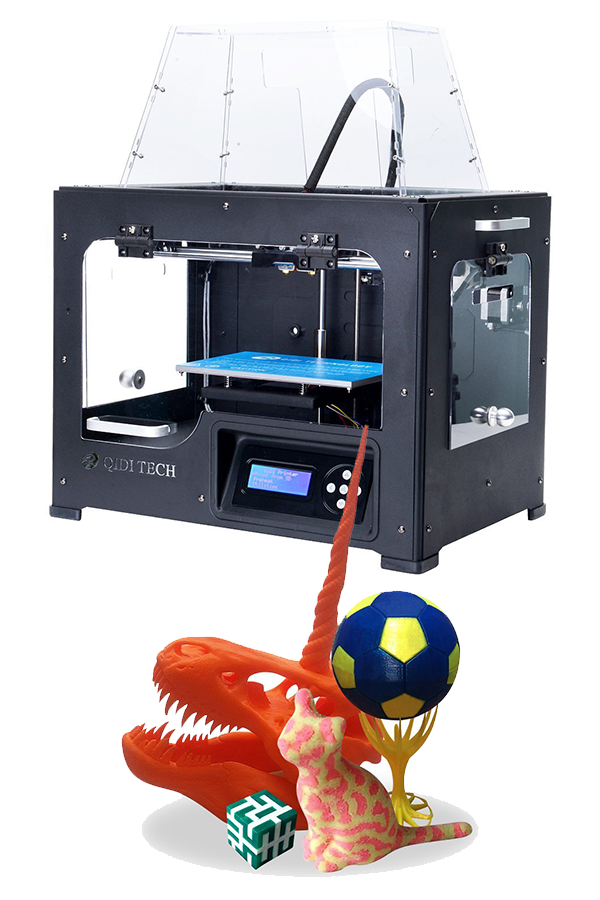

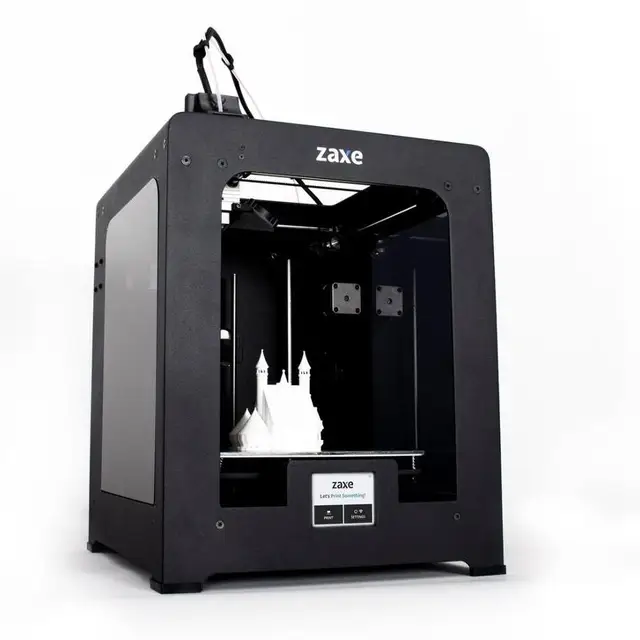

Industrial 3D printers take manufacturing to the next level by providing commercial-quality prototypes and end-user products quickly. Check out our reviews and learn what to look for in an industrial 3D printer in 2022.

Most Versatile Printer

FormLabs Form 3

checkmarkCost-effective

checkmarkEasy to use and maintain

checkmarkCompact design

Best Precision Printer

MakerBot Replicator Z18

checkmarkProfessional functionality

checkmarkWidespread design community

checkmarkFast production times

Most Innovative Printer

Ultimaker

checkmarkProfessional quality

checkmarkAdvanced functionality

checkmarkVersatile materials

Best Value Printer

Formlabs Form 2

checkmarkImproved process

checkmarkCompact design

checkmarkVersatile materials

Best Picks

Compare Our Best Picks

Our Reviews

Pricing

Buying Guide

Industrial 3D printers take manufacturing to the next level by providing commercial-quality prototypes and end-user products quickly. Check out our reviews and learn what to look for in an industrial 3D printer in 2022.

Check out our reviews and learn what to look for in an industrial 3D printer in 2022.

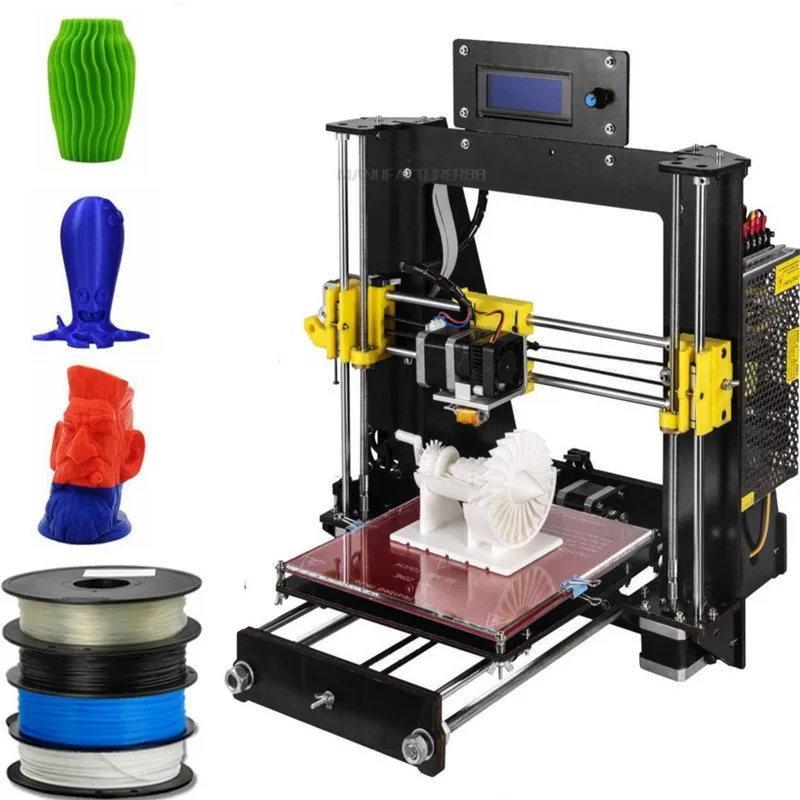

3D printers are becoming a go-to option for small-scale manufacturing of finished products and parts alike, helping businesses save money by printing real-world products directly from digital files. To determine our best picks for 3D printers, we examined more than 50 models and chose 10 to thoroughly research. Of those 10 finalists, we selected four as best picks. When choosing our best picks, we looked at a range of factors, including price, accuracy, resolution, materials and process.

How We Decided

Our team spends weeks evaluating dozens of business solutions to identify the best options. To stay current, our research is regularly updated.

Considered

Researched

Selected

Compare Our Best Picks

| FormLabs Form3 | MakerBot z18 | Ultimaker S5 Pro | FormLabs Form 2 | |

| Pricing | $5,000 | $6,500 | $9,100 | $2,850 |

| Process | Inverse stereolithography | Fused deposition modeling | Fused | Inverse stereolithography |

| Materials | Resin | PLA, composites | PLA, ABS, nylon, polycarbonate, polypropylene, CPET, carbon fiber | Resin |

| Dimensions (w x d x h) | 15. 9 x 14.8 x 20.9 inches 9 x 14.8 x 20.9 inches | 18 x 12 x 11.8 inches | 19.5 x 19.5 x 47.1 inches | 20.5 x 13.5 x 13 inches |

Our Reviews

FormLabs Form 3: Most Versatile Printer

FormLabs Form 3

proThe Form 3 offers improved control and precision due to an integrated laser and mirror.

proIt is relatively cost-effective for its level of precision and resolution.

conIt only produces relatively small parts compared to other 3D printers on the market.

By re-engineering how its stereolithography printers work, the FormLabs Form 3 not only can make precise parts, and offers a good variety of materials, but does so at a cost that is tiny compared to its competitors. With a simple and straightforward process, the Form 3 is one of the best values in 3D printing but tops out with the ability to only make comparatively small parts, although the company has a super-sized version in the works.

FormLabs continues with its inverse stereolithography process, but its laser and mirror have been integrated for better control and precision, yielding a simpler and more direct way to make a variety of parts. With the ability to use a range of plastics, ceramics and engineered polymers, the Form 3 is a versatile system that, at $5,000 for its three components, is a steal compared to the competition. It may not be able to make large components, but the company’s eagerly expected Form 3L should be able to upsize its abilities and the ambitions of small businesses.

With the ability to use a range of plastics, ceramics and engineered polymers, the Form 3 is a versatile system that, at $5,000 for its three components, is a steal compared to the competition. It may not be able to make large components, but the company’s eagerly expected Form 3L should be able to upsize its abilities and the ambitions of small businesses.

Features

FormLabs latest effort, the Form 3 printer, continues to use the company’s inverse stereolithography process but with a twist. It still uses a 405-nanometer laser beam that’s aimed vertically through the liquid resin tank to selectively harden the plastic to create the model. The twist uses what FormLabs calls low-force stereolithography on the new Form 3 model where the light processing unit’s laser is integrated with its parabolic mirror. This not only ensures correct beam placement, but it simplifies the process and makes it easier to peel the completed component off the building stage as well as requiring fewer support structures to prevent sagging during the build.

Like earlier FormLabs printers, the Form 3 works with a variety of liquid photopolymer raw materials, but not metals or carbon fiber. They come in 1-liter cartridges that fill the resin tank and run from $150 to $200; the company sells Explorer packs of four or five cartridges for between $680 and $900.

The Standard resin should be fine for most work, like product cases and a variety of structural parts. It’s available in clear, white, gray and black; if you want a custom color, FormLabs offers cyan, magenta, yellow, black and white dyes so that you can mix your own. By contrast, the draft resin yields faster access to completed parts, but they have lower resolution and can be made in gray, black or white.

There are also engineering and tough resins for specialty applications, where strength or temperature resistance are paramount, such as for gears or the lid for a coffee pot. By contrast, the wax resin is used to make items that easily melt for creating sand- or die-cast molds. Finally, FormLabs also has dental, ceramic and jewelry materials.

Finally, FormLabs also has dental, ceramic and jewelry materials.

Using one of their 3D printers can streamline a company’s operations. For instance, Ashley Furniture uses the company’s earlier Form 2 printer to replace expensive machined alignment pins for some of its products. This seemingly small production change led to a savings of $4.10 per part and did away with the one-month lead time to replenish its stock. Now, Ashley makes the pins as needed. After the change to 3D-printed pins, the factory raised its productivity by 10% using 15% less labor.

With a resolution of up to 25 microns and the ability to vary layer thickness to as high as 300 microns, the Form 3 provides an extra degree of accuracy and flexibility when going from CAD model to finished part. Because the resin’s viscosity varies with temperature, as the part is built, the printer’s chamber is kept at a constant temperature to maintain predictable build speeds and reliable results. This is done automatically by the Form 3 printer behind the scenes.

When the build is done, some of the resins require a two-step post-production process to fully harden the parts. It starts with a wash station that cleans off residual resin leftover from the stereolithography printing process. This is followed by a cure stage that combines 405-nanometer light with a heat treatment at between 140 and 175 degrees Fahrenheit to fully consolidate and harden the part. This step varies from an hour to cure the engineering resin to a half-hour for the standard resin.

The Form 3 is only 15.9 x 14.8 x 20.9 inches, making it perfect for place on a desk, table, or lab bench; FormLabs doesn’t sell stands or carts for it. This size limits the Form 3 to items no bigger than 5.7 x 5.7 x 7.3 inches, potentially restricting its usefulness. The upcoming Form 3L will be able to make parts five times as big and should be available by the end of the year.

The Form 3 family is inexpensive, with all three devices selling for $5,000, although the printer on its own costs $3,500. By contrast, the EnvisionTec Micro Plus HD sells for $10,000, yet can’t come close to the Form 3’s maximum part size and resolution.

By contrast, the EnvisionTec Micro Plus HD sells for $10,000, yet can’t come close to the Form 3’s maximum part size and resolution.

Ease of Use

The Form 3’s production sequence is simple and straightforward. It starts with a standard .STL or .OBJ file of the item to be made. The company’s PreForm software divides it into production slices, adds supports, and does a preprint check of the resin tank cartridge and build platform before the build can start.

The Form 3 connects with the company’s IT infrastructure via an Ethernet port or Wi-Fi link. After pressing Start, the Form 3 does the rest. While the build is taking place. The Form 3’s dashboard software monitors the system, what it’s making and its material supplies. It can monitor several printers at once.

With a 5.5-inch color touchscreen, the Form 3’s commands and adjustments can be directly entered into the Form 3 printer. The screen shows the entire process, and the printer can run unattended. It sends alerts and emails if something goes wrong, and the screen shows when the build is complete. The one thing it lacks is a built-in web cam for a technician to remotely view the process.

The one thing it lacks is a built-in web cam for a technician to remotely view the process.

Customer Service

As is the case with most of its competitors, the Form 3 comes with a one-year warranty. Trained technicians are available 24/7 to help with problems or answer questions about everything from which resin is the best to use for a specific application to how to update the system’s software. The optional Pro Service plan includes training, priority service and the ability to get a hot swap replacement machine.

Online, FormLabs provides a lot of material to help make the most of the Form 3 and the company’s other 3D printers. This ranges from a valuable quick start guide for getting the machine set up to a full manual to variety of maintenance tips. The most useful is help diagnosing what caused a defect in the part, which reads like a detective novel at times. All firmware and software upgrades are available for the life of the printer.

MoreMakerBot Replicator Z18: Best Precision Printer

MakerBot Replicator Z18

proMakerBot maintains a sprawling 3D design community for the provision of CAD files.

The Z18 bridges the gap between personal and industrial 3D printers.

conIt cannot work with metal or carbon fiber materials.

Owned by Stratasys, MakerBot was an early entry in the hobbyist 3D printer market. Its Replicator Z18 system crosses over from hobbyist into the professional realm with a high-quality fused deposition modeling (FDM) printer.

Small, inexpensive, and up to date, the MakerBot Replicator Z18 is a prototyping and production system that bridges the gap between consumer and industrial 3D printers. At $6,500, it is not only one of the best values in the 3D printer market but is a great pick because of the wide array of items it can make.

Features

The MakerBot Replicator Z18 can precisely create small and midsize models out of polylactic acid (PLA), but not acrylonitrile butadiene styrene (ABS). MakerBot’s tough PLA, though, is formulated to be just as strong as ABS and with greater tensile strength. It can resist deformation better than PLA materials.

The printer can work with composites, like bronzefill, copperfill and woodfill, although it lacks the ability to form steel or titanium components.

The Z18 builds up the model a layer at a time from softened PLA filament to correctly create critical overhangs, angled elements and compound curves without warping the material. However, it might not be appropriate for items that need to be used as functional parts or structural elements. Both an American auto parts maker and a German robotics company use the Z18 to create prototypes for new products.

Able to build with 100- or 200-micron layers, the Z18 outdoes the much more expensive Stratasys Fortus 250mc’s ability to create thin layers. It can lay down details with an accuracy of 11 microns for length and width, and 2.5 microns in height.

The filament spools come in three sizes: 2 pounds, 5 pounds and 10 pounds. The palette includes 10 PLA colors and four for the tough filament. The Z18’s waste can’t be recycled, but you don’t have to fuss with expensive filament cartridges that double the cost of the raw material. Many of the printer’s filament spools go for $50 each, while some of the specialty ones cost more.

Many of the printer’s filament spools go for $50 each, while some of the specialty ones cost more.

Its Smart Extruder Plus assembly is designed to resist clogging with super slippery, Teflon-like PTFE coatings on key internal parts. Even if it does clog, the extruder can be snapped out and replaced with a new one in a matter of seconds, reducing downtime. Replacement extruders cost $200.

The Z18’s single-extruder design means that its supports are made from the same PLA material. When the project is finished, they need to be carefully removed before the item can be used.

Speed is of the essence for the Z18. Capable of laying down material at up to 150 mm per second, it can buzz through items quickly. It tops out at items that are a maximum 18 x 12 x 11.8 inches. The Z18 is versatile enough to make items as diverse as prototype engine parts, models of fossils, action figures and artistic vases.

The Z18 is small and light enough for a desktop or shelf at 33.9 x 22. 2 x 19.4 inches – one-third the size of the Fortus 250mc. It weighs just 90 pounds. MakerBot sells a $1,250 matching cart for it to sit on that raises the build chamber to eye level and provides storage for consumables.

2 x 19.4 inches – one-third the size of the Fortus 250mc. It weighs just 90 pounds. MakerBot sells a $1,250 matching cart for it to sit on that raises the build chamber to eye level and provides storage for consumables.

Ease of Use

It may not have a touchscreen, but the Z18’s 3.5-inch color screen has two buttons and an innovative dial for controlling the printer’s settings and operations. Each screen has six icons that represent settings, modes and utilities. Just spin the dial through potential choices and pick the one you want. As the item is created, the screen shows the system’s progress.

MakerBot has done its homework for software. To use a desktop or notebook computer, you’ll need to load the included MakerBot Print software; Version 4.7 is available for 64-bit versions of Windows 7 and 10, as well as OS X 10.9 or newer operating systems, although not for Windows 8. MakerBot also has a mobile app for iOS and Android systems, and the MakerBot Cloud site to prep the model for printing from within a web browser, which is a good way to integrate Linux computers into the 3D printing process.

Turning a design into a physical object starts with a variety of CAD files, including .STL and .OBJ designs, and the software can directly print Thingiverse’s library of 1.6 million design files. The MakerBot Print program not only corrects faults in the design and adds supports as needed, but digitally slices the structure into manufacturable layers. It can even arrange a bunch of small parts on the build stage to reduce costs and build time.

The company has enhanced the print software with lots of changes to make the slicer more efficient. The updates include things like the ability to choose from standard build, extra strong and solid construction, as well as reducing distortion that is sometimes encountered.

For when you’re in a hurry, MakerBot Print’s MinFill mode creates hollow structures to speed construction and cut costs for quickie models. It can speed up production by 30%.

The printer can run unattended, but, unlike older 3D printers, the Z18 has a built-in webcam for remotely monitoring the system’s progress. Its video stream shows a 320 x 240-pixel view at a few frames per second.

Its video stream shows a 320 x 240-pixel view at a few frames per second.

You can set the Z18 up with a stand-alone workstation or on your company’s network, with the choice of gigabit Ethernet or 802.11n Wi-Fi. It lacks the option of the newer and faster 802.11ac format, but it can connect to a system directly via USB cable. At any point, you can plug a flash drive with the needed files into its USB port.

The system is light on maintenance, which translates into more uptime for printing. Other than keeping the extruder clean and emptying the waste filament bin when it fills up, you’ll need to occasionally lubricate the printer’s threaded vertical Z-axis rods.

Customer Service

MakerBot recently doubled the warranty period for new machines to a full year. It costs $799, $1,549 or $2,199 to add one, two or three years, respectively.

The site has a slew of items to help you get started and make the most of the Z18, including a detailed manual and startup guide, training topics, and downloads of updated software. Rather than 24/7 support, MakerBot technicians are available from 9 a.m. to 6 p.m. ET, Monday through Friday, so late-night problems will have to wait until the next morning. It promises next-day or better service on email questions and there’s a chat window option.

Rather than 24/7 support, MakerBot technicians are available from 9 a.m. to 6 p.m. ET, Monday through Friday, so late-night problems will have to wait until the next morning. It promises next-day or better service on email questions and there’s a chat window option.

Ultimaker: Most Innovative Printer

Ultimaker

proThe S5 Pro automatically switches filament spools and keeps dust out of the build chamber.

proThe printer offers supreme precision; it has four print cores, with nozzles ranging from 0.25 to 0.8 mm.

conWhile it is relatively cost-effective for its functionality, the price tag is higher than our other best picks.

A mainstay of professional 3D printing since 2016, Ultimaker has pushed current technology to its limits with the company’s S5 Pro system. Its three machines combine to form a groundbreaking 3D printing powerhouse that can act as a small company’s self-contained digital factory. Capable of creating precise parts quickly in a wide variety of materials, the best part is that at $9,100, the S5 Pro is a genuine bargain.

By controlling every aspect of the 3D printing process – from design to slicing to material selection to final product – Ultimaker has taken fused filament fabrication printing to new heights. At less than $10,000, the three-part S5 Pro package pushes conventional 3D printing technology to the limit, yet is simple to use and can do things other 3D printers can’t, like automatically switch filament spools and keep dust out of the build chamber. Small businesses on a budget take note: The S5 Pro package punches above its weight and is a pioneering system that advances 3D printing technology across all fronts.

Features

The Ultimaker S5 Pro system starts with an already masterful 3D printer. The S5 uses a dual extruder that can work with two materials at once. This allows the use of nylon next to polycarbonate, or the use of the build material and Ultimaker’s Breakaway supports.

The key to its precision is the choice of four print cores whose nozzles range from 0. 25 to 0.8 mm. They are easy to swap in a moment, and can yield a maximum resolution of final parts of 6.9 microns in the X or Y direction, and 2.5 microns in the Z direction. The action takes place on a heated glass building platform.

25 to 0.8 mm. They are easy to swap in a moment, and can yield a maximum resolution of final parts of 6.9 microns in the X or Y direction, and 2.5 microns in the Z direction. The action takes place on a heated glass building platform.

To this admirable printer, Ultimaker has added two support machines in the Pro bundle. The three can help make every build come out the way it looks onscreen. The most forward-thinking add-on is the S5’s materials station that sits below the printer and holds up to six spools of filament in low humidity conditions. It not only allows quick swaps of material spools from the front but can change between materials mid-build or even continue a project uninterrupted even if its filament spool runs out. This provides tremendous flexibility and reliability that the part will be correctly produced without anyone watching it.

The key to making the materials station work is that each spool of Ultimaker filament has a near-field communications (NFC) identification patch on it. When the system either runs out of filament or wants to switch to a different material, it reads all the NFC IDs on the materials station’s installed spools and automatically picks the right one.

When the system either runs out of filament or wants to switch to a different material, it reads all the NFC IDs on the materials station’s installed spools and automatically picks the right one.

On the downside, despite supporting numerous third-party filaments with printing profiles, these spools lack the NFC advantage. That could change soon, but for the time being, the material data needs to be entered manually.

By contrast, the S5’s Air Manager sits on top of the printer and turns it into a mini cleanroom. Its filter removes up to 95% of ultra-fine dust in the air while optimizing the build’s parameters with controlled temperature and humidity. It’s essential, because some materials work best with a warm ambient temperature, while others are aided by a cooler environment. The company recommends that the filter be changed every 1,500 hours of use; it costs $40.50 and takes couple a few minutes to change.

With a peak build temperature of 536 degrees Fahrenheit, the S5 Pro can work with a wide variety of materials, but neither metals nor ceramics. By using its own dozen materials and allowing the use of hundreds of others from the likes of Dupont and DSM, Ultimaker leads in variety of materials available for printing. They range from PLA, ABS and nylon to polycarbonate, polypropylene and CPET. The S5 Pro can even make things out of glass filled or carbon fiber materials. The materials are inexpensive at between $25 and $70 a spool.

By using its own dozen materials and allowing the use of hundreds of others from the likes of Dupont and DSM, Ultimaker leads in variety of materials available for printing. They range from PLA, ABS and nylon to polycarbonate, polypropylene and CPET. The S5 Pro can even make things out of glass filled or carbon fiber materials. The materials are inexpensive at between $25 and $70 a spool.

There’s also the choice of three support materials that can prevent the item from sagging while being built. In addition to using the same material as the part is made of, you can use polyvinyl alcohol, which washes away in water, or Ultimaker’s breakaway material that snaps off when done. There are colored filaments, and even glow in the dark ones, but Ultimaker doesn’t offer custom colors.

In addition to the Royal Netherlands Navy using Ultimaker S5 printers for creating repair parts and prototypes on all of its ships, Killa Design of Dubai uses this technology to plan new buildings before a shovelful of dirt is moved. A city planning and architectural firm, Killa Design uses Ultimaker printers to make models of existing and planned buildings in an effort to simulate what the urban landscape will actually look. Printing them, rather than cutting and pasting foamboard, not only gives a more realistic appearance, but is quicker, more detailed and cheaper.

A city planning and architectural firm, Killa Design uses Ultimaker printers to make models of existing and planned buildings in an effort to simulate what the urban landscape will actually look. Printing them, rather than cutting and pasting foamboard, not only gives a more realistic appearance, but is quicker, more detailed and cheaper.

Tall and narrow, the Ultimaker S5 Pro bundle measures 19.5 x 19.5 x 47.1 inches and weighs 93 pounds. It’s fine to set it up on a tabletop or workbench, but Ultimaker doesn’t sell a cart or stand for the S5 Pro. The largest items it can make mirror the S5 Pro’s dimensions, with it able to pump out items as big as 23 liters.

At $9,100 for the entire package, the S5 Pro rivals the cost of competitive printers on their own, but turns a 3D printer into a digital factory. On its own, the printer can be had for about $6,000.

Ease of Use

The center of attention for setting up and controlling the build process is the Ultimaker Cura software. It works with Macs, Windows and Linux computers, and Ultimaker’s iOS and Android apps can help manage and monitor build progress.

It works with Macs, Windows and Linux computers, and Ultimaker’s iOS and Android apps can help manage and monitor build progress.

The software not only prepares and slices the model into manufacturing segments, but can create honeycomb structures in large solid pieces. It controls all three machines, from filament selection to chamber temperature.

In addition to the expected use of .STL and .OBJ files as a starting point, Cura can work with a dozen different 3D printing file formats. In addition to Ultimaker’s in-house software team, there’s a vibrant open-source community that helps with plug-ins available for SolidWorks, Siemens NX and Autodesk Inventor packages.

The printer can connect via a wired Ethernet infrastructure, Wi-Fi or a technician inserting a USB flash drive with all the instructions on it. With a 4.7-inch color screen, the entire process can be monitored, and the printer has a web cam for remote viewing.

Customer Service

Ultimaker stands by its S5 Pro package with a standard one-year warranty that covers all its parts. A two-year extension is available for $895.

A two-year extension is available for $895.

The company has offices in Utrecht, the Netherlands, Boston, and Singapore as well as production facilities in Memphis, Tennessee, and Zaltbommel, the Netherlands. There are technicians standing by for questions about anything from filament qualities to clogged extruders. They’re available from 9 to 5:30 local time, but lack 24/7 coverage. The Ultimaker site has loads of DIY material to help solve problems and aid in the designer’s creativity, including a “fix an ugly part” section.

MoreFormlabs Form 2: Best Value Printer

Formlabs Form 2

proA cost-effective option for businesses on a budget.

proThe Form 2 is compact enough for desktop usage.

conParts must be washed to remove unreacted resin before finished product can be used.

If you think you need to spend upwards of five or six figures to get the accuracy and precision of a stereolithographic 3D printer, times have changed. The FormLabs Form 2 not only downsizes costs to as little as $2,850, but it can reliably create parts and products from a variety of materials.

The FormLabs Form 2 not only downsizes costs to as little as $2,850, but it can reliably create parts and products from a variety of materials.

FormLabs takes the best attributes of stereolithographic 3D printers – accuracy and the ability to make functional parts – and trims them to the desktop level. In other words, the Form 2 is entry level in price only.

Features

The system uses a powerful 405-nanometer violet laser and steerable mirrors to selectively cure a liquid photopolymer raw material into a solid structure. Its spot size of 140 microns allows the Form 2 to create layers of 25-, 50- or 100-micron thickness at a resolution of 25 microns. That should be more than enough for making prototypes, tools and jigs as well as most small products.

FormLabs sells 17 different photoreactive materials for the Form 2 that create methacrylate polymers with a variety of properties. In addition to draft resins for quick prototyping, the Form 2 can make items that are translucent, clear, gray or black. While none of FormLabs’ materials are brightly colored, the company sells a $175 kit that lets you mix your own. The kit comes with white base resin, along with black, white, yellow, cyan and magenta pigments and syringes, to precisely measure and mix a rainbow of shades.

While none of FormLabs’ materials are brightly colored, the company sells a $175 kit that lets you mix your own. The kit comes with white base resin, along with black, white, yellow, cyan and magenta pigments and syringes, to precisely measure and mix a rainbow of shades.

The Form 2 can use specialty resins for toughened parts, flexible and elastic ones, as well as resins designed to take high temperatures, and those used for dental prosthetics and jewelry. On the downside, not all of the resins work with the Form 2’s three thickness levels.

The latest addition is a silica-filled ceramic material that, after firing, is chemically inert and an insulator. It can withstand temperatures of up to about 1,800 Fahrenheit for functional parts that can stand up to abuse.

The resins come in cartridges with a shelf life of at least a year, and sell for between $150 and $400 a liter. Each container has enough raw material to make three complete chess sets with intricate pieces that are about 2 inches tall. It takes about 45 minutes to print each piece at the Form 2’s top speed of 1 to 3 centimeters an hour of build height.

It takes about 45 minutes to print each piece at the Form 2’s top speed of 1 to 3 centimeters an hour of build height.

Ease of Use

Loading new raw material couldn’t be easier. It takes a minute to open the printer’s cover, open the resin cartridge’s vent cap, slide it into place and get the job going. In fact, it’s cleaner than changing the ink on many printers.

Rather than being out in the open, like extrusion designs, the Form 2 has an orange cover that prevents ordinary daylight from prematurely hardening the resin. It doesn’t need to operate in an inert atmosphere that industrial sintering designs require.

Because its output is smooth with sharp edges and accurate dimensions, every day thousands of companies use the Form 2 to create everything from custom orthodontics to elaborate earrings to prototype parts. Pankl Racing uses the device to make the tooling, jigs and manufacturing fixtures needed for the consistent production of custom race car parts. Using the Form 2, instead of traditional materials and techniques, shortens the time and cost of the completed product by as much as 90%, according to the company.

The biggest compromise with the Form 2 is size. Its build volume of 6.9 x 5.7 x 5.7 inches adds up to a maximum item of 3.7 liters, one-tenth the size of things the Nyomo Makyn 6 can produce. On the other hand, the Form 2 costs one-third that of the Makyn 6.

Still, at 20.5 x 13.5 x 13 inches and weighing 28.5 pounds, the Form 2 is one of the smallest and lightest 3D printers of its type. It can easily be stashed in the corner of a desk, on a shelf or moved to where it’s needed on a wheeled cart. The company doesn’t sell a stand.

To get inside, slide up the orange cover, and you’re looking at the machine’s build stage with the resin cartridge in the back and the system’s 4.3-inch color touchscreen up front. In addition to showing that the job is underway and its progress, the screen displays how long it’s going to take to finish. You can pause or stop the job at any point with a tap of a finger.

When the Form 2 has finished printing, the part might not be quite ready for use. It needs to be washed to remove unreacted resin with isopropyl alcohol for at least 10 minutes. Then the part needs to be cured at 170 degrees Fahrenheit while rotating until it attains its full hardness. FormLabs sells a pair of similarly sized Form Wash and Form Cure chambers to do this post-processing. They sell for $500 and $700, or you get the printer and the two post-processing stations for under $5,000. FormLabs is phasing out the Form 2 printer in favor of the Form 3 model that uses a new stereolithography process. In the meantime, they have reconditioned units for $2,850 (with a one-year warranty).

It needs to be washed to remove unreacted resin with isopropyl alcohol for at least 10 minutes. Then the part needs to be cured at 170 degrees Fahrenheit while rotating until it attains its full hardness. FormLabs sells a pair of similarly sized Form Wash and Form Cure chambers to do this post-processing. They sell for $500 and $700, or you get the printer and the two post-processing stations for under $5,000. FormLabs is phasing out the Form 2 printer in favor of the Form 3 model that uses a new stereolithography process. In the meantime, they have reconditioned units for $2,850 (with a one-year warranty).

The printer comes with FormLabs’s PreForm software for prepping the model. It starts with a standard .STL or .OBJ file and outputs the .FORM format that the printer uses. It has all the manufacturing information embedded, including slice thickness, supports and orientation. The app is available for Windows (version 7 or newer) and Macs (OSX 10.7 or newer), but not Linux systems. While the company lacks full apps for setting up print jobs with a phone or a tablet, you can remotely monitor progress.

While the company lacks full apps for setting up print jobs with a phone or a tablet, you can remotely monitor progress.

Recent updates have increased the unit’s build speed while including the ability to have several PreForm windows open at once. The Form 2 printer can now also use the Tough 1500 (at the 50- and 100-micron setting) and surgical resin (at the 50-micron level).

While the Form 2 can be left on its own to build its parts without supervision, there’s no webcam to remotely monitor its progress. You can get the Form 2 online with either wired Ethernet or Wi-Fi networking, or use the included USB cable with a dedicated workstation. There’s a USB outlet for inserting a flash drive with the part’s file for quick prints.

In addition to changing the raw material cartridge as it empties, you’ll need to occasionally clean the antireflective surface below the resin tank. Every 1,000 or so layers that are created, the tank will need to be cleaned or replaced; a new one costs $59. FormLabs’s new longer life LT resin tray costs $99 but should last 10 to 20 times longer.

FormLabs’s new longer life LT resin tray costs $99 but should last 10 to 20 times longer.

Customer Service

FormLabs includes a one-year warranty with the Form 2. A two-year warranty extension costs $899. If you’re new to stereolithography printing, get the $499 Pro Service Plan, which includes a half-hour of online personalized training and rapid response to questions or problems.

While the Form 2 lacks a comprehensive manual, the support site is the go-to place with startup guides, videos and help with error messages. The company’s technicians are available from 9 a.m. to 5 p.m., ET, Monday through Friday, but FormLabs lacks 24/7 response.

MorePricing

The price tags on 3D printers cover a lot of territory, from small desktop extrusion systems that might cost only $1,000, all the way to room-sized behemoths capable of replacing a machine shop that might cost more than a million dollars. In between is a world of midsize printers that can create a wide variety of parts and objects.

Getting the printer is just the start: A 3D printer needs the raw materials to transform designs into the final product. Some of the simpler materials, like polylactic acid, are inexpensive and versatile. More exotic materials – like stainless steel, carbon fiber or methacrylate plastics – are more expensive, but sometimes, the unused leftovers can be recycled for the next print run. On the other hand, materials, like titanium or polyvinyl alcohol, can get very pricey.

Using a 3D printer can help a small business in several ways. To start, the machine can manufacture parts and products of exceptional accuracy that might have previously been made by a contractor. Basically, if you can see it on the screen, a 3D printer can make it.

3D printing ignores the time-honored techniques of casting, molding, milling and finishing the item using subtractive technologies that get to a final shape by taking material away. By contrast, a 3D printer creates the object directly from a CAD file with additive manufacturing technologies, where the piece is built up a layer at a time. It can all be done with a single machine and not a room of old-school tools, reducing capital costs and overhead to a minimum.

It can all be done with a single machine and not a room of old-school tools, reducing capital costs and overhead to a minimum.

Because it skips the molding or casting process, 3D printing can create huge shortcuts to producing all manner of industrial prototypes and products today. This allows you to shave valuable months off a product’s development cycle, and try out different design iterations on a daily, even hourly, basis, speeding up the evolutionary nature of the design and manufacturing process.

For a small business, the payoff can be speed, efficiency and the power to change the way things are made. For instance, Nieka Systems, a Quebec-based maker of flux furnaces uses crucibles that hit a peak temperature of 1,000 degrees centigrade for analyzing ore and cement samples. The company uses a Markforged Metal X 3D printer to make the crucibles out of heat-resistant Inconel and along the way saved $80,000 in the first year of use, and reduced the amount of time needed to get new crucibles by 86%.

The technology is quickly moving into new materials, like metals and composites based on wood and carbon fiber. If you think of 3D printing as the equivalent of a laser printer for real-world items – not just paper documents – you get an idea of its potential.

3D printing has the power to change the entire industrial landscape, because you don’t need to make or buy special molds or tools. That way, you can still make a profit from production runs as small as a single unit. A 3D printer-based factory floor can customize products to the customer’s needs – like a lock for a nonstandard door thickness or turbine blade for a jet engine– all without having to get new machinery or tooling.

Buying Guide

What Can a 3D Printer Do?

Thanks to their ability to churn out a variety of parts and products directly from computer files, 3D printers are replacing traditional manufacturing techniques like injection molding, casting, milling and lathing, allowing the quick creation of everything from prototype engine parts to custom phone cases.

Industrial 3D printers can produce a dazzling array of items. They are used every day to make architectural models, robotics, jewelry and eyewear. These industrial-strength printers – some the size of refrigerators – can create compound curves and sharp edges with precision, in the exact dimensions required.

With a CAD design and a 3D printer, you can make just about anything that a machine shop can produce. The process looks something like this: A designer creates a 3D model with a sophisticated CAD program. The model is then turned into machine instructions for creating the object one ultra-thin layer at a time. The printer creates it and the final part emerges, often ready for use.

By moving away from traditional factory processes, 3D printers have the power to transform entire industries and create the basis for the factory floor of the future. One thing is certain: 3D printing is here to stay.

3D Printer Types and Technologies

Rather than a single technology, there’s a range of techniques that different 3D printers use. All are based on the concept of additive manufacturing rather than traditional subtractive technology in that the item is built up a layer at a time. As a result, additive manufacturing (and 3D printing) can be quicker, more flexible and more efficient than old-school manufacturing. It can also make a single part that might need to be assembled from several individual pieces made with traditional techniques.

All are based on the concept of additive manufacturing rather than traditional subtractive technology in that the item is built up a layer at a time. As a result, additive manufacturing (and 3D printing) can be quicker, more flexible and more efficient than old-school manufacturing. It can also make a single part that might need to be assembled from several individual pieces made with traditional techniques.

The most popular 3D printer technologies boil down to five main techniques:

- Fused deposition modeling is the simplest technique and is used by extrusion machines. They work by softening a plastic filament and extruding it while precisely moving the extruder back and forth to build the item layer by layer. Polylactic acid and acrylonitrile butadiene styrene are the most popular FDM materials, but some contours and curves can be roughly formed, and the final product can lack the internal strength required. The process is for rapid prototyping of all sorts of parts and things like customized phone cases.

- The latest advance in FDM combines the economy and efficiency of extrusion with the ability to use more exotic materials. Called ADAM for atomic diffusion additive manufacturing, it starts by extruding a composite mixture of the plastic and a metal, fiberglass or carbon fiber material. It’s extruded as if it were pure plastic; then the plastic is burned off and the final part is sintered in a furnace.

- Binder jetting starts out with a powdered base material that is precisely sprayed with a curing agent that selectively hardens it into its final shape. Binder jetting can create not only metallic objects – like stainless steel and bronze – but silica as well, for making sand casting molds. It can create jewelry, bearings and small engine parts.

- Vat polymerization uses stereolithography to solidify a liquid polymer resin by curing it with a beam of ultraviolet light. The light source, often a laser, is precisely aimed with steerable mirrors to where the liquid needs to be hardened into its final shape.

Because the polymerization requires light, these machines often have orange windows to prevent outside light from penetrating and prematurely curing the resin. The output is smooth with good details, making it a good technique for airplane parts and models for complex surgery.

Because the polymerization requires light, these machines often have orange windows to prevent outside light from penetrating and prematurely curing the resin. The output is smooth with good details, making it a good technique for airplane parts and models for complex surgery.

- Powder bed fusion starts with a powdered raw material that is selectively fused into a solid from a laser’s heat. The beam moves back and forth selectively hardening areas that need to be built up. It can be used with nylons and metals, like titanium, steel and copper, for complicated items like pump housings and gears.

- Directed energy deposition focuses a high-energy laser or plasma arc to fuse metals together, building the object by solidifying the metallic raw material a layer at a time. The output is solid, strong and durable, but is expensive and restricted to metal items, such as jet engine parts.

What to Look for in a 3D Printer

When getting a 3D printer for your company, you need to consider numerous factors, from its materials, size, and consumables to its speed and software. After all, for a small company, it can be a big investment, so aim for the most flexible device you can get in terms of size, speed and variety of materials.

After all, for a small company, it can be a big investment, so aim for the most flexible device you can get in terms of size, speed and variety of materials.

Here are the criteria that lead to making a best pick for your small business.

Industrial 3D Printer Features

Look for a range of features that can help maximize the printer’s time being used and speed set up of new print runs. Remember, the more the 3D printer is used, the less it costs per item to make.

- Connections: Industrial 3D printers typically have a wired networking connection that’s often augmented by the ability to use Wi-Fi. Many also have a USB port for using a flash drive that contains the printer instructions.

- Raw material control: Some printers make you pour the material into a hopper or thread a filament, while others package it in a cartridge for quick, clean changes. Before buying, do some calculations to estimate what the typical parts you make will cost.

- Color: The raw materials for some 3D printers are available in a variety of colors, including neon shades and some that glow in the dark. Some makers even have custom mixing kits.

- Touchscreen control: Look for printers that have a touchscreen for setup, configuration and for customizing the building process.

- Stands: The smaller 3D printers can sit on a table or shelf, but they often have cabinets or stands available that can store maintenance products and the raw materials you’ll need.

- Build plate: Everything a 3D printer builds happens on a secure and level stage. It’s a good idea to buy several spares so as soon as the build is done, it can be pulled out and the next job started with an alternate tray.

- Monitoring: Most 3D printers have web cams built in to remotely watch its progress from the other side of the factory or globe.

Others have a laser inspection process that scans the item as it’s created looking for flaws or problems.

Others have a laser inspection process that scans the item as it’s created looking for flaws or problems.

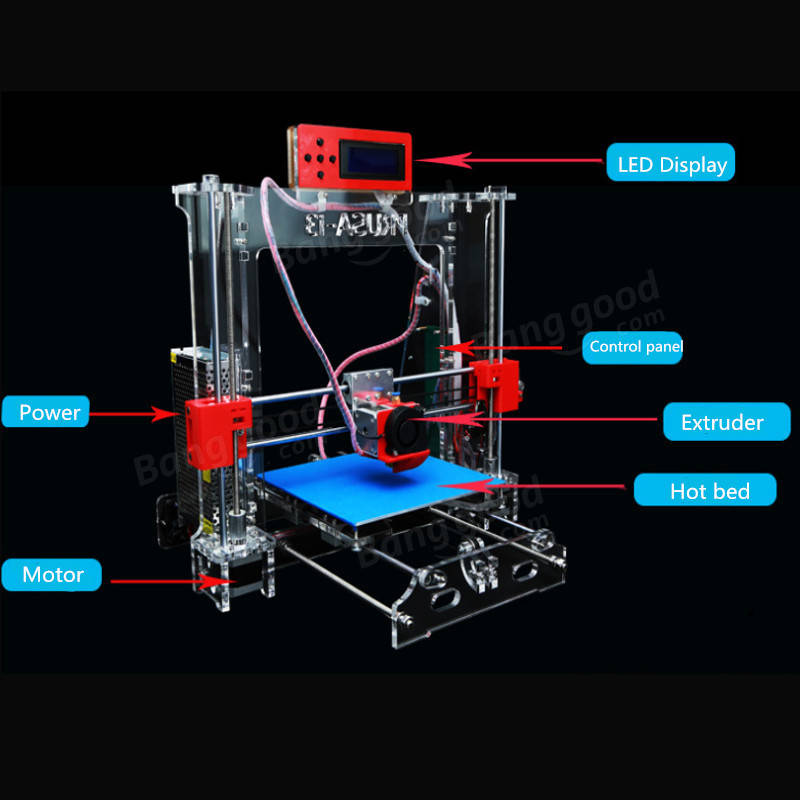

- Extruders: This is the actual printing nozzle. You’ll want more than one on hand because they can clog up and shut the machine down.

Materials

Letting the material fit the use is the best way to pick the printer. After all, you wouldn’t want a brittle plastic used for a race car’s engine cam, nor would you spend a fortune to make a titanium gear for a food mixer.

By far, plastics – nylon, polyactic acid, methacrylates and acrylonitrile butadiene styrene – are the most popular materials for 3D printing, and are generally inexpensive. Many 3D printer makers have enhanced these basic materials to be stronger. In fact, there are PLA materials that are as strong as ABS.

Many of the newer printers can work with ceramics and metals, including steel, bronze and gold. Some use formerly exotic materials, like carbon fiber and Kevlar.

Size

After you’ve chosen the technology and the material, you’ll need to select a size. Be careful, because as the 3D printing machinery grows, it can get exponentially more expensive. For instance, a small and simple extrusion machine capable of making things that are at most five inches long might cost about $1,000. If you want to double that to 10 inches, the cost could jump to between $7,000 and $20,000. How about items that are up to five feet long? It’ll cost you roughly $250,000.

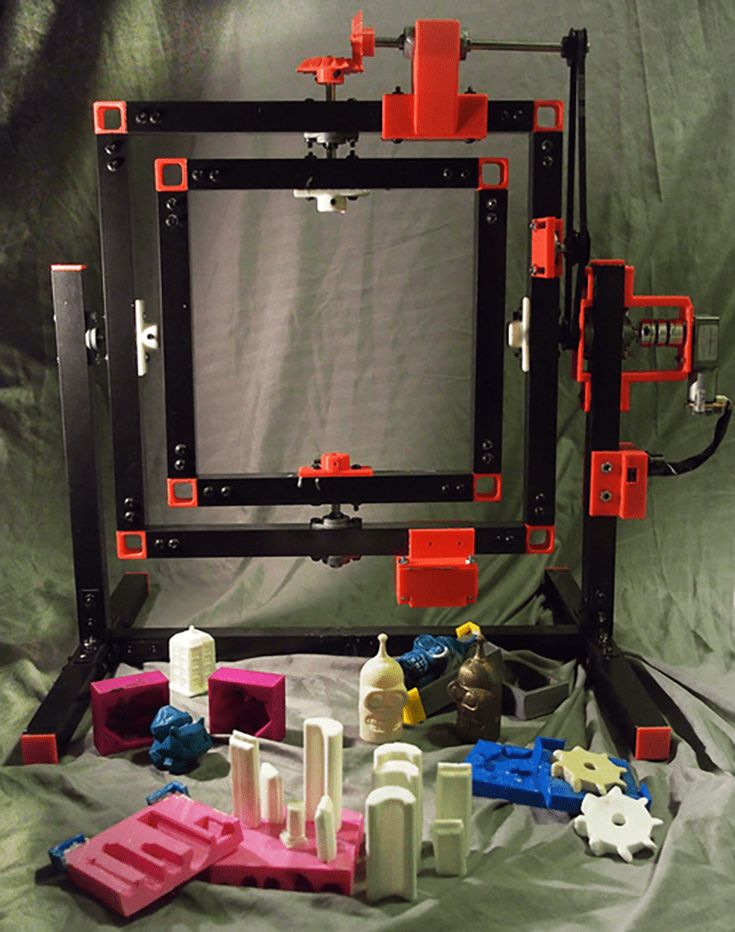

You’ll also want to keep printer assembly in mind. Some can have an Ikea-like, build-it-yourself quality, so you’ll want to be sure you have the manpower and know-how to set up a bigger machine. They sometimes require higher-voltage electrical service, ventilation and access to a steady supply of an inert gas.

Resolution

While 3D printers vary, each device is capable of a specified resolution. This roughly corresponds with the smallest feature that can reliably be made by the material and machine. A simple extrusion printer might have a resolution of about 100 to 150 microns, which is fine for most uses: A micron is one millionth of a meter, 0.001mm or about 0.00004 inch.

A simple extrusion printer might have a resolution of about 100 to 150 microns, which is fine for most uses: A micron is one millionth of a meter, 0.001mm or about 0.00004 inch.

Need more exacting designs? The resolution can be more exacting, with the ability to create items with a tolerance of 75 or 50 microns, or roughly the thickness of a human hair. Some stereolithography-based printers can build details as small as 16 microns – slightly larger than a grain of pollen.

Finally, there’s a new generation of 3D printers that can create items that go as low as a micron or 1/2,000th of the width of a human hair. Today, these are specialty machines that might be used for precise impeller blades or micro-optics, but they may soon be used to make prosthetic devices and microscopic machinery.

Software

Whether it’s a prototype light switch or a jet part, every 3D model starts at the screen of a computer-aided design (CAD) workstation. Once it’s ready, you’ll need to use the printer’s software to digitally slice it into the layers that the machine will build.

Generally, the final prebuild step is a preview with all the parameters listed. If all looks good, the program adds supports to prevent sagging, and renders large solid regions as honeycomb structures that are lighter and use less material. With the machine’s build file ready, all you do is press the Start button.

Although you can use the included software to prep the file, there are alternatives. In addition to cloud-based apps that work via a web browser, there are several generic 3D printer preparation apps programs such as Materialise, Slicr and Octoprint. A single program can work with several 3D printers.

Performance and Speed

When it comes to 3D printing, speed is important but not crucial. A faster printer obviously lets you move on to another item quickly. On the other hand, a slow but large printer lets you create several items on a single stage at once.

While an industrial stereolithographic system might push 15 mm of building per second, an extruder might be closer to 100 or 150 mm/sec. This translates into it taking an hour with the former, or a few minutes with the latter. The typical three-inch wide gear might be producible in about 10 minutes, while a complex model of a patient’s heart prior to surgery might require a full day or more.

This translates into it taking an hour with the former, or a few minutes with the latter. The typical three-inch wide gear might be producible in about 10 minutes, while a complex model of a patient’s heart prior to surgery might require a full day or more.

Resources, Contracts and Customer Service

Because 3D printers are expensive and potentially finnicky machines, there is an art to getting them to do your bidding. The bigger manufacturers have a slew of online resources that go beyond simple manuals and setup instructions. The best companies have training videos and white papers on how to best utilize the machinery, and offer troubleshooting help.

On the downside, even some market leaders don’t provide 24/7 support. Most limit it to business hours in the U.S., which can be bad for companies that need to run at night or those in far-away time zones.

They typically include a one-year warranty and support, although some limit this to a scant six months and charge for software upgrades. Look for a company that provides assistance setting up and using the printer but also provides documentation and online help.

Look for a company that provides assistance setting up and using the printer but also provides documentation and online help.

It’s a good idea to extend coverage with a service contract that covers repairs and support. It just might keep a major failure from shutting your company down.

Third-Party 3D Printing Services

You may be able to get the benefits of 3D printing without the expense and hassles of owning or leasing one at all.

There are hundreds of 3D services that will create your part or product from scratch and ship it to you. After designing the part and specifying what type of material or printer should be used, the file is uploaded to the service bureau’s servers. They make it and overnight it to you.

Service bureaus, such as Sculpteo, Shapeways, Materialise and Protolabs, typically have the newest machines and can be more efficient than in-house 3D printing, but you’ll have to wait for it to arrive.

Best of the Best

When selecting our best picks, we take a holistic approach. We include everything from the quality of the parts produced and tolerances to the cost of the machine and its raw materials. The availability of support is factored in, as is the warranty and what self-serve options the company offers online.

We include everything from the quality of the parts produced and tolerances to the cost of the machine and its raw materials. The availability of support is factored in, as is the warranty and what self-serve options the company offers online.

Because the 3D printer in a small business needs to perform a variety of roles, the big things we look for are overall value and flexibility. We recognize the printers that are fast, the most precise and offer the best value.

Any way you use these exciting new technologies, one thing is certain: 3D printing is shifting and improving the landscape of manufacturing in the 21st century.

The only question that remains is which 3D printer is best for your company’s needs.

Refurbished vs. Leasing vs. Third-Party Services: Alternatives to Buying a New 3D Printer

If all this sounds good for your company, but it can’t afford the capital outlay required, there are alternatives that can reduce the upfront money required. Each involves a compromise, however.

Is buying a refurbished printer a good idea?

Like getting a used car, a refurbished machine might cut the purchase price in half, but it’s a good idea to try it out, and have an expert look the system over and make a few models before buying a used printer.

How about leasing a printer?

The initial cash outlay for leasing is much lower, although you’ll likely be paying for the entire printer over three to four years, and you don’t get to keep it. On the upside, you can avoid technological obsolescence by going this route.

State of the Industry

The 3D printer market is a vibrant one, with 177 makers of industrial machines, according to the Wohlers Report 2019. It is forecast to grow from 2019’s $15.8 billion in machine sales to $23.9 billion in 2022, a compound growth rate of nearly 15% per year. By 2024, the industry could be worth $35.6 billion.

Under the surface, there are five major manufacturers of 3D printing gear that account for more than half of the sales of machinery. This “big five” includes Stratasys, MarkForged, 3D Systems, Envisiontec and HP. This still leaves lots of room for smaller and more nimble companies, like Ultimaker and FormLabs.

This “big five” includes Stratasys, MarkForged, 3D Systems, Envisiontec and HP. This still leaves lots of room for smaller and more nimble companies, like Ultimaker and FormLabs.

Source: Wohlers Report 2019

Top Five 3D Printer Manufacturers

- Stratasys: 19.2%

- MarkForged: 14.7%

- 3D Systems: 12.3%

- Envisiontec: 6.2%

- HP: 2.7 %

Brian Nadel

business.com Contributing Writer

Brian is a technology writer based north of New York City. He writes stories for Business.com, Tom's Guide, ComputerWorld and Scholastic Magazines. He is the former editor-in-chief of Mobile Computing & Communications magazine.

Back to TopBack to Tophigh performance low cost industrial 3D printer

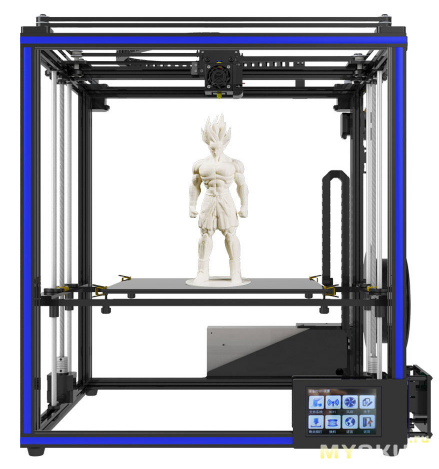

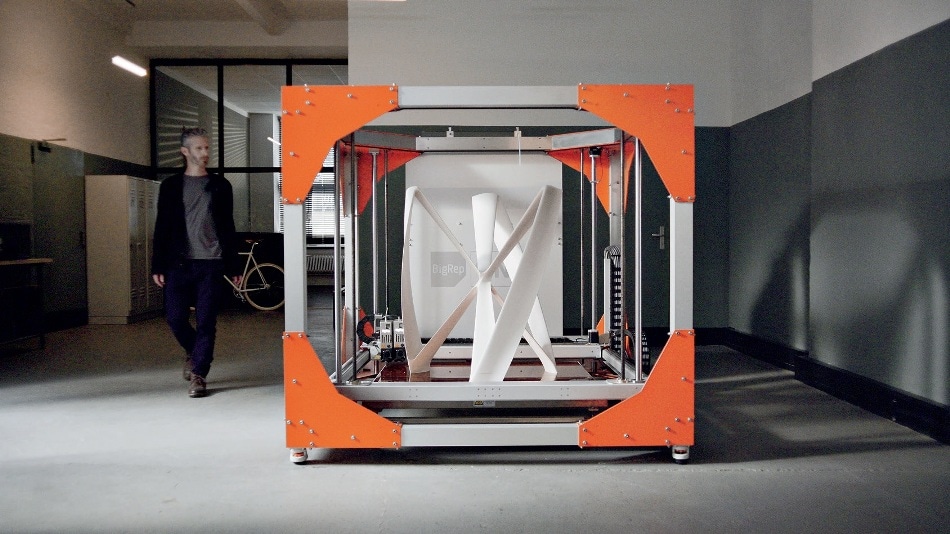

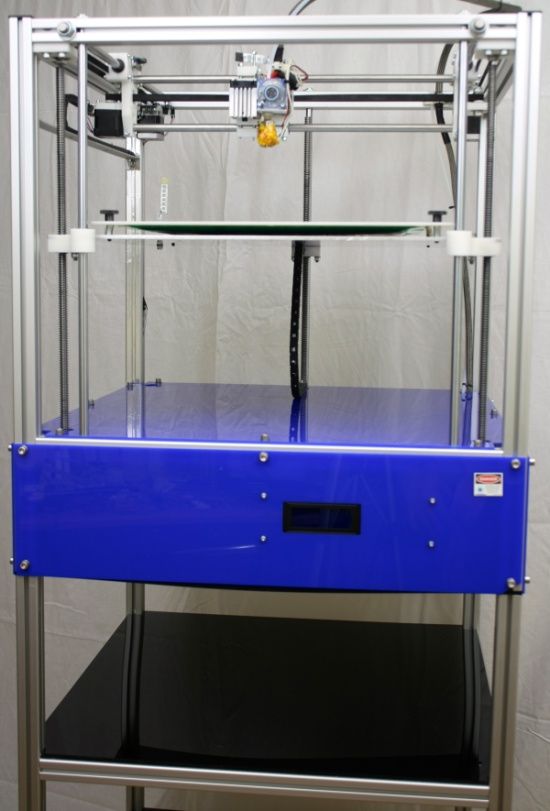

The CreatBot F1000 is an industrial size 3D printer with auto-elevating dual extruders, 1000x1000x1000mm build volume and other great features at a lower price than other brands.

Large scale FDM 3D printers tend to be expensive, especially those capable of printing high quality models using professional grade materials. The high price tag of these massive industrial machines has kept many small businesses and manufacturers from using 3D printing technology to create prototypes or even make functional parts.

The high price tag of these massive industrial machines has kept many small businesses and manufacturers from using 3D printing technology to create prototypes or even make functional parts.

The new CreatBot F1000 aims to make large-scale 3D printing more accessible. How? Combining serious print volume and an impressive array of professional features with a secret ingredient – affordability.

CreatBot F1000: large build volume and smart features

CreatBot F1000 offers a full cubic meter of build volume (1000 x 1000 x 1000 mm) as well as:0018

Accuracy and reliability make the CreatBot F1000 a terrific option for both industrial and professional users who need to print large prototypes or functional parts in one go.

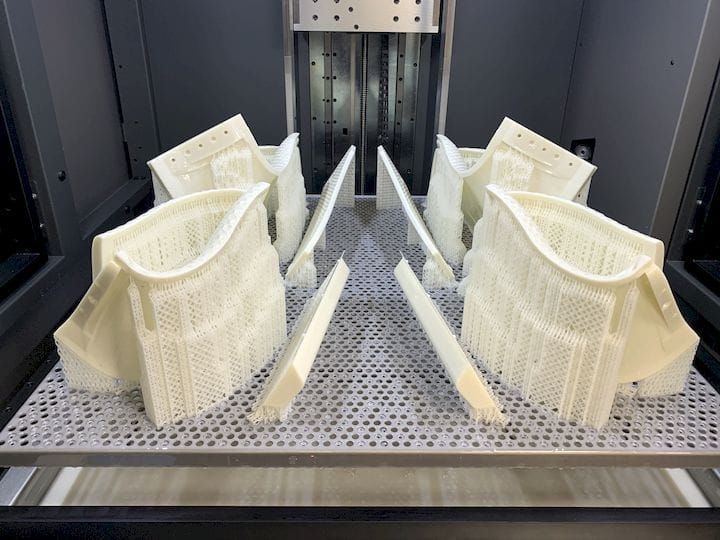

One cubic meter for 3D assembly is quite a lot. Such a space could allow 3D printing of small production runs or huge prototypes, or even mass production of standard quality products! Here is one of the happy customers of the F1000 3D printer:

Such a space could allow 3D printing of small production runs or huge prototypes, or even mass production of standard quality products! Here is one of the happy customers of the F1000 3D printer:

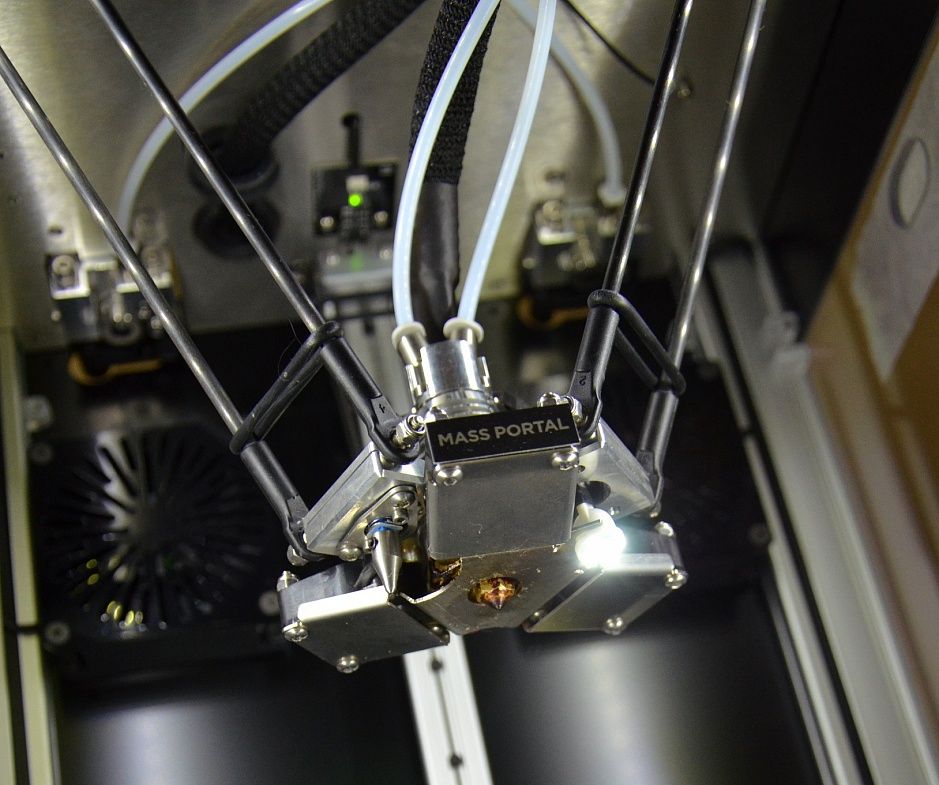

Besides the outstanding build volume, there are a few other big features that make this new big 3D printer a big deal (pun intended). The CreatBot F1000 features new dual auto-elevating extruders, a heated enclosed chamber, an auto-leveling system, and a built-in monitoring system that allows you to control your printing process with an easy-to-use app.

This massive workhorse also features a fast build plate heat that, together with a heated chamber, produces incredible results from professional quality materials. Needless to say, the CreatBot F1000 sets a new standard in additive manufacturing and expands the material capabilities of large-scale FDM 3D printers, which in turn saves our customers significant time and money.

The CreatBot F1000 has more than enough capacity for all real-world applications

The CreatBot F1000 is designed to make 3D printing large-scale objects and prototypes as easy as possible. This industrial 3D printer is the answer to growing market demand across a range of industries.

This industrial 3D printer is the answer to growing market demand across a range of industries.

The F1000 has recently been printed with a large theme park snake head (pictured). The result was a high-resolution object, one meter high and weighing 35 kg. Can you imagine how this huge 3D printer prints such a heavy model 24/7? A nozzle with a diameter of 1.5 mm was used, it took more than 200 hours to print.

There are many other examples of real work CreatBot F1000 in professional conditions. For example, one global supplier of advanced automotive systems and equipment used the CreatBot F1000 to design and develop molds for Audi, Volkswagen, Nissan, and GM car seats.

This video shows how these forms are printed. The bowl and lid must withstand pressure up to 100 MPa, so 50% nylon carbon fiber materials were used for production. The final accuracy of the model was +0. 1 mm and passed the rigorous tests often required in the automotive industry.

1 mm and passed the rigorous tests often required in the automotive industry.

The mold cover took 120 hours to 3D print and weighed 9 kg. The size of the part was 820 × 748 × 160 mm.

The mold bowl took 200 hours and weighed 16 kg. The size of this part was 820 × 748 × 200 mm.

After test runs, the performance of the CreatBot F1000 proved to be on par with or even better than some well-known brands of industrial 3D printers from Germany or the USA, with the difference, however, that this printer is more than three times cheaper than competitors. Someone now regrets buying expensive large-scale 3D printers instead of the impressively inexpensive and equally capable CreatBot F1000!

Without a doubt, the CreatBot F1000 is the best choice for an industrial large scale 3D printer that can handle engineering grade materials.

Specifications CreatBot F1000

| Displacement | 1000 × 1000 × 1000 mm |

| Extruders | Automatic rising double extruder |

| Minimum layer thickness | 0. |

| Maximum print speed | 120 mm/s |

| Maximum nozzle temperature | 420°C |

| Maximum platform temperature | 100 °C |

| Maximum temperature of assembly chamber | 60°C |

| Filament storage temperature | 45/65°C |

| XY positioning accuracy | 11 µm |

| Z positioning accuracy | 2.5 µm |

| Dimensions | 1740 × 1300 × 1920 mm |

| Weight | 550 kg |

Why mass 3D printing is still not a trend

Photo: asharkyu / Shutterstock, Chris McGrath / Getty Images

The production of goods with individual characteristics is one of the trends in the consumer market. However, personification has not yet become a popular phenomenon. Is this idea promising for business development?

However, personification has not yet become a popular phenomenon. Is this idea promising for business development?

When there was an acute shortage of personal protective equipment (PPE) for doctors, the owners of 3D printers united in the volunteer movement #3Dfor doctors. They began to print adapters, which made it possible to connect diving masks with virus-bacterial filters. Manufacturers were able to quickly develop and release adapters in various configurations for popular types of masks found in stores, quickly covered burning needs and saved many lives - and then began to make full-fledged protective masks and shields.

Adapters for masks - example of a customized product (made to order. - RBC Trends ), that is, adapted to different types of masks. How quickly manufacturers were able to design and release a new product with unique characteristics demonstrates the main advantages of 3D printing.

3D printing allows you to create products based on the preferences or personal characteristics of the buyer - personalized goods. This idea arose in the early 2000s, but so far, contrary to forecasts and the rapid development of additive technologies, has not become a mass phenomenon.

This idea arose in the early 2000s, but so far, contrary to forecasts and the rapid development of additive technologies, has not become a mass phenomenon.

Personalization Challenges

Nike and Adidas have been experimenting with 3D printing for sneakers since 2012. The goal is to create sports shoes in the presence of the buyer according to the individual characteristics of his foot. For example, Adidas announced in 2015 that a consumer could walk into a store, spend a couple of minutes on the treadmill, and immediately receive a printed pair of running shoes that take into account the contours of the foot and pressure points while running. At the same time, Nike announced the possibility of printing shoes directly at the customer's home. To do this, you just need to download the file with the parameters of the sneakers and the characteristics of the foot from the corporation's website to your home 3D printer.

However, by 2020, these opportunities remained unrealized. In practice, everything turned out to be more difficult.

In practice, everything turned out to be more difficult.

The point is the high cost of such products: the consumer is not ready to pay for customized sneakers many times more expensive when you can choose the right model from thousands of more affordable options.

Customization does not take root among automakers either. For example, in 2017, BMW launched the MINI Yours Customized service, which allows you to customize a new or previously purchased MINI car using decorative elements printed on a 3D printer. For example, it was possible to order individual side body inserts, trim parts, LED door sills and LED door projectors. However, the service is currently unavailable.

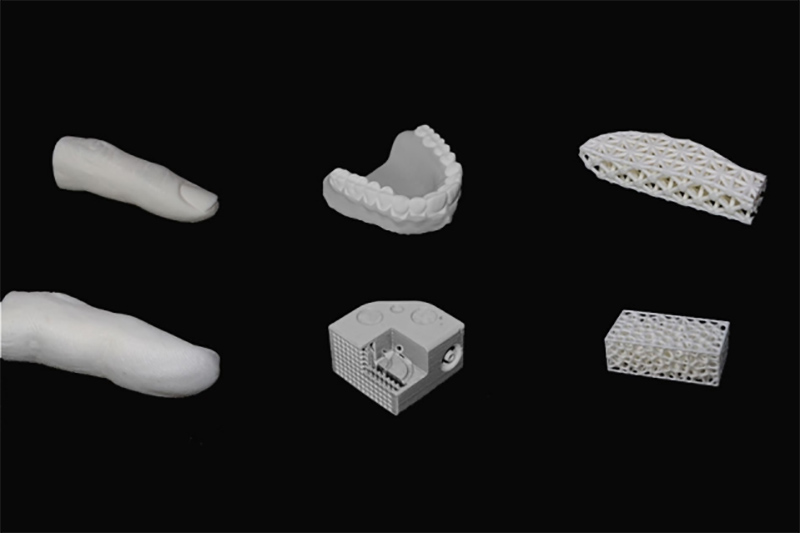

Where personification has taken root

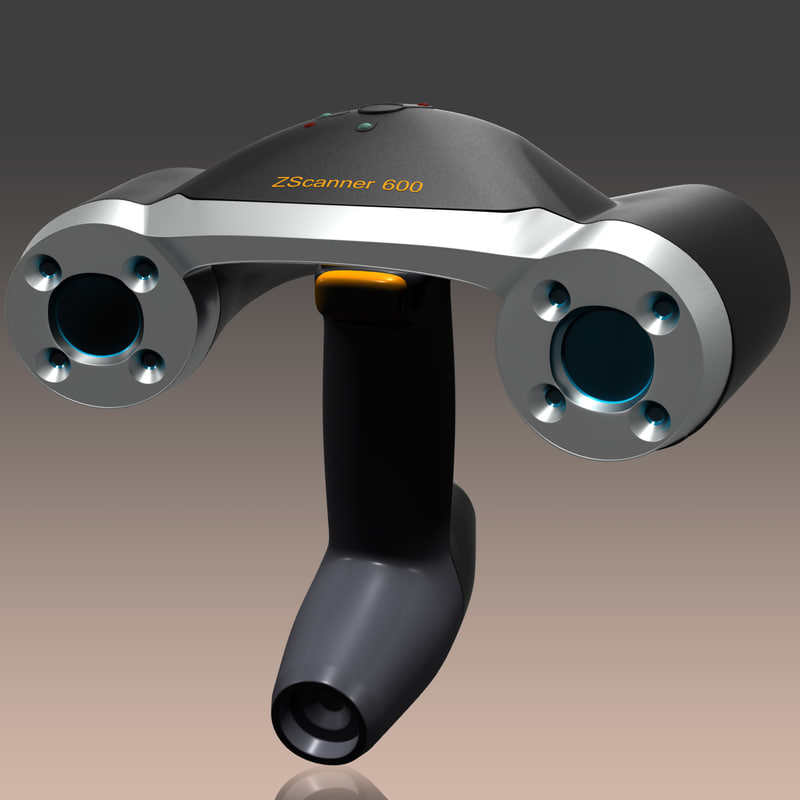

So far, 3D printing is most actively used in medicine, where it is vital to take into account the individual characteristics of a person. First of all, the technology is useful in orthopedics and dentistry for the manufacture of prostheses and implants. Customization is especially in demand in the production of prosthetic limbs. With the help of 3D scanning, the parameters of the patient are determined, a digital model of the prosthesis is created, which is printed on a 3D printer. In this case, you can create a unique design of the artificial limb. For example, they produce children's prostheses stylized as favorite movie characters.

Customization is especially in demand in the production of prosthetic limbs. With the help of 3D scanning, the parameters of the patient are determined, a digital model of the prosthesis is created, which is printed on a 3D printer. In this case, you can create a unique design of the artificial limb. For example, they produce children's prostheses stylized as favorite movie characters.

Another area where 3D printing is being used to customize products is in the jewelry and fashion jewelry industry. There are enterprises that produce mass products using 3D printing, for example, the American brands LACE, Nervous System and others. Customization is carried out, first of all, by small studios and workshops offering exclusive jewelry. They print digital models created according to customer sketches or cast them from precious materials using 3D printed molds.

Economics of innovation Living hand: who creates bionic prostheses in Russia

As for the majority of goods, the price works here in 99% of cases. Especially when the share of online sales is growing. You type in Google "buy a fountain pen is the cheapest" - and no matter where you are, you buy this fountain pen cheaper. This is where mass production wins.

Especially when the share of online sales is growing. You type in Google "buy a fountain pen is the cheapest" - and no matter where you are, you buy this fountain pen cheaper. This is where mass production wins.

You can think of many products that could be customized. But you need to be clear about who you will sell them to. Are there enough people willing to overpay for customization to keep your business alive? “In your calculations, you need to take into account real consumer demand, and not the desire to make money on hype,” says Vlasov. “The conclusion is simple: personalized production is possible when it will give approximately the same price as mass production.”

Denis Alekseev, Head of Development and Production at ROBBO JSC (educational robotics, Skolkovo resident), is confident that personalized production will become a popular trend of the future. But in order to attract the mass consumer to this segment, it is necessary to overcome a number of technical and organizational issues.:quality(80)/images.vogel.de/vogelonline/bdb/1486200/1486287/original.jpg) For the end user, the process of ordering a customized product should be as simple as possible: with a few steps, order what he wants, while receiving the finished product quickly and conveniently. The cost of individual products may be higher, but this increase must be of value to the customer.

For the end user, the process of ordering a customized product should be as simple as possible: with a few steps, order what he wants, while receiving the finished product quickly and conveniently. The cost of individual products may be higher, but this increase must be of value to the customer.

Main disadvantages of 3D printing:

-

low production rate;

-

often low quality products;

-

high cost of the product when trying to mass production.

How to reduce the cost of a customized product?

The cost of the finished product primarily depends on the materials for 3D printing. One way to cut costs is to produce consumables yourself.

Another option to reduce the cost of consumables is possible with the development of additive technologies and the development of new printing materials.

05 mm

05 mm