3D printing pen juboury

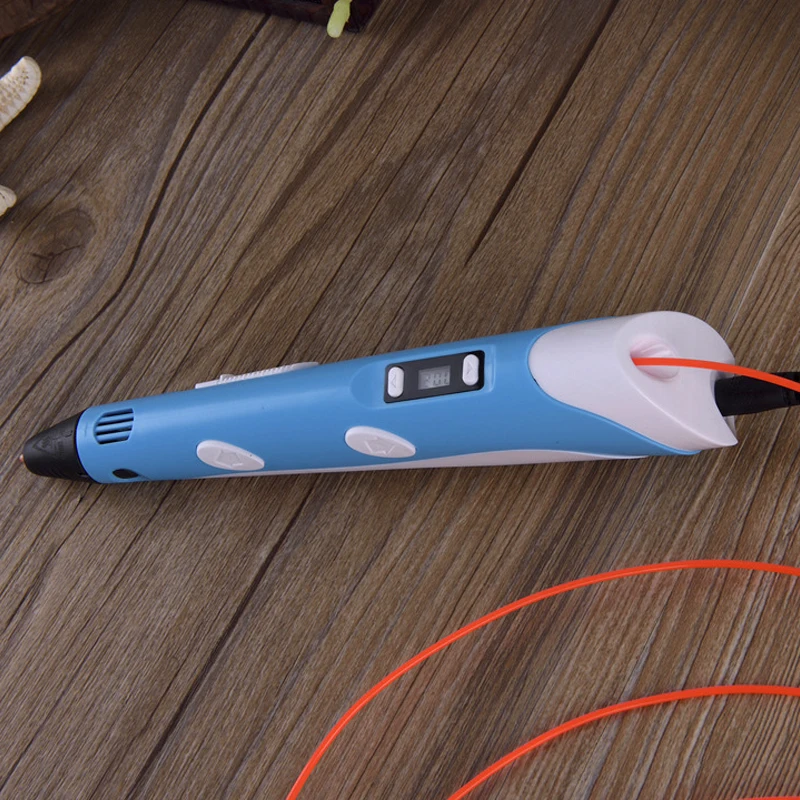

3D Printing Pen for Kids,Juboury JBY-II 3D Drawing Pen with LCD Temperature Display for Model Printing,Art Design,DIY and Crafts Drawing-Compatible with 1.75mm ABS and PLA Filament (Blue)

Brand : Juboury

Brand : Juboury

from USA

to Fiji

Description

Related Pages

Industrial And Scientific › Additive Manufacturing Products › 3 D Printing Supplies

Browse pages with similar products: draw tools, the best 3d pen. desertcart delivers over 100M+ products to Fiji from around the world.

Disclaimer: The price shown above includes all applicable taxes and fees. The information provided above is for reference purposes only. Products may go out of stock and delivery estimates may change at any time. desertcart does not validate any claims made in the product descriptions above. For additional information, please contact the manufacturer or desertcart customer service. While desertcart makes reasonable efforts to only show products available in your country, some items may be cancelled if they are prohibited for import in Fiji. For more details, please visit our Support Page.

Frequently Asked Questions About 3 D Printing Pen For Kids Juboury JBY II 3 D Drawing Pen With LCD Temperature Display For Model Printing Art Design DIY And Crafts Drawing Compatible With 1 75 Mm ABS And PLA Filament Blue in Fiji

Where can I buy 3 D Printing Pen For Kids Juboury JBY II 3 D Drawing Pen With LCD Temperature Display For Model Printing Art Design DIY And Crafts Drawing Compatible With 1 75 Mm ABS And PLA Filament Blue online at the best price in the Fiji?

desertcart is the best online shopping platform where you can buy 3 D Printing Pen For Kids Juboury JBY II 3 D Drawing Pen With LCD Temperature Display For Model Printing Art Design DIY And Crafts Drawing Compatible With 1 75 Mm ABS And PLA Filament Blue from renowned brand(s). desertcart delivers the most unique and largest selection of products from across the world especially from the US, UK and India at best prices and the fastest delivery time.

Is 3 D Printing Pen For Kids Juboury JBY II 3 D Drawing Pen With LCD Temperature Display For Model Printing Art Design DIY And Crafts Drawing Compatible With 1 75 Mm ABS And PLA Filament Blue available and ready for delivery in in Fiji?

desertcart ships the 3 D Printing Pen For Kids Juboury JBY II 3 D Drawing Pen With LCD Temperature Display For Model Printing Art Design DIY And Crafts Drawing Compatible With 1 75 Mm ABS And PLA Filament Blue to and more cities in Fiji. Get unlimited free shipping in 164+ countries with desertcart Plus membership. We can deliver the 3 D Printing Pen For Kids Juboury JBY II 3 D Drawing Pen With LCD Temperature Display For Model Printing Art Design DIY And Crafts Drawing Compatible With 1 75 Mm ABS And PLA Filament Blue speedily without the hassle of shipping, customs or duties.

Is it safe to buy 3 D Printing Pen For Kids Juboury JBY II 3 D Drawing Pen With LCD Temperature Display For Model Printing Art Design DIY And Crafts Drawing Compatible With 1 75 Mm ABS And PLA Filament Blue on desertcart?

Yes, it is absolutely safe to buy 3 D Printing Pen For Kids Juboury JBY II 3 D Drawing Pen With LCD Temperature Display For Model Printing Art Design DIY And Crafts Drawing Compatible With 1 75 Mm ABS And PLA Filament Blue from desertcart, which is a 100% legitimate site operating in 164 countries. Since 2014, desertcart has been delivering a wide range of products to customers and fulfilling their desires. You will find several positive reviews by desertcart customers on portals like Trustpilot, etc. The website uses an HTTPS system to safeguard all customers and protect financial details and transactions done online. The company uses the latest upgraded technologies and software systems to ensure a fair and safe shopping experience for all customers. Your details are highly secure and guarded by the company using encryption and other latest softwares and technologies.

Since 2014, desertcart has been delivering a wide range of products to customers and fulfilling their desires. You will find several positive reviews by desertcart customers on portals like Trustpilot, etc. The website uses an HTTPS system to safeguard all customers and protect financial details and transactions done online. The company uses the latest upgraded technologies and software systems to ensure a fair and safe shopping experience for all customers. Your details are highly secure and guarded by the company using encryption and other latest softwares and technologies.

Juboury ABS-Filament Test - Kleine Knicke tun dem 3D-Stift nicht weh

3D Stifte ABS Filament

| Eigenschaft | Details |

|---|---|

| Modellbezeichnung | Juboury ABS-Filament 1.75mm für 3D-Stifte |

| Bewertung | (4.5 von 5) |

| Farben | |

| Features |

|

€13,43

Auf Amazon ansehen

Kategorie: 3D Stifte ABS Filament Schlüsselworte: 1.75mm, 3D Ink, 3D Stift Filament, 3D-Stift ABS-Filament, ABS, Extrudieren, Farben, Filament, Führungsdraht, Juboury, nachfüllen, Patrone, PLA, Rollen, Spulen ID: 1059

- Beschreibung

Für Produkte wie Fitnessarmbändern und Health Trackern bekannt, wagt sich Juboury auch in den Bereich des 3D Druckens. Zumindest 3D Stifte möchte das Unternehmen versorgen. Diese Entscheidung scheint die richtige gewesen zu sein, ganzheitlich betrachtet hat dieses ABS Filament im Vergleich nämlich sehr gut abgeschnitten. Die Pro- und Kontrapunkte werden anschließend im Juboury ABS-Filament Test klar aufgestellt.

Die Pro- und Kontrapunkte werden anschließend im Juboury ABS-Filament Test klar aufgestellt.

Durchmesser und Verkaufsmenge

Eine enorme Menge an Nachfüllmaterial wird beim Kauf dieses Pakets geboten. Gleich 12 Rollen Filament zu je 10m Länge befinden sich im Lieferumfang. Um das zu erhalten, müsste man bei vielen Konkurrenten gleich zwei Päckchen bestellen. Einzusetzen sind diese Spulen für alle Geräte, die mit einem Durchmesser von 1.75mm kompatibel sind. Die Abweichung beträgt hierbei nur +/- 0.02mm was weder für 3D Drucker, noch für die eigentlich gedachten 3D Stifte ein Problem darstellt.

Juboury ABS-Filament Herstellerinfos

33 Bewertungen

Juboury 120 Laufmeter Filament für 3D Druckstifte. Paket mit 12 1,75mm PLA Filament Schleifen in 12 unterschiedlichen Farben zu je 10 Meter Länge. Inklusive Schablonen Heft mit 120 Schablonen.(PLA)

- ✔HOHE QUALITÄT & UNIVERSAL EINSETZBAR: Das Juboury PLA Filament kann mit den meisten 3D-Druckstiften oder 3D-Druckern für 1,75mm Materialstärke eingesetzt werden.

Durch die hohe Materialqualität des PLA-Kunststoffs ist das Filament von seiner Konsistenz perfekt für eine optimale Strömung durch das Extruder-Rohr und die Extruder-Düse.

Durch die hohe Materialqualität des PLA-Kunststoffs ist das Filament von seiner Konsistenz perfekt für eine optimale Strömung durch das Extruder-Rohr und die Extruder-Düse. - ✔12 EINZIGARTIGE FARBEN: Das Filament-Paket kommt mit einer großen Auswahl von 12 unterschiedlichen Farben, die Ihnen mehr Freiheit und Möglichkeiten für Ihre künstlerische Entfaltung geben. Schaffen Sie einzigartige Meisterwerke.

- ✔BONUS – 120 VORLAGEN: Mit diesem Paket erhalten Sie kostenlos ein Buch mit 120 Schablonen. Davon sind 25 Vorlagen für 3-dimensionale und 95 Schablonen für 2-dimensionale Objekte. Öffnen Sie Ihre Fantasie und fangen Sie jetzt mit der Gestaltung an!

- ✔ÜBER 100 METER FILAMENT: Dieses Paket besteht aus 1,75mm starkem PLA Filament in 12 unterschiedlichen Farben zu je 10 lfm, mit dem Sie gesamt 120 Laufmeter Filament für Ihren 3D-Stift oder Ihren 3D-Drucker erhalten.

- ✔KAUFEN MIT VERTRAUEN: 100% Zufriedenheitsgarantie hat für unser Kundenservice oberste Priorität. Bitte zögern Sie nicht uns zu kontaktieren, wenn Sie Fragen, Anregungen oder Beschwerden haben.

Drucktemperatur und Geruchsentwicklung

Aus Sicht des Herstellers sollte das Material mit einer Temperatureinstellung im Bereich von 230° bis 265° Celsius gedruckt werden. Im Juboury ABS-Filament Test zeigte sich allerdings, dass bereits 220° Celsius ausreichend sein können und die Höchstwerte für zielführendes Drucken eher bei 260° Celsius liegen. Dabei entstehen keinerlei unangenehme Gerüche, wie es für das Extrudieren solch kleiner Mengen aus dem 3D Stift auch üblich ist.

Qualität und Verarbeitung von Juboury ABS-Filament

Aus qualitativer Sicht stellt dieses Filament ein top Produkt dar. Es schreibt und zeichnet sich damit zu jedem Zeitpunkt problemlos. Selbst bei deutlich von den empfohlenen Drucktemperaturen abweichenden Werten, ist es unter dem Einfluss gewisser Probleme mit gleichmäßigem Extrudieren immer noch möglich zu drucken. Bei vollständigem Aufhitzen des 3D Stifts und einer für das Filament passenden Temperatureinstellungen gab es gänzlich keine Probleme. Verarbeitungstechnisch lässt sich festhalten, dass kleinere Knicke im ABS vorkommen können. Das führt allerdings üblicherweise zu keinem Fehlverhalten im Druckvorgang. Im schlimmsten Fall kann es lästig sein, das geknickte Filament per Hand in das Nachschubloch einzuführen. Das ist jedoch schnell erledigt und trat im Juboury Filament Test nicht all zu oft auf.

Verarbeitungstechnisch lässt sich festhalten, dass kleinere Knicke im ABS vorkommen können. Das führt allerdings üblicherweise zu keinem Fehlverhalten im Druckvorgang. Im schlimmsten Fall kann es lästig sein, das geknickte Filament per Hand in das Nachschubloch einzuführen. Das ist jedoch schnell erledigt und trat im Juboury Filament Test nicht all zu oft auf.

Farbauswahl und -echtheit

In 12 verschiedenen Farben bietet Juboury sein 1.75mm ABS-Filament für 3D Stifte an. Darunter sind selbstverständlich die drei Grundfarben rot, gelb und blau enthalten, sowie weitere gängige töne wie grün, orange, lila als auch schwarz und weiß. Ein Paket wird mit 12 unterschiedlichen Farbtönen geliefert. Man muss also keine Bedenken haben, mehrmals die gleiche Farbe zu erhalten. Die Echtheit der Farben bleibt nach dem Druck erhalten und bietet damit schöne, kräftige Ergebnisse. Das ist besonders dann erfreulich, wenn man detailgetreue Gebilde und Objekte erschafft oder verziert.

Fazit: Juboury ABS-Filament Test

In vielen Punkten legt das hier vorgestellte Produkt eine perfekte Leistung hin. Kleinere Probleme in Bezug auf das Knicken und noch seltenere Brechen des Filaments sind vor allem in Anbetracht des Preises verkraftbar. Ein nettes Extra bleibt noch offen: Im Lieferumfang befindet sich ein Heft mit Modellen, die sich zum Teil einfach nachproduzieren lassen. Wer dennoch zu einem noch günstigeren Artikel greifen möchte, ist mit YESTECH Ink ABS-Filament sehr gut beraten.

Kleinere Probleme in Bezug auf das Knicken und noch seltenere Brechen des Filaments sind vor allem in Anbetracht des Preises verkraftbar. Ein nettes Extra bleibt noch offen: Im Lieferumfang befindet sich ein Heft mit Modellen, die sich zum Teil einfach nachproduzieren lassen. Wer dennoch zu einem noch günstigeren Artikel greifen möchte, ist mit YESTECH Ink ABS-Filament sehr gut beraten.

Zur Merkliste hinzufügen

3D-pen for 3D-printer, fixing bloatware / Habr

Almost everyone has heard about 3D-pens. Many have tried them, many have them. So, perhaps, this gadget will surprise no one. And, probably, if there is a 3D printer at home, then the pen against its background will look very funny. But... Do not rush, a 3D pen can become an indispensable assistant and a very handy tool for any maker. Now, using my example, I will show how easy it is to save a three-dimensional model that took 41 hours to print using a 3D pen.

Let's start by inspecting the gadget.

Everything is standard, the box contains instructions, power supply and the pen itself.

Power supply cable is 1.4 m long, should be enough for most outlets near tables.

12 volt, 3 amp power supply.

It easily gives out the declared volts at idle, I didn’t measure the current, sorry. Let's go straight to the test.

Handle like a handle. Of the interesting - this is the specified nozzle diameter - 0.7 mm. A big plus for me personally is that the pen is omnivorous. You can print both PLA and ABS. There is also a manual temperature control.

Mode selection is intuitive. You just need to press the buttons on the sides of the screen.

Next, press the feed button, you can release it once. Heating starts. Heats up quickly, faster than a 3D printer.

When the desired temperature is reached, the indicator to the left of the screen changes from red to green.

In addition to adjusting the temperature, there is an adjustment for plastic feed (speed) on the handle.

On the other side of the feed adjustment there are 2 buttons - “squeeze out” and “pull out”.

Filled for the first test with a piece of plastic left over from the last print.

On the first delivery, you can see that there was already some plastic in the nozzle. This is good, since the handle was really checked. Some printer manufacturers supply them with a printed figure on the table, the user immediately sees that the device is working and prints as it should.

I had test plastic right away for a reason, I refilled transparent SBS, it is quite soft and often there are problems with it when printing on a printer. Here, everything immediately went briskly.

A small digression.

I was given a set of plastic along with the pen.

3D palette.

By the way, a very good addition to the 3D pen. In addition to conveniently located plastic in separate pockets, there is a compartment for storing a pen, as well as an envelope with sketches on tracing paper for easy creation of three-dimensional models.

In addition to conveniently located plastic in separate pockets, there is a compartment for storing a pen, as well as an envelope with sketches on tracing paper for easy creation of three-dimensional models.

We take a tracing paper and draw glasses along the contour.

Once the plastic has cooled, it can be easily removed from the tracing paper. We're filming.

Draw the second bow.

Next, melt the temples to the glasses.

PLA plastic is very pleasant to work with, easy to soften and stick to each other. But there is one drawback, it should not be overheated, it becomes too fluid, but more on that later.

Glasses are ready.

Now let's get down to business. I printed a Pinky monster figurine from DOOM 3. Printing did not work right away, the model is very complex with spikes and other details sticking out in all directions. I printed both in 2 extruders with supports from HIPS, and with supports generated in MeshMixer. But when moving to the beginning of the hands, something always fell off and I had to stop printing. Perhaps the plastic is to blame, it is almost a year old and it was stored without a package and a box, just like that.

But when moving to the beginning of the hands, something always fell off and I had to stop printing. Perhaps the plastic is to blame, it is almost a year old and it was stored without a package and a box, just like that.

In general, for the third time I combined printing methods and added supports from HIPS plastic to the model with supports from MeshMixer. In the middle of printing, I saw that my hands were torn off again, but I spat and finished printing to the end, deciding to simply glue the damaged parts.

The parts have been reprinted and now with the help of a 3D pen I can easily glue them to the main model.

With such a seam, glued parts are obtained, but firmly. And the protruding excess plastic can be ground off or cut off with a knife after treatment with dichloromethane.

Saw off the muzzle.

And glue a new, high-quality one.

This is a darned creation of Frankenstein.

Here you can see the comparison of the quality of the old and new muzzle.

Let's move on to the hands. It’s more difficult here, in some places it turned out to be a big gap.

But, in principle, the handle easily copes with wide slots.

It remains only to process the seams.

I didn't sand or dry sharpen them. I decided to treat the entire model with methylene chloride, it dissolves both PLA and ABS equally well.

The seams have become smoother, but most importantly, the top layer of plastic has become soft and can be easily cut with a knife, like plasticine. Align all the seams, cutting off the excess, and once again go through the brush with DCM.

And here is the result:

Finally, let's look inside the 3D pen.

Remove the black tip and unscrew one single screw.

Here you can see a ceramic nozzle with a heater and a thermistor, a short bowden tube and an extruder on a simple brushed motor. The feed is controlled by the rotation speed of the motor shaft. On the motor there is a small brass gear pushing through plastic, on the other hand, all this is pressed by a small bearing with a flat side. In general, everything is very simple, like Kalash. Yes, and remember, I wrote about the fact that you should not overheat PLA plastic. In the disassembled photo, it is noticeable that there is something red on the back of the heater, where the tube enters it. It's just PLA plastic, I painted it a little in the heating mode for ABS, and it became so liquid that it went in the opposite direction. If this is abused, then I think a lot of it can accumulate there and this will lead to overheating and failure of the handle. Be careful.

On the motor there is a small brass gear pushing through plastic, on the other hand, all this is pressed by a small bearing with a flat side. In general, everything is very simple, like Kalash. Yes, and remember, I wrote about the fact that you should not overheat PLA plastic. In the disassembled photo, it is noticeable that there is something red on the back of the heater, where the tube enters it. It's just PLA plastic, I painted it a little in the heating mode for ABS, and it became so liquid that it went in the opposite direction. If this is abused, then I think a lot of it can accumulate there and this will lead to overheating and failure of the handle. Be careful.

In conclusion, I would like to say that earlier, when I didn't have a pen, I was angry… I'm sorry. :) Before, when I didn't have such a pen, I used a soldering iron to close the damaged seal. A soldering iron with temperature control helped a lot. But ... you understand - this is not the best tool for repair. You need to hold the soldering iron with one hand, feed the rod with the other, and hold the part itself with the third. Another option is to chemically dissolve the plastic and seal the gaps. But when the solution dries, it shrinks a lot and dips appear. Ideally, it turns out with a 3D pen. Among the shortcomings of the pen itself, I will note only 12 V power supply. Since now there are already 5 V pens and you can carry them with you, and power them from a USB battery, it is more convenient than sitting at the outlet.

Another option is to chemically dissolve the plastic and seal the gaps. But when the solution dries, it shrinks a lot and dips appear. Ideally, it turns out with a 3D pen. Among the shortcomings of the pen itself, I will note only 12 V power supply. Since now there are already 5 V pens and you can carry them with you, and power them from a USB battery, it is more convenient than sitting at the outlet.

To potential buyers

With a 10% discount, the Dali Plus 3D Pen and PLA Palette can be purchased with the promo code GT-3D.

3D Pen

- 1 Description

- 2 History

- 3 Design

- 4 Materials

- 5 Application

- 6 Development

- 7 Interesting 3Dtoday blog posts about using 3D pens:

Description

FDM printing is the logical evolution of CNC machines. The only fundamental difference was the use of a specialized nozzle (extruder) for melting and feeding plastic. By the same logic, hot glue guns, which are widespread in everyday life, have also been developed. The use of thermoplastics instead of thermoplastic adhesives allows devices like these, dubbed 3D pens, to be used as hand-held additive manufacturing devices.

The only fundamental difference was the use of a specialized nozzle (extruder) for melting and feeding plastic. By the same logic, hot glue guns, which are widespread in everyday life, have also been developed. The use of thermoplastics instead of thermoplastic adhesives allows devices like these, dubbed 3D pens, to be used as hand-held additive manufacturing devices.

Parts of the future model can be drawn on paper and glued together

History

One of the latest developments is the Dim3W 3D pen

The pioneer of a new direction in the development of 3D printing was the pen from Wodoodleworksr.

The team turned to Kickstarter to raise the funds needed to bring the project to life.

With a $30,000 goal, Wobbleworks had raised over $2 million by the end of the campaign, indicating strong public interest.

Amid the success of 3Doodler, a competitive wave swept through. At the moment, the range of 3D pens includes actual 3Doodler clones like 3DYAYA or SwissPen, as well as more original designs including Dim3W and LIX.

At the moment, the range of 3D pens includes actual 3Doodler clones like 3DYAYA or SwissPen, as well as more original designs including Dim3W and LIX.

The basic principle of operation of all these devices is the same, but there are some design features aimed at improving a fairly young concept.

Construction

In essence, a 3D pen is nothing more than a manual extruder. The user himself acts as the CNC of the machine.

3Doodler disassembly. The nozzle in the lower part and the pulling mechanism in the middle of the handle are clearly visible

The main elements of the 3D pen: nozzle, plastic filament feeder, heating element, fan for cooling the upper part of the nozzle and the handle as a whole, microcontroller for controlling the operation of the fan, feeder and heating element.

Since almost all software functions of 3D printers are performed by the user, 3D pens do not require a connection to a computer or the creation of digital models. Only a power supply is required - as a rule, conventional power supplies with a 12V voltage converter are used.

Only a power supply is required - as a rule, conventional power supplies with a 12V voltage converter are used.

As with FDM printers, it takes a few minutes for the nozzle to heat up, after which the pen is ready to print. The supply of material is carried out by pressing the corresponding button. Some models, such as the Dim3W, are equipped with a print speed control.

Also available with reversible feeder. This feature allows you to quickly remove the plastic filament from the pen and replace it with a different color material.

Materials

3Doodler complete with colorful ABS plastic packs

Two of the most popular plastics in FDM 3D printing are currently used as materials for 3D pens - ABS plastic and organic, biodegradable polylactide (PLA plastic). Theoretically, it is possible to use other materials - polycarbonate, nylon, etc. At the same time, existing models do not provide the ability to accurately adjust the nozzle temperature, which is important when switching to other materials. Temperature characteristics are embedded in the firmware. In the future, we can expect more variety in the range of materials and the ability to fine-tune the temperature if there is a corresponding demand.

Temperature characteristics are embedded in the firmware. In the future, we can expect more variety in the range of materials and the ability to fine-tune the temperature if there is a corresponding demand.

Like full-fledged FDM printers, 3D pens use thermoplastic filaments with a diameter of 1.75 or 3mm. For ease of use with the pen, the threads are usually supplied as scraps rather than spools, but it is ultimately up to the user to choose.

Applications

Similar voids formed during plastic delamination due to uneven cooling can be filled with a 3D pen

3D pens are positioned as a means for creative work, three-dimensional drawing. Although devices can indeed fulfill such a role, creating more or less decent-looking models requires serious skill.

However, initially 3D pens were conceived for a completely different purpose, similar to the purpose of their ancestors - hot glue guns. It's about repairs. The fact is that some types of plastics used in FDM 3D printing (for example, the very popular ABS plastic) have a high degree of shrinkage and a tendency to deform during uneven cooling. All this often leads to cracking of the manufactured models. 3D pens were supposed to be a tool for manually repairing printed models. These devices allow you to fill in missing layers or faults.

The fact is that some types of plastics used in FDM 3D printing (for example, the very popular ABS plastic) have a high degree of shrinkage and a tendency to deform during uneven cooling. All this often leads to cracking of the manufactured models. 3D pens were supposed to be a tool for manually repairing printed models. These devices allow you to fill in missing layers or faults.

Particularly good results can be achieved by careful treatment of cracks with acetone, which dissolves ABS plastic. The surface softened in this way will adhere well to freshly applied plastic with a 3D pen.

3D pens allow you to draw in the air instead of paper

The surface of the repaired area can be leveled by sanding and gently working with the same acetone. Similarly, household products can be repaired - many of them are made from the same ABS plastic that has become widespread in the industry.

As for artistic applications, 3D pens will appeal to those who love to draw and want to move from 2D sketches to 3D physical models.

The main difficulty lies in purely human limitations - any unwanted hand movement will affect the quality of the model, especially when drawing the model "in the air".

One interesting way to improve the quality was to divide the models into their component parts using sketches on paper as templates. Finished parts are simply glued together.

BioPen allows surgeons to “paint over” damaged areas of bone or cartilage tissue, contributing to its restoration.

Of course, the method is applicable only when creating parts of models with relatively flat surfaces.

The possibility of using a variety of 3D pens in medicine is very promising.

Devices called "bio-pens" (BioPens) are being tested as tools for applying live cell layers mixed with biopolymers that act as support matrices and contain essential nutrients.

The original 3D BioPen was developed by Australian scientists at ASEC and is designed to repair cartilage and bone tissue.

75mm Durchmesser

75mm Durchmesser