3D printer computer requirements

Which computer is best for 3d printing? All the specs! – 3D Solved

There is a lot of talk around the type of computer that is required to successfully run a 3d printing operation. Much of this debate is based on the (false) idea that all 3D-related fields do need considerable processing power.

You may be interested in getting your hands on your first 3D printer but before doing so, you might wonder if your current PC or Laptop is enough for this new hobby.

3D printing does not require an expensive PC or Laptop with lots of processing power. For most users, a computer with 8GB of ram, a 4 core Intel i5 or Ryzen comparable processor, and a few gigabytes of available storage space will be enough.

The only case in which a better setup is recommended is for users that also want to design their own objects since 3D CAD software tends to be resource-intensive.

Although I go into further detail and answer other questions in this article, the following table should be useful!

| 3D Printing | 3D Printing | 3D Printing | 3d Modeling | 3d Modeling | 3d Modeling | |

| Budget | Low | Medium | High | Low | Medium | High |

| Processor | 2 cores i3 | 4 cores i5 | 6 cores i7 | 4 cores i5 | 6 cores i7 | 8 cores i7 |

| Ram | 4GB | 8GB | 16GB | 8GB | 16GB | 32GB |

| Graphics Card | NO | NO | NO | NO | NVIDIA 1650ti | NVIDIA 3060ti |

| Hard Drive | 128GB | 512GB | 1TB | 512GB | 1TB | 2TB |

What type of computer do you need for 3d printing?

3D printing is not inherently processing power-intensive, so a regular PC or laptop should be enough for most use cases. If you only plan on using the computer for slicing, you should not worry about this issue and just go with the computer that is available to you.

Most 3d printing enthusiasts only use their computers to store files and “translating” them into G-Code (“slicing”). Users that do require a powerful and somewhat expensive computer are those that are interested in also modeling their own objects.

Because of the fact that 3D CAD modeling is resource-intensive, a better computer will be required. Although a graphics card is also recommended, a budget GPU like NVIDIA’s 1650ti is more than enough. Expensive cards are only necessary for rendering scenes, which is unrelated to 3d printing.

Computer requirements for 3d printing

| Specifications | |

| Processor | 4 cores i5 |

| Ram | 8GB |

| Graphics Card | Not necessary |

| Hard Drive | 512GB |

A budget computer with 8GB of ram and an Intel or AMD processor with 2 cores should be more than enough for comfortably using any slicer, aka the software that converts a 3d file into machine instructions). In fact, you could also use a cheaper computer, but some features could run slow when dealing with more complex objects (and thus larger files).

Take Ultimaker’s Cura as an example: the developers state that only 4GB of ram and a single-core processor are required to run the slicer. Being a user of that app myself, I would recommend installing the slicer on a slightly better computer. Other similar programs like Simplify3D and PrusaSlicer all have similar requirements. I would recommend aiming at the recommendations that I listed above and not just the bare minimum required by the developers.

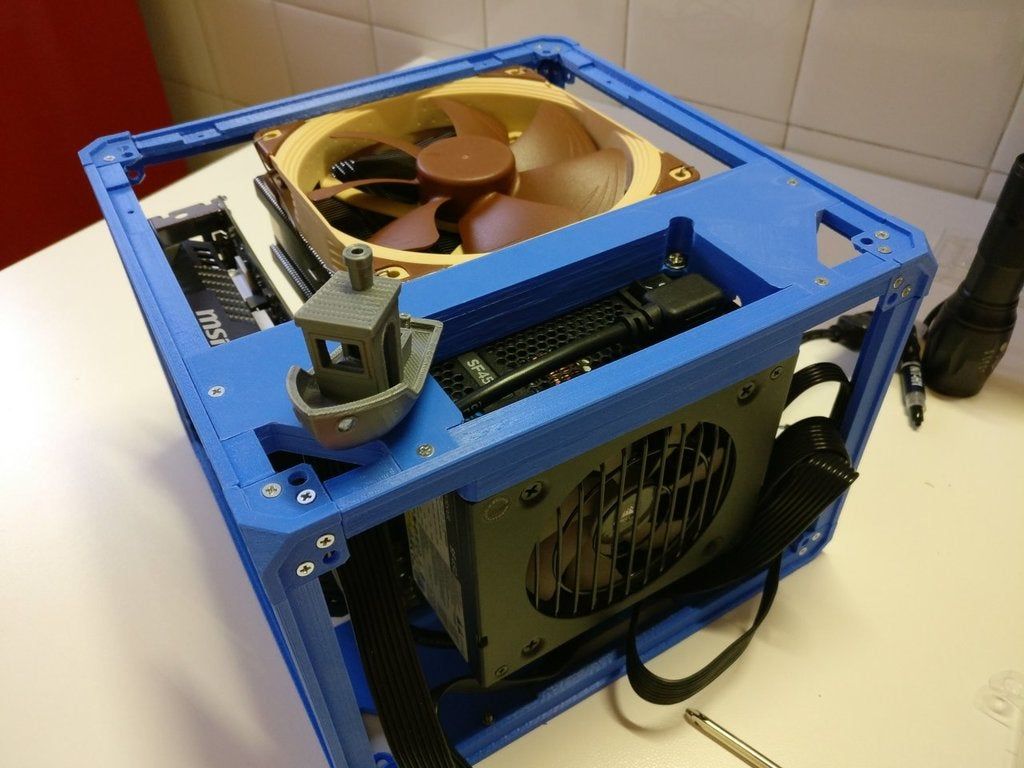

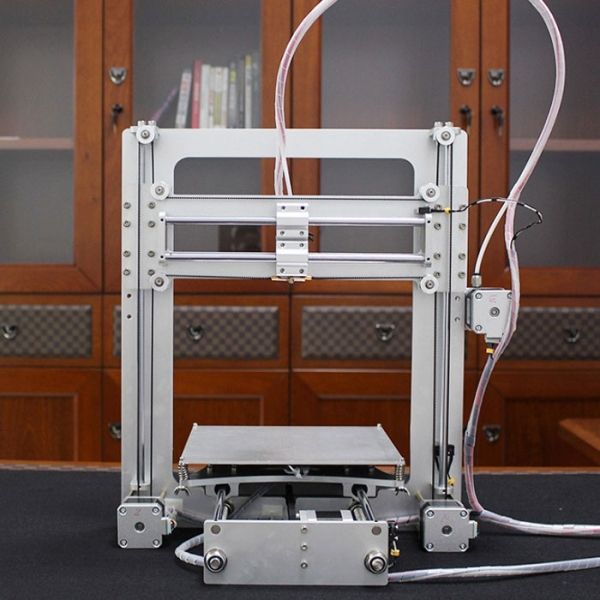

Example of useful 3D printing computer: Business PC (All business PC’s are more than enough).

Do you need a graphics card for 3d printing?

A graphics card is not required for 3d printing comfortably and having a good user experience. It is often thought that all 3d related fields require expensive computers, but 3d printing deals with a reduced amount of objects at the same time, all of which have no textures.

It is often thought that all 3d related fields require expensive computers, but 3d printing deals with a reduced amount of objects at the same time, all of which have no textures.

A graphics card would only slightly increase the processing times of a slicer when dealing with very large files that have a huge amount of details in high resolution.

How good of a computer do you need for 3d modelling?

A complex model in Fusion360 will require computing powerWhen it comes to 3d CAD modeling, a somewhat powerful computer is required. This is mostly due to the fact that modeling programs are resource-intensive and perform an enormous amount of parallel computations per second.

Unless you are designing simple shapes with little to no details and definition, the usability of these apps will be heavily affected by the lack of resources of the computer.

Keep in mind that if you are just getting started with 3d modeling, you will most probably only be able to create simple objects. Due to this, a budget PC or laptop is also going to be enough to start learning and figure out if a more robust setup is justified for you.

Due to this, a budget PC or laptop is also going to be enough to start learning and figure out if a more robust setup is justified for you.

Computer requirements for 3d CAD modelling

| Specifications | |

| Processor | 6 cores i7 |

| Ram | 16GB |

| Graphics Card | NVIDIA 1650ti |

| Hard Drive | 1TB |

Since 3D CAD modeling does require some computing capabilities, you should aim at a computer with at least 16GB of ram, an Intel i5 or Ryzen comparable processor, and a budget NVIDIA or AMD graphics card. An NVIDIA 1650ti or the comparable AMD Radeon 5500XT are going to exceed the expectations of all beginner and intermediate modelers.

Since the requirements stated almost everywhere are always really the bare minimum, I should clarify that the specifications I listed above do not follow that convention. My goal is to recommend a setup that is going to be enjoyable to use in the years to come.

My goal is to recommend a setup that is going to be enjoyable to use in the years to come.

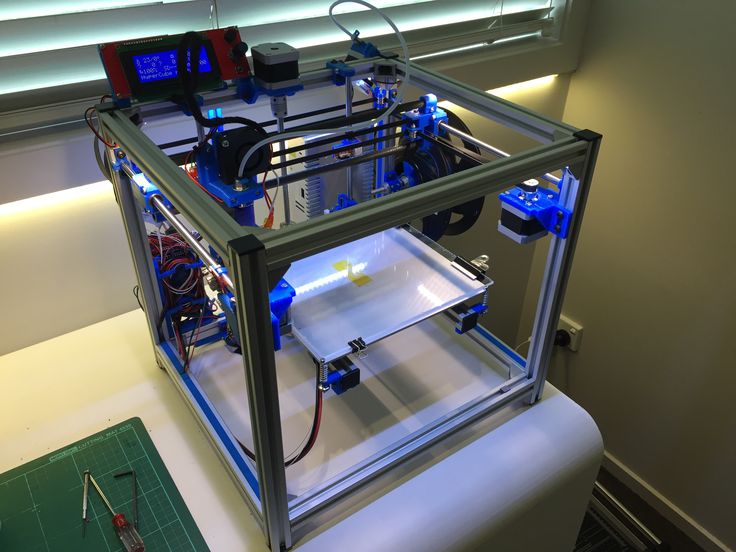

Example of useful 3D modelling computer: Gaming PC (Gaming PC’s have everything you need for 3D modelling).

Frequently asked questions

Can you use a 3d printer with a laptop?

A Laptop is more than enough for 99% of possible use cases related to 3d printing. Keep in mind that, much like with PCs, laptops also come in a wide range of prices. Regardless of that, a budget laptop of no more than $500 is going to exceed all the requirements posed by 3d printing-related programs (excluding 3d modeling).

Affordable Laptop Example: Lenovo IdeaPad.

Is it possible to 3d print without a computer?

It is not necessary to have a computer in order to use a 3d printer. This is due to the fact that almost all 3d printers have an SD card reader that is used to read files and start printing them. If you already have an SD card with your files stored in it, a computer is no longer necessary to use the printer.

Having said that, in the off case that you don’t already own a computer, I would definitely recommend getting one before getting your hands on a 3d printer. It’s just a matter of priorities…

What software do you need for 3d printing?

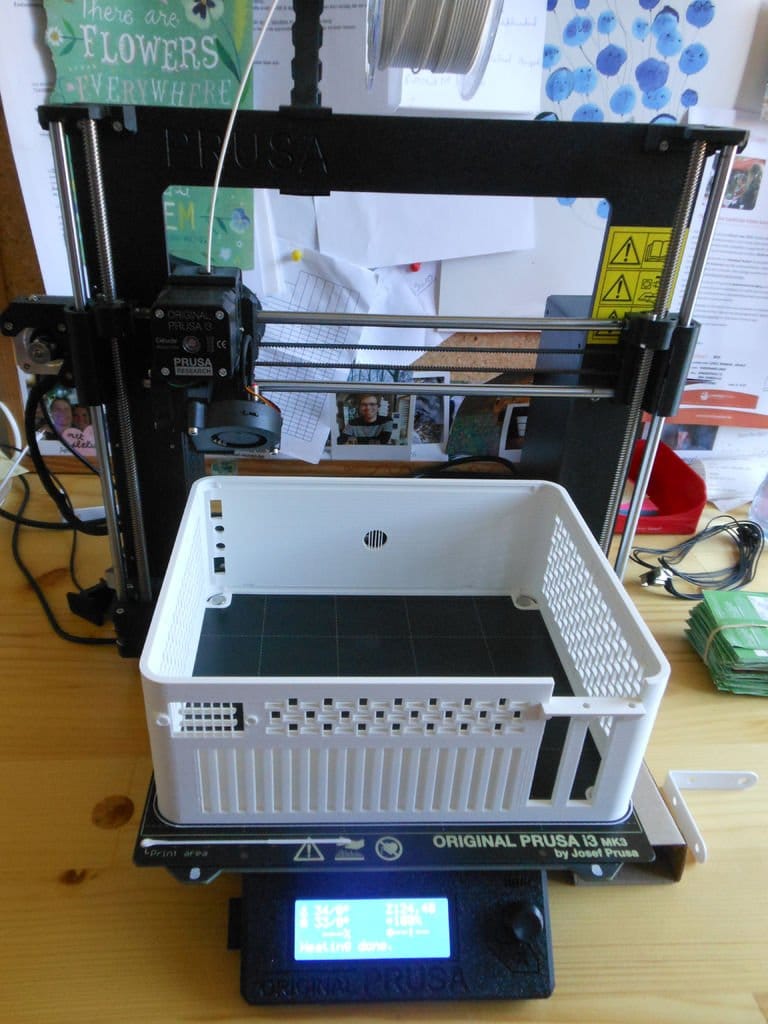

The only required software for being able to 3d print an object of your choosing is a slicer. This is the program that takes a 3d object, normally saved as an STL file, and translates it into commands that can be understood by any 3D printer (G-Code). The most popular slicers are Cura (free), PrusaSlicer (free), and Simplify3D (paid).

In addition to a slicer, you can also benefit from installing modeling, mesh repair, and printer management applications.

Modeling software, formally known as 3D CAD software, is used by designers to create custom-made objects. Unless you learn the basics of one of these programs, you will only be able to print objects that other people designed and shared. There are very simple apps for beginners like Tinkercad (our review) and more advanced and feature-rich programs like Fusion 360 (our review) or SolidWorks (our review)

Mesh Repair programs are used to repair a file that, due to a wide number of possible reasons, is not being properly sliced. Tools such as Meshmixer, Netfabb, and Meshlab are used in these cases.

Tools such as Meshmixer, Netfabb, and Meshlab are used in these cases.

Last but not least, print management tools are used to control multiple printers simultaneously without the need to be physically close to the machines. Examples of these tools are OctoPrint, AstroPrint, and Repetir, among others.

Which operating system is best for 3d printing?

When it comes to 3d printing, the choice of the operating system of your computer is completely irrelevant. Cura, PrusaSlicer, and Simplify 3d (the most popular slicers) are all compatible with Windows, macOS, and Linux.

Which operating system is best for 3d modeling?

For 3D CAD modeling, both MacOs and Windows are excellent choices. It used to be the case that Apple’s operating system was the default choice for designers, but this has changed in the last couple of years.

All popular programs offer versions for both operating systems. Such is the case for Fusion360 (our review), ZBrush, Blender (our review), and many others.

The list of available modeling software for Linux is more limited. Although some developers do offer Linux compatible releases, the community of designers using this OS is smaller, which means that you may have to solve the issues you encounter by yourself.

Conclusion

Having gone through more than enough things to consider when deciding about which PC or Laptop is best for 3d printing, we can conclude that almost any decent computer will comfortably exceed most requirements.

As we saw, 3d printing is not very taxing in terms of computing power, and most likely than not, your current setup is going to be enough for this new hobby of yours. The only case in which you should be interested in getting your hands on a better computer is if you also want to design your own 3d objects.

We created a recommended products section that will allow you to remove the guesswork and reduce the time spent researching what printer, filament, or upgrades to get, since we know that this can be a very daunting task and which generally leads to a lot of confusion.

We have selected just a handful of 3D printers that we consider to be good for beginners as well as intermediates, and even experts, making the decision easier, and the filaments, as well as the upgrades listed, were all tested by us and carefully selected, so you know that whichever one you choose will work as intended.

Do You Need a Good Computer for 3D Printing? Best Computers & Laptops – 3D Printerly

3D printing is a somewhat complex task that may require advanced computer specifications to handle. I wondered just how good of a computer you would need, to know you won’t run into problems when 3D printing, so I decided to make a post about it.

Do You Need a Good Computer for 3D Printing? No, generally you don’t need a particularly good computer for 3D printing. STL files, the common file for models to print, tend to be small files and are recommended to be below 15MB, so any computer can handle this. Most models are simple, but high-resolution models can be very large files.

A higher specification computer system can be an advantage in some cases when it comes to 3D printing. I will explain some cases where you may want to upgrade your computer system to operate your 3D printer smoothly.

Will an Average Computer Be All I Need for 3D Printing?

For the simple process of operating your 3D printer you won’t need any type of high-end specs and an average computer will be just fine.

There are methods for controlling your printers where just a connection to the internet is adequate, with a tablet, computer, or phone.

There is however a difference when we are talking about generating the code from 3D printer files. The software that you need to generate can be highly CPU intensive for models which are complex.

With beginners, the models that they will print are most likely to be quite basic models which should be fine in terms of file size and processing.

With experience comes greater desire to print more complex objects, where the file sizes will be much larger.

With 3D printing, you need to be able to generate a code from 3D files which is done through software called a Slicer program. The process to generate these codes can be very CPU intensive with hi-polygon (shapes with many sides) models.

A computer system with 6GB ram, Intel I5 quad-core, clock speeds of 3.3GHz and fairly good graphics card such as a GTX 650 should be enough to process these files.

Best Computers/Laptops for 3D Printing

The ideal desktop to go for with the above specs would have to be the Dell Inspiron 3471 Desktop (Amazon). It has an Intel Core i5-9400, 9th Gen processor with processor speeds up to 4.1GHz which very fast! You’re also getting 12GB RAM, 128GB SSD + 1 TB HDD.

I have to add, it looks really cool too! The Dell Inspiron Desktop includes a wired mouse and keyboard, all at a very competitive price.

If you’re the laptop type I’d go for the Fast Dell Latitude E5470 HD Laptop (Amazon). Although it’s Dual-Core, it has an I5-6300U which is a high performance processor with 3. 0 GHz speeds.

0 GHz speeds.

When you have very hi-poly parts to process, it could take a long time. Some could take a few hours just to process. Slicing 3D files with more complex codes will require high spec computer systems, like 16GB RAM, clock speeds up to 5GHz and a GTX 960 graphics card.

So, the real answer here is that it depends on what kind of models you plan to print, whether they be simple designs or complex, hi-poly designs.

If you want a fast computer system that will be able to handle all your 3D printer processing needs, the Skytech Archangel Gaming Computer from Amazon will definitely do the job well. It’s an official ‘Amazon’s Choice’ and is rated 4.6/5.0 at time of writing.

It has a Ryzen 5 3600 CPU (6-core, 12-thread) system which has a processor speed of 3.6GHz (4.2GHz Max Boost), along with an NVIDIA GeForce GTX 1660 Super 6GB Graphics Card & 16GB of DDR4 RAM, perfect for your 3D printing needs!

Gaming desktops work really well with processing because they require very similar power to operate at their full potential.

On the laptop side of things for serious power, I’d go with the ASUS ROG Strix G15 Gaming Laptop (Amazon) with an i7-10750H processor, 16 GB RAM & 1TB of SSD for all your computing needs.

It also has an amazing NVIDIA GeForce RTX 2070 8GB GDDR6 graphics card for the best quality picture. I’ve got something very similar and it works great for 3D printing tasks such as modeling, slicing, and other intensive tasks.

Laptops aren’t as powerful as desktops, but this one should be able to handle a good amount of processing.

There are many people who simply use an SD card with the 3D print file on it which inserts into the 3D printer.

In this case, a computer isn’t even fully necessary to operate the printer, but you’d need a way to put the file on the SD card. Prints can be lost if your PC fails so having an independent SD card to run your prints can be a good idea.

Any computer within the decade can run a 3D printer just fine. In general, 3D printing is not a resource intensive task. The resource intensive task comes into play when you are rendering complex 3D patterns and shapes within your software.

The resource intensive task comes into play when you are rendering complex 3D patterns and shapes within your software.

How File Resolution Comes Into Play on File Size

3D printer users do many things from prototyping to designing something creative. In order to do these things, we use Computer-Aided Design (CAD) software applications. The files within these softwares can differ greatly.

The most common file format for these designs is Stereolithography (STL). The simple explanation for this format is your designs are translated into triangles within the 3D space.

After you’ve designed your model, you’ll have the option to export the design into an STL file and set your desired resolution.

Resolutions of STL files will have a direct impact on modeling for 3D printing.

Low-Resolution STL Files:

In terms of triangle size, these will bigger and result in the surface of your prints not being smooth. It’s very similar to digital imagery, looking pixelated and low quality.

High-Resolution STL Files:

When files have high resolution, the file can become too large and add difficulties in the printing process. The higher level of detail will consume a lot of time to render and print, and depending on the printer might not be able to print at all.

The recommended file size for 3D printing, when passing files over to 3D printer companies is 15MB.

Recommended Specifications for 3D Printing & 3D Modelling

Most PCs and laptops these days will equipped with the necessary hardware requirements to run a standard 3D printer.

When it comes to 3D modeling, the most important specs is the clock speed (rather than number of cores) and the GPU or graphics card.

The graphics card is what renders the model on your screen in real-time as you are working on it. If you have a low-spec graphics card, you wouldn’t be able to handle hi-poly files in your Slicer application.

The CPU (clock speeds & cores) will be doing most of the work in rendering your 3D models. 3D modeling is a mostly single-threaded operation, so faster clock speeds will be more advantageous than many cores.

3D modeling is a mostly single-threaded operation, so faster clock speeds will be more advantageous than many cores.

After your model is complete, when it comes time to render, this will require most of the technical lifting with the CPU. Rather than single-threaded operations, this will be multithreaded operations and the more cores and clock speeds here, the better.

Graphics cards that use shared system memory aren’t the best, which is common in laptops. You ideally want graphics cards which have dedicated memory just for the GPU if you have high resolution files, otherwise this shouldn’t matter much.

Gaming laptops will usually have good enough specs to process models at a good speed.

Recommended Hardware Requirements:

Memory: 16GB RAM or higher

Free Disk Space: Win 64-bit Operating System with at least 20GB free disk space (ideally SSD memory)

Graphics Card: 1 GB memory or higher

CPU: AMD or Intel with quad-core processor and at least 2. 2 GHz

2 GHz

Recommended Software Requirements:

Operating System: Windows 64-bit: Windows 10, Windows 8, Windows 7 SP1

Network: Ethernet or wireless connection to Local Area Network

Using a Laptop To Process 3D Prints

There can be issues that arise when using a laptop to send information to your 3D printer. Laptops sometimes send information to your 3D printer in chunks leading to your printer starting and stopping.

A good fix for this could be to set your laptop to not go into power-saving mode or sleep mode and just run all the way through.

Computers tend to pack more power and higher specs so it’s ideal to use a decent computer rather than a laptop. Computers will send a smoother stream of information and you’ll be able to use it while processing your 3D prints.

With a laptop, using it at the same time as your 3D printer may cause issues.

The best solution to not have issues between your computer/laptop and your 3D printer is to make use of an SD card which inserts directly into your printer with the 3D print file you want to use.

Related Questions

Is it Worth Getting an Expensive Computer for 3D Printing? If you are a beginner, it’s not necessary but if you have more experience and want to go further into the 3D printing process like designing your own models, it could be worth doing. You would only want an expensive computer for high-resolution designing and rendering.

Can I 3D Print Without a Computer? It is entirely possible to 3D print without a computer on hand. Many 3D printers have their own control panel where you can simply insert an SD card with the 3D print file and begin the process directly. There are also methods to control your 3D prints through a browser or application.

So to summarize, you can’t go wrong with the Skytech Archangel Gaming Computer from Amazon. It has amazing specs, serious speed, and really good graphics. The good thing about a desktop versus a laptop is you can upgrade it in the future.

Get yourself the Skytech Archangel Gaming Computer from Amazon today!

How to choose a computer for 3D.

Recommendations for 3D masters (part 1)

Recommendations for 3D masters (part 1) - Lessons and articles 3D Master

- How to choose a computer for 3D

This series of short articles was written by Alexander Milovsky, an instructor at the 3D Master training center, as a universal instruction for purchasing a computer for 3D graphics. Read and much will become clear to you. The somewhat straightforward tone of the presentation is due to the fact that the articles were originally intended to be read by close friends of the author who read his blog.

While it is highly recommended to use a regular desktop computer for 3D, there are detailed instructions for choosing a laptop for 3D ( new! ).

| Features | Minimum computer | Good computer |

|---|---|---|

| Operating system | Windows 10 (64-bit) | Windows 10 (64-bit) |

| Processor | Intel i5 (or better) minimum 4 cores required | Intel i7 (or better) recommended 6 cores or more |

| Memory | minimum 4 GB (mandatory expandable) | 16 GB minimum (mandatory, expandable to 32-48 GB) |

| Video card | nVidia GeForce 750/950/1050 or better | nVidia GeForce 760/960/1060 or better ideally 780/980/1080/2080 |

| Disc system | Same as normal computer | SSD drive for system and programs + separate drive for projects and data |

Course Total Modeling A special course by Alexander Milovsky for the training of 3d modeler generalists who are able to create models of any level of complexity and for any task. |

The most common question I get asked by 3D beginners is: What computer should I buy for 3D graphics?

Although this is a thankless task, I will still try to recommend it.

I perfectly understand that everyone has different financial possibilities. Therefore, I will start with the minimum conditions, but then at your discretion.

I’ll clarify right away that we are talking about a computer for work, and I don’t care how suitable it is for games.

So, let's start with the main thing, briefly:

0. The 3D computer is a large desktop computer. NOT A LAPTOP! AND NOT MAC! Not a glamorous silent box, but a healthy ugly bandurina that can buzz like a hair dryer and heat up as well as a battery (well, maybe I got a little excited with the “ugly” one). In a computer for a 3D-shnik, the main thing is performance! And this means that if the performance is insufficient, then something is replaced in the computer (I would like to see how the owner of the MacBook Air will replace the video card). Actually, a 3D life on a Mac is quite possible, but it begins with the words: "now install in parallel with Windows, and now install under Windows ..."

Actually, a 3D life on a Mac is quite possible, but it begins with the words: "now install in parallel with Windows, and now install under Windows ..."

1. 64-bit operating system required .

When purchasing a computer, make sure that it has a 64-bit operating system. It's damn important! Moreover, when buying a new computer, the right operating system will cost you much less. I recommend Windows 10 (64-bit) (now it's the only correct choice).

2. nVidia video card based on CUDA with as much memory as possible on board

Feel free to treat AMD's (ATI) competitor products however you like, but take it on faith that for now, the choice should be made in favor of nVidia's CUDA technology. CUDA technology is required for GPU rendering. This technology is gaining momentum and in the next two or three years it will turn from exotic into the norm. I recommend the GeForce 7xx/8xx/9xx/10xx series (which will be the latest at that time). I strongly DO NOT recommend the Quadro series (pay a lot of money for mediocre performance).

I strongly DO NOT recommend the Quadro series (pay a lot of money for mediocre performance).

3*. At least 8 GB of memory (and better in one piece)

For modern computers, the amount of RAM should not be less than 8 GB (and it must be expandable up to 16-48 GB). At the initial stage, it is normal to save on memory and buy it minimally, i.e. 8GB and always in one piece (and not two 4GB each, as they usually offer). Do not get fooled by talk about 2-channel operation mode and so on. Believe me, when you need more memory, you will be deep, no matter what mode this memory works in, as long as it is enough.

4*. At least 4 cores in the processor

The most difficult thing with the processor is now. Let me just say that it should have at least 4 cores. No two- or three-core compromises (with laptops, again, a different story). The processor is needed for the final visualization (rendering), therefore, on the one hand, the more productive the processor, the better, but the price can be simply prohibitive. So ask yourself if you would be sorry to just throw this processor away in a year or two at a scheduled replacement. Remember that you don't buy a computer forever. In three years it will become a weak mediocre machine.

So ask yourself if you would be sorry to just throw this processor away in a year or two at a scheduled replacement. Remember that you don't buy a computer forever. In three years it will become a weak mediocre machine.

Intel or AMD? The most difficult thing is to choose a manufacturer for the processor. My choice is Intel. Although at different times I have had computers and AMD, but for work I choose Intel. I have no confirmation of the correctness of my choice, I can not provide calculations or test data.

The old AMD song about getting better performance for less money is often true, but it's also possible that AMD's six cores will perform as well as Intel's 4 cores. That is why, for reasons of succession of solutions, reliability of specialized software, which 3D applications are undoubtedly, I choose Intel. But it would be wrong to take this as an unequivocal recommendation. So do your best (just don't listen to the boys in computer stores, go and look for render time testing in your future 3D application - this is the only objective test).

Continuation about the characteristics of video cards (part 2) ...

Author: Alexander Milovskiy

Part 1. General recommendations for choosing a computer for 3D

Part 2. Characteristics of video cards

Part 3. Intermediate results

Part 4. Budget solutions

Part 5. Why you need Quadro

video cards Part 6. Recommendations for choosing a laptop for 3D new!

Requirements for 3D models for 3D printing and CNC processing

01/16/2017 in 3D modeling, Instructions

Contents:

- Introduction

- Product creation process.

- Requirements for models for 3D printing and CNC processing.

- Fixing non-critical bugs with NetFabb.

- Fixing non-critical bugs with MeshMixer.

- Fixing non-critical bugs with Materialize Magic.

- Examples of the most common errors.

Introduction.

In this article, we will talk about the basic and general parameters that a model must meet in order to obtain high-quality 3D printed products. Let's discuss common errors that occur in the process of creating three-dimensional models in terms of a high-quality polygonal mesh and how to quickly fix them. Requirements for 3D models and quality issues in terms of the accuracy of manufactured parts are described in another article: The actual size of the product after 3D printing.

Let's discuss common errors that occur in the process of creating three-dimensional models in terms of a high-quality polygonal mesh and how to quickly fix them. Requirements for 3D models and quality issues in terms of the accuracy of manufactured parts are described in another article: The actual size of the product after 3D printing.

The process of creating a product.

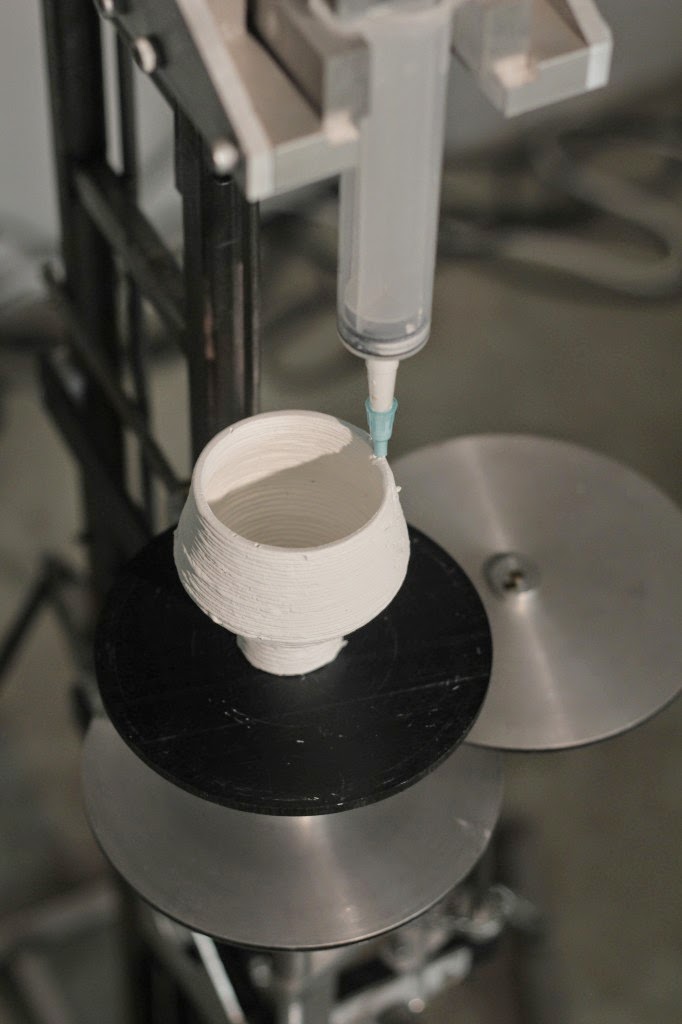

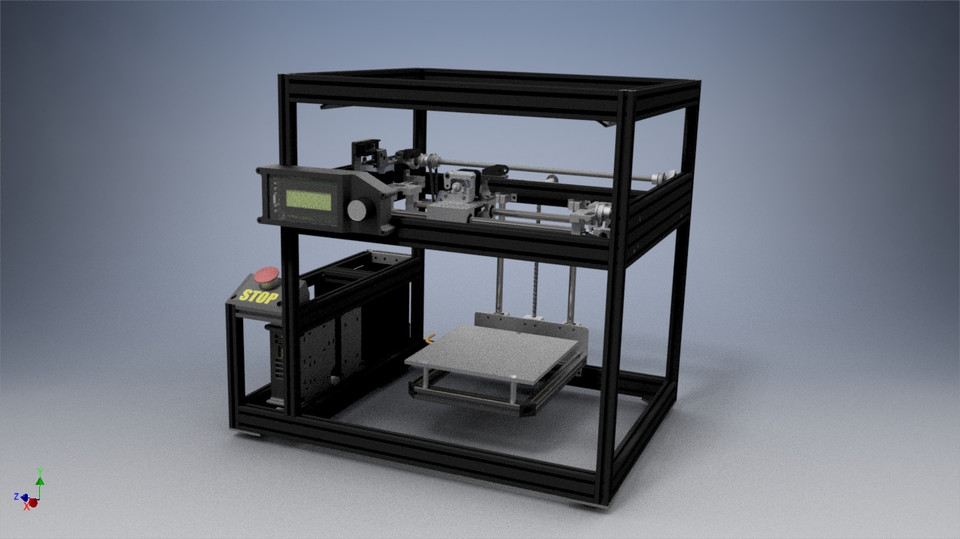

Structure of the additive manufacturing process for the production of products:

| Designer / 3Dartist | 3D printing service | Discussed errors |

| 1. Creation of 3D model | ||

| 2. Export/convert 3D model to required format | 3. Model validation | 4. Compliance / non-compliance with the minimum allowable thicknesses. |

| 6. Preparation of control program for 3D printer (GCode) | 5. Compliance / non-compliance with the requirements for the polygonal mesh of the 3D model. | |

| 7. 3D printing process. | ||

| 9. Quality control. | 8. Post-processing process. |

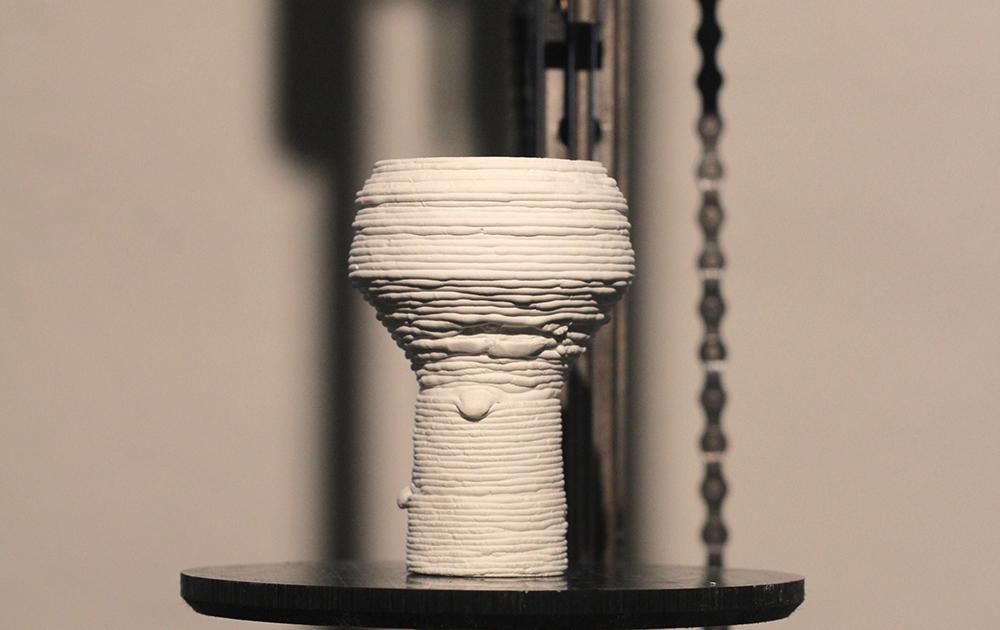

In accordance with the presented algorithm, at the first stage of product creation, a 3D model is developed using modeling programs in accordance with the terms of reference and standards requirements. After that, it is necessary to export the data of the simulation result program file to a format accepted by the program of the additive manufacturing control machine (for example, “STL”). The modeling process can now be done not only in solid format, but also immediately in STL. Before the next stage, possible defects in the model are identified. A model intended for 3D printing must be hermetic, monolithic and not contain cavities and gaps in the walls, which is ensured using special programs. Next, the information from the STL file is converted into commands, following which the 3D printer produces a product, this is the so-called GCode.

During this procedure, you must select the desired scale of the part, the correct position in space, and accurately position the model on the work surface. The result of the whole process, strength, surface roughness of the part and material consumption depend on this . After the settings are made, the model is divided into layers of material, which are “fitted” into the body of the part in one working cycle of the additive machine. This process is called slicing. Slicing is done using the software supplied with the machine, or using special tools (Simplify, Skein-forge, Slic3r, KISSlicer, MakerWare, etc.). The G-code obtained in the previous step is transferred to the 3D printer via flash memory or via a USB cable. In the process of preparing and setting up the additive machine, calibration, preheating of the working bodies, selection of the model material and setting the parameters of the equipment operation modes that depend on it are performed. On professional level devices, this step can be combined with the slicing process procedures. After all the preparatory operations are completed, the printing process starts, that is, the layer-by-layer combination of materials. Its duration depends on the type of technology and the selected parameters for the accuracy and quality of the part.

After all the preparatory operations are completed, the printing process starts, that is, the layer-by-layer combination of materials. Its duration depends on the type of technology and the selected parameters for the accuracy and quality of the part.

Requirements for models for 3D printing and CNC processing.

- List of file formats by 3D technologies.

- FDM (ABS, PLA, FLEX, HIPS, etc.): .STL .OBJ

- SLS (polyamide): .STL .OBJ

- SLA, DLP (photopolymer): .STL .OBJ

- SLM (metal): .STL+STP(STEP) .OBJ+STP(STEP)

- Multicolour plaster: .OBJ+texture .WRL+texture

- Polygon mesh.

- The mesh must be uniform and closed. A model consisting of several polygonal meshes is not allowed! Intersection of polygonal meshes is not allowed! Holes in the grid are not allowed!

- Multiple models in one file are not allowed.

Each object needs to be saved as a separate file.

Each object needs to be saved as a separate file. - The number of polygons must not exceed 500,000.

- The wall thickness must be at least the specified values for each technology.

- Inverted normals are not allowed! The outer normal should face outward. This problem is especially common when mirroring the model in some 3D modeling programs.

- The dimensions of the model must correspond to the dimensions of the real object.

In 95% of cases, errors in files are not critical and can be easily fixed using specialized programs that can be easily found on the Internet. Even if you are sure that everything is in order with the model, it does not hurt to check it once again for correctness.

NETFABB - as a solution to most file errors.

MESHMIXER is a powerful and convenient alternative.

- Wall thickness analysis of the model.

It should be understood that there are several 3D printing technologies. They differ not only in the materials used, but also in the accuracy of the equipment. Different equipment has its own resolution. Therefore, before sending the file for printing, it is necessary to make sure the quality of the model in terms of the specified thicknesses in the walls, rods, mesh ceilings. Detailed article about checking models for thickness.

They differ not only in the materials used, but also in the accuracy of the equipment. Different equipment has its own resolution. Therefore, before sending the file for printing, it is necessary to make sure the quality of the model in terms of the specified thicknesses in the walls, rods, mesh ceilings. Detailed article about checking models for thickness.

Fixing non-critical bugs with NetFabb.

NETFABB (download for PC or download for Mac) is a program that allows you to solve almost any issue related to 3D printing. Let's go through the main functions of this software, which AutoDesk itself bought at one time.

The program shows the outer part of the polygon in green, its inner normal in red. Ideally, the model should be all green. If you observe red spots, then these are polygons that are turned outward. If the entire model is highlighted in red, then the entire mesh is turned inside out.

Even if the model is green, but there are errors in your file, the program will display a big exclamation point in the lower right corner of the screen, and will not be able to calculate the volume of your model.

To treat the model, click on the red cross on the toolbar at the top of the screen. The program will put you into the treatment mode, and will indicate in yellow the breaks in the polygonal mesh, if any.

This program has functions for removing or adding polygons, changing sizes or proportions. (I will leave these functions for independent study). I recommend that you study the entire toolbar in order to easily understand how, where and which polygons we can select and what we can change.

To invert normals, select the polygons that look “in the wrong direction” and click on the “invert normals” button. Then click on the “Apply Repair” button.

If your model was initially all green or inverting the normals didn't remove the exclamation mark, and the volume has not yet been calculated, you need to apply automatic treatment. To do this, go back to the treatment mode by clicking on the red plus. In the treatment mode, select "Automatic treatment", then select "Default Repair" and click "Extrude".

The program has now done its best to repair the model automatically. Click "Apply Repair".

Typically, these steps should have fixed your model. If after the performed operations an exclamation mark is on and there is still no volume, then you are among those 5% when the model has critical errors and errors are laid down at the modeling stage.

Fixing non-critical bugs with MeshMixer.

Autodesk MeshMixer is a free program for working with 3D mesh models. You can download the program from the link. The program does not have tools for creating 3D models, but a wide range of tools for modifying them and preparing them for 3D printing. The main difference between this software and NETFABB is that MESHMIXER officially supports the latest versions of macOS. For me, this is a decisive factor, because I always carry a MacBook with me, and a Windows computer is only in the office. In turn, NetFabb stopped supporting software for macOS.

As in the case of Netfabb, you need to drop the model in STL format into the MeshMixer program window.

At first glance, the model looks good, but let's try to test it for suitability for 3D printing (mesh requirements). To do this, you need to analyze the model for errors. To do this, go to the “Analisis” section, then click on the “Inspector” button.

On the screen, we can see how the program highlighted areas on the model with bright colors that do not meet the requirements, which means they have errors.

In order to fix (cure) these errors, click on the “Auto Repair All” button. The program will try to remove errors automatically. Checking before 3D printing is a must. Even if outwardly the model seems suitable to you, it is still worth checking. In the picture below, you can see the errors that are inside the mesh, although everything looks good with the model.

However, this treatment does not always help. For example, if the model has a huge number of errors that the program is not able to remove automatically, then you will have to correct the model yourself in the program where the model was originally created. In case of a large number of errors, the program will indicate their presence even after you have tried to do automatic treatment. The picture below is an example of a very large number of shortcomings and errors that the program is not able to remove by itself.

For example, if the model has a huge number of errors that the program is not able to remove automatically, then you will have to correct the model yourself in the program where the model was originally created. In case of a large number of errors, the program will indicate their presence even after you have tried to do automatic treatment. The picture below is an example of a very large number of shortcomings and errors that the program is not able to remove by itself.

This usually happens when the model is being prepared for rendering rather than 3D printing. That is, there is a huge number of surfaces, but they are not connected into a single grid.

Fixing non-critical errors with Materialize Magic

The 3D model healing feature in Materialize Magic is located in the Fix tab.

After that, select the “Correction Wizard” command. Next, you need to alternate the “Update” and “Autocorrect” buttons.

You have to do this several times.

Read more…

Read more…