Asterid 3d printer review

Snap! -- Digital IDs, Reading Minds, Asteroid, 3D Printed Rockets, Costly Phone

Your daily dose of tech news, in brief.

Welcome to the Snap!

Flashback: Back on October 25, 2001, Microsoft released Windows XP. (Read more HERE.)

Bonus Flashback: Back on October 25, 1671, Italian astronomer Giovanni Cassini discovers another moon orbiting Saturn: Iapetus. (Read more HERE.)

You need to hear this.

Japan steps up push for digital IDs

They compare this to Social Security Numbers, but microchips seem to take the effort well beyond what is done in the US.

According to AP News:

"Japan has stepped up its push to catch up on digitization by telling a reluctant public they have to sign up for digital IDs or possibly lose access to their public health insurance.

As the naming implies, the initiative is about assigning numbers to people, similar to Social Security numbers in the U. S. Many Japanese worry the information might be misused or that their personal information might be stolen. Some view the My Number effort as a violation of their right to privacy.

So the system that kicked off in 2016 has never fully caught on. Fax machines are still commonplace, and many Japanese conduct much of their business in person, with cash. Some bureaucratic procedures can be done online, but many Japanese offices still require “inkan,” or seals for stamping, for identification, and insist on people bringing paper forms to offices.

Now the government is asking people to apply for plastic My Number cards equipped with microchips and photos, to be linked to drivers' licenses and the public health insurance plans. Health insurance cards now in use, which lack photos, will be discontinued in late 2024. People will be required to use My Number cards instead. "

Apparently only about half the Japanese population currently have a "MyNumber" ID.

Learn more about Japan's digital IDs at AP News.

And Another Thing...

New Technique For Decoding People's Thoughts Can Now Be Done From a Distance

It isn't as cool as the title makes it sound, but lots of possibilities here.

According to Science Alert:

"For the new study, which has not yet been peer-reviewed, the team scanned the brains of one woman and two men in their 20s and 30s. Each participant listened to 16 total hours of different podcasts and radio shows over several sessions in the scanner.

The team then fed these scans to a computer algorithm that they called a "decoder," which compared patterns in the audio to patterns in the recorded brain activity.

The algorithm could then take an fMRI recording and generate a story based on its content, and that story would match the original plot of the podcast or radio show "pretty well," Huth told The Scientist.

In other words, the decoder could infer what story each participant had heard based on their brain activity. "

"

So, you know, bot reading your brain is just not there yet, but they are moving in that direction.

Learn more about mind reading algorithms at Science Alert.

But there's more going on in the world than that.

A big asteroid scheduled to pass relatively close to Earth on November 1st

Don't worry. No danger of it landing on us.

According to Interesting Engineering:

"Grab your telescope and ready yourself for quite a show on Nov .01. An asteroid measuring between 1,000 and 2,430 feet (304 - 740 meters) in diameter is due to fly past Earth.

To put those numbers into perspective, the world's tallest tower, the Burj Khalifa, stands at 2,716 feet (828 meters) tall, and the One World Trade Center measures 1,792 feet (546 meters) at its tip.

This asteroid was only recently discovered on September 12, 2022 by the Pan-STARRS2 telescope in Hawaii. Observations by the Pan-STARRS2 telescope as well as the Steward Observatory at the University of Arizona in October were able to determine the asteroid's path. "

Observations by the Pan-STARRS2 telescope as well as the Steward Observatory at the University of Arizona in October were able to determine the asteroid's path. "

This one should be viewable by normal consumer grade telescopes, so check it out.

Learn more about Asteroid 2022 RM4 at Interesting Engineering.

Here's Something Interesting...

Meta Quest Pro Demo

The reviewer was not impressed overall, but it also sounds like part of the problem was the way it was set up at the store he went to.

According to Ars Technica:

"The Quest Pro is noticeably more comfortable than previous Quest headsets. The flimsy straps on those earlier units have been replaced with a thick headband and large, semicircular cushions that rest on the forehead and the back of the skull. Once it's wrapped around your eyes, an easy-to-turn knob in the rear gets a fit that feels secure without being too tight.

This new design means the "ski goggles" pressure that old Quest headsets exert on the area around your eyes is almost completely gone here. While the Quest Pro exerted a little bit of pressure on the bridge of my nose, it was no more distracting than wearing a pair of sunglasses. I could even reach up and scratch my nose without taking off the headset, thanks to a new open-bottomed design that allows much better airflow as well (the demo unit did have magnetic "blinders" preinstalled on the sides, though, to eliminate real-world distractions. I had to ask to have them popped off).

While I only spent about an hour total in the Quest Pro during my demo, I felt like I could have kept it on indefinitely without complaining."

The headset sounds like an improvement, although the demo was geared toward the workplace rather than games, which is interesting. Do people really use these at work?

Learn more about the Quest Pro at Ars Technica.

And you can't not know this.

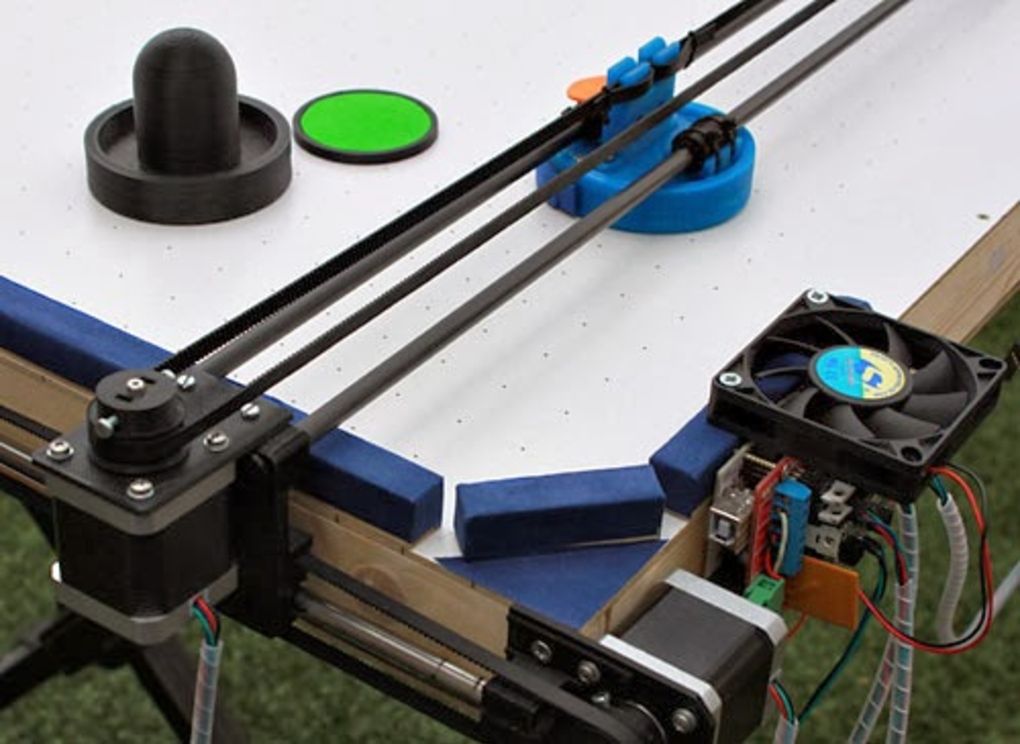

Relativity Space releases new metal 3D printer which it uses to print rockets

3D printed rockets sounds cool.

According to Space Daily:

"Relativity Space, the first company to 3D print rockets and build the largest metal 3D printers in the world, today unveiled the latest iteration of its first-of-its-kind proprietary manufacturing platform, Stargate 4th Generation metal 3D printers. These printers will underpin both the development and rate production of Terran R, Relativity's fully reusable, 3D printed rocket that will be capable of launching 20,000 kg to low Earth orbit (LEO)."

These printers can build 4 rockets a year. I have no idea if that is fast or slow based on everything involved, but I mean... rockets. 3D printing is changing everything. :)

Learn more about metal 3D printers at Space Daily.

A final note...

Luxury smartphone brand returns with $41,500 device

Wow. I already don't use most of what my phone can do... wondering what additional things there are to ignore with that price tag.

According to The Register:

"Vertu, the ostentatious luxury phone brand that began as a brainchild of Nokia, has launched METAVERTU, the "world's first Web3 phone."

The device, which supposedly integrates smart terminals, crypto-mining nodes, separate OSs for NFTs and blockchain, high-end service, and whatever other buzzwords you can think of into one phone, comes with prices ranging from a no-frills $3,300 version to a Himalayan Alligator Leather version encrusted with 18k gold and diamonds at $41,500.

For the record, an iPhone 14 Pro and a Galaxy S22+ both cost about $1,000 each.

"We define METAVERTU as a phone, a power bank, a 10T hard disk, a dual system machine, a light node, a NFT pass holder, a privacy guardian," said the company. "

"

I liked the subtitle for the article; "If your mobile's not 18k gold with diamonds, do you even crypto bro?"

Learn more about insanely priced phones at The Register.

What was the most interesting story today? Vote in our poll below.

Also, follow Snap! or check out previous editions to stay in the know on important and entertaining tech and science news.

Reading the email notification and want to chat with others? Go directly to this Snap!'s community topic and join in on the conversation.

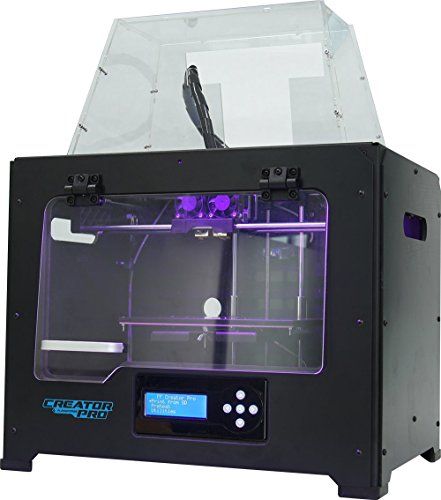

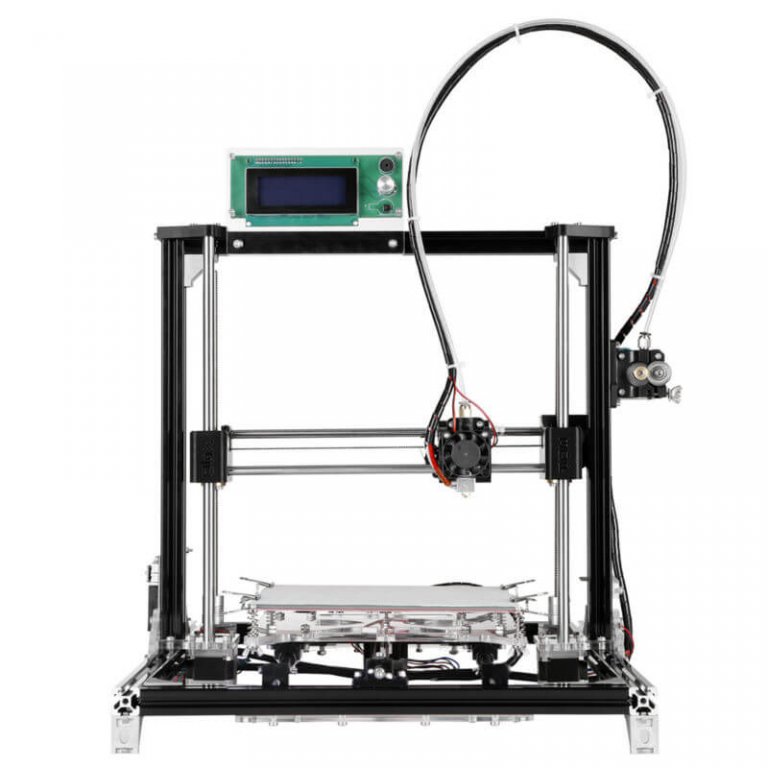

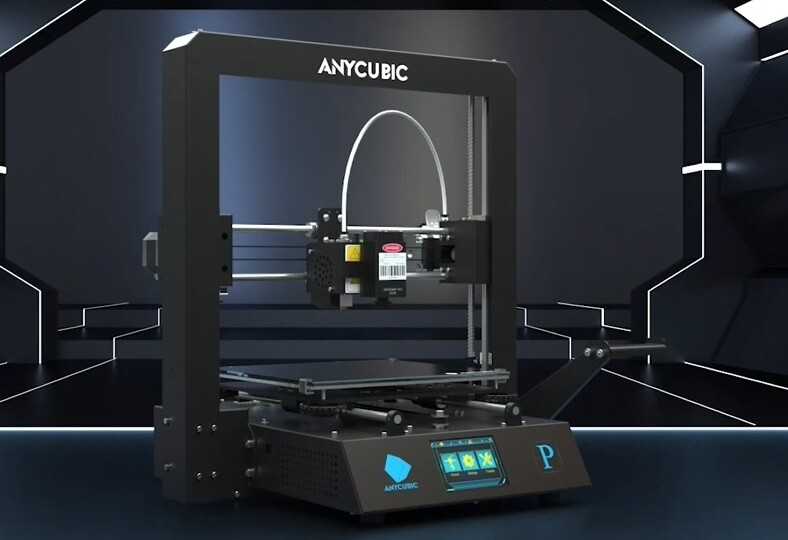

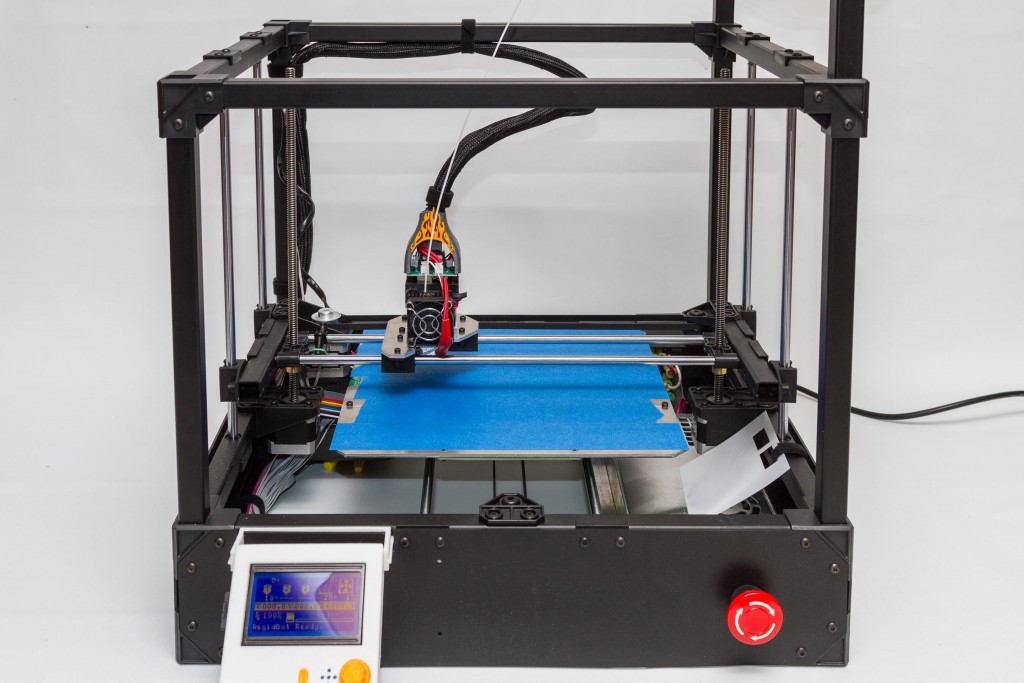

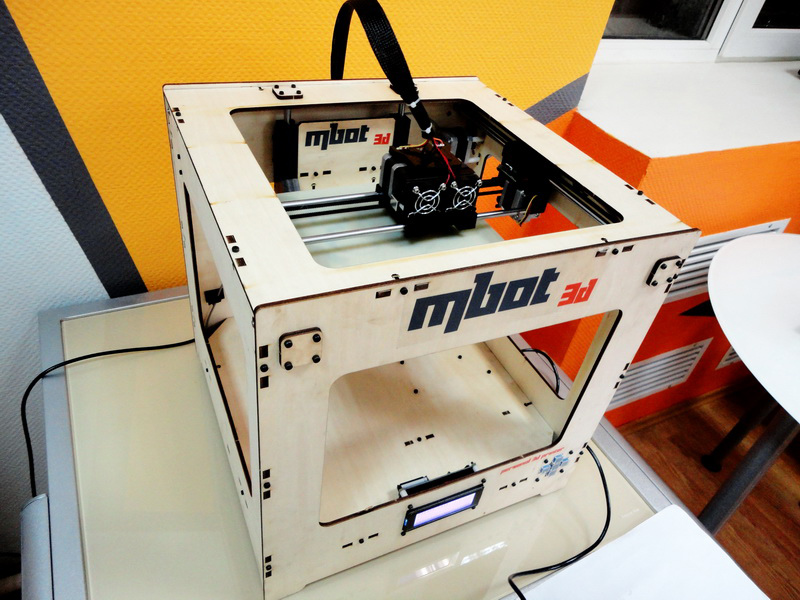

M3D Printer Review 2022 - Is This 3D Printer Worth The Money?

2.2

See Price

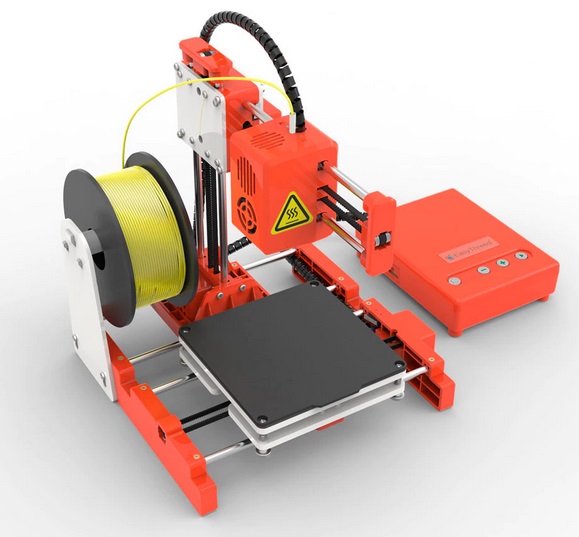

Usually, when you see a seemingly great product for a very low price, alarm bells start ringing. However, every once in a while, you’ll find a product that genuinely lives up to the hype. Today, we’re taking a look at the M3D (Micro 3D) – an extremely compact, budget 3D printer.

We’ll be looking out for any areas it excels, but won’t shy away from mentioning any flaws we uncover. This way, you’ll know our coverage is balanced and impartial. This not only benefits us but lets you decide if a given printer is right for your needs. With that said, let’s begin.

| Filament Diameter | 1.75mm |

| Extruders | 1 |

| Supported Materials | PLA, ABS, Nylon |

| Connectivity | USB only |

| Printing Speed | Up to 55mm/s |

| Build Volume | 4.2 x 4.6 x 4.4” |

Table of ContentsShow

Design

This printer comes in five bold shades: red, blue, green, grey, and black. It’s cube-shaped, 7.3” in every direction, meaning it’s among the most compact 3D printers on the market – perfect for sitting atop a standard desk. The whole thing weighs just 2.2lbs, too, thanks to its lightweight, carbon fiber frame.

The whole thing weighs just 2.2lbs, too, thanks to its lightweight, carbon fiber frame.

As you might expect, the build area is fairly small. It’s not uniform either, as it’s a little wider than it is deep. Still, this offers enough flexibility for most small projects, and larger models can always be printed in several parts. That said, the print speed isn’t fascinating, so it might take slightly longer this way.

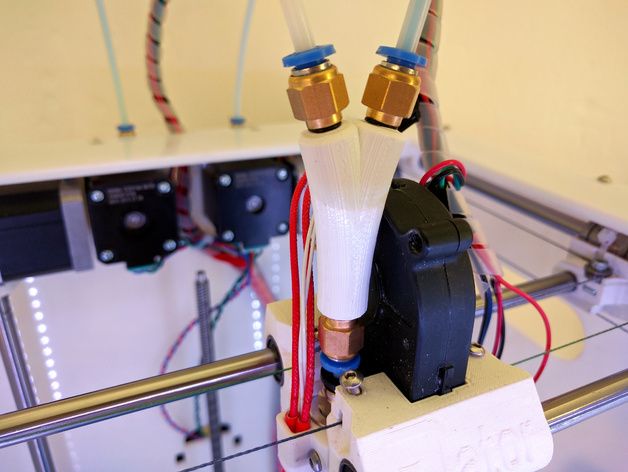

Notice the lack of a filament spool – it’s actually contained underneath the print bed! Now, this printer can only fit about half a spool at a time, so you’ll have to either buy smaller rolls or re-spool half of it each time. This isn’t a huge problem, but it’s definitely worth bearing in mind.

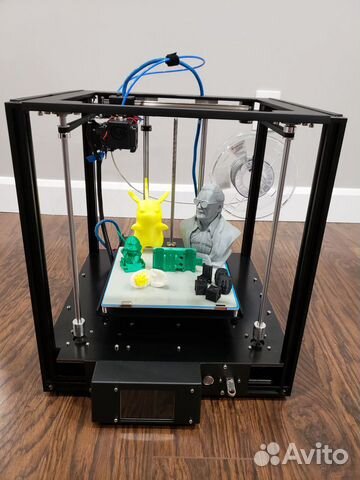

Printing

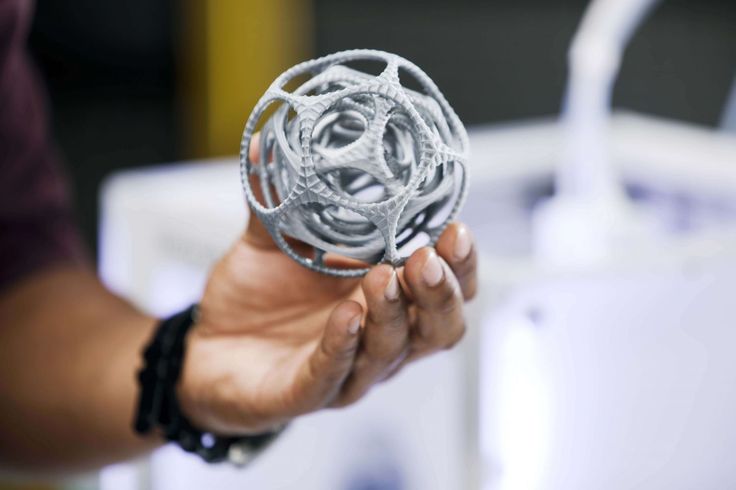

For its size and price, the M3D actually produces decent-quality prints. It has a layer resolution of between 50 and 350 microns, so you can reproduce fairly detailed models. However, it does have a tendency to produce loose threads and extra hanging material, particularly on areas with an overhang.

The edges come out crisp and well-defined, although supporting structures are often wispy. A quick buffing with a cloth will remove most of these imperfections after the fact, though, and supports are intended to be removed, so as long as they do their job, there’s no problem. All in all, not bad.

Usually, entry-level printers only support a handful of different materials, but this one is capable of printing with a whole host of different filaments. With the right nozzle upgrade, you can even use carbon fiber, if you’d like – something very few budget printers support.

Features

One of the best things about the M3D is the lack of fuss. Normally, there are several things to check before getting started, but the M3D does a whole range of checks and calibrations automatically. Everything is taken care of, leaving you free to get the good bit: the printing itself.

This printer comes with its own, specially-designed software, which is available for Windows and Mac. There’s no Linux support, unfortunately. This software is easy to use, although it does have to be left running for the entirety of the print. There’s a handy little percentage notice, though, to give you a vague idea of when it’ll be finished.

There’s no Linux support, unfortunately. This software is easy to use, although it does have to be left running for the entirety of the print. There’s a handy little percentage notice, though, to give you a vague idea of when it’ll be finished.

You can, of course, use different software if you’d like. However, for new users, the M3D application allows you to hit the ground running. It’s straightforward but allows for a good degree of versatility and control over your models.

Cost

Considering this model retails for less than $300, its print quality is astounding. This is among the least expensive printers available, yet it outperforms some far more expensive models. Sure, it’s likely not going to be enough to satisfy pro users, and it absolutely can’t stand up to commercial use, but for beginners, it’s perfect.

This unit doesn’t offer any upgrades or variants (other than the color), plus the software it uses is included for free. As such, there are no hidden costs beyond those of the proprietary, smaller spools of filament. These are entirely optional, though, and third-party filament can be used if you spool them manually.

These are entirely optional, though, and third-party filament can be used if you spool them manually.

As far as pricing goes, there’s nothing to complain about. What you see is what you get: a low-cost, compact printer with no additional charges.

Support

Micro 3D provide a good range of support options in case you run into trouble. There are tutorials, a Discord-based user forum, and even a dedicated area where you can log in and raise a support ticket. This is how you’re supposed to do customer support: as simply as possible.

That said, the warranty period is pretty short at just three months. You can extend this by a year or two for a price, but at the time of writing, the page to do so returned a 404 error. Still, we’d expect the price to be fairly low given the cost of the printer. We’ve seen printers where the extended warranty costs more than a brand new M3D though, so don’t take it for granted!

The knowledge base is pretty extensive, with guides covering everything from the basics of 3D printing to advanced tips for the software. Really, just about any issue you could face will be addressed in here somewhere, so in all likelihood, you’ll never need to request help from support.

Really, just about any issue you could face will be addressed in here somewhere, so in all likelihood, you’ll never need to request help from support.

Summary

Update: As of May 2019, we can no longer recommend this 3D printer.

The M3D was once a powerful and versatile printer, but it is no longer recommended due to its substandard customer service. It won’t do in 2022. If you want to buy a 3D printer but don’t know where to start, you could do far better than the M3D.

Overview of 3D printer manufacturers

3D printing appeared in the late 1980s, but 2020 became a breakthrough year for the technology. The pandemic disrupted supply chains, and it was 3D printing that made it possible to quickly obtain the necessary items and spare parts, ranging from consumables for hospitals and clinics to parts for medical, industrial and other equipment.

The prospects and pace of development of the sector in recent years have significantly increased its investment attractiveness, however, there are certain risks that should not be discounted.

Vadim Kizimov

private investor

Author profile

Buy

Buy

Buy

Buy

Service in partnership with Investment mi.koff Quotes are updated every 15 minutes

Brief overview of technology

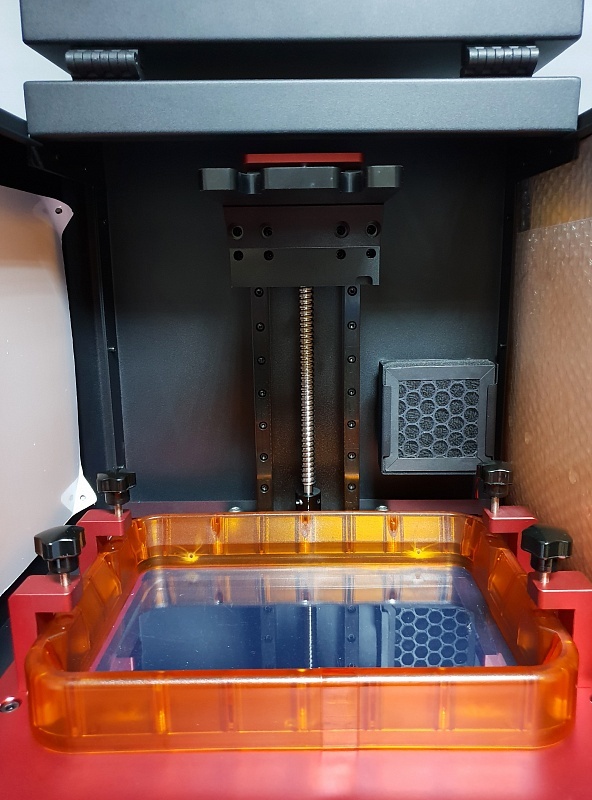

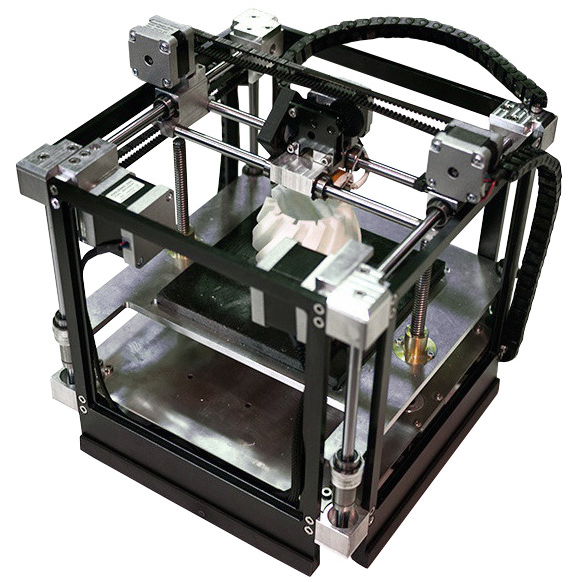

3D printing is the process of converting a model developed on a computer into a real three-dimensional object. Printing occurs due to the successive layering of thin layers of material. These are mainly thermoplastics of various types, but ceramic, biocompatible and other composite mixtures can also be used. That is why this technology is called additive.

3D printing technologies differ depending on the materials and equipment used, but the general scheme of the process is always the same:

- A virtual model of the object is created on the computer, and in order to make a model, you do not need to have 3D modeling skills. A special scanner photographs a real object from different angles, creating a digital copy of it.

- The program is slicing - splitting the model into many thin horizontal layers.

- The template is loaded onto the 3D printer, the device reads the diagram and prints it layer by layer in volumetric form.

Applications

Using a 3D printer, you can copy any object or create your own. The possibilities for additive printing are almost limitless. Now the technology has already found application in various industries:

- health care: the creation of orthopedic orthoses, dentistry, transplantology, the manufacture of prostheses;

- industrial production: parts of machine tools and equipment;

- space, aviation and automotive industry;

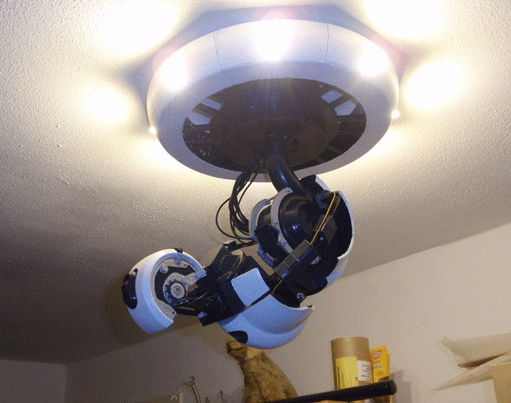

- robotics;

- construction: models of buildings or individual structural elements;

- food production: figured chocolate, jellies and other desserts;

- household items: from smartphone cases and collectible figurines to shoes and interior items;

- jewelry.

At the moment, additive technologies are most in demand in medicine — 3D printing makes it possible to create consumables, prostheses, orthoses, mouth guards, and even absolutely accurate models of human organs — and in industrial production when creating parts and equipment elements.

But the scope of 3D printing is constantly expanding, opening up new opportunities for both large companies and small start-ups.

Industry Prospects

At the moment, 3D printing does not yet allow you to get fast and large-scale results, but the technology has proven itself in areas that require precision and uniqueness.

The increased availability of equipment and the absence of the need for long training of personnel to work with 3D printers also played a role. Over the past six years, the number of global and specific industries that use 3D printing technology has increased, and this market is truly limitless:

- large companies or organizations may refuse to purchase the necessary consumables or parts, producing them on their own in the volumes they need;

- The role of additive printing in medicine has already been discussed above, and there are also broad development prospects here;

- 3D solutions lower the barrier to entry for new players.

Now, to launch your own production, there is no need to rent a room and purchase sophisticated equipment. For example, niches for creating custom car tuning parts, collectible figurines for computer game fans or unique gifts have just begun to open and have already begun to gain popularity.

Now, to launch your own production, there is no need to rent a room and purchase sophisticated equipment. For example, niches for creating custom car tuning parts, collectible figurines for computer game fans or unique gifts have just begun to open and have already begun to gain popularity.

At the end of 2021, the additive printing market was worth $15 billion, calculations were based on the cost of 3D printing and the production of printers and components. In the coming years, the expert agency Business Insights predicts an annual growth of the segment by more than 24%. At this pace, by the beginning of 2029, the size of the 3D printing market will grow at least five and a half times.

Technology deficiencies and risks of companies

Despite the prospects for the development of 3D technologies, 3D printing cannot yet be unequivocally called a profitable industry. There are a number of difficulties that do not allow you to fully rely on additive technologies.

Still high cost of equipment. Cheap 3D printers can print small objects. To create parts of large dimensions, it is necessary to purchase expensive equipment, which may turn out to be unprofitable.

Poor performance. This drawback should be considered in conjunction with the previous one: now the speed and cost of 3D printers do not allow them to be used in mass production, making a tangible profit.

Insufficient strength of manufactured parts. The layered structure is more brittle in the direction of the layers than the monolith and cannot withstand heavy loads.

Lack of stability. The use of additive technologies on an industrial scale requires equipment and materials that can provide higher production reliability. At the moment, 3D printing is most often used for prototyping, quality control, or for the production of single parts.

The need for post-processing , which increases the cost and time of production of each unit.

Unpredictability. Additive manufacturing is constantly evolving, new materials and printer models are emerging, and there is always a risk that equipment that has been heavily invested in will suddenly become obsolete.

3D printing companies on the St. Petersburg Stock Exchange

There are quite a few companies associated with 3D printing on the St. Petersburg Stock Exchange, and it is not their main activity. This industry is so young that at the moment it does not even have a benchmark significant index.

But the global trend of increasing demand for additive technologies in various areas of life can open up new prospects for industry pioneers.

Proto Labs (NYSE: PRLB). Capitalization - 2.56 billion Proto Labs was founded in 1999 in Minnesota, and by 2022 it already has more than ten branches in seven countries of the world. The company specializes in the creation of prototypes and finished parts for individual orders. In this niche, Proto Labs is one of the largest and fastest manufacturers: it takes only a few days to create a part of any complexity.

In this niche, Proto Labs is one of the largest and fastest manufacturers: it takes only a few days to create a part of any complexity.

Since 2014, Proto Labs has been using additive technology for manufacturing parts. In total, the company operates in four areas:

- Injection molding, revenue growth +4% year-on-year.

- CNC machining, +41%.

- 3D printing, +17%.

- Sheet metal production, +24%.

While 3D printing still only accounted for 14.8% of the company's revenue as of the end of 2021, the technology's growth trends could bring more tangible profits in the future.

Source: Tinkoff Investments Source: Tinkoff Investments3D Systems Corp (NYSE: DDD). Capitalization - 1.88 billion. The company was founded in 1986, headquarters - in Rock Hill, South Carolina.

3D Systems manufactures and sells equipment, software and materials for additive manufacturing. Most often, the company's products are used in the aerospace, automotive, semiconductor and healthcare industries.

In 2021, 3D Systems announced two separate acquisitions. The company has agreed to acquire Titan Additive LLC, a developer and manufacturer of large-format industrial 3D printers, and Kumovis, a German provider of additive manufacturing solutions for personalized medical applications.

After the announcement of the results for the fourth quarter of 2021, the company's quotes increased by 15%. This positive reaction was driven by double-digit revenue growth of 13.1% yoy, excluding sales of part of the business. In addition, 3D Systems reduced its net loss by almost three times, and the revenue forecast for 2022 was increased by 10%.

Source: Tinkoff Investments Source: Tinkoff Investments Align Technology (NYSE: ALGN). Capitalization - 32.4 billion American company Align Technology is a manufacturer of medical equipment for dentistry and orthodontics. The patented Invisalign bite treatment system is based on the use of transparent removable orthodontic caps, which are printed on a 3D printer individually for each client.

The company is headquartered in Silicon Valley and has a rapidly growing branch network covering Russia, Mexico, Costa Rica, the Netherlands, Australia and Japan.

Digital orthodontics is rapidly evolving, and Align Technology is not going to give up just yet. The percentage structure of revenue for 2021 is distributed as follows: 80% - sales of Invisalign products, 20% - sales of intraoral scanners and other dental equipment.

Source: Tinkoff Investments Source: Tinkoff InvestmentsHP Inc. (NYSE: HPQ). Capitalization - 39.7 billion. The company does not specialize in the production of 3D printers, but is still one of the leaders in the additive printing market.

In 2014, HP developed Multi Jet Fusion 3D powder printing technology to lower the price and speed of industrial 3D printers, and two years later, the first HP Multi Jet Fusion models went on sale.

In 2017, Hewlett Packard introduced the world's first 3D lab for testing various types of additive printing raw materials. And in 2018, it announced Metal Jet technology for 3D printing of industrial quality metal products.

And in 2018, it announced Metal Jet technology for 3D printing of industrial quality metal products.

HP Metal Jet Printer delivers 50 times the performance and significantly lower cost of finished parts than other technologies.

On April 7, 2022, investors were shocked by the news that Warren Buffett had bought $4.2 billion worth of shares in the company. Immediately after the announcement of the deal, HP shares grew by 14.75%.

Compare companies by multiples, growth rates, and R&D spending.

Source: Tinkoff Investments Source: Tinkoff InvestmentsCompany multiples

| Capitalization, billion dollars | P/E | Forecast P/E | P/S | Debt to equity | |

|---|---|---|---|---|---|

| PRLB | 2.56 | 38.00 | 28.00 | 2.81 | 0.01 |

| ALGN | 32.40 | 41.00 | 32.00 | 8.18 | 0.04 |

| DDD | 1. 88 88 | 5.30 | 5.00 | 2.88 | 0.60 |

| HPQ | 39.70 | 6.80 | 8.70 | 0.69 | −3.58 |

Capitalization, billion dollars

PRLB

2.56

ALGN

32.4

DDD 9008

0002 HPQ

39,7,000

Algn

32

HPQ

8.7

PRLB

2.81

Algn

8,18

DDD

2.88

HPQ

0.69

DEBT TO equity

PRLB

0.01

Algn

0.04

DDD

0.6

HPQ

−3.58

Power growth rate, million dollars

| 8888 | 2019 | 2020 | 2021 |

|---|---|---|---|

| PRLB | 458 (+2.69%) | 434 (−5.24%) | 488 (+12.44%) |

| ALGN | 2406 (+22%) | 2471 (+3%) | 3952 (+60%) |

| DDD | 636 (−8%) | 557 (−12%) | 615 (+10. 4%) 4%) |

| HPQ | 58,760 (+1.3%) | 56,630 (−3.62%) | 63,000 (+11.25%) |

2019

458 (+2.69%)

2020

434 (−5.24%)

200003

488 (+12.44%)

2019

2406 (+2222 %)

2020

2471 (+3%)

2021

3952 (+60%)

2019

636 (−8%)

2020

557 (−12%)

2021

615 (+10.4%)

2019

58 760 (+1.3%)

2020

56 630 (−3.62%)

2021

63 000 (+11.25%)

Help growth, million dollars

| 2019 | 2020 | 2021 | |

|---|---|---|---|

| PRLB | 63 | 50 | 35 |

| ALGN | 442 | 1775 | 772 |

| DDD | −69 | −149 | 322 |

| HPQ | 3152 | 2884 | 6503 |

2019

63

2020

50

2021

35

2019

442

2020

1775

2021

772

2019

−69

2020

−149

2021

322

2019

3152

2020

2884

2021

6503

R&D costs, as a percentage of revenue

| 2019 | 2020 | 2021 | |

|---|---|---|---|

| PRLB | 7. 2% 2% | 8.5% | 9.0% |

| ALGN | 6.5% | 7.1% | 6.3% |

| DDD | 13.1% | 13.3% | 11.2% |

| HPQ | 2.6% | 2.6% | 3.0% |

2019

7.2

2020

8.5

2019

6.5

20200003

7.1

2021

6.3

2019

13.1

2020

13.3

2021

11,2,2

2019

9000

2020 9,0003

2.6

Summarizing the data, several conclusions can be drawn:

- All companies are profitable, with the exception of DDD, which received a one-time profit in 2021 through the sale of non-core assets.

- ALGN and PRLB have the lowest leverage.

- All companies are growing.

- DDD has the highest R&D spending and the lowest revenue growth rate. Investors should pay attention to this.

What's the bottom line

Modern 3D printers can significantly reduce time and costs when solving geometry control and reverse engineering problems in the automotive, aviation, mechanical engineering, shipbuilding, jewelry and medicine industries.

However, in any industry, especially in a start-up one, it is necessary to carefully select companies for investment, since you can always get on a promising, at first glance, start-up, whose management, carried away by development costs, will not be able to turn a profit.

3d printers. Overview of achievements in 2013 / Sudo Null IT News

Prostheses for humans and animals, 3D printing of space structures, food and shoes, improved printing accuracy, new materials, new software.

A bunch of projects on crowdfunding platforms.

Well, pistols, where would we be without them.

China, Japan, Australia, USA, Netherlands, Africa and Haiti, 3D printing seems to be everywhere in the world.

In 2014, 3D printing will go into space.

(Review of the achievements of 3D printing 2012 here)

We read what we achieved for 2013 under the cut ( 54 photos ).

January

The Chinese printed a 5 meter one-piece aircraft part from titanium

more pictures

This is what a laser 3D printer looks like

Selective laser sintering technology in action

Smaller parts

2

30003

Here is an aircraft that uses 3D printed parts

Hackerspace BioCurious offers a self-assembly bioprinter based on HP 5150 inkje

(the first inscription where instead of ink - "Escherichia coli")

The European Space Agency is conducting experiments to build a shelter on the moon using a 3D printer

one and a half ton building block

February

A team of scientists from Scotland, for the first time, using a 3D printer, print three-dimensional tissue from stem cells

Article PDF

3D printed Urbee 2 is ready for production

change the way we make most things”

In February, there was a buzz with 3doodler, a 3D pencil that can “draw in the air”.

In just a few hours, they raised over a million dollars on Kickstarter.

Articles on Habré about this:

With the 3Doodler pen, you can draw three-dimensional objects directly in the air

Our answer is 3doodler. Assembled in 20 minutes

3Doodler is in a hurry to you! (Bonus: clone review)

In November, the "pencil" was delivered to Russia - the first (and last) review

Scientists printed an artificial ear

original article

Nike presented the world's first boots printed on a 3D printer

4D printing. Self-transforming objects

TED 4D printing video

March

The government of Singapore intends to invest $500 million in the development of the 3D printing industry.

3D printing makes it possible to create low-cost implants tailored to the anatomy of patients

83-year-old inventor wins $40,000 in a competition for his DIY extruder

April

Oxford University scientists say their 3D printer is capable of creating materials with some of the properties of living tissue0003

Created a 3D scanner capable of obtaining images from a distance of 1 km

The Chinese government intends to invest $6. 5M in the development of 3D printing technologies

5M in the development of 3D printing technologies

GE prints fuel injectors for aircraft engines

in two days

Printed ear capable of capturing radio frequencies

NASA awarded a $125K grant to develop a 3D food printer for astronauts who will fly into deep space

Saved life to the child, printing the trachea

NASA plans to send a 3D printer on the ISS in August 2014

Japanese printed a carbon bunny the size of a

Chinese, Chinese showed the largest detail for a combat aircraft, printed on 3D printer

June

UK government invests £14.7m in 3D printing projects

Polymers create 'artificial bone' that is 22 times stronger than the composite component

Microsoft built support for 3D printers in Windows 8.1

A foot was printed for a wounded duck

July

MIT develops software that makes it easier to work with composite materials

British children will learn robotics and 3D printing from the age of 5

Telegraph article

August

3D printed rocket engine passed NASA test, which was the starting point for many innovations to reduce the cost of spare parts production

Melbourne scientists have proposed a technology that allows you to grow your own cartilage for the knee joint from stem cells using a 3D printer

MIT scientists have developed a lightweight structure, the smallest details of which can be 3D printed and assembled like a Lego constructor. The intended use is in the construction of aircraft, spacecraft, dams and bridges.

The intended use is in the construction of aircraft, spacecraft, dams and bridges.

The world's first full-scale architectural installation Echoviren

September

Breakthrough technology - printing with dissimilar materials, both organic and inorganic materials: ceramics, metal, plastic and even biological cells

Developers from Disney introduced software that will allow you to create and print mechanical toys on a 3D printer

$100 3D printer - The Peachy Printer0012

Scientists from the Netherlands using a 3D scanner and 3D printer created reproductions of paintings by Rembrandt and Van Gogh

October

UK provides £500K grant to equip 60 schools with 3D printers

HP plans to enter the 3D printing market in mid-2014

Scientists have discovered that natural components (vitamin B2) can be used in the 3D printing process to create implants

Haiti has a 3D printer 9

November

Encryption software for 3D models released

Gelatin bio-ink for printing organs

Scientists printed 20 layers of liver tissue that lived for 40 days0012

Desktop metal 3D printer

Progress in the manufacture of lithium-ion batteries using 3D printers.