Dual extrusion 3d printers

The Best Dual Extruder 3D Printers in 2022 (for Dual 3D Printing and Multicolor 3D Printing)

Welcome to the Thomas guide to the best dual extruder 3D printers 2022. Thomas has been connecting North American industrial buyers and suppliers for more than 120 years. When you purchase products through our independent recommendations, we may earn an affiliate commission.

3D printing in itself is a progressive technology that is extremely useful in many businesses, but it's also a fun activity for DIY hobbyists too. With rapid advancements taking place in the sector regularly, we have seen a lot of impressive things from this industry and can expect to see a lot more in the near future.

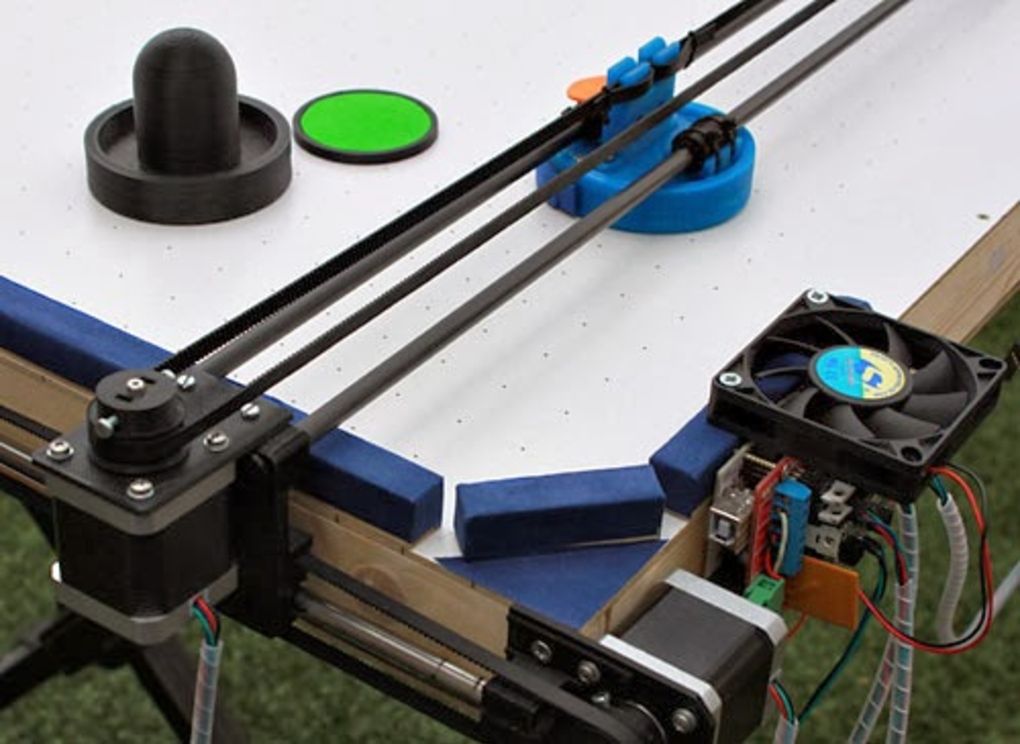

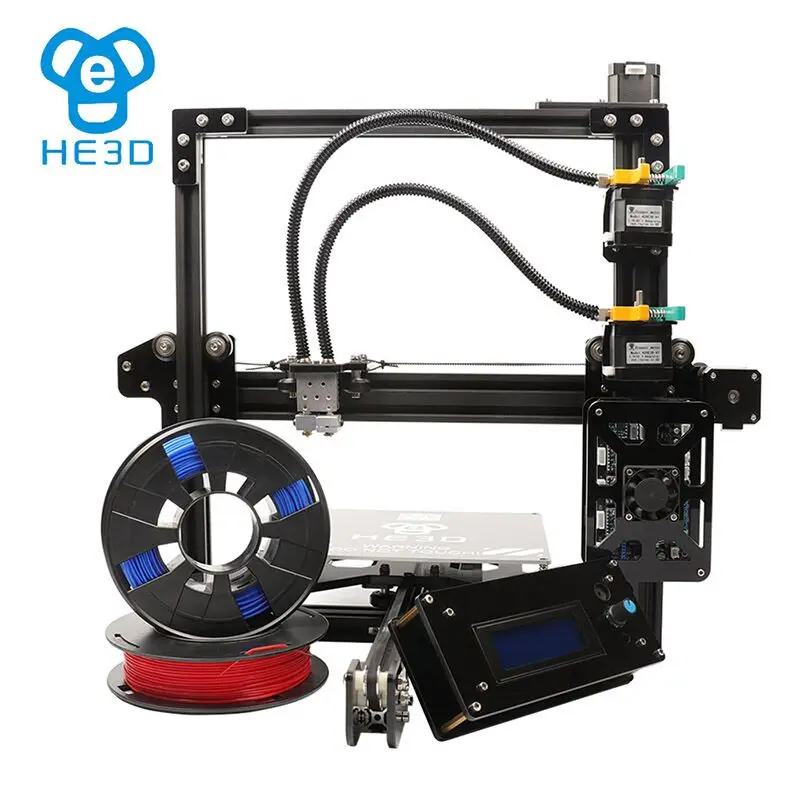

Dual extruder 3D printers can produce colorful and creative projects with two different filamentsImage credit: Shutterstock/Alex_Traksel

Although it's been around for a long time in the professional 3D printing world, one of the newer technologies introduced to at-home 3D printers is dual extrusion which allows users to print with two filaments at the same time, meaning you can mix colors and multiple materials—from PETG, ABS, PLA, and carbon, to metal, wood fill, and multicolor printing filaments—to produce extremely creative projects that can even be created simultaneously.

What is a Dual Extruder 3D Printer?

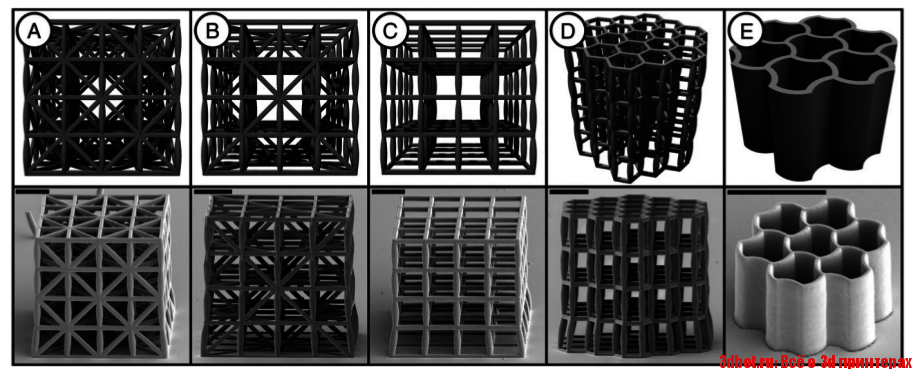

Dual extrusion in 3D printing refers to the art of printing using different materials, whether you choose different colors or different types of filaments with various effects, such as plastic filaments with metallic, or wooden effects.

This gives you the ability to make superior and more impressive products, and many professionals, as well as 3D printing enthusiasts, and those who own small businesses, i.e. Etsy shops selling 3D printed creations, swear by it.

Dual Extruder Printer—Buying Guide

3D printers with dual extruding capacity are, understandably, slightly pricier than single extruders, but it is a major upgrade from the single types, and there are many dual extruder 3D printers on the market at reasonable prices of around US$300-US$400. Since you’ll be spending quite a bit on this impressive piece of equipment, you want to make sure you’re buying the best one for your needs.

Types of Dual Extruder 3D Printers

Though most dual printing machines allow for multi-color printing with different materials, there are two main types of dual extruder 3D printers available:

Independent dual extruder system

IDEX printers have two print heads and two nozzles with each print head able to either mirror the other in mirror mode, duplicate items with duplication mode, or print two completely separate objects.

Dependant dual extruders

These dual extruders have two extruders that are connected and move together to create one object using two different filaments. Two spools are loaded on the 3D printer and the printer alternates using them. These printers have the key advantage of reducing printing time since more print material can be produced than with just a single print head.

Dual Extrusion Printers—Considerations

Here are some other factors to consider why trying to find the best dual extruder 3D printers for your needs.

Print bed

As with regular 3D printers, print beds in dual extruder printers come in heated or non-heated options. A 3D printer with a heated print bed is, understandably, usually more expensive than a non-heated option but a heating plate can offer better print quality by keeping the bottom layers warm and reduce the chances of your prints warping during the printing process.

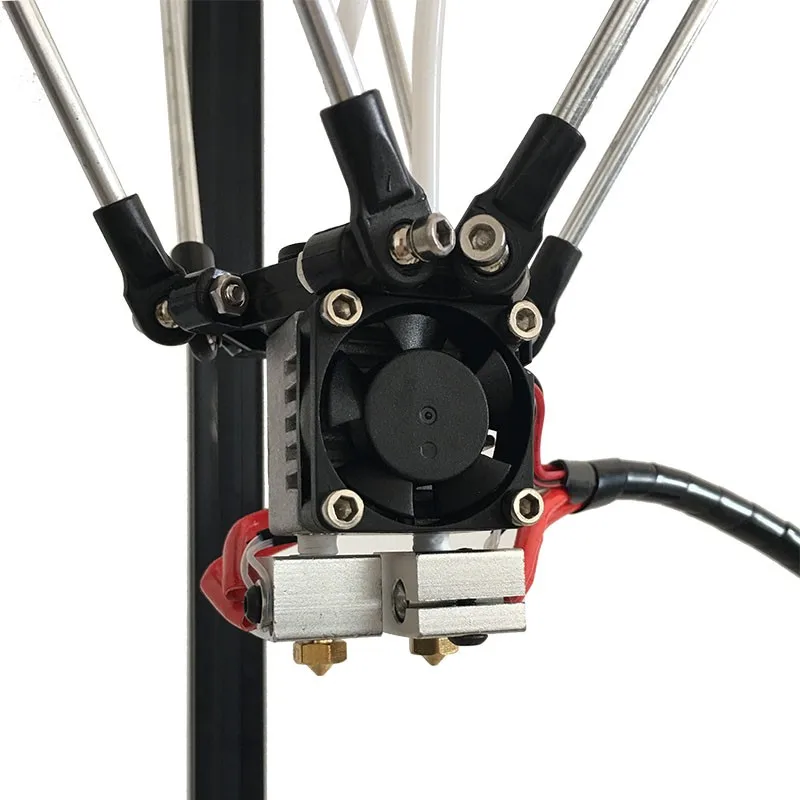

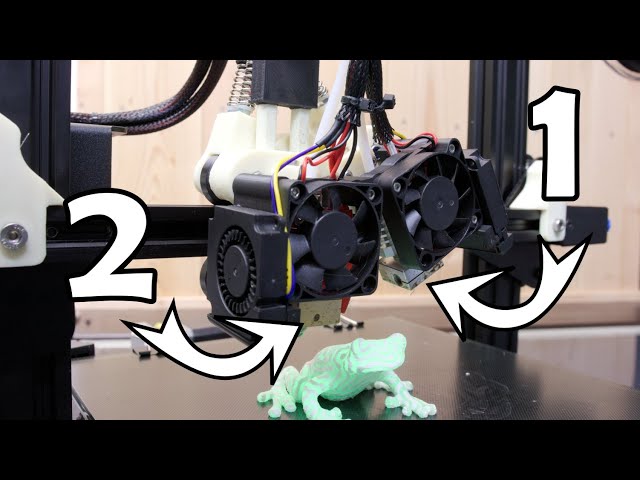

Print heads

Whereas a regular 3D printer just has one print head, a dual extruder printer will have more than one print head, with either two extruders, and sometimes even three. Some dual extruder 3D printers might have just one print head but a dual nozzle that can use two separate filaments on one print. A dual nozzle is great for printing an object in several materials or colors.

Print volume

Print volume, also referred to as the printing volume or the build volume, is how big an object you can build on any given printer. For an at-home printer, projects that would need a huge build volume would likely involve a printing process that would see the object printed off in separate parts and then stuck together afterward. The average size of a 3D printer with a larger build plate would be around 300 x 300 x 400mm.

For an at-home printer, projects that would need a huge build volume would likely involve a printing process that would see the object printed off in separate parts and then stuck together afterward. The average size of a 3D printer with a larger build plate would be around 300 x 300 x 400mm.

Calibration

If you’re a beginner to the world of 3D printing, a printer with automatic calibration is highly recommended. As with most aspects in 3D printing, calibrating a 3D printer has a learning curve and an automatic calibration feature can save you time and hassle and do the hard work for you.

Other factors

Another consideration you may want to keep in mind is cost. A dual extruding printer will be priced higher than a regular single head printer, plus maintenance costs will be higher, too, because there are more parts to this machine. In addition, if you’ll be working with various filaments at the same time (or even the same filament but with two extruders), factoring in higher costs for different materials is also a must.

Some machines even come with an added laser engraver feature or you could buy a compatible laser engraver to use with it. Whatever you’re after in a dual extruding 3D printer, our below list has some of the best models on the market to suit an array of styles, needs, and budgets.

Thomas’ Top Picks for the Best Dual Extruder 3D Printers 2022

We've scoured around and found some of the best 3D dual extruders worth taking a look at.

Best-Rated Dual Extruder 3D Printer: BIBO 3D Dual Extruder Printer | Buy Now

Best Dual Independent Extruder 3D Printer: TENLOG TL-D3 Pro Dual Extruder 3D Printer | Buy Now

Best Enclosed Dual Extruder 3D Printer: FlashForge Dreamer Dual Extruder 3D Printer | Buy Now

Best Cheap Dual Extruder 3D Printer: Sovol SV02 3D Printer | Buy Now

Best Professional Dual Extruder 3D Printer: Raise3D E2 Desktop 3D Printer | Buy Now

Best Quiet Dual Extrusion Machine: JG AURORA Artist-D Pro IDEX 3D Printer | Buy Now

Scroll down to read more about our top picks for the best dual extruder 3D printers according to thousands of happy buyers.

*Prices listed in this article were as shown in US$ on Amazon.com (USA) as of April 2022

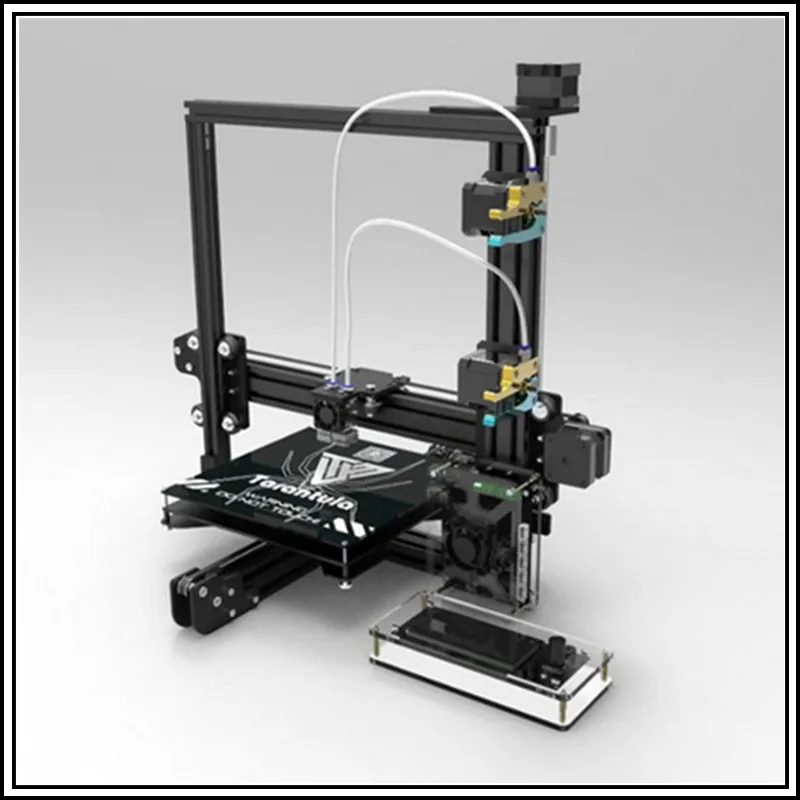

1. Best-Rated Dual Extruder 3D Printer—BIBO 3D Printer Dual Extrusion

A great printer well under the US$1000 mark, is this BIBO dual extruding 3D printer; a fully enclosed model with a very sturdy frame, full-color touch screen, WiFi capabilities, a demountable glass bed, and a low filament detector to let you know when you need to replace it before it's too late.

You can operate it via your phone or tablet if you so wish, and, in addition to printing two colors, it also has the ability to print two objects at the same time. This printer can print in two colors or filament materials, and can also print the dissolvable filament for support material.

One five-star review reads, "The dual extruder function is great, I'm able to use PLA filament and a soluble filament to print out some gears that impressed my friends and coworkers. .. Customer support is AMAZING. Every problem I had is solved very promptly and professionally, even though my printer is well out of their warranty."

.. Customer support is AMAZING. Every problem I had is solved very promptly and professionally, even though my printer is well out of their warranty."

Specifications

Build volume: 8.4 x 7.3 x 6.3 inches

Layer resolution: 0.05-0.3mm

Filament compatibility: multiple filaments including ABS, PLA, HIPS, TPU, PETG, nylon, PC, carbon fiber

BUY NOW:

US$579, Amazon2. Best Independent Dual Extruder 3D Printer—TENLOG Independent Dual Extrusion 3D Printer with Dual Nozzle

Whereas other dual extruding printers have one nozzle that can print from two pre-loaded filament spools, a 3D printer with independent dual extruding capabilities, like this model from TENLOG, has two separate nozzles, each with its own spool, that print at the same time but independently from each other.

This dual nozzle printer can print a duplicate in one go with its duplication or mirroring print modes, in the same or multiple colors, and many customers were left impressed with the high print quality this printer offers.

One happy buyer who described himself as a "3D printing veteran", wrote that the printer is "amazing" and that its print quality is "gorgeous", while another reviewer added "the touch screen and print quality are excellent."

Specifications

Build volume: 11.8 x 11.8 x 13.8 inches

Print speed: 10-150mm/s

Layer thickness: 0.1-0.4mm

Filament compatibility: PVA, TPU, ABS, PLA, nylon

BUY NOW:

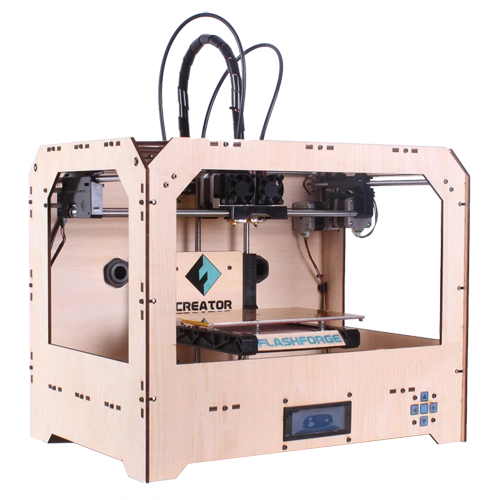

US$499.99, Amazon3. Best Enclosed Dual Extruder 3D Printer—FlashForge Dreamer Dual Extruder 3D Printer

The Dreamer by FlashForge is a fan favorite for many reasons; its fully enclosed design and sleek look, WiFi connectivity, user-friendly and high-res color touch screen, built-in 4G memory, full manufacturer's warranty, FlashForge's superior customer service, and, of course, it's dual extruder capabilities.

In addition, some consider this dual extrusion printer to be a professional piece of kit at the price of more beginner-level 3D printers and its large printing volume helps users get creative.

"This printer is the best bang for your buck to create large, very high-quality prints," one happy buyer reviewed. "[It] has a very high quality, well planned/built enclosure, which you won't find in many printers at this price. It even has two filament spool holders inside the enclosure."

Specifications

Build volume: 230 x 150 x 150 mm

Print speed: “100 micron and can really go to 75 micron at slower printing speed” (as per one customer)

Resolution: 0.1-0.2mm

Filament compatibility: ABS, PVA, PLA,

BUY NOW:

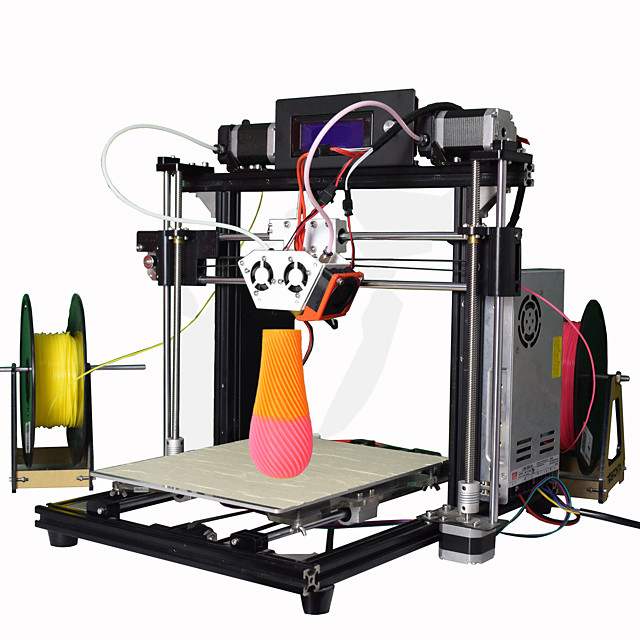

US$699, Amazon4. Best Cheap Dual Extruder 3D Printer—Sovol SV02 3D Printer

Great for beginners, this dual extrusion 3D printer from Sovol with large print volume capacity comes 95% pre-assembled so you can get to printing pretty much straight out of the box. Its full-metal body is stable and made to last, and the touch-screen is user-friendly.

Its full-metal body is stable and made to last, and the touch-screen is user-friendly.

With an impressive build volume, and the ability to print in two colors (or two types of filament), you'd be hard-pressed to find another 3D printer with the same capabilities at this price. In addition, you could buy an extra kit that will turn this thing into a laser engraving machine too if you’d like to add that something special that laser engraving can bring to your projects.

"I purchased it for the dual extrusion capability, and the large build area," wrote one buyer. "I was very impressed with the smoothness of this printer. The only sound during operation is the sound from the fans." Another happy purchaser helpfully added that the "dual extrusion is awesome, but for most prints, you will waste a lot of filament with the purge tower due to the shared hot end. It is a necessary evil."

Specifications

Build volume: 240 x 280 x 300 mm

Print precision: ±0. 1mm

1mm

Layer thickness: 0.1-0.4mm

Filament compatibility: can support material including PLA, ABS, PETG, WOOD, TPU

BUY NOW:

US$359, Amazon5. Best Professional Dual Extruder 3D Printer—Raise3D E2 3D Printer

For a professional 3D printing matching (with a price tag to match), the Raise3D is actually rather simple to use and even easier to set up. It has an auto bed leveling system and will guide you through the offset calibration system via a video.

It has an intuitive user interface with a large 7-inch touchscreen, and also many other features such as independent dual direct-drive extruders, a filament run-out sensor, resume-printing function, WiFi connectivity, and a live, built-in camera so you can monitor your prints remotely.

There's even a HEPA filter to clear any harmful and annoying fumes. It's compatible with almost any filament available. "This is my second dual-extruder printer," wrote one thrilled customer, "and compared to all of the less expensive units, the difference is night and day... Where the less expensive printers leave you feeling like the printer itself is more of a prototype, this one screams quality polished product."

"This is my second dual-extruder printer," wrote one thrilled customer, "and compared to all of the less expensive units, the difference is night and day... Where the less expensive printers leave you feeling like the printer itself is more of a prototype, this one screams quality polished product."

Specifications

Build volume: 11.6 x 9.4 x 9.4 inches

Minimum layer height: 20 microns (0.02 – 0.25 mm)

Precision: 0.78125, 0.78125, 0.078125 micron

Filament compatibility: practically all of them (PLA, ABS, HIPS, PC, TPU, TPE, Nylon, PETG, ASA, PP, PVA, glass fiber infused, carbon fiber infused, metal fill, wood fill)

BUY NOW:

US$3,499, Amazon6. Best Quiet Dual Extrusion Machine—JG AURORA Artist-D Pro IDEX 3D Printer

With super quiet functioning so that you can leave it printing all night if needed without waking up the whole household, the Artist-D Pro 3D printer by JG AURORA has an IDEX system, an ejectable nozzle for easy replacement, changes, and maintenance, and an industrial-grade linear rail for smooth and practically friction-free precision.

It provides the option to change to an optical limit switch, and, as a step up from the Artist-D, has a color touch screen. There are power-resume and filament runout detector functions and duplicate as well as mirror printing options.

One customer with a lot of experience in 3D printing with industrial printers felt that this printer is “the best desktop printer I have ever purchased,” and added, “it has features that my more expensive desktop printers do not have… It has been printing since it showed up at my door, well-needed production parts.”

Specifications

Build volume: 300 x 300 x 340mm build plate

Precision: up to 0.001 mm

Filament compatibility: PLA, TPU, PETG, PVA

BUY NOW:

US$599, AmazonThe BIBO 3D Printer (US$579, Amazon) is a great foray into the world of dual extruding, but for something a bit more economical, the price-performance ratio of the Sovol SV02 3D printer (US$359, Amazon) is impressive too.

We hope our review of the best dual Extruder 3D printers has been helpful and you found the best dual extrusion printer for your needs to get creative and print objects in multiple colors, shapes, and sizes, and perhaps even add laser engraving to the mix too. For more 3D printers and other 3D printing suppliers, including 3D printer filaments suppliers, additive manufacturing suppliers, 3D photographic printing services, and 3D sand printing additive manufacturing, consult our additional guides, or visit the Thomas Supplier Discovery Platform.

Other 3D Printing Articles- The Best 3D Printers under $300

- The Best 3D Printers under $200

- The Best 3D Printer Under $1000

- The Best 3D Printer Under $500

- Top 3D Printing Services Companies in the USA

- Origins of 3D Printing and Additive Manufacturing

- Overview of 3D Printing Technologies

- Top 3D Printing Manufacturers and Suppliers (Publicly Traded and Privately-Owned)

- Top Suppliers of Additive Manufacturing Consulting Services

Other Best Product Articles

- The Best Cordless Impact Wrenches

- The Best Portable Generators

- The Best Portable Band Saws

- The Best Electric Space Heaters

- The Best Mini Milling Machine

- The Best Attic Ladders

- The Best Air Purifiers for Smoke

- The Best Circuit Breaker Locator

- The Best Engine Hoists and Accessories

- The Best Drywall Lifts

- The Best Whole-House Generators

- The Best Home Automation Systems

- The Best Quietest Portable Generators

- The Best Uninterruptible Power Supply Systems

- The Best Commercial Patio Heaters

- The Best Electric Bikes

- The Best Electric Pressure Washers

- The Best Keyless Door Locks

- The Best Electric Lawnmowers

- The Best Electric Hand Warmers

More from Custom Manufacturing & Fabricating

Dual Extrusion 3D Printers | MatterHackers

Whether you need to 3D print with two different colors, two different types of filament or support material for 3D prints that have complex geometries or overhangs, this collection of 3D printers fit the bill. Dual extrusion 3D printers can take advantage of the second material to create a scaffolding for the main 3D print, allowing for much more complex designs using PVA from a variety of manufacturers like Ultimaker, E3D, 3DFuel and more. Creators are also able to 3D print with an additional color or even another type of filament at the same time for endless possibilities.

Dual extrusion 3D printers can take advantage of the second material to create a scaffolding for the main 3D print, allowing for much more complex designs using PVA from a variety of manufacturers like Ultimaker, E3D, 3DFuel and more. Creators are also able to 3D print with an additional color or even another type of filament at the same time for endless possibilities.

Guides & Articles

How to Succeed with Quantum Dichromatic PLA Filament

Follow this guide for tips and tricks on how to get the best results when 3D printing with Quantum Dichromatic PLA filament.

How To Succeed with LayerLock SLA Build Surfaces

Successfully achieve strong bed adhesion for Laser, DLP, and SLA resin prints using LayerLock SLA Resin 3D Printing Build Surfaces.

How To Build A Successful Makerspace

Find out the necessary components to create an effective space for your maker community.

How to Succeed When 3D Printing with Polypropylene

Successfully produce 3D printed parts out of polypropylene filament with these tips on achieving stronger bed adhesion and minimizing shrinkage.

Tech Breakdown and How to Succeed: Ionic Hybrid Support Material

Supporting engineering-grade filament has been difficult without a support material dedicated to higher temperature 3D printing. Ionic aims to solve that.

How To Succeed with OBC 3D Printing Filament

From Dow Chemical, OBC combines flexible and rigid into one unique material with properties of both.

How To Succeed with LayerLock Garolite Build Surfaces

Successfully achieve strong bed adhesion for NylonX, NylonG, and standard filaments using LayerLock Garolite Build Surfaces.

How to Succeed with LayerLock Powder Coated PEI Build Plates

Powder coated PEI steel sheets are a great alternative build surface for strong bed adhesion. Here's how you can succeed using this durable build plate.

How To Succeed When 3D Printing With Nylon

Learn how to 3D print Nylon like a pro. Nylon is a stronger and more durable alternative to PLA or ABS and easy to 3D print with using these Tips and Tricks.

Nylon is a stronger and more durable alternative to PLA or ABS and easy to 3D print with using these Tips and Tricks.

How To Succeed When 3D Printing With ASA Filament

Follow this step-by-step guide to learn how to print with ASA, the perfect material for any outdoor projects.

How to Succeed when 3D Printing with Polycarbonate Filament

Follow these helpful steps to start successfully printing with this extremely tough, professional grade material.

How to Succeed with NylonX

NylonX has quickly become one of our favorite filaments for strong, durable, and ready-to-use parts. Here's an in-depth look at Nylon X, and some printing tips to get the most out of this great new material.

Manufacture of 3D printers in Russia. Review and Interview - PICASO 3D / Sudo Null IT News This time we will tell you about the production of 3D printers in Russia using the example of PICASO 3D. You will see a tour of the factory in Zelenograd and an interview with the founder, find out how it all began and what are the plans of the well-known Russian manufacturer of 3D printers for the near future.

The history of PICASO 3D began in 2010, when two students, Andrey Isupov and Maxim Onisimov, got acquainted with the Rep-Rap project and in a couple of months printed and assembled their first GEN X printer in a city apartment.

In 2011, they have already sold more than 50 of these devices.

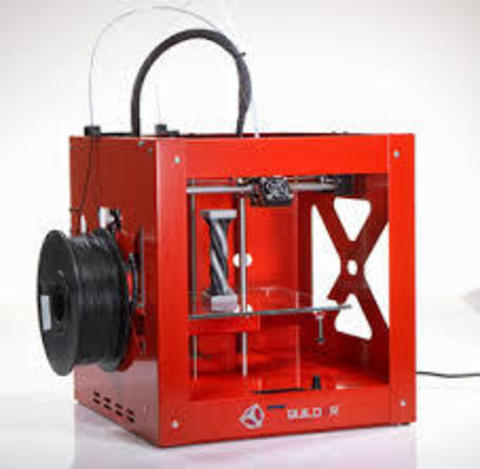

Then came PICASO 3D Builder and the first batch production experience.

In 2014, the PICASO 3D Designer series was launched, within which the PRO 250 is popular and is still produced and sold today.

This printer's fast dual-extruder technology, JetSwitch, has revolutionized the idea of what should be FDM printing with two materials.

Finally, the senior model of the line, Designer X PRO, which has been reincarnated in a new case, is still one of the best personal 3D printers with FDM technology.

At the production of PICASO 3D, we were met by the co-founder and CEO of the company - Andrey Isupov.

Andrey told us about the full cycle of equipment production, its stages and the division of work on the conveyor. You can see all this in the video.

Manufacturing

Automation is included in the workflow where special accuracy is required - when placing elements on printed circuit boards, assembling them and soldering. Most of the work, including the assembly of units with multiple checks of performance and quality, is done manually.

The chief engineer of the production site, Vyacheslav, told us about the assembly of printed circuit boards.

“Special automatic machines stencil solder paste onto boards.

Place transistors and capacitors, other elements.

Small components are fed into the assembly machine on tapes from reels.

After assembly, the board is automatically and visually inspected.

The boards are checked by a scanning system and employees at several stages of assembly.

After assembly, the board is baked at 270 degrees Celsius - the solder melts and the components are firmly connected.

As a result, we have a soldered board.

Then it is sent for quality control, firmware, output wiring, checks, and then goes to the assembly.

The number of defects in the production of circuit boards is 0.02%.”

The printer assembly area is divided into sections.

Electronics compartments are assembled in one place - a printed circuit board is installed in the electronics compartment, then the compartment is sent for testing.

In the next section, the tables are assembled - the shafts are installed, all dimensions and rigidity are checked, then the table also goes to the Quality Control Department.

Belts are tightened on the mechanical assembly, the print head is installed.

The printhead assembly section gathers the pride of the company - printheads with JetSwitch technology.

The main feature of this printhead is very fast media switching and high print quality.

Head includes encoders, temperature and other sensors. The construction is made to micron tolerances and contains high-quality components, which greatly increases the cost of it, but serves as a guarantee of quality.

JetSwitch is a unique development of PICASO 3D, patented in Russia, USA, EU, China and India. At the moment, JetSwitch provides the fastest and highest quality two-material FDM printing, the developments of other companies are lagging behind, even such as Ultimaker.

The printers are assembled on a frame, then moved to the enclosure department, where an external case is mounted on them, after which they are sent for testing.

Printers are tested for several days, switching, feed uniformity, table alignment, all printer components are checked in operation.

Most parts of the printer, such as the frame, body elements, boards, are produced by various enterprises in Russia. The guides are made by the German company BOSCH.

The guides are made by the German company BOSCH.

In China, stepper motors, power supplies, fans and standard components are now being ordered, which already have a fairly high quality there.

Only quality parts from trusted manufacturers are purchased, this is not cheap, but it helps to make the printer fault-tolerant and able to work 24/7.

Assembled, tested and packaged printers are stored at the final production site until shipped to customers.

Interview

From production, we went to the PICASO 3D office for a more detailed conversation.

About the name. Why PICASO?

We chose a name for a very long time, there were other similar options, but we settled on this one, as the most understandable, simple and beautiful, incl. and to enter the European market, which we immediately set our sights on.

How did your passion for rap rap turn into a commercial product, how did that happen?

At that time there were very few printer offers on the market, there were some semi-finished products, no hint of user friendliness and ergonomics, ease of operation. Simply put, there was not a single professional product ready to go. We realized that this is a good free niche, and we had an idea of \u200b\u200bwhat we want to fill it with.

Simply put, there was not a single professional product ready to go. We realized that this is a good free niche, and we had an idea of \u200b\u200bwhat we want to fill it with.

Were manufacturing companies among the first customers?

Not much. There were more entrepreneurs who had free money and decided to try something new, like 3D printing on order.

How has the target audience changed during this time?

The technology itself is developing, the equipment is becoming more professional, more customers are coming from businesses of various sizes. We see the growth of the market in industrial applications, in work with serious engineering plastics that can withstand extreme loads and temperature conditions.

What's new in materials?

Carbon fiber filled materials are relatively recent. This direction is very interesting because the materials are relatively inexpensive and have very good strength characteristics, and prints from them can withstand temperatures of about 200 degrees Celsius.

Are you preparing any new materials for the market?

Yes, we are preparing two new materials. Both are carbon-filled, these are the materials of the Ultran line. One of them is more industrial, having higher output characteristics in finished products, but more hygroscopic and requiring drying at a temperature of about 120 degrees for three hours before printing. If you keep it at 80 degrees or in an atmosphere protected from moisture, it will work stably. The second material is more expensive, gives less durable parts, but absorbs moisture from the air much less. Now we are just conducting tests, compiling tables of properties, and by Top 3D Expo we will have all the characteristics that we will present at the exhibition along with the materials themselves. The main application of our materials is all kinds of engineering parts. High strength, low friction - very well suited for all kinds of gears. Tensile strength is 2-2.5 times higher than ABS.

Very interesting. How much will this plastic cost?

How much will this plastic cost?

While I will not disclose the order of prices, we will name them when we announce the line of materials for sale. Of course, the cost will be higher than that of household plastics such as PLA, because these are target materials intended for industry.

How successful is PICASO 3D in the international market?

While we travel to international exhibitions, we arouse interest among foreign colleagues and potential customers. We created the X PRO model specifically for the international market. This year we will start sending out demonstration samples to foreign distributors, and by the end of the year we plan to enter full-fledged international sales.

How many printers do you sell each year?

The figures vary from year to year, on average it is about 1500 cars, this year we want to sell 2000.

How did it happen that you have any competitors in Russia at all?

One company cannot occupy the entire market - there is antitrust law. We do not strive to create machines to close all segments. There are niches that are not yet included in our range of interests, our main goal is to create the highest quality devices in their segment, and not to close the entire market with anything. From the very beginning, we did not want to make small hobby printers - we are simply not interested in them. We make devices for practical industrial applications, that's a completely different story. By creating JetSwitch and X PRO based on it, we have prepared a platform for the production of new products that meet our quality standards and are in our circle of interests.

We do not strive to create machines to close all segments. There are niches that are not yet included in our range of interests, our main goal is to create the highest quality devices in their segment, and not to close the entire market with anything. From the very beginning, we did not want to make small hobby printers - we are simply not interested in them. We make devices for practical industrial applications, that's a completely different story. By creating JetSwitch and X PRO based on it, we have prepared a platform for the production of new products that meet our quality standards and are in our circle of interests.

Anything new? When will we know about it?

We will show part of it already at Top 3D Expo on April 10, the rest later, we'll see when.

How do you see the development of additive technologies and digital manufacturing in general? Do you think that a personal 3D printer will be on the desk of every engineer?

There was such a slogan “3D printer in every home”, but I don't believe in it..jpg) This product is not for the home. Of course, there are enthusiastic people who install machines at home, and for them the operation of a 3D printer will not be a problem. But the main target audience is professionals for whom this is an indispensable tool - designers, engineers. Yes, in the work of a designer, the best option is when each workplace has its own personal 3D printer.

This product is not for the home. Of course, there are enthusiastic people who install machines at home, and for them the operation of a 3D printer will not be a problem. But the main target audience is professionals for whom this is an indispensable tool - designers, engineers. Yes, in the work of a designer, the best option is when each workplace has its own personal 3D printer.

How do you see the development of additive technologies in the near future?

No one knows what new technologies may appear on the market at any moment and change the “rules of the game”. An example is CLIP technology, which appeared suddenly and changed SLA technologies. As for FDM, if you look at what we have now, most likely - the inexpensive segment of personal FDM printers will begin to change - machines will gradually become more expensive, but increase their capabilities much faster. First of all, this concerns printing with more durable and more constructive materials.

The history of PICASO 3D is an excellent example of the fact that digital production in Russia lives and develops, as well as a great illustration of the fact that ordinary students can create their own cool project and it will become commercially successful. I wish the PICASO 3D team development in the Russian market, recognition in the international arena, as well as even more new products.

I wish the PICASO 3D team development in the Russian market, recognition in the international arena, as well as even more new products.

We invite you to the Top 3D Expo exhibition-conference, which will be held on April 10 in the Moscow Technopolis. Admission is free, register on the website and come with your passport.

At the exhibition, you will be able to see live PICASO 3D printers and samples printed on them, ask questions to company employees and learn a lot of new and interesting things.

Also on display are a KUKA industrial robot, a Bauman Racing Team car, a VR Concept virtual reality booth and much more.

🌐 Best low poly STL files for 3D printing・Cults

🌐 Best low poly STL files for 3D printing

Download Low Poly Design 3D Files

Low poly is perhaps the very first graphic trend to emerge in the 3D printing community. Designers, both working and not working in the field of 3D printing, immediately adopted this graphic novelty and made it popular.

Low Poly Pikachu

Free

Low Poly Bulbasaur

Free

Low polymer toy

Free

Low Poly Charmander

Free

Low Poly Eevee

Free

Low Poly Squirtle

Free

Low Poly Skull

Free

Geometric mold for concrete pot

Free

Alduin's Dragon Wall trophy in Skyrim

Free

Low Poly Fox

Free

Gengar Low Poly Pokémon

Free

Low poly masks

1.52 €

Figurine of a sitting cat

Free

Low polymer toy - multi and dual extrusion version

Free

Low polymer toy

Free

Resin rabbit lamp

Free

Low poly toys

Free

Low Poly Rose

Free

Low Poly Totodil

Free

Low poly dog - Beto

Free

Volkswagen Golf GTI - low poly miniature

Free

Low poly wolf paper mask

Free

Low Poly Yoda

Free

Low Poly Cat

Free

Low Poly Moai

Free

Low Poly T-rex

Free

Low-Poly Squirtle - multi and dual extrusion version

Free

Low Poly Cyndacil

Free

Foldable Pokeball Box Decoration

Free

Low Poly Pug

Free

Low Poly Hulk

1. 52 €

52 €

Clamp with low-poly inlay \ dual extruder

Free

Low polymer toys - double extrusion version

Free

Low Poly Pikachu - Multi and Dual Extrusion Version

Free

Low Poly Doge

Free

LowPolyHorse

Free

Low Poly Fawn

Free

Low Poly Stanford Bunny

Free

Cup of cubes

1.27 €

Low Poly Optimus Prime

3.04 €

SEKOND IKEHACK

Free

Low poly Chocobo

Free

Low Poly Planter

Free

Low-poly retro characters

Free

LowPolyPanther

Free

Low Poly Squirrel

Free

Low Poly Spiderman

1. 52 €

52 €

Captain America

1.51 €

Gengar Low Poly Pokémon

Beam Table

Low Poly Charmander

Low Poly Fox

Here is our selection of best lowpoly STL files , all these beautiful creations are taken from Cults 3D file library and beautifully prints in 3D . Most of these models can even print on the spot without support because they have been optimized for their rather simple aesthetic.

Initially not very accurate and powerful 3D printers could not create such beautiful 3D models as today . So designers have had to adapt by creating much simpler models or even simply reducing the polygon count in existing models.

The result is low poly trend : objects or things from everyday life that can be recognized at a glance, despite their low accuracy.