3D printing boats

Navigating the Best Examples of 3D Printed Boats

Published on July 30, 2021 by Amelia H.

Additive manufacturing is now a production method used everywhere, whether on Earth, in the air, in space or even underwater. Some players in the maritime sector are turning to 3D technologies to design components for their boats, spare parts for submarines and even components of currents turbines. We won’t go into these initiatives today, but we will focus on 3D printed boats: whether they are fully or partially 3D printed, more and more of them are incorporating additive manufacturing. From bow to stern, discover how 3D technologies are impacting the construction of our boats through some innovative applications.

The world’s largest 3D printed boat

In September 2019, the University of Maine’s Advanced Structures and Composites Center made headlines when it announced that it had made the world’s largest 3D printed boat. The 3Dirigo was printed in 72 hours by the world’s largest thermoplastic 3D printer and measures 25’ (7. 62m) long and weighs 5,000lbs (2,268kg). Beyond holding the Guinness World Record for largest 3D printed boat, it also holds a record for being the world’s largest solid 3D printed item. Though the boat will not actually be used, it was tested in a pool at the Alfond 22 Ocean Engineering Laboratory test site, with U.S. senators as well as U.S. Representative from Maine, boarding the boat for a test ride. The project is part of a partnership with the U.S. Department of Energy’s Oak Ridge National Laboratory in Tennessee (ORNL) to develop a large-format AM program based on 3D printing materials that contain wood fiber.

Photo Credits: University of Maine’s Advanced Structures and Composites Center

MAMBO, a functional 3D printed fiberglass boat

Unveiled in 2019 during the FormNext international trade show, the MAMBO boat was designed by Moi Composites, in collaboration with Autodesk, Catmarine, Micad and Owens Corning. It is 12’4″ (6.5 meters) long, 8’2″ (2.5 meters) wide and weighs about 1763. 7lbs (800 kg). The peculiarity of the project is that it turned out to be the first functional 3D printed fiberglass boat to sail in Italian waters during the Genoa boat show. For its development, the company relied on additive manufacturing technology with continuous fiber composite materials. The process involved two robots that fabricated the boat’s components to be assembled. This system allows the creation of much lighter, yet strong and durable parts, limiting material waste and without the need for molds – a successful example of the possibilities of 3D printing in the maritime sector!

7lbs (800 kg). The peculiarity of the project is that it turned out to be the first functional 3D printed fiberglass boat to sail in Italian waters during the Genoa boat show. For its development, the company relied on additive manufacturing technology with continuous fiber composite materials. The process involved two robots that fabricated the boat’s components to be assembled. This system allows the creation of much lighter, yet strong and durable parts, limiting material waste and without the need for molds – a successful example of the possibilities of 3D printing in the maritime sector!

Photo Credits: Moi Composites

Europe’s first seaworthy 3D-printed boat

A collaboration between RISE (Research Institute of Sweden) and Cipax, the owner of the boat company Pioner, resulted in Europe’s first seaworthy 3D-printed boat to be manufactured in one piece. The Pioner 14 Active Dark Line model was produced layer by layer from a plastic and glass fiber mixture using ABB robotic arms. In order for customers, such as the police or the military, to be equipped with the 3D printed boats in the future, it is still necessary to compensate for the excessive material density with floating hulls. If this goal is achieved, nothing should stand in the way of commercialization of the model.

In order for customers, such as the police or the military, to be equipped with the 3D printed boats in the future, it is still necessary to compensate for the excessive material density with floating hulls. If this goal is achieved, nothing should stand in the way of commercialization of the model.

3D printing the AC9F

The New Zealand company Yachting Developments has been building boats for a few years now, particularly with composite materials. It has developed a branch dedicated to additive manufacturing in order to accelerate the production of its ships. One of its latest projects was to 3D print all the tooling needed to build the AC9F, a boat that took part in the 36th edition of the America’s Cup, which took place from March 10 to 21. Thanks to 3D printing, the teams were able to drastically reduce the manufacturing time of the final boat.

Photo Credits: Yachting Developments / Georgia Schofield

The One Minute Boat project

Every minute, no less than 20 tons of plastic waste is dumped into the oceans. Despite the fact that they are very harmful to marine life, millions of plastic bottles are thrown into the sea every day. That’s why Searious Business, a company that specializes in the fight against plastic pollution, has developed the “One Minute Boat” project, named after the data mentioned above. The sailboat, printed in 3D, will be built from 20,000 kg of PET plastic recovered from discarded plastic bottles. In order to obtain a model of the project, Searious Business collaborated with the company Lay3rs, which 3D printed a replica of the boat with recycled PET. An initiative that proves that additive manufacturing also has a role to play in the fight against ocean pollution.

Photo Credits: Searious Business

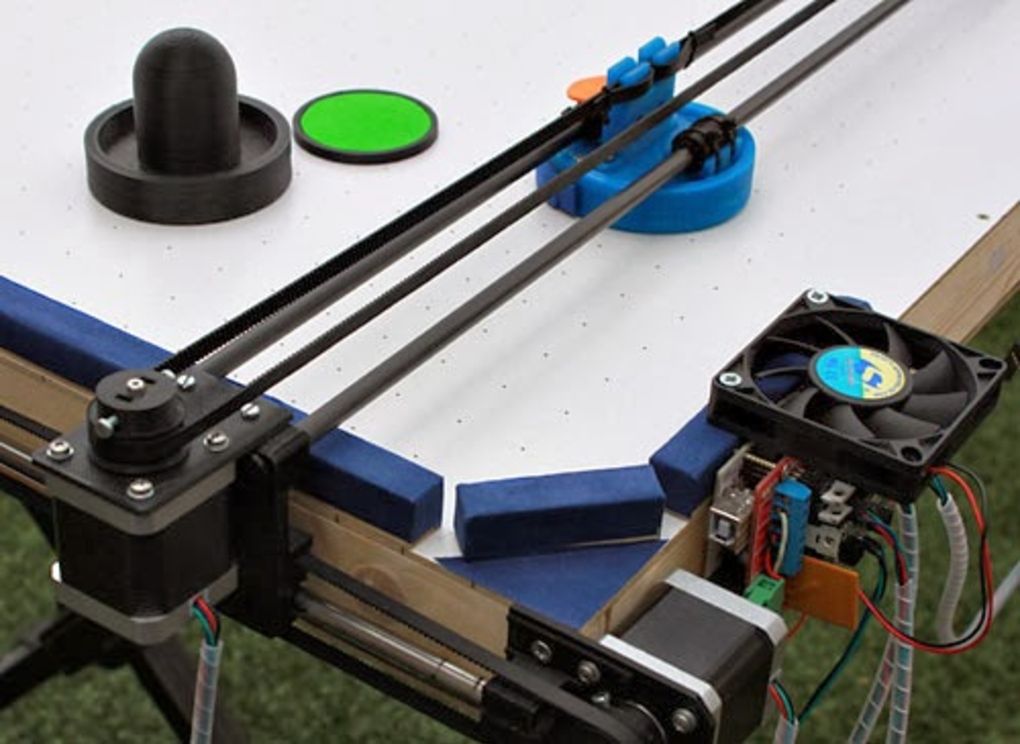

The world’s first autonomous 3D printed boats

Roboat is the central focus of a five-year research project conducted by the Amsterdam Institute for Advanced Metropolitan Solutions and MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL). The institutes intend to manufacture the world’s first (3D printed) fleet of autonomous floating vessels. These will rely on self-driving technology set to change cities and their waterways through automation. Autonomous platforms will be integrated to form floating bridges and stages, collect waste, deliver goods, and transport people, all while collecting data about the city.

The institutes intend to manufacture the world’s first (3D printed) fleet of autonomous floating vessels. These will rely on self-driving technology set to change cities and their waterways through automation. Autonomous platforms will be integrated to form floating bridges and stages, collect waste, deliver goods, and transport people, all while collecting data about the city.

A 3D-printed version of the Livrea26

The next boat on our list is the Livrea26, prototyped by CRP Group, an industry group specializing in additive manufacturing and rapid prototyping, among other things. The inspiration for the 3D project, which is the result of a collaboration with Livrea Yacht Italia, comes from the traditional fishing boats on the Italian island of Pantelleria. Together, the partners aim to contribute to the development of innovative materials for boat building, with the goal of revolutionizing watercraft construction methods and designs. The 3D-printed version of the Livrea26, which has a scale of 1:14, is made of Windform materials. Thanks to additive manufacturing and Windform materials, the boat was built in just a few days, maintaining the most complex de-tails and strong aesthetics.

The 3D-printed version of the Livrea26, which has a scale of 1:14, is made of Windform materials. Thanks to additive manufacturing and Windform materials, the boat was built in just a few days, maintaining the most complex de-tails and strong aesthetics.

Thermwood’s 3D printed boat hull

Last year, Thermwood, a company specializing large format additive manufacturing solutions, used 3D printing to manufacture a hull mold for a 51-foot-long yacht with carbon fiber reinforced ABS. In order to do so, the company used its smallest 3D printer, the LSAM MT, which possesses a print volume of 10 x 10 feet. Thermwood then 3D printed four parts taking 65.5 hours (just under 3 days), weighing a total of 4,012 pounds (about the same as a hippo), which it later bolted together to form the whole boat hull.

Thermwood’s 3D printed hull. (Photo Credits: Thermwood)

(Photo Credits: Thermwood)

A 3D printed Kayak

Our final boat is not a prototype, nor a miniature but rather a fully functional kayak and the first of its kind. The genius behind this invention is Jim Smith of Grass Roots Engineering. He was able to create a kayak that is 5 meters long, 0.5 meters wide, and weighs about 30 kilograms, using 28 different ABS plastics. Other than that, Jim used only screws, threaded inserts and some silicone sealant. To make his project a reality, the 3D Systems engineer even created a custom, large-scale 3D printer. One thing’s for sure: no challenge could stop him from this innovation, and we can’t wait to see if more kayaks are 3D printed in the future.

Photo Credit: Grass Roots Engineering

What do you think about these 3D printed boats? Let us know in a comment below or on our Linkedin, Facebook and Twitter pages! Sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox!

Tanaruz plans to produce 300 3D printed boats by 2023

0Shares

Customizable 3D printed boat manufacturer Tanaruz is reportedly planning to scale up the production of its commercial boats to 300 by 2023.

3D printed using reusable polymers, the boats are claimed to be more sustainable and cheaper to produce than conventionally manufactured models, and come in a range of four models spanning 4.5-10 meters in length.

Tanaruz’s DSI model 3D printed yacht. Photo via Tanaruz.Improving sustainability with 3D printing

Tanaruz’s boats are manufactured at its Rotterdam facility using a 14-meter long 3D printer, and are designed to embody the principles of a circular economy. All of the firm’s boats are made from reclaimed and recycled polymers which, at the end of a boat’s life, can be shredded down and reused to print a new boat.

According to Tanaruz, this means the production of its boats results in zero material costs and waste. In particular, the boats are printed with reclaimed polypropylene containing 30 percent glass fiber to offer desirable mechanical properties such as resilience to elongate strain up to five percent, alongside resistance to heat, fire, and chemicals.

Further eco-friendly additions include electrical engines to power the boats, and the option of mounting solar panels to generate renewable energy.

Tanaruz’s DDM model 3D printed boat. Photo via Tanaruz.A custom boat 3D printer

Traditional methods of making pleasure yachts and boats tend to require a lot of manual labor, making them expensive and often time-consuming to produce.

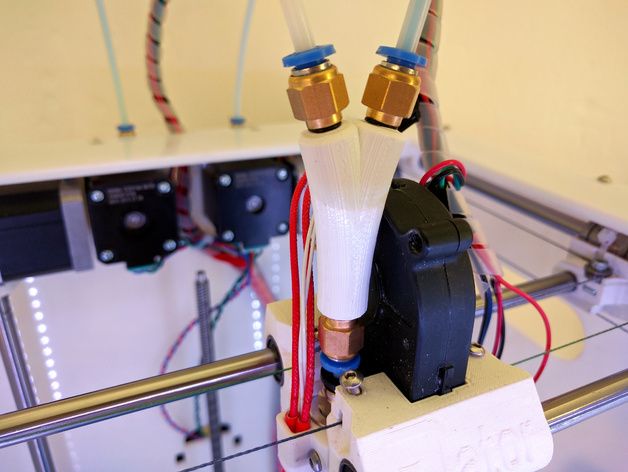

To manufacture its boats, Tanaruz deploys a specially-designed 3D printer produced by Swiss-Swedish multinational electrical equipment firm ABB. The firm’s robotic Track Motion system is reportedly the only track on the market offering high speed, precision accuracy, and flexibility, and has been optimized with the ideal parameters to robotically 3D print Tanaruz’s various boats.

The 3D printer also features an extruder manufactured by Dutch firm Xtrution, which handles the process of melting and extruding the reclaimed polymers to Tanaruz’s specifications.

According to the firm, 3D printing technology facilitates the smart and efficient production of its boats through greater accuracy control and shorter production times, while also minimizing waste during the building process. The technology also boosts creativity and flexibility throughout the production process, in line with circular economy processes and decreasing Tanaruz’s impact on the environment.

The technology also boosts creativity and flexibility throughout the production process, in line with circular economy processes and decreasing Tanaruz’s impact on the environment.

Scaling up production

Tanaruz currently produces four models of boats, ranging from 4.5 meters in length up to 10 meters. The boats can be personalized and equipped with electric motors, batteries, and solar panels, while customers can choose the color, interior, and equipment of their vessel.

In addition to the sustainability and production cost benefits of leveraging 3D printing to build its boats, the technology also enables Tanaruz to lower the price of its yachts for its customers. The firm’s entry-level model is priced at around €15,000 which, while still not affordable for many, could be reduced further as the company scales up its production.

This year, the firm aims to 3D print around 100 pleasure yachts and aims to increase this number to 300 boats by 2023. The yachts are produced at the company’s Rotterdam facility, and plans are currently underway to find and open a second location in order to install more 3D printers to boost production.

The yachts are produced at the company’s Rotterdam facility, and plans are currently underway to find and open a second location in order to install more 3D printers to boost production.

With the addition of the new facility, Tanaruz says two printers could work on one boat at the same time, potentially allowing boats larger than 10 meters to be 3D printed.

Going forwards, the firm is looking for partners and investors to grow its reach internationally, offering shipyards and print shops around the world the opportunity to get started with its ‘plug-and-play’ additive manufacturing technology.

Tanaruz’s 3D printed S model. Photo via Tanaruz.3D printing sea-faring vessels

Tanaruz is not the only player making headway in deploying 3D printing for boats and pleasure yachts. Just last month, the University of Maine (UMaine) 3D printed two new large-scale boats, one of which is reportedly the largest vessel ever to be additively manufactured. The vessels were developed for the US Marine Corps as logistical support vessels, and will be tested for field use by the armed forces.

In fact, UMaine broke its own record for the world’s largest 3D printed boat, which until the unveiling of its new boats was its 3Dirigo model, measuring 25 feet long and printed in just 72 hours. Elsewhere, tech start-up Moi Composites displayed what it claimed was the world’s first boat 3D printed in continuous fiberglass thermoset material at the 2020 Genoa Boat show.

Tanaruz’s 3D printed DS model. Image via Tanaruz.Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews, and webinar replays.

Featured image shows Tanaruz’s DSI model 3D printed yacht. Image via Tanaruz.

Image via Tanaruz.

Tags 3Dirigo ABB Moi Composites Tanaruz University of Maine US Marine Corps Xtrution

Hayley Everett

Hayley is a Technology Journalist for 3DPI and has a background in B2B publications spanning manufacturing, tools and cycling. Writing news and features, she holds a keen interest in emerging technologies which are impacting the world we live in.

⛵ Best Boat 3D Models・Cults

⛵ Best Boat 3D Models

3D Printable Boats

On this page you will find a large number of free or paid 3D files for boat lovers. Some boats are purely decorative, while others can easily navigate the water. There are sailboats, catamarans, fishing boats and even huge cargo ships.

#3DBenchy - fun 3D printing torture

Free

BEN floating BENCHMARK (Benchy)

Free

Caravel Columbus "Nina" (1492)

Free

RMS TITANIC - scale 1/1000

Free

bathtub boat

Free

LEO the little fishing boat (visual benchy)

Free

Smoke for #3DBenchy boat

Free

JUN - the Jungle Queen

Free

Small fishing boat - floating toy for kids

Free

CAS - the modular xyz-cube cargo ship

Free

Small compressed Titanic and scale example of the iceberg

Free

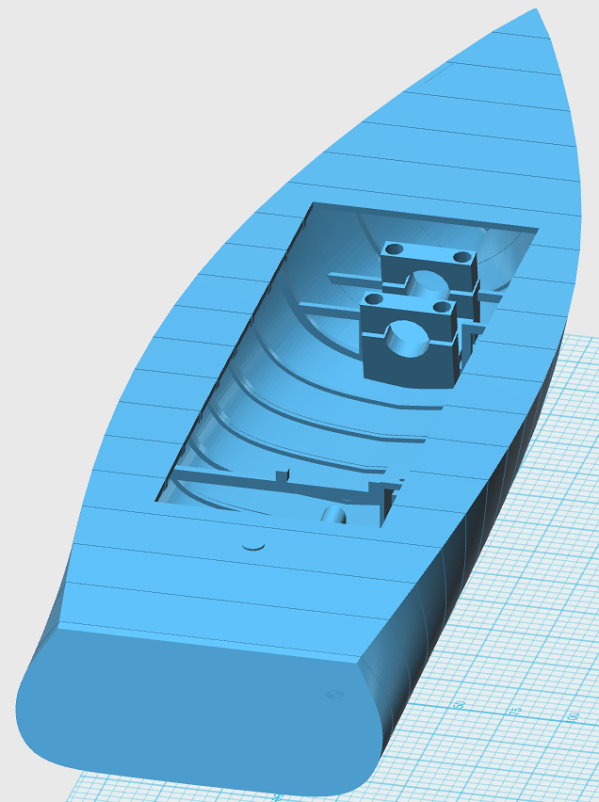

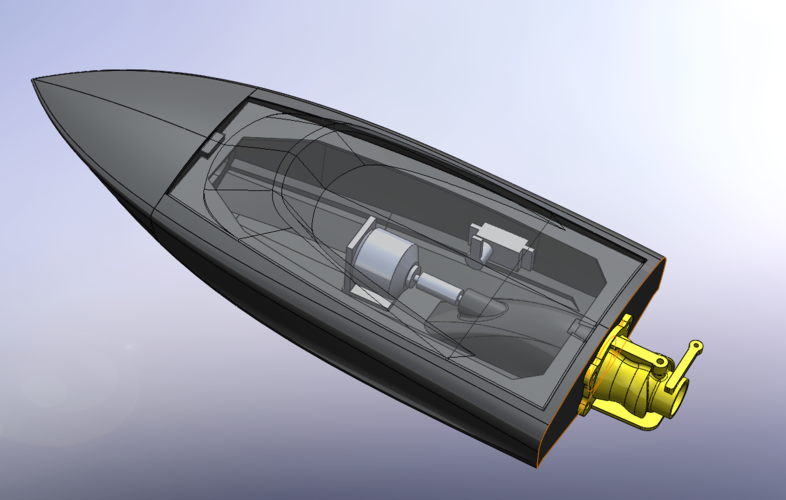

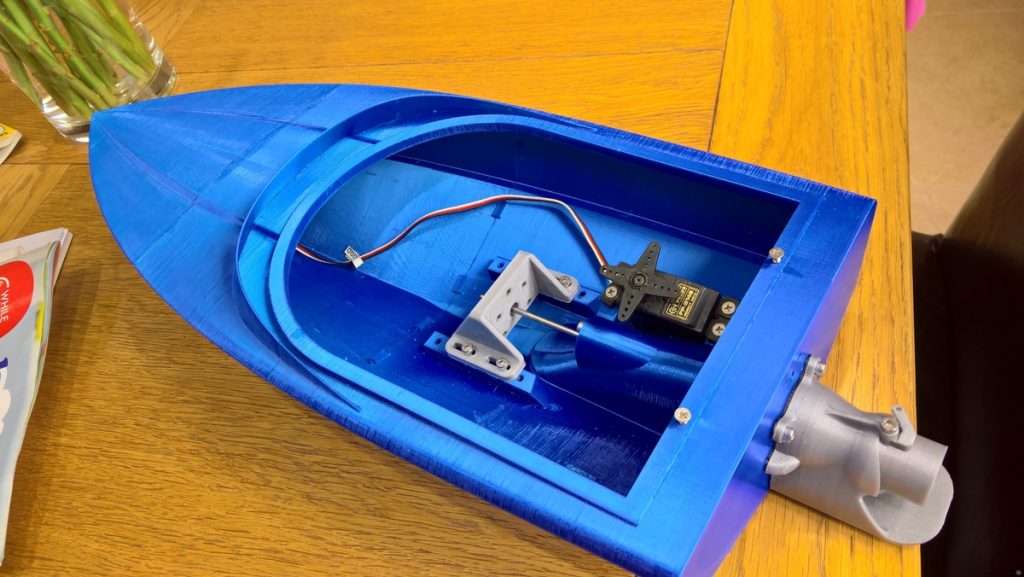

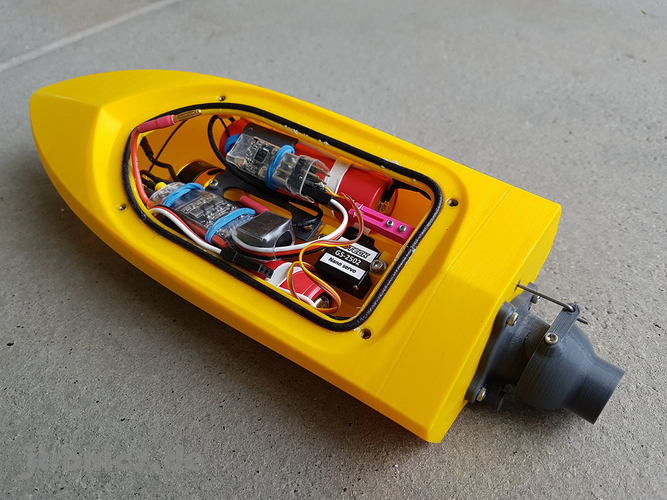

Mini RC Jet Boat 200 Mono

8 €

Container Ship

Free

Little bathtub tug boat (visual benchy)

Free

The Endeavor

Free

FIN the little Trawler (visual benchy)

Free

Paddle Boat

Free

The Trinidad

Free

Battleship - Recreated

Free

Tug Boat

Free

The Bao Chuan

Free

Sailboat Scale Model Esc: 1:43, based on Westerly Tiger 25

Free

Motor Boat RC small (experimental)

Free

EMMA - a Maersk Ship

Free

COS - the Container Ship

Free

Toy Boat

Free

The Sao Cristovao

Free

Sailboat

Free

RS1: Cargo ship

Free

Cargo container for cargo ship Marauda

0,50 €

ICE - the icebreaker

Free

ship (battle)

Free

Impeller Boat RC - spiral vase printable

Free

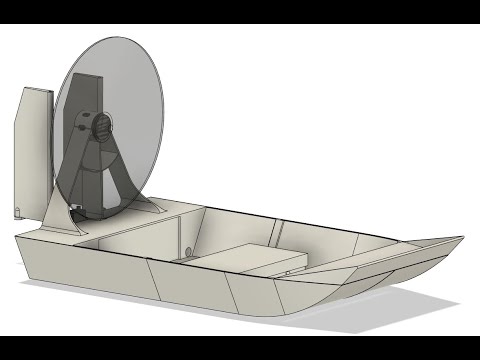

Research Vessel

Free

FERRY - the little transport miracle

Free

Turbo-BOAT --> Print in Place / NO SUPPORTS / No assemble

Free

Sailboat

Free

Sailboat

Free

Two Hulled Impeller Boat RC (experimental)

Free

VOS - the Supply Ship

Free

Speed Boat 2 RC

Free

Antique boat

1 €

Cruise Ship

Free

OLI - the little Ocean Liner

Free

Speed Boat RC (experimental)

Free

titanic

5. 49 €

49 €

Sail Boat

Free

Speed Boat 3 RC

Free

RC Benchy

Mini RC Jet Boat 200 Mono

bathtub boat

#3DBenchy - fun 3D printing torture

Here is our selection of best STL files of boats , all these beautiful boats from 3D file library Cults and are perfectly printable in 3D .

This collection includes many free and paid 3D files of that will allow you to 3D print at home many variations of boats. Each Cults 3D designer has their own vision of a boat, so you will find incredibly realistic boats created as models, but also more childish boats to play in the bathtub. Obviously, it's impossible to talk about 3D printing and boats without mentioning the famous Benchy , this boat that floats and is an excellent calibration test for your 3D printer.

Then, of course, there are purely decorative boats that can be neatly shelved, then 3D printed boats that float and can go on an adventure, and finally remote RC 3D printed boats . Some 3D designers of have even created boats with a 3D printed motor that works great ! In terms of format, there is everything you can imagine: large cargo ships, catamarans, sailboats, fishing boats...

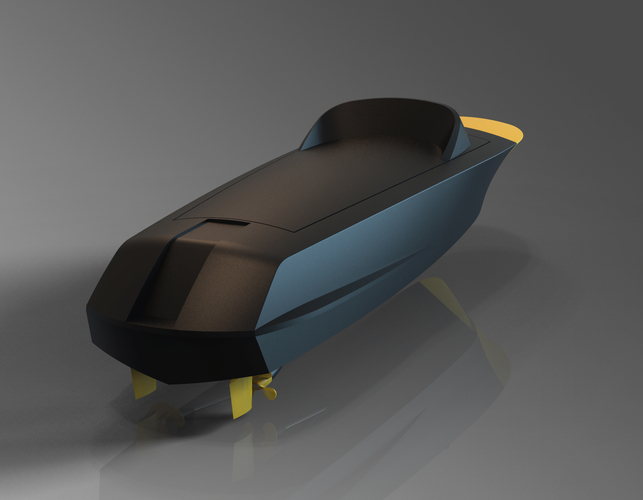

The world's first 3D printed fiberglass boat

Technologically, our reality is evolving at a pace that our parents never dreamed of. Proof of this is the latest fiberglass motorboat, which is fully 3D printed.

The MAMBO (Motor Additive Manufacturing Boat), designed and 3D printed by the startup team Moi Composites, using innovative robotic machines and a uniquely shaped advanced composite material, is the first boat of its kind. The boat is built using the innovative Continuous Fiber Manufacturing (CFM) technology. In this method, continuous fibers are injected into a thermosetting resin to produce a material that is as strong as traditional fiberglass but much easier to form. It is time- and money-efficient and therefore widely used, making it possible to create glass fiber reinforced products with mechanical characteristics similar to unidirectional glass fiber without the use of models, molds or other equipment.

In this method, continuous fibers are injected into a thermosetting resin to produce a material that is as strong as traditional fiberglass but much easier to form. It is time- and money-efficient and therefore widely used, making it possible to create glass fiber reinforced products with mechanical characteristics similar to unidirectional glass fiber without the use of models, molds or other equipment.

A team from a start-up subsidiary of the Politecnico di Milano was looking for ways to overcome manufacturing constraints after discovering that new designs could not be realized with existing manufacturing methods. The production of boats from composite materials is currently costly as it requires moulds, wastes time and material, and is limited to standard moulds. Since no other company could offer them the boat of their dreams, they made their own. MAMBO was developed using patented continuous fiber technology, an innovative process that combines advanced materials and 3D robot printing to produce strong, powerful, lightweight products with no waste.

More news in our Icon Life telegram channel, subscribe to be the first to know!

Parts of the ship were printed using two robots: KUKA Quantec High Accuracy. Located in Milan, at the headquarters of Moi Composites, and in Birmingham, at AMF (Advanced Manufacturing Facility) Autodesk. After printing was completed, the parts were joined and laminated at the Catmarine shipyard, creating a one-piece sandwich structure with no separation of hull and deck. The tireless and passionless work of the robots, combined with the skillful and passionate craftsmanship of the shipyard craftsmen, gave birth to a new hybrid industrial system, as technological and digital as analog and manual, which today makes the impossible possible.

At 6.5 meters long and weighing 800 kg, MAMBO would be impossible to create in the traditional way. The advanced technology of Moi Composites proves that both real and fantastic products that were previously unimaginable can now be 3D printed anytime, anywhere and in any shape.