Aon 3d printer review

AON M2+ High Temp Industrial 3D Printer

The M2+ is the fastest and most affordable way to get strong, high-performance parts in the hands of engineers and designers. The AON M2+ drives value chain efficiency, from product development to manufacturing.

Achieve the Best Final Part Properties

Achieve high crystallinity parts, reduce part porosity, and more with precision thermals and advanced process controls.

→ Configurable Process Parameters

→ Actively Heated Build Volume

→ Water-Cooled Hot Ends

High-Crystallinity, Low Porosity Parts — Achieve close to zero porosity and high in-situ crystallization through careful extrusion control, configurable process parameters, and optimized thermal management.

Create Large Functional Parts

Print full scale designs in the world’s most advanced thermoplastics. A massive 114,412 cm³ heated build volume enables full-scale additive manufacturing.

→ Open Materials Format

→ Largest-in-Class Build Volume

→ Composite-Ready Extruders

-

?>

Production Ready Printing

Print more, reliably and repeatably, and reduce time consuming post processing.

→ No Fuss First Layers

→ Independent Dual Extruders

→ Access Sensor Data

Get a Quote

Key M2+ Features

Download Spec Sheet

Key M2+ Features

01

Remote Access Wi-Fi

Disconnectable upon request

02

Configurable Process Parameters

03

Dual Independent 500ºC+ Extruders

04

Stainless Steel Extruders Carbon/Glass Fiber-Ready

05

Swappable Print Surfaces

06

Heated 200ºC+ Print Bed

07

Largest In-Class Build Volume 450 x 450 x 640 mm

08

Actively Heated 135ºC+ Build Chamber

Download Spec Sheet

Open Materials, Infinite Applications

Print high-performance polymers with better strength to ratio than aluminum, economical prototyping materials, and polymers capable of withstanding the harshest environments.

The AON M2+ manufactures parts that meet or exceed functional requirements, unlocking additive potential across the value chain.

The AON M2+ manufactures parts that meet or exceed functional requirements, unlocking additive potential across the value chain.

Part Properties

Materials

Applications

Achieve a wide range of part properties

High Strength

Print materials with higher strength-to-weight ratio than aluminum. The PAEK family of materials, PEI, and PPSU offer the highest mechanical and thermal properties of all currently available filaments.

Materials: PEEK, PEKK, ULTEM™ 9085, PPSU

Impact Resistant

Full-density 3D printed parts have been tested up to 50,689 J/m2 in a single direction via ASTM IZOD Type E tests with a 2.7J pendulum.

Materials: PC, PA66

Biocompatibility

Print high-strength, durable, biocompatible and skin contact safe parts suitable for a wide range of medical applications. In addition, implant-grade materials, such as PEEK, have proven low cytotoxicity, genotoxicity, and immunogenic properties.

Material: PEEK

Sterilizable

High-strength materials, like PPSU, provide exceptional heat, radiation, and chemical resistance enabling the material to be treated with EtO gas, radiation, autoclaving, plasma, dry heat and cold sterilization

Materials: PPSU

Heat Resistant

Print strong, engineering-grade materials that can operate in temperatures up to 120º C for extended periods of time. For extreme temperature applications, materials like PEEK provide heat deflection up to 159°C and can withstand extended exposure in temperatures up to 260°C.

Materials: PEEK, ULTEM™ 9085

Flame, Smoke, Toxicity (FST)

Print heat and flame resistance parts (FAR25.853, UL 94 V-0) with desirable flame, smoke, and toxicity (FST) characteristics, and with supporting UL Blue Card certifications.

Materials: PEEK, ULTEM™ 9085

Chemical Resistance

Create high-strength, high-heat parts resistant to most organic and inorganic chemicals.

9 Ohm. ESD safe materials come in a variety of affordable, engineering-grade polymers, as well as high performance polymers.

9 Ohm. ESD safe materials come in a variety of affordable, engineering-grade polymers, as well as high performance polymers. Materials: 10+ options

Abrasion & Wear Resistance

Print parts with low friction, self-lubricating, and high wear / abrasion resistance properties. Find affordable and versatile materials for a wide range of applications such as gears, bearings, nuts, washers, and structural components in demanding environments.

Materials: POM, PEEK, PVDF, PA

Affordability

Print high-quality materials up to 700% cheaper than comparable proprietary filaments. In addition, the AON M2+ does not require material licenses or upgrades to print new materials.

Carbon Fiber & Glass- Filled Composites

Print parts with increased strength, stiffness, and improved dimensional stability across a wide range of thermoplastics.

Materials: 10+ options

More on Materials

Base Polymers

ABS

ASA

Nylon (PA 6, 6/66, 12)

PAEK

PC

PEEK

PEI (ULTEM™ 9085, 1010)

PEKK

PETG

POM

PP

PPSU

PSU

PVDF

TPE

TPU

Composites

CF ABS

CF PA

CF PC

CF PEEK

CF PEI

CF PEKK

CF PETG

CF PP

ESD ABS

ESD PA

GF ABS

GF PA

GF PETG

GF PP

Supports

Aquasys® 120

Aquasys® 180

High Temp Support

HIPS

PEI Support

PVA

More on Materials

Jigs & Fixtures

Tooling

Rapid Prototyping

End-Use parts

Additive

R&D

Materials Development

Explore Sample Parts Printed on an M2+

Aerospace Y-Duct

Heat Resistant + High Strength

ULTEM™ 9085

Details

Aerospace Y-Duct

A high-strength, high-heat material resistant to most organic and inorganic chemicals with the exception of aggressive reagents like fuming sulfuric and nitric acid, methylene chloride.

Size (mm)

105 x 105 x 54

Cost to print

$271.00

Print time

1hr 20m

Savings vs. machining

52.30%

End of Arm Tooling

Affordable + High Strength

CF Nylon

Details

End of Arm Tooling

A high-strength, high-heat material resistant to most organic and inorganic chemicals with the exception of aggressive reagents like fuming sulfuric and nitric acid, methylene chloride.

Size (mm)

105 x 105 x 54

Cost to print

$271.00

Print time

1hr 20m

Savings vs. machining

52.30%

Craniofacial Implant

Biocompatible

Implant-Grade PEEK

Details

Craniofacial Implant

A high-strength, high-heat material resistant to most organic and inorganic chemicals with the exception of aggressive reagents like fuming sulfuric and nitric acid, methylene chloride.

Size (mm)

105 x 105 x 54

Cost to print

$271.00

Print time

1hr 20m

Savings vs. machining

machining

52.30%

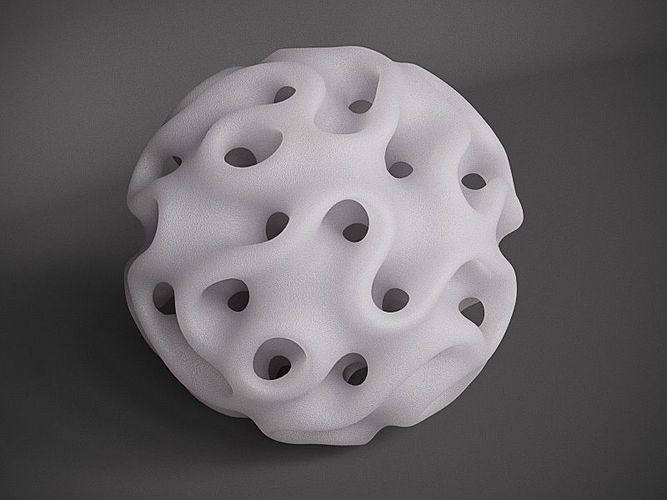

Fluid Mixer

Chemical Resistant

PEKK

Details

Fluid Mixer

A high-strength, high-heat material resistant to most organic and inorganic chemicals with the exception of aggressive reagents like fuming sulfuric and nitric acid, methylene chloride.

Size (mm)

105 x 105 x 54

Cost to print

$271.00

Print time

1hr 20m

Savings vs. machining

52.30%

Layup Tooling

Low Cost + Easy Release

PETG

Details

Layup Tooling

A high-strength, high-heat material resistant to most organic and inorganic chemicals with the exception of aggressive reagents like fuming sulfuric and nitric acid, methylene chloride.

Size (mm)

105 x 105 x 54

Cost to print

$271.00

Print time

1hr 20m

Savings vs. machining

52.30%

PCB Enclosure

ESD Safe

ESD ABS

Details

PCB Enclosure

A high-strength, high-heat material resistant to most organic and inorganic chemicals with the exception of aggressive reagents like fuming sulfuric and nitric acid, methylene chloride.

Size (mm)

105 x 105 x 54

Cost to print

$271.00

Print time

1hr 20m

Savings vs. machining

52.30%

Gear

Wear Resistant

PA

Details

Gear

A high-strength, high-heat material resistant to most organic and inorganic chemicals with the exception of aggressive reagents like fuming sulfuric and nitric acid, methylene chloride.

Size (mm)

105 x 105 x 54

Cost to print

$271.00

Print time

1hr 20m

Savings vs. machining

52.30%

Dimple Die

High Strength

PC

Details

Dimple Die

CNC Dovetail Clamps

High Strength

CF PEEK

Details

CNC Dovetail Clamps

Laparascopic Surgical Scissors

Sterilizable

PPSU

Details

Laparascopic Surgical Scissors

A high-strength, high-heat material resistant to most organic and inorganic chemicals with the exception of aggressive reagents like fuming sulfuric and nitric acid, methylene chloride.

Size (mm)

105 x 105 x 54

Cost to print

$271.00

Print time

1hr 20m

Savings vs. machining

52.30%

Prosthetic Test Fit Socket

Optical Clarity

Transparent PC

Details

Prosthetic Test Fit Socket

AON3D Sample Kit

AON3D Sample Kit

Explore Sample Parts Printed on an M2+

Aerospace Y-Duct

Heat Resistant + High Strength

ULTEM™ 9085

Details

Aerospace Y-Duct

A high-strength, high-heat material resistant to most organic and inorganic chemicals with the exception of aggressive reagents like fuming sulfuric and nitric acid, methylene chloride.

Size (mm)

105 x 105 x 54

Cost to print

$271.00

Print time

1hr 20m

Savings vs. machining

52.30%

End of Arm Tooling

Affordable + High Strength

CF Nylon

Details

End of Arm Tooling

A high-strength, high-heat material resistant to most organic and inorganic chemicals with the exception of aggressive reagents like fuming sulfuric and nitric acid, methylene chloride.

Size (mm)

105 x 105 x 54

Cost to print

$271.00

Print time

1hr 20m

Savings vs. machining

52.30%

Craniofacial Implant

Biocompatible

Implant-Grade PEEK

Details

Craniofacial Implant

A high-strength, high-heat material resistant to most organic and inorganic chemicals with the exception of aggressive reagents like fuming sulfuric and nitric acid, methylene chloride.

Size (mm)

105 x 105 x 54

Cost to print

$271.00

Print time

1hr 20m

Savings vs. machining

52.30%

Fluid Mixer

Chemical Resistant

PEKK

Details

Fluid Mixer

A high-strength, high-heat material resistant to most organic and inorganic chemicals with the exception of aggressive reagents like fuming sulfuric and nitric acid, methylene chloride.

Size (mm)

105 x 105 x 54

Cost to print

$271.00

Print time

1hr 20m

Savings vs. machining

machining

52.30%

Layup Tooling

Low Cost + Easy Release

PETG

Details

Layup Tooling

A high-strength, high-heat material resistant to most organic and inorganic chemicals with the exception of aggressive reagents like fuming sulfuric and nitric acid, methylene chloride.

Size (mm)

105 x 105 x 54

Cost to print

$271.00

Print time

1hr 20m

Savings vs. machining

52.30%

PCB Enclosure

ESD Safe

ESD ABS

Details

PCB Enclosure

A high-strength, high-heat material resistant to most organic and inorganic chemicals with the exception of aggressive reagents like fuming sulfuric and nitric acid, methylene chloride.

Size (mm)

105 x 105 x 54

Cost to print

$271.00

Print time

1hr 20m

Savings vs. machining

52.30%

Gear

Wear Resistant

PA

Details

Gear

A high-strength, high-heat material resistant to most organic and inorganic chemicals with the exception of aggressive reagents like fuming sulfuric and nitric acid, methylene chloride.

Size (mm)

105 x 105 x 54

Cost to print

$271.00

Print time

1hr 20m

Savings vs. machining

52.30%

Dimple Die

High Strength

PC

Details

Dimple Die

CNC Dovetail Clamps

High Strength

CF PEEK

Details

CNC Dovetail Clamps

Laparascopic Surgical Scissors

Sterilizable

PPSU

Details

Laparascopic Surgical Scissors

A high-strength, high-heat material resistant to most organic and inorganic chemicals with the exception of aggressive reagents like fuming sulfuric and nitric acid, methylene chloride.

Size (mm)

105 x 105 x 54

Cost to print

$271.00

Print time

1hr 20m

Savings vs. machining

52.30%

Prosthetic Test Fit Socket

Optical Clarity

Transparent PC

Details

Prosthetic Test Fit Socket

AON3D Sample Kit

Get Yours Today

Contact Sales

Details

AON3D Sample Kit

1 / 12

Request Sample Kit

Bring High Performance 3D Printing In-House

Get a Quote

Not ready for a quote? No worries.

Download the M2+ Spec and Request a Demo.

Learn About High-Temperature 3D Printing

“What’s Next” Pioneering Expandable Space Structures

Sep 29, 2022

•

2 min read

An aerospace company advances the future of space structures with 3D printed composite tooling ProblemConventional manufacturing was cost and time prohibitive for pioneering the field ...

Case Study: Why the Canadian Space Agency Chose 3D Printing

Jul 20, 2022

•

2 min read

Developing functional parts for applications in space is challenging for several reasons From a manufacturing perspective, engineers are faced with unique design constraints and tight deadlines to ...

Jul 12, 2022

•

5 min read

Webinar

3D Printing with PEEK, PEKK, & ULTEM™

Join AON3D's 3D printing application and materials experts for a 30-minute session that covers all the key information

Watch Now

AON3D to Feature High Temperature Duplication Mode at RAPID + TCT

May 10, 2022

•

2 min read

Today, AON3D announced they will showcase High Temperature Duplication Mode at RAPID + TCT, a first for the FFF 3D Printer market It is well known that widespread adoption of Additive . ..

..

AON3D Doubles High Temperature 3D Printer Output with Duplication Mode

Mar 10, 2022

•

1 min read

Today, Montreal-based AON3D announced their AON M2+ High Temperature Industrial 3D Printer will be receiving an optional firmware upgrade to enable Duplication Mode and Mirror Mode 3D printing This ...

New Validated Materials for AON3D Printers – March 2022 Update

Mar 1, 2022

•

2 min read

The AON3D line of high temperature industrial 3D printers, currently in their 5th generation, are designed to 3D print nearly any thermoplastic currently available on the market To provide an easy ...

Calculator: Finding the ‘reel’ cost of volumetric filament pricing

Feb 18, 2022

•

2 min read

The cost of materials are an important factor when calculating a 3D printer's total cost of ownership Closed material systems, especially for industrial 3D printers, often mark up the cost of their . ..

..

Shrinkage, Residual Stress and Poor Layer Welding in 3D Printing

Feb 10, 2022

•

6 min read

Additive manufacturing has been celebrated as a revolution in manufacturing technologies, with applications ranging from low-cost prototypes to high performance end-use parts But the merits of 3D ...

3D Printer Material Property Comparison Tool

Jan 24, 2022

•

15 min read

Final part properties are extremely important in additive manufacturing They dictate how AM can be applied, overall program success, and return on investment Below, find just a few of the 100's of ...

3D Printing Speeds Show-Ready Parts for Ford Booth

Dec 13, 2021

•

1 min read

Nov 2021, Las Vegas, Nv – Ford Motors showcased several custom vehicles at the 2021 SEMA show but one of the most impressive, a highly customized Ford Mustang Mach-E GT built with EV speed records . ..

..

Replacing Metals with 3D Printed Polymers

Nov 29, 2021

•

4 min read

Replacing metals with polymers is not only possible but becoming increasingly more prevalent The current generation of high-performance polymers and composites has similar mechanical properties to ...

PEEK and PEKK: How these 3D printing materials compare

Nov 9, 2021

•

4 min read

PEEK and PEKK are two of the highest performance polymers that are printable through fused filament fabrication (FFF) But what gives rise to their unique properties and what differentiates the two ...

CAD to Finished Print: How to 3D Print on the AON M2+

Nov 8, 2021

•

2 min read

Getting started with the AON M2+ is easy With AON3D hardware, customers enjoy access to on-demand polymer focused PhDs, applications engineers, and hardware support In addition, the AON3D . ..

..

Choosing a 3d printer for the home. Category Archives: Tests, Comparisons & Reviews

TOP 10 CAD Software for 3D Printing The software you should use when designing a 3D print depends entirely on its nature. The complexity of your object will influence your final choice. In general, modeling software can be divided into two categories: CAD software and 3D modeling software. In most cases, CAD software will be used…

TOP 12 Inexpensive 3D Scanners Introduced in the late 1970s, laser triangulation technology paved the way for the first devices capable of digitizing objects in 3D. This tool, long reserved for industrialists, has gradually become so popular that we are now finding affordable 3D scanners that are easy to use. From Einscan-SE by Shining 3D to Ciclop by BQ, find our TOP 12 low cost… about the appearance in its portfolio of 3D technologies that do not require the use of markers, a novelty - the Artec Ray scanner. The new 3D scanner digitizes large objects with metrological, submillimeter accuracy and minimal noise levels –…

AON3D Launches AON-M2 Professional 3D Printer Canadian 3D printer company AON3D has launched a new AON-M2 3D printer, a large-format, high-temperature 3D printer for printing with refractory engineering thermoplastics. The machine is aimed at professional users. The AON-M2 features best-in-class thermal performance, adaptive build surface calibration, and a host of other features to create remarkably strong parts. Full feature list: High performance…

The machine is aimed at professional users. The AON-M2 features best-in-class thermal performance, adaptive build surface calibration, and a host of other features to create remarkably strong parts. Full feature list: High performance…

EinScan-SE 3D Scanner Overview Shining 3D's EinScan-SE 3D is a high quality 3D scanner at a reasonable price. Check out our review of the EinScan-SE 3D Scanner to learn more about it! In our articles, we love to talk about new 3D printers, test and tune them. But from time to time, it's important to take a look at the technologies that complement and enhance 3D printing. One of them, of course, is…

Effect of Layer Height on 3D Printing All 3D printing processes build parts in stages. Due to the additive nature of 3D printing, the thickness of each layer determines the resolution of the print in the same way that the number of pixels determines the resolution of a television or computer monitor. The height of the bottom layer usually results in parts with smoother surfaces. The disadvantage is that the lower the layer height, the longer it takes to print. It is important for a designer…

The disadvantage is that the lower the layer height, the longer it takes to print. It is important for a designer…

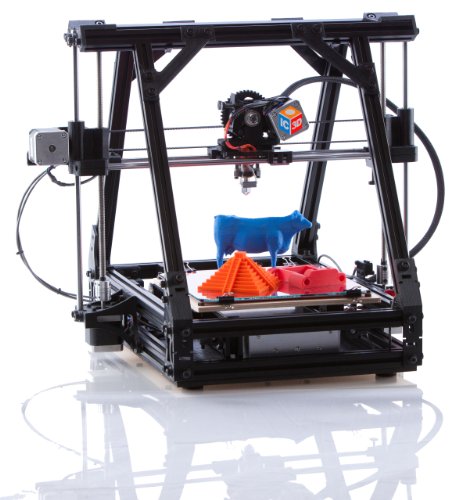

For beginners: 3D printing steps 3D printing, also known as additive manufacturing, is the process by which solid objects can be created from digital files. This can be achieved using various 3D printing techniques. Most of these methods are associated with the creation of an object by sequential deposition of thin layers. Below we will reveal the contents of the stages of 3D printing using the most common technology as an example ...

9 best 3D printers Devices that perform 3D printing have long ceased to amaze. Many people know about their abilities, as well as the fact that the scope of this technique is quite wide. These are not only all kinds of scientific laboratories and paramilitary facilities, but also creative workshops, design bureaus, and even private users. At the same time, despite the fact that demand…

It is, in fact, a machine with numerical control for the manufacture of parts from polymer materials.

The size and shape of the part, the possible layers are set by a special program, the program sends signals to the nozzle, which in turn ejects a certain amount of molten plastic to a certain place, the nozzle can move horizontally and vertically, the program controls the movement. Ultimately, the nozzle, moving and throwing the right amount of molten plastic into certain places, creates a certain part, which is the final product of the 3d printer.

Currently, 3d printers are mass-produced by various companies, they have found application both in everyday life and in industry.

What features should I look for when choosing a printer?

1. Print functions

The main functionality includes such parameters as the maximum print size of an object, print speed, accuracy tolerances. Now we can say that the standard for printing the maximum size is formed by size: 22.86x22.86x22.86cm.

If your print object is larger, then it will have to be divided into components that fit into the specified size.

Speed is inversely proportional to print quality or accuracy, tolerances, resolution.

The printer prints (creates a part) in layers, the smaller the layer, the higher the accuracy and the lower the speed.

Currently, the middle layer is 0.1 mm, which corresponds to the size of the extruded filament of the printing substance.

2. Cartridges

The most common 3D printed materials are ABS (acrylonitrile butadiene styrene) and PLA (polylactic acid).

ABS is similar to the material Lego blocks are made from.

ABS has a characteristic smell, this must be taken into account in the sense that when printing at home or in the office, the room will be filled with this smell.

PLA comes in a wide variety of colors.

Some of the plastic 3D printers on our list can handle nylon, Play-Doh, and other experimental materials.

The number of printheads, or extruders, on a color 3D printer reflects the ability to print simultaneously, which affects the overall print speed.

Printers with one print head can only print one color.

3. Printer design

3d printer can have a metal or plastic body base. Printers with metal cases are heavy, but they are resistant to micro-vibration, which partly improves the print quality.

4. Help and support from the manufacturer, warranty

Some printers are not currently under warranty. Pay attention to the forms of contact with the support service, at least it should be email and phone, the more forms of contact with the support service, the easier it is for you to get an answer to your question about the operation of the 3d printer.

5. Compatibility and connections

Some 3d printers have a built-in processor, but you must buy a monitor, keyboard and mouse to go with it. Some printers are designed to work with a separate computer, pay attention to the methods of communication with a PC. As a rule, and at a minimum, this should be a USB connector.

Some printers require you not to turn off the PC until the end of printing, some printers save information on their storage device and turning off the PC during printing is possible.

6. Accessories

Pay attention to the scope of delivery, namely the presence of cables with USB connectors? charger or power supply.

An important point is the availability of software that comes with the printer, it can be designed for beginners and easy to use, or it can be designed for professionals.

Touch 3D printer

This is an extruder-type printer (an extruder is a machine for softening (plasticizing) materials and shaping them by forcing through a profiling tool (the so-called extrusion head), the cross section of which corresponds to the configuration of the product). Files are printed from a flash drive, and there is also a touch interface. The device has an exceptionally large printable area of 27.5x 27.5x 21 cm.

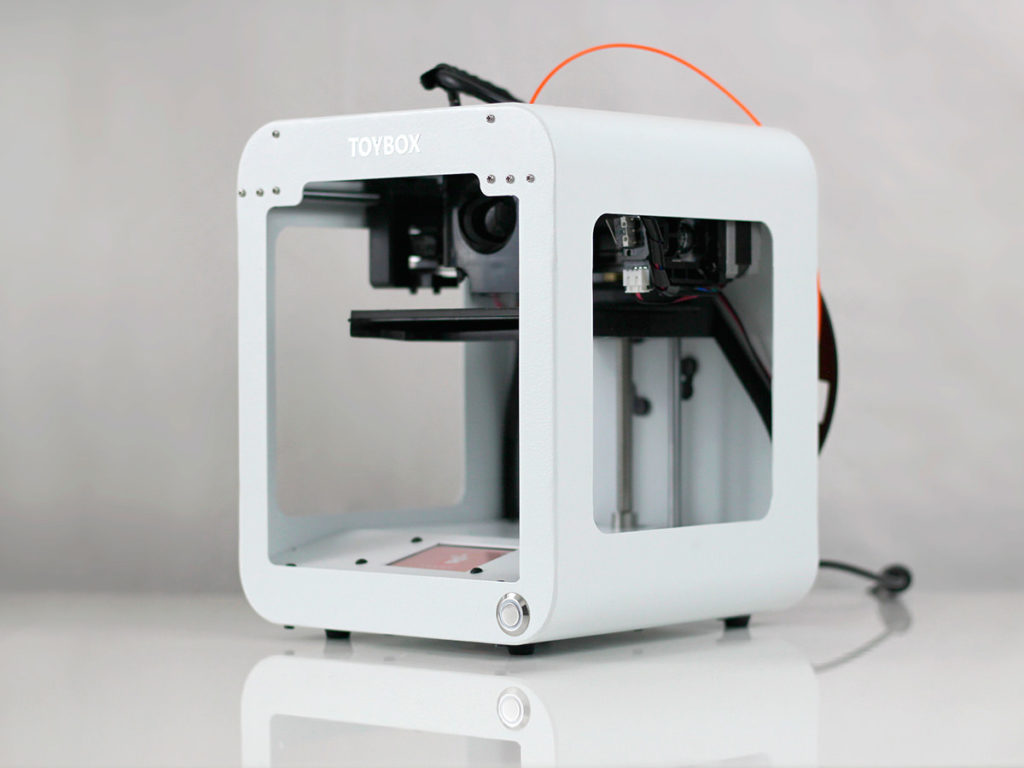

CB printer

Portable printer. Will fire models up to 20 x 26 x 18 cm albeit slowly at 100mm/min. Two nozzles are available in 0.3mm and 0.5mm. These machines have been available since summer 2012.

Only a prototype so far, so excuse the photo, but the model is listed for and cool: File2Part Gutenberg is the first full color printer for the hobbyist. Future plans include the use of chemicals in inkjet printing prior to plastic processing, which will give the product a variety of flexibility, all within a single printer model. The machine is able to create things up to 13.6 x 13.6 x13.6 cm.

A highly anticipated stereolithography printer for beginner hobbyists. Product dimensions are 12.5 x 12.5 x 16.5 cm. The model's dual extruder prints in two colors but cannot mix them. The maximum build size is 28.5 x 15.5 x 15.3 cm.

This is a Bugatti Veyron desktop priced at just under £100,000. What makes Connex really special is that it can jet two materials at the same time, which means you can mix colors, although the choice of colored resins is limited. One object can have 14 levels of flexibility. Assembly size 34.2 x 43.2 x 20 cm.

Budget 300 lb 3D printer model: the device works with low melting points. The model is made of wood. . There is a portable version for those looking to save space, although it costs more because it runs on batteries. One can only guess what you would like to produce if, say, you took it on a plane as hand luggage. The maximum assembly size is 11.4 x 14 x 10.2 cm.

The model is made of wood. . There is a portable version for those looking to save space, although it costs more because it runs on batteries. One can only guess what you would like to produce if, say, you took it on a plane as hand luggage. The maximum assembly size is 11.4 x 14 x 10.2 cm.

Stratasys Mojo 3D Printer

This device is out of reach for hobbyists as it is an industrial printer. The print resolution is 0.17 mm and the maximum object size is 12.7 x 12.7 x 12.7 cm. Build speed isn't great, but for an inexpensive entry into the market for someone with decent engineering skills, this is a great place to start.

Up! 3D Plus

One of the simplest 3D printers, but steel and quite reliable. It is possible to build objects with a layer thickness of 0.2, 0.25, 0.35 and 0.4 mm. No built-in memory, no warning lights other than LEDs that flash when the temperature has risen. The output quality is excellent for such a cheap model, perhaps due to the relatively slow print speed. The included software calculates the estimated print time and the amount of materials required for a job. For a budget printer, I get quite large models with sizes up to 14 x 14 x 13.5 cm.

The included software calculates the estimated print time and the amount of materials required for a job. For a budget printer, I get quite large models with sizes up to 14 x 14 x 13.5 cm.

Leave your comment!

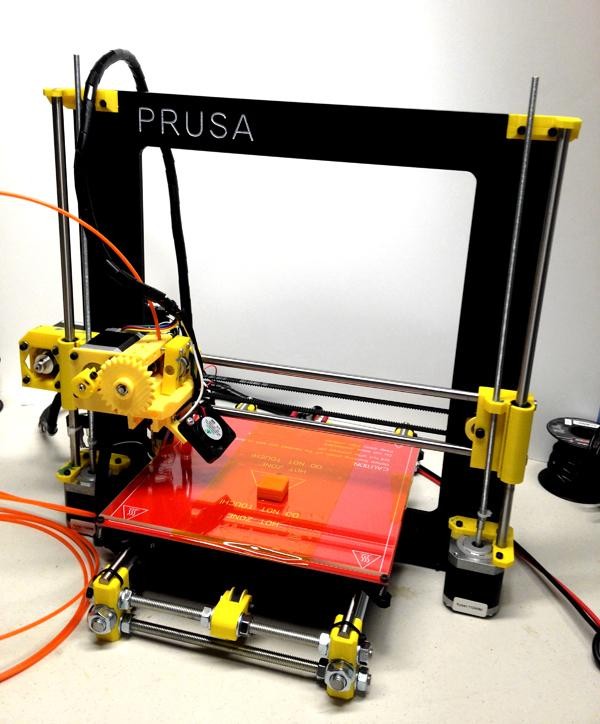

The period of formation of any new industry generates a lot of concepts and their practical implementations. Three-dimensional printing has become widespread only in recent years, and it is still quite difficult to predict the prospects of a particular technology. To date, the largest representation in the "home" segment of this market is 3D printers with layer by layer deposition (FDM) , and the complex geometry of increased accuracy can be realized stereolithography (SLA) . At the same time, already within the framework of these technologies, there is also a competitive struggle for a place under the sun. More precisely, a kind of differentiation according to "niches".

How to choose a good 3D printer?

Types of 3D printers

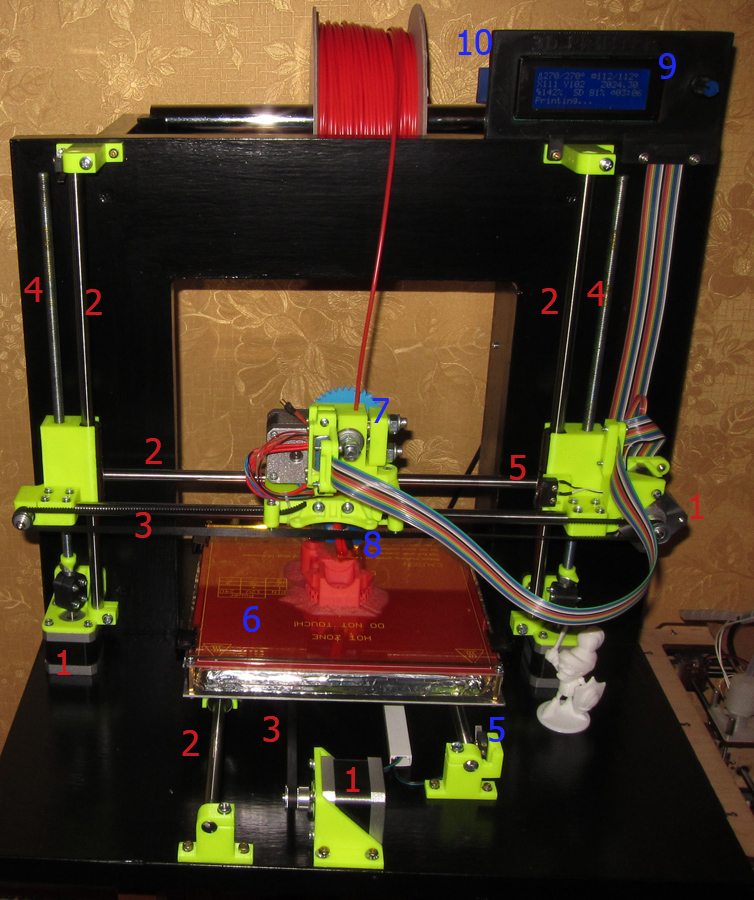

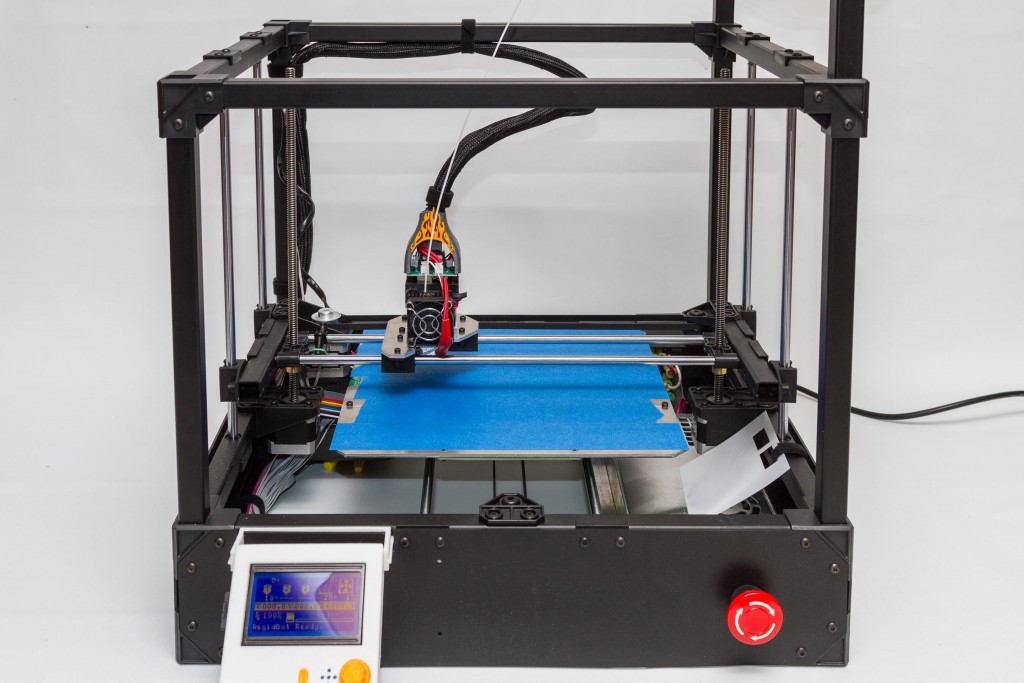

Fused 3D printers is usually classified according to the types of implemented kinematic scheme.

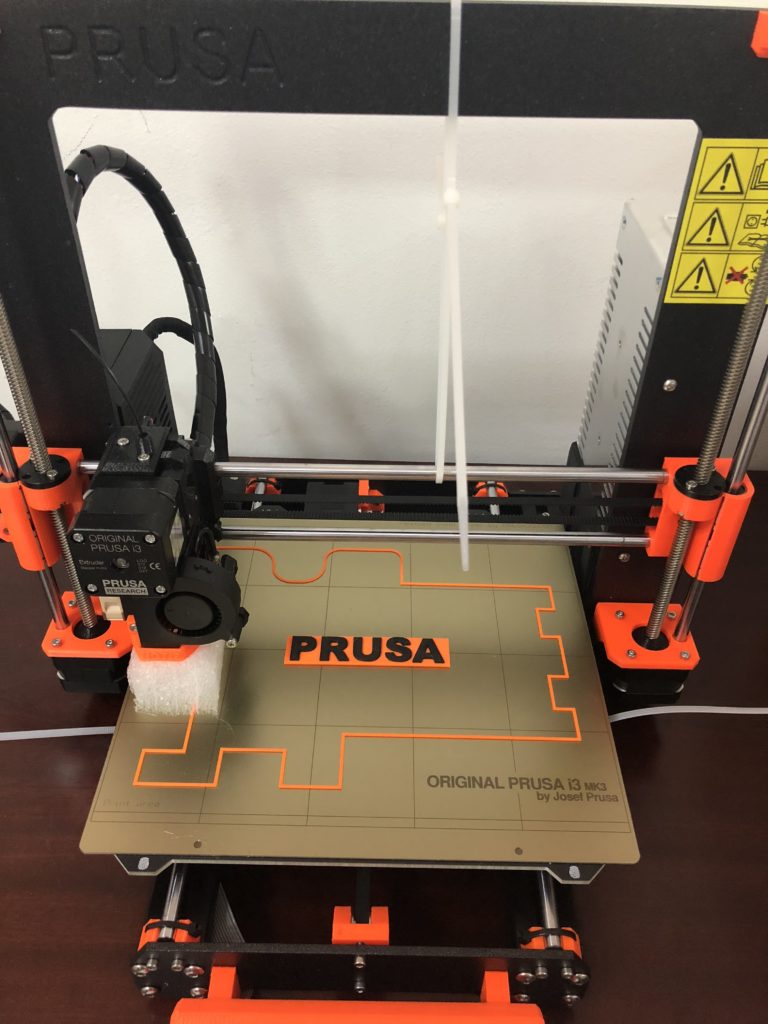

- With table moving horizontally (designed by Josef Pryusha). The most simple and affordable. Due to objective reasons, they have low accuracy and limitations on the types of plastic used due to the difficulty of ensuring the desired temperature regime.

- With table that moves vertically only (H-bot, CoreXY, Ultimaker and variations). Each subspecies has its advantages and disadvantages, but in general, 3D printers of this class print better than the first ones, have good potential for improvement and support all the existing variety of modern plastic (theoretically).

- Delta printers and robots . The fastest of the FDM models, but with very high requirements for frame rigidity, manufacturing accuracy of supports and guides, the weight of the moving part, the power of the "brains", etc.

First stereolithographic printers was based on the technology of polymerization of a special resin under the influence of laser radiation of a certain wave and cost a lot of money. In principle, over the past couple of years, the situation has changed only in relation to the price of photopolymers. The indisputable advantage of this category of devices is the high printing accuracy, sufficient for master modeling, jewelry business and elite dentistry.

In principle, over the past couple of years, the situation has changed only in relation to the price of photopolymers. The indisputable advantage of this category of devices is the high printing accuracy, sufficient for master modeling, jewelry business and elite dentistry.

The second, no less important aspect of the quality of 3D printing is the materials used. For FDM printers, their diversity is an order of magnitude higher. What is worth only a large group of engineering plastics: glass- and carbon-filled, refractory, conductive, flexible, etc. Naturally, all this wealth works correctly only if the necessary temperature conditions are observed during the printing process, which is achieved mainly in closed cube-type structures.

In the camp of photopolymers, things are even sadder, since their assortment is much more modest. In addition, the print time depends on the color of the material (wavelength), and the difference is really impressive. Well, the price tags are relatively humane here can only be called "consumer goods". At the same time, the pace of development of this category of consumables is higher, as is the dynamics of their cost reduction.

At the same time, the pace of development of this category of consumables is higher, as is the dynamics of their cost reduction.

In our review, we tried to cover all popular areas of conditionally home 3D printing as of the end of spring 2019of the year.

PEEK 3D printer overview

Contents:

- Introduction

- Material Features PEEK

- Professional and industrial 3D printers

- Apium P220

- TOTAL Z Anyform 500-PRO HOT+

- Creatbot PEEK-300

- AON3D M2 2020

- IEMAI Magic HT Pro

- TSAR 3D TS547-PEEK

- Tractus T850P

- Stratasys F900 Pro

- Conclusion

Introduction

PEEK material is widely used in traditional manufacturing, but it is also used in some 3D printers. The thermoplastic polymer offers impressive mechanical properties including high temperature performance, mechanical strength and excellent chemical resistance. These properties make it popular in additive manufacturing, especially for metal replacement.

These properties make it popular in additive manufacturing, especially for metal replacement.

It would be a crime to ignore such a versatile polymer, and 3D printer manufacturers have not ignored it. With the development of additive technologies, 3D printers that print, among other things, with PEEK material, are becoming more accessible not only for large-scale industries with large budgets, but also for medium and small businesses and even for private clients. From PEEK it is convenient to print prototypes of future metal products and even final products that will immediately go to work. The market for printing with engineering materials is constantly expanding, which invariably causes two consequences: a decrease in the cost of the installation itself and an increase in its build chamber.

PEEK material features

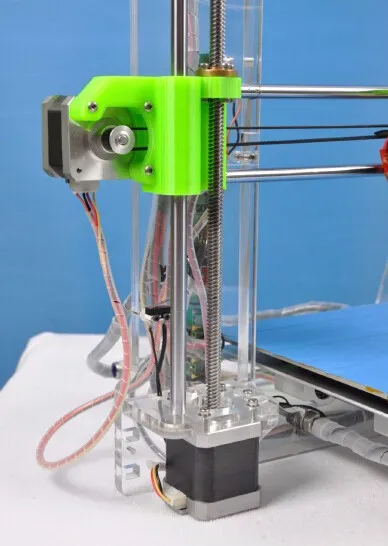

To print PEEK, the printer must have 3 important features:

- High temperature extruder

The melting point of PEEK is 343° C. This means that the extruder must be heated to at least this temperature, and in fact to a higher temperature. The hot end of the extruder must also be all-metal and resistant to abrasives.

This means that the extruder must be heated to at least this temperature, and in fact to a higher temperature. The hot end of the extruder must also be all-metal and resistant to abrasives. - Heated print bed

For printing high performance resins, a heated bed is required, which must be heated to at least 120° C. This ensures the correct adhesion of the first layers and the overall quality of the 3D print. - Closed heated chamber

PEEK is very prone to shrinkage and warpage. Ideally (and this is especially important for large parts), the printer should have a closed chamber and maintain the temperature in it at 143 ° C, i.e. glass transition temperature of PEEK. Otherwise, the product will delaminate after printing.

It is extremely important to control these temperatures and keep them constant, as fluctuations can ruin the print.

Using their experience, our company's engineers have compiled a list of modern 3D printers capable of printing with PEEK and other refractory plastics. If you are planning to get acquainted with printing with engineering plastics or start production using 3D printing, we offer our TOP printers in 2020.

If you are planning to get acquainted with printing with engineering plastics or start production using 3D printing, we offer our TOP printers in 2020.

Professional and industrial 3D printers

Apium P220

I would like to start with the Apium P220 printer. Apium is one of the first printers to print with PEEK, the benchmark in print quality in the industry. The manufacturer deliberately does not increase the print chamber, as is fashionable with other manufacturers, in favor of the quality of the resulting products. The

P220 is classified as a professional printer only because of its small size and low noise level, in fact, in terms of print quality and technologies used in the installation, this printer can be safely called industrial. The printer produces all the required temperatures: the extruder is heated up to 540° C, the table - up to 160° C, and the temperature in the chamber can be stably maintained at 180° C. Build area 205x155x150mm

In addition, the printer has a unique technology for maintaining the temperature in the print area, thus allowing the lower layers already printed to cool down a little. This approach as a result increases the accuracy of printing, adhesion between layers and improves the controllability and predictability of the entire process. Even the smallest details are printed perfectly.

This approach as a result increases the accuracy of printing, adhesion between layers and improves the controllability and predictability of the entire process. Even the smallest details are printed perfectly.

TOTAL Z Anyform 500-PRO HOT+

Undoubtedly the best domestic industrial printer that prints with engineering plastics. There is a large insulated build chamber measuring 500x500x500mm and the ability to maintain a temperature of 300°C, which is even redundant for PEEK printing. The basic printer is equipped with one extruder with a working temperature of 500 ° C, optionally you can install another one of the same.

The printer fits through a 900mm doorway, which in turn means it will fit in almost any lab or office.

Creatbot PEEK-300

PEEK 300 is a 3D printer from Chinese manufacturer Creatbot. It offers a lot of features that are usually found only in more advanced industrial-grade 3D printers. Thanks to the high temperature extruder and closed chamber, this machine can print consistently good results on both PEEK and PEI. The extruder is heated up to 500°C, and the platform - up to 200°C, constantly maintained temperature in the chamber - up to 120°C.

The extruder is heated up to 500°C, and the platform - up to 200°C, constantly maintained temperature in the chamber - up to 120°C.

It also has a low filament sensor to alert the user when the filament is about to run out. In addition, it is equipped with the function of baking the product directly in the build chamber. The printer has an impressive build area of 300x300x400 mm.

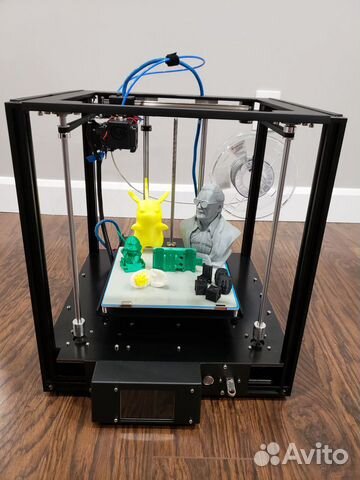

AON3D M2 2020

Aon-M2 2020 is one of the largest printers, the build area has dimensions of 454x454x640 mm and allows you to print complex tooling, cases and many other large format products.

Aon-M2 2020 is designed for printing on high performance thermoplastics such as PEEK, PEKK, ULTEM. It is compatible with many material brands including Solvay, Sabic, DSM, Infinite Material Solutions and more and comes with proven print profiles for them. This printer has two independent extruders, one for printing polyetheretherketone (PEEK) parts directly, the other for printing supports.

Despite its size, the printer is up and running in less than 15 minutes.

IEMAI Magic HT Pro

Another Chinese-made printer. The unit has all the necessary kit for printing PEEK plastic and fits easily on the desktop. The printer is also the most budget-friendly in the line of high-temperature printers. The size of the construction area is 310x310x480 mm, with a maximum temperature in the chamber up to 120° C.

The unit is perfect for the production of product prototypes.

TSAR 3D TS547-PEEK

Another domestic printer, which, according to the manufacturer, allows you to print PEEK plastic. The printer has an impressive build area and supports the ability to print with any plastic available on the market.

The printer stands out with a patented extruder change mechanism that allows you to change the extruder in less than a minute. You can even add a pellet extruder to the printer.

Tractus T850P

The Dutch company Tractus 3D specializes in the development of Delta printers. In fact, the T850P is the only delta printer on the market that prints with engineering plastics. This FDM printer has a build area of 550x476x1140mm and is great for the office. It can process materials such as PLA, PEEK and ULTEM. The T850 extruder heats up to 450°C and the platform heats up to 175°C. According to the manufacturer, the extruder requires less than 90 seconds to warm up to operating temperature. The T850P can print at speeds up to 450 mm per second with a resolution of 10 microns.

In fact, the T850P is the only delta printer on the market that prints with engineering plastics. This FDM printer has a build area of 550x476x1140mm and is great for the office. It can process materials such as PLA, PEEK and ULTEM. The T850 extruder heats up to 450°C and the platform heats up to 175°C. According to the manufacturer, the extruder requires less than 90 seconds to warm up to operating temperature. The T850P can print at speeds up to 450 mm per second with a resolution of 10 microns.

The printer is equipped with a filament dryer, which is also unique to delta printers.

Stratasys F900 Pro

The F900 is an industrial 3D printer manufactured by FDM patent holder Stratasys. Currently the largest PEEK printer. The printer works only with Stratsys materials, but it gives the user guaranteed print quality right out of the box, there is no need to test and configure the printer for each new spool.

The printer software provides a preview of the model. The printer has a built-in video camera with which you can monitor printing in real time. The build chamber size is 914x609x914 mm.

The printer has a built-in video camera with which you can monitor printing in real time. The build chamber size is 914x609x914 mm.

Conclusion

In conclusion, I would like to say that despite the apparent similarity, each printer has its own unique set of functions and purpose. This once again proves that the printer must be selected based primarily on the planned tasks.

If you have any questions about printing PEEK plastic, we will be happy to answer them.

Buying a PEEK printer from our company you get 20% discount on filament. You can choose a printer at the link: https://topstanok.ru/oborudovanie_dlya_3d_pechati/professionalnye_3d_printery/f/materialpechati-2098/

At TopStanok you can order not only equipment for printing with engineering plastics PEEK and ULTEM, but also printing products from engineering plastics. plastics to order. Turning to our company, you get an engineering study, assistance in the selection and operation, as well as an official manufacturer's warranty!

Read our other articles about engineering plastics and PEEK printing:

- Features of printing with PEEK plastic

- Printing with PEEK and ULTEM (PEI) engineering plastics

For all questions, our specialists will be happy to advise you, you can contact them in any convenient way: