Amsterdam 3d printing

3D Printing Service Amsterdam | Instant Quotes Online

Our 3D printing capabilities

We have over 90 3D printing shops in our network and are well known for manufacturing high-quality parts at competitive prices, from rapid prototyping with Fused Deposition Modeling (FDM) to functional end parts made with Selective Laser Sintering (SLS) or Multi Jet Fusion (MJF).

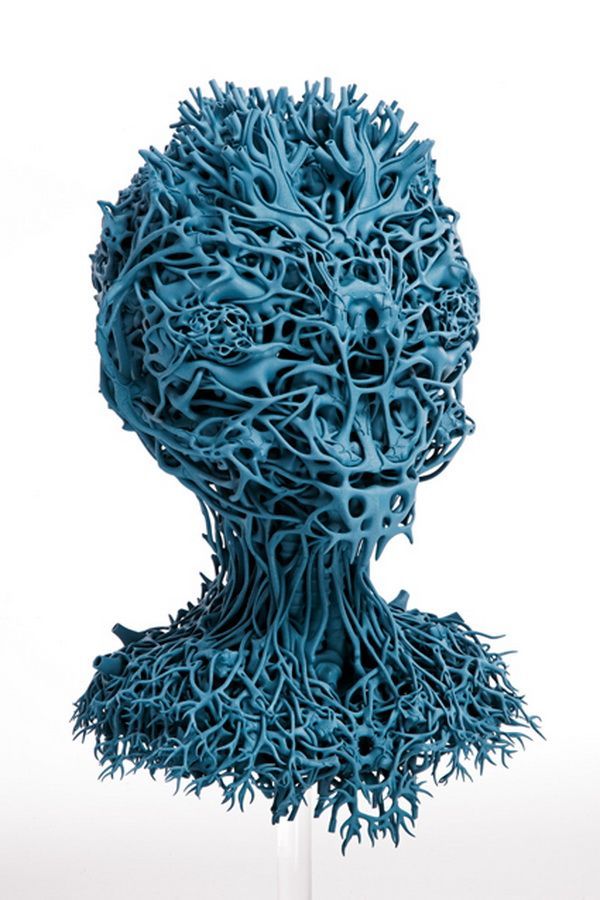

Gallery of 3D printed parts manufactured by Hubs

With over 65,000 customers from every industry, including aerospace, defense, robotics, medical, machinery, automotive and electronics, we have extensive experience meeting a diverse range of 3D printing requirements, from prototyping to production: Visual aids, concept models, injection-molding prototypes, form-fit & function prototypes, tooling and casting patterns, jigs, grips and fixtures, and durable end parts.

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

Instant, online 3D printing quotes

-

Upload a CAD to start (STEP, STP, IGES, IGS, SLDPRT, 3DM, SAT, STL, OBJ or X_T)

-

Price updates in real-time as you change materials, lead time, etc.

.

. -

No hidden costs. Our instant quotes are not just indications, but the actual price, and include shipping and customs up front.

Learn about how our quoting algorithm works

Our ordering process

Receive instant quote

Upload your CAD to our online quoting platform

Confirm specs

Configure your part specifications and select a lead time that suits your schedule

Production

We select the best manufacturer for your order, and production begins immediately

Quality control

We take full responsibility for making sure your parts are manufactured according to our standards

Delivery

Our 3D printing service has been rated 4.9/5

Over 228 customers are satisfied with our 3D printing service.

“Perfect print and very fast turn around time. Will definately use again.”

“As always fast, precise printing, pro advice and prompt communication. 100% recommended!”

“Great fast service and good print quality!”

“Eerste een printje ontvangen waar ik niet geheel tevreden mee was, daarna netjes een nieuwe opgesruurd gekregen die wel goed was. Thanks!”

“Super fast! (Much faster than promised). Print quality is good.”

“great job, very good quality, big thank you !”

“very helpful, good communication and fast printing. Thanks!”

“My experience was very good. The service super fast, I got it in one day only, without any advance. The personal was really kind with me, ready to answer to all my question, available and really helpful. The quality of the print was perfect and the price are really cheap!! Really recommended!!!”

“Quick turn-around and the parts came out as well as expected.”

“Excellent service and quality, communicated well to confirm the same !”

“Fantastic service and step by step update on the status. Very impressed.”

Very impressed.”

“Excellent communication and print quality.”

“Great service! one of the prints broke, but he repaired it and gave me a second print free! the parts worked better than expected, and the delivery went smooth. All in all, nothing to complain about!”

“Prompt service, communication and delivery. Was everything we were looking for!”

“Fast service, thinks along and good quality”

“Good quality and amazingly fast communication and turnover. I definitely recommend it and will use this service again!”

“de prints waren top....kan iedereen aanraden om hier je prints te laten printen”

“Doing the job as you would like to expect. Quality is good.”

“Fast, reliable, good communications, flexible pickup time”

“Good quality, delivers on time and overall good experience.”

“Great service. I definitely will come back ”

“Quick and clear communication. Quick delivery.”

“Op korte termijn een print van formaat laten maken, erg tevreden over de kwaliteit en de vriendelijkheid waarmee je geholpen word. ”

”

“Good communication, fast printing! TOP!!!”

“Superb communication and smooth delivery just before the holidays!”

Show more reviews

Show less reviews

Teams build better parts

Create your Hubs team and start collaborating

Read more

The Hubs Standard - consistent quality, every time

Hubs takes the stress out of manufacturing by guaranteeing the quality and consistency of every part. Each order is dimensionally and visually inspected to make sure it meets the Hubs Standard.

3D printing materials

We can generate instant 3D printing quotes for 25+ plastics. For metal 3D-printed parts, you can request a quote from our parent company, Protolabs.

Available materials

SLS

PA 12 Glass filled PA 12

Desktop FDM

Prototyping PETG Prototyping ASA Prototyping TPU Prototyping ABS Prototyping PLA

Desktop SLA

Formlabs Standard Resin Formlabs Clear Resin Formlabs Tough Resin 2000 Formlabs Rigid Resin 4000 Formlabs Grey Pro Resin Formlabs Flexible Resin 80A Formlabs High Temp Resin Formlabs Durable Resin

MJF

HP PA 12 Glass filled HP PA 12

Industrial FDM

Markforged Onyx ABSplus Stratasys ULTEM 9085 Stratasys Stratasys ASA ABS M30 Stratasys ULTEM 1010 Stratasys

Industrial SLA

Accura 25 (PP-like) Accura ClearVue Accura Xtreme White 200 (ABS-like)

3D printing locations near Amsterdam

Nieuwegein Utrecht Zeist

Hilversum Amsterdam Dordrecht

Amersfoort Hoofddorp Tiel

Den Bosch

The 3D Printing Handbook

No one understands 3D printing like us - our founders literally wrote the book. Click here to download the sample chapters.

Click here to download the sample chapters.

Buy the book from Amazon

FAQ's

How much does your 3D printing service cost?

The cost of your 3D printed parts depends on factors such as part volume, part complexity, choice of material, which 3D printing technology is used, and if any post processing is required. For more details on these cost factors, see our article on the cost of 3d printing. To check the cost of your 3D printed part, simply upload a CAD (.STL) file and select your material and 3D printing technology to receive a quote within seconds.

How do you guarantee the quality of my prints?

Your parts are made by experienced 3D printing shops within our network. All facilities are regularly audited to ensure they consistently meet the Hubs quality standard. We include a standardized inspection report with every order and offer a First Article Inspection service on orders of 100+ units.

We have partners in our network with the following certifications, available on request: ISO9001, ISO13485 and AS9100.

Follow this link to read more about our quality assurance measures.

How do I select the right 3D printing process for my prints?

You can select the right 3D printing process by examining which materials suit your need and what your use case is.

By material: if you already know which material you would like to use, selecting a 3D printing process is relatively easy, as many materials are technology specific.

By use case: once you know whether you need a functional or visual part, choosing a process is easy.

For more help, read our guide to selecting the right 3D printing process. Find out more about Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF) and Stereolithography (SLA).

How can I reduce the cost of my 3D prints?

In order to reduce the cost of your 3D prints you need to understand the impact certain factors have on cost. The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

Once these have been decided, an easy way to further cut costs is to reduce the amount of material used. This can be done by decreasing the size of your model, hollowing it out, and eliminating the need for support structures.

To learn more, read our full guide on how to reduce the cost of 3D printing.

Where can I learn more about 3D printing?

Our knowledge base is full of in-depth design guidelines, explanations on process and surface finishes, and information on how to create and use CAD files. Our 3D printing content has been written by an expert team of engineers and technicians over the years.

See our complete engineering guide to 3D printing for a full breakdown of the different 3D printing technologies and materials. If you want even more 3D printing, then check out our acclaimed 3D printing handbook here.

We have an extensive range of online resources developed to help engineers improve their capabilities.

Introductory guides

Design guides

Material guides

Applications

CAD & file preparation

Post processing & finishing

Our other manufacturing capabilities

CNC machining

CNC machining

Milling (3-, 4- & full 5-axis), turning and post-processing

-

50+ metals and plastics & 10 surface finishes

-

Tolerances down to ±.0008” (0.020 mm)

-

Lead times from 5 business days

See our CNC machining services

Put your 3D printed parts into production today

Get an instant 3D printing quote

Long-awaited 3D-printed stainless steel bridge opens in Amsterdam

James Parkes | Leave a comment

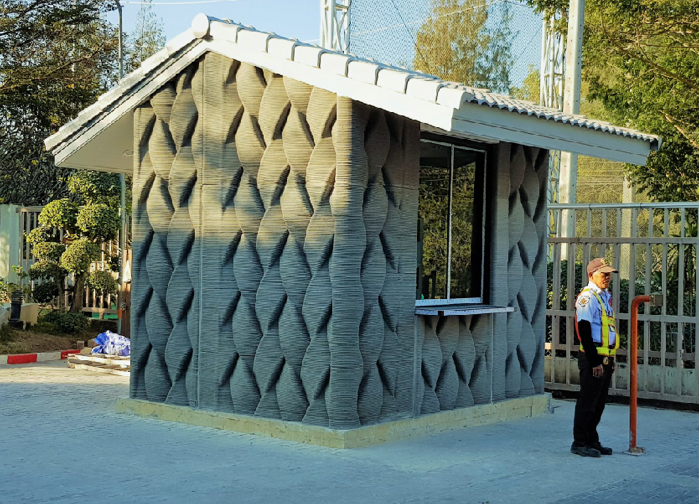

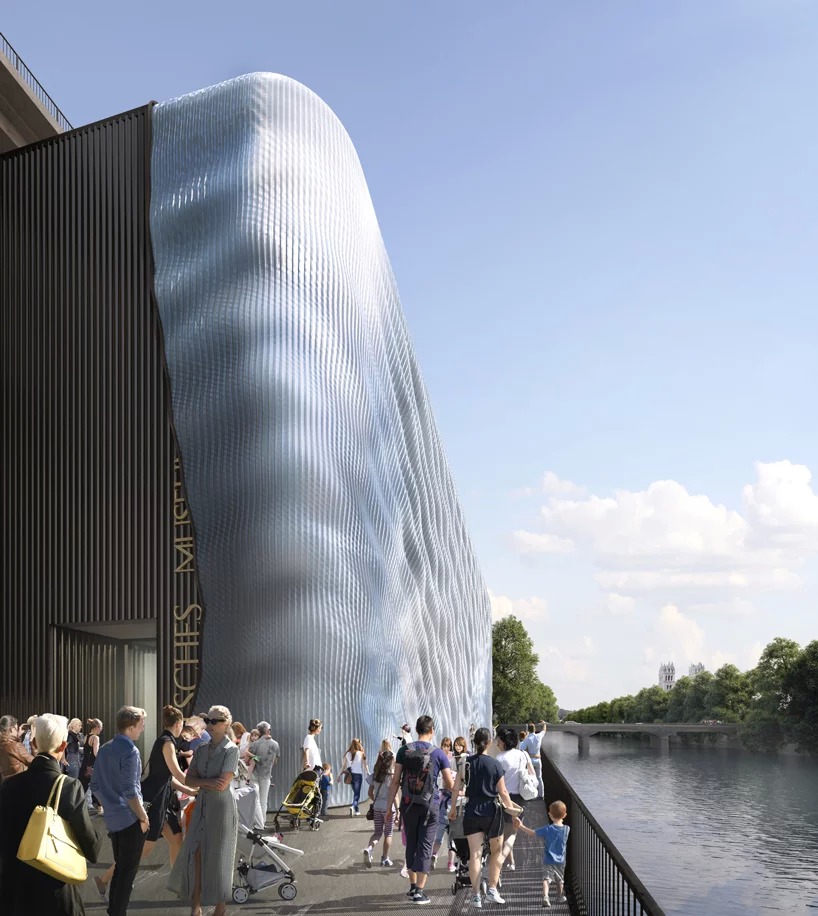

A 12-metre 3D-printed pedestrian bridge designed by Joris Laarman and built by Dutch robotics company MX3D has opened in Amsterdam six years after the project was launched.

The bridge, which was fabricated from stainless steel rods by six-axis robotic arms equipped with welding gear, spans the Oudezijds Achterburgwal in Amsterdam's Red Light District.

Top: MX3D Bridge is located in the Red Light District. Above: it was 3D-printed from stainless steelNamed MX3D Bridge, it was designed by Dutch studio Joris Laarman Lab in collaboration with MX3D, a technology company co-founded by Laarman, and engineering firm Arup.

The structure used 4,500 kilograms of stainless steel, which was 3D-printed by robots in a factory over a period of six months before been craned into position over the canal this year.

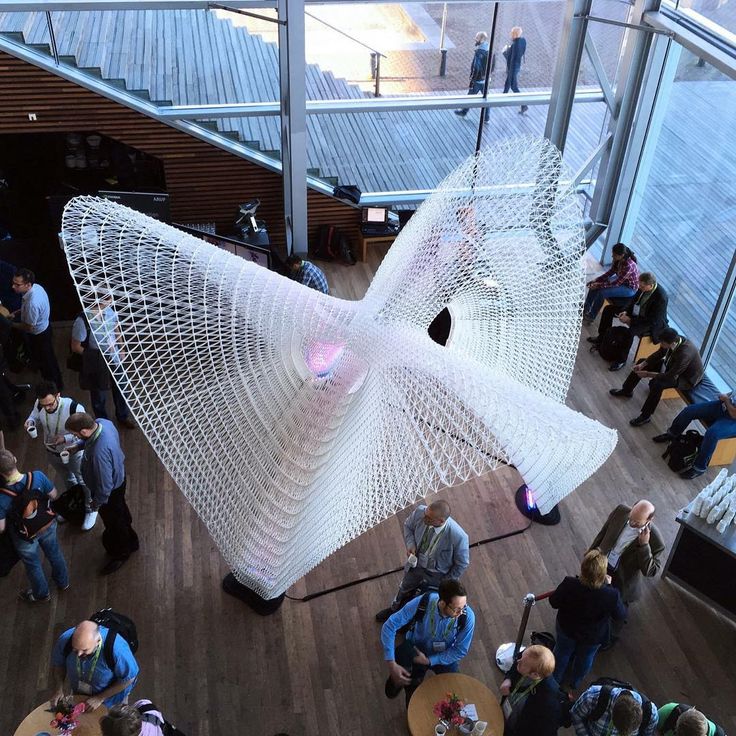

Its curving S-shaped form and balustrades with lattice-style perforations were designed using parametric modelling software.

The bridge was constructed using robotic printers. Photo is by Adriaan de GrootThe team behind the bridge claimed the technique showed how 3D-printing technology can lead to more efficient structures that use less material.

"This robotic technology finally allows larger optimized designs to be 3D-printed in metal," said MX3D co-founder Gijs van der Velden.

"This causes significant weight reduction and reduced impact for parts manufactured in the tooling, oil and gas and construction industries."

It has perforated balustrades. Photo is by Jande GroenThe technique can lead to more sustainable structures, the team claimed. "The industry is facing a huge challenge in becoming carbon-neutral in 2050," said Arup structural engineer Stijn Joosten.

"By stepping up our game and the will to make a change as designers and engineers, we can bring the necessary innovation to make a difference in tomorrow's built environment."

Joris Laarman's canal bridge in Amsterdam could take 3D printing "to a higher level"

However, architect Philip Oldfield calculated that the stainless steel used in the structure has 27.7 tonnes of embodied carbon.

"Stainless steel has an embodied carbon of 6. 15kgCO2/kg," tweeted Oldfield, who is head of the art, design and architecture school at the University of New South Wales in Australia. "This bridge then has an #embodiedcarbon of at least 27.7 tonnes of CO2 to span a few metres."

15kgCO2/kg," tweeted Oldfield, who is head of the art, design and architecture school at the University of New South Wales in Australia. "This bridge then has an #embodiedcarbon of at least 27.7 tonnes of CO2 to span a few metres."

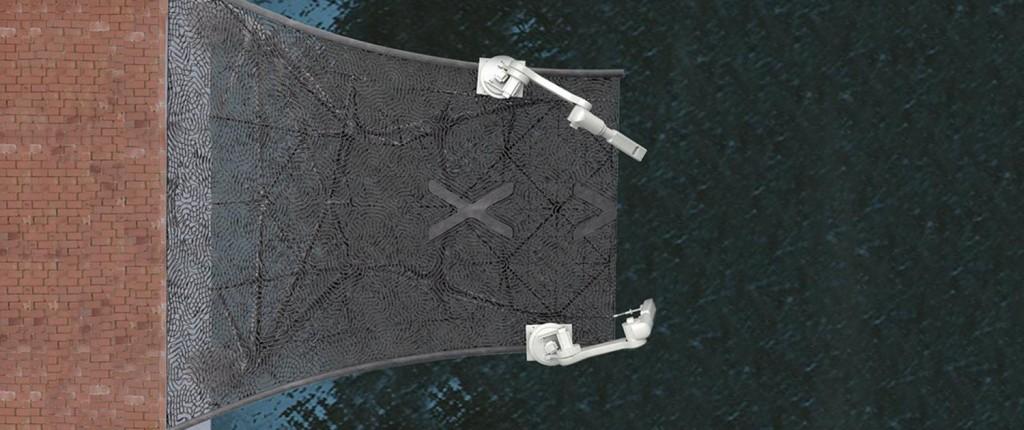

The Alan Turing Institute and Arup fitted the structure with a network of sensors that allows the bridge to collect data and build a digital twin to keep track of its performance and health.

The digital twin will monitor corrosion, load changes, environmental conditions and pedestrian use in efforts to further data-centric design.

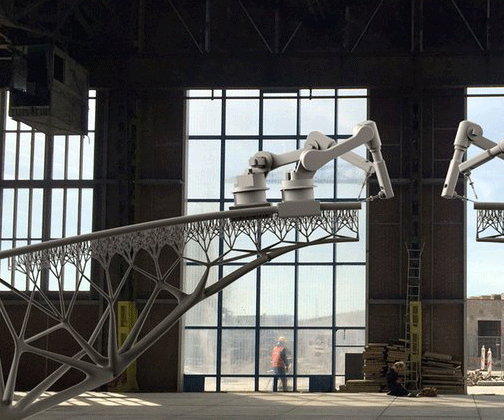

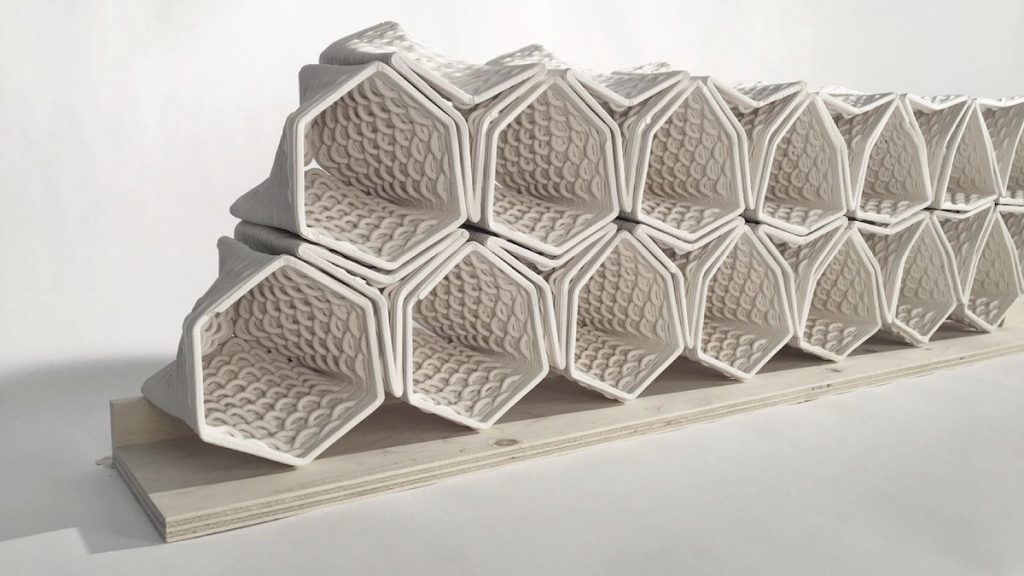

It was made from 4,500 kilograms of stainless steel. Photo is by Thijs WolzakLaarman had the idea for the bridge after combining robotic arms with welding machines to create a machine capable of printing furniture. "By adding small amounts of molten metal at a time, we are able to print lines in mid-air," explained Laarman at the time.

The welding machine later formed the basis of MX3D, which Laarman co-founded to explore the potential for printing larger-scale objects.

The bridge has undergone multiple iterations since the project was launched in 2015, with the opening originally slated for 2017.

The original plan was to print the structure across the canal in situ, with robots working from both banks welding the bridge beneath them until they met in the middle.

The final iteration saw the bridge built in two parts at an off-site facility. Its main span was completed in April 2018 with the deck printed in October that year.

The structure was strengthened to be more in line with council regulations and to protect the structure against any potential boat collisions.

First tenants move into 3D-printed home in Eindhoven

Although this is believed to be the first 3D-printed stainless steel bridge, bridges have previously been 3D printed from other materials. In 2017, construction company BAM Infra built what they claimed was the world's first 3D-printed concrete bridge.

Photography is by Thea van den Heuvel unless stated otherwise.

Subscribe to our newsletters

Your email addressDezeen Debate

Our most popular newsletter, formerly known as Dezeen Weekly. Sent every Thursday and featuring a selection of the best reader comments and most talked-about stories. Plus occasional updates on Dezeen’s services and breaking news.

New! Dezeen AgendaSent every Tuesday and containing a selection of the most important news highlights. Plus occasional updates on Dezeen’s services and breaking news.

Dezeen DailyA daily newsletter containing the latest stories from Dezeen.

Dezeen JobsDaily updates on the latest design and architecture vacancies advertised on Dezeen Jobs. Plus occasional news.

Dezeen AwardsNews about our Dezeen Awards programme, including entry deadlines and announcements. Plus occasional updates.

Dezeen Events GuideNews from Dezeen Events Guide, a listings guide covering the leading design-related events taking place around the world. Plus occasional updates.

Plus occasional updates.

We will only use your email address to send you the newsletters you have requested. We will never give your details to anyone else without your consent. You can unsubscribe at any time by clicking on the unsubscribe link at the bottom of every email, or by emailing us at [email protected].

For more details, please see our privacy notice.

Thank you!

You will shortly receive a welcome email so please check your inbox.

You can unsubscribe at any time by clicking the link at the bottom of every newsletter.

What the first 3D printed steel bridge looks like

Trends

TV channel

Newspaper

Pro

Investments

RBC+

New economy

Trends

Real estate

Sport

Style

National projects

City

Crypto

Debating club

Research

Credit ratings

Franchises

Conferences

Special projects St. Petersburg

Petersburg

Conferences St. Petersburg

Special projects

Checking counterparties

RBC Library

Podcasts

ESG index

Politics

Economy

Business

Technology and media

Finance

RBC CompanyRBC Life

RBC Trends

Photo: Mashable / YouTube

The world's first 3D printed steel bridge has been installed in Amsterdam. The project was ready three years ago, but the installation of the bridge was constantly delayed

What's happening

- On July 15, the world's first 3D printed steel bridge was opened in Amsterdam.

It connects the embankments of the Oudesijds Achterburgwal canal. The grand opening was attended by Queen Maxima of the Netherlands.

It connects the embankments of the Oudesijds Achterburgwal canal. The grand opening was attended by Queen Maxima of the Netherlands. - The structure weighs 6 tons and is 12 meters long.

- The bridge was printed by four robots by welding layers of stainless steel wire, it took them 4.5 tons of steel and six months to make a span of 12 meters. Then coastal supports and decorative elements were made.

- This project was developed by the laboratory of Joris Laarmann and ABB, Air Liquide, ArcelorMittal, Autodesk, AMS Institute and Lenovo, while the Amsterdam-based company MX3D was fabricating and installing the structure.

- More than ten sensors are built into the bridge, with the help of which it will be possible to monitor its condition and deformation. Thus, he will himself indicate the need for repair. The sensors will also count the number of pedestrians crossing the bridge each day.

- The structure was installed for two years as a replacement for the conventional bridge, which will be under reconstruction at that time.

- This bridge was first presented at Dutch Design Week Eindhoven 2018, where the project won the Dutch Design Award and the Audience Award. After that, the finished bridge lay in storage for another three years: first, in anticipation of the reconstruction of the canal, then due to the coronavirus pandemic and lockdown.

What does it mean

In recent years, there has been an active development of 3D printing technology in construction. The Netherlands seems to be on a roll with this trend, with the first fully 3D-printed residential building in the EU populated in the suburbs of Eindhoven in early May, followed by the opening of the world's first 3D-printed steel bridge.

We have already said that 3D printing is the future of construction and design. Compared to classic buildings, 3D printing has a number of undeniable advantages, such as short construction times, reduced economic and environmental costs, and ease of execution of complex shapes.

“This is not just about reducing and optimizing construction costs, but about giving architects and designers a new tool, a very cool new tool, with which they can rethink the design of their architecture and their projects,” notes Tim Görtjens, co-founder of MX3D, a bridge builder.

Mika Mos, member of the council of the municipality of Amsterdam, expressed the hope that this construction will also help the city attract quality new tourists:

“This could attract a new type of visitor, those more interested in architecture and design, which will change the perception of this area (famous for nightclubs and noisy parties. — RBC Trends ).”

Updated on 07/30/2021

Text

Ksenia Yanushkevich

Top of the trend

Related materials

World's first 3D printed steel bridge installed in Amsterdam

News

a robotic 3D printer using electric arc deposition technology was thrown through one of the canals in the center of Amsterdam.

It remains only to install the sensors and weld the missing elements.

It remains only to install the sensors and weld the missing elements.

The project took nearly six years to complete. In addition to the obvious difficulties with the development of production technology, the company also faced other obstacles. Work on the metal structure itself was completed back in 2018, after which the bridge was sent to storage pending the completion of the reconstruction of the water channel, as the municipal authorities feared that the old masonry could collapse under the weight of the new structure. Then a covid surprise arrived from Wuhan, and only now they finally decided to install the bridge in the allotted place.

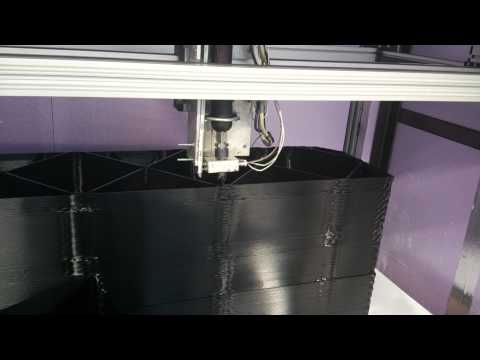

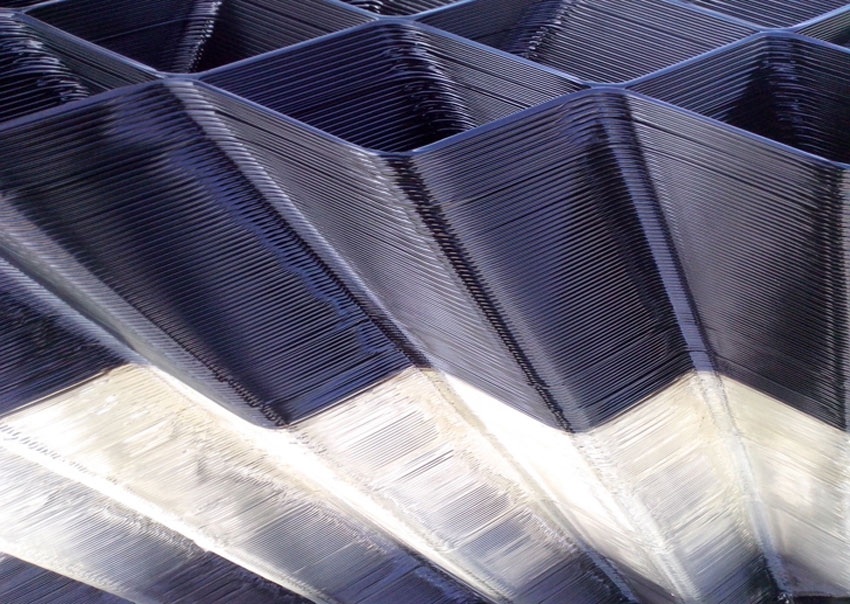

This is an all steel structure made by a multi-axis robotic arm with a welding machine. The consumable material, of course, is the usual welding wire, the productivity reaches about two kilograms per hour. This is the main advantages of the technology of additive manufacturing by electric arc deposition or WAAM (Wire Arc Additive Manufacturing): such a scheme is much faster and cheaper than laser or electron beam synthesis technologies on a substrate using expensive fine powders, moreover, there are no strict restrictions on the dimensions of printed materials. products. On the other hand, the resolution is not high, and the compatibility with various metals and alloys is limited, but in this particular case, both the material and the resolution are quite suitable for the task.

products. On the other hand, the resolution is not high, and the compatibility with various metals and alloys is limited, but in this particular case, both the material and the resolution are quite suitable for the task.

Designed using Autodesk Dreamcatcher CAD using topological optimization, reducing the weight of the 12-meter bridge to approximately four tons.

Designed with multiple sensors to monitor structural integrity, vibration, strain, stress and weather conditions. All this will help, on the one hand, ensure the safety of the pedestrian flow, and, on the other hand, improve the design methodology and 3D printing algorithms for future projects.

In terms of algorithms, MX3D has been offering its software developments to the commercial market since 2019. This is partly a forced measure, because due to the low payback and high costs of research and development work, the company faced serious financial difficulties. The guys decided to get additional income from licensed sales of the Metal XL software package, which provides support for the full cycle of additive manufacturing using WAAM technology - from design to 3D printing.

Installation of the sensors, finishing touches on the welding machine and testing of the design will take a few more days, the commissioning of the bridge is scheduled for the second half of this month.

MX3D WAAM bridge Amsterdam

Follow author

Follow

Don't want

7

More interesting articles

13

Subscribe to the author

Subscribe

Don't want

Last Saturday, September 24, the third 3D-printing festival 3Dtoday Fest took place in St.

.jpg)