3D printed succulent pot

3d Printed Planter - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

( 1,000+ relevant results, with Ads Sellers looking to grow their business and reach more interested buyers can use Etsy’s advertising platform to promote their items. You’ll see ad results based on factors like relevancy, and the amount sellers pay per click. Learn more. )

Related to 3d printed planter

- 3d printed jewelry

- 3d printed vase

3d Printed Succulent - Etsy.

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

( 1,000+ relevant results, with Ads Sellers looking to grow their business and reach more interested buyers can use Etsy’s advertising platform to promote their items. You’ll see ad results based on factors like relevancy, and the amount sellers pay per click. Learn more. )

Top 10 3D Printable Vase Models

3DPrintStory 3D printing process 3D Printed Vase: Top 10 3D Printable Vase Models

Polygon flower pot

Small but perfectly shaped, overall simple but extremely effective. This small flower pot, created by designer Clement C based on polygon models, is a great start for fans of functional 3D printing. The version shown here was printed at 125% scale.

This small flower pot, created by designer Clement C based on polygon models, is a great start for fans of functional 3D printing. The version shown here was printed at 125% scale.

You can download this 3D model at MyMiniFactory.

Tear Drop Vase

This elegant design from New York enthusiast Victoria Crettenand is actually a fairly simple 3D printable model. However, remember that it is not so easy to achieve the smooth surface shown in the image above. Instead, the end result without post-processing will be more faceted and textured if you print with PLA. If you want to achieve a smooth surface when printing with PLA, take a look at our recommendations for smoothing 3D PLA models. An alternative for more experienced 3D printer users is to print with ABS plastic and then use an acetone bath to smooth the surface. But in general, if you do not wedge on the quality of the surface, this 3D model is suitable even for beginners in the field of 3D printing.

You can download this 3D model at Thingiverse.

Curvy vase

Designer Libero Rutilo combines 3D printing and recycling in this unusual solution. The container part of the vase is an old PET bottle with a volume of 0.5 liters. The 3D printed model is placed over the bottle like an outer mesh and held in place by an inner neck that screws onto the bottle like a cap. As a result, the inner plastic bottle is cleverly disguised and gives the impression of a rather stylish and modern piece of art.

You can order a printed vase or download a 3D model file to print it yourself, at a price of 10 euros.

You can download this 3D model on Tessa's Curated Boutique.

Aqua

This fabulous exotic style comes from Dutch designer Virtox, also known as Stijn van der Linden. The 3D model of the vase was created using a morph animation algorithm, which is then folded and shaped into the shape of a vase. This particular model is called Aqua and is part of the Julia Vase collection.

This model's intricate, organic, and flowing shape means it's probably not the ideal first vase to choose if you're new to 3D printing. Perhaps even for more experienced 3D printer users, this model will cause difficulties when printing. However, its incredible and unique aesthetic is worth it.

You can download this 3D model on Thingiverse.

Art Deco Light Bulb Vase

This 3D art deco vase by Conor Devine is another example of 3D printing combined with recycling. In this case, the beautiful simplicity of the light bulb is integrated into the organic stand to create a very elegant result. A design is available to connect both standard bayonet and screw-in lamps. The model is free, so it's worth a try.

You can download this 3D model at MyMiniFactory.

The author also posted instructions on how to empty the glass bulb.

Drawstring Tile Vase

This unusual design from Clockspring consists of many interlocking triangular tiles that can be 3D printed. The vase is not completely water resistant and requires a bit more effort compared to other models to assemble the final design. But if you're up to the challenge, this is definitely an outstanding specimen. Read the designer's instructions carefully before printing!

The vase is not completely water resistant and requires a bit more effort compared to other models to assemble the final design. But if you're up to the challenge, this is definitely an outstanding specimen. Read the designer's instructions carefully before printing!

You can download this 3D model at MyMiniFactory.

Spiral Vase

Another set of twisting designs, these vases from YSoft_be3D are truly beautiful examples of 3D printing as art. However, these are not the easiest examples, so it's worth reading the 3D printing guidelines, as well as the comments of those who have printed them before, if you want to get a good result. But persistence and a little bit of trial and error will result in a quality 3D print that fully matches this stunning design.

You can download this 3D model at Thingiverse.

Baby Groot Flower Vase

And now a very interesting model: this vase model is based on the character Baby Groot from Marvel Guardians of the Galaxy (or maybe in the current context it should be "Gardens of the Galaxy"?)! In any case, this is a very popular model. So popular that apparently the Chinese manufacturer has released a commercial plastic version for sale (the copyright issue doesn't seem to bother them, although Marvel may well think otherwise...). According to those who have already printed it, the model seems to scale well and can be used as a general container for pens, pencils or whatever, in addition to the functions of a regular vase.

So popular that apparently the Chinese manufacturer has released a commercial plastic version for sale (the copyright issue doesn't seem to bother them, although Marvel may well think otherwise...). According to those who have already printed it, the model seems to scale well and can be used as a general container for pens, pencils or whatever, in addition to the functions of a regular vase.

You can download this 3D model at MyMiniFactory.

Honeycomb Vase

This stunning vase by artist, engineer and fabricator Alexey Grishchenko looks like it came straight out of the world of Minecraft. But 3D printing this model can cause some difficulties. This model will also require additional processing if you want it as a water vase. Some users have commented that using a clear epoxy coating both inside and out will help bring this model to perfection. With or without additional post-processing, this design is eye-catching anyway.

You can download this 3D model at Thingiverse.

Mini Flower Vase

Well, the prize for the smallest 3D printable vase in this carefully selected collection goes to this very pretty model from Atlanta designer Colleen Jordan. Since the size is small to print. this vase can be pretty fast. Colleen also provided a helpful set of instructions on how to place a succulent (small plant) in a printed vase. It looks great, and the plant lives and blooms!

You can download this 3D model at Thingiverse.

Unusual DIY pots for succulents

05/12/2021

Created by: Ivan Sobolev

I have long wanted to talk about the technology of making my pots. In this article I will describe in detail how you can make them yourself.

Pots are made from polymer composite in several steps.

1. Modeling

First, the pot needs to be designed taking into account the laws of physics and the peculiarities of printing a 3D printer. To do this, you will need a 3D modeling program and skills to work with it. Then you simply draw the image that has been formed in your head for a long time and does not come out of it. You can take a ready-made pot model, for example, on site thingiverse.com. But in my opinion, the most interesting thing is to use the opportunity to translate your idea into an object that exists in the real world. Therefore, even a simple, but my own project is more significant for me than a complex someone else's.

Then you simply draw the image that has been formed in your head for a long time and does not come out of it. You can take a ready-made pot model, for example, on site thingiverse.com. But in my opinion, the most interesting thing is to use the opportunity to translate your idea into an object that exists in the real world. Therefore, even a simple, but my own project is more significant for me than a complex someone else's.

2. Matrix printout

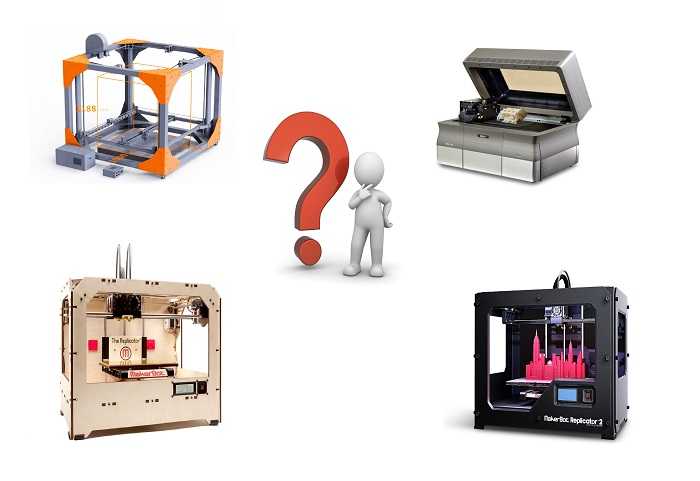

It is necessary to prepare and set up a 3D printer. This is one of the most creative parts of the process. Due to the large number of moving parts, 3D printers are quite complex and capricious devices. Therefore, refeeding/setting up the printer may take an unexpectedly long time. The good news is that for the manufacture of a pot, it is necessary to print not a finished product with a high-quality surface, but a "carrier matrix" for impregnation. Therefore, an average (draft) print quality is acceptable, which can be produced by almost any 3D printer.

If you have already learned how to work with the printer, the printout itself will not cause problems. Any plastic can be used to print the matrix. I mostly use white PLA as it is the easiest to print with.

3. Manual processing

After printing, remove the supports and all unnecessary, and assemble the model if it consists of several parts. Large gaps must be sealed.

Next, we prepare the epoxy putty with which we will cover the matrix. You will need any epoxy resin with a hardener, filler, dry dark dye.

In order for the epoxy to thickly cover the matrix and not drip, I add a filler. Glass microspheres are well suited as a filler (a teaspoon with a slide for 10 grams of resin). The surface of putty with such filler is well processed. I also add dye. With black dye, gray putty is clearly visible on white plastic and you can determine where the model has not yet been coated with putty, what is the thickness of the layer, or where the putty has been strongly absorbed and more needs to be added.

Mix the resin, filler and dye well, trying not to have lumps of filler. Then stir well again.

Add the hardener, stir very well and apply the putty with a small stiff brush, well smearing hard-to-reach places. Remove the excess with a brush. If you guessed right with the amount filled, the surface will smooth out before the resin hardens.

After curing, wash with soap and hot water. After drying, we process the entire surface of the product with a knife, sandpaper, files and needle files and wash again.

A well-dried model is coated with a plastic primer. You don't need much primer. In the photo below there are 3 pot trays: 1 - printed matrix, 2 - sanded model covered with putty, 3 - primed model.

4. Painting

Next, paint the pot in accordance with our idea. I use acrylic paints that I apply with a brush or foam pad. After the acrylic has dried for a day, cover the pot with a matte varnish. I usually do not paint the inner surface, I varnish it immediately after the primer.

.jpg)