Scanner un objet en 3d

⇒ Scanner 3D pour imprimante 3D : Prix et caractéristiques

Longtemps confinés à des domaines précis comme celui du contrôle qualité en milieu industriel, celui du reverse engineering ou celui des films d’animation et des jeux vidéo par exemple, le scanner 3D connait un essor fulgurant. Une des causes de cet essor est le développement de l’impression 3D.

En effet, la maîtrise des logiciels de Conception Assistée par Ordinateur étant loin d’être diffusée à grande échelle, et les modèles 3D disponibles sur Internet restant en nombre relativement limités pour l’instant, l’utilisation d’un système de capture 3D est parfois indispensable. Par ailleurs, la technologie évolue à vitesse grand V, et les prix deviennent de plus en plus abordables.

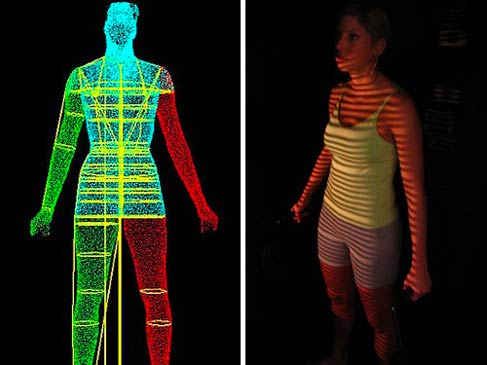

Les scanners de référence pour l’impression 3D utilisent la technologie laser à triangulation ou la lumière structurée. Depuis quelques mois, on assiste également à un foisonnement d’applications de numérisation 3D utilisant la technologie de la première Kinect, en lumière structurée, et bientôt celle de la Kinect 2, en détection de temps de vol (Time-of-Flight).

Par ailleurs, une autre solution est prise de plus en plus au sérieux et considérée comme particulièrement prometteuse : l’utilisation d’un smartphone ou d’une tablette, grâce à des logiciels de traitement d’image.

Comment choisir son appareil ?Le choix d’un scanner va dépendre d’un certain nombre de facteurs, notamment :

- le type d’objets à scanner : pour des visages humains par exemple, on va écarter les technologies laser qui peuvent être dangereuses. Ensuite, on va choisir l’appareil en fonction de la taille des objets qu’il peut scanner et s’orienter soit vers un appareil mobile, soit vers un scanner fixe intégrant une table tournante.

- la résolution, c’est-à-dire le niveau de détail de l’objet à numériser

- la précision : c’est le niveau de fidélité entre le modèle 3D et l’objet physique.

- le besoin de numériser en couleur ou en noir & blanc et de capturer la texture d’un objet

- la vitesse de scan, plus importante pour un visage que pour un objet statique

- l’environnement de numérisation, et notamment la luminosité

- le niveau de connaissances de l’utilisateur

- et bien sûr le budget

Un scanner 3D va produire ni plus ni moins qu’un nuage de points qui ne pourra pas être interprété par une imprimante 3D tel quel. C’est un logiciel, souvent propriétaire, qui va permettre de transformer ce nuage de points en un maillage polygonal qui permettra l’impression 3D. Au final, les informations concernant la géométrie de l’objet sont stockées dans un fichier au format STL. Les logiciels permettent également l’exportation dans d’autres formats, notamment OBJ, pour être ensuite manipulés dans des logiciels de CAO.

C’est un logiciel, souvent propriétaire, qui va permettre de transformer ce nuage de points en un maillage polygonal qui permettra l’impression 3D. Au final, les informations concernant la géométrie de l’objet sont stockées dans un fichier au format STL. Les logiciels permettent également l’exportation dans d’autres formats, notamment OBJ, pour être ensuite manipulés dans des logiciels de CAO.

Selon la qualité du matériel et du logiciel, cette étape, que l’on appelle le post-processing, peut être relativement longue. Elle consiste notamment à supprimer les éléments parasites de l’ensemble des prises de vue 3D, à boucher les trous, à mailler l’objet bien évidemment, et à effectuer quelques réparations du modèle 3D si nécessaire.

- Pour moins de 1000 €

Pour environ 600 € TTC, le Starter-kit comprend notamment une webcam HD et un module laser à ligne portatif de haute qualité. Le principe est de tenir le laser dans sa main et de diriger la ligne laser vers l’objet à scanner. Le Starter-kit peut numériser des objets de 10 à 400 mm, en couleur, avec une résolution allant jusqu’à 0,2 mm. On peut lui reprocher une certaine lenteur d’acquisition des données, mais à ce prix, cela reste acceptable.

Le Starter-kit peut numériser des objets de 10 à 400 mm, en couleur, avec une résolution allant jusqu’à 0,2 mm. On peut lui reprocher une certaine lenteur d’acquisition des données, mais à ce prix, cela reste acceptable.

Particulièrement compact, mobile et facile d’utilisation, le scanner de 3D Systems, leader mondial de l’impression 3D, permet de numériser des objets de tailles différentes, de la petite tasse à café jusqu’à une personne entière, rapidement. Son prix est d’environ 430 €. Sa résolution relativement limitée conviendra cependant à de nombreuses applications. Enfin, ce modèle est résolument tourné vers le grand public, grâce à des fonctionnalités comme la reconnaissance automatique d’objets, qui permet de différencier l’objet dans un arrière-plan encombré, et son intégration avec le logiciel de traitement 3D Cubify Sculpt. Le Sense est réellement le symbole de la démocratisation de la numérisation et de l’impression en trois dimensions, aux côtés bien sûr des scanners de type Kinect.

Sorti en novembre 2015, XYZPrinting 3D-Scanner est né d’un partenariat entre le taiwainais XYZPrinting et le géant américain Intel. Reposant sur la technologie Realsense, ce scanner de poche ultra léger (198 g seulement) est capable de numériser des objets de taille 60 x 60 x 30 cm à une distance d’1 mètre jusqu’à 30 fps. Le scanner fonctionne avec les pc (uniquement 4th Generation Intel® Core™ i5 Process) équipés de Windows 8.1. Capable de numériser des objets en full-color XYZPrinting 3D-Scanner exporte les formats de fichiers suivants : stl, obj et ply. Le scanner est livré avec le logiciel XYZscan au prix de 199 €.

- De 1000 à 5000 €

Dans la gamme de prix supérieure, environ 1.000 € TTC, le Cubik est un modèle de bureau aux performances remarquables : une résolution et une précision professionnelles allant jusqu’à 0,05 mm (50 microns), une numérisation en couleur, rapide et simple, d’objets ayant un diamètre et une hauteur maximum de 220 mm. Comprenant une table tournante automatique et un logiciel de traitement 3D puissant, ce scanner simplifie la numérisation des objets. Problème : il semble être difficile de le trouver sur le marché, suite à des ruptures de stock. En savoir plus.

Comprenant une table tournante automatique et un logiciel de traitement 3D puissant, ce scanner simplifie la numérisation des objets. Problème : il semble être difficile de le trouver sur le marché, suite à des ruptures de stock. En savoir plus.

Makerbot Digitizer

Avec la ferme volonté de maîtriser l’ensemble du workflow de l’impression tridimensionnelle, Makerbot, racheté par Stratasys, s’est lancé dans la numérisation 3D en 2013, avec la sortie du Digitizer. Ce modèle aux performances honorables (résolution allant jusqu’à 0,5 mm et précision allant jusqu’à 2 mm), ne suscite pas que des avis positifs : la nécessité de le recalibrer fréquemment (tous les 20 scans selon Makerbot, mais plus probablement tous les 10 ou 15), et surtout la sensibilité du scanner et les exigences en termes de luminosité, de brillance et de reflets des objets scannés, en font un outil parfois frustrant.

Heureusement, la version 2.4 du logiciel Makerware offre un mode Multiscan qui permet d’obtenir un fichier acceptable en 3 numérisations de 9 à 10 minutes chacune, pour des objets dont la taille est inférieure à un cylindre de 203×203 mm. On attendait cependant mieux pour un scanner dont le prix est d’environ 1100 €.

On attendait cependant mieux pour un scanner dont le prix est d’environ 1100 €.

Pour environ 2799 €, le scanner à lumière structurée de David, fabricant allemand, offre des possibilités et des performances plus qu’intéressantes. La taille des objets que l’on peut scanner va jusqu’à 500 mm, la résolution et la précision se montent à 0,1% de la taille de l’objet (jusqu’à 0,06 mm), et un scan ne dure qu’environ 2 à 4 secondes. Un point faible cependant : le temps d’installation de tout le matériel (caméra, vidéoprojecteur, câbles de connexion) et la relative complexité des opérations. A l’évidence, ce ne sera pas le scanner de M. Tout-le-Monde mais plutôt celui réservé aux geeks.

Nextengine 3D Scanner HDCe scanner fixe, de la taille d’une boite de céréales, offre une résolution et une précision correctes, de l’ordre de 0,2 mm. Equipé de 2×4 lasers, plus rapide que son prédécesseur le SD, le scanner HD effectue un scan en 1 minute 30 environ. Il est simple à installer et à utiliser, notamment grâce au logiciel fourni StudioScan HD, et à la compatibilité avec SolidWorks. Fourni avec une table tournante et divers accessoires, NextEngine qui est de très bonne qualité de fabrication, coûte environ 2.300 €.

Il est simple à installer et à utiliser, notamment grâce au logiciel fourni StudioScan HD, et à la compatibilité avec SolidWorks. Fourni avec une table tournante et divers accessoires, NextEngine qui est de très bonne qualité de fabrication, coûte environ 2.300 €.

Pour une utilisation plus intensive et plus exigeante, il est possible de choisir le logiciel HD PRO, qui permet de doubler la vitesse de traitement, de scanner des objets de plus de 75 cm, en obtenant un nombre de points 4 fois supérieur. Le supplément coûte 700 $. On peut regretter que la fonctionnalité de numérisation de gros objets ne soit pas inclue dans le logiciel de base.

- Plus de 5000 €

L’objectif de cette rubrique n’est pas d’être exhaustif, mais de présenter quelques exemples de scanners 3D professionnels. En effet, il en existe une vaste gamme d’appareils et dont les prix peuvent atteindre plusieurs dizaines de milliers d’euros, voire plus.

3D Digital Corp. eScan 2.0

eScan 2.0

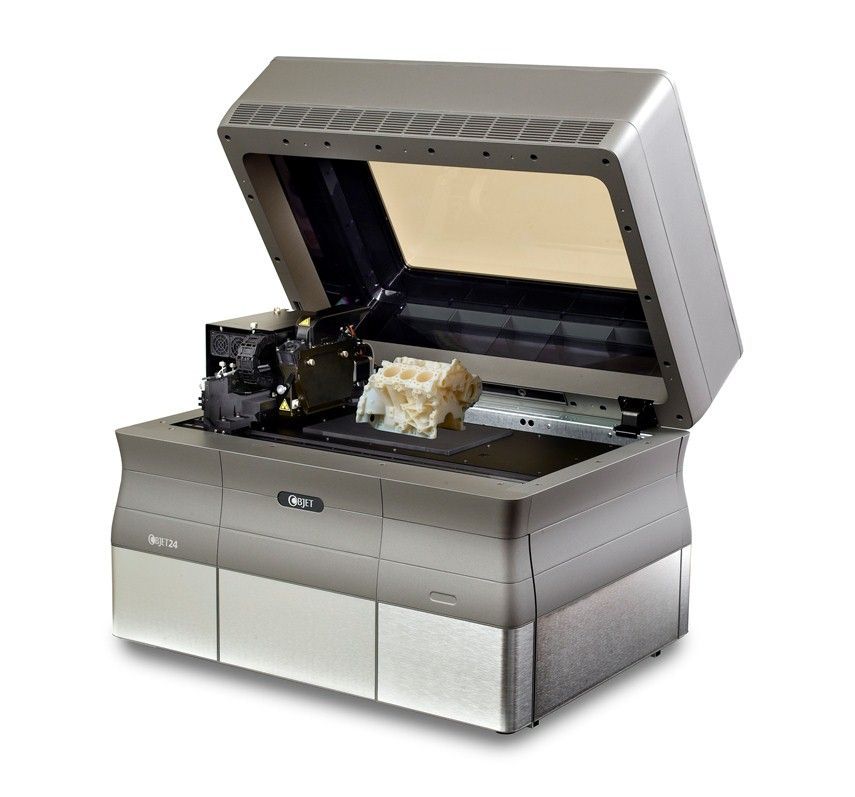

Avec son apparence trompeuse de vidéoprojecteur, l’eScan 2.0 offre, pour un prix somme toute raisonnable (environ 6.000 € HT), une résolution et une précision excellente. En version de base, le scanner offre une surface de scan limitée à 150×100 mm, mais peut numériser avec une résolution de 0,05 mm en 30 secondes (7 secondes par scan pour la résolution la moins élevées).

Dans sa version étendue, la surface de scan est étendue à 300×250 mm, et la résolution passe à 0,1 mm. Scanner des objets plus grands est possible, en numérisant les différentes parties de l’objet, puis en utilisant les capacités d’alignement automatique des scans qu’offre le logiciel. En résumé, Digital Corp est un excellent choix pour ceux qui ont besoin d’une forte résolution et d’une excellente précision (30 à 70 microns), et qui veulent numériser des objets de petite ou moyenne taille.

Artec Spidercrédits photo artec.com

D’un prix avoisinant les 16. 000 €, le scanner 3D portatif Artec Spider a été spécialement conçu pour les utilisations nécessitant une résolution (0,1 mm) et une précision (0,03 mm) importante, tout en fonctionnant de manière rapide et simple. Ne nécessitant pas de calibrage ni de marqueur, le Spider est équipé de nombreuses caméras qui prennent des clichés et puis les alignent pour finaliser le modèle 3D. Cette technologie permet entre autres de détecter les angles aigus et les parois fines. Outre ses performances de numérisation, notamment en terme de texture et de couleur, le scanner présente l’avantage de fonctionner sur batterie avec une bonne autonomie.

000 €, le scanner 3D portatif Artec Spider a été spécialement conçu pour les utilisations nécessitant une résolution (0,1 mm) et une précision (0,03 mm) importante, tout en fonctionnant de manière rapide et simple. Ne nécessitant pas de calibrage ni de marqueur, le Spider est équipé de nombreuses caméras qui prennent des clichés et puis les alignent pour finaliser le modèle 3D. Cette technologie permet entre autres de détecter les angles aigus et les parois fines. Outre ses performances de numérisation, notamment en terme de texture et de couleur, le scanner présente l’avantage de fonctionner sur batterie avec une bonne autonomie.

AIO Robotics Zeus

Nous connaissons une période incroyablement riche pour la numérisation 3D, autant par la diffusion à plus grande échelle des scanners de bureau et des scanners mobiles, et donc de leur baisse de prix, que par l’arrivée massive de scanners à base de Kinect ou d’applications utilisant les fonctionnalités des smartphones et des tablettes. Dans les scanners à moins de 1.000€, on peut citer l’Occipital Structure Sensor (base Kinect), le Robocular LLC Mini Scanner et le Matterform Photon 3D Scanner.

Dans les scanners à moins de 1.000€, on peut citer l’Occipital Structure Sensor (base Kinect), le Robocular LLC Mini Scanner et le Matterform Photon 3D Scanner.

On a vu également apparaître des scanners multifonctions, qui reproduisent donc le concept à succès de l’impression 2D en intégrant imprimante 3D et scanner 3D. Vu les changements technologiques majeurs qui se produisent depuis quelques années dans les deux domaines, impression et numérisation, je ne suis pas persuadé que cela représente un avantage pour l’instant de cumuler les 2 fonctions en un seul appareil. Mais on peut tout de même regarder avec intérêt l’arrivée du FABTotum Personal Fabricator et du Radiant Lionhead Bunny

AIO Robotics a dévoilé son imprimante 3D Zeus, un modèle polyvalent combinant impression 3D et scan.

XYZPrinting propose désormais les versions améliorées de ses Da Vinci 1.0 et 2.0, des modèles avec scanner intégré.

3D Systems présente iSense, un scanner 3D clipsable sur votre tablette.

Microsoft développe une application pour smartphone afin de scanner objets et images.

Le fabricant taïwanais a dévoilé le XYZprinting scanner, un appareil de numérisation bon marché.

Auteur invité

Philippe Heinrich

Philippe Heinrich est consultant en Nouvelles Technologies, Innovation et Systèmes d’Information. Il intervient notamment auprès des pouvoirs publics, des entreprises et du grand public pour promouvoir la technologie de l’impression 3D. Il aide les entreprises et les porteurs de projets à se préparer aux changements radicaux que cette technologie va avoir sur les différents secteurs de l’économie française.

Site : www.heinrich-consultant.fr/

Best free 3D scanning apps for smartphones in 2022 (iOS/Android)

What is a 3D scanner app?

A 3D scanner app or 3D scanning app can turn almost any smartphone into a pocket-sized 3D scanner. Most of these apps are based on photogrammetry, a 3D scanning technology that creates 3D models out of 2D photos. You take pictures of an object from different angles and then the app’s algorithms “stitch” the images together.

You take pictures of an object from different angles and then the app’s algorithms “stitch” the images together.

With a 3D scanning app, you can 3D scan objects and rooms, and even people (3D body scanning). You can use a 3D scanner app to create 3D objects for augmented reality. It’s also possible to create 3D models for 3D printing.

Here is a scan we did with a 3D scanning application (KIRI Engine):

Of course, 3D scanner apps for smartphones are less accurate than actual 3D scanners. However, they are a great, affordable way to learn more about 3D scanning without investing in complex hardware.

In this article, we provide a comprehensive list of the best 3D scanner apps for iPhone and Android smartphones.

The 5 best 3D scanning apps for smartphones (free)

Expand to see more specs

How do 3D scanning apps work?

Photogrammetry 3D scanning technology

By definition, photogrammetry is “the science of making measurements from photographs”. Put simply, you take photos of a 3D object, and then the software stitches the pictures together. With this technology, the final 3D scan features color and texture.

Put simply, you take photos of a 3D object, and then the software stitches the pictures together. With this technology, the final 3D scan features color and texture.

3D scanning using a smartphone (iOS or Android)

You need to take several pictures of the object from different angles (usually 360° around the object) with your phone. 3D scanning apps generally provide you with tips and guidance to help you properly take the pictures.

The app then processes these pictures and aligns them together to form a 3D model. The 3D model is then available for export or editing using additional 3D software. In some cases, users may also print their 3D models with a 3D printer.

3D scanner apps overview (iOS and Android)

In this section, we give some more context and information about each 3D scanning app from our selection.

KIRI Engine is a free 3D scanning app for Android and iOS smartphones. All the processing happens on KIRI’s servers, not your phone, so the only thing you need is a recent smartphone with a decent camera.

All the processing happens on KIRI’s servers, not your phone, so the only thing you need is a recent smartphone with a decent camera.

The free version of KIRI Engine has a 70-photo limit, which is enough for most simple scans. It’s excellent for makers, students, and anyone who wants to try 3D scanning or do the occasional scan (for small or simple objects).

Read our in-depth KIRI Engine review article for more information about this app.

Contact manufacturer Add to comparison

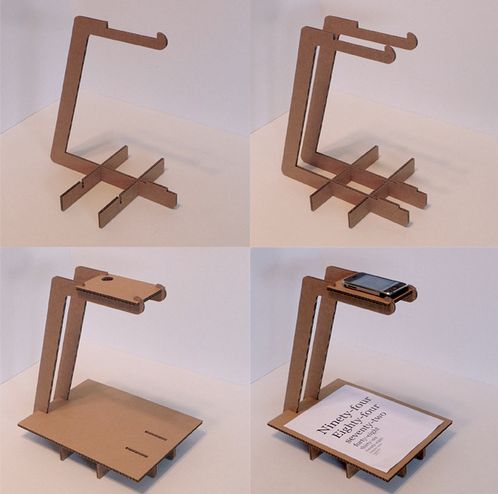

To use Qlone, you need to print a special black and white paper mat. The mat looks like a QR code and is used by the app as a marker.

Qlone offers a useful guiding system. A grey dome surrounds the object you’re scanning and lets you know which angle you need to capture next. The app generates the results locally (without going through a cloud platform) and almost in real time.

Users can easily share 3D scans via social media apps such as Facebook and WhatsApp.

Contact manufacturer Get a quote Add to comparison

Scandy Pro for iOS is a free 3D scanning app that turns your iPhone into a full-color 3D scanner. Within the app, you can edit your scans with various tools. This app is available for iPhone X/XS, iPhone XS Max and iPhone XR.

Within the app, you can edit your scans with various tools. This app is available for iPhone X/XS, iPhone XS Max and iPhone XR.

The 3D scans are easy to export in PLY, OBJ, and STL formats. You can also upload them directly to Sketchfab. In the free version, you get a free mesh save every week. If you need to save more scans, you can purchase single saves or get a subscription for unlimited saves. The Scandy Pro app is free and receives frequent updates.

Scandy developers also offer their Cappy app, which allows you to capture small 3D scans for augmented reality. You can’t export the scans though!

Contact manufacturer Get a quote Add to comparison

This free 3D scanner app is ideal for professionals such as designers, architects, real estate agents, and more.

Canvas is easy to use– you only need to walk around the room while holding up your iPad. The app creates your 3D model in real time, and provides exact floor-plan measurements.

Canvas allows you to save your scans on your iPad or e-mail them to friends or colleagues. This 3D scanning app also offers a Scan To CAD service for $29.95 per scan.

This 3D scanning app also offers a Scan To CAD service for $29.95 per scan.

Contact manufacturer Get a quote Add to comparison

This 3D scanner app offers quality 3D scans by processing the photos on its cloud platform. itSeez3D is able to capture people in 3D, a process known as 3D body scanning.

itSeez3D offers unlimited scanning, but exports cost $7 each. The two paid versions of itSeez3D offer a limited amount of free exports and other benefits. The “Scale Up” package at $250/month lets you export up to 1,200 models per year.

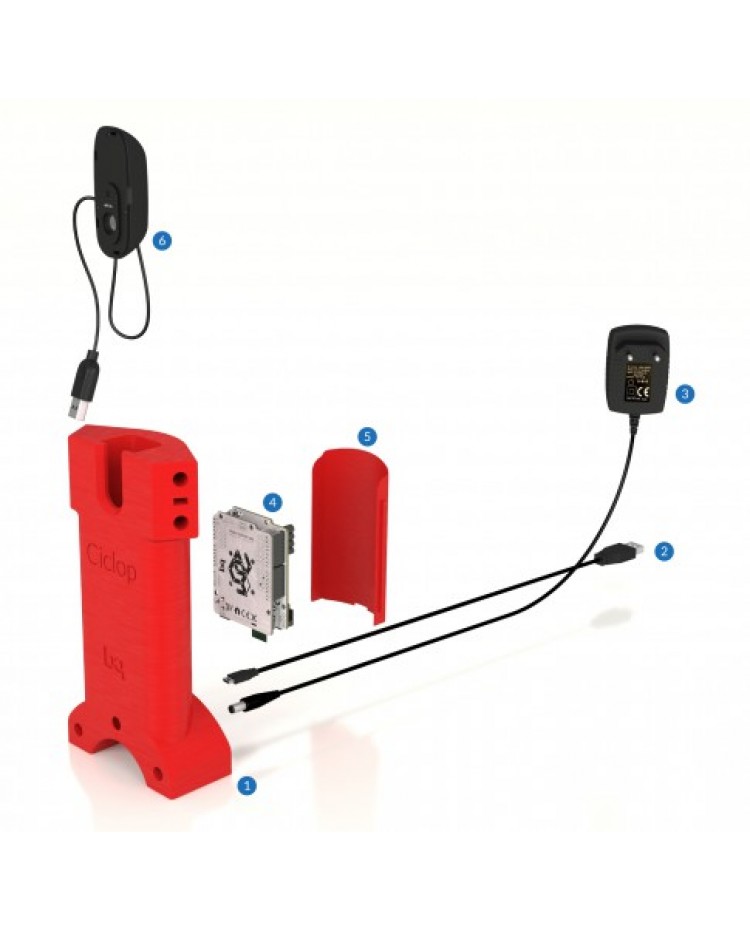

This application requires an Occipital Structure Sensor to operate.

Contact manufacturer Get a quote Add to comparison

3D scanning with a smartphone: special mentions

3DF Zephyr, a 3D scanning software for PC, enables you to create 3D scans from your smartphone pics. You can then export the 3D scans in common 3D file formats.

3DSizeME is a 3D body scanning app developed by TechMed3D, a Canadian company. This free 3D scanning app works with a Structure Sensor and targets medical clinics and professionals. The 3DSizeME app provides precise body measurements.

This free 3D scanning app works with a Structure Sensor and targets medical clinics and professionals. The 3DSizeME app provides precise body measurements.

TechMed3D can customize the app to specific professional needs and use cases.

Bevel launched on Kickstarter on July 28th, 2015 and was successfully funded only two weeks later. Bevel, a small dongle-like device, officially started shipping in April 2017 after almost 2 years of development. The app hasn’t received any updates since late 2017 but is still available.

Trnio, developed in 2013, is one of the first 3D scanning apps to be released. This app used to be free but is now priced at $4.99. It is only available for iOS.

iPhone 3D scanning apps

The iPhone TrueDepth sensor has made it possible to develop a variety of selfie 3D scanning apps. Some interesting iPhone 3D scanning apps include:

- Bellus3D: the app itself is free, but you need to pay in order to export your scans.

For three days of unlimited 3D scan exports, the price is $7.99. For more accurate 3D scans, users may opt for the Bellus3D Face Camera add-on (see on Amazon).

For three days of unlimited 3D scan exports, the price is $7.99. For more accurate 3D scans, users may opt for the Bellus3D Face Camera add-on (see on Amazon). - Heges: like Bellus3D, the app is free to download. However, the in-app option to export 3D scans costs $2.99.

- 3D Scanner Pro: this iPhone 3D scanning app by Laan Labs targets professional use cases (real estate, architecture, etc.).

What is 3D photo or spatial photography?

Spatial photography is a hybrid between capturing a video and taking photographs. 3D photos combine the perspective of a panoramic photo and the 3D features of a video.

Differences between 3D photo and 3D scanning apps

3D photos are similar to 3D scans, at least in the way they are seen, but they are still both different:

- 3D photos can only be stored and accessed through a specific viewing app

- Spatial photography photos can’t be 3D printed

- 3D scans can be edited

- You can’t export 3D photos to external software such as Sketchfab

Discontinued 3D scanner apps

A number of 3D scan apps have come and gone. We list them here so you know what’s been going on!

We list them here so you know what’s been going on!

3D Creator by Sony

The “3D Creator” 3D scanning app by Sony is no longer available on the Play Store. It seems to have been discontinued for a while.

123D Catch

123D Catch, which was once the most famous 3D scanning mobile app, was discontinued in April 2017. 123D Catch was compatible with iOS, Android, and Windows smartphones.

Trimensional

Although Trimensional is still available on the App Store, it hasn’t been updated since late 2014.

Seene

Seene is a 3D scanning app for smartphones that has been acquired by Snapchat.

Pixelio

PIXELIO is a portable turntable that uses 123D catch, a 3D scanning app that was discontinued in April 2017. The creators of PIXELIO have yet to deliver on their promise.

3Dignite Scanner

This app was supposed to let you export 3D scans to the VR world (and to Minecraft). However, the company seems to be inactive since 2017.

However, the company seems to be inactive since 2017.

EORA 3D

EORA 3D is an Australian Kickstarter project that launched in October 2015. Their website has disappeared and they are no longer providing support for their product.

Conclusion

In this article, we provide a comprehensive overview of 3D scanning apps for smartphones. The market is still too small to create a ranking or leave out certain 3D scanning apps.

These apps and their accessories are able to create decent 3D models. However, they don’t offer the high quality that actual 3D scanners do. 3D scanning apps are a great solution for beginners, hobbyists and even professionals that don’t require much precision.

FAQ

Can 3D printers scan objects?

3D printers can scan objects if they are in a 2-in-1 printer scanner combo. Very few of these machines exist.

How do 3D scanners work?

3D scanners capture 3D data of a given space or object. To do so, the scanner can use a laser, structured light, a photo camera, or a touch probe.

What is the best 3D laser scanner?

The best 3D laser scanner is the one that best fits your needs.

Is there an app to create 3D models?

There are various apps available to create 3D models, as seen in this article. You can create a model by 3D scanning an object with your phone. You can also find thousands of pre-made models on STL file websites.

technologies, methods and principles of operation of 3D scanners

Main / Blog / Useful / Principles of operation of a 3D scanner. Types of scanners, technologies and scanning methods

04/16/2021

Content

-

- What is 3D scan and for which it is used by

- How 3D scanner

- 3D scan technologies

- 3D scan methods

- Contact 3D scanners

- Non-contact 3D scanners

- Types of 3D scanners by usage

- Advantages and disadvantages of 3D scanners

- Things to consider when choosing a 3D scanner

- Applications

Currently, few people are not familiar with such a concept as 3D printing. Many companies are using modern 3D printers with might and main, recreating layouts of various shapes and sizes with their help. There are also those that recreate whole objects - not only small ones (for example, phone cases, souvenirs, sneakers), but also large ones (houses, engine parts, etc.). But all this would not be possible without 3D scanners. It is they who allow you to accurately copy almost anything - from huge buildings and structures to humans, animals, small objects and much more.

Many companies are using modern 3D printers with might and main, recreating layouts of various shapes and sizes with their help. There are also those that recreate whole objects - not only small ones (for example, phone cases, souvenirs, sneakers), but also large ones (houses, engine parts, etc.). But all this would not be possible without 3D scanners. It is they who allow you to accurately copy almost anything - from huge buildings and structures to humans, animals, small objects and much more.

What is 3D scanning and what is it used for

Three-dimensional scanning is a technology that appeared in the 60s of the 20th century. It was created in order to transfer the physical parameters of the object into a digital format in the form of a three-dimensional model. The need for this naturally arose when people around the world increasingly began to use computers both in everyday life and in production.

The first samples of 3D scanners were quite simple and did not have wide functionality. Gradually, they became more complex and improved, making it possible to achieve an ever clearer image of the object. This has become especially relevant with the advent of lasers.

Gradually, they became more complex and improved, making it possible to achieve an ever clearer image of the object. This has become especially relevant with the advent of lasers.

3D scanners allow you to transfer object data into digital format

3D scanning has opened up new opportunities in various areas of human activity - from the automotive industry and the military industry to design, medicine and cinema.

How a 3D scanner works

A 3D scanner is a device that examines an object by digitizing it using sensors and using the information received to create a three-dimensional model. In fact, a 3D scanner creates a digital copy of a physical object of any configuration and complexity. In this, it fundamentally differs from its predecessors - conventional scanners that can only read information from documents and photos.

The scanning process itself can take place in different ways - depending on the type of 3D device and the technology used, as well as on what object you want to process with it - moving or static.

3D Scanning Technologies

There are 2 main types of 3D scanners - laser and optical. Their fundamental difference lies in how and with the help of what the “removal” of data takes place. Let's take a closer look at both.

Laser 3D scanning, as the name implies, uses a laser and can be carried out both at short and long distances from the object.

Laser scanner

For the most part, 3D laser scanners work on the principle of triangulation, when the camera finds a beam on the surface of an object and measures the distance to it, after which a cloud of points is created, each of which has its own coordinates in space, and a 3D model is built. Their "advantages" are affordable price and ease of use combined with high scanning accuracy. Of the "minuses" - there are restrictions on the remoteness and size of the object.

Another type of laser scanner works by measuring the response time of a beam from the surface of an object - the so-called laser range finder. They are widely used where it is necessary to create 3D models of various buildings and structures. It is not advisable to use them at short distances, since in such cases the response time is very short and the accuracy of the data is reduced. Otherwise, this type of scanner is characterized by high scanning speed and the ability to read all the details.

They are widely used where it is necessary to create 3D models of various buildings and structures. It is not advisable to use them at short distances, since in such cases the response time is very short and the accuracy of the data is reduced. Otherwise, this type of scanner is characterized by high scanning speed and the ability to read all the details.

The disadvantage of laser scanners is the impossibility of their use on moving objects. Then optical 3D scanners come to the rescue, which shoot with one or more cameras from different angles an object illuminated by a special projector. Based on the received image, a three-dimensional image is built.

Optical scanner

A "contraindication" for the use of this technology are reflective and translucent surfaces - shiny, mirror or transparent. But when scanning a person, they are simply irreplaceable.

3D scanning methods

Any object can be digitized both by contact and non-contact methods. In the first case, active interaction with the subject is necessary, in the second, accordingly, no. Both of these methods have their advantages and disadvantages.

In the first case, active interaction with the subject is necessary, in the second, accordingly, no. Both of these methods have their advantages and disadvantages.

Contact 3D scanners

They have a mechanical probe with a special sensor that measures parameters and transmits the collected information to the device. To do this, the object under study is placed on a special surface and fixed (if necessary). Such tight physical contact makes it possible to determine and then build a 3D image as accurately as possible, however, there is a small risk of damage to the prototype.

Non-contact 3D scanners

This category includes all devices capable of scanning at a distance. This is especially true for objects located in hard-to-reach places.

Non-contact 3D scanner

A stream of radiation (it can be ultrasound, light, X-rays or a laser) is directed to the object and reflected from it, it is recognized by the 3D scanner. They are similar in principle to a video camera and may require the use of additional devices for better lighting.

They are similar in principle to a video camera and may require the use of additional devices for better lighting.

Non-contact 3D scanners come in 2 types:

-

Active - work with a laser beam or structured light directed at an object, which, when reflected, give information about the location of the object in the form of coordinates.

-

Passive - use time-of-flight rangefinders that read the time and distance that the laser beam travels to the object, and so - for each point in space, which ultimately allows you to accurately recreate its three-dimensional image.

Desktop 3D scanners are very popular and widespread, since they are mostly simple and safe to use, do not require any special technical skills and are quite cheap. The EinScan-SE 3D scanner is one such example. It can be used both at home and in the office. It has access to the API of many popular 3D printers, which makes it possible to immediately print the created three-dimensional model.

Add to compare

Product added to compare Go

| Manufacturer | Thor3D |

Add to compare

Product added to compare Go

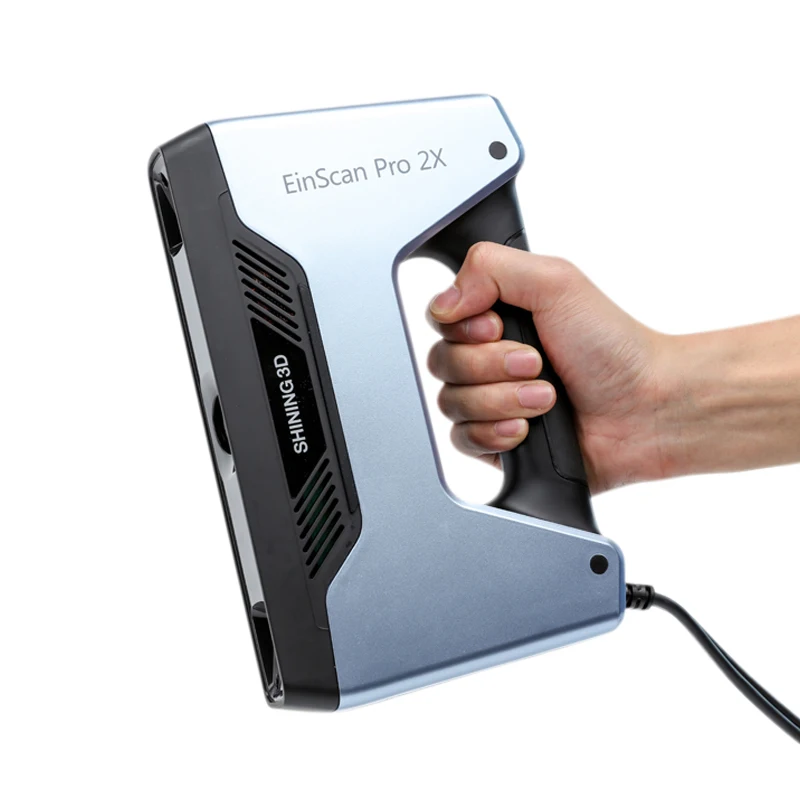

| Manufacturer | Shining 3D |

Add to compare

Product added to compare Go

| Manufacturer | Shining 3D |

Add to compare

Product added to compare Go

| Manufacturer | Range Vision |

Types of 3D scanners according to the principle of use

There is also a variety of species here. Let's highlight the main ones:

Manual: The are handy and simple models that are easy to use as they are quite compact and do not require special skills. True, their technical capabilities may be somewhat limited.

-

Portable: are mainly used for field work, they are convenient to take with you.

-

Desktop: have extended functionality and are used to create high-quality 3D models. Most often used in offices.

-

Stationary: are used, as a rule, in production, various enterprises, as they can scan a large number of objects of the same type at once. Mounted on special turntables.

Handheld 3D Scanner Calibry

Such a choice of products allows you to select the right model for a specific task. In some cases, scanners independently measure objects, in others - with the help of a person who sequentially moves the device until all the necessary information is collected.

Such options for hand-held 3D scanners as Calibry are in high demand among buyers. Despite the apparent simplicity of execution, it has a high resolution and scanning accuracy, due to which it is able to digitize objects with a length of 0.2 to 10 meters. Objects that have a non-standard surface - dark or shiny, with a large number of corners and small details will not become a problem either. Among other things, its undoubted advantage is its low weight, only 900 grams.

Among other things, its undoubted advantage is its low weight, only 900 grams.

Advantages and disadvantages of 3D scanners

Surely, many of the potential buyers are wondering: do you really need a 3D scanner to invest a lot of money in it? What can this acquisition give and will such an investment be justified?

3D scanning has become an integral part of any modern manufacturing process

In order to understand how much you need this equipment, we will list its advantages and disadvantages.

Benefits:

-

They make it possible to scan objects located at a remote distance and in places inaccessible to the presence.

-

They have the ability to "read" not only colors and images, but also to convey the texture of the surface.

-

Significantly speed up the process of "taking" data from any object, even a very complex one with a large number of planes.

-

A variety of models allows you to choose the most convenient version of the scanner, including manual or portable, which can be easily taken with you.

Weaknesses:

-

Some scanners are unable to recognize transparent or black and white objects. In this case, their preliminary preparation (treatment with a special composition) is required.

-

I do not always display complex objects correctly, with a large number of inserts and partitions.

-

To obtain a high-quality result, they require skills and abilities to work with certain computer programs for creating 3D models.

-

If the rules of operation are constantly violated, it may become necessary for expensive repairs to the equipment.

If you need high-precision and high-quality three-dimensional copies of objects, then you cannot do without a 3D scanner. It makes it possible to work in almost any conditions - indoors and outdoors, and with any objects by type and size. It is not surprising that now these devices are in great demand, which gives rise to the annual release of a large number of models, from which you can always choose the one that suits you in terms of quality and price.

It is not surprising that now these devices are in great demand, which gives rise to the annual release of a large number of models, from which you can always choose the one that suits you in terms of quality and price.

Things to consider when choosing a 3D scanner

The computer equipment market offers a huge amount of all kinds of equipment, including devices for three-dimensional scanning. Navigating that variety is sometimes not at all easy: some buyers are only concerned about the cost, others are interested in the number of options (sometimes completely useless), but the most far-sighted look at the ratio of the first and second.

Choosing the right 3D scanner is a responsible matter

It is not always easy to take into account all the technical points that can significantly affect what result will be ultimately achieved. We will tell you what you should pay attention to if you are thinking about buying a 3D scanner.

Be guided by the following parameters:

-

How high is the accuracy of the 3D scanner. This is one of the most important features. It needs to be targeted first.

-

Resolution also plays an important role. It follows from the first, since the accuracy of measurements and the quality of copying depend on the resolution.

-

In what range the device operates, how close / far it can be from the scanned object.

-

The scanning field is the parameters of that object, thing that it is able to process in 1 session.

-

Does the scanner capture various atypical types of surfaces with complex terrain - channels, partitions, holes, etc.).

-

Portability, mobility of the device - how easy it can be moved if desired, taken with you, its size.

-

The time it takes to prepare for work, as well as the duration of the digitization process itself.

-

The range of possibilities in terms of copying: are there any restrictions on shapes, textures, material, as well as operating conditions - temperature, light, etc.

Of course, the better the quality of the 3D scanner, the more expensive it is. However, you should focus primarily on the tasks that you face, and only then take into account everything else.

Applications

Three-dimensional scanners are in demand in many areas of human life. They are irreplaceable both in the industry, and for household needs. The range of their application is so wide that it is possible to list for a very long time. It's easier to say where they are not needed.

The most common areas of use are, of course, medicine, industry, architecture, construction, film industry and design.

For example, in dentistry, these devices allow you to create ultra-precise three-dimensional models of dentures. One type of such a scanner is Shining 3D's AutoScan DS-EX PRO, which does a great job with a variety of tasks while being quite affordable and reliable.

Medical 3D Scanner

In engineering, such technologies are also indispensable. Digital building prototypes are now much easier and faster to obtain than in the past, when it required multiple manual measurements and then entered into a database. Any physical object can now be recreated in three-dimensional form, moreover, in the shortest possible time and with a minimum error.

In cinemas, we can see with our own eyes "revived" fantastic characters, which were created using motion capture technology, which made them as realistic and impressive as possible. This would not have been possible without 3D scanners.

A few decades ago, it was even difficult to imagine all the things that we use all the time today. And in many ways this has become achievable thanks to three-dimensional digitization. This approach provides huge advantages in work (especially for technical specialists - engineers, designers, designers), however, in order to use them to the maximum, it is also necessary to understand computer programs for 3D scanning.

We will talk more about this topic in one of our next articles. And if you want to know more about it, stay tuned.

#Useful

Expert in the field of additive and subtractive technologies, 3D equipment and CNC machines with over 10 years of experience.

Share

all materials

Do you have any questions?

Our experts will help you with the choice of 3D equipment or accessories, consult on any questions.

How a 3D scanner works

What a 3D scanner does

A 3D scanner is a device designed to reproduce the shape of a physical object in a digital format in order to build its virtual three-dimensional model.

How a 3D scanner works

During the 3D scanning procedure, an array of digital data is collected. It is a set of points, each of which has strictly defined coordinates in space - a "cloud of points". Computer program connects adjacent points and builds a digital copy of the scanned object, accurately reproducing it geometric shapes.

Types of 3D scanners

3D scanning can be done in a variety of ways.

Depending on the process technology, the principles of operation of 3D scanners also differ.

There are the following types of these devices:

Contact scanners

3D scanning is carried out by direct contact with the object.

Proximity scanners

They work by capturing waves reflected by the surface of an object with sensitive cameras. They are divided into two types:

- Active: they emit waves of a certain frequency to the scanned object and analyze the reflected signal. AT As waves, an LED or laser beam is usually used. Designed for specific purposes specialized 3D scanners emitting ultrasonic, infrared or X-ray radiation;

- Passive: not equipped with radiation sources, but process the light reflected by the scanned object.

Easier speaking, taking many successive photographs of an object from different angles, they allow you to build it 3D model. These are the simplest devices with low measurement accuracy. Their role may be for example, smartphones loaded with a 3D scanning application.

Easier speaking, taking many successive photographs of an object from different angles, they allow you to build it 3D model. These are the simplest devices with low measurement accuracy. Their role may be for example, smartphones loaded with a 3D scanning application.

Contact scanners

A contact 3D scanner is a manipulator, at the end of which there is a special mechanical device - probe. This probe is a sensitive sensor. When scanning, the operator moves the sensor along the surface of the object, as if “feeling” it. In this case, the computer captures the slightest changes in the position sensor and enters the coordinates into a special program that creates a three-dimensional model of the scanned object.

Non-contact scanners

Active type laser scanners direct a laser beam onto the surface of an object. Fixation of the reflected beam allows you to measure the distance to an object at given points with high accuracy. Further, based on the obtained information, the coordinates of the points are determined. This scanning principle is widely used in the creation of three-dimensional models of large stationary objects, such as rooms.

Further, based on the obtained information, the coordinates of the points are determined. This scanning principle is widely used in the creation of three-dimensional models of large stationary objects, such as rooms.

During scanning, the device at each individual moment of time "sees" only that part of the surface of the object, to which the beam is directed. Therefore, you need to either move the scanner itself, or move the scanned object. AT as a result, separate fragments of the surface are obtained, which are then “sewn together” by software in a single whole - a three-dimensional model.

The most common optical active 3D scanners work on the principle of formation and comparison object images from two cameras. This process is almost identical to when a person determines the distance to the object with both eyes. The role of the eyes is played by the cameras. The scanner measures the distance to an object from different angles. angles. The resulting images are analyzed, compared, and based on the data obtained, the computer builds three-dimensional model of the object.

angles. The resulting images are analyzed, compared, and based on the data obtained, the computer builds three-dimensional model of the object.

To improve the measurement accuracy, such scanners use backlighting - LED lamps or the same lasers. A powerful beam of light or a precise laser beam help achieve maximum measurement accuracy.

A variant of optical technology is the use of modulated or structured subject illumination. With modulated illumination, light pulses are directed at the object. However, in a certain way they change. The camera captures reflections and obtains a picture of the surface of the scanned object from distortions. At structured illumination, the 3D scanner includes, in addition to cameras, another projector. It projects onto the surface of an object contrasting pattern, such as black and white stripes. The camera is directed to the same point, it captures the received image. Then a special program analyzes and calculates the pattern of fringe distortions on the surface subject. Based on these data, the computer reproduces the relief and forms a 3D model.

Then a special program analyzes and calculates the pattern of fringe distortions on the surface subject. Based on these data, the computer reproduces the relief and forms a 3D model.

It is important that optical scanners allow you to read and reproduce not only the geometric shapes of objects, but also the structure and color of their surface.

The main goal of 3D scanning is the most accurate reproduction of the shape of a physical object in the smallest details. Therefore, all the efforts of developers are aimed at improving the accuracy of measurements. For this, they create devices not with two, but with several cameras. For example, 3D scanners have been developed to digitize works of art, which have nine cameras and nine powerful LED lights mounted on a movable arc-shaped frame. The object is fixed in the center inside this frame, and then the frame with cameras and lights moves, describing how would have a hemisphere around the object.

.jpg)