American 3d printer companies

Top 3D Printer Manufacturers and Suppliers in the USA and Canada

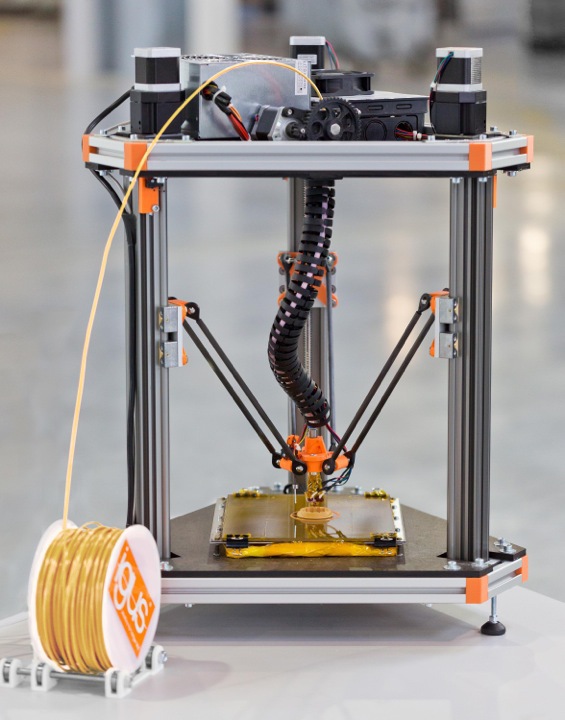

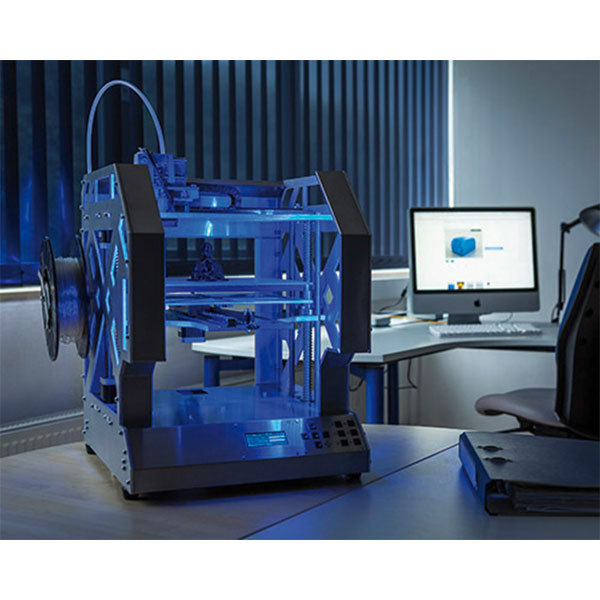

A 3D printer uses CAD to create 3D objects from a variety of materials,like molten plastic or powders

Image credit: Shutterstock/Aumm graphixphoto

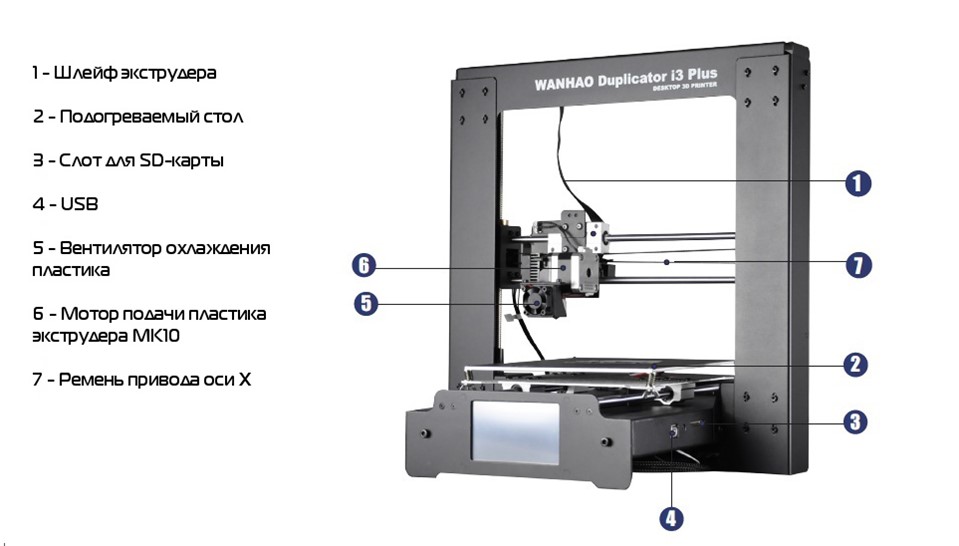

3D printers also called additive manufacturing printers or fabrication printers are a type of material design printer that designs and builds 3D models and products of devices and components using an additive manufacturing process.

3D printers design three-dimensional prototypes and create the end product by directly building them using computer-aided design (CAD) or software-created 3D design diagrams, figures, and patterns.

3D printers utilize additive manufacturing, where the printer designs the object by applying sequential layers of raw material to print a three-dimensional object.

In this article, we'll cover details on the top U.S. providers of 3D printers, along with our featured list of top 3D printer suppliers on Thomasnet. com.

Top Featured U.S. & Canada Suppliers of 3D Printers

Below is a list of featured suppliers of 3D printers from our platform. The company name, year, location, and employee count are also listed in the table.

| Position | Company Name | Year Established | City | State | Zip | Employee Size | Sales Revenue |

| 1 | Sciaky, Inc. | 1939 | Chicago | IL | 60638 | 50-99 | $100 - 249. |

| 2 | AON3D | 2015 | Montreal | QC | h3N1P4 | NA | NA |

| 3 | Nexa3D | NA | Ventura | CA | 93003 | 10-49 | $5 - 9.9 Mil |

| 4 | Terrafilum | 2017 | Cary | IL | 60013 | 1-9 | Under $1 Mil |

| 5 | Raise 3D Technologies, Inc. | 2018 | Irvine | CA | 92618 | 10-49 | $10 - 24. |

Company Summaries

Established in 1939, Sciaky, Inc. specializes in electron beam 3D printers for nuclear, medical, semiconductor, marine, aircraft, power generation, oil & gas sectors. The company uses materials such as titanium, tantalum, tungsten, niobium, aluminum, steel, and Inconel® for printing.

Located in Montreal, QC, AON3D is an industry-leading manufacturer of high-temperature 3D printers. The company's printers prints with polyetheretherketone (PEEK), polyvinylidene fluoride (PVDF), polyphenylene sulfide (PPS), acrylonitrile butadiene styrene (ABS), thermoplastic elastomer (TPE), thermoplastic polyurethanes (TPU), polyphthalamide (PPA), polypropylene (PP), polyvinyl chloride (PVC), polycarbonate and nylon materials.

Nexa3D specializes in manufacturing 3D printers for engineering, dental, medical and education industries. The company is situated in Ventura, CA.

The company is situated in Ventura, CA.

Headquartered in Cary, IL, Terrafilum manufactures 3D printers since 2017. The company meets the demands of the commercial and educational sectors.

Raise 3D Technologies, Inc. is a leading manufacturer of industrial-grade 3D printers. The company's 3D printers offer HEPA filters and WiFi, LAN, USB port and live camera connectivity.

Top U.S. Suppliers of 3D Printers Based on Sales

Below we have assembled information on the top suppliers of 3D printers in the U.S. based on currently available public sales data. The table also includes the company name, location and the number of employees.

| Position | Company Name | Year Established | City | State | Zip | Employee Size | Sales Volume |

| 1 | HP Inc. | 1938 | Palo Alto | CA | 94304 | 500-999 | $118,004,000,000 |

| 2 | Trumpf, Inc. | 1934 | Farmington | CT | 06032 | 1000+ | $2,700,000,000 |

| 3 | Stratasys Ltd. | NA | Eden Prairie | MN | 55344 | 200-499 | $672,458,000 |

| 4 | Sciaky, Inc. | 1939 | Chicago | IL | 60638 | 50-99 | $107,000,000 |

| 5 | 3D Systems - Quickparts Solutions | 1986 | Atlanta | GA | 30346 | 50-99 | $99,999,999 |

| 6 | XYZprinting, Inc. | NA | San Diego | CA | 92121 | 200-499 | $75,000,000 |

| 7 | MakerBot Industries, LLC | 2009 | Brooklyn | NY | 11201 | 100-199 | $74,716,906 |

| 8 | MarkForged | NA | Cambridge | MA | 02138 | 100-199 | $30,000,000 |

| 9 | Mimaki USA | 1999 | Suwanee | GA | 30024 | 50-99 | $26,785,966 |

| 10 | Raise 3D Technologies, Inc. | 2018 | Irvine | CA | 92618 | 10-49 | $24,999,999 |

Company Summaries

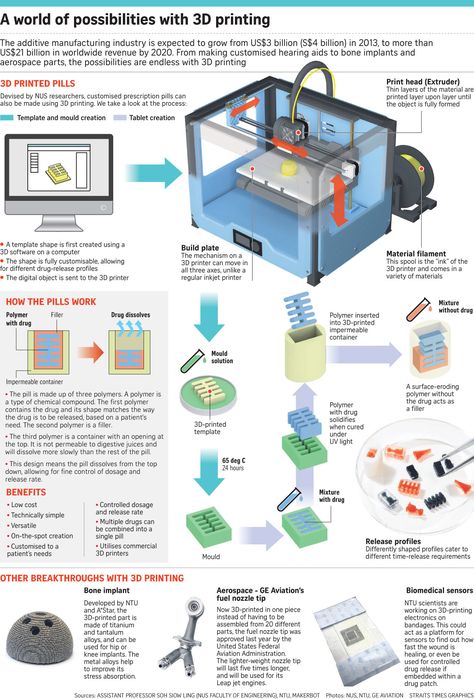

With over 80 years of experience, HP Inc. is a manufacturer of 3D printers. The company meets the demands of consumer goods or electronics, orthotics, prosthetics, health care, medical, higher education, transportation, automotive, and aerospace industries.

Located in Farmington, CT, Trumpf, Inc. manufactures laser metal fusion (LMF) and laser metal deposition (LMD) printers for over 20 years. Data communications, electronics, photovoltaics, science, tool or mold making, transport, display, dental, aviation, aerospace, medical technology, jewelry, automotive, construction, and sheet metal processing are some of the industries served by the company.

Stratasys Ltd. manufactures 3D printers serving industries such as consumer products, aerospace, automotive, dental, medical, education, railway, art, fashion, and government. PolyJet, stereolithography (SLA), and fused deposition modeling (FDM) technology 3D printers are offered by the company.

Established in 1939, Sciaky, Inc. specializes in electron beam 3D printers for nuclear, medical, semiconductor, marine, aircraft, power generation, oil & gas sectors. The company uses materials such as titanium, tantalum, tungsten, niobium, aluminum, steel, and Inconel® for printing.

3D Systems - Quickparts Solutions manufactures metal, plastic, and casting 3D printers. The company meets the demands of motorsports, aerospace, defense, automotive, consumer technology, jewelry, semiconductor, truck, bus, rail, and turbomachinery markets.

Founded in 2013, XYZprinting, Inc. specializes in 3D printers including fused filament fabrication (FFF), stereolithography (SLA), and digital light processing (DLP). The company is situated in San Diego, CA.

specializes in 3D printers including fused filament fabrication (FFF), stereolithography (SLA), and digital light processing (DLP). The company is situated in San Diego, CA.

MakerBot Industries, LLC manufactures 3D printers that print with polymers, composites, and metal materials. Aerospace, automotive, education, and manufacturing are some of the industries served by the company.

MarkForged is a leader in manufacturing 3D printers that prints using materials such as continuous fibers, plastics, stainless steel, tool steel, copper, and Inconel®. The company serves consumer packaged goods, electronics, automotive, aerospace, education, research, energy, defense, federal, energy, and medical markets.

Founded in 1975, Mimaki USA specializes in manufacturing 3D printers. The company is headquartered in Suwanee, GA.

Raise 3D Technologies, Inc. is a leading manufacturer of industrial-grade 3D printers. The company's 3D printers offer HEPA filters and WiFi, LAN, USB port and live camera connectivity.

The company's 3D printers offer HEPA filters and WiFi, LAN, USB port and live camera connectivity.

Summary

With the help of the provided details on the 3D printer suppliers in the United States and Canada in the above tables and descriptions, we hope you can use this data to further aid your sourcing decisions.

You can also look at our Supplier Discovery page, which has information on more than 150 suppliers of 3D printers.

Trademark Notice

Sources

-

3D Printers

Other 3D Printing Articles

- Types of 3D Printing Technologies

- Top 3D Printing Services Companies in the USA

- Origins of 3D Printing and Additive Manufacturing

- Top 3D Printing Manufacturers and Suppliers (Publicly Traded and Privately-Owned)

- Top Suppliers of Additive Manufacturing Consulting Services

- The Best 3D Printers under $300

- The Best 3D Printers under $200

- The Best 3D Printing Software

- The Best 3D Printer Under $1000

- The Best 3D Printer Under $500

- All About Material Jetting

- All About Multi-Jet Modeling (MJM) 3D Printing

Other Top Suppliers Articles

- Top RFID Antenna Manufacturers USA and Internationally

- Top Thermocouple Manufacturers in the USA - By Revenue, Location and Product Type

- Top Suppliers of Integrated Circuit Design Services in the USA and Globally

- Top Industrial Automation Software Companies in the USA and Globally

- Top Cloud Services Providers and the USA and around the Globe

- Top Battery Enclosure Manufacturers and Suppliers in the US and Globally

- Top Proximity Sensors Suppliers and Manufacturers in the USA and Worldwide

- Top Resistor Suppliers and Manufacturers in the US and Globally

- Top RFID Tag Manufacturers in the USA and Internationally

- Top Temperature Sensors Manufacturers and Suppliers

- Top Cable Assembly Manufacturer Companies in the USA

- RFID Software Companies in the USA and Internationally

- Top Predictive Maintenance Companies in the USA and Globally

- Top Pipe and Tube Bending Companies in the USA

- Top EDM Services Suppliers in the USA

- Top RFID Reader Manufacturers and Suppliers in the USA and Internationally

- Top RFID Inventory Control Software Companies in the USA and Internationally

- Top U.

S. Screw Machining Service Suppliers

S. Screw Machining Service Suppliers - Top Sensors Manufacturers and Suppliers in the USA

- Top Graphene Companies and Manufacturers in the USA

- Top Suppliers of Polyvinyl Chloride (PVC)

Top Laboratory Supply Companies in the USNext Story »

More from Custom Manufacturing & Fabricating

About Us - Fusion 3 Design

Fusion3: USA-Made Commercial-Grade 3D Printers

OUR HISTORY

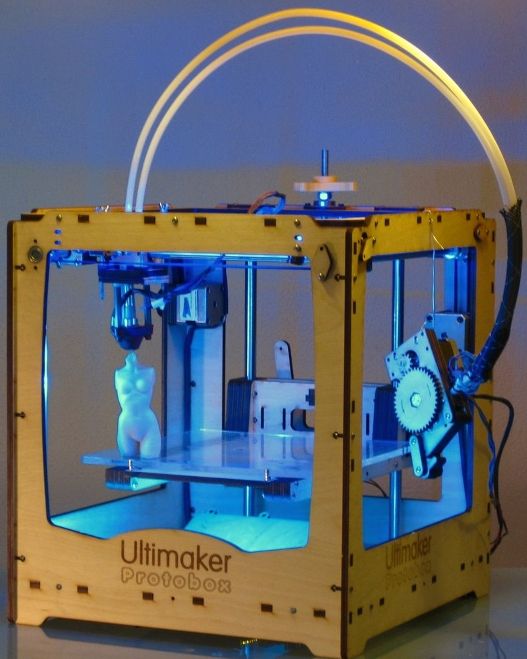

Founded in 2012, Fusion3 has consistently focused on delivering high performance, USA-made 3D printers for B2B business users. Our belief is that businesses – both large and small – have needs that are poorly met by low cost, hobbyist 3D printers and also by expensive, overly complex industrial systems.

As one of the first manufacturers to pioneer the creation of 3D printers for B2B business use, Fusion3 is ideally positioned to deliver not only the right 3D printers for your application, but we have the expertise to ensure your organization is successful in integrating 3D printing into your mission. We are 3D printer experts and will work with you to find a solution that best fits your unique needs.

We are 3D printer experts and will work with you to find a solution that best fits your unique needs.

View 3D Printer Models

Who We Serve

Our products are powerful, robust general-purpose 3D printers that are used in a variety of industries. Our customers operate in industries including:

- Business

- Commercial

- Industrial

- Education

- Libraries

- Aerospace/ Defense

- Automotive

- Energy

Made in USA 3D Printers

Fusion3 proudly manufactures our products in Greensboro, North Carolina, USA. We believe that keeping all aspects of our operations – sales, customer support, manufacturing, and product development – under one roof drives innovation, improves product quality, and delivers the best customer experience possible. In today’s global environment, having our key suppliers nearby enables us to continue to serve our customers with minimal supply chain interruptions.

| Do you know the manufacturing locations for each of these 3D printer manufacturers? | |

| Raise3D | China |

| Ultimaker | Netherlands |

| Makerbot | China |

| Zortrax | Poland |

3D printing is a complex technology that is sensitive to having the right workflows. Thanks to our extensive experience and partnership with our customers over the years, we’re well-versed in ensuring you have the tools (literal and metaphysical) to successfully integrate 3D printing into your business.

Quality products and long lasting customer relationships are our priority. A key part of our process is our in-house, USA-based customer support team. Our support technicians are drawn from our manufacturing team, so they know our products and technology inside and out.

Have some questions before you get started? Contact a member of our staff to get answers!

FREQUENTLY ASKED QUESTIONS

Where is Fusion3 based?

Fusion3 is based in the US in Greensboro, North Carolina. All of our production takes place in North Carolina and we are proud to produce some of the best USA made 3D printers.

What 3D printers are made in the USA?

If buying a USA-made 3D printer is important to you, you should make sure the 3D company you are evaluating manufactures in the US. While many 3D printer companies have corporate offices based in the US, they often outsource their manufacturing to other countries. At Fusion3, we are proud to not only have our office located in the USA, but also our manufacturing in the USA.

USA builds largest metal 3D printer

News

Subscribe author

Subscribe

Don't want

2

Ingersoll, MELD Manufacturing and Siemens will build the largest metal 3D printer. The system will rely on adapted friction welding technology and will be able to grow parts up to ten meters long.

The system will rely on adapted friction welding technology and will be able to grow parts up to ten meters long.

The work is carried out in the interests of the US military: such 3D printers are planned to be used primarily in the production of mine protection for army vehicles. During the Vietnam War, 73 percent of equipment losses were due to explosions on anti-personnel and anti-tank mines. Modern armored vehicles and armored personnel carriers are designed with enhanced protection, and an important role is played by thick, armored bottoms, often V-shaped and with a minimum of welds.

An American Cougar armored vehicle that hit a mine in Iraq in 2006 and drove another three kilometers to the safe zone. The personnel escaped with minor injuries. Photo: Marine Sergeant Christopher Clare

Previous work on the Jointless Hull project of the Army ManTech research program has looked at forging, forming and welding at high current density to reduce weld porosity. The results were rated as satisfactory in terms of strength, but at the same time, there was a lack of geometric freedom and manufacturing flexibility.

The results were rated as satisfactory in terms of strength, but at the same time, there was a lack of geometric freedom and manufacturing flexibility.

As a result, they decided to abandon forging, forming and welding in favor of another technology - production by the method of additive friction deposition with mixing (Additive Friction Stir Deposition, AFSD), that is, Friction Stir Welding, adapted for 3D printing, FSW).

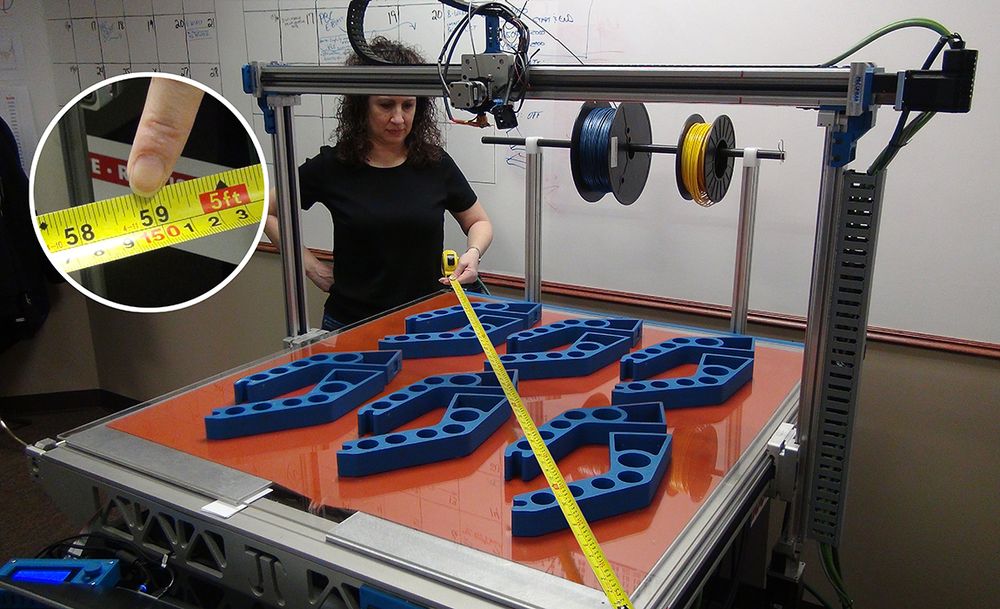

Development work consists of two stages. Not the first one is planned to assemble a demonstrator with a construction area measuring 1x1x1 meter to test the technology and software. The design must then be scaled up to a working volume of 10x6.5x4 meters - the largest among "metal" 3D printers. Length is a conditional characteristic, since the portal structure will move along the rails. Siemens is responsible for the control systems and software.

The large-format version is already being assembled by Ingersoll, which has considerable experience in working on large additive systems. In 2019, this venture helped the University of Maine set three Guinness records at once: to make the largest 3D printed boat (seven meters in length), aka the largest one-piece 3D printed object, on the largest 3D printer for working with polymers and polymer composites. The same system is used in the production of large molding tooling, for example for the manufacture of helicopter blades.

In 2019, this venture helped the University of Maine set three Guinness records at once: to make the largest 3D printed boat (seven meters in length), aka the largest one-piece 3D printed object, on the largest 3D printer for working with polymers and polymer composites. The same system is used in the production of large molding tooling, for example for the manufacture of helicopter blades.

The new 3D printer, as already mentioned, will deposit metals using friction stir deposition. This technology is being developed by MELD Manufacturing using the Edison Welding Institute (EWI). The build-up is carried out by plastic deformation at temperatures below the melting threshold, thereby achieving high isotropy and density without shrinkage and the risk of hot cracks, without the need for a vacuum chamber or protective gas environment. The technology also allows you to create gradient structures from different metals or alloys. Consumables are usually rounded bars with the possibility of using powders of different fractions and even metal shavings.

MELD Manufacturing already offers several models of additive systems. The latest commercial offer is the L3 3D printer released in 2020 with a working area of 1143x584x584 mm, although the K2 system with a useful volume of 2100x1100x1000 mm is the leader in terms of dimensions. The equipment allows you to work with various steel grades, as well as aluminum, copper, titanium, magnesium and nickel alloys. As a rule, such 3D printers stack layers about one millimeter thick and 38 mm wide, keeping the temperature of the material at 60-90% of melting point. Since the resolution of 3D printing is low, the resulting blanks require intensive machining, but with much less labor and waste than milling from blanks, and with high scalability, which is planned to be demonstrated in practice by the joint efforts of Ingersoll, MELD Manufacturing and Siemens. The commissioning of the large-format system is scheduled for the fourth quarter of this year.

Siemens MELD Ingersoll rotary welding

Subscribe to the author

Subscribe

Don't want

2

How an American company prints space rockets on a 3D printer

Trends

TV channel

Pro

Investments

Events

RBC+

New economy

Trends

Real estate

Sport

Style

National projects

City

Crypto

Debating club

Research

Credit ratings

Franchises

Newspaper

Special projects St. Petersburg

Petersburg

Conferences St. Petersburg

Special projects

Checking counterparties

RBC Library

Podcasts

ESG index

Policy

Economy

Business

Technology and media

Finance

RBC CompanyRBC Life

RBC Trends

Relativity Space aerospace engineers, former employees of Blue Origin and SpaceX. Their plans are to change the traditional way of building rockets and build a 3D printing factory on Mars, for which they have already raised more than $1. 3 billion in investments. Relativity Space plans to launch its first rocket on October 31, 2022.

3 billion in investments. Relativity Space plans to launch its first rocket on October 31, 2022. Simplified Rocket Science

Traditionally, rockets are built from separate components - a space agency or a private company orders parts of a future spacecraft from different factories. This method has a major drawback: the industry depends on many third-party factories and their machines. This slows down the process.

Relativity Space can create its own rockets by simply programming a 3D printer. For production, only raw materials are needed, for example, steel and titanium. Relativity Space does not use manual labor and does not need a complex supply chain. In this way, 3D printing radically automates and simplifies production. Founder Tim Ellis notes: “Our goal is to reduce the number of parts for rockets by 100 times.”

Relativity Space hopes that with fewer parts, the number of production steps will be reduced. Josh Brost, vice president of the company, notes: “It takes about two years to build a conventional rocket, and then you need to purchase equipment. We are working to ensure that only 60 days pass from the receipt of raw materials to the launch of the launch vehicle on the market.”

We are working to ensure that only 60 days pass from the receipt of raw materials to the launch of the launch vehicle on the market.”

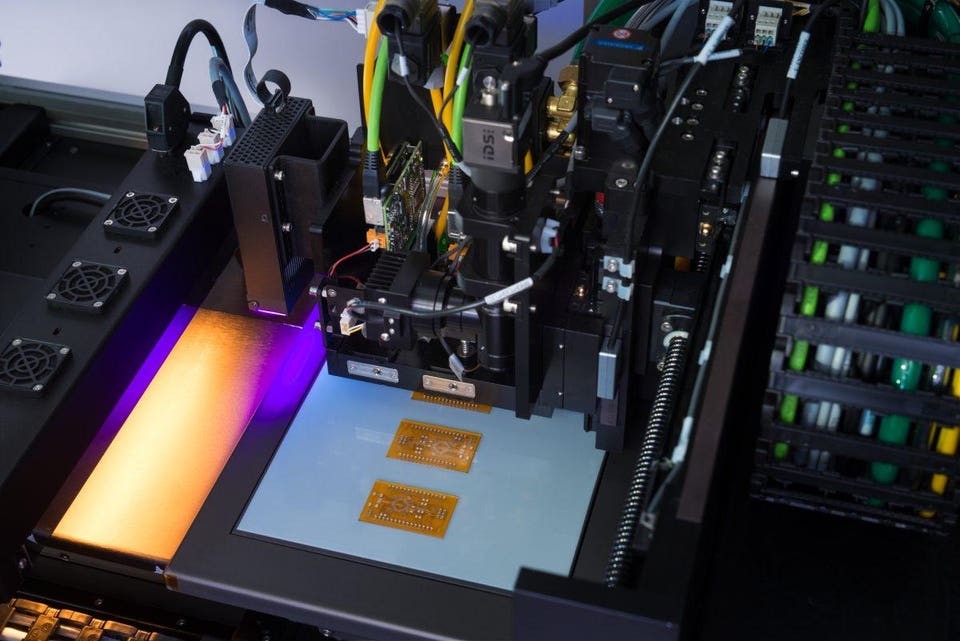

How rockets are made with a printer

For rocket science, Relativity Space uses two industrial 3D printers. The first uses a process called direct metal laser sintering. The necessary parts are created from metal powder, up to engines. The second 3D printer consists of three robotic arms that assemble parts by stacking layers of metal on top of each other. They can be quickly reconfigured to create other parts of the rocket.

After the launch of Terran 1 and Terran 2, Relativity Space plans to construct a full-fledged factory for 3D printing rockets to Mars.

Mars Plans

Tim Ellis emphasizes that sending humans to Mars requires detailed planning for everything from the actual launch from Earth to generating electricity, building new infrastructure and growing food. He is sure that the achievements of Relativity Space can also be useful on Mars - with the help of 3D printing, it will be possible to create the infrastructure necessary for astronauts on the planet.

9 Mil

9 Mil 9 Mil

9 Mil